Page 1

Instructions for the Use and Care and Installation of

BIC90X

BIC120X

BICG90X

Rangehood

Page 2

Page 3

Dear Customer

You will find that the modern look of your Blanco rangehood blends in perfectly with your

kitchen décor. It is easy to use and performs to a high standard.

Blanco also makes a range of products that will enhance your kitchen – such as cooktops,

ovens, dishwashers, microwaves, sinks and taps. There are models to complement your

new Blanco rangehood. Blanco now has a range of laundry products to choose from.

Of course, we make every effort to ensure that our products meet all your requirements, and

our Customer Service Department is at your disposal, to answer your questions and to

listen to your suggestions.

Please complete the warranty section of this manual and keep your receipt as proof of

purchase. Retain all documents relating to the purchase of Blanco product.

Blanco is committed to providing increasingly efficient products that are easy to use, respect

the environment and are attractive and reliable.

BLANCO

Page 4

Fig.1

A

B

max 80 cm

A

X

B

B

Fig.2

Fig.3

B

Fig.4

- 4 -

Page 5

G

G

B

B

G

C

Fig.5 Fig.6

Fig.7 Fig.8

- 5 -

C

P

M

Page 6

A

O

O

E

F

Fig.9

Fig.11 a Fig.11 b

L

Max 3 mm

O

O

N

O

Fig.10

L

N

O

Fig.11

- 6 -

Page 7

H

Fig.13

F

F

Fig.12

Fig.14

Fig.15 a Fig.15 b

X

A

C

B

90

650

X = C - (90+A+650+B)

- 7 -

P

B

C

Page 8

Fig.16

C

B

A

Fig.18 Fig.19

E

D

F

Fig.17

BIC120X

G

E

D

A

C

B

B

A

Push Push

Open - Closed

Fig.20

- 8 -

Page 9

GENERAL

These warnings are provided in the interest of safety. Carefully read the following important information regarding

installation safety and maintenance . You MUST read them carefully before installing or using the appliance.

It is most important that this instruction book be retained with the appliance for future reference. Should the

appliance be sold or transferred , always ensure that the book is left with the appliance in order that the new owner

can get to know the function of the appliance and the relevant warnings .

