Page 1

MODELS: BCGC74 - BCGC52

CRYSTAL GLASS COOKTOP

We ask that you carefully read the instructions within this booklet to enable you to abtain quality results from the outset.

The appliance must be installed only by an authorised person in compliance with the instructions provided. The manufacturer

declines all responsability for improper installation which may harm persons and animals and damage property.

The appliance must be used for the purpose for which it was expressly designed. Any other use (eg heating rooms) is considered to

be improper and consequently dangerous. The manufacturer declines all responsability for damage resulting from improper and

irresponsible use.

The manufacturer shall not be held responsible for any inaccuracies in this handbook due to printing or transcription errors. The

designs in the figures are purely indicative.

The manufacturer also reserves the right to make any modifications to the products as may be considered necessary, useful or in

the interests of the user, without jeopardizing the main functional and safety features on the products themselves.

If your cooktop requires service, please contact your local customer service centre or your nearest Blanco agent listed at the back of

this booklet.

COD. 01019GG - 18.07.2006

Dear Customer

Thank you for purchasing a Blanco Cooktop.

Before we continue telling you about this cooktop, we cordially invite you to become part of the Blanco family by

subscribing to ongoing information and invitations. Please visit our website where you can subscribe and request

such things as invitations to future cooking classes and gourmet recipes. Go to www.meaappliances.com.au and

fill in the subscription details.

You will find that the clean lines and modern look of your Blanco Cooktop blends perfectly with your kitchen décor.

It is easy to use and performs to a high standard.

Blanco also makes a range of products that will enhance your kitchen such as ovens, rangehoods, dishwashers,

microwaves, sinks and taps.

There are models to complement your new Blanco Cooktop.

Of course we make every effort to ensure that our products meet all your requirements, and our Customer

Relations department is at your disposal, to answer your questions and to listen to all your suggestions (see back

cover of manual).

Please complete the warranty section of this manual and keep your receipt as proof of purchase. Retain all

documents relating to the purchase of this products.

Blanco is committed to providing increasingly efficient products that are easy to use, respect the environment and

are attractive and reliable.

BLANCO

USE, INSTALLATION AND MAINTENANCE

INSTRUCTIONS FOR BUILT-IN HOT PLATES

MOD.: .......................

Page 2

2

Natural U-LPG

1 Ultra rapid gas burner of 11.9 MJ 11.9 MJ

2 Semirapid gas burner of 6.3 MJ 6.3 MJ

3 Auxiliary gas burner of 3.6 MJ 3.6 MJ

4 Cast iron trivet 1 burner

5 Cast iron trivet 2 burner

6 Cast iron trivet 3 burner

7 Burner control knobs

Attention: this appliance has been manufactured for domestic use only and is for use by private

persons.

DESCRIPTION OF THE HOT PLATES

Page 3

3

1) BURNERS

A diagram is screen-printed above each knob on the

front panel. This diagram indicates to which burner

the knob in question corresponds. After having

opened the gas mains or gas bottle tap, light the

burners as described below:

- Manual ignition

Push and turn the knob corresponding to the

required burner in an anticlockwise direction until it

reaches the full on position (large flame fig. 1), then

place a lighted match near the burner.

- Electrical ignition

Push and turn the knob corresponding to the

required burner in an anticlockwise direction until it

reaches the full on position (large flame fig. 1), then

depress and release the ignition button.

- Automatic electrical ignition

Push and turn the knob corresponding to the

required burner in an anticlockwise direction until it

reaches the full on position (large flame fig. 1), then

depress the knob.

- Lighting burners equipped with flame failure

device

The knobs of burners equipped with flame failure

device must be turned in an anticlockwise direction

until they reach the full on position (large flame

fig. 1) and come to a stop. Now depress the knob in

question and repeat the previously indicated

operations.

Keep the knob depressed for about 10 seconds

once the burner has ignited.

Note: you are advised not to try and light a burner if

the flame divider (Burner Cap) is not correctly placed.

In the event of burner flames being accidentally

extinguished, turn off the burner control and do not

attempt to re-ignite the burner for at least 1 minute.

