Page 1

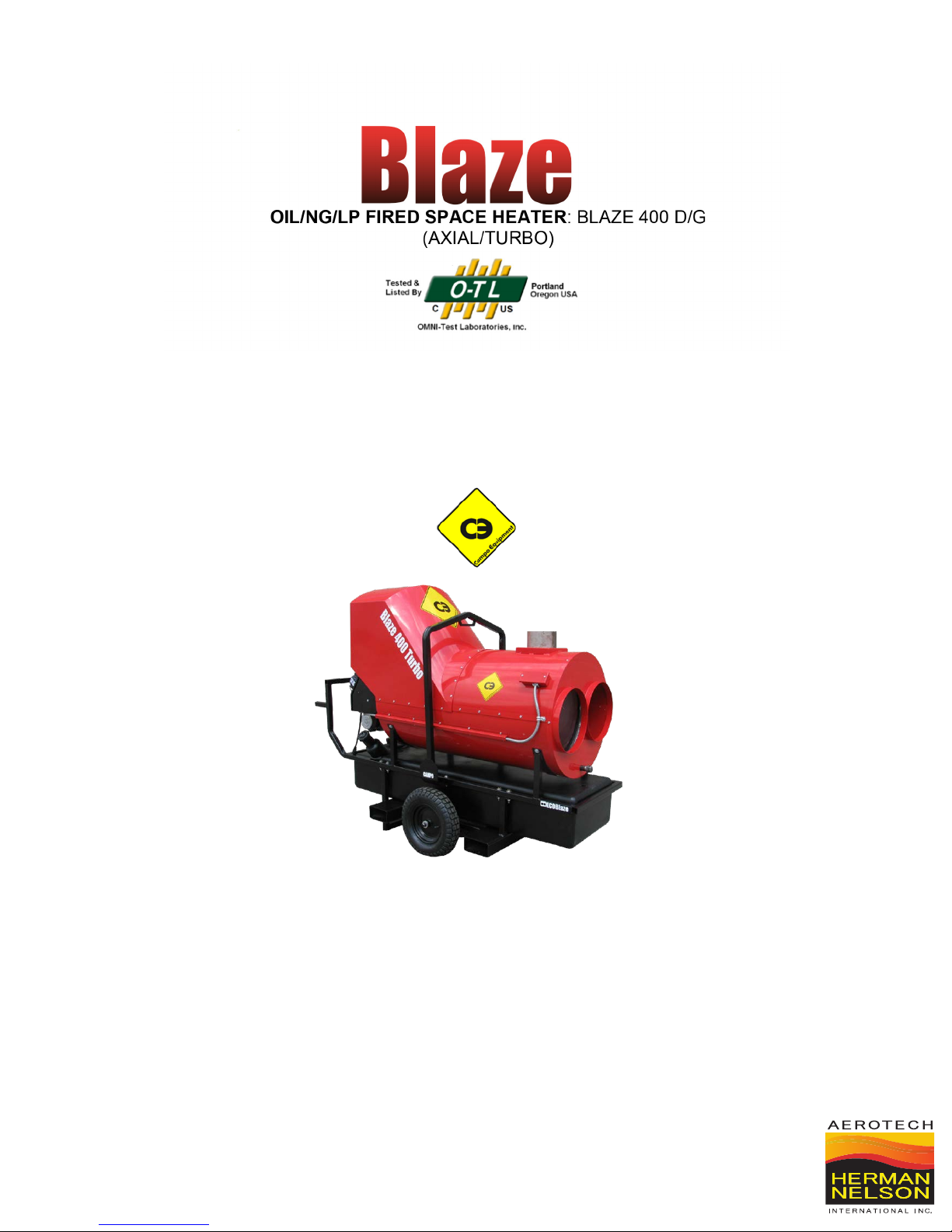

OIL/NG/LP FIRED SPACE HEATER: BLAZE 400 D/G

(AXIAL/TURBO)

REPORT # 0367MH007S

Installation Instructions-Manual-Maintenance-Parts List

CAUTION: DO NOT TAMPER WITH HEATER OR ITS CONTROLS. CALL A QUALIFIED SERVICE TECHNICIAN

Retain manual for future reference June 19/14

CERTIFIED FOR USE IN CANADA AND THE U.S.A.

1-800-486-4328

1-204-633-1999

100 Eagle Drive

Winnipeg, MB Canada

sales@hermannelson.com

www.hermannelson.com

Page 2

1-800-486-4328

1-204-633-1999

100 Eagle Drive

Winnipeg, MB Canada

sales@hermannelson.com

www.hermannelson.com

Page 3

READ INSTRUCTIONS PRIOR TO STARTING HEATERS

THIS HEATER IS DESIGNED AND APPROVED FOR USE AS A CONSTRUCTION HEATER

UNDER STANDARD ANSI Z83.7-2011/CSA2.14-2011, UL 733-2013 and CAN/CSA B140.81967(R2011)

THESE HEATERS ARE SUITABLE FOR OUTDOOR USE

THE REQUIREMENTS OF LOCAL AUTHORITIES HAVING JURISDICTION SHALL BE

FOLLOWED

BLAZE 400 G

NOTE: THIS HEATER IS INTENDED FOR USE PRIMARILY AS TEMPORARY HEATING OF BUILDINGS UNDER

CONSTRUCTION, ALTERATION OR REPAIR

THIS UNIT IS APPROVED FOR USE WITH PROPANE OR NATURAL GAS. NEVER ATTEMPT TO BURN

GARBAGE OR PAPER IN THE HEATER AND REMOVE ALL PAPER AND RAGS FROM AROUND THE

HEATER. FOR YOUR SAFETY, DO NOT STORE OR USE GASOLINE OR OTHER FLAMMABLE

LIQUIDS OR VAPOURS IN THE VICINITY OF THE HEATER.

DO NOT TAMPER WITH THE HEATER AND CONTROLS! THE HEATER MUST BE SERVICED BY

QUALIFIED SERVICE PERSONNEL.

WARNING: THOSE WHO INSTALL THE HEATER MUST HAVE THE TRAINING AND EXPERIENCE

NECESSARY TO DO SO. READ THIS MANUAL CAREFULLY. FAILURE TO PROPERLY INSTALL

AND SETUP THE HEATER COULD RESULT IN PROPERTY DAMAGE, PERSONAL INJURY, OR LOSS

OF LIFE. THE QUALIFIED SERVICE PERSONNEL PERFORMING THIS WORK ASSUMES A SERIOUS

RESPONSIBILITY FOR THE CORRECT INSTALLATION, SETUP, AND START-UP OF THE HEATER.

THIS HEATER IS DESIGNED AND APPROVED FOR USE AS A CONSTRUCTION HEATER IN

ACCORDANCE WITH STANDARD ANSI Z83.7-2011/CSA2.14-2011. CHECK WITH YOUR

LOCAL FIRE SAFETY AUTHORITY IF YOU HAVE QUESTIONS ABOUT APPLICATIONS.

WARNING: INTENDED USE IS PRIMARILY THE TEMPORARY HEATING OF BUILDINGS UNDER

CONSTRUCTION, ALTERATION, REPAIR OR EMERGENCIES ONLY.

WARNING: ALWAYS PROVIDE ADEQUATE VENTILATION. MINIMUM ACCEPTABLE VENTILATION

REQUIRED: 1 SQ. IN. OF FRESH AIR MUST BE SUPPLIED FOR EVERY 1000 BTU/H OF HEAT.

WARNING: THIS HEATER SHALL BE INSTALLED SUCH THAT IT IS NOT DIRECTLY EXPOSED TO

WATER SPRAY, AND/OR DRIPPING WATER.

CHECK WITH YOUR LOCAL FIRE SAFETY AUTHORITY IF YOU HAVE QUESTIONS ABOUT

APPLICATIONS

THESE INSTRUCTIONS HAVE BEEN THOROUGHLY WRITTEN, BUT THEY CANNOT COVER EVERY

PECULIAR INSTALLATION AND CONTINGENCY. THEREFORE IF THERE IS ANY DOUBT AS TO

1-800-486-4328

1-204-633-1999

100 Eagle Drive

Winnipeg, MB Canada

sales@hermannelson.com

www.hermannelson.com

Page 4

INTERPRETATION OF ANY REQUIREMENTS, CONTACT YOUR LOCAL AUTHORITY HAVING

JURISDICTION, YOUR LOCAL DISTRIBUTOR, OR THE FACTORY.

INSTALLATION REGULATIONS:

1.) THE INSTALLATION OF THE UNIT SHALL BE IN ACCORDANCE WITH THE REGULATIONS OF

THE AUTHORITIES HAVING JURISDICTION.

WIRING: ALL INTERNAL WIRING OF THE HEATER IS COMPLETED BY THE MANUFACTURER. ALL

EXTERNAL WIRING MUST CONFORM TO EXISTING ELECTRICAL CODES AS LAID DOWN BY THE

AUTHORITIES HAVING JURISDICTION.

THE INSTALLATION OF THIS HEATER FOR USE WITH NATURAL GAS SHALL CONFORM WITH

LOCAL CODES OR, IN THE ABSENCE OF CODES, WITH THE NATIONAL FUEL GAS CODE ANSI

Z223.1/NFPA 54 AND THE NATURAL GAS AND PROPANE INSTALLATION CODE, CSA B149.1-00.

THIS HEATER MUST BE INSTALLED BY A QUALIFIED GAS TECHNICIAN, FOLLOWING LOCAL

CODES PUBLISHED BY THE AUTHORITY HAVING JURISDICTION. ALL INSTALLATIONS

PERFORMED IN THE STATE OF MASSACHUSETTS MUST BE COMPLETED BY A QUALIFIED

PLUMBER AND GAS FITTER OF THE STATE OF MASSACHUSETTS.

THE INSTALLATION OF THIS HEATER FOR USE WITH A PROPANE TANK OR CYLINDER SHALL

CONFORM WITH LOCAL CODES OR IN THE ABSENCE OF LOCAL CODES, WITH THE STANDARD

FOR THE STORAGE AND HANDLING OF LIQUEFIED PETROLEUM GASES, ANSI/NFPA 58 AND THE

NATURAL GAS AND PROPANE INSTALLATION CODE, CSA B149.1

THIS HEATER MUST BE LOCATED AT LEAST 10FT (3M) FROM ANY PROPANE GAS CYLINDER.

THIS HEATER SHALL NOT BE DIRECTED TOWARD ANY PROPANE GAS CONTAINER WITHIN 20FT

(6M).

OTHER STANDARDS GOVERN THE USE OF FUEL GASES AND HEAT PRODUCING

PRODUCTS IN SPECIFIC APPLICATIONS. YOUR LOCAL AUTHORITY CAN ADVISE YOU

ABOUT THESE.

READ INSTRUCTIONS PRIOR TO STARTING HEATERS

BLAZE 400 D

THIS UNIT IS APPROVED FOR USE WITH NO. 1 AND NO. 2 FUEL OIL. NEVER USE GASOLINE OR

CRANKCASE OIL WHICH MAY CONTAIN GASOLINE AS FUEL FOR THE HEATER. NEVER ATTEMPT

TO BURN GARBAGE OR PAPER IN THE HEATER AND REMOVE ALL PAPER AND RAGS FROM

AROUND THE HEATER. FOR YOUR SAFETY, DO NOT STORE OR USE GASOLINE OR OTHER

FLAMMABLE LIQUIDS OR VAPOURS IN THE VICINITY OF THE HEATER.

FOR YOUR SAFETY DO NOT ATTEMPT TO START THE HEATER IF:

1.) EXCESS OIL HAS ACCUMULATED

2.) THE HEATER IS FULL OF VAPOUR

3.) THE COMBUSTION CHAMBER IS EXTREMELY HOT

1-800-486-4328

1-204-633-1999

100 Eagle Drive

Winnipeg, MB Canada

sales@hermannelson.com

www.hermannelson.com

Page 5

DO NOT TAMPER WITH THE HEATER AND CONTROLS! THE HEATER MUST BE SERVICED BY

WARNING: LACK OF COMBUSTION AIR CAN CAUSE A DIRTY FIRE, ODOURS IN ENCLOSED

THE OCCUPANTS.

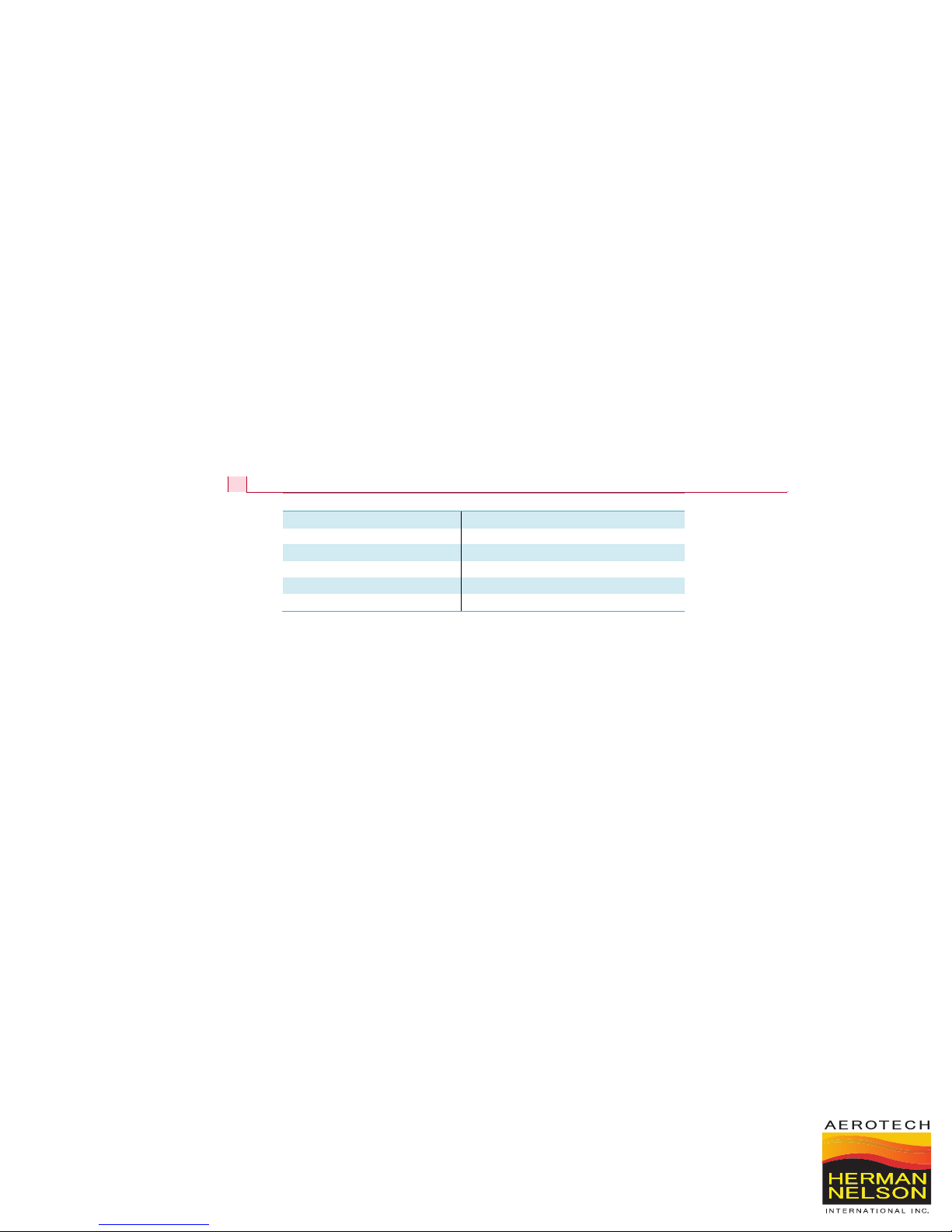

BLAZE 400 D/G

SPECIFICATIONS

BLAZE 400GBECKETT (NG/LP)

BLAZE 400GRIELLO (NG/LP)

BLAZE 400DBECKETT (OIL)

BLAZE 400DRIELLO (OIL)

Burner Make & Model

CG10 -24

G400

CF375

F10

Voltage

120V

120V

120V

120V

Input (BTU/h)

399,000

399,000

NO.1 (277,000) @ 100 PSI

NO.2 (396,000) @ 200 PSI

NO.1 (339,325) @ 150 PSI

PSI

QUALIFIED SERVICE PERSONNEL.

WARNING: THOSE WHO INSTALL THE HEATER MUST HAVE THE TRAINING AND EXPERIENCE

NECESSARY TO DO SO. READ THIS MANUAL CAREFULLY. FAILURE TO PROPERLY INSTALL

AND SETUP THE HEATER COULD RESULT IN PROPERTY DAMAGE, PERSONAL INJURY, OR LOSS

OF LIFE. THE QUALIFIED SERVICE PERSONNEL PERFORMING THIS WORK ASSUMES A SERIOUS

RESPONSIBILITY FOR THE CORRECT INSTALLATION, SETUP, AND START-UP OF THE HEATER.

THESE INSTRUCTIONS HAVE BEEN THOROUGHLY WRITTEN, BUT THEY CANNOT COVER EVERY

PECULIAR INSTALLATION AND CONTINGENCY. THEREFORE IF THERE IS ANY DOUBT AS TO

INTERPRETATION OF ANY REQUIREMENTS, CONTACT YOUR LOCAL AUTHORITY HAVING

JURISDICTION, YOUR LOCAL DISTRIBUTOR, OR THE FACTORY.