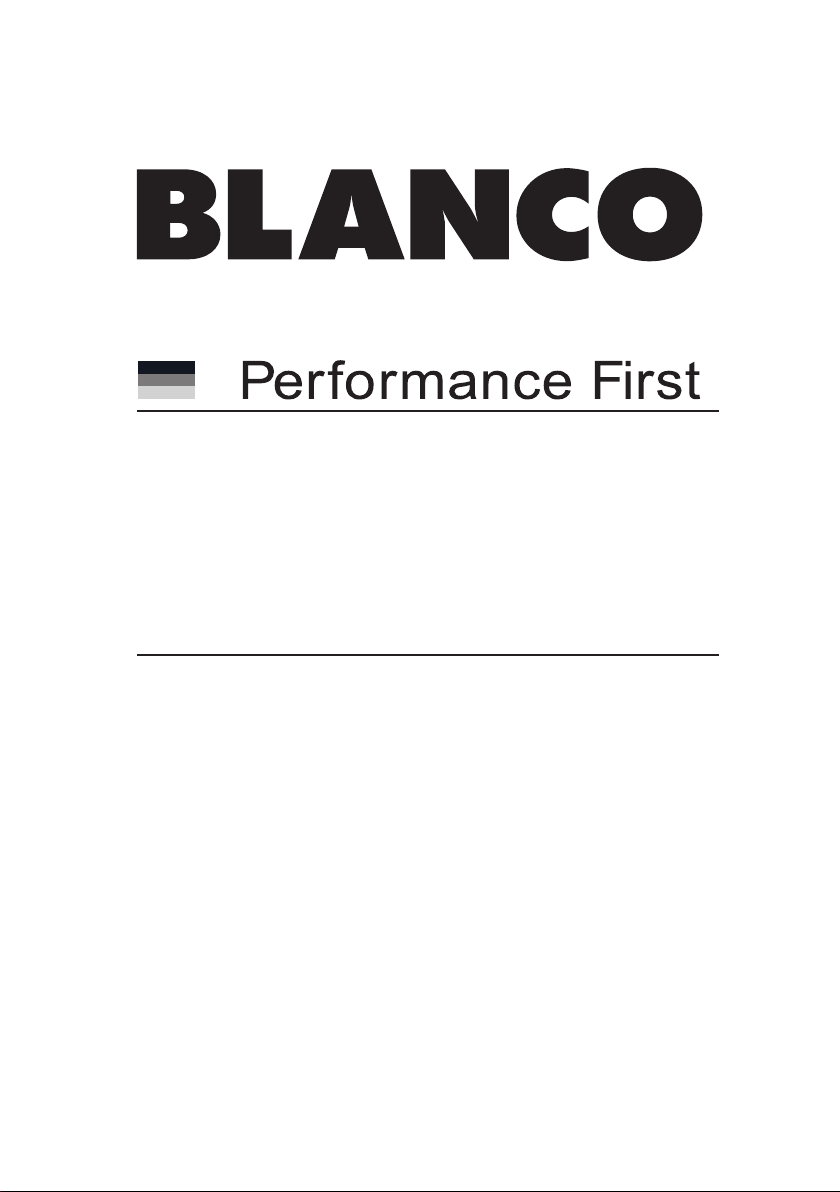

The appliance has been designed for use in the ducted version (Fig.1B) and recirculated version (Fig.1A).

SAFETY PRECAUTION

1.Take care when the rangehood is operating in the same room as an open fireplace or burner that requires air in the

environment and uses an energy source other than electrical energy – this because the rangehood removes air

from the environment which a burner or fireplace may need for combustion. The negative pressure in the environment

must not exceed 4Pa (4x10-5 bar).

2. Provide adequate ventilation in the environment for a safe operation of the rangehood.

3. Follow the local laws applicable for external air evacuation.

4. If the supply cord is damaged, it must be replaced by the manufacturer or its service agent or a similarly qualified

person in order to avoid a hazard.

WARNING !

In certain circumstances electrical appliances may be a danger hazard.

A) This appliance is not intended for use by young children or infirm persons without supervision.

B) Young children should be supervised to ensure they do not play with the appliance.

C) Do not check or remove the filters when the rangehood is operating.

D) Flambè cooking is prohibited underneath the rangehood.

E) Constantly check food frying to avoid that the overheated oil may become a fire hazard.

F) Disconnect the electrical plug prior to any maintenance.

G) Do not touch lighting or adjacent areas when lighting is on - and for a period of time after using the light.

H) Avoid leaving cooktop on (gas and electric) without the saucepan covering the burner or cooking zone. This is

because heat transferring upwards to the rangehood will be damaging to the filters and a fire hazard.

I) Ensure adequate ventilation of the room where the rangehood is used at the same time as appliances burning gas

or other fuels. Exercise care when a rangehood is installed in an area where a gas burner is operating. Depending

on the size of the room, the rangehood may draw from the room air that is necessary for proper combustion of the

burner.

J) Ensure the rangehood is cleaned frequently.

L) There is a risk of fire if cleaning is not carried out in accordance with the instructions.

M) For any repairs always contact an authorised Technical Customer Service Centre and ask for original spare

parts. Repairs by untrained people may lead to damage and void warranty.

Warnings for Installation:

a) The exhaust air must not be discharged into a flue which is used for exhausting fumes from appliances burning

gas or other fuels.

b) The minimum distance from the cooktop surface and the lowest part of the range hood must not be less than

65cm. If the instructions for the cooktop specify a greater distance, please consider this.

c) The regulations concerning the discharge of exhaust air have to be fulfilled.

d) All Blanco rangehoods are used for indoor application/installation only.

Other Information:

This appliance conforms to the European Directive EC/2002/96, Waste Electrical and Electronic Equipment (WEEE).

By making sure that this appliance is disposed of in a suitable manner, the user is helping to prevent potential

damage to the environment or to public health.

The

symbol on the product or on the packaging label on the carton indicates that the appliance should not be

treated as domestic waste, but should be delivered to a suitable electric and electronic appliance recycling collection

point. Follow local guidelines when disposing of waste. For more information on the treatment, re-use and recycling

of this product, please contact your local authority or domestic waste collection service.

INSTALLATION INSTRUCTIONS

Assembly and electrical connections must be carried out by specialised personnel.