HOW TO USE THE BURNERS

In order to achieve maximum efficiency with the least

possible gas consumption:

- Use adequate pans for each burner (consult the

following table and fig. 2).

- When the pan comes to the boil, set the knob to the

reduced rate position (small flame fig. 1).

- Always place a lid on the pans.

Burners Power ratings Pan Ø in cm

Natural U-LPG

Ultra rapid 11.9 MJ 11.9 MJ 22 ÷ 28

Semirapid 6.3 MJ 6.3 MJ 16 ÷ 18

Auxiliary 3.6 MJ 3.6 MJ 10 ÷ 14

WARNINGS:

- Burners with flame failure device may only be

ignited when the relative knob has been set to

the Full on position (large flame fig. 1).

- Matches can be used to ignite the burners in a

blackout.

- Never leave the appliance unattended when the

burners are being used. Make sure there are no

children in the near vicinity. Particularly make

sure that the pan handles are correctly

positioned and keep a check on foods requiring

oil and grease to cook since these products can

easily catch fire.

- Do not spray aerosols in the vicinity of this

appliance while it is in operation.

- This appliance is not to be installed in marine

craft. Where this appliance is installed in a

caravan, it shall not be used as a space heater.

- Do not store or use flammable liquids or items in

the vicinity of the hotplate.

USE

FIG. 1 FIG. 2

Page 4

4

USE

Notes:

Use of a gas cooking appliance produces heat and moisture in the room in which it is installed. The

room must therefore be well ventilated by keeping the natural air vents clear (fig. 3) and by activating

the mechanical aeration device (rangehood or electric fan fig. 4 and fig. 5).

Intensive and lengthy use of the appliance may require additional ventilation. This can be achieved by

opening a window or by increasing the power of the mechanical exhausting system if installed.

Star Trivet: use star trivet whenever using a small pot.

Abnormal Operation:

Any of the following are considered to be abnormal operation and may require servicing:

- Yellow tipping of the hob burner flame.

- Sooting up of cooking utensils.

- Burners not igniting properly.

- Burners failing to remain alight.

- Burners extinguished by cupboard doors.

- Gas valves which are difficult to turn.

In case the appliance fails to operate correctly, contact the authorised service provider in your area.

FIG. 3 FIG. 4 FIG. 5

(*) Air inlet - minimum section 100 cm

2

Do not place anything, eg. flame tamer, asbestos

mat, between pan and pan support as serious

damage to the appliance my result.

Do not remove the pan support and enclose the

burner with a wok stand as this will concentrate and

deflect heat onto the hotplate.

Do not use large pots or heavy weights which can

bend the pan support or deflect flame onto the

hotplate.

Symbol 1

Symbol 2

Symbol 3

Page 5

5

CLEANING

IMPORTANT:

Always disconnect the appliance from the gas

and electricity mains before carrying out any

cleaning operation.

