Page 1

SERVICE & OPERATING MANUAL

AIR OPERATED DOUBLE DIAPHRAGM PUMP

B25 & X25

2505 Metallic

High Pressure W1 Series

This pump is Atex approved for use

in potentially explosive atmospheres

Group II category 2

Table of Contents

Service / Maintenance Log, Recycling 2

Dimensions 3

Performance Curve 3

Technical Data & Temperature limitations 4

Explanation of Pump Nomenclature 4

Principle of Pump Operation 5

Installation guide 5

Important Warnings & Safety Information 6

Troubleshooting 7

Grounding the Pump 7

Warranty 8

Service 8

Air Valve Overhaul 8

Wet-side Overhaul 8

Exhaust Safety 9

High Temperature Inst. 9

Parts List 10

Assembly Drawing 11

Declaration of Conformity 12

HG-CF-1197 Rev. 0 - 15.12.09 Page 1

HG-CF-1197

b25_HP_W1_manual-rev1210

II 2 GD c

Page 2

Service / Maintenance Log

Date Details Completed

RECYCLING

Many components of BLAGDON air operated double diaphragm pumps are made of recyclable materials. We encourage pump

users to recycle worn out parts and pumps whenever possible, after any hazardous pumped fluids are thoroughly flushed.

Contact Information

Contact Phone / Fax No.