• Electric Connection

The appliance has been manufactured as a class II, therefore no earth cable is necessary.

- 9 -

Page 10

The connection to the mains is carried out as follows:

BROWN = L line

BLUE = N neutral

If not provided, connect a plug for the electrical load indicated on the description label. Where a plug is provided, the

cooker hood must be installed in order that the plug is easily accessible.

An omnipolar switch with a minimum opening of 3mm between contacts, in line with the electrical load and local

standards, must be placed between the appliance and the network in the case of direct connection to the electrical

network.

• The minimum distance between the support surfaces of the cooking pots on the cooker top and the lowest part of

the cooker hood must be at least 65 cm.

If a connection tube composed of two parts is used, the upper part must be placed outside the lower part.

Do not connect the cooker hood exhaust to the same conductor used to circulate hot air or for evacuating fumes

from other appliances generated by other than an electrical source.

Before proceeding with the assembly operations, remove the anti-grease filter(s) (Fig.16) so that the unit is easier to

handle.

In the case of assembly of the appliance in the suction version prepare the hole for evacuation of the air.

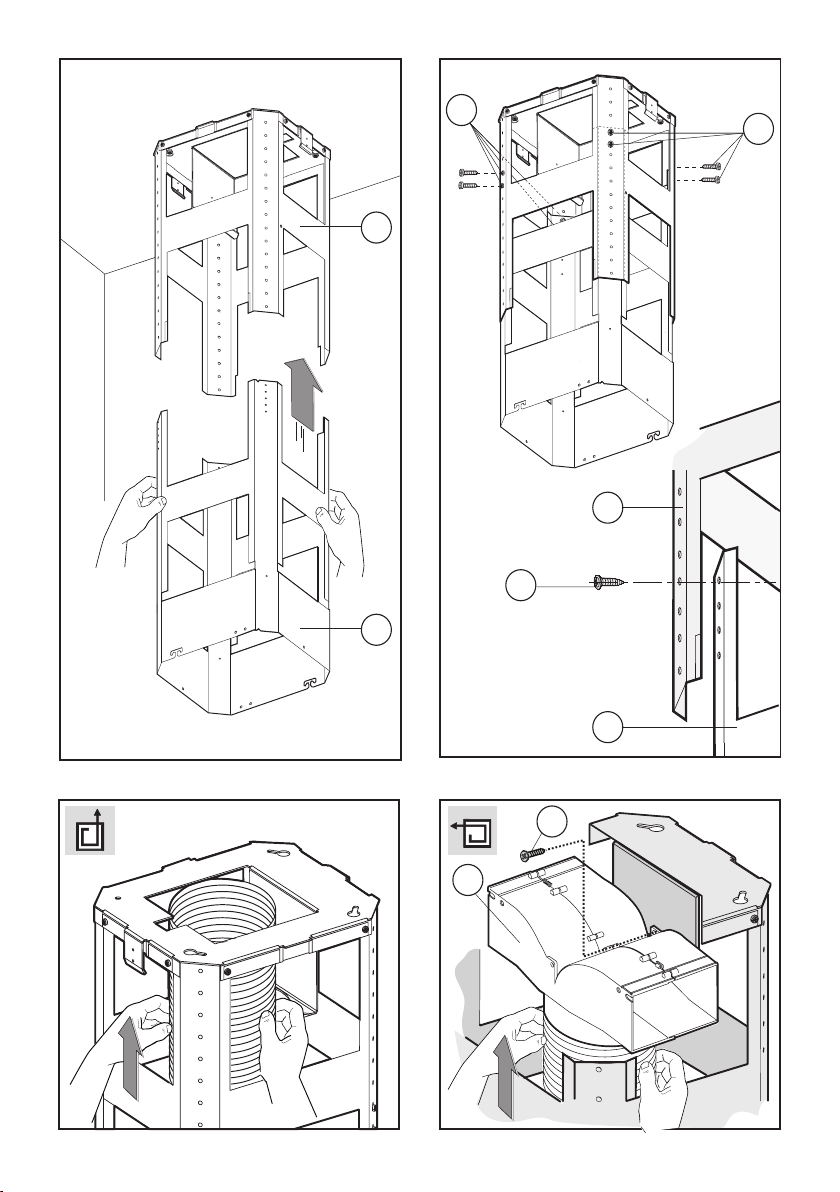

Perimeter Exhaust System BIC120X.