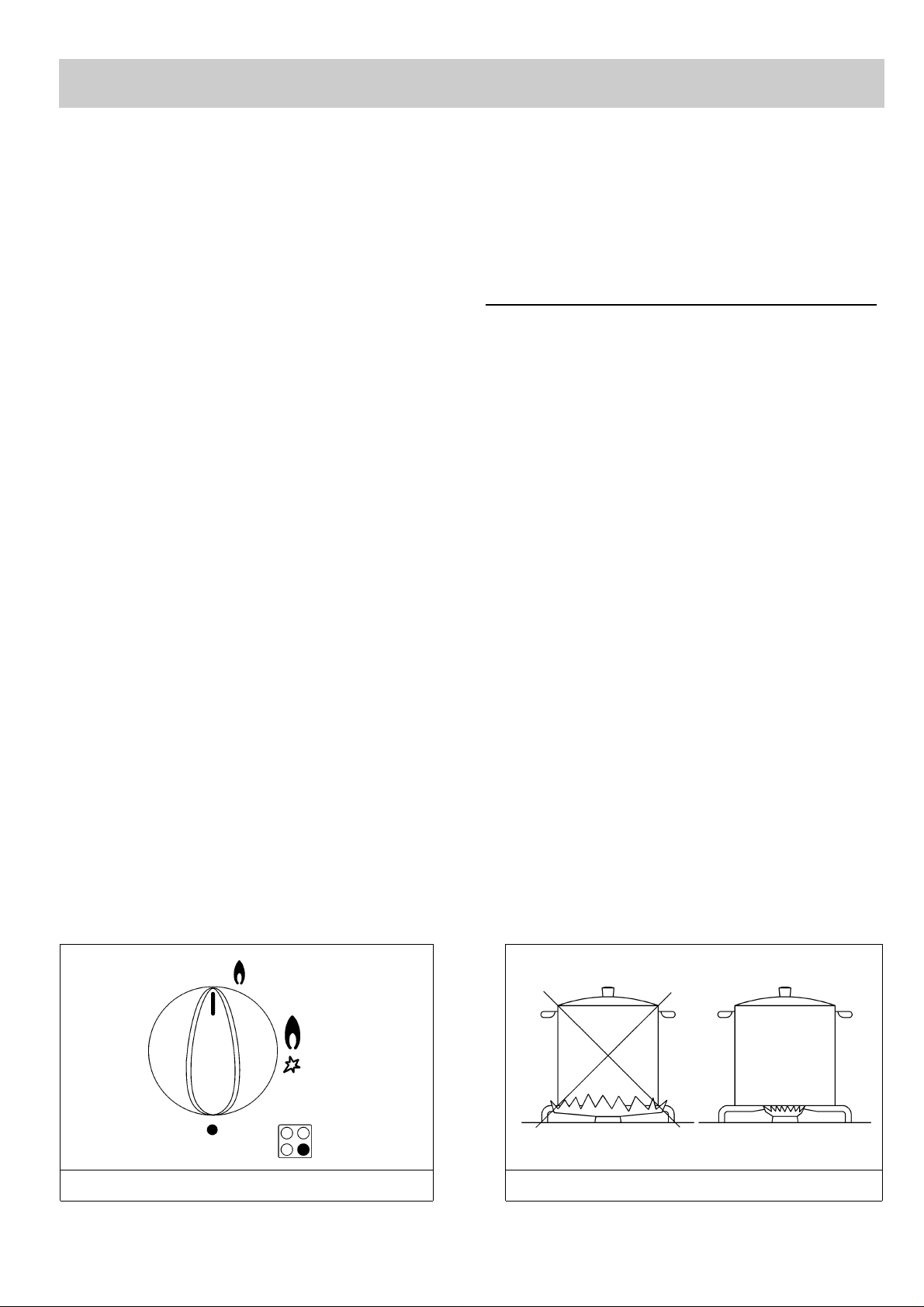

2) HOT PLATE

Periodically wash the hot plate, the cast iron pan

support, the enamelled burner caps “C” and the

burner heads “M” (see fig. 6) with lukewarm soapy

water. Following this, all parts should be thoroughly

rinsed and dried. Never wash them while they are

still warm and never use abrasive powders. Do not

allow vinegar, coffee, milk, salted water, lemon or

tomato juice from remaining in contact with the

enamelled surfaces for long periods of time.

WARNINGS:

Comply with the following instructions, before

remounting the parts:

- Check that burner head slots “M” (fig. 6) have

not become clogged by foreign bodies.

- Check that enamelled burner cap “C” (fig. 6)

have correctly positioned on the burner head. It

must be steady.

- The exact position of the pan support is

established by the rounded corners, which

should be set towards the side edge of the hot

plate.

- Do not force the taps if they are difficult to open

or close. Contact the technical assistance

service for repairs.

- Do not use steam jets for cleaning the cooktop.

PREVENTATIVE MAINTENANCE

This cooktop should not require ongoing

maintenance provided you ensure:

- All spillages are cleaned up as soon as they occur.

- Burners are kept clean.

- Burner ports are free of debris, food any anything

else that may cause an obstruction.