HG-CF-1197 Rev. 0 - 15.12.09 Page 2

HG-CF-1197

b25_HP_W1_manual-rev1210

Page 3

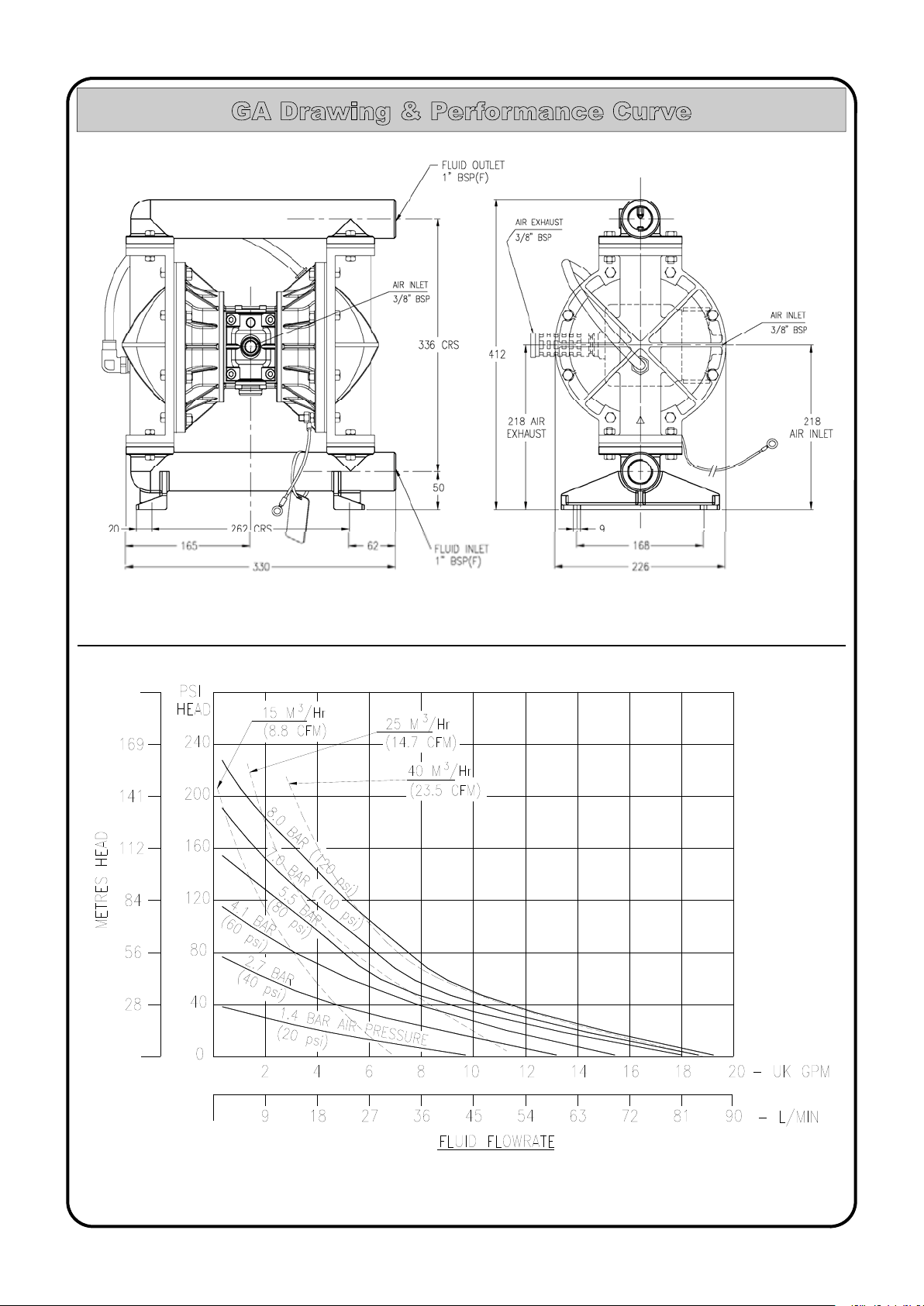

GA Drawing & Performance Curve

B2505 Metallic H.P. pump, General Assembly :- All dimensions +/- 3mm

B2505 Metallic H.P. Pump Performance Curve, based on water at ambient temperature