This system is based on the Venturi Principle:

The air extraction system is defined around the perimeter of the stainless steel panels. The effect of this increases

the intake air flow resulting in a more effective air extraction system.

Before installing the appliance, open the panels (A, fig. 20) and remove the anti-grease filter(s) (B, fig. 20).

• We recommend the use of an air exhaust pipe with a diameter of 150. If a pipe with a smaller diameter is used, the

efficiency of the product may be reduced and its operation may become noisier

• Hood assembly

Remove the structure from the packaging and remove the 2 screws A to separate the upper part from the lower part

(fig.2).

- Position hole template on the ceiling paying attention that the arrow is positioned on the same side as the appliance

controls (Fig.3).

Make 4, Ø8 holes in the ceiling and drive in 3 screws without completely tightening them. Pay attention not to insert

the screw into the hole marked with an X on the hole template (the screws and expansion plugs must be suitable for

the type of wall).

- Take the upper part of the structure B (fig.4) and insert the 3 slots onto the 3 screws that are not completely

tightened.

Rotate slightly to fit (fig.4) .

Drive in the fourth screw X and tighten the remaining 3 to allow definitive blocking of the upper part of structure B

- Take the lower part of the telescopic structure C and insert it into the upper structure B (fig.5).

Adjust the height by referring to the amounts indicated in (fig.15) and block it using the 8 screws G that are supplied

(fig.6).

- Ducted version: fix the flexible pipe to the prepared air evacuation hole (fig 7).

- Recirculating version: fix the flexible pipe to the deflector M and fix screw I as indicated in (Fig.8), the active

carbon filters must be applied to the suction unit positioned inside the hood (Fig.17).

- If your product is fitted with a connector flange, perform the assembly steps indicated in fig. 9 before fixing the

cooker hood to the structure.

Take connector flange F and fit it to the upper part of the cooker hood suction assembly using the 2 screws E (fig. 9).