- Electrode and thermocouples are kept clean.

- Burners are re-assembled correctly.

- Do not get water in the area where the injectors are

located.

FIG. 6

Page 6

6

TECHNICAL INFORMATION FOR THE

INSTALLER

This appliance shall be installed only by authorised

personnel and in accordance with the manufacturer’s

installation instructions, local gas fitting regulations,

municipal building codes, water supply regulations,

electrical wiring regulations, AS 5601/AG 601 – Gas

Installations and any other statutory regulations.

3) INSTALLING THE HOT PLATE

Check that the appliance is in a good condition after

having removed the outer packaging and internal

wrappings from around the various loose parts. In

case of doubt, do not use the appliance and contact

qualified personnel.

Never leave the packaging materials (cardboard,

bags, polystyrene foam, nails, etc.) within

children’s reach since they could become

potential sources of danger.

The measurements of the opening made in the top

of the modular cabinet and into which the hot plate

will be installed are indicated in fig. 7.

Always comply with the measurements given for

the hole into wich the appliance will be recessed

(see fig. 7).

Any adjoining wall surface situated within 200 mm

from the edge of any hob burner must be a suitable

non-combustible material for a height of 150 mm for

the entire length of the hob. Any combustible

construction above the hotplate must be at least 600

mm above the construction above the top of the

burner and no construction shall be within 450 mm

above the top of the burner. A minimum depth of 60

mm from the top of the work surface must be

provided for this appliance.

4) FIXING THE HOT PLATE

The hot plate has a special seal which prevents

liquid from infiltrating into the cabinet. Strictly comply

with the following instructions in order to correctly

apply this seal:

- Take off all the movable parts of the hob.

- Cut the seal in 4 parts of the necessary length to

positioning it on the 4 edges of the crystal.

- Overturn the hot plate and correctly position seal

“E” (fig. 8) under the edge of the hob itself, so that

the outer side of the seal perfectly matches the

outer perimetral edge of the hob. The ends of the

strips must fit together without overlapping.

- Evenly and securely fix the seal to the hob,

pressing it in place with the fingers.

- Remove the strip of protective paper from the seal.

Fit the hot plate into the hole in the cabinet and lock

it in place with the relative fixing screws “F” of the

fixing hooks “G” (see fig. 9).

INSTALLATION

FIG. 8 FIG. 9

FIG. 7

COMPLY WITH THE DIMENSIONS

Overall Dimensions: 680 x 500 mm

AB

2B 480 328

4B 645 470

Page 7

5) LOCATION AND VENTILATION

Ventilation must be in accordance with

AS5601/AG 601 – Gas Installations.

In general, the appliance should have adequate ventilation for

complete combustion of gas, proper flueing and to maintain

temperature of immediate surroundings within safe limits.

The wall and bench surfaces must be capable of sustaining

temperatures of 75°C.

All laminates, fixing adhesive and surfacing materials should

be certified suitable for this temperature.

6) GAS CONNECTION

This gas connection is male 1/2” BSP and is situated at the

rear of the appliance, 415 mm from the right hand side and

55 mm from the rear of the cooktop.

A. The hotplate can be connected with rigid pipe as specified

in AS5601 table 3.1.

B. If installing with a hose assembly, install with a hose

assembly that complies with AS/NZS 1869 (AGA

Approved), 10mm ID, class B or D, no more than 1.2m long

and in accordance with AS5601. Ensure that the hose does

not contact the hot surfaces of the hotplate, oven,

dishwasher or any other appliance that may be installed

underneath or next to the hotplate. The hose should not be

subjected to abrasion, kinking or permanent deformation and

should be able to be inspected along its entire length with the

cooktop in the installed position.

Unions compatible with the hose fittings must be used and

all connections tested for gas leaks.

The gas supply connection for the hose assembly must be

accessible.

Natural Gas

Natural Gas installations require the connection of a gas

regulator at the appliance. This regulator is supplied with

the appliance on purchase.

Assemble the regulator (noting the gas flow direction) and

transition pieces (supplied with the appliance), in

accordance with figure 10.