HG-CF-1197 Rev. 0 - 15.12.09 Page 3

HG-CF-1197

b25_HP_W1_manual-rev1210

Page 4

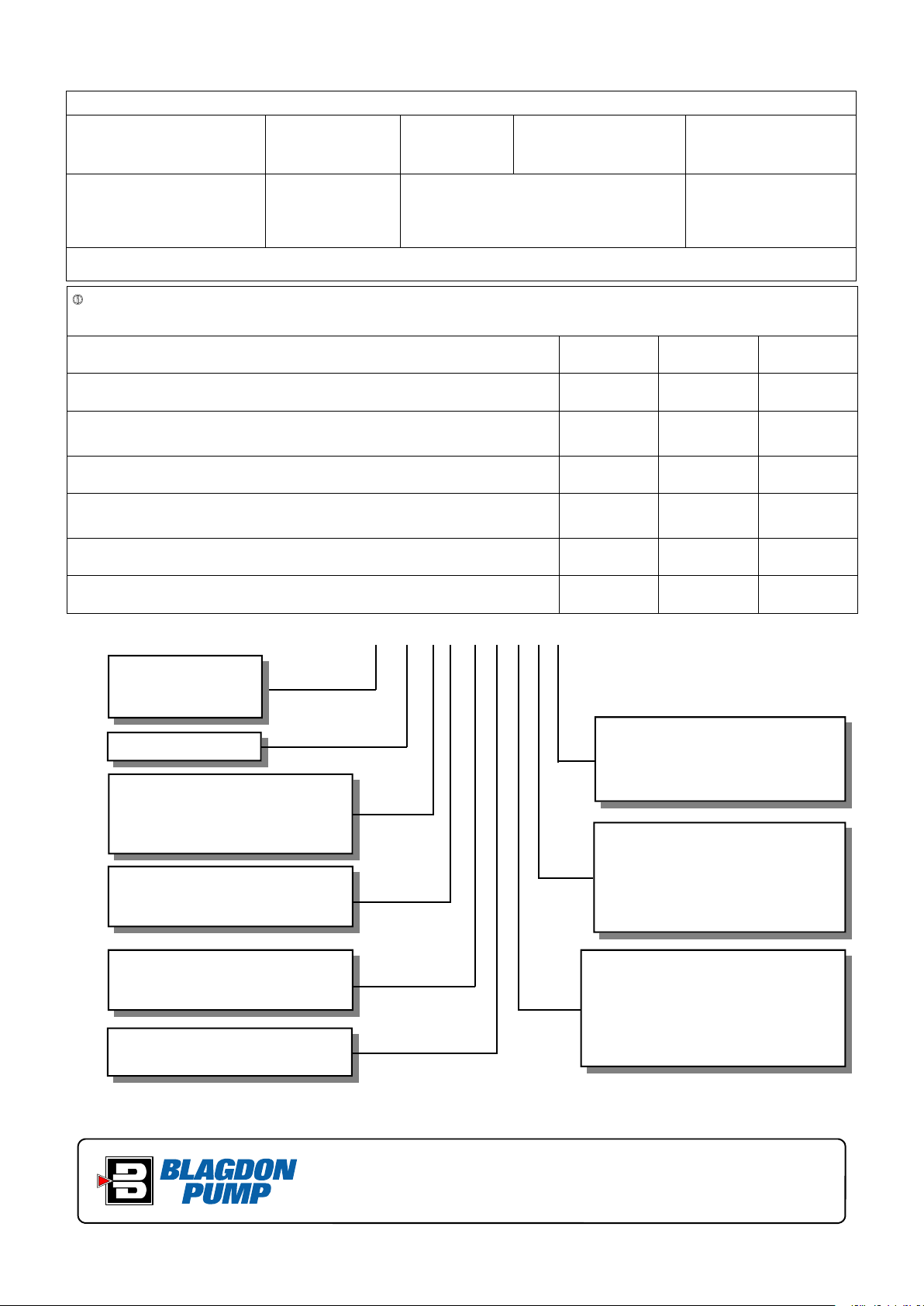

TECHNICAL DATA

FLUID CONNECTIONS CAPACITY MAX SOLIDS MAX DISCHARGE HEAD DISPLACEMENT/STROKE

1” BSP (F) 0 - 88 Liters/Minute

(0 - 19.4 Gallons/Minute)

3 MM

(1/8”)

102 Meters

(335 ft)

0.475 Litres

(0.1 UK Gallons)

MAX. WORKING PRESSURE AIR INLET TEMPERATURE LIMITS PUMP WEIGHTS :-

10 Bar (145 psi) 3/8” BSP (F) Determined by Elastomers AA :- 16.3 Kg CA :- 27.8 Kg

SA :- 31.8 Kg CC :- 34.8 Kg

SC :- 38.8 Kg SS :- 39.8 Kg

Note! Maximum Discharge pressure not to exceed 10 bar

� Caution - Operating temperature limitations are as follows:

Materials

Buna-n - General purpose, oil resistant. Shows good solvent, oil, water and hydraulic fluid resistance. Should not

be used with highly polar solvents like acetone and MEK, ozone, chlorinated hydrocarbons and nitro hydrocarbons.

EPDM - Shows very good water and chemical resistance. Has poor resistance to oils and solvents, but is fair on

ketones and alcohols.

Neoprene - All purpose. Resistant to vegetable oil. Generally not affected by moderate chemicals, fats greases

and many oils and solvents. Generally attacked by strong oxidising acids, ketones, esters, nitro hydro carbons and

chlorinated aromatic hydrocarbons.

Santoprene® - Injection moulded thermoplastic elastomer with no fabric layer. Long mechanical flex life.

Excellent abrasion resistance.

Virgin PTFE - Chemically inert, virtually impervious. Very few chemicals are known to react chemically with

PTFE : molten alkali metals, turbulent liquid or gaseous fluorine and a few fluoro-chemicals such as chlorine

trifluoride or oxygen difluoride which readily liberate free fluorine at elevated temperatures.

Viton® - Shows good resistance to a wide range of oils and solvents : especially all alphatic, aromatic and

halogenated hydrocarbons, acids, animal and vegetable oils.

Polypropylene - High strength, light weight, corrosion resistant polyolefin which easily withstands most

chemicals, with no known solvent at room temperature.

TYPICAL CODE = B25.05. S A. B 1. N N S

MODEL

B25 : STANDARD

X25 : ATEX CAT. 2

DESIGN LEVEL

Operating Temperatures

Maximum Minimum Optimum

176oF

o

80

212oF

100

212oF

100

212oF

100

356oF

180

356oF

180

158oF

o

70

C

o

C

o

C

o

C

o

C

o

C

C

-18oF

-28

-11oF

-24

-4oF

-20

-10oF

-23

32oF

o

0

C

0oF

-18

32oF

o

0

C

o

C

o

C

o

C

o

C

o

C

50o to 140oF

o

10

to 60oC

50o to 212oF

o

10

to 100oC

50o to 130oF

o

10

to 54oC

50o to 212oF

o

10

to 100oC

50o to 212oF

o

10

to 100oC

75o to 212oF

o

24

to 100oC

50o to 140oF

o

10

to 60oC

VALVE SEATS

S : 316L STAINLESS STEEL

WETTED COMPONENTS

A : ALUMINIUM

S : 316L STAINLESS STEEL

C : CAST IRON

NON - WETTED COMPONENTS

A : ALUMINIUM

S : 316L STAINLESS STEEL

VALVE TYPE

B : BALL

W : WEIGHTED BALL

MODEL DESIGNATION

1 : BOTTOM SUCTION, W1 SERIES

This pump should be used in accordance with the requirements of the Safety, Health & Welfare at Work Act 2005.

All business conducted subject to IDEX Pump Technologies, Ireland. Terms and Conditions of Sale, available on request.

IMPORTANT

VALVE BALLS

T : PTFE E : EPDM

N : NEOPRENE V : VITON

B : BUNA-N S : ST. STEEL

D : ACETAL

DIAPHRAGMS

N : NEOPRENE V : VITON

H : POLYESTER (HYTREL) B : BUNA-N

R : SANTOPRENE

®

T : PTFE

P : POLYURETHANE E : EPDM

O : ONE-PIECE PTFE

IDEX Pump Technologies (Ireland) Ltd.,

A Unit of IDEX Corporation,

R79, Shannon, Co Clare, IRELAND.

TEL. : +353 61 471933 FAX. : +353 61 475046

Web Site : www.blagdonpump.com

E-Mail : sales@blagdonpump.com

HG-CF-1197 Rev. 0 - 15.12.09 Page 4

HG-CF-1197

b25_HP_W1_manual-rev1210

Page 5

PRINCIPLE OF PUMP

OPERATION

This ball valve type diaphragm pump is

powered by compressed air and is a 2:1 ratio

design. The inner side of one diaphragm

chamber is alternately pressurised while

simultaneously exhausting the other inner

chamber. This causes the diaphragms, which are

connected by a common shaft secured by plates

to the centres of the diaphragms, to move in a

reciprocating action. (As one diaphragm

performs a discharge stroke the other diaphragm

is pulled to perform the suction stroke in the

opposite chamber.) Air pressure is applied over

the entire inner surface of the diaphragm while

liquid is discharged from the opposite side of

the diaphragm. The diaphragm operates in a

balanced condition during the discharge stroke

which allows the pump to be operated at

discharge heads of over 300 feet (91 meters) of

water.

For maximum diaphragm life, keep the pump as

close to the liquid being pumped as possible.

Positive suction head in excess of 10 feet of

liquid (3.048 meters) may require a back

pressure regulating device to maximize

diaphragm life.

Alternate pressurising and exhausting of the

diaphragm chamber is performed by an

externally mounted, pilot operated, 2 way type

distribution valve. When the spool shifts to one

end of the valve block body, inlet pressure is

applied to one chamber and the other diaphragm

chamber exhausts. When the spool shifts to the

opposite end of the valve body, the pressure to

the chambers is reversed. This alternating

movement of the spool inside the valve body is

controlled by a pilot air pressure signal held

against the diaphragm shaft, between seals in the

diaphragm shaft bushes. This signal is released,

triggering the movement of the spool, when pilot

holes in the diaphragm shaft align with the held

pilot signal, sending the signal to exhaust, which

in-turn causes a pressure imbalance around the

spool, sending it to the opposite end of the valve

body. This simultaneously sends inlet pressure

to the opposite chamber.

The chambers are connected by manifolds with a

suction and discharge ball valve in one chamber

only, the opposite chamber being blanked off,

and pressurised on the fluid side also, to create

the 2:1 ratio, maintaining flow in one direction

through the pump.

INSTALLATION

The typical installation shown in FIG. 1 is only a

guide to selecting and installing system

components. Your installation will depend on

the type of fluid being pumped and your

application needs. To reduce the risk of serious

bodily injury and damage to property, never use

fluids in this pump which are not compatible

with the wetted components. Contact your local

distributor or the manufacturer for system design

assistance & compatibility if necessary.

Mount the pump in an upright position. Failure

to ensure an upright position may result in loss

of or poor priming characteristics. Ensure the

pump is securely mounted to avoid movement

and possible risk of bodily injury.

PRESSURE The pump delivers the same

pressure at the discharge outlet as the air

pressure applied at the air inlet (unless pump is

configured as a 2:1 ratio model).

NOTE: Pressure Regulator (H) should be

installed where air supply could exceed 125

psi.

SAFETY

Your BLAGDON PUMP is a high

performance unit capable of achieving

high outputs at high efficiencies. However, as

is common with pneumatic equipment, the

pump efficiencies is reliant upon the air being

clean, dry and filtered. Failure to comply with

these requirements may lead to loss of

performance and reduced component life and in

extreme cases, permanent damage to the pump.

To avoid leaks, ensure that all fluid connections

are tight. The use of PTFE thread tape correctly

applied should be used to ensure 100% leak

proof connections. Failure to ensure 100%

sealability of the suction connection could

adversely affect suction performance.

If you are pumping hazardous fluids, or

operating the pump in an enclosed area, it is

essential that the exhaust from the pump is

piped away to a safe location. When pumping

hazardous fluids the above instructions must be

adhered to in order to ensure safe operating

procedures. (Under certain operating

conditions the failure of internal components

can lead to the pumped fluid being exhausted

via the pump exhaust outlet).

WARNING

Available from

Blagdon Pump :-

1. Pulsation Dampener

2. Filter/Regulator

3. Lubricator

4. Air Dryer

Installation Guide

Fig. 1

Shut-off

Valve

SUCTION

Drain Port

Air Inlet

Pipe Connection

(Style Optional)

Gauge

Exhaust

Flexible

Connection

Air Exhaust

LCAUTION !

The air exhaus t should be piped

to an area for safe disposition of

the product being pumped, in the

1

event of diaphragm failure.

NEVER place your hands over or near the

pump suction inlet. Powerful suction could

cause serious bodily injury.

FLUSH THE PUMP This pump was tested

with water containing an oil-based rust

inhibitor. If this solution could contaminate or

Pulsation

Dampener

Pipe Connection

(Style Optional)

Flexible

Connection

Gauge

Shut-off

Valve

DISCHARGE

react with the fluid you are pumping, flush the

pump thoroughly with a solvent/detergent to

clean internal components. The solvent/

detergent must be compatible with the pump

materials of construction. Care should be taken

to flush the pump each time it is disassembled

for maintenance or repair.

CAUTION

All BLAGDON PUMPS are built lubricated

with grease during assembly and need no

further lubrication. If the use of oil cannot be

Drain Port

avoided, this will not present any problems. A

light No. 2 class lithium grease is

recommended. Other grades may cause the Air

Air Shut-Off

Air Dryer

Valve

AIR

INLET

Filter

Regulator/Lubricator

Air

Logic System to operate intermittently, thereby

causing a loss of output and failure to operate.

Other seals are available for “clean room”

conditions

If the pump accelerates or is running too fast

due to a lack of fluid, then stop it immediately

by shutting off the air supply. A dry pump will

accelerate to a high speed causing wear to

elastomers.

4

If the fluid you are pumping tends to dry up or

set when it is not moving, then flush the pump

2

3

as often as necessary to prevent the fluid from

drying in the pump. Drain the pump thoroughly

before storing.

If feasible, invert pump to allow any fluid to

drain from the non-return valves

HG-CF-1197 Rev. 0 - 15.12.09 Page 5

.

HG-CF-1197

b25_HP_W1_manual-rev1210

Page 6

Important Warnings and Safety Information

IMPORTANT

Read these safety warnings and instructions in this manual completely, before installation and start-up of the pump. It

is the responsibility of the purchaser to retain this manual for reference. This manual must be kept with, and supplied

with the pump at all times. Failure to comply with the recommendations stated in this manual will damage the pump,

and void factory warranty. These instructions are available if required, in the language or languages of the country or

countries in which the equipment is used. Please refer to the manufacturer for details.

IMPORTANT!

This pump is pressurized internally with air pressure during operation. Always make certain that all bolting is in good condition and that

all of the correct bolting is reinstalled during assembly. End-user must ensure correct fitting of Inlet / Outlet connections. Crossed

threads or over tightening of connections will result in leaks. Quick action/release connections are not recommended. If their use is

unavoidable, the levers must be locked to avoid them being forced apart in a hazardous manner.

WARNING!

Before maintenance or repair, shut off the compressed air line, bleed the pressure, and disconnect the air line from the pump. The discharge line may be pressurized and must be bled of its pressure. End-user must ensure correct regulation of air supply pressure, as any

increase in air pressure results in a similar increase in product pressure if stalled-out.

WARNING!

Before doing any maintenance on the pump, be certain all pressure is completely vented from the pump, suction, discharge, piping, and

all other openings and connections. Be certain the air supply is locked out or made non-operational, so that it cannot be started while

work is being done on the pump. Be certain that approved eye protection and protective clothing are worn at all times in the vicinity of

the pump. Failure to follow these recommendations may result in serious injury or death.

WARNING!

Airborne particles and loud noise hazards. Wear ear and eye protection.

WARNING!

Take action to prevent static sparking. Fire or explosion can result, especially when handling flammable liquids. The pump, piping,

valves, containers or other miscellaneous equipment must be grounded. Refer to exhaust safety instructions on page 9.

WARNING!

When used for toxic or aggressive fluids, the pump should always be flushed clean prior to disassembly. User must ensure chemical

compatibility, and any pressure / temperature limits are not exceeded. These instructions include all the information for relevant

diaphragm temperature limits. Pump temperature range can also be found on data-plate attached to the pump.

If pump is not used for more than 5 days, care must be taken when restarting. If in any doubt, remove pump from line and flush with a

suitable cleaner. Solidified deposits within the pump may cause damage to the diaphragms.

CAUTION!

Before pump operation, inspect all gasketed fasteners for looseness caused by gasket creep. Re-torque loose fasteners to prevent

leakage. Follow recommended torques stated in this manual. In cases of excess vibration, Blagdon recommend fitting a Pulsation

Dampener to remove effects of pulse actions from pump operation. Flexible connections can be used, but must be kept to a minimum

length necessary to avoid sharp flexing or straining movements

HG-CF-1197 Rev. 0 - 15.12.09 Page 6

.

HG-CF-1197

b25_HP_W1_manual-rev1210

Page 7

TROUBLE SHOOTING GUIDE

NOTE :- Check all solutions before dismantling the pump.

PROBLEM CAUSE SOLUTION

Pump will not start Air valve assembly malfunction/Siezure

Obstructed fluid line.

Obstructed diaphragm chamber.

Diaphragm failure causing fluid & excessive air to be

expelled through the exhaust.

Diaphragm seal failure.

Air valve system malfunction.

Air connected to exhaust.

Erratic flow Diaphragm failure on one side.

Pump strokes but will not

discharge

Fluid discharged from air

exhaust

Intermittent stroke rate Over lubrication

Valve ball not seating.

Suction leakage.

Diaphragm failure causing fluid & excessive air to be

expelled through the exhaust.

Diaphragm seal failure.

Air valve system malfunction.

Excessive suction lift.

Suction line leakage.

Valve ball not seating correctly or damaged.

Suction line or strainer clogged.

Diaphragm failure.

Diaphragm Failure.