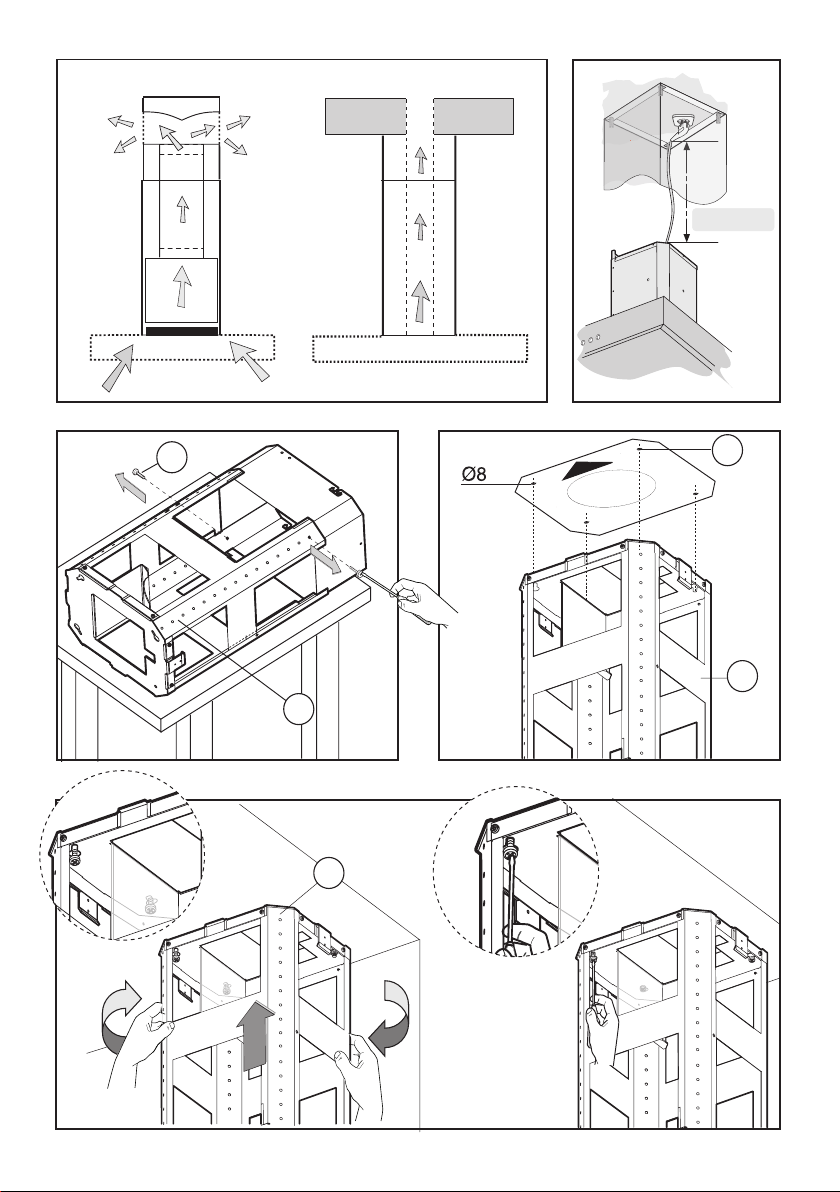

- Take the upper chimney piece and fix it to the structure using the 2 screws A (Fig.10).

Join the lower chimney piece with the upper one and fix it carefully using adhesive tape L (Fig.11a).

- Unscrew the 2 screws O, max 3 mm (Fig.11a).

Insert the suction unit inside the structure paying attention that the previously unscrewed screws O, hook into the

slots in the lower part as indicated in (Fig.11b).

Drive in the 3 screws N (supplied) and tighten the 2 screws O (Fig.11b).

- Fix the air evacuation pipe H (not supplied) onto the connection flange F (Fig.12)

- Remove adhesive tape L and rest the lower chimney piece above the cooker hood (Fig.13).

-If the cooker hood is supplied with a lower chimney piece that must be fixed to the hood body with screws, remove

the anti-grease filters from the hood by acting on the relevant handles (Fig.16 ). Then screw the lower chimney piece

pipe to the inside of the hood, using screws P (Fig.14). Re-locate the filters in their seat.

Rangehoods may be ducted in two ways:

1. Ducted to the atmosphere (outside).

2. Recirculating.

We recommend ducting to the atmosphere to ensure optimum performance. Recirculating the air back into the room

- 10 -

Page 11

should only be used when outside extraction is not possible. To ensure maximum performance when ducting it is

important the ducting that carries the fumes away, be as short and as straight as possible.

When incorporating a rangehood in the design of a kitchen the following points need to be considered to

achieve the most benefit from the rangehood.

1. Ducting from a rangehood carrying the exhaust air, should not exceed a length of three (3) metres.

2. For ducted installation we recommend using galvanised or similar metal type flue pipe. PVC pipe is not recommended.

3. Ducting containing a 90° degree bend will encounter a loss in efficiency of approximately 35%. Additional 90°

degree bends can cause losses of up to 15% per bend.

4. Ducting size should always comply with the manufacturers specification.

5. We recommend carbon filters be used when re-circulating the air into the room. There will be some loss of air

Recirculated to kitchen area via bulkhead Recirculated to kitchen area via ceiling cavity

Ducted to atmosphere through wall Ducted to atmosphere through roof

USE AND MAINTENANCE

• It is recommended to operate the appliance prior to cooking.

It is recommended to leave the appliance in operation for 15 minutes after cooking is ter minated in order to help

eliminate cooking vapours and odours.

The proper function of the cooker hood is conditioned by the regularity of the maintenance operations, in particular,

the active carbon filter.

• The anti-grease filters capture the grease particles suspended in the air, and are therefore subject to clogging

according to the frequency of the use of the appliance.

In order to prevent fire hazard, it is recommended to clean the filter at a maximum of 2 months by carrying out the

following instructions:

- Remove the filters from the cooker hood and wash them in a solution of water and neutral liquid detergent, leaving

to soak.

- Rinse thoroughly with warm water and leave to dry.

- 11 -

Page 12

- The filters may also be washed in the dishwasher.

The aluminium panels may alter in colour after several washes. This is not cause for customer complaint nor

replacement of panels.

• The active carbon filters help to purify the air that is replaced in the environment.

request from your retailer.

The filters are not washable nor re-useable and must be replaced at maximum every four months. The saturation of

the active carbon filter depends on the frequency of use of the appliance, by the type of cooking and the regularity

of cleaning the anti-grease filters.