The transition piece on the supply side of the regulator

must be provided by the installer.

The appliance is factory set for Natural Gas. The test point

pressure should be adjusted to 1.00 kPa with the wok

burner operating at maximum.

Liquified Petroleum Gas

In a Universal LPG installation the gas regulation is made

at the gas cylinder and regulation at the appliance is not

required. The supply pressure should be 2.75 kPa. To

connect supply to the appliance use transition pieces as

shown in figure 11. These pieces are supplied with the

appliance on purchase.

WARNING:

THE BURNER FLAME MUST BE ADJUSTED BY THE

INSTALLER.

FAULTY INSTALLATION WILL NOT BE COVERED

UNDER WARRANTY.

7

INSTALLATION

FIG. 10

FIG. 11

Page 8

8

INSTALLATION

7) ELECTRICAL CONNECTION

The appliance is supplied with a 1800 mm long

flexible supply lead.

The point of attachment for this lead is located at

the rear and on the underside of the appliance

380 mm from the right hand side.

The voltage and power consumption are detailed on

the underside of the appliance. Ensure that the

appliance is correctly rated to the supply.

Connect appliance by way of a switched power

point.

THE APPLIANCE MUST BE EARTHED

Ensure that this power point is properly earthed.

Look at the connection wiring diagrams

(fig. 12 or 12/A).

a) Data Label

The Data Label is located on the underside of the

hotplate. A duplicate Data Label is supplied to adhere

in an accessible area next to the hotplate. This

hotplate is suitable for Natural Gas and Universal

LPG; ensure that the available gas supply matches

the Data Label.

b) Before Leaving

Check that there are no gas leaks, but do not use a

naked flame to detect gas leaks. Ignite all burners to

ensure correct operation of gas valves, burners,

ignition and if fitted, flame failure valves. Turn gas

taps to low flame position and observe stability of the

flame. When satisfied with the hotplate, please

instruct the user on the correct method of operation.

In case the appliance falls to operate correctly after

all checks have been carried out, refer to the

authorised service provider in your area.

FIG. 12 FIG. 12/A

Page 9

9

Always disconnect the appliance from the

electricity main before making any adjustments.

All seals must be replaced by the technician at

the end of any adjustments or regulations.

Our burners do not require primary air

adjustment.

8) TAPS

Our taps are suitable for all gas, they are male conical

type.

“Reduced rate” adjustment

- Switch on the burner and turn the relative knob to

the “Reduced rate” position (small flame fig. 1).

- Remove knob “M” (fig. 13) of the tap, which is simply

pressed on to its rod.

- Insert a small screwdriver “D” into hole “C” (fig. 13)

and turn the throttle screw to the right or left until the

burner flame has been adequately regulated to the

“Reduced rate” position.

Check that the flame does not go out when the knob

is sharply switched from the “Full on” to the “Reduced

rate” position.

It is understood that only burners operating with

Natural gas should be subjected to the above

mentioned adjustments. The screw must be fully

locked when the burners operate with Liquid gas.

ADJUSTMENTS

FIG. 13

Page 10

10

9) U-LPG TO NATURAL GAS

CONVERSION PROCEDURE

Appliance models: Gas crystal glass hotplate

models:

BCGC74 4 Burners

BCGC52 2 Burners

1. Remove each burner cap and burner skirt.

2. Remove the U-LPG main injector with a

7 mm/VF tube spanner and replace with the

appropriate size Natural Gas main injector for each

burner. The following injector sizes are required for

Natural Gas:

Burner Main injector

Wok 1.55 mm

Semi Rapid 1.12 mm

Auxiliary 0.85 mm

3. Shut off gas supply to the appliance.

4. Disconnect gas inlet pipe from the U-LPG Gas

test point inlet fitting.

5. Remove the U-LPG test point inlet fitting from the

appliance.

6. Fit the Natural Gas Regulator supplied in the

conversion kit.

7. Connect the gas supply to the Regulator.

8. Check for gas leaks. Do not use a naked flame to

check for gas leaks.