IMPORTANT: IF YOU OBSERVE THE PRIMARY CONTROL IS LOCKED OUT, PUSH THE RED RESET

BUTTON ONLY ONCE. IF THE BURNER DOES NOT RE-LIGHT, DO NOT PUSH THE BUTTON A

SECOND TIME OR EXCESS OIL WILL ACCUMULATE IN THE COMBUSTION CHAMBER—CALL A

QUALIFIED SERVICE PERSON.

INSTALLATION REGULATIONS:

1.) INSTALLATION SHOULD BE IN ACCORDANCE WITH ALL LOCAL AND NATIONAL

REGULATIONS.

2.) IN CANADA USE THE CSA B139-1962 INSTALLATION CODE FOR OIL BURNING EQUIPMENT,

FOR RECOMMENDED INSTALLATION PRACTICE.

WIRING: ALL INTERNAL WIRING OF THE HEATER IS COMPLETED BY THE MANUFACTURER. ALL

EXTERNAL WIRING MUST CONFORM TO EXISTING ELECTRICAL CODES AS LAID DOWN BY THE

AUTHORITIES HAVING JURISDICTION. IN CANADA, REFER TO CSA C22.1 CANADIAN ELECTRICAL

CODE AND IN THE UNITED STATES AS OUTLINED IN THE BOCA CODE, OR THE NFPA 70 NATIONAL

ELECTRICAL CODE.

SPACES, AND BACKDRAFTING, POTENTIALLY RESULTING IN NAUSEA OR ASPHYXIATION OF

NO.2 (280,000) @ 100 PSI

NO.1 (310,240) @ 120 PSI

NO.2 (313,600) @ 120 PSI

NO.1 (339,325) @ 150 PSI

NO.2 (343,000) @ 150 PSI

NO.1 (391,955) @ 200 PSI

NO.2 (343,000) @ 150 PSI

NO.1 (391,955) @ 200

NO.2 (396,000) @ 200 PSI

1-800-486-4328

1-204-633-1999

100 Eagle Drive

Winnipeg, MB Canada

sales@hermannelson.com

www.hermannelson.com

Page 6

CFM/AMPS

3,500 (Axial) 11.5/

5,500 (Turbo) 8.5

3,500 (Axial) 11.5/

3,500 (Axial) 11.5/

3,500 (Axial) 11.5/

MOTOR HP

Ductability (Axial/Turbo)

upto 0.65"/3"

upto 0.65"/3"

upto 0.65"/3"

Outlet Duct Size

Inlet Duct Size

Gas Conversion

Easy switch over

Natural Gas

Easy switch over

Natural Gas

Manifold pressure “W.C.

Minimum/Maximum

OPERATION

OPERATION

Nozzle

Pump Pressure

GPH

Fuel

1 1 1 1

5,500 (Turbo) 8.5

5,500 (Turbo) 8.5

5,500 (Turbo) 8.5

Static Pressure

(Axial/Turbo)

Supply Pressure “W.C.

24ft/150ft

upto 0.65"/3"

2 X 12" OR 1 X 16 2 X 12" OR 1 X 16 2 X 12" OR 1 X 16 2 X 12" OR 1 X 16

2 X 12" OR 1 X 16 2 X 12" OR 1 X 16 2 X 12" OR 1 X 16 2 X 12" OR 1 X 16

Blue handle Ball

Valve on Gas

manifold.

Closed position:

Propane

Open position:

3.5”NG or 4LP

(Pressure to be set

before NG/LP

switchover valve

and after adjusting

valve on manifold)

7/10

FOR NG AND LP

N/A N/A 2 X 60b 2 X 60B

24ft/150ft

Blue handle Ball

Valve on Gas

manifold.

Closed position:

Propane

Open position:

3.5”/NG or 3.5LP

(Pressure to be

set before NG/LP

switchover valve

and after adjusting

valve on manifold)

7/9

FOR NG AND LP

24ft/150ft

N/A N/A

N/A

N/A N/A

24ft/150ft

N/A

1-800-486-4328

1-204-633-1999

100 Eagle Drive

Winnipeg, MB Canada

N/A N/A 100/120/150/200 150/200

N/A N/A 2.82 2.82

NG or LP NG or LP

No. 1 or No. 2 /

Kerosene or Furnace

Oil

No. 1 or No. 2 /

Kerosene or Furnace

sales@hermannelson.com

www.hermannelson.com

Oil

Page 7

Head Setting

10.1 4 1 4

Air Setting (Beckett-

200 PSI 5/3

APPROVAL AGENCY

OMNI

OMNI

OMNI

OMNI

DRY WEIGHT (lbs.)

Dimensions

76.7” x 31” x 58”

76.7” x 31” x 58”

76.7” x 31” x 58”

76.7” x 31” x 58”

FLUE SIZE

Shutter/Band)

10/0 3.5

470 470 500 500

6” 6” 6” 6”

100 PSI 3/1

120 PSI 3/1

150 PSI 2/2

150 PSI 3.4

200 PSI 4.5

CONNECTING THE CYLINDER

Clearance to LP containers: 10 feet (3M)

IF CYLINDERS ARE USED TO SUPPLY THE HEATER, NO CYLINDERS SMALLER THAN 100

LB CAPACITY SHALL BE USED. THESE CYLINDERS MUST SUPPLY A VAPOUR

WITHDRAWAL ONLY.

1.) ALL CYLINDER CONNECTIONS MUST BE MADE USING A WRENCH TO TIGHTEN THE

POL FITTING.

2.) BE SURE THAT THE CYLINDER VALVE IS IN THE CLOSED POSITION WHEN

CONNECTING OR DISCONNECTING THE CYLINDER.

3.) PROPER PROCEDURE FOR GAS LEAK TESTING: A SOAP AND WATER SOLUTION

MUST BE APPLIED TO ALL CONNECTIONS IN ORDER TO LEAK CHECK THE SYSTEM.

4.) THE HOSE ASSEMBLY MUST BE VISUALLY INSPECTED PRIOR TO EACH USE OF

THE HEATER.

THE GAS MUST BE TURNED OFF AT THE PROPANE SUPPLY CYLINDER(S) WHEN THE

HEATER IS NOT IN USE. WHEN THE HEATER IS TO BE STORED INDOORS, THE

CONNECTION BETWEEN THE PROPANE SUPPLY CYLINDER(S) AND THE HEATER MUST

BE DISCONNECTED AND THE CYLINDERS REMOVED FROM THE HEATER AND STORED IN

ACCORDANCE WITH STANDARDS FOR THE STORAGE AND HANDLING OF LIQUIFIED

PETROLEUM GASES, ANSI/NFPA 58 AND CSA B149.1, NATURAL GAS AND PROPANE

INSTALLATION CODE.

PIPING: THIS HEATER MUST BE INSTALLED BY A QUALIFIED GAS TECHNICIAN

FOLLOWING LOCAL CODES PUBLISHED BY THE AUTHORITY HAVING JURISDICTION.

SIZING OF SUPPLY PIPING MUST BE DETERMINED USING THE LENGTH OF PIPE RUN AS

1-800-486-4328

1-204-633-1999

100 Eagle Drive

Winnipeg, MB Canada

sales@hermannelson.com

www.hermannelson.com

Page 8

WELL AS TOTAL BTUH RATING OF THE APPLIANCE(S). APPROPRIATE PIPING TABLES

MUST BE USED AND RATING PLATE MUST REFLECT THE FUEL THE HEATER IS BURNING.

MUST BE USED TO DETERMINE SIZE OF SUPPLY PIPING DEPENDANT ON THE LENGTH

OF RUN FROM SOURCE.

CONNECTING TO AN EXTERNAL FUEL TANK

(BLAZE 400 D)

Beckett CF375 and Riello F10 are fitted with 3/8” SAE male fittings and is set up for a 2 line system

to eliminate priming. Ensure fuel tank has a supply line and a return line and connect the supply

line to the 3/8” SAE fitting on the inlet side of the fuel filter and the return line to the return fitting

located on the Beckett Burner pump. For a 1 line system remove bypass plug located on inlet port

of Beckett Pump and just connect fuel line to inlet side of fuel filter.

FUEL (BLAZE 400 G)

THIS HEATER WILL OPERATE ON PROPANE OR NATURAL GAS—NOT BOTH. THE

MANIFOLD PRESSURES ARE LISTED ON THE APPROVAL LABEL. TO DETERMINE WHICH

FUEL TO USE SEE RATING PLATE. DO NOT ATTEMPT TO USE THE HEATER WITHOUT

CONSULTING THE RATING PLATE.

NOTE: THE PROPER POSITION ON THE EASY SWITCH OVER BLUE HANDLE BALL VALVE

DO NOT OPERATE THE HEATER WITHOUT CONSULTING THE RATING PLATE.

HEATER CONVERSION MUST BE DONE BY A QUALIFIED TECHNICIAN AND RATING PLATE

MUST REFLECT ANY CHANGE.

THIS UNIT HEATER IS EQUIPPED FOR NATURAL GAS OR LP GAS. THIS UNIT HEATER IS

EQUIPPED WITH ORIFICES SIZED FOR OPERATION WITH NATURAL OR LP GAS VIA THE

EASY SWITCH OVER BLUE HANDLE BALL VALVE. FOR CONVERSION TO LP (OR

NATURAL) GAS SEE INSTRUCTION PLATE ON THE APPLIANCE.

Easy switch over Blue handle Ball Valve on Gas manifold.

Closed position: Propane

Open position: Natural Gas

HOSES

ALL HOSES USED TO CONNECT THIS HEATER TO FUEL SUPPLY MUST BE TYPE 1

APPROVED PROPANE/NATURAL GAS HOSE ASSEMBLIES.

1-800-486-4328

1-204-633-1999

100 Eagle Drive

Winnipeg, MB Canada

sales@hermannelson.com

www.hermannelson.com

Page 9

ELECTRICAL

BLAZE

400 D/G

WARNING: ELECTRICAL GROUNDING INSTRUCTIONS

THIS APPLIANCE IS ABLE IS TO RECEIVE 1 PHASE POWER.

120V SUPPLY MUST BE AVAILABLE.

INSTALLATION

12/3 AWG UPTO 50FT

10/3 AWG BEYOND 50FT

NOTE: IF ANY OF THE ORIGINAL WIRE AS SUPPLIED WITH THE APPLIANCE MUST BE

REPLACED, IT MUST BE REPLACED WITH TYPE TEW 14GA WIRE OR ITS EQUIVALENT.

ELECTRICAL SYSTEM

Volts-Hertz-Phase

120-60-1

Full Load (Amps) (Axial/Turbo)

Max fuse size in AMPS (Axial/Turbo)

with time delay

11.5/8.5

15

The electrical grounding of the heater shall be in compliance with the National Electrical Code, ANSI/NFPA

70, or the CSA C22.1, Canadian Electrical Code, Part I

1-800-486-4328

1-204-633-1999

100 Eagle Drive

Winnipeg, MB Canada

sales@hermannelson.com

www.hermannelson.com

Page 10

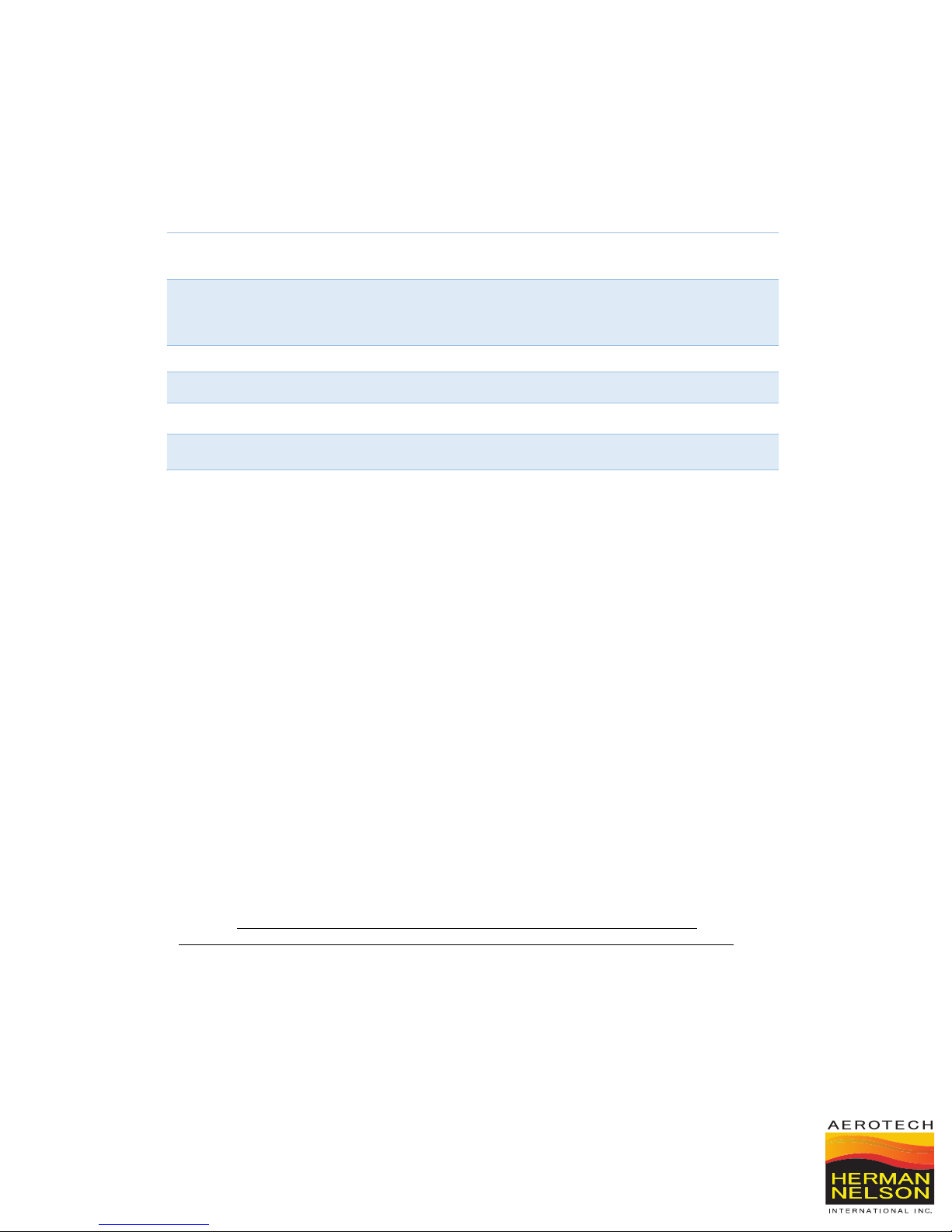

Blaze 400G Sch. with E Fan-Beckett CG10 -24

Blaze 400G Schematic with Axial Fan

(Beckett CG10 -24 NG/LP Burner)

1-800-486-4328

1-204-633-1999

100 Eagle Drive

Winnipeg, MB Canada

sales@hermannelson.com

www.hermannelson.com

Page 11

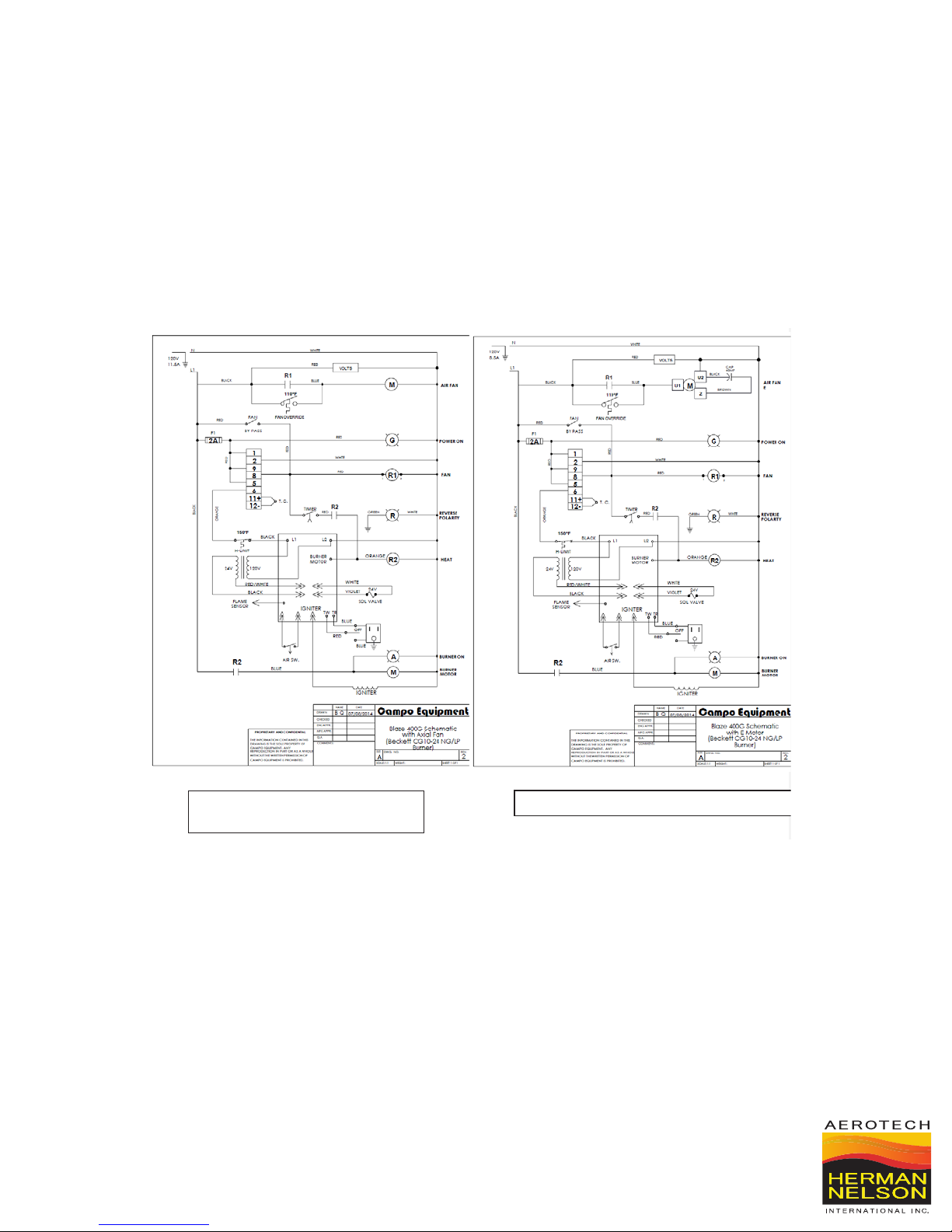

1-800-486-4328

Blaze 400G Sch. with Axial Fan-Riello G400

Blaze 400G Sch. with R Fan-Beckett CG10-24

1-204-633-1999

100 Eagle Drive

Winnipeg, MB Canada

sales@hermannelson.com

www.hermannelson.com

Page 12

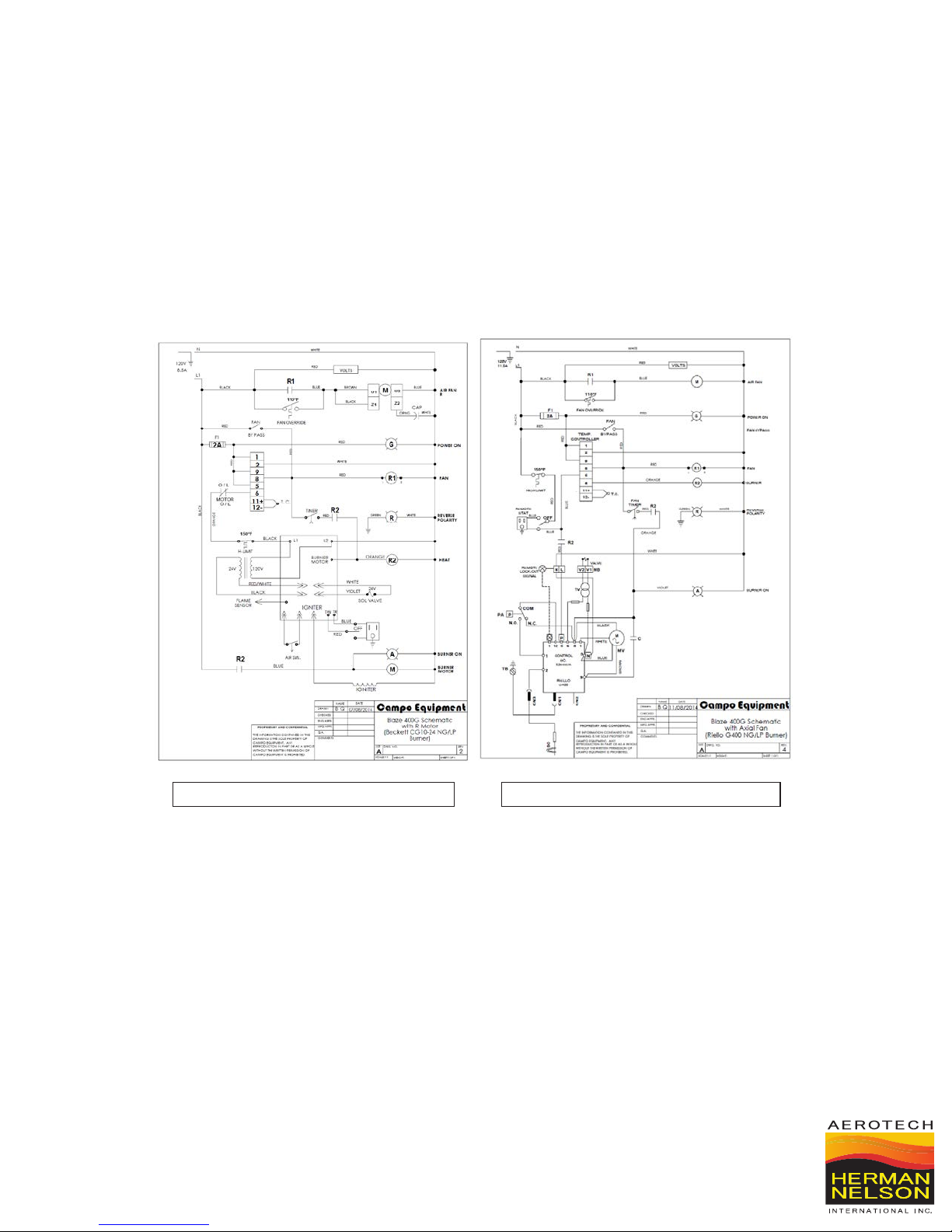

1-800-486-4328

Blaze 400G Sch. with R Fan-Riello G400

Blaze 400G Sch. with E Fan-Riello G400

1-204-633-1999

100 Eagle Drive

Winnipeg, MB Canada

sales@hermannelson.com

www.hermannelson.com

Page 13

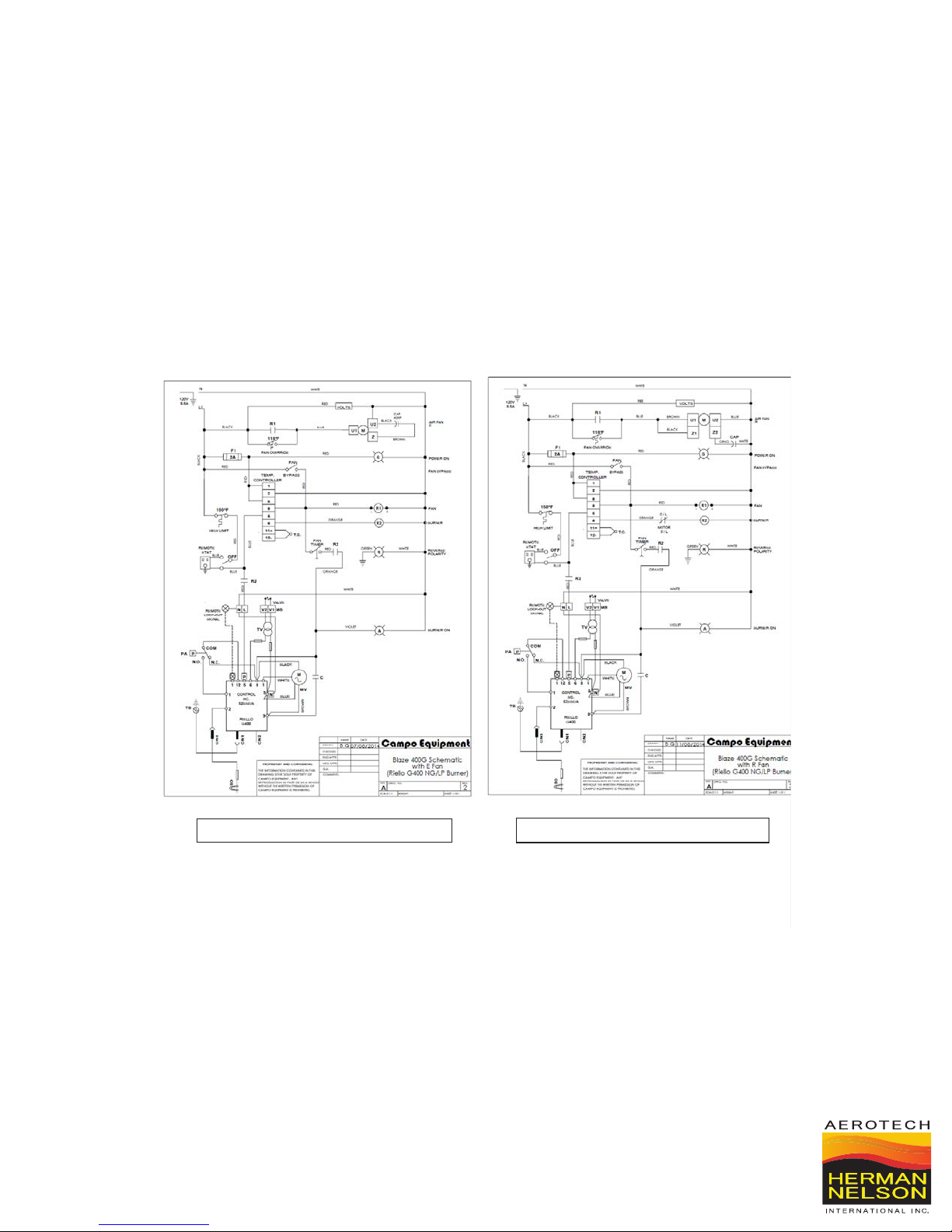

1-800-486-4328

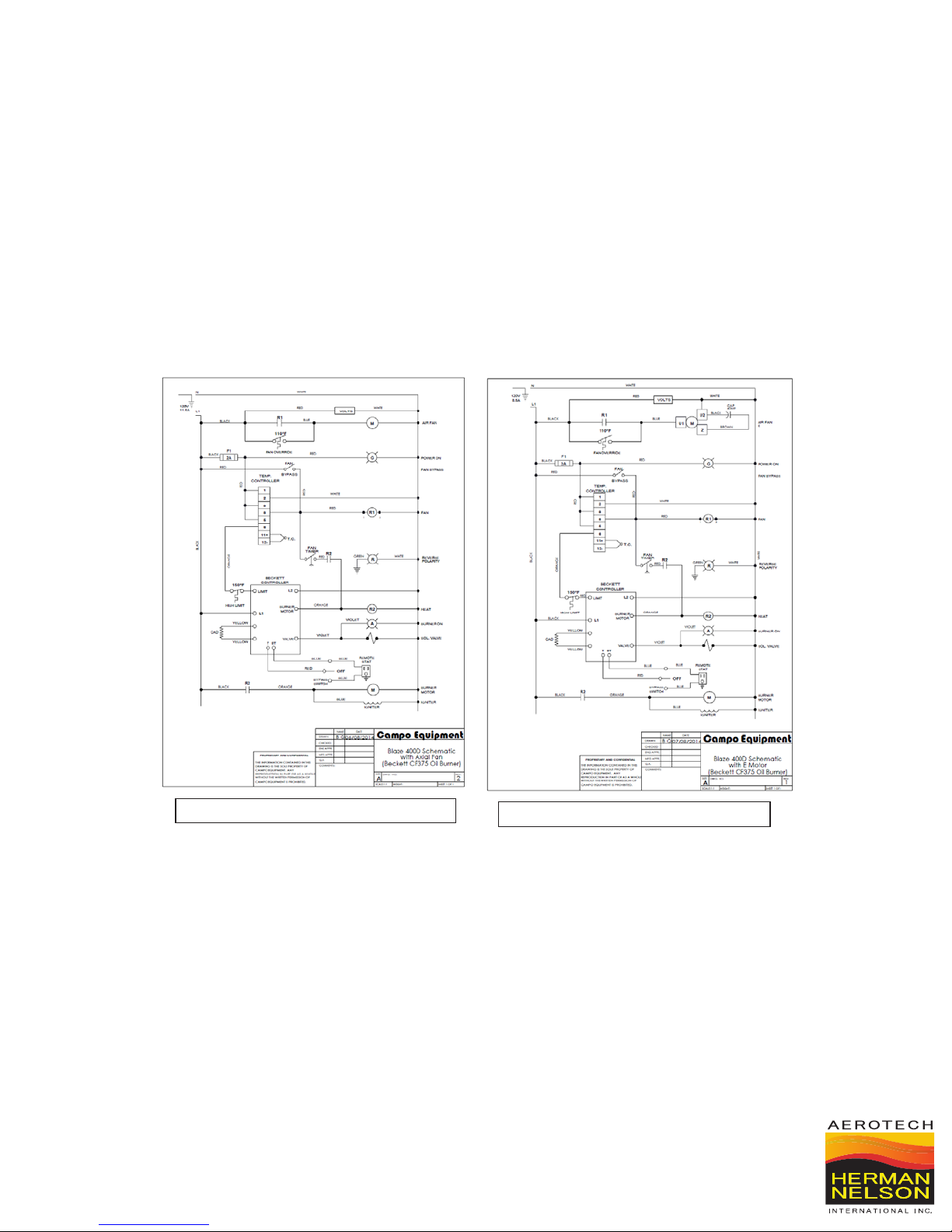

Blaze 400D Sch. with E Fan-Beckett CF375

Blaze 400D Sch. with Axial Fan-Beckett CF375

1-204-633-1999

100 Eagle Drive

Winnipeg, MB Canada

sales@hermannelson.com

www.hermannelson.com

Page 14

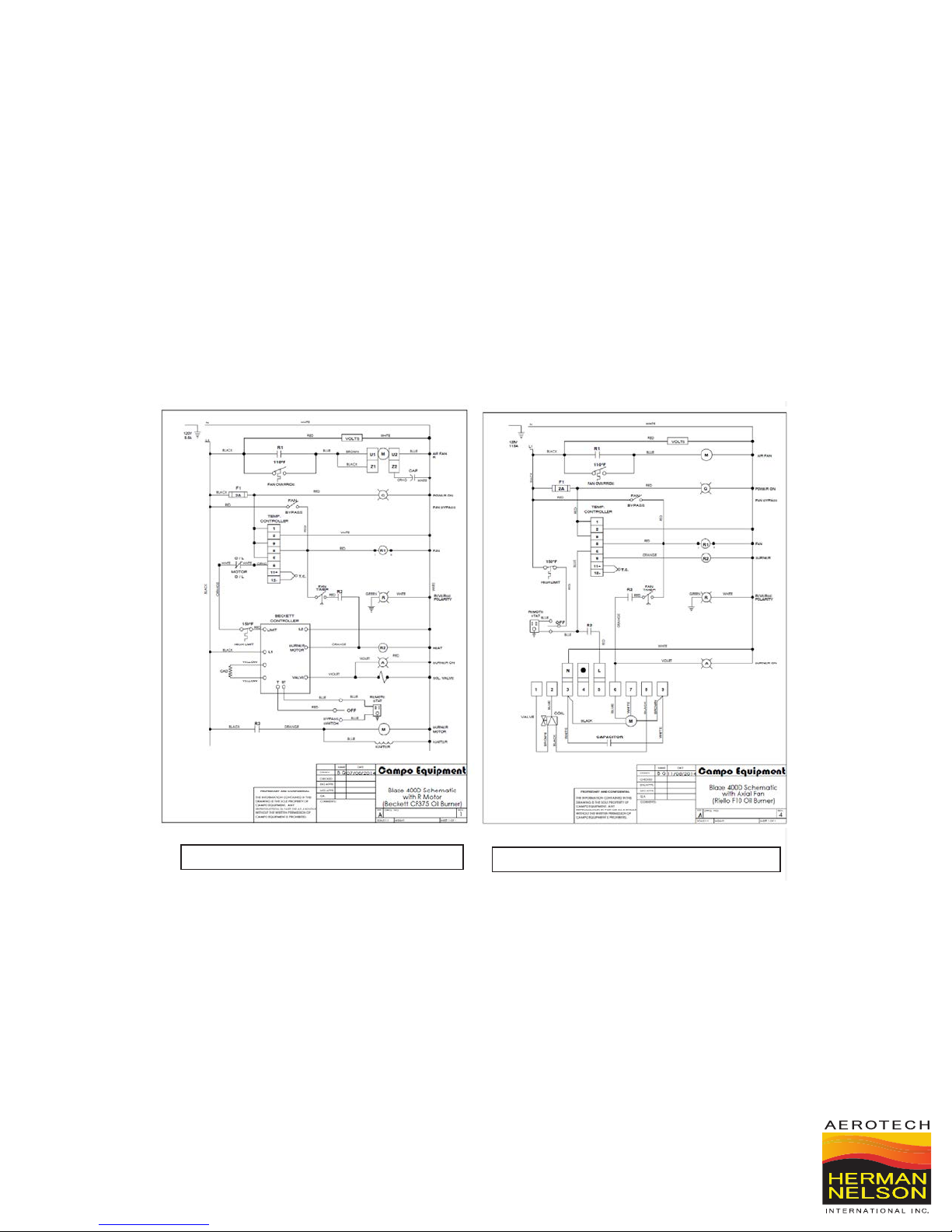

1-800-486-4328

Blaze 400D Sch. with Axial Fan-F10 Oil Burner

Blaze 400D Sch. with R Fan-Beckett CF375

1-204-633-1999

100 Eagle Drive

Winnipeg, MB Canada

sales@hermannelson.com

www.hermannelson.com

Page 15

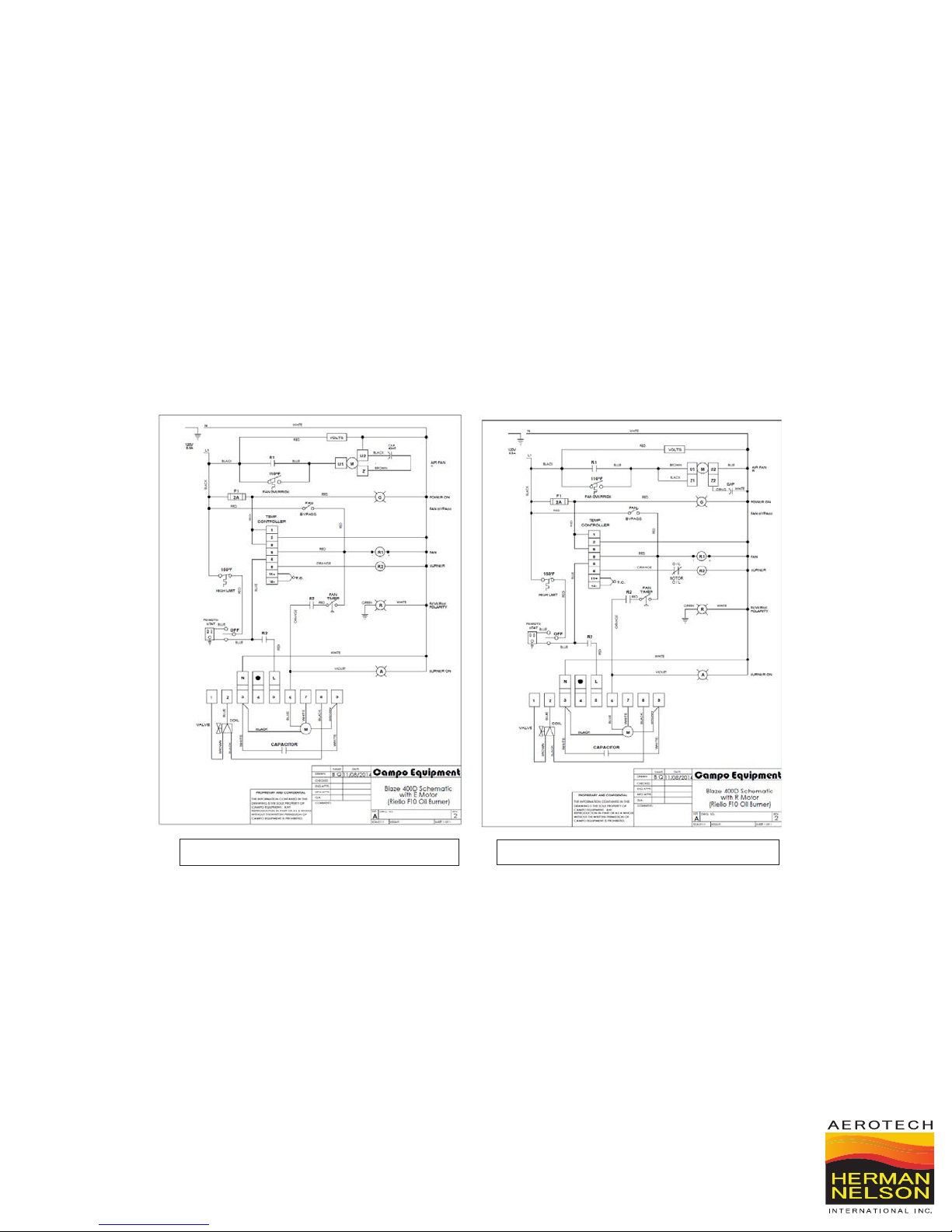

1-800-486-4328

Blaze 400D Sch. with R Motor-F10 Oil Burner

Blaze 400D Sch. with E Motor-F10 Oil Burner

1-204-633-1999

100 Eagle Drive

Winnipeg, MB Canada

sales@hermannelson.com

www.hermannelson.com

Page 16

SEQUENCE OF OPERATION FOR BLAZE 400 D/G

FOR THERMOSTAT OPERATION FLIP SELECTOR SWITCH TO “STAT ON” POSITION. IF YOU ARE NOT

With “Selector Switch” in “ON” position and selector switch in “STAT ON” position and remote

thermostat plugged into receptacle:

1: Remote Thermostat senses a drop in temperature and the ignition control module is energized.

2: The module performs a safe start check and the burner and spark generator start. Burner lights, ignition

stops, and flame current is sensed.

For oil: the Genisys primary control contacts close, the burner motor and ignitor are

energized after a 15 second delay. The primary control energizes the pump solenoid valve and flame is

established. The cad cell senses flame and the burner continues to fire.

3: Temperature controller thermocouple heats up to factory set point (90F) OR after Time Delay of 1

minute and circulating air blower starts.

4: When the remote thermostat senses space temperature at set point, the burner shuts down.

5: The circulating blower continues to operate until the air in the unit cools to the factory set point (80 ºF)

then turns off.

With selector switch in “BYPASS” position:

1: The module performs a safe start check and the burner and spark generator start.

2: Burner lights, ignition stops, and flame current is sensed.

3: Temperature controller thermocouple heats up to factory set point (90F) and circulating air blower starts.

4: When the selector switch is placed to the off position the burner shuts down.

5: The circulating blower continues to operate until the air in the unit cools to the factory set point (80F)

then turns off.

OPERATING INSTRUCTIONS FOR BLAZE 400 D/G

STARTING HEATER

1.) ENSURE HEATER IS ON FLAT, LEVEL GROUND BEFORE STARTING, CANOPY AND FAN GUARDS

MUST BE CLOSED.

2.) MAKE SURE “SELECTOR SWITCH” IS IN “OFF” POSITION.

3.) WIRE IN SUPPLY CORD TO 120V SUPPLY WITH GROUND.

INSTALLATION

12/3 AWG UPTO 50FT

10/3 AWG BEYOND 50FT

4.) TURN “SELECTOR SWITCH” TO “ON” POSITION.

5.)

USING A THERMOSTAT FLIP SELECTOR SWITCH TO “BYPASS” POSITION.

Please Note: When using a generator for electrical supply, make sure the generator is properly grounded and

is running at a 60HZ frequency. In the event that a generator is being used and the generator runs out of fuel,

make sure the heater “SELECTOR SWITCH” is in the “OFF” position before restarting generator, failure to do

so may damage heater.

STOPPING HEATER

1.) Close main gas supply valve while heater is operating or if operating heater with oil skip to # 2.)

2.) Flip “SELECTOR SWITCH” to “OFF” position. The supply fan will continue to operate until the heat exchanger

has sufficiently cooled. Do not disconnect main power until supply fan has stopped running and “SELECTOR

SWITCH” is on “OFF” position.

3.) Disconnect heater from gas supply OR disconnect fuel oil lines.

1-800-486-4328

1-204-633-1999

100 Eagle Drive

Winnipeg, MB Canada

sales@hermannelson.com

www.hermannelson.com

Page 17

CAUTION

ELECTRICAL REQUIREMENTS: 15 AMPS (1PH)

WARNING BEFORE REMOVING ANY GUARDS OR SAFETIES TURN “SELECTOR SWITCH” TO “OFF”

POSITION AND DISCONNECT THE MAIN POWER AS THE SUPPLY FAN WILL CYCLE AUTOMATICALLY.

IF HEATER FAILS TO START

1.) PRESS BURNER RESET BUTTON TO RESET CONTROL ON RIELLO F10 or G400. FOR BECKETT

BURNERS 7505 or 7595 PRESS AND HOLD THE RED BUTTON ON THE BECKETT GENISYS

CONTROLLER LOCATED ON THE CONTROL PANEL FOR 3 SECONDS TO RESET. FOR 7540 PRESS

RED BUTTON TO RESET.

2.) FOR GAS OPERATION CHECK GAS PRESSURE SUPPLY. SUPPLY AND MANIFOLD PRESSURE MUST

FOLLOW THOSE ON RATING PLATE. FOR OIL OPERATION CHECK FUEL LEVEL, FILTER, NOZZLE

AND SUCTION TUBING.

3.) ENSURE PROPER POWER SUPPLY AND WIRE GAUGE IS BEING USED.

4.) IF HEATER FAILS TO IGNITE AFTER 3 ATTEMPTS, CALL YOUR SUPPLIER FOR SERVICE.

NOTE: IF UNIT HAS BEEN RESET A NUMBER OF TIMES WITHOUT IGNITION -- DO NOT ATTEMPT TO START

THE HEATER: CONTACT A QUALIFIED SERVICE TECHNICIAN.

NOTE: IN OIL OPERATION IF UNIT HAS BEEN RESET A NUMBER OF TIMES WITHOUT IGNITION THERE WILL

BE AN ACCUMULATION OF OIL IN THE COMBUSTION CHAMBER! DO NOT ATTEMPT TO START THE

HEATER: CONTACT A QUALIFIED SERVICE TECHNICIAN.

1.) DO NOT SHUT OFF BY DISCONNECTING SUPPLY CORD. THE HEAT EXCHANGER SHOULD BE

PROPERLY COOLED BEFORE POWER SHUTDOWN.

2.) ALWAYS MAINTAIN ADEQUATE FUEL SUPPLY.

3.) IF GAS BURNER IS INSTALLED HEATER IS FOR USE WITH PROPANE OR NATURAL GAS ONLY.

SEE APPROVAL LABEL.

4.) DO NOT PLUG ANYTHING OTHER THAN THE THERMOSTAT INTO THE “REMOTE STAT” PLUG.

5.) FOLLOW ELECTRICAL REQUIREMENTS SHOWN ON RATING PLATE AND/OR ELECTRICAL

REQUIREMENTS SECTION OF THIS MANUAL.

6.) IN OIL OPERATION DO NOT START THE HEATER WHEN EXCESS OIL HAS ACCUMULATED IN

CHAMBER.

7.) IN OIL OPERATION DO NOT FILL TANK WHILE UNIT IS OPERATING.

8.) IN NO CASE SHOULD POWER CABLES BE SMALLER THAN WHAT IS STIPULATED ON

NAMEPLATE AND INSTRUCTION MANUAL.

9.) IN OIL OPERATION DO NOT USE GASOLINE, CRANKCASE OIL OR HEAVIER THAN NO. 2 FURNACE

OIL.

10.) DO NOT START THE HEATER WHEN THE CHAMBER IS HOT

11.) DO NOT FILL THE TANK WHILE THE UNIT IS OPERATING

12.) DO NOT TAMPER WITH THE UNIT. HAVE A COMPETENT SERVICE-TECHNICIAN MAKE ANY

ADJUSTMENTS

13.) MAX OUTLET TEMPERATURE (U.S./CA) 280F

14.) AT INSTALLATION ELEVATIONS ABOVE 2000 FT (610m), THE APPLIANCE SHALL BE DERATED 4

PERCENT FOR EACH 1000 FT (305m) OF ELEVATION ABOVE SEE LEVEL

15.) SHOULD OVERHEATING OCCUR, OR THE GAS SUPPLY CONTROL SYSTEM FAIL TO SHUT OFF

THE FLOW OF GAS, SHUT OFF THE MANUAL GAS VALVE TO THE UTILITY HEATER BEFORE

SHUTTING OFF THE ELECTRICAL SUPPLY.

16.) DO NOT USE THIS UTILITY HEATER IF ANY PART HAS BEEN UNDER WATER. IMMEDIATELY CALL

A QUALIFIED SERVICE TECHNICIAN TO INSPECT THE HEATER AND REPLACE ANY GAS

CONTROL WHICH HAS BEEN UNDER WATER.

1-800-486-4328

1-204-633-1999

100 Eagle Drive

Winnipeg, MB Canada

sales@hermannelson.com

www.hermannelson.com

Page 18

INSTALLATION INSTRUCTIONS

NOTE: Installation clearances are as follows:

TOP

3 feet

SIDES

3 feet

BURNER END

3 feet

DISCHARGE END

10 feet

VENT CONNECTOR

3 feet

COMBUSTIBLE FLOOR

6 feet

Commented [L1]: Added here

1.) The recommendations of local authorities having jurisdiction must be followed. For

recommended installation practices refer to C.S.A. standard B139. (CANADA)

2.) When firing the unit in an enclosed area allow 1 square inch per thousand BTU’s (refer to

C.S.A. B139) to allow the free entry of the air required for operation.

3.) For electrical supply: 120V

INSTALLATION

12/3 AWG UPTO 50FT

10/3 AWG BEYOND 50FT

Do not operate the unit in partly ventilated areas without a flue pipe or in close proximity to

combustible surfaces or materials. Non Combustible floor must extend 6 feet on all sides of

the unit.

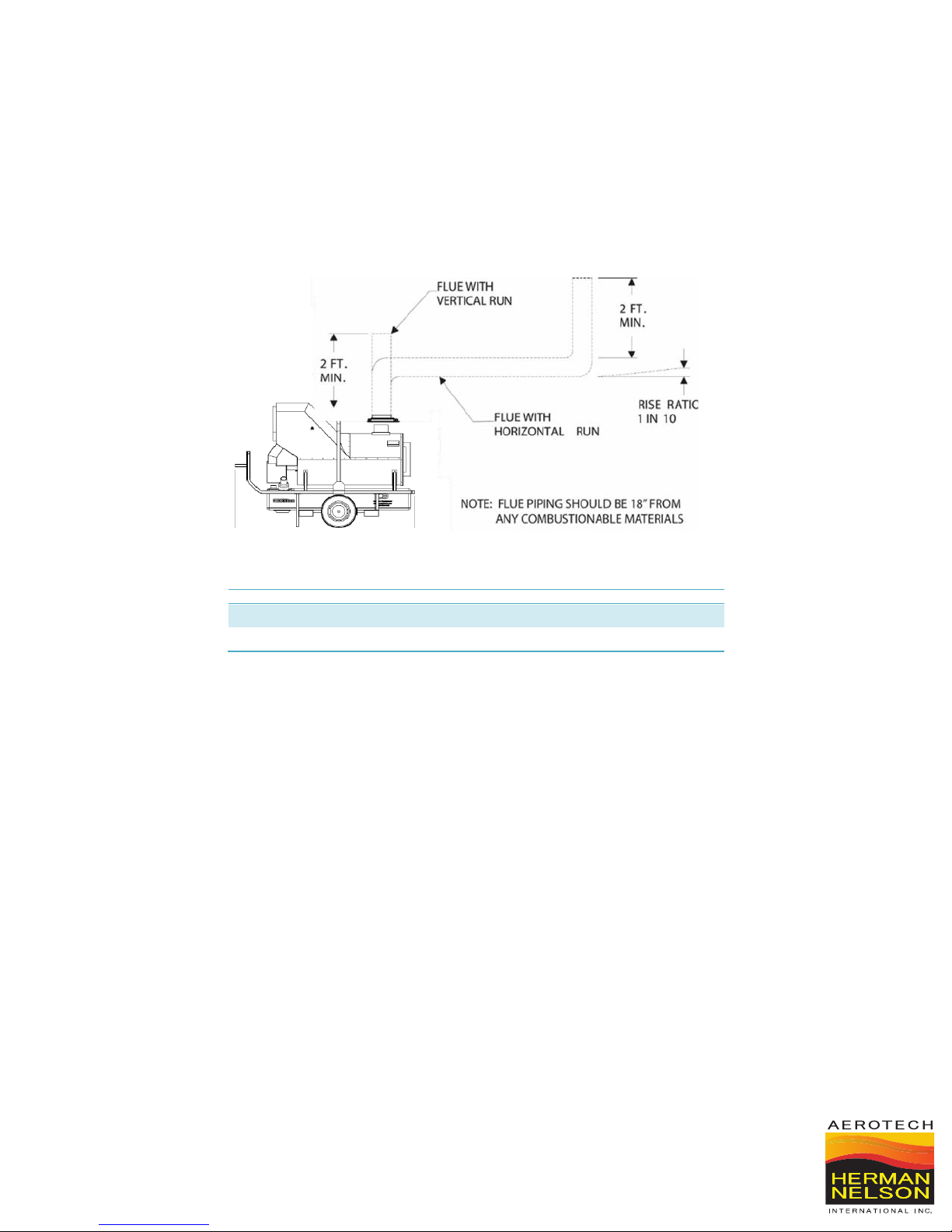

FLUE PIPE CONNECTIONS

VENT TO OUTDOORS

FOR INSTALLATION ON NON-COMBUSTIBLE FLOORS ONLY

When the heater is connected to a flue pipe the flue pipe shall terminate in a vertical section at

least two feet long. Horizontal runs should have rise ratio of 1 in 10 away from the heater. Where

down drafts are liable to occur a vent cap should be used. All venting should correspond with the

CSA B139 standard or local codes.

CAUTION: HEATER FLUE TEMPERATURES CAN REACH 700 °F TO 900 °F THEREFORE IT IS

A RANGE THAT IS BOTH HAZARDOUS TO HUMANS AND HIGHER THAN THE AUTOIGNITION TEMPERATURES OF MANY MATERIALS. THEREFORE EXERCISE CAUTION IN

HEATER PLACEMENT AND THE USE OF AN INSULATED GUARD AND STACK IS HIGHLY

RECOMMENDED.

Horizontal venting runs shall always terminate with a minimum 24” vertical.

NOTE: FOR OPTIMAL COMBUSTION PERFORMANCE A 30” C-VENT FLUE EXTENSION WITH

RAIN CAP IS RECOMMENDED AT ALL TIMES.

Recommended chimney draft - .05 inches of water column

1-800-486-4328

1-204-633-1999

100 Eagle Drive

Winnipeg, MB Canada

sales@hermannelson.com

www.hermannelson.com

Page 19

INSTALLATION

MAXIMUM ALLOWABLE DUCT LENGTHS BL AZE 400 D/G

RETURN DUCTS upto 12’ on Axial and 24’ on Turbo

SUPPLY DUCTS upto 24’ on Axial and 150’ on Turbo

CLEARANCES

THIS HEATER IS FOR USE WITH AND WITHOUT DUCTWORK

WHEN USING DUCTWORK AVOID ANY KINKS OR SHARP BENDS.

INSUFFICIENT INLET AIR OR INSUFFICIENT DISCHARGE AIR WILL CAUSE

THE HEATER TO OVERHEAT.

BLAZE 400 D/G MAINTENANCE INSTRUCTIONS

WARNING EVERY CONSTRUCTION HEATER SHOULD BE INSPECTED

BEFORE EACH USE, AND AT LEAST ANNUALLY BY A QUALIFIED SERVICE

PERSON. INCORRECT MAINTENANCE MAY RESULT IN IMPROPER

OPERATION OF THE HEATER AND SERIOUS INJURY COULD OCCUR.

HOSE ASSEMBLIES

The hose assemblies shall be visually inspected prior to each use of the heater. If it is evident there is excessive

abrasion or wear, or the hose is cut, it must be replaced prior to the heater being put into operation. The replacement

hose assembly shall be that specified by the manufacturer.

1-800-486-4328

1-204-633-1999

100 Eagle Drive

Winnipeg, MB Canada

sales@hermannelson.com

www.hermannelson.com

Page 20

TEMPERATURE CONTROLLER AND THERMOCOUPLE

The temperature controller protocols should be checked every heating season to ensure the burner will shutdown if

temperature exceeds 280F at the outlet duct. This can be accomplished by restricting the air flow through the unit.

After tests are complete, remove restrictors as both inlet and outlet ducts must be open for proper operation.

The temperature controller setting of 90F and time delay of 1 minute has been selected to allow for preheating of the

heat exchanger to ensure that only heated air is allowed to enter the space. Upon satisfying the need for heat, the

temperature controller will continue to run the supply fan until the heat exchanger has cooled sufficiently. This feature

will help prolong the life of the heat exchanger. The temperature controller must be replaced if the fan motor does not

shut off after the heat exchanger has cooled down.

Temperature Controller Protocols

Fan Turns on at 90 F OR time delay of 1 minute

Out # 2 is set at 275º (This will cycle the burner off 280º and back on at 275º.) If the burner reset light goes on; you

need to go to the control panel. For the Beckett CG10A and CF375 the controller must be reset by pressing the reset

button. For the Riello G400 and F10 burners the primary controller located on the burner must be reset.

There is a redundant 150F high limit switch.

During cool down the unit cools to 80F and then shuts down.

ELECTRICAL

Ensure all conduit (BX) connectors are tight. Open control panel door and burner compartment and check connections

are tight and no frayed wires exposed.

FAN

Check for dust or dirt build up on blades. Run heater to check for fan vibration. Replace fan blade if vibration is

noticeable. The flow of combustion and ventilation air must not be obstructed. Be sure to check the fan assembly and

ensure that the motor and blade are operating properly.

MOTOR

No lubrication is necessary since the bearings are the sealed type. Clean motor of existing dust or dirt.

GAS TRAIN (annual basis)

Connect gas supply to gas train with gas safety shut-off valves closed. Spray all of gas train components including

safety shut-off valves with soap and water solution to check for leaks. Open safety shut off valves on gas train and

spray with soap and water solution to check for leaks.

HEAT EXCHANGER

If a smoky condition continues even after adjusting the air assembly, the heat exchanger should be thoroughly

cleaned.

FUEL FILTER (OIL OPERATION)

Replace cartridge every six months of normal usage.

NOTE: FLOW OF COMBUSTION AND VENTILATION AIR CANNOT BE OBSTRUCTED

FLAME DETECTOR (OIL OPERATION)

When doing maintenance, turn on machine and run. After having machine run for a few minutes, press red button on

primary control. Hold for one second and then release. If light flashes once or twice or three times, cad cell is

functioning properly. If flashes four times, check alignment and proper flame. If correct a cleaning of the face of the

1-800-486-4328

1-204-633-1999

100 Eagle Drive

Winnipeg, MB Canada

sales@hermannelson.com

www.hermannelson.com

Page 21

cad cell with a soft non-abrasive cloth is recommended. If light flashes 4 times, follow above steps. If flashing four

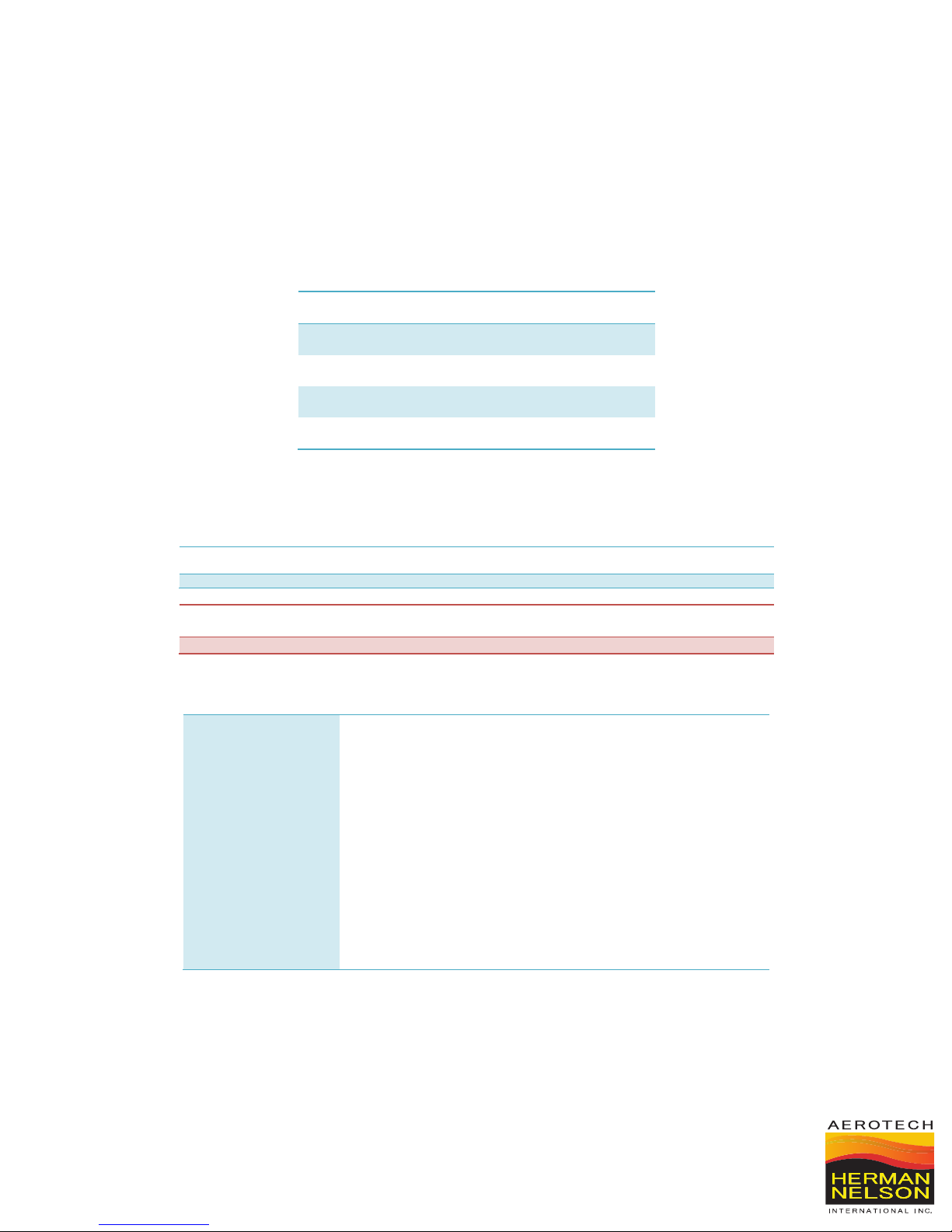

LED FLASHES

CAD CELL RESISTANCE

1

0-400 Ohms

2

400-800 Ohms

3

800-1600 Ohms

4

>=1600 Ohms

AFTER INSPECTION, A COMPLETE COMBUSTION TEST MUST BE PEFORMED AFTER EACH ANNUAL

SERVICE OF THE UNIT TO MAINTAIN OPTIMUM PERFORMANCE AND RELIABILITY.

WARNING: TURN OFF THE FUEL SUPPLIES AND POWER BEFORE PERFORMING

SERVICE WORK. THE 120V CIRCUIT IS A POTENTIAL ELECTROCUTION HAZARD.

BLAZE 400G-

BLAZE 400G-

BLAZE 400D-

BLAZE 400D-

Easy switch over

Easy switch over

N/A

N/A

3.5NG/4LP

3.5 NG/3.5 LP

N/A

N/A

times persists, replace cad cell.

BURNER (OIL OPERATION)

The electrode spacing must be checked and adjusted, if necessary after every nozzle change. Nozzle should be

replaced annually or sooner if burner cannot be set up to operate properly. Nozzle size and type are marked on the

rating plate.

COMBUSTION AIR ADJUSTMENTS

BLAZE 400 D/G

SPECIFICATIONS

Gas Conversion

Manifold pressure “W.C.

1-204-633-1999

1-800-486-4328

100 Eagle Drive

Winnipeg, MB Canada

BECKETT (NG/LP)

Blue handle Ball

Valve on Gas

manifold.

Closed position:

Propane

Open position:

Natural Gas

(Pressure to be set

before NG/LP

switchover valve

and after adjusting

valve on manifold)

RIELLO (NG/LP)

Blue handle Ball

Valve on Gas

manifold.

Closed position:

Propane

Open position:

Natural Gas

(Pressure to be

set before NG/LP

switchover valve

and after adjusting

valve on manifold)

sales@hermannelson.com

www.hermannelson.com

BECKETT (OIL)

RIELLO (OIL)

Page 22

Minimum/Maximum

OPERATION

OPERATION

200 PSI 5/3

WARNING: LACK OF COMBUSTION AIR CAN CAUSE A DIRTY FIRE, ODOURS IN ENCLOSED

THE OCCUPANTS.

ALL AIR ADJUSTMENTS MUST BE DONE BY A QUALIFIED SERVICE TECHNICIAN

Supply Pressure “W.C.

7/10

FOR NG AND LP

7/9

FOR NG AND LP

N/A N/A

Nozzle

Pump Pressure

Head Setting

Air Setting (BeckettShutter/Band) (Riello Air

Gate)

NOTE: The above settings are approximations based upon clean equipment in proper working order. Combustion air

adjustments will vary with location, altitude and type of fuel used.

BECKETT CG10-24 (THE BECKETT CG10-24 BURNER IS DESIGNED TO BE USED SOLELY WITH THE

BECKETT 7590 GAS BURNER PRIMARY CONTROL AND THE 7474 GAS IGNITER.

1.) Loosen shutter and band and move to desired settings.

2.) Once desired settings are attained lock in place by tightening back shutter and band screws.

N/A N/A 2 X 60B 2 X 60B

N/A N/A 100/120/150/200 150/200

10.1 4 1 4

10/0 3.5 100 PSI 3/1

120 PSI 3/1

150 PSI 2/2

150 PSI 3.4

200 PSI 4.5

SPACES, AND BACKDRAFTING, POTENTIALLY RESULTING IN NAUSEA OR ASPHYXIATION OF

1-800-486-4328

1-204-633-1999

100 Eagle Drive

Winnipeg, MB Canada

sales@hermannelson.com

www.hermannelson.com

Page 23

RIELLO G400

1 – Control box

2 – Air pressure switch

3 – Screw for fixing the cover

4 – Cable grommet

5 – Wiring terminal block

6 – Screws for fixing the air-damper

7 – Air damper

8 – Capacitor

9 – Reset button with lock-out lamp

10 – Gas valve transformer 120V / 24V

1-800-486-4328

1-204-633-1999

100 Eagle Drive

Winnipeg, MB Canada

sales@hermannelson.com

www.hermannelson.com

Page 24

RIELLO F10 OIL BURNER

1-800-486-4328

1-204-633-1999

100 Eagle Drive

Winnipeg, MB Canada

sales@hermannelson.com

www.hermannelson.com

Page 25

1-800-486-4328

1-204-633-1999

100 Eagle Drive

Winnipeg, MB Canada

sales@hermannelson.com

www.hermannelson.com

Page 26

BECKETT CF375 OIL BURNER

COMBUSTION AIR ADJUSTMENTS

For proper combustion air adjustment a calibrated

gas analyzer and smoke tester should be used to

ensure complete combustion. Air adjustment should

be made at the correct input and be adjusted to

achieve 5% Oxygen and 12% CO2. For optimum

combustion efficiency the combustion air control

should be set to provide no more than No. 1 smoke

(Bacharach Scale). The Beckett burner has a

calibrated air band, which will assist in adjusting the

primary air for a good oil/air mixture. Adjust the air

band supply by loosening lock screws and moving air

shutter and if necessary the bulk air band. Begin by

reducing the air until the unit begins to produce

smoke. Increase air until no smoke is produced.

Check for excessive heat build up in the heat

exchanger. Insufficient air will cause flame

impingement and reduced heat exchanger life.

Increase air until heat build up has been eliminated.

Check for proper ignition. Once satisfied re-tighten all

screws and locking mechanisms.

This adjustment is to be carried out while the unit is operating and after 5 minutes of firing. Rotating the air bands on

the burner housing makes the adjustment.

1-800-486-4328

1-204-633-1999

100 Eagle Drive

Winnipeg, MB Canada

sales@hermannelson.com

www.hermannelson.com

Page 27

SETTING GAS FIRING RATES

1.) Choose BTU required and fuel supplied. For example 399,000 BTU and Natural Gas with the Beckett CG10-24.

2.) Adjust the manifold pressure to the recommended setting (5).

3.) Check nameplate for recommended air setting. A 10/0 air setting is recommended.

4.) Measure the carbon monoxide level and adjust air settings, if necessary, to regulate it to about 50 PPM for a

starting point.

5.) Measure the O2 or CO2 at the 50 PPM level. For example, assume the O2 is 1.5% (11% CO2).

6.) Open the air adjustment until the O2 level is increased to 3% O2. This should reduce the CO level and provide a

margin of reserve air to accommodate variable conditions.

7.) Sample the CO level again. It should be in the 0 to 50 PPM range—50 according to settings.

8.) Check the draft to ensure it still meets specifications. If a major change in draft is required, repeat the above

steps.

9.) Perform any final adjustments and lock the air settings securely. Run the burner through several cycles to verify

prompt ignition and stable burner operation.

SETTING OIL FIRING RATES

1.) Choose BTU required. For example 396,000 BTU with the Beckett CF375 oil burner.

2.) Check name plate for recommended pump pressure. 200 psi is recommended.

3.) Check nameplate for recommended air setting. A 5/3 air setting is recommended.

4.) Look at pressure gauge in pump gauge port and start the burner. Operate for 5 minutes until blower fan starts.

5.) Adjust pump pressure to 200 PSI.

6.) Adjust air band to 3 and adjust air shutter to 5.

7.) Check smoke and CO2 levels. Once attained, lock air band and shutter in place.

8.) Shut off burner, let unit cool down. The unit is now adjusted for 396,000 input BTU’s.

THERMOSTAT OPERATION

The BLAZE 400 D/G can be operated with a thermostat control.

An optional remote thermostat is available for temperature control for the space being heated. To connect the

heatstat, simply plug the heatstat into an extension cord and the extension cord into the outlet marked “REMOTE

STAT”. Make sure selector is in the “STAT ON” position. Place the remote thermostat into the space that is being

heated. The unit will now shut down at the remote thermostat temperature setting.

1-800-486-4328

1-204-633-1999

100 Eagle Drive

Winnipeg, MB Canada

sales@hermannelson.com

www.hermannelson.com

Page 28

BECKETT CG10-24 PARTS BREAKDOWN

Major Components

Item

Description

1

Jacking Screw

2

Ignition Transformer

3

Primary Control

4

Blower Motor

5

Air Flow Proving Switch

6

Electrode Cable

7

Not used

8

Shutter

9

Air Band

10

Not used

11

Manifold Pressure Test

Connection

12

Gas Gun Assembly

1-800-486-4328

1-204-633-1999

100 Eagle Drive

Winnipeg, MB Canada

sales@hermannelson.com

www.hermannelson.com

Page 29

For replacement parts please contact Campo Equipment 1.866.323.0042

Item

Description

Part #

1

Ignition Transformer

747400RU

2

Not Used

N/A

3

Primary Control

7590 DOOIU

4

NOT USED

N/A

5

Shutter

3215U

6

Not Used

7

Air Band

3819A

8

Motor -120v

21341U

9

Blower Wheel -CG10 -24

21448U

10

Air Proving Switch

52264002U

11

Electrode Set

21912014

12

Spring Clamps (4 in pckg.)

3236501U

Item

Description

Part #

13

Head

101U

14

Cable, Ignition Electrode

5990130U

15

O-ring set (2 in package)

3226401U

16

Gas Tube Assembly

5193201U

17

Jacking Screw

5193401U

18

Air Tube

Call for Part #

19/20

Cable, Flame Rod

7590FRU

NG/LP Easy Switchover

Valve

78896

24V Transformer

5231OU

1-800-486-4328

1-204-633-1999

100 Eagle Drive

Winnipeg, MB Canada

sales@hermannelson.com

www.hermannelson.com

Page 30

RIELLO G400 PARTS BREAKDOWN

1-800-486-4328

1-204-633-1999

100 Eagle Drive

Winnipeg, MB Canada

sales@hermannelson.com

www.hermannelson.com

Page 31

1-800-486-4328

Item

Name/Description

Part Number

1

Air Tube

NLH100KZU

2

Spline Nut

3666

3

Adjusting plate assembly

5721

4

Blocking Oil Solenoid

Valve

21755U

5

Igniter

51771U

6

Control

7575

7

Air Band

3492

8

Air Shutter

3709

9

Fuel Pump

21844U

10

Fuel lines

Call for part

#s

11

Head Assembly

KZ (Tube B)

51820U

12

Electrode Assembly

51859

13

Nozzle Line Assembly

NLH100KZU

14

Motor – 1/7 PSC

21805U

15

Blower Wheel

21837U

16

Coupling

2454

1-204-633-1999

100 Eagle Drive

Winnipeg, MB Canada

sales@hermannelson.com

www.hermannelson.com

Page 32

RIELLO F10 PARTS BREAKDOWN

1-800-486-4328

1-204-633-1999

100 Eagle Drive

Winnipeg, MB Canada

sales@hermannelson.com

www.hermannelson.com

Page 33

GÉNÉRATEUR DE CHALEUR À POLYCOMBUSTIBLE: BLAZE 400 D/G

Juin, 2014)

Certifié Pour Utilisation Au Canada Et Les États-Unis

(AXIAL/TURBO)

RAPPORT # 0367MH007S

Instructions D’installation-Manuel-Entretien-Liste des

AVERTIR : Ne Modifiez Pas Le Radiateur Ou Ses Contrôles. Consultez Un Technicien De Service Qualifié

Conservez ce manuel pour référence (19

1-800-486-4328

1-204-633-1999

100 Eagle Drive

Winnipeg, MB Canada

Pièces

sales@hermannelson.com

www.hermannelson.com

Page 34

1-800-486-4328

1-204-633-1999

100 Eagle Drive

Winnipeg, MB Canada

sales@hermannelson.com

www.hermannelson.com

Page 35

LISEZ LES INSTRUCTIONS AVANT D’UTILISER LES RADIATEURS

CET APPAREIL EST CONÇU ET APPROUVÉ POUR ÊTRE UTILISÉ COMME CHAUFFERETTE

DE CONSTRUCTION CONFORME AUX NORMES ANSI Z83.7-2011/CSA2.14-2011, UL 7332013 (R2010) ET CAN/CSA B140.8-1967 (R2011)

CES RADIATEURS SONT POUR USAGE EXTÉRIEUR

LES EXIGENCES DES COLLECTIVITES LOCALES QUI ONT COMPÉTENCE DOIT ÊTRE

SUIVIE

BLAZE 400 G

NOTE : CE RADIATEUR EST PRÉVU PRINCIPALEMENT POUR UN CHAUFFAGE PROVISOIRE DES BÂTIMENTS

EN CONSTRUCTION, EN RÉNOVATION OU EN RÉPARATION

CET APPAREIL EST APPROUVÉ POUR LE PROPANE OU LE GAZ NATUREL. N'ESSAYEZ JAMAIS DE BRÛLER

LES ORDURES NI PAPIER DANS LE RADIATEUR; ET RETIREZ TOUT LE PAPIER ET LES CHIFFONS DES

ALENTOURS DU RADIATEUR. POUR VOTRE SÉCURITÉ, NE PAS CONSERVER OU UTILISER D'ESSENCE OU

AUTRES LIQUIDES OU VAPEURS INFLAMMABLES À PROXIMITÉ DE L'APPAREIL.

NE MODIFIEZ PAS LE RADIATEUR ET LES CONTRÔLES ! LE RADIATEUR DOIT ÊTRE ENTRETENU PAR UN

PERSONNEL DE SERVICE QUALIFIÉ.

AVERTISSEMENT : CEUX QUI INSTALLENT LE RADIATEUR DOIVENT AVOIR LA FORMATION ET

L'EXPÉRIENCE NÉCESSAIRES POUR LE FAIRE. LISEZ CE MANUEL AVEC SOIN. SI LE RADIATEUR N’EST

PAS CORRECTEMENT INSTALLÉ, IL POURRAIT CAUSER DES DÉGATS MATÉRIELS, DES BLESSURES,

VOIRE DES PERTES DE VIE. LE PERSONNEL DE SERVICE QUALIFIÉ QUI EFFECTUE CE TRAVAIL A UNE

GRANDE RESPONSABILITÉ POUR LA BONNE INSTALLATION ET LA MISE EN MARCHE CORRECTE DU

RADIATEUR.

CET APPAREIL EST CONÇU ET APPROUVÉ POUR ÊTRE UTILISÉ COMME CHAUFFERETTE DE

CONSTRUCTION CONFORME AUX NORMES ANSI Z83.7-2011/CSA2.14-2011.

CONSULTEZ LES

COLLECTIVITES LOCALES DE SÉCURITÉ INCENDIE SI VOUS AVEZ DES QUESTIONS À

PROPOS DES APPLICATIONS.

AVERTISSEMENT : CHAUFFAGE EST DESTINÉ À ÊTRE UTILISÉ PRINCIPALEMENT COMME CHAUFFAGE

TEMPORAIRE DES IMMEUBLES EN CONSTRUCTION, DE MODIFICATION, DE RÉPARATION OU D'URGENCE

SEULEMENT.

AVERTISSEMENT : PRÉVOYEZ TOUJOURS UNE VENTILATION ADÉQUATE. VENTILATION ACCEPTABLE

MINIMUM REQUISE : 1 PO CA D'AIR FRAIS DOIT ÊTRE FOURNI POUR CHAQUE 1000 BTU/H DE CHALEUR.

AVERTISSEMENT : CE RADIATEUR NE DOIT PAS ÊTRE INSTALLÉ DIRECTEMENT EXPOSÉES À UN JET

D'EAU OU UNE EAU QUI DÉGOUTTE.

VÉRIFIEZ AVEC L’AUTORITÉ LOCALE DE SÉCURITÉ-INCENDIE SI VOUS AVEZ DES QUESTIONS AU SUJET

DES APPLICATIONS

1-800-486-4328

1-204-633-1999

100 Eagle Drive

Winnipeg, MB Canada

sales@hermannelson.com

www.hermannelson.com

Page 36

CES INSTRUCTIONS ONT ÉTÉ PRÉPARÉES AVEC SOIN, MAIS ELLES NE PEUVENT PAS COUVRIR CHAQUE

INSTALLATION ET ÉVENTUALITÉ PARTICULIÈRE. PAR CONSÉQUENT, S'IL Y A DES DOUTES QUANT À

L'INTERPRÉTATION DES EXIGENCES, COMMUNIQUEZ AVEC L’AUTORITÉ LOCALE DE VOTRE JURIDICTION,

VOTRE DISTRIBUTEUR LOCAL OU L'USINE.

RÈGLES D'INSTALLATION:

1.) L'INSTALLATION DEVRAIT ÊTRE CONFORME À TOUS LES RÈGLEMENTS LOCAUX ET NATIONAUX.

CÂBLAGE: TOUT LE CÂBLAGE INTERNE DU RADIATEUR EST FAIT PAR LE FABRICANT. TOUT LE CÂBLAGE

EXTERNE DOIT ÊTRE CONFORME AUX CODES D’ÉLECTRICITÉ ACTUELS ÉT ABLIS PAR LES AUTORITÉS

AYANT JURIDICTION.

L'INSTALLATION DE CE RADIATEUR UTILISÉ AVEC LE GAZ NATUREL DOIT ÊTRE CONFORME AUX CODES

LOCAUX; S’IL N’Y A PAS DE CODE, L’INSTALLATION DOIT ÊTRE CONFORME À LA NORME NATIONALE DU

CODE DE GAZ UTILISÉ COMME CARBURANT Z223.1/NFPA 54 ET AU CODE D'INSTALLATION POUR LE GAZ

NATUREL ET LE PROPANE, CSA B149.1-00. CE RADIATEUR DOIT ÊTRE INSTALLÉ PAR UN TECHNICIEN

QUALIFIÉ EN GAZ ET EN OBSERVANT DES CODES LOCAUX PUBLIÉS PAR L'AUTORITÉ AYANT

JURIDICTION. TOUTES LES INSTALLATIONS EFFECTUÉES DANS LE MASSACHUSETTS DOIVENT ÊTRE

FAITES PAR UN PLOMBIER OU UN MONTEUR D’INSTALLATION AU GAZ DU MASSACHUSETTS.

L'INSTALLATION DE CE RADIATEUR RACCORDÉ À UNE RÉSERVOIR OU À UNE BOUTEILLE DE PROPANE

DOIT ÊTRE CONFORME AUX CODES LOCAUX; S’IL N’Y A PAS DE CODE, L’INSTALLATION DOIT ÊTRE

CONFORME À LA NORME CONCERNANT L’ENTREPOSAGE ET LA MANUTENTION DES GAZ DE PÉTROLE

LIQUÉFIÉS, NORME ANSI/NFPA 58 ET AU CODE D’INSTALLATION DU GAZ NATUREL ET DU PROPANE, CSA

B149.1

CE RADIATEUR DOIT SE TROUVER À AU MOINS 10 PI (3 M) DE TOUTE BOUTEILLE DE PROPANE.

CE RADIATEUR NE DOIT PAS ÊTRE ORIENTÉ VERS UN CONTENANT DE PROPANE SITUÉ À MOINS DE 20 PI

(6 M).

D'AUTRES NORMES RÉGISSENT L'UTILISATION DES GAZ COMBUSTIBLES ET LES APPAREILS THERMIQUES

UTILISÉS DANS DES APPLICATIONS PARTICULIÈRES. VOTRE AUTORITÉ LOCALE PEUT VOUS CONSEILLER

SUR CES DERNIÈRES.

LIRE LES INSTRUCTIONS AVANT DE METTRE L'APPAREIL

DE CHAUFFAGE EN MARCHE

BLAZE 400 D

CET APPAREIL EST APPROUVÉ POUR L'UTILISATION DE MAZOUT NUMÉRO 1 ET NUMÉRO 2. NE

JAMAIS UTILISER DE L'ESSENCE OU DE L’HUILE À MOTEUR QUI PEUT CONTENIR DE L'ESSENCE

COMME COMBUSTIBLE. NE JAMAIS TENTER DE BRÛLER DES DÉCHETS OU DU PAPIER DANS CET

APPAREIL ET RETIRER TOUT LE PAPIER ET LES CHIFFONS QUI SE TROUVENT AUTOUR. POUR

VOTRE SÉCURITÉ, NE PAS RANGER OU UTILISER D'ESSENCE OU D'AUTRES LIQUIDES

INFLAMMABLES PRÈS DE L'APPAREIL.

POUR VOTRE SÉCURITÉ, NE TENTEZ PAS DE DÉMARRER L'APPAREIL:

1.) SI UN EXCÉDENT DE MAZOUT S'EST ACCUMULÉ

2.) SI L'APPAREIL EST REMPLI DE VAPEUR

3.) SI LA CHAMBRE DE COMBUSTION EST TRÈS CHAUDE

1-800-486-4328

1-204-633-1999

100 Eagle Drive

Winnipeg, MB Canada

sales@hermannelson.com

www.hermannelson.com

Page 37

NE PAS MANIPULER L'APPAREIL OU SES COMMANDES. IL DOIT ÊTRE ENTRETENU PAR DU

AVERTISSEMENT : L'INSUFFISANCE D'AIR DE COMBUSTION PEUT ENGENDRER LE BRÛLAGE

CAUSER LA NAUSÉE OU L’ASPHYXIE CHEZ LES OCCUPANTS.

BLAZE 400 D/G

FICHE TECHNIQUE

BLAZE 400GBECKETT (NG/LP)

BLAZE 400GRIELLO (NG/LP)

BLAZE 400DBECKETT (OIL)

BLAZE 400DRIELLO (OIL)

Marque et modèle de

brûleur

CG10-24

G400

Beckett CF375

F10

Tension

120V

120V

120V

120V

Entrée (BTU/h)

399,000

399,000

NO.1 (277,000) @ 100 PSI

NO.1 (391,955) @ 200 PSI

NO.1 (339,325) @ 150 PSI

PERSONNEL D'ENTRETIEN QUALIFIÉ.

AVERTISSEMENT : LES PERSONNES QUI INSTALLENT CET APPAREIL DE CHAUFFAGE DOIVENT

AVOIR LA FORMATION ET L'EXPÉRIENCE NÉCESSAIRES. IL FAUT PAR CONSÉQUENT LIRE

ATTENTIVEMENT LE PRÉSENT MANUEL. LE DÉFAUT D'INSTALLER ET DÉ RÉGLER

CORRECTEMENT L'APPAREIL PEUT ENGENDRER DES DOMMAGES À LA PROPRIÉTÉ, DES

BLESSURES AUX PERSONNES OU LA PERTE DE VIE. LE PERSONNEL QUALIFIÉ QUI EFFECTUE

CES TÂCHES ASSUME DE SÉRIEUSES RESPONSABILITÉS POUR EXÉCUTER CORRECTEMENT

L'INSTALLATION, LE RÉGLAGE ET LE DÉMARRAGE DE L'APPAREIL.

LES PRÉSENTES INSTRUCTIONS ONT ÉTÉ RÉDIGÉES DE FAÇON EXHAUSTIVE, MAIS ELLES NE

PEUVENT PAS TENIR COMPTE DE CHAQUE INSTALLATION SPÉCIALE OU DE CHAQUE

IMPONDÉRABLE. PAR CONSÉQUENT, S'IL Y A UN DOUTE QUANT À L'INTERPRÉTATION DE L'UNE

OU L'AUTRE DES EXIGENCES, COMMUNIQUER AVEC LE RESPONSABLE LOCAL AYANT AUTORITÉ,

LE DISTRIBUTEUR LOCAL OU L'USINE.

IMPORTANT : SI VOUS OBSERVEZ QUE LA COMMANDE PRINCIPALE EST VERROUILLÉE FERMÉE,

APPUYEZ SUR LE BOUTON DE RÉINITIALISATION ROUGE UNE SEULEMENT FOIS. SI LE BRÛLEUR

NE DÉMARRE PAS DE NOUVEAU, NE PAS APPUYER SUR LE BOUTON UNE DEUXIÈME FOIS OU UN

EXCÉDENT DE COMBUSTIBLE S’ACCUMULERA DANS LA CHAMBRE DE COMBUSTION. APPELEZ

UN TECHNICIEN QUALIFIÉ.

NOTICE D'INSTALLATION :

1) L'INSTALLATION DOIT SE FAIRE CONFORMÉMENT À TOUS LES RÈGLEMENTS LOCAUX ET

NATIONAUX.

2) AU CANADA, CONSULTEZ LE CODE D'INSTALLATION CSA B139 POUR L'ÉQUIPEMENT DE

CHAUFFAGE AU MAZOUT.

3) CÂBLAGE : TOUT LE CÂBLAGE INTERNE DE L'APPAREIL DE CHAUFFAGE EST INSTALLÉ

PAR LE FABRICANT. TOUT LE CÂBLAGE EXTERNE DOIT ÊTRE CONFORME AU CODE DE

D'ÉLECTRICITÉ EXISTANT, ÉDICTÉ PAR LES AUTORITÉS COMPÉTENTES. AU CANADA,

CONSULTEZ LA NORME CSA C22.1 ET LE CODE CANADIEN DE L’ÉLECTRICITÉ. AUX ÉTATSUNIS, CONSULTEZ LE CODE BOCA OU LE NFPA 70 (NATIONAL ELECTRICAL CODE)

ÉLECTRIQUE NATIONAL

.

CODE

SALE, DES ODEURS DANS LES ESPACES FERMÉS ET UN REFOULEMENT D'AIR, QUI POURRAIT

NO.2 (280,000) @ 100 PSI

NO.1 (310,240) @ 120 PSI

NO.2 (313,600) @ 120 PSI

NO.1 (339,325) @ 150 PSI

NO.2 (343,000) @ 150 PSI

1-800-486-4328

1-204-633-1999

100 Eagle Drive

Winnipeg, MB Canada

sales@hermannelson.com

www.hermannelson.com

NO.2 (343,000) @ 150 PSI

NO.1 (391,955) @ 200 PSI

NO.2 (396,000) @ 200 PSI

Page 38

NO.2 (396,000) @ 200 PSI

CFM/Ampères

3,500 (Axial) 11.5/

3,500 (Axial) 11.5/

3,500 (Axial) 11.5/

3,500 (Axial)

HP DU MOTEUR

111

1

Longueur des

canalisations

24ft/150ft

24ft/150ft

24ft/150ft

24ft/150ft

Pression Statique

upto 0.65"/3"

upto 0.65"/3"

upto 0.65"/3"

upto 0.65"/3"

Grandeur des sorties

2 X 12" OR 1 X 16

2 X 12" OR 1 X

2 X 12" OR 1 X 16

2 X 12" OR 1 X 16

Grandeur de l’entrée

2 X 12" OR 1 X 16

2 X 12" OR 1 X

2 X 12" OR 1 X 16

2 X 12" OR 1 X 16

Conversion au Gaz

Passage facile sur

Passage facile

S/O

S/O

Pression au

3.5” NG ou

3.5” NG ou 3.5 LP

S/O

S/O

Pression

C.E. »

7/10

LP

7/9

NT LP

S/O

S/O

Buse

S/O

S/O

2 X 60b

2 X 60B

Pression à la Pompe

S/O

S/O

100/120/150/200

150/200

MAX. GPH

S/O

S/O

2.82

2.82

(Axial/Turbo)

(Axial Turbo)

5,500 (Turbo) 8.5

5,500 (Turbo) 8.5

5,500 (Turbo) 8.5

11.5/ 5,500 (Turbo)

8.5

des canalisations

(Temp. max. : 300 ºF)

des canalisations

collecteur « C.E. »

d’alimentation

minimum/maximum «

Bleu poignée Ball

Valve sur le collecteur

de gaz.

Position fermée:

Propane

Position ouverte:

gaz naturel

4 LP (pression d'être

mis devant vanne

d'inversion NG / LP et

après ajustement

valve sur le collecteur)

POUR NG ET

FONCTIONNEMENT

16

16

sur Bleu poignée

Ball Valve sur le

collecteur de gaz.

Position fermée:

Propane

Position ouverte:

gaz naturel

(pression d'être

mis devant vanne

d'inversion NG /

LP et après

ajustement valve

sur le collecteur)

POUR NG ET

FONCTIONNEME

1-800-486-4328

1-204-633-1999

100 Eagle Drive

Winnipeg, MB Canada

sales@hermannelson.com

www.hermannelson.com

Page 39

INET DE LA BOUTEILLE EST FERMÉ LORS DU RACCORDEMENT OU DU

Carburant

NG or LP

NG or LP

N ° 1 ou n ° 2 / kérosène

ou du mazout de

N ° 1 ou n ° 2 /

chauffage

Réglage de la tête

10.141

4

Réglage de l’air

10/0

3.5

100 PSI 3/1

200 PSI 5/3

AGENCE

D’APPROBATIO N

OMNI

OMNI

OMNI

OMNI

POIDS SEC (lb)

470

470

500

500

Dimensions

76.7” x 31” x 58”

76.7” x 31” x 58”

76.7” x 31” x 58”

76.7” x 31” x 58”

GROSSEUR DE LA

6 po

6 po

6 po

6 po

chauffage

kérosène ou du

mazout de

(BeckettShutter/Band)

CHEMINÉE

120 PSI 3/1

150 PSI 2/2

150 PSI 3.4

200 PSI 4.5

RACCORDEMENT DE LA BOUTEILLE

Dégagement à LP conteneurs: 10 pieds (3 mètres)

SI DES BOUTEILLES SONT UTILISÉS POUR ALIMENTER LE RADIATEUR, AUCUNE BOUTEILLE DE MOINS DE

100 LB DE CAPACITÉ NE DOIT ÊTRE UTILISÉE. CES BOUTEILLES DOIVENT PERMETTRE UN SOUTIRAGE DE

GAZ SEULEMENT.

1.) TOUS LES RACCORDS À LA BOUTEILLE DOIVENT ÊTRE FAITS EN UTILISANT UNE CLÉ POUR

SERRER LE RACCORD DE PRODUITS PÉTROLIERS.

2.) ASSUREZ-VOUS QUE LE ROB

DÉBRANCHEMENT DE LA BOUTEILLE.

3.) MÉTHODE APPROPRIÉE DE VÉRIFICATION DES FUITES DE GAZ : UNE SOLUTION D’EAU ET DE

SAVON DOIT ÊTRE APPLIQUÉE À TOUS LES RACCORDS POUR VOIR SI LE RACCORD FUIT.

4.) IL FAUT FAIRE UNE INSPECTION VISUELLE DES TUYAUX AVANT CHAQUE UTILISATION DU

RADIATEUR.

L’ALIMENTATION EN GAZ DOIT ÊTRE COUPÉE AU NIVEAU DE LA BOUTEILLE DE PROPANE QUAND LE

RADIATEUR N’EST PAS UTILISÉ. QUAND LE RADIATEUR DOIT ÊTRE ENTREPOSÉ À L'INTÉRIEUR, LE

RACCORD ENTRE LA BOUTEILLE D’ALIMENTATION EN PROPANE ET LE RADIATEUR DOIT ÊTRE

DÉBRANCHÉ ET LES BOUTEILLES RETIRÉES DU RADIATEUR ET ENTREPOSÉES SELON LES NORMES

TOUCHANT L’ENTREPOSAGE ET LA MANUTENTION DES GAZ DE PÉTROLE LIQUÉFIÉS, NORMES ANSI/NFPA

58 ET CSA B149.1, CODE D’INSTALLATION DU GAZ NATUREL ET DU PROPANE.

TUYAUTERIE : CE RADIATEUR DOIT ÊTRE INSTALLÉ PAR UN TECHNICIEN QUALIFIÉ EN GAZ EN

OBSERVANT DES CODES LOCAUX PUBLIÉS PAR L'AUTORITÉ AYANT JURIDICTION. LA GROSSEUR DE LA

TUYAUTERIE D'ALIMENTATION DOIT ÊTRE DÉTERMINÉ EN UTILISANT LA LONGUEUR DU TUYAU ET LE

NOMBRE DE BTUH DE L'APPAREIL. IL FAUT UTILISER LES TABLEAUX APPROPRIÉS POUR LES TUYAUX

POUR DÉTERMINER LA GROSSEUR DU TUYAU D’ALIMENTATION SUIVANT LA LONGUEUR DU TUYAU

RELIANT L’APPAREIL À LA BOUTEILLE.

1-800-486-4328

1-204-633-1999

100 Eagle Drive

Winnipeg, MB Canada

sales@hermannelson.com

www.hermannelson.com

Page 40

RACCORDEMENT À UN RÉSERVOIR DE CARBURANT EXTERNE

(BLAZE 400 D)

Le Beckett CF375 and Riello F10 est branché à l’aide de raccords males SAE de 3/8 po et il fait

appel à un système à deux canalisations pour ne pas devoir amorcer le système. Assurez-vous

que le réservoir de carburant a une canalisation d’alimentation, une canalisation de retour et et

connecter la ligne d'alimentation de la 3/8 po SAE installée du côté entrée du filtre de carburant et

la canalisation de retour au raccord de retour situé sur la pompe du brûleur Beckett. Pour un

système de ligne 1 enlever le bouchon de dérivation située sur le point d’entrée de la pompe

Beckett et raccordez la canalisation de carburant au côté alimentation du filtre de carburant.

CARBURANT (BLAZE 400 G)

CE RADIATEUR PEUT ÊTRE UTILISÉ AVEC LE PROPANE OU LE GAZ NATUREL, MAIS PAS

LES DEUX. LES PRESSIONS AU COLLECTEUR SONT INDIQUÉES SUR L'ÉTIQUETTE

D'APPROBATION. POUR DÉTERMINER QUEL COMBUSTIBLE UTILISER, CONSULTEZ LA

PLAQUE SIGNALÉTIQUE. N'ESSAYEZ PAS D'UTILISER LE RADIATEUR SANS CONSULTER

LA PLAQUE SIGNALÉTIQUE

NOTE: LA BONNE POSITION SUR LE COMMUTATEUR FACILE SUR MANCHE BLEU

ROBINET DOIT ETRE UTILISE ET PLAQUE D'DOIT REFLETER LA CARBURANT L'APPAREIL

S'ALLUME. NE PAS FAIRE FONCTIONNER LE CHAUFFAGE SANS CONSULTER LA PLAQUE

SIGNALETIQUE.

CONVERSION DE CHAUFFAGE DOIT ÊTRE FAITE PAR UN PERSONNEL QUALIFIÉ ET

PLAQUE SIGNALETIQUE DOIT REFLETER TOUT CHANGEMENT.

CET APPAREIL DE CHAUFFAGE EST EQUIPEE POUR UTILISATION DU GAZ NATUREL OU

GAZ DE PETROLE LIQUEFIE. CET APPAREIL EST ÉQUIPÉ D'ORIFICES DE TAILLE POUR LE

FONCTIONNEMENT AU GAZ NATUREL OU PROPANE VIA L'INTERRUPTEUR FACILE SUR

MANCHE BLEU ROBINET. POUR LA CONVERSION EN LP (OU NATURELLE) GAZ PLAQUE

VOIR L'INSTRUCTION SUR L'APPAREIL.

Passage facile sur Bleu poignée Ball Valve sur le collecteur de gaz.

Position fermée: Propane

Position ouverte: Gaz naturel

TUYAUX

TOUS LES TUYAUX UTILISÉS POUR RACCORDER CE RADIATEUR À L'ALIMENTATION EN COMBUSTIBLE

DOIVENT ÊTRE DES ENSEMBLES DE TUYAUX APPROUVÉS DE TYPE 1 POUR LE PROPANE/GAZ NATUREL

1-800-486-4328

1-204-633-1999

100 Eagle Drive

Winnipeg, MB Canada

sales@hermannelson.com

www.hermannelson.com

Page 41

RACCORDEMENT ÉLECTRIQUE

BLAZE

400 D/G

AVERTISSEMENT: INSTRUCTIONS POUR LA MISE À LA TERRE

CET APPAREIL PEUT RECEVOIR UNE ALIMENTATION ÉLECTRIQUE MONOPHASÉ.

UNE ALIMENTATION ÉLECTRIQUE DE 120V DOIT ÊTRE DISPONIBLE.

INSTALLATION

12/3 AWG JUSQU'A 50 PIEDS

10/3 AWG AU-DELÀ 50 PIEDS

NOTE : SI UNE PARTIE DU CÂBLAGE ÉLECTRIQUE FOURNI AVEC L’APPAREIL DOIT ÊTRE

REMPLACÉ, IL DOIT ÊTRE REMPLACÉ PAR UN CÂBLAGE DE TYPE TEW DE JAUGE 14

(14GA) OU SON ÉQUIVALENT.

SYSTÈME ÉLECTRIQUE

Volts-Hertz-Phase

120-60-1

À pleine charge (Ampères) (Axial/Turbo)

Calibre max. du fusible (Ampères)

(Axial/Turbo) avec temporisation

11.5/8.5

15

La mise à la terre électrique de l’appareil doit être conforme au Code national de l’électricité, la

norme ANSI/NFPA 70 ou la norme CSA C22.1, le Code national de l’électricité, partie I.

1-800-486-4328

1-204-633-1999

100 Eagle Drive

Winnipeg, MB Canada

sales@hermannelson.com

www.hermannelson.com

Page 42

1-800-486-4328

Blaze 400G Schématique avec Ventilateur Axial

(Brûleur du Beckett CG10-24 NG/LP)

Blaze 400G schématique avec Moteur E

(Brûleur du Beckett CG10-24 NG/LP)

1-204-633-1999

100 Eagle Drive

Winnipeg, MB Canada

sales@hermannelson.com

www.hermannelson.com

Page 43

1-800-486-4328

Blaze 400G Schématique avec Ventilateur Axial

(Brûleur Riello G400 NG/LP)

Blaze 400G Schématique avec Moteur R

(Brûleur du Beckett CG10-24 NG/LP)

1-204-633-1999

100 Eagle Drive

Winnipeg, MB Canada

sales@hermannelson.com

www.hermannelson.com

Page 44

1-800-486-4328

Blaze 400G Schématique avec Ventilateur R

(Brûleur Riello G400 NG/LP)

Blaze 400G Schématique avec Ventilateur E

(Brûleur Riello G400 NG/LP)

1-204-633-1999

100 Eagle Drive

Winnipeg, MB Canada

sales@hermannelson.com

www.hermannelson.com

Page 45

1-800-486-4328

Blaze 400D Schématique avec Moteur E

(Brûleur à Mazout Beckett CF375)

Blaze 400D Schématique avec Ventilateur Axial

(Brûleur à mazout Beckett CF375 Oil)

1-204-633-1999

100 Eagle Drive

Winnipeg, MB Canada

sales@hermannelson.com

www.hermannelson.com

Page 46

1-800-486-4328

Blaze 400D Schématique avec Ventilateur Axial

(Brûleur à Mazout Riello F10)

Blaze 400D Schématique avec Moteur R

(Brûleur à mazout Beckett CF375)

1-204-633-1999

100 Eagle Drive

Winnipeg, MB Canada

sales@hermannelson.com

www.hermannelson.com

Page 47

1-800-486-4328

Blaze 400D Schématique avec Moteur R

(Brûleur à Mazout Riello F10)

Blaze 400D Schématique avec Moteur E

(Brûleur à Mazout Riello F10)

1-204-633-1999

100 Eagle Drive

Winnipeg, MB Canada

sales@hermannelson.com

www.hermannelson.com

Page 48

SÉQUENCE D’UTILISATION DE L’APPAREIL BLAZE 400 D/G

Con Sélecteur («Selector Switch») en position « ON » et le sélecteur en position « STAT ON » et le mécanisme

de chauffage branché dans la prise de courant :

1 : Le thermostat de chauffage perçoit une baisse de la température et le module de contrôle de l’allumage est mis

sous tension.

2 : Le module fait une vérification de sécurité du démarrage; le brûleur et le générateur d’étincelles se mettent en

marche. Le brûleur s’allume; l’allumage s’arrête et le courant de la flamme est perçu.

Pour le mazout : Les contacts du contrôle primaire Genisys se ferment; le moteur du brûleur et l’allumoir sont mis

sous tension après 15 secondes. Le contrôle primaire met sous tension la vanne du solénoïde de la pompe et une

flamme est produite. La cellule cad détecte la présence d’une flamme et le brûleur reste allumé.

3 : Le thermocouple du régulateur de température se réchauffe jusqu’au point réglé à l’usine (9O ºF) ou après la

temporisation de 1 minute et le ventilateur de circulation de l’air se met en marche.

4 : Quand le thermostat de chauffage perçoit la température de l’espace à chauffer est parvenu au point demandé, le

brûleur s’arrête.

5 : Le ventilateur continue de fonctionner jusqu’à ce que l’air contenu dans l’appareil soit parvenu au point établi à

l’usine (80 ºF) avant de s’arrêter.

Lorsque le sélecteur est en position « BYPASS » (dérivation) :

1 : Le module fait une vérification de sécurité du démarrage et le brûleur et le générateur d’étincelles se mettent en

marche.

2 : Le brûleur s’allume; l’allumage s’arrête et le courant de la flamme est décelé.

3 : Le thermocouple du contrôleur de la température se réchauffe jusqu’au niveau établi à l’usine (90 ºF) et le

ventilateur de circulation de l’air se met en marche.

4 : Lorsque le sélecteur de chauffage/ventilateur est tourné en position « OFF », le brûleur s’éteint.

5 : Le ventilateur de circulation de l’air continue de fonctionner jusqu’à ce que l’air contenu dans l’appareil soit parvenu

au réglage établi à l’usine (80 ºF) avant de s’arrêter.

INSTRUCTIONS D’UTILISATION DE L’APPAREIL BLAZE 400 D/G

DÉMARRAGE DE L’APPAREIL

1.) ASSUREZ-VOUS QUE L’APPAREIL EST PLACÉ SUR UNE SURFACE PLATE ET DE NIVEAU AVANT DE LE

METTRE EN MARCHE; LE COUVERT ET LES PROTECTEURS DU VENTILATEUR DOIVENT TOUJOURS

ÊTRE FERMÉS.

2.) ASSUREZ-VOUS QUE LE SÉLECTEUR (« SELECTOR SWITCH ») EST EN POSITION « OFF ».

3.) INSTALLEZ LE CÂBLAGE D’ALIMENTATION ÉLECTRIQUE SUR UNE PRISE D’ALIMENTATION DE 120V

AVEC MISE À LA TERRE.

Installation de l’alimentation électrique

12/3 AWG JUSQU'A 50 PIEDS

10/3 AWG AU-DELÀ 50 PIEDS

4.) TOURNEZ LE SÉLECTEUR (« SELECTOR SWITCH ») À LA POSITION « ON ».

5.) POUR L’UTILISATION DU THERMOSTAT, PLACEZ LE SÉLECTEUR EN POSITION « STAT ON ». SI VOUS

N’UTILISEZ PAS DE THERMOSTAT, PLACEZ LE SÉLECTEUR EN POSITION DE DÉRIVATION (« BYPASS »).

Note : Lors de l'utilisation d'un générateur pour l'alimentation électrique, assurez-vous que la génératrice est

bien mise à la terre et qu’elle utilise une fréquence de 60 Hz. Si une génératrice est utilisée et si elle manque

de carburant, assurez-vous que l’interrupteur principal (« MAIN SWITCH») de l’appareil est en position « OFF »

avant de remettre la génératrice en marche; autrement, l’appareil pourrait être endommagé.

1-800-486-4328

1-204-633-1999

100 Eagle Drive

Winnipeg, MB Canada

sales@hermannelson.com

www.hermannelson.com

Page 49

ARRÊT DE L’APPAREIL

MISE EN GARDE

EN MARCHE.

1.) Fermez le robinet principal d’alimentation en gaz pendant que l’appareil est en marche; si l’appareil est utilisé

avec du mazout, passez au # 2.)

2.) Placez le SÉLECTEUR « SELECTOR SWITCH » en position « OFF ». Le ventilateur d’alimentation continue

de fonctionner jusqu’à ce que l’échangeur de chaleur se soit suffisamment refroidi. Ne débranchez pas

l’alimentation électrique principale avant que le ventilateur d’alimentation ne se soit arrêté et que SÉLECTEUR

(«SELECTOR SW ITCH») soit en position « OFF ».

3.) Débranchez l’appareil de l’alimentation en gaz OU débranchez la canalisation de mazout.

AVERTISSEMENT : AVANT DE RETIRER LES PROTECTEURS OU LES ARTICLES DE SÉCURITÉ, PLACEZ

SÉLECTEUR EN POSITION « OFF » ET DÉBRANCHEZ L’ALIMENTATION PRINCIPALE PUISQUE LE

VENTILATEUR D’ALIMENTATION FERA SON CYCLE AUTOMATIQUEMENT.

SI LA CHAUFFERETTE NE SE MET PAS EN MARCHE

1.) APPUYEZ SUR LE BOUTON DE REMISE À ZÉRO DU BRÛLEUR POUR RÉTABLIR LE CONTRÔLE DE

L’APPAREIL SUR RIELLO F10 G400. POUR LE BRÛLEUR BECKETT 7505 OU 7595 FEUX APPUYEZ LE

BOUTON ROUGE DE LA BECKETT GENISYS CONTROLLER (SITUÉE SUR LE PANNEAU DE

CONTRÔLE) ET MAINTENEZ PENDANT 3 SECONDES POUR RÉINITIALISER. POUR LE 7540 APPUYEZ

LE BOUTON ROUGE POUR RÉINITIALISER

2.) S’IL S’AGIT D’UN APPAREIL AU GAZ, VÉRIFIEZ LA PRESSION DE L’ALIMENTATION EN GAZ. LA

PRESSION DE L’ALIMENTATION ET AU COLLECTEUR DOIT CONCORDER AVEC LES VALEURS

APPARAISSANT SUR LA PLAQUE SIGNALÉTIQUE. S’IL S’AGIT D’UN APPAREIL AU MAZOUT, VÉRIFIEZ

LE NIVEAU DE CARBURANT, LE FILTRE, LA BUSE ET LA CANALISATION D’ASPIRATION.

3.) ASSUREZ-VOUS QUE L’ALIMENTATION ÉLECTRIQUE EST APPROPRIÉE ET QU’UN CÂBLAGE

ÉGALEMENT APPROPRIÉ EST UTILISÉ.

4.) SI L’APPAREIL NE S’ALLUME PAS APRÈS 3 TENTATIVES, CONSULTEZ VOTRE FOURNISSEUR POUR

QUE LES TRAVAUX DE SERVICE SOIENT FAITS.

NOTE : SI L’APPAREIL A ÉTÉ REMIS À ZÉRO UN CERTAIN NOMBRE DE FOIS SANS QUE L’ALLUMAGE NE SE

FASSE -- N’ESSAYEZ PAS DE REMETTRE L’APPAREIL EN MARCHE : COMMUNIQUEZ AVEC UN

TECHNICIEN DE SERVICE QUALIFIÉ.

NOTE : FONCTIONNEMENT AU MAZOUT – SI L’APPAREIL A ÉTÉ REMIS À ZÉRO UN CERTAIN NOMBRE DE

FOIS SANS S’ALLUMER, DU MAZOUT SE SERA ACCUMULÉ DANS LA CHAMBRE DE COMBUSTION !

N’ESSAYEZ PAS DE DÉMARRER L’APPAREIL : COMMUNIQUEZ AVEC UN TECHNICIEN DE SERVICE

QUALIFIÉ.

1.) N’ARRÊTEZ PAS L’APPAREIL EN DÉBRANCHANT LE CORDON D’ALIMENTATION ÉLECTRIQUE.

L’ÉCHANGEUR DE CHALEUR DOIT ÊTRE REFROIDI SUFFISAMMENT AVANT QUE

L’ALIMENTATION NE SOIT COUPÉE.

2.) CONSERVEZ TOUJOURS UNE RÉSERVE SUFFISANTE DE CARBURANT.

3.) SI UN BRÛLEUR AU GAZ EST INSTALLÉ, L’APPAREIL NE PEUT ÊTRE UTILISÉ QU’AVEC DU

PROPANE OU DU GAZ NATUREL. CONSULTEZ L’ÉTIQUETTE D’APPROBATION

4.) NE BRANCHEZ RIEN D’AUTRE QUE LE THERMOSTAT DANS LA PRISE « REMOTE STAT ».

5.) EN MATIÈRE D’ÉLECTRICITÉ, OBSERVEZ LES EXIGENCES AFFICHÉES SUR LA PLAQUE

SIGNALÉTIQUE OU CELLES DE LA RUBRIQUE DE CE MANUEL CONCERNANT LES EXIGENCES

ÉLECTRIQUES.

6.) SI VOUS UTILISEZ DU MAZOUT, NE METTEZ PAS L’APPAREIL EN MARCHE SI UNE QUANTITÉ

EXCESSIVE DE MAZOUT S’EST ACCUMULÉE DANS LA CHAMBRE DE COMBUSTION.

7.) SI VOUS UTILISEZ DU MAZOUT, NE REMPLISSEZ PAS LE RÉSERVOIR LORSQUE L’APPAREIL EST

1-800-486-4328

1-204-633-1999

100 Eagle Drive

Winnipeg, MB Canada

.

sales@hermannelson.com

www.hermannelson.com

Page 50

8.) LE CÂBLAGE D’ALIMENTATION ÉLECTRIQUE NE DOIT JAMAIS ÊTRE PLUS PETIT QUE CE QUI EST

INDIQUÉ SUR LA PLAQUE SIGNALÉTIQUE ET DANS LES INSTRUCTIONS CONTENUES DANS CE

VALEURS ÉLECTRIQUES REQUISES : 15 A (1PH)

Pour

NOTE : Espaces libres autour du radiateur :

DESSUS

3 pouces

CÔTÉS

3 pouces

EXTRÉMITÉ DE BRÛLEUR

3 pieds

DÉCHARGE

10 pieds

CONNECTEUR DE

L’ÉVENT

3 pieds

PLANCHER

6 pieds

Commented [L2]: Added here

MANUEL.

9.) SI VOUS UTILISEZ DU MAZOUT, N’UTILISEZ PAS D’ESSENCE, D’HUILE DE CARTER DE MOTEUR

OU UN MAZOUT PLUS LOURD QUE L’HUILE À FOURNAISE NO. 2.

10.) NE METTEZ PAS L’APPAREIL EN MARCHE LORSQUE LA CHAMBRE DE COMBUSTION EST

CHAUDE.

11.) NE REMPLISSEZ PAS LE RÉSERVOIR QUAND L’APPAREIL EST EN MARCHE.

12.) N’ENDOMMAGEZ PAS L’APPAREIL. DEMANDEZ À UN TECHNICIEN DE SERVICE COMPÉTENT DE

FAIRE LES AJUSTEMENTS REQUIS.

13.) LA TEMPÉRATURE MAXIMALE À LA SORTIE EST DE (É.-U./CA) 280 ºF

14.) SI L’APPAREIL EST UTILISÉ À UNE ALTITUDE DE PLUS DE 2000 PI (610 m), LES VALEURS

NOMINALES DE L’APPAREIL SONT RÉDUITES DE 4 POUR CENT POUR CHAQUE 1000 PI (305 m)

D’ALTITUDE AU-DESSUS DU NIVEAU DE LA MER.

15.) EN CAS DE SURCHAUFFE, LE CAS ÉCHÉANT, OU SI LE SYSTÈME DE CONTRÔLE DE

L’ALIMENT ATION EN GAZ. FERMEZ LE ROBINET MANUEL DE GAZ DU CHAUFFE-UTILITAIRE

AVANT DE COUPER L'ALIMENTATION ÉLECTRIQUE

16.) N’UTILISEZ PAS CET APPAREIL SI DES COMPOSANTS ONT ÉTÉ SUBMERGÉS DANS L’EAU.

COMMUNIQUEZ IMMÉDIATEMENT AVEC UN TECHNICIEN DE SERVICE QUALIFIÉ POUR QU’IL

INSPECTE L’APPAREIL ET QU’IL REMPLACE LE CONTRÔLE DU GAZ QUI A ÉTÉ SUBMERGÉ SOUS

L’EAU.

INSTRUCTIONS D'INSTALLATION

1.) Les recommandations des autorités locales ayant juridiction doivent être suivies.

avoir les pratiques d'installation recommandées, consultez la norme CSA B139, POUR LA

PRATIQUE D'INSTALLATION RECOMMANDÉS. (CANADA)

2.) En allumant le radiateur dans un espace fermé, prévoyez 1 pouce carré/1000 BTU

(consultez la norme CSA B139) pour permettre l'entrée d'air pour utiliser le radiateur.

3.) Pour l'alimentation électrique: 120V

INSTALLATION

12/3 AWG JUSQU'A 50FT

10/3 AWG-DELÀ 50FT

4.) N'utilisez pas le radiateur dans les secteurs mal ventilés sans cheminée ou près de

surfaces ou de matériaux combustibles. Étage non combustible doit s'étendre de 6 pieds de tous

les côtés de l'appareil.

1-800-486-4328

1-204-633-1999

100 Eagle Drive

Winnipeg, MB Canada

sales@hermannelson.com

www.hermannelson.com

Page 51

RACCORDEMENTS DE LA CHEMINÉE

LONGUEURS MAXIMALES PERMISES DES CANALISATIONS BLAZE 400 D/G

CANALISATION D'ADMISSION Jusqu'à 12 pieds sur Axiale et 24 pieds sur Turbo

CANALISATION DE DÉCHARGE Jusqu'à 24 pieds 'sur Axiale et 150 pieds sur Turbo

VENT POUR L'EXTÉRIEUR

POUR INSTALLATION SUR PLANCHER NON COMBUSTIBLES

Quand le radiateur est branché à une cheminée, cette dernière doit se terminer à la verticale sur

au moins deux pieds de long. Les longueurs horizontales devraient s’élever graduellement d’une

unité pour chaque longueur de 10 unités à partir du radiateur. Si des courants d’air descendants

risquent de se produire, il faut utiliser un chapeau de cheminée. Toute la ventilation devrait

observer les dispositions de la norme CSA B139 ou les codes locaux.

ATTENTION : LA TEMPÉRATURE DE LA CHEMINÉE DE RADIATEUR PEUT ATTEINDRE 700 À

900 °F; PAR CONSÉQUENT, CELA PEUT ÊTRE DANGEREUX POUR LES HUMAINS ET MÊME

DÉPASSER LA TEMPÉRATURE D'AUTO-ALLUMAGE DE BIEN DES MATÉRIAUX. IL FAUT

DONC ÊTRE PRUDENT CONCERNANT L’EMPLACEMENT DU RADIATEUR ET L’UTILISATION

DE PROTECTEURS ISOLÉS EST VIVEMENT RECOMMANDÉE.

Les canalisations horizontales de mise à l’air libre doivent toujours se terminer par une longueur

verticale d’au moins 24 po.

NOTE : POUR LA PERFORMANCE THERMIQUE OPTIMAL, IL EST RECOMMANDÉ DE

TOUJOURS UTILISER UN 30 pouces C-VENT PROLONGEMENT DE CONDUIT DE PLUIE PAC.

Tirage de la cheminée recommandée - 0,05 pouces de colonne d'eau

Autorisations D’installation

1-800-486-4328

1-204-633-1999

100 Eagle Drive

Winnipeg, MB Canada

sales@hermannelson.com

www.hermannelson.com

Page 52

CE RADIATEUR PEUT ÊTRE UTILISÉ AVEC OU SANS CANALISATIONS; LORSQU’IL EST

BRANCHÉ SUR DES CANALISATIONS, ÉVITEZ LES REPLIS OU LES COUDES COURTS. SI

L’ADMISSION D'AIR OU SI LA DÉCHARGE NE SONT PAS SUFFISANTS, LE RADIATEUR

SURCHAUFFERA.

INSTRUCTIONS D'ENTRETIEN DU BLAZE 400 D/G

AVERTISSEMENT : CHAQUE RADIATEUR DE CONSTRUCTION DEVRAIT ÊTRE INSPECTÉ

AVANT CHAQUE UTILISATION ET AU MOINS CHAQUE ANNÉE PAR UNE PERSONNE DE

SERVICE QUALIFIÉE. UN ENTRETIEN INCORRECT PEUT DONNER UN MAUVAIS

FONCTIONNEMENT DU RADIATEUR ET DES DOMMAGES GRAVES POURRAIENT SE

PRODUIRE.

TUYAUX

Les tuyaux doivent être visuellement inspectés avant chaque utilisation du radiateur. S'il y a une abrasion ou une

usure excessive ou si le tuyau est coupé, il doit être remplacé avant d’utiliser le radiateur. Les tuyaux de rechange

doivent être ceux indiqués par le fabricant.

RÉGULATEUR DE TEMPÉRATURE ET THERMOCOUPLE

Les protocoles du régulateur de température devraient être vérifiés avant chaque saison de chauffage pour s’assurer

que le brûleur s’éteindra si la température dépasse 280 ºF à la canalisation de sortie. Cela peut être fait en

restreignant le débit d’air qui passe dans l’appareil. Lorsque les vérifications sont terminées, retirez les restrictions

parce que les canalisations d’entrée et de sortie doivent être ouvertes pour que l’appareil fonctionne correctement.

Le réglage du contrôleur de température de 90 ºF et le retard de temps de 1 minute a été choisi pour permettre un

préchauffage de l’échangeur de chaleur et s’assurer que seul l’air réchauffé entre dans l’espace à chauffer. Lorsque

les besoins en chaleur sont comblés, le régulateur de température continue de faire fonctionner le ventilateur jusqu’à

ce que l’échangeur de chaleur se soit refroidi suffisamment. Cette fonction aide à prolonger la durée de vie de

l’échangeur de chaleur. Le régulateur de température doit être remplacé si le moteur du ventilateur ne s’arrête pas

lorsque l’échangeur de chaleur s’est refroidi.

Protocoles du régulateur de température

Le ventilateur se met en marche à 90 ºF ou délai de 1 minute

La sortie # 2 est réglée à 280 ºF (ce réglage éteint le brûleur lorsque la température parvient à 280 ºF et il le remet en

marche lorsque la température parvient à 280 ºF.) Si le brûleur se remet à zéro, le voyant s’allume; il faut alors aller

dans le compartiment où se trouve le brûleur dans la porte qui se trouve sous l’alimentation en air. Pour l’appareil

Beckett CG10A and CF375 le régulateur Honeywell doit être remis à zéro en appuyant sur le bouton de remise à zéro.

Pour le brûleur du Riello G400 et le F10, le contrôleur principal situé sur le brûleur doit être réinitialisé.

Il s'agit d'un 150 ºF fin de course haute redondant.

Pendant la période de refroidissement, la température de l’appareil revient à 80 ºF avant de s’arrêter.

ÉLECTRICITÉ

Assurez-vous que tous les connecteurs des conduits (BX) sont bien serrés. Ouvrez la porte du tableau de contrôle et

le compartiment du brûleur; assurez-vous que les raccordements sont bien serrés et qu’aucun câblage effiloché n’est

exposé.

1-800-486-4328

1-204-633-1999

100 Eagle Drive

Winnipeg, MB Canada

sales@hermannelson.com

www.hermannelson.com

Page 53

VENTILATEUR

vous que le moteur et les pales

êt de sécurité, une solution d’eau et de

LE VOYANT CLIGNOTE

RÉSISTANCE DE LA

1

0-400 Ohms

2

400-800 Ohms

3

800-1600 Ohms

4

>=1600 Ohms

APRÈS L’INSPECTION, UN ESSAI COMPLET DE COMBUSTION DOIT ÊTRE FAIT APRÈS CHAQUE PÉRIODE

RADIATEUR.

Voyez si de la poussière ou de la saleté s’est accumulée sur les pales du ventilateur. Faites fonctionner le brûleur

pour voir si le ventilateur vibre. Remplacez les pales du ventilateur si vous constatez des vibrations. Le débit d’air de

combustion et de ventilation ne doit pas être obstrué. Vérifiez le ventilateur et assurezsont en bon état de fonctionnement.

MOTEUR

Aucune lubrification n'est nécessaire puisque les roulements sont scellés. Nettoyez le moteur de toute poussière ou

saleté.

CIRCUIT DE GAZ (annuel)

Branchez l’alimentation en gaz sur le circuit de gaz alors que les vannes d’arrêt de sécurité du gaz sont fermées.

Pulvérisez sur tous les composants du circuit de gaz, y compris les vannes d’arr

savon pour vérifier l’étanchéité du circuit. Ouvrez les vannes d’arrêt de sécurité du circuit de gaz et pulvérisez la

solution d’eau et de savon pour vérifier l’étanchéité du circuit.

ÉCHANGEUR DE CHALEUR

Si de la fumée se produit même après avoir ajusté la bande d'air, l'échangeur de chaleur devrait être nettoyé à fond.

FILTRE DU COMBUSTIBLE (MAZOUT)

Remplacez la cartouche à tous les six mois d’utilisation normale.

REMARQUE: FLUX DE COMBUSTION ET DE VENTILATION NE PUISSE ÊTRE OBSTRUÉE

DÉTECTEUR DE FLAMME

Lorsqu'on entretient l’appareil, il faut l’allumer et le faire fonctionner. Après qu'il a fonctionné quelques minutes,

appuyer sur le bouton rouge de la commande principale, le maintenir enfoncé pendant une seconde puis relâcher. Si

le voyant clignote une ou deux ou même trois fois, c'est que la cellule au CdS fonctionne correctement. S'il clignote

quatre fois, vérifier que l’alignement est bon et que la flamme est correcte. Si le tout est correct, il est recommandé de