• Clean the fan and other surfaces of the cooker hood regularly using a cloth moistened with denatured alcohol or

non abrasive liquid detergent.

• The illumination installation is designed for use during cooking and not for prolonged general illumination of the

environment. Prolonged use of the illumination installation notably reduces the duration of the bulb.

• LIGHT REPLACEMENT - HALOGEN

12 volt 20 W Halogen.

Remove the glass retaining ring and glass.

Replace the globe with another of the same type.

Replace the glass and retaining ring.

• CONTROLS: (Fig.18) For model BIC120X - BICG90X only:

A = LIGHT

B = OFF

C = SPEED I

D = SPEED II

E = SPEED III

F = AUTOMATIC STOP TIMER - 15 minutes (*)

• INTENSIVE speed function: press key E for two seconds and it will be activated for 10 minutes after which it will

return to the previously set speed. When the function is active the LED flashes. To interrupt it before the 10 minutes

have expired press key E again.

• By pressing key F for two seconds (with the hood switched off) the “clean air” function is activated. This function

switches the appliance on for ten minutes every hour at the first speed. As soon as this function is activated the

motor starts up at the first speed for ten minutes, During this time key F and key C must flash at the same time.

After ten minutes the motor switches off and the LED of key F remains switched on with a fixed light until the motor

starts up again at the first speed after fifty minutes and keys F and C start to flash again for ten minutes and so on.

By pressing any key for the exclusion of the hood light the hood will return immediately to its normal functioning (e.g.

if key D is pressed the “clean air” function is deactivated and the motor moves to the 2nd speed straight away. By

pressing key B the function is deactivated).

Carbon filters are available on

(*) The “automatic stop timer” delays stopping of the hood, which will continue functioning for 15 minutes at the

operating speed set at the time this function is activated.

• Active carbon/grease filter saturation: Fig.19B / Fig.20

- When button A flashes at a frequency of 2 seconds, the grease filters must be cleaned.

- When button A flashes at a frequency of 0.5 seconds, the carbon filters must be replaced.

After the clean filter has been replaced, the electronic memory must be reset by pressing button A for approximately

5 seconds, until the light on the button stops flashing.

•CONTROLS :(Fig.19) For model BIC90X only:

A = LIGHT

B = OFF

C = SPEED I

D = SPEED II

E = SPEED III

G = MOTOR WORKING indicator

THE MANUFACTURER DECLINES ALL RESPONSIBILITY FOR EVENTUAL DAMAGES CAUSED BY BREACHING

THE ABOVE WARNINGS.

- 12 -

Page 13

Blanco Contact Information.

NEW SOUTH WALES

Head Office, Sales & Marketing Office

104 Vanessa Street

Kingsgrove NSW 2208

Telephone: 02 9503 2888

Facsimile: 02 9503 2810

NSW Showroom*

40 Ebley Street

Bondi Junction NSW 2022

Telephone: 02 9386 1190

Facsimile: 02 9386 1671

Service and Spare Parts

All General Whitegoods Service

Telephone: 02 8788 8666

Facsimile: 02 9756 1091

AUSTRALIAN CAPITAL TERRITORY

Service and Spare Parts

Detlevs Appliance & Electrical Care

1/88 Sheppard Street

Hume

ACT 2905

Telephone: 02 6280 1033

Facsimile: 02 6260 1035

VICTORIA

State Office and Showroom*

35 Centre Road

Scoresby VIC 3179

Telephone: 03 8756 7888

Facsimile: 03 8756 7907

Service and Spare Parts

Advantage Appliances

Telephone: 03 9874 4222

Facsimile: 03 9874 6917

QUEENSLAND

State Office and Showroom*

148 Robinson Road - East

Geebung

QLD 4034

Telephone: 07 3259 2555

Facsimile: 07 3265 6933

Service and Spare Parts

Endeavour Appliances

Telephone: 07 3872 7444

Facsimile: 07 3852 2465

Platinum Appliance Service

Telephone: 07 3862 1154

Facsimile: 07 3862 1114

Roshad (Gold Coast)