9. Adjust the gas pressure to 1.00 kPa.

10. Remove the control knob, with a thin shaft blade

screwdriver down the centre of each gas valve

shaft, screw the by-pass injector anti-clockwise.

Test the appliance on both high and low flame for

each burner. If the burner fails to remain alight or

the flame is not stable on the simmer setting, adjust

the by-pass screw, until flame is stable.

11. If not already removed, remove the “Only for

use with U-LPG” label adhered to the bottom panel

near the gas connection.

10) NATURAL GAS TO UNIVERSAL

LPG CONVERSION PROCEDURE

Appliance models: Gas crystal glass hotplate

models:

BCGC74 4 Burners

BCGC52 2 Burners

1. Remove each burner cap and burner skirt.

2. Remove the Natural Gas main injector with a

7 mm/VF tube spanner and replace with the

appropriate size U-LPG main injector for each

burner. The following injector sizes are required for

U-LPG:

Burner Main injector

Wok 0.95 mm

Semi Rapid 0.70 mm

Auxiliary 0.53 mm

3. Remove the control knob, with a thin shaft blade

screwdriver down the centre of each gas valve

shaft, screw the by-pass injector fully clockwise.

4. Shut off gas supply to the appliance.

5. Disconnect gas inlet pipe from the Natural Gas

Regulator.

6. Remove the Natural Gas Regulator from the

appliance.

7. Fit the U-LPG test point inlet fitting supplied in

the conversion kit.

8. Connect the gas supply to the inlet fitting.

9. Check for gas leaks. Do not use a naked flame to

check for gas leaks.

10. Adjust the gas pressure to 2.75 kPa.

11. Test the appliance on both high and low flame

for each burner and check the gas pressure. If the

burner fails to remain alight or the flame is not

stable on the simmer setting, adjust the by-pass

screw until flame is stable.

12. If not already removed, remove the “Only for

use with Natural Gas” label adhered to the bottom

panel near the gas connection.

CONVERSIONS

Page 11

11

CONVERSIONS

FIG. 14

BURNER ARRANGEMENT ON THE HOT PLATE

U-LPG 2.75 95 11.9

NATURAL 1.00 155 11.9

U-LPG 2.75 70 6.3

NATURAL 1.00 112 6.3

BURNERS

N°

DESCRIPTION

GAS

NORMAL

PRESSURE

INJECTOR

DIAMETER

NOMINAL HEAT

INPUT (MJ/h)

(kPa) (1/100 mm) MAX.

TABLE

U-LPG 2.75 53 3.6

NATURAL 1.00 85 3.6

1 ULTRA RAPID

2 SEMIRAPID

3 AUXILIARY

BY

PASS

(1/100 mm)

85

85

32

32

30

30

Page 12

12

SERVICING

WARNING:

Always disconnect the appliance from the

electricity and gas mains before proceeding

with any servicing operation.

Servicing should be carried out only by

authorised personnel.

11) COMPONENTS REPLACEMENT

NOTE:

BEFORE ANY MAINTENANCE REQUIRING

REPLACEMENT OF A COMPONENT IS

UNDERTAKEN ENSURE THAT THE

ELECTRICAL LEAD HAS BEEN ISOLATED AND

REMOVED FROM THE POWER POINT.

To replace the components fit inside the hob, it is first

necessary to remove the hot palte itself from the

cabinet, to overturn it, unscrew screws “V” and to

remove part “T” (fig. 15).

After having carried out the above listed operations,

the burners (fig. 16), taps (fig. 17) and electrical

components can all be replaced (fig. 18).

It is advisable to change seal “D” each time a tap is

changed in order to ensure a perfect tightness.

Greasing the taps (see fig. 19 - 20)

If a tap becomes stiff to operate, it must be

immediately greased in compliance with the

following instructions:

- Remove the tap.

- Clean the cone and its housing using a cloth

soaked in diluent.

- Lightly spread the cone with the relative grease.

- Fit the cone back in place, operate it several times

and then remove it again. Eliminate any excess

grease and check that the gas ducts have not

become clogged.

- Fit all parts back in place, complying with the

demounting order in reverse.

- The tight closure test must be done using a foamy

liquid, the flame use is forbidden.

To facilitate the servicing technician’s task, here is a

chart with the types and sections of the powering

cables and the ratings of the electrical components.

FIG. 18 FIG. 19 FIG. 20

FIG. 15 FIG. 16 FIG. 17

Page 13

13

SERVICING

TYPE OF TYPE OF SINGLE - PHASE

HOT PLATE CABLE POWER SUPPLY

CABLE TYPES AND SECTIONS

ATTENTION!!!

If the power supply cable is replaced, the installer should leave the ground wire longer than the phase

conductors (fig. 21) and comply with the recommendations given in paragraph 8.

FIG. 21

H05 RR - F Section 3 X 0.75 mm

2

Gas hot plate

Page 14

TECHNICAL ASSISTANCE AND SPARE PARTS

MEA – BLANCO

TECHNICAL ASSISTANCE AND SPARE PARTS

14

NEW SOUTH WALES

Head Office, Sales & Marketing Office

104 Vanessa Street

Kingsgrove NSW 2208

Telephone: 02 9503 2888

Facsimile: 02 9503 2810

NSW Showroom*

40 Ebley Street

Bondi Junction NSW 2022

Telephone: 02 9386 1190

Facsimile: 02 9386 1671

Agent and Sales Office.

Hi –Performance Marketing

7 Coleman Street

Mascot NSW 2020

Telephone: 02 88354937

Facsimile: 02 90048739

Service and Spare Parts

All General Whitegoods Service

Telephone: 02 8788 8666

Facsimile: 02 9756 1091

AUSTRALIAN CAPITAL TERRITORY

Service and Spare Parts

Detlevs Appliance & Electrical Care

1/88 Sheppard Street

Hume

ACT 2905

Telephone: 02 6280 1033

Facsimile: 02 6260 1035

VICTORIA

State Office and Showroom*

35 Centre Road

Scoresby VIC 3179

Telephone: 03 8756 7888

Facsimile: 03 8756 7907

Service and Spare Parts

Advantage Appliances

Telephone: 03 9874 4222

Facsimile: 03 9874 6917

QUEENSLAND

State Office and Showroom*

148 Robinson Road - East

Geebung

QLD 4034

Telephone: 07 3259 2555

Facsimile: 07 3265 6933

Endeavour Appliances

Telephone: 07 3872 7444

Facsimile: 07 3852 2465

Platinum Appliance Service

Telephone: 07 3862 1154

Facsimile: 07 3862 1114

Roshad (Gold Coast)

Telephone 07 5535 7044

Facsimile 07 5535 7407

SOUTH AUSTRALIA & NORTHERN TERRITORY

Agent and Sales Office

S C Lighting & Electrical Supplies

47 North Terrace

Hackney SA 5069

Telephone: 08 8362 4599

Facsimile: 08 8362 4591

Service and Spare Parts

Prestige Appliance Repair Centre

Telephone: 08 8352 2022

Facsimile: 08 8352 3044

WESTERN AUSTRALIA

Agent and sales Office

Elite Appliance Marketing Pty Ltd

P.O. Box 2387, Warwick, 6024

Telephone: 08 9201 0311

Facsimile: 08 9201 0366

Service and Spare Parts

Metropolitan Appliance Repairs

Telephone: 08 9330 1724

Facsimile: 08 9317 1296

TASMANIA

Agent and Sales Office

Mark Pearce Agencies

23 Tranmere Road

Howrah TAS 7018

Tel/Fax: 03 6247 9215

Service and Spare Parts

Electrical Equipment Service (Launceston)

Telephone: 03 6339 3873

Facsimile: 03 6339 4588

Baldocks Appliance Service (Hobart)

Telephone: 03 6234 5995

Facsimile: 03 6234 8134

BLANCO CUSTOMER SERVICE

1300 739 033

Website: www.meaappliances.com.au

* Showrooms open six days a week

Page 15

16

Loading...

Loading...