BLAUBERG Ventilatoren KOMFORT EC S160 S15, KOMFORT EC SB550 S15, KOMFORT EC S350 S11, KOMFORT EC S550 S11, KOMFORT EC S160 S11 Operation Manual

...Page 1

HEAT RECOVERY

AIR HANDLING UNITS

KOMFORT EC S S11/S15

KOMFORT EC SB S11/S15

EN

OPERATION MANUAL

Page 2

KOMFORT EC S/SB

www.blaubergventilatoren.de

CONTENTS

3 Introduction

3 General

3 Safety regulations

3 Transportation and storage regulations

3 Manufacturer's warranty

4 Delivery set

4 Design

5 Operation modes

5 Technical data

7 Unit mounting

12 Condensate drainage

12 Connection to power mains

14 Unit control

25 Technical maintenance

26 Troubleshooting

27 Acceptance certi cate

27 Connection certi cate

27 Warranty card

2

Page 3

www.blaubergventilatoren.de

!

KOMFORT EC S/SB

BLAUBERG Ventilatoren GmbH Company is happy to o er your

attention a heat recovery air handling unit KOMFORT EC S/SB.

INTRODUCTION

The present operation manual contains a technical description, technical

data sheets, operation and mounting guidelines, safety precautions and

warnings for safe and correct operation of the unit.

Read carefully and understand the operation manual, especially the

safety requirements, before the unit mounting and start up.

Keep the operation manual available as long as you use the unit.

GENERAL

The heat recovery air handling unit KOMFORT EC S/SB is designed for

e cient and energy saving ventilation of domestic and public premises.

The unit is not a ready to use product but a component part of central air

conditioning and ventilation network.

The unit is designed for suspended mounting.

The unit is designed for indoor application with the ambient temperature

ranging from +1 °C up to +40 °C and relative humidity up to 80 %.

Hazardous parts access and water ingress protection rating:

unit motors - IP 44;

assembled unit connected to air ducts - IP 22.

The unit design is regularly improved, so some models can slightly di er

from those ones described in this operation manual.

SAFETY REGULATIONS

All operations related to the unit electrical connections, servicing and

repair works are allowed only after the unit is disconnected from power

supply.

All mounting and servicing operations are allowed by duly quali ed

personnel.

Please, follow the safety regulations and working instructions (DIN EN 50

110, IEC 364).

Make sure the impeller and the casing are not damaged before connecting

the unit to power supply. The casing internals must be free of any foreign

objects which can damage the impeller blades or the motor.

The appliance maintenance and repair is allowed only after power cut-o

and full stop of the rotating parts.

Misuse of the unit or any unauthorized modi cation are not allowed.

The appliance is designed for connection to power supply in compliance

with the «Technical data» section.

The unit is rated for permanent operation.

Take steps to prevent ingress of smoke, carbon monoxide and other

combustion products into the room through open chimney ues or other

re-protection devices. Su cient air supply must be provided for proper

combustion and exhaust of gases through the chimney of fuel burning

equipment to prevent back drafting. The maximum permitted pressure

di erence per living units is 4 Pa.

The transported air must not contain any dust or other solid impurities,

sticky substances or brous materials.

The appliance is not rated for operation in a ammable or explosive

medium.

Ful l the operation manual requirements to ensure a trouble-free and

long service life of the unit.

TRANSPORTATION AND STORAGE REGULATIONS

Transportation of the unit is allowed by any vehicle provided the unit is

transported in the original package and is protected against weather and

mechanical damages.

Use hoist machinery for handling and transportation to prevent possible

mechanical damages of the unit. Ful l the requirements for transportation of

the speci ed cargo type during cargo-handling operations.

Store the unit in a dry and cool place in the original packing.

The storage environment must not be subjected to any aggressive and/

or chemical evaporations, admixtures, foreign objects that may provoke

corrosion and damage connection tightness.

Store the unit in an environment with minimized risk of mechanical

damages, temperature and humidity uctuations.

Do not expose the unit to the temperatures below +5 °C and above +40 °C .

Connection of the unit to power supply is allowed after the appliance has

been kept indoors for minimum two hours.

MANUFACTURER’S WARRANTY

The unit complies with the requirements according to the EU norms

and directives, to the relevant EU-Low Voltage Equipment Directives, EUDirectives on Electromagnetic Compatibility.

We hereby declare that the unit complies with the essential protection

requirements of Electromagnetic Council Directive 2004/108/EC, 89/336/EEC

and Low Voltage Directive 2006/95/EC, 73/23/EEC and CE-marking Directive

93/68/EEC on the approximation of the laws of the Member States relating

to electromagnetic compatibility, which relate to electrical appliances used

in set voltage classes.

The manufacturer hereby warrants normal operation of the unit over the

period of two years from the retail purchase date provided observance of the

installation and operation regulations.

In case of a failure due to a manufacturing fault during the warranty

period the consumer has the right to exchange it.

The replacement is o ered by the Seller.

In case of no con rmation of the purchase date, the warranty period shall

be calculated from the manufacturing date.

The MANUFACTURER is not responsible for any damage resulting from

any misuse of or gross mechanical interference with the unit.

The MANUFACTURER is not responsible for the damages resulted due to

the use of third party equipment or to third party equipment.

WARNING

The unit is not allowed for use by children and persons with reduced

physical, mental or sensory capacities, without proper practical experience

or expertise, unless they are controlled or instructed on the product operation by the person(s) responsible for their safety.

Supervise the children and do not let them play with the product.

WARNING

The unit contains in part materials that can be

recycled and in part substances that should not end up

as domestic waste.

Dispose of the unit once it has reached the end of its

working life according to the regulations valid in your

country.

3

Page 4

KOMFORT EC S/SB

!

DELIVERY SET

www.blaubergventilatoren.de

Air handling unit - 1 item

Operation manual - 1 item

S11 or S15 control panel (depending on the model) − 1 item

Mounting box for wall ush mounting (for S15 models) - 1 item

Mounting box for wall surface mounting (for S15 models) - 1 item

Drain pipe − 1 item

Packing box – 1 item.

DESIGN

The casing is made of double-skinned polymer-coated steel panels,

internally lled with mineral wool layer 20-40 mm for heat- and soundinsulation. The unit is equipped with a hinged panel to enable convenient

access for maintenance or repair operations. The spigots are located at the

side of the unit and are equipped with rubber seals for airtight connection

to the air ducts.

The casing is universal. While mounting the side of air duct connection

can be changed by turning the unit through 180° and by interchanging the

front and the back panels.

The unit is equipped with high-e cient EC-motors with an external rotor

and a centrifugal impeller with backward curved blades.

The unit is equipped with a high-e cient counter- ow polystyrene heat

exchanger with a large surface area.

A drain pan under the heat exchanger block is used for condensate

collection and drainage. The drain pan is equipped with a drain pipe for

condensate removal outside the unit.

The electronic frost protection system is used to prevent the heat

exchanger freezing in cold seasons. In case of heat exchanger freezing

danger communicated by the temperature sensor the supply fan is stopped

to let warm extract air warm up the heat exchanger. After that the supply fan

is turned on and the unit reverts to normal operation.

The KOMFORT EC SB units are equipped with a 100 % bypass for summer

ventilation (air cooling by the cool air from outside).

Built-in panel lter with F7 ltering class provides e cient supply air

ltration, while panel lter with G4 ltering class provides e cient exhaust

air ltration.

ATTENTION

Make sure the unit has no visible transport damages

while accepting the goods. Check the ordered and the

delivered goods for compliance.

The KOMFORT EC S S11 / KOMFORT EC SB S11 units have a wall-mounted

control panel S11 with a touch screen.

The KOMFORT EC S S15 / KOMFORT EC SB S15 units have a wallmounted control panel with a LED indication. The units are equipped with

an USB connector (Type B) and can be connected to a PC for con guring

the advanced settings in a special software (available for download on the

website blaubergventilatoren.de).

A standard delivery set includes a 10 m cable for connection of the unit

to the control panel.

Units are designed for mounting on the wall.

The installation place must allow connection to the sewage drain system

using the KIT SFK 20x32 kit (available upon separate order).

At the request of the customer the unit can be equipped with a humidity

sensor HV1. The humidity sensor is purchased separately as an accessory (see

Table 2). The unit with an installed humidity sensor maintains a set indoor

humidity point. As the extract air humidity rises above the set point, the

system automatically switches to the maximum speed. As the humidity drops

down below the set point the unit returns to the previous mode. Installation

and connection of the humidity sensor as well as setting of the humidity level

using the software is carried out on site by the service technician.

At the request of the customer the unit can be equipped with a duct heater

for supply air pre-heating. The heater maintains the duct air temperature at a

point that prevents the heat exchanger freezing. A control system regulates

heater operation. Mounting and connection of the heater, see page 8.

Bypass damper (for SB models)

Supply air temperature sensor

Fig. 1. Unit design

Counter-ow heat exchanger

Extract lter

Supply fan

Outdoor air

Electric lead-ins

Control unit

Drain pan

Drain pipe

Supply lter

Freeze protection sensor

Extract fan

S15 control panel

S11 control panel

Service panel

4

Page 5

www.blaubergventilatoren.de

OPERATION MODES

KOMFORT EC S/SB

The unit has several operation modes (see Fig. 2).

Heat recovery mode: Warm extract air from the room ows into the unit

and is cleaned in the extract lter. Then the air is moved through the heat

exchanger and is exhausted outside with the extract fan. Cold fresh air from

outside ows into the unit, where it is cleaned in the supply lter. Then the

air ows through the heat exchanger and is moved to the room with the

supply fan. Supply air is heated in the heat exchanger by transferring the

heat energy of warm and humid extract air to the cold fresh air. The air ows

are fully separated while owing through the heat exchanger. Heat recovery

minimizes heat losses, which reduces the cost of space heating in the cold

season.

HEAT RECOVERY MODE DEFROSTING MODE

EXTRACT AIR

SUPPLY AIR

EXHAUST AIR

INTAKE AIR

SUMMER COOLING MODE

INTAKE AIR

EXHAUST AIR

Summer cooling mode: the bypass damper is opened, the extract air

that is removed from the premises bypasses the heat exchanger. The intake

air temperature remains constant.

Defrosting mode: to prevent the heat exchanger freezing in the cold

season the unit has an automatic Defrosting mode according to the freeze

protection temperature sensor readings in the exhaust air duct downstream

of the heat exchanger. The unit switches to the Defrosting mode at the

extract air temperature +3 ° C. As the temperature rises the unit returns to

the previous mode. Only the extract fan operates in the Defrosting mode, the

supply fan is switched o .

SUPPLY AIR

EXTRACT AIR

EXTRACT AIR

SUPPLY AIR

EXHAUST AIR

INTAKE AIR

Service side view

Back side view

Service side view

Fig. 2. Operation modes

TECHNICAL DATA

Table 1. Technical data

Parameters KOMFORT EC S160 KOMFORT EC SB350 KOMFORT EC SB550

Unit voltage [V /50-60 Hz] 1 ~ 230

Power [W] 51 166 333

Current [A] 0,4 1,3 2,3

Max. air capacity [m3/h] 180 415 700

RPM 3770 3200 3230

Sound pressure level at 3 m distance [dB(A)] 24 28 28

Transported air temperature [°C] from -25 to +60

Casing material polymer-coated steel

Insulation

40 mm mineral wool (KOMFORT EC SB350 / KOMFORT EC SB550)

Extract lter G4

Supply lter F7 (optional G4)

Connected air duct diameter [mm] 125 160 200

Weight [kg] 34 56 65

Heat recovery e ciency [%] from 88 to 98 from 85 to 98 from 81 to 97

Heat exchanger type counter- ow

Heat exchanger material polystyrene

SEC class A+

20 mm mineral wool (KOMFORT EC S160)

5

Page 6

KOMFORT EC S/SB

FS2

Table 2. Accessories

www.blaubergventilatoren.de

Model

G4 replaceable lter

(panel type)

KOMFORT EC S160 S11 FP-EC S160 G4 FP-EC S160 F7

KOMFORT EC SB350 S11 FP-EC SB350 G4 FP-EC SB350 F7

F7 replaceable lter

(panel type)

Duct humidity sensor Condensate drainage kit

FS1

KIT SFK 20x32

KOMFORT EC SB550 S11 FP-EC SB550 G4 FP-EC SB550 F7

KOMFORT EC S160 S15 FP-EC S160 G4 FP-EC S160 F7

FS2

KOMFORT EC SB350 S15 FP-EC SB350 G4 FP-EC SB350 F7

KOMFORT EC SB550 S15 FP-EC SB550 G4 FP-EC SB550 F7

Table 3. Overall dimensions

Model

ØD ØD1 B B1 H H1 L L1 L2

Dimensions [mm]

KOMFORT EC S160 125 18 348 330 650 550 600 388 143

KOMFORT EC SB350 160 18 610 592 758 675 775 426 230

KOMFORT EC SB550 200 18 741 722 758 675 825 493 284

B

B1

ØD

L1L2

H1

ØD1

Fig. 3. Overall dimensions of the unit

130

88

Fig. 4. Overall dimensions of the S11 control panel

30

24

H

L

Table 4. Technical parameters of the S11 control panel

58

Ambient temperature [°C] from +5 to +40

Relative humidity [%]

72

4

Cable cross section [mm

Cable length [m] to 15

58

Ingress protection rating IP20

Parameter Value

from 5 to 80

(no condensation)

2

] from 0,25 to 0,35

6

Page 7

www.blaubergventilatoren.de

!

KOMFORT EC S/SB

Table 5. Technical parameters of the S15 control panel

86

86

62,3

39

21

11,2

R1,5

52

4

58

-

OUTOUT OUT IN

+RxTx

Fig. 5.Overall dimensions of the S15 control panel

The S15 control panel can be wall-mounted using the mounting box for

ush mounting, Fig. 6 (included in the delivery set).

78

78

Parameter Value

Ambient temperature [°C] from 0 to +40

Humidity range [%]

Cable cross section [mm

2

] from 0,25 to 0,5

from 5 to 80

(no condensation)

Cable length [m] to 10

Ingress protection rating IP30

The S15 control panel can be mounted on the wall using the mounting

box for surface mounting, Fig. 7 (included in the delivery set).

88

88

3758

58

32

Fig. 6. Overall dimensions of the mounting box for wall ush mounting Fig. 7. Overall dimensions of the mounting box for wall surface mounting

UNIT MOUNTING

WARNING

Safety precautions:

The unit must be mounted to a rigid and stable structure.

The unit must be suspended using anchor bolts. Make sure that the base structure is capable of sustaining the unit weight.

The unit mounting is allowed only after power cut-o and full stop of the rotating parts.

Restrictions:

• Do not operate the unit beyond the determined temperatures, in aggressive and in explosive environment.

• Do not connect the clothes dryer or other similar equipment to the ventilation system.

• Do not use the unit for air/dust mixture handling.

The unit mounting position must provide condensate drainage and access

to the hinged service panel for electric connection, maintenance and lter

replacement.

To attain the best performance of the unit and to minimise turbulenceinduced air pressure losses connect the straight air duct section to the spigots

on both sides of the unit while mounting.

Minimum straight air duct length:

• equal to 1 air duct diameter on intake side

• equal to 3 air duct diameters on outlet side

If the air ducts are too short or not connected, protect the unit parts from

ingress of foreign objects. To prevent uncontrollable access to the fans the

spigots may be covered with a protecting grille or other protecting device

with mesh width not more than 12.5 mm.

The unit must be mounted on a plane wall. Mounting of the unit to

an uneven surface can lead to the unit casing distortion and operation

disturbance.

When ordering an optional humidity sensor install it prior to unit

mounting.

7

Page 8

KOMFORT EC S/SB

www.blaubergventilatoren.de

UNIT WALL MOUNTING Fig. 8.

Fasteners for wall mounting are not included into delivery set and should

be ordered separately. While choosing fasteners consider the material of the

mounting surface as well as the weigh of the unit, refer to Technical Data.

Fasteners for unit mounting should be selected by the quali ed specialist.

Fix the wall-mounted hook at the required height and x the unit on the

hook.

158 mm

Fig. 8. Unit wall mounting

FS1 HUMIDITY SENSOR MOUNTING Fig. 10.

The FS1 humidity sensor is not included in the delivery set and can be

ordered separately for S11 units.

The humidity sensor must be installed prior to unit mounting.

Install the humidity sensor at the extract spigot into the mount in the

inner wall of the casing. Connect the humidity sensor plug to the respective

socket on the control unit. See the wiring diagram.

UNIT FLOOR MOUNTING Fig. 9.

Install the unit on pre-mounted oor supports, minimum 150 mm height,

to ensure su cient access for the drain pipe connection to the U-trap and for

condensate drain system mounting.

min 150 mm

Fig. 9. Unit oor mounting

FS2 HUMIDITY SENSOR MOUNTING Fig. 11.

The FS2 humidity sensor is not included in the delivery set and can be

ordered separately for S15 units. The humidity sensor must be installed prior

to unit mounting.

Install the humidity sensor at the extract spigot into the mount in the inner wall of the casing. Connect the humidity sensor plug to the respective

socket on the control unit. See the wiring diagram.

FS1 humidity sensor

Contact plug for

connection to the control unit

Contact plug for

connection to the control unit

Mount

Extract air duct

Contact socket

for connection

to the humidity sensor

Contact socket

for connection

to the humidity sensor

Fig. 10. FS1 humidity sensor mounting Fig. 11. FS2 humidity sensor mounting

HEATER MOUNTING FIG. 12

The heater is not included in the delivery and can be ordered separately.

The heater is rated for connection to single-phase AC 230 V/50 (60) Hz.

The heater is designed for mounting in the air duct connected with the

supply spigot of the unit.

The heater and the air handling unit must be connected via the cable with

the DB-9M connectors through the prewired DB-9F connectors.

FS2 humidity sensor

Extract air duct

Mount

1

2

3

Fig. 12. Heater mounting

8

Page 9

www.blaubergventilatoren.de

KOMFORT EC S/SB

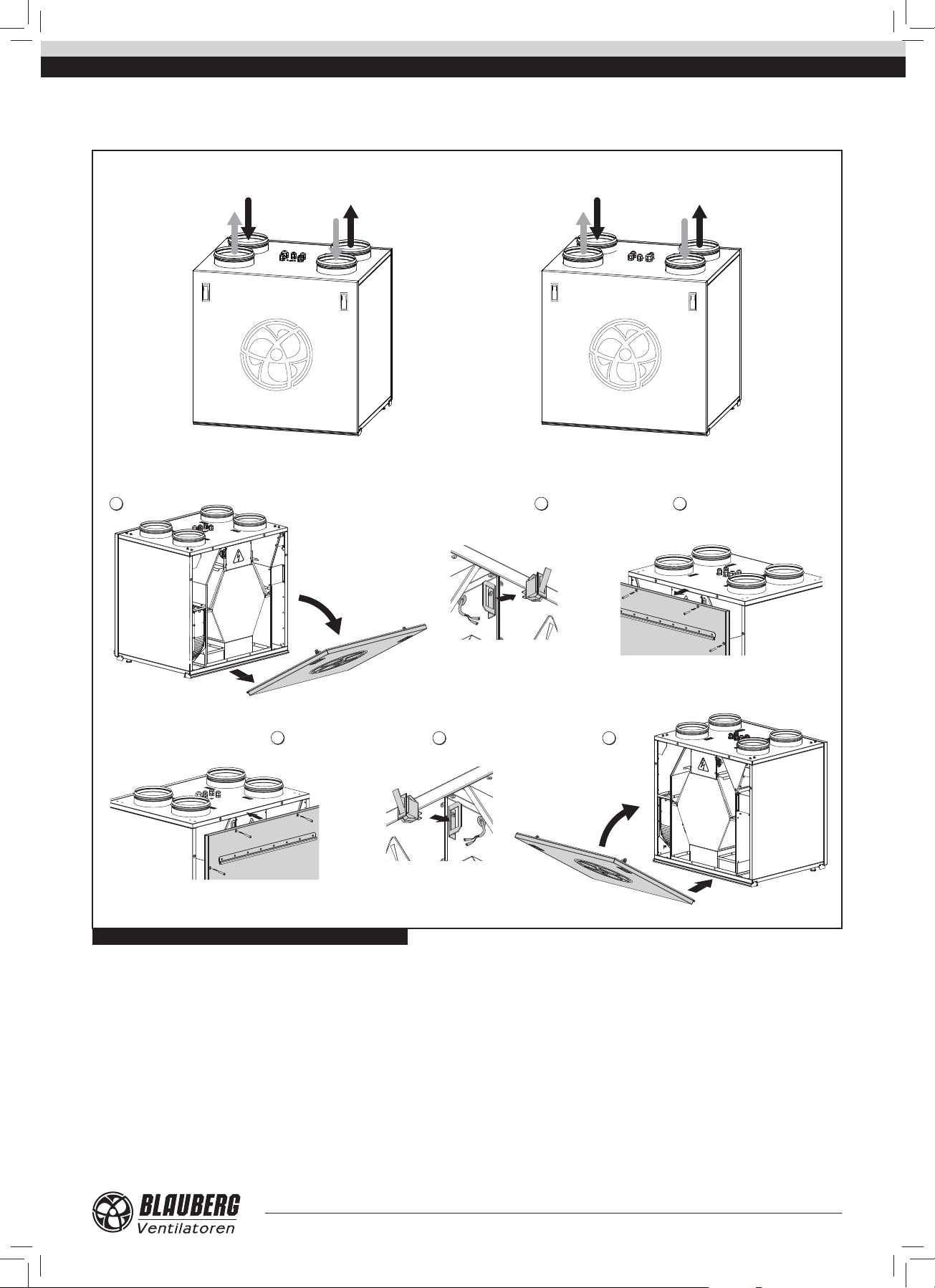

SERVICE SIDE CHANGE

Make sure of the correct unit service side selection (Fig. 12). Unit mounting position should enable free access to the removeable service panel for

maintenance and service operations.

Left-handed modication Right-handed modication

EXTRACT AIR EXHAUST AIR

INTAKE AIRSUPPLY AIR

INTAKE AIR

EXHAUST AIR

SUPPLY AIR

EXTRACT AIR

1

4

5 6

2 3

Fig. 12. Service side of the unit and the order of changing it

9

Page 10

KOMFORT EC S/SB

!

www.blaubergventilatoren.de

S11 CONTROL PANEL MOUNTING

The KOMFORT EC S S11 / KOMFORT EC SB S11 units have a wall-

mounted control panel S11 with a touch screen. The standard delivery set

includes a 10 m cable for connection of the unit and the control panel. The

control panel installation chart is shown in Fig. 13. The room temperature

sensor is integrated into the control panel. For that reason the control panel

must be installed in a temperature balanced place, at least 1 m away from the

heating equipment, doors and windows.

Fix the control panel to the wall using the screws and connect it to the air

handling unit using a supplied four-wire connecting cable.

For control panel mounting refer to Fig. 13.

WARNING

Make sure that the control panel is not damaged. Do not use a damaged control panel! Do not install the control panel on an uneven

surface! While tightening the screws do not apply excessive force to prevent the control panel casing deformation. Do not lay the

control panel cable in close proximity parallel to a power cable! Do not coil the cable from the control panel in loops while laying it.

1 2

3

Fig. 13. S11 control panel mounting

The S11 control panel includes a lithium cell CR1220 with a limited time

resource.

The battery keeps the internal clock running while the unit is

disconnected from power supply. If the unit is disconnected from power

supply and the battery is low, the clock stops and the day and time settings

are reset. This leads to incorrect date and time indication when the unit is on

and, as a result, to incorrect scheduled operation of the unit. In this case, the

battery should be replaced. To replace the battery use a new battery only.

Battery replacement:

1. Disconnect the air handling unit from power supply.

2. Remove the two screws in the bottom part of the casing.

4

3. Remove the Display. Replace the battery as shown.

4. 4. Assemble the control panel in the reverse order. If the terminal

block wires on the upper circuit board were unplugged make sure to reconnect them correctly. Failure to re-connect the wires properly will result in

operating failure of the equipment.

5. Connect the panel to the power supply and set the current date and

time.

10

Page 11

www.blaubergventilatoren.de

!

KOMFORT EC S/SB

S15 CONTROL PANEL MOUNTING

The KOMFORT EC S S15 / KOMFORT EC SB S15 units have a wall-

mounted control panel with a LED indication. The standard delivery set

includes a 10 m cable for connection of the unit and the control panel.

The control panel wall ush mounting is shown in Fig. 14. The control

panel wall surface mounting is shown in Fig. 15. Connect the control panel to

the air handling unit using a supplied connecting cable and x it to the wall

using one of the mounting boxes and the screws.

WARNING

Make sure that the control panel is not damaged. Do not use a damaged control panel! Do not install the control panel on an

uneven surface! While tightening the screws do not apply excessive force to prevent the control panel casing deformation. Do

not lay the control panel cable in close proximity parallel to a power cable! Do not coil the cable from the control panel in loops while laying it.

Wall ush mounting of the S15 control panel (Fig. 14):

1. Make a hole in the wall to install the control panel. Insert all the

necessary cables and wires into the hole, install the mounting box from the

delivery set in the wall.

2. Use a screwdriver to carefully undo the clips on the backside of the

control panel and remove the back cover.

3. Fix the back side of the casing to the mounting box through the

mounting holes, then connect the cable to the control panel in accordance

with the wiring diagram Fig. 18.

4. Fix the front side of the control panel using the latches.

1 2 3 4

Fig. 14. S15 control panel wall ush mounting

Wall surface mounting of the S15 control panel (Fig. 15):

1. Lead all necessary cables and wires to the control panel mounting place

and install the mounting box from the delivery set on the wall.

2. Use a screwdriver to carefully undo the clips on the backside of the

control panel and remove the back cover.

1 2 3 4

Fig. 15. S15 control panel wall surface mounting

3. Fix the back side of the casing to the mounting box through the

mounting holesusing two screws from the delivery set, then connect the

cable to the control panel in accordance with the wiring diagram Fig. 18.

4. Fix the front side of the control panel using the latches.

11

Page 12

KOMFORT EC S/SB

!

CONDENSATE DRAINAGE

www.blaubergventilatoren.de

The hole for the drain pipe is at the bottom of the unit. Remove the plug

from the hole, open the service panel and install the drain pipe from the

delivery set into the hole, then connect the drain pipe to the sewage system

using the KIT SFK 20x32 condensate drainage kit (available upon separate

order).

The condensate drainage system is designed for normal operation in

premises with air temperatures above 0 °C!

If the expected ambient air temperatures are below 0 °C the

condensate drainage system must be equipped with heat insulation and

pre-heating facilities.

Drain pipe

U-trap

Drain hose

Sewage system

min 3°

Fig. 16. Condensate drainage

WARNING

In case of several units mounting connect each unit to an individual U-trap.

Direct condensate drainage with no connection to the drain system is not allowed.

CONNECTION TO POWER MAINS

WARNING

Read the service instruction prior to any electric installations. Connection of the unit to power mains is allowed by a

quali ed electrician only.

The rated electrical parameters are stated on the rating plate. Any tampering with the internal connections is prohibited

and will void the warranty.

Connect the unit only to power mains with valid electric standards.

Follow the respective electric standards, safety rules (DIN VDE 0100), TAB der EVUs. The house cabling system must be

equipped with a magnetic trip automatic switch at the external input. The contact gap on all poles must be at least 3 mm (VDE

0700 T1 7.12.2 / EN 60335-1).

The automatic switch trip current must be not below the rated current consumption (ref. Table 1). Enable quick access to an

automatic switch installation place.

Cut power supply to the unit o by turning the automatic electric switch

QF to OFF position prior to any operations.

Take steps to prevent activation of the automatic switch before nishing

all the operations.

Connect the KOMFORT EC S S11 / KOMFORT EC SB S11 units to single-

phase AC 230 V/50-60 Hz power mains using the power cord with the Euro

Plug, pre-wired at the factory. The unit must be grounded in compliance with

the valid electrical standards of the user country!

Connect the unit to the terminal block X1, located in the control unit, in

12

compliance with the external connections wiring diagram. The unit has an

option of additional external controls connection to the X1 terminal block

(Fig. 17). The unit must be grounded in compliance with the valid electrical

standards of the user country!

QF

Page 13

www.blaubergventilatoren.de

KOMFORT EC S/SB

14151617

13

12

11

10no9

76 5

Х1

Gnd

Out

Gnd

Out

TE1

Design. Name Type Wire**

CCU* DX cooler N0 2x0,75 mm

SM1* Supply air damper actuator LF 230 2x0,75 mm

SM2* Extract air damper actuator LF 230 2x0,75 mm

PK1* Contact from re alarm panel N0 2x0,75 mm

P1 S11 control panel 4x0.25 mm

TE1 Outdoor air temperature sensor

*Is not included in the delivery set, should be ordered separately.

** Maximum connecting cable length is 20 m!

Fig. 17. External connections wiring diagram of the KOMFORT EC S S11 / KOMFORT EC SB S11 units

DO NOT LAY THE CONTROL PANEL CABLE IN CLOSE PROXIMITY

PARALLEL TO A POWER CABLE! DO NOT COIL THE CABLE FROM THE

AE+

E+

t C

P1

+12V

B

Gnd

BA

Gnd

+12V

c8no

CCU

(no-contact)

PK1

LLN LN

c

2121 21

L

N

SM2

LN

SM1

CONTROL PANEL IN LOOPS WHILE LAYING IT.

4

3PE2N1

LL

Power input

230 VAC

Recommended cross section of the data cable

2

2

2

2

2

between the control panel and the unit

Cable cross

section

Cable

length

ELECTRIC SHOCK HAZARD!

≥ 0,12 mm

up to 15 m up to 50 m

2

≥ 0,25 mm

2

Connect the unit KOMFORT EC S S15 / KOMFORT EC SB S15 to single-

phase AC 230 V/50-60 Hz power mains using the power cord with the Euro

Plug, pre-wired at the factory. The unit must be grounded in compliance with

the valid electrical standards of the user country!

The unit has an option of additional external controls connection to the

X2 terminal block, which is located on the hinged electrical mounting plate of

the control unit. Extra connections to the unit are shown in dotted lines in the

Wiring diagram, see Fig. 18.

• PK - connection of the automatic re extinguishing system con-

tact.

Upon connecting the automatic re extinguishing system contact remove

the jumper between the 1 and 2 terminals. In case of re the normally closed

dry contact breaks the control circuit from the central re- ghting board and

cuts o power supply to the unit.

• Connection of the external control unit contact, such as CO2

PK re alarm panel

(remove the jumper while

connecting the contact)

Humidity

sensor

+U

0-10V

3

21GND

230 V/ 50-60 Hz

XP

X1 X2

QF

L

sensor (NO, C).

Connect the CO2 sensor to the 6 and 7 terminals by using a normally opened

dry contact. If the contact is closed, the unit turns to the maximum speed.

FS2 (+U, 0-10 V, GND) humidity sensor connection.

Connect the FS2 humidity sensor (not included in the delivery set, can

be ordered separately) to the contact socket located on the side panel of the

control unit from the side of the extract pipe in accordance with the Wiring

diagram.

• Connection of outer air dampers (SM1 supply air damper, SM2

exhaust air damper).

The air dampers and the actuator are not included in the delivery set and

can be purchased separately. For controlling the air dampers use the LF 230

BELIMO electric actuator with a voltage of 230 V and an open-close controlling.

Connect the electric actuators to the 12 and 13 terminals (refer to the Wiring

diagram).

External device

NO contact

(CO2 sensor)

GND+U 0-10V NONPEPKPK C

GND Tx Rx +U

-

White

Control

panel

Tx Rx +

Green

Brown

Electric actuators

of the external air dampers

SM1

supply

L1 N

Yellow

exhaust

L1 N

SM-L13SM-N

SM2

234 1098765432111

1

Fig. 18. Wiring diagram of the KOMFORT EC S S15 / KOMFORT EC SB S15 units

12

13

Page 14

KOMFORT EC S/SB

UNIT CONTROL

The KOMFORT EC S S11 / KOMFORT EC SB S11 units are controlled from

the wall-mounted control panel with a sensor display (Fig. 19). Unit control and

adjustment of operating parameters are shown in Table 6. Possible error codes

are shown in Table 7. Factory settings are shown in Table 8.

Fig. 19. S11 control panel

Table 6. Unit control and adjustment of operating parameters of the unit with the S11 control panel

Function Indication

1 Main menu

The Main menu contains the date, current humidity, time, temperature and

set air ow.

MENU - access to the User menu, see clause 5.

AUTO - scheduled operation activation/deactivation.

TEMPERATURE - display of the current indoor temperature. After pressing

this button the Temperature Setting menu is opened, see clause 4.

ON/OFF - turning air handling unit ON/OFF or Standby mode activation.

TIMER - turning the timer on/o .

AIR FLOW - current fan speed display. The Fan Speed Setting menu is

accessible through this button, see clause 3.

The network connection status indicator is displayed:

www.blaubergventilatoren.de

− the unit is connected to network.

− the unit is disconnected from network.

2 Unit activation and deactivation

The unit is activated with ON

Press OFF for the unit deactivation or Standby mode activation. The

indicator changes its colour from red to green as the unit is turned on. In the

Standby mode the unit operates at the rst speed and set temperature, see

clause 12.

button.

14

Page 15

www.blaubergventilatoren.de

Table 6. Unit control and adjustment of operating parameters of the unit with the S11 control panel (continued)

Function Indication

3 Fan speed changeover

Fan speed setting:

Press the AIR FLOW button ;

The unit has four speed stages:

- Speed 1;

- Speed 2;

- Speed 3;

- Humidity Control mode. The fan speed is regulated depending on

the humidity setting. The humidity level is set via the Engineering menu, see

clause 14.

If the AUTO or TIMER mode is activated the current air

ow value is displayed in real time operation no matter of the set air ow

value.

KOMFORT EC S/SB

Set the required speed using the buttons or .

Then press ENTER

To return to the Main menu without saving changes press EXIT .

4 Temperature setting

Temperature setting:

Press the TEMPERATURE button

Select the set temperature type:

DUCT

ROOM

(temperature in the air duct);

(temperature in the room).

.

.

Set the desired temperature using or .

Then press ENTER

To return to the Main menu without saving changes press EXIT

.

.

15

Page 16

KOMFORT EC S/SB

Table 6. Unit control and adjustment of operating parameters of the unit with the S11 control panel (continued)

Function Indication

5 User menu

www.blaubergventilatoren.de

To enter the User menu press MENU

The User menu contains basic menu items and functions for parameters

setting:

ENG. MENU - access to the Engineering menu. The menu is passwordprotected.

AUTO ADJUST. - scheduled operation setting.

DATE/TIME - date and time setting.

TIMER ADJUST. - setting time and speed operation on timer basis.

MOTOR HOURS - setting lter replacement periodicity.

EXIT - return to the Main menu.

6 Engineering menu

in the Main menu.

To enter the Engineering menu press ENG. MENU

menu.

To access the Engineering menu enter the password. The

default setting is 1111.

Press OK.

To change the password use the RESET button.

Press RESET to clear the password eld.

To return to the User menu press EXIT .

If you forgot the user-de ned password, see clause 11 Password Change,

press and hold RESET until you hear a long sound signal (20 clicks,

approximately 20 seconds). The default password 1111 is set.

in the User

16

Page 17

www.blaubergventilatoren.de

Table 6. Unit control and adjustment of operating parameters of the unit with the S11 control panel (continued)

Function Indication

For navigating in the Engineering menu use the following buttons:

- moving upwards in the list.

- moving downwards in the list.

- select the value from the parameter list.

- return to the User menu.

KOMFORT EC S/SB

7 Air flow setting

Select the AIR FLOW SETTING item from the Engineering menu and

press ENTER .

Select the edited speed value (the selected value is highlighted with a

rectangle).

Use

stage.

The air ow is set as a percentage of the maximum performance of each fan.

To return to the Engineering menu without saving changes press EXIT

8 Temperature sensor

To select the heating control sensor from the Engineering menu select

the TEMPERATURE SENSOR submenu and press ENTER

Select a desired temperature sensor type.

Press ENTER to con rm.

To return to the Engineering menu without saving changes press EXIT

or buttons to set the air ow value for each fan speed

.

.

.

17

Page 18

KOMFORT EC S/SB

Table 6. Unit control and adjustment of operating parameters of the unit with the S11 control panel (continued)

Function Indication

9 Language selection

To select the control panel interface language select the LANGUAGE

www.blaubergventilatoren.de

submenu from the Engineering menu and press ENTER

Select the desired language from the list.

Press ENTER

To return to the Engineering menu without saving changes press EXIT

.

10 Extra options

Select the EXTRA OPTIONS submenu from the Engineering menu and

press ENTER .

The SUPPLY FAN OFF mode helps to prevent heat exchanger freezing

and requires disabling of the HEATING CONTROL parameter.

To activate the heat exchanger freezing protection function by means of

the supply fan deactivation set the HEATING CONTROL parameter value

to OFF. To proceed to the function setup set the SUPPLY FAN OFF MODE

parameter to ON.

TTo select a humidity sensor type set 1 for the duct sensor (exhaust duct)

or 2 for the room sensor in the HUMIDITY SENSOR SELECTION menu item.

For selecting the bypass operation mode set 1 in the BYPASS

OPERATION MODE to select the regular operation mode, which prevents

heat exchanger freezing, or 2 to enable bypass opening in the ventilation

mode.

To save the changes and return to the Engineering menu press EXIT

.

.

.

If the SUPPLY FAN OFF MODE parameter is set to ON the control panel

switches to the SUPPLY FAN OFF MODE setting.

Select an item by touching the respective eld: WORKING HOURS,

DOWNTIME and SWITCH-OFF TEMPERATURE (the temperature is set

according to the outdoor temperature sensor readings de ned in the range

from 0 °C to -30 °C).

Then use

Press ENTER

To return to the Engineering menu without saving changes press EXIT

.

11 Password change

Select the PASSWORD CHANGE submenu from the Engineering menu

and press ENTER

Then enter the new password for accessing the Engineering menu.

Press OK.

To re-enter the password press RESET. This operation clears the

ENTER NEW PASSWORD eld.

or buttons to set the desired value.

to con rm the parameters.

.

To return to the Engineering menu press EXIT .

18

Page 19

www.blaubergventilatoren.de

Table 6. Unit control and adjustment of operating parameters of the unit with the S11 control panel (continued)

Function Indication

12 Standby mode setting

Select the STANDBY MODE item in the Engineering menu and press

KOMFORT EC S/SB

ENTER

Use the buttons

window:

• 0 − deactivation of the unit.

• 1 − activation of the Standby mode. In the Standby mode the unit

operates at the rst speed at temperature set by

buttons in TEMPERATURE window.

Press ENTER .

To return to the Engineering menu without saving changes press EXIT

13 Display brightness adjustment

Select the BRIGHTNESS ADJUSTMENT submenu from the Engineering

menu and press ENTER

Then use the

Operation and Sleep modes. The panel switches to the Sleep mode 30

seconds after the last screen interaction.

Press ENTER to con rm.

To return to the Engineering menu without saving changes press EXIT

.

or to select 0 or 1 in the AIR FLOW

or

.

.

or buttons to set the brightness for the

.

14 Humidity setting

Select the HUMIDITY SETTING item in the Engineering menu and press

ENTER .

Select the humidity sensor type used to control the humidity:

• DUCT

included into the basic delivery set);

• ROOM humidity sensor

Then use

Press ENTER to con rm.

To return to the Engineering menu without saving changes press EXIT

.

In the Humidity Control mode the minimum air ow is equal to the air

ow at the low speed.

15 Error control

To receive information regarding the last error select ERROR CONTROL

(the duct humidity sensor is optional and is not

.

or buttons to set the desired humidity level.

submenu from the Engineering menu and press ENTER

The display shows the error date and code.

To return to the Engineering menu press EXIT .

Errors description is stated in Table 7.

.

19

Page 20

KOMFORT EC S/SB

Table 6. Unit control and adjustment of operating parameters of the unit with the S11 control panel (continued)

Function Indication

16 Control panel temperature sensor correction

To correct the panel temperature sensor indications select

TEMPERATURE CORRECTION submenu from the Engineering menu and

www.blaubergventilatoren.de

press ENTER

Then use

the room temperature sensor installed in the control panel casing.

The default factory setting for the temperature sensor correction is -6°C.

To return to the Engineering menu without saving changes press EXIT

.

17 Default settings

To reset the controller settings to the factory defaults select DEFAULT

SETTINGS submenu from the Engineering menu and press ENTER

To con rm the reset press ENTER

To return to the Engineering menu without saving changes press EXIT

.

The default settings are given in Table 8.

18 Current temperature review

.

or buttons to set the temperature correction for

.

.

To review the current temperatures select the CURRENT TEMPERATURES

submenu from the Engineering menu and press ENTER

The display shows all the current temperature information.

If any temperature sensor of the ventilation unit is missing its

con guration value is displayed as OFF.

To return to the Engineering menu press EXIT .

19 AUTO Mode (scheduled operation)

The AUTO mode enables scheduled operation of the ventilation unit. The

unit runs at the pre-set speed and temperature during the speci ed time

periods. The unit is in the Standby mode between the operating periods.

To activate the AUTO mode press AU TO

Main menu. Activation of the AUTO mode is con rmed with a tick —

.

. in the control panel

.

20

Page 21

www.blaubergventilatoren.de

Table 6. Unit control and adjustment of operating parameters of the unit with the S11 control panel (continued)

Function Indication

To set up the AUTO mode press the button to enter the User

menu and press AUTO ADJUST.

While the TIMER is active the AUTO mode is disabled due to a lower

priority.

Select the day to enable the AUTO mode. Upon entering the menu the

value is set to the current day. To change the day press the DAY eld.

KOMFORT EC S/SB

Then use the

temperature for the selected day by pressing the respective parameter eld.

Depending on the Standby mode settings, the unit remains in the

Standby mode or turns o between the operating periods.

To return to the Engineering menu and save changes automatically

press EXIT .

20 Timer

To activate the timer press TIMER

menu.

To set up the timer enter the User menu and press TIMER ADJUST.

or buttons to set the time, air ow and

in the control panel Main

.

Activation of the TIMER function is con rmed with a tick — .

If the AUTO and TIMER functions are activated synchronously, TIMER

function will operate as it supersedes the AUTO function.

The timer cannot be activated once the Humidity Control mode is on.

Use or buttons to set the time, air ow and air temperature

values.

Press ENTER to con rm the set parameters.

To return to the Engineering menu without saving changes press EXIT

.

21

Page 22

KOMFORT EC S/SB

Table 6. Unit control and adjustment of operating parameters of the unit with the S11 control panel (continued)

Function Indication

21 Motor hours

The MOTOR HOURS function enables the user to set up lter cleaning or

replacement periodicity. Upon expiration of the pre-set time the panel

displays a lter cleaning or replacement indicator. The indicator is displayed

every 24 hours.

To set up the MOTOR HOURS function enter the User menu and press

www.blaubergventilatoren.de

MOTOR HOURS

Then use the or buttons to set the lter replacement

interval.

The OPERATING HOURS window shows the time elapsed from the lter

installation.

Press RESET

To save the changes and return to the Engineering menu press EXIT

.

22 Errors

The control panel displays the following message in case of any

malfunctions in the ventilation unit operation.

.

after replacement of the lter.

To enter the ERROR LIST press EXIT .

The ERROR LIST can also be accessed from the Engineering menu.

The error code details are stated in Table 7.

The error message appears every 30 seconds until the system emergency

cause has been troubleshooted.

To reset the error alert restart the unit once the malfunction cause has been

eliminated.

22

Page 23

www.blaubergventilatoren.de

Table 7. Error code description for the S11 control panel

Error code Description

TE1 Outdoor temperature sensor malfunction.

TE2 Malfunction of the temperature sensor for heat exchanger freezing protection.

TE5 Duct temperature sensor malfunction.

TE6 Malfunction of the duct humidity sensor.

MIN Supply fan malfunction.

MEX Extract fan malfunction.

ERP Control panel communication error.

DI2 Fire alarm sensor actuation.

Table 8. Factory settings for the S11 control panel

Parameter Factory setting

Air ow rate 1

Temperature

Air ow setting

Temperature sensor Duct

Extra options

Supply Fan O mode

Standby mode setting

Display brightness adjustment

Humidity setting

Temperature sensor correction - 6 °C

Timer settings

Motor hours

Duct + 25 °C

Room + 20 °C

Air supply Speed 1 - 40 %, Speed 2- 70 %, Speed 3 - 99 %

Air extract Speed 1 - 40 %, Speed 2- 70 %, Speed 3 - 99 %

Heating control O

Supply Fan O mode O

Humidity sensor selection 2

BYPASS Operation mode 1

Working hours 20 minutes

Downtime 5 minutes

Switch-o temperature + 3 °C

Air ow rate 1

Temperature + 20 °C

Operation 50

Sleep 1

Duct 50 %

Room 50 %

Hours 01

Minutes 00

Air ow rate 1

Temperature + 20 °C

Setting 4000 hours

KOMFORT EC S/SB

23

Page 24

KOMFORT EC S/SB

www.blaubergventilatoren.de

The KOMFORT EC S S15 / KOMFORT EC SB S15 units are operated from

the wall-mounted control panel using the touch buttons (Fig. 20). Unit control

and adjustment of operating parameters are shown in Table 9. Factory settings

and parameters adjustment range are shown in Table 10.

Indication variants when the unit is o :

• The touch buttons on the control panel are not highlighted;

• Filter maintenance indicator and emergency indicator are highlighted

in the respective cases.

Touch button

High speed

Touch button

Medium speed

Touch button

Low speed

Fig. 20. S15 control panel

Table 9. Unit control and adjustment of operating parameters of the unit with the S15 control panel

Button Function

Unit activation:

Press one of three speed setting buttons. The selected button will be highlighted and the unit switches to the required speed.

Speed changeover:

Press the inactive speed setting button once. The selected button will be highlighted and the unit will switch to the required speed.

Unit deactivation:

To turn the unit o press the highlighted speed setting button.

Touch button

Filter maintenance

Touch button

Bypass damper control

Emergency indicator

Summer Cooling mode:

Press the touch button once. When the touch button is activated the display lights up and the unit switches to the Summer Cooling

mode in one of the ways, depending on the unit model:

• KOMFORT EC SB350 S15 and KOMFORT EC SB550 S15: the bypass damper is opened.

• KOMFORT EC S160 S15: the supply fan is turned o and only the extract fan is in operation.

Each time a touch button is pressed, the current unit status is changed and saved in the control panel memory.

Filter maintenance:

As the unit reaches the set value of operating hours, the touch button is highlighted to remind about cleaning or replacing of the

Table 10. Factory settings for the S15 control panel

Zero speed (the unit is o ) [%] 0 0 - 100

Low speed [%] 40 0 - 100

Medium speed [%] 70 0 - 100

High speed [%] 100 0 - 100

Unit speed with the closed dry contact of the external control unit [%] 100 0 - 100

Filter cleaning (replacement) interval 2160 (3 months) 0 - 10000

Humidity level [%] 60 30 - 80

lters.

After lter replacement or cleaning, reset the motor hours. Press and hold the touch button for 5 seconds. Resetting of the timer is

con rmed by the touch button light turning o .

Alarm:

In case of alarm, the alarm indicator is highlighted.

In case of alarm indication, contact the Seller!

Parameter Factory setting Adjustment range

24

Page 25

www.blaubergventilatoren.de

KOMFORT EC S/SB

The KOMFORT EC S S15 / KOMFORT EC SB S15 units are equipped with

a USB connector (Type B) and can be connected to a PC for con guring the

advanced settings in a special software (available for download on the website

eng.blaubergventilatoren.de).

To work with the pre-installed software connect the unit to a laptop or

to a PC via a USB cable with the Type A and Type B contact sockets. The USB

cable is not included in the delivery set. The software enables editing the unit

parameters (see Table 10).

The list of the adjustable parameters can be expanded in new versions of

the software.

Setting, troubleshooting and upgrading of the software version is made by

the servicetechnician.

The software is available for downloading on our website:

blaubergventilatoren.de.

TECHNICAL MAINTENANCE

WARNING

Cut power supply to the unit o by turning the automatic electric switch QF to OFF position prior to

any maintenance operations.

Take steps to prevent activation of the automatic switch before nishing all the operations.

USB Type A

USB Type B

Fig. 21. Connection of a PC to the units with the S15 control panel

Regular technical supervision and maintenance of the unit are required to

ensure the product long service life and non-stop operation.

Disconnect the unit from power supply prior to any maintenance

operations.

The unit must undergo technical maintenance 3 to 4 times a year.

The unit technical maintenance includes regular cleaning and other works:

1. Filter maintenance (3-4 times per year).

Dirty lters increase air resistance in the system and reduce supply air

volume. The lters require cleaning not less than 3-4 times per year. Vacuum

cleaning is allowed. After two consecutive cleanings lters must be replaced.

For new lters contact the Seller.

2. Heat exchanger maintenance (once a year).

Some dust may accumulate on the heat exchanger block even in case of

regular maintenance of the lters. To maintain the high heat recovery e ciency,

regular cleaning is required. To clean the heat exchanger pull it out, ush the

heat exchanger with warm detergent solution. After cleaning install the dry

heat exchanger back to the unit.

3. Fan maintenance (once a year).

Even in case of regular maintenance of the lters, some dust may

accumulate inside the fans and reduce the fan performance and supply air ow.

Clean the fans with a soft brush or cloth. Do not use water, aggressive

solvents or sharp objects as they may damage the impeller.

4. Technical maintenance of condensate drainage system (once a year).

The drain pipes may get clogged with the extracted particles. Pour some

water inside the drain pan to check the pipe for clogging. Clean the U-trap and

the drain pipe if required.

5. Technical maintenance of an air duct system (every 5 years).

Even regular ful lling of all the prescribed above maintenance operations

may not completely prevent dirt accumulation in the air ducts which reduces

the unit capacity. Duct maintenance means regular cleaning or replacement.

WARNING! Consider the unit sharp edges! Ful l maintenance

operations in work gloves!

6. Control unit maintenance (if necessary).

The control unit maintenance must be performed by an expert quali ed for

unassisted operations with electrical installations with the voltage up to 1000 V

after careful reading of the user’s manual.

Access to the control board of the control unit:

1 2

3

25

Page 26

KOMFORT EC S/SB

TROUBLESHOOTING

Table 11. Possible faults and troubleshooting

Fault Possible reason Troubleshooting

www.blaubergventilatoren.de

The fan(s) does not

start when the unit

is on

Automatic switch

tripping

Low air ow

Cold supply air

Noise, vibration

No power supply or wrong connection to power mains.

The motor is jammed, the impeller blades are soiled. Remove the motor jam, clean the impeller blades.

Short circuit in power grid. Turn the unit o and contact the unit Seller for fault diagnostics.

Too low set speed. Set higher speed.

The lters and the fans are soiled, the heat exchanger is soiled. Clean or replace the lters, fans and the heat exchanger.

The air dampers, the supply di users or the exhaust grilles are

closed or soiled.

The extract lter is soiled. Clean or replace the extract lter.

The heat exchanger is frozen.

The impeller is soiled. Clean the impeller.

The screw connection is loose. Tighten the screws.

Connect the unit to power supply. Troubleshoot the connection

error.

Open and clean the air dampers, the supply di users, the

exhaust grilles to ensure free air ow.

Check the heat exchanger condition. Turn the unit o if

required and restart it after the freezing danger is no longer

imminent.

No exible anti-vibration connectors. Install the exible anti-vibration connectors.

Condensate leakage The drain system is clogged, damaged or wrong installed.

Clean the condensate drain system. Check the drain hose slope.

Make sure the U-trap is lled with water and the drain system is

frost-protected.

26

Page 27

www.blaubergventilatoren.de

KOMFORT EC S/SB

ACCEPTANCE CERTIFICATE

The air handling unit with heat recovery

KOMFORT EC S160 S11 KOMFORT EC S160 S15

KOMFORT EC SB350 S11 KOMFORT EC SB350 S15

KOMFORT EC SB550 S11 KOMFORT EC SB550 S15

is recognized as serviceable.

The unit complies with the requirements according to the EU norms and directives, to the relevant EU-Low Voltage Equipment Directives, EU-Directives

on Electromagnetic Compatibility. We hereby declare that the unit complies with the essential protection requirements of Electromagnetic Council Directive

2004/108/EC, 89/336/EEC and Low Voltage Directive 2006/95/EC, 73/23/EEC and CE-marking Directive 93/68/EEC on the approximation of the laws of the

Member States relating to electromagnetic compatibility, which relate to electrical appliances used in set voltage classes.

This certi cate is issued following test carried out on samples of the product referred to above.

Approval mark Manufacturing date ____________________

CONNECTION CERTIFICATE

Heat recovery air handling unit

KOMFORT EC S160 S11 KOMFORT EC S160 S15

KOMFORT EC SB350 S11 KOMFORT EC SB350 S15

KOMFORT EC SB550 S11 KOMFORT EC SB550 S15

is connected to power mains in compliance with the operation manual requirements by the professional:

Company:

Expert’s Full Name

Date Signature

WARRANTY CARD

KOMFORT EC S160 S11 KOMFORT EC S160 S15

KOMFORT EC SB350 S11 KOMFORT EC SB350 S15

KOMFORT EC SB550 S11 KOMFORT EC SB550 S15

SELLER

PURCHASE DATE

REPRESENTATIVE IN EU

BLAUBERG Ventilatoren GmbH

Aidenbachstr. 52a,

D-81379 München,

Deutschland

27

Page 28

www.blaubergventilatoren.de

KOMFORT EC S/SB v.3(5+4) / EN

Loading...

Loading...