Telephone 07 5535 7044

Facsimile 07 5535 7407

SOUTH AUSTRALIA & NORTHERN TERRITORY

Agent and Sales Office

S C Lighting & Electrical Supplies

47 North Terrace

Hackney SA 5069

Telephone: 08 8362 4599

Facsimile: 08 8362 4591

Service and Spare Parts

Prestige Appliance Repair Centre

Telephone: 08 8352 2022

Facsimile: 08 8352 3044

WESTERN AUSTRALIA

1 Alvan Street

SUBIACO WA 6008

Telephone: 08 9382 1611

Facsimile: 08 9382 1622

Service and Spare Parts

Metropolitan Appliance Repairs

Telephone: 08 9330 1724

Facsimile: 08 9317 1296

TASMANIA

Agent and Sales Office

Mark Pearce Agencies

23 Tranmere Road

Howrah TAS 7018

Tel/Fax: 03 6247 9215

Service and Spare Parts

Electrical Equipment Service (Launceston)

Telephone: 03 6339 3873

Facsimile: 03 6339 4588

Baldocks Appliance Service (Hobart)

Telephone: 03 6234 5995

Facsimile: 03 6234 8134

BLANCO CUSTOMER SERVICE

1300 739 033

Website: www.meaappliances.com.au

* Showrooms open six days a week

- 13 -

Page 14

BLANCO COOKING PRODUCT WARRANTY

STATEMENT OF STANDARD

WARRANTY CONDITIONS

1. Subject to the “Statement of Standard Warranty

Conditions” this product is covered by the following

Warranty.

TWO (2) YEARS WARRANTY from date of

purchase, covering all parts and labour.

2. The appliance is warranted under normal

single family domestic installation and use, as

set out in the instruction manual, against

manufacturing defects for the Warranty periods

shown above.

3. Should service be required under this Warranty,

the purchaser should contact an approved BLANCO

Service Provider during their normal business

hours.

4. At no time does BLANCO/MEA have liability for

any freight or transportation costs or for any damage

during transit or for any consequence of failure of

this appliance outside of the normal service area,

unless such limitation of liability is prohibited by

statute.

5. This Warranty excludes replacement of par ts

required due to normal wear and tear including light

globes.

6. This Warranty only applies, provided the

appliance has been used in accordance with the

manufacturer’s instructions and provided an

accident, misuse, neglect or abuse has not

damaged the appliance.

7. None of the above Warranties purport to exclude, restrict or modify either the application or the

exercise of a right conferred by any applicable

Statute.

8. Please complete the details below, which should

be retained for future reference along with your proof

of purchase:

Date of Purchase: ……………………...................

1. The Warranty only applies provided that the

appliance has been used in accordance with the

manufacturer’s instructions and provided that the

appliance has not been damaged by an accident,

misuse, neglect or abuse of any person other than

the manufacturer or BLANCO/Major Electrical

Appliances (“MEA”) or from faulty installation, misadjustment or tampering by unauthorised persons.

2. When a service inspection reveals the alleged

fault or faults are caused by incorrect operation,

contrary to the instruction manual, and otherwise

the appliance is in good order and working

condition, the purchaser shall be liable for a service

fee charged by BLANCO/MEA or one of its’ Service Providers.

3. If the appliance is used in Commercial Applications or for Rental purposes, a separate warranty

of Twelve (12) months covering all parts with Three

(3) months on the labour will apply.

4. Subject to the provisions of any applicable

statute this Warranty applies to the original retail

purchaser only and is not transferable.

5. Subject to the provisions of any applicable

statute, at no time does BLANCO/MEA have liability for freight, transport or travel costs outside normal

service areas.

6. None of the above Warranties purpor t to exclude, restrict or modify either the application or the

exercise of a right conferred by any applicable

statute.

7. Subject to any Warranties implied by statute,

at no time will BLANCO/MEA or its’ Service

Providers be liable for any economic loss consequent upon the failure of the appliance.

8. This Warranty is only valid for major appliances imported and distributed by BLANCO/MEA,

purchased and used in Australia.

Model No: ……………………………………......….

Serial No: ………………………………………........

MEA0702

- 14 -

Page 15

328

284

150 / 120

80

min. 740 - max 1105

700

BIC120X

75

min. 735 - max 1100

600

BIC90X

328

328

1200

284

150 / 120

900

284

50

min. 710 - max 1075

600

BICG90X

150 / 120

900

- 15 -

Page 16

3LIK0383

Loading...

Loading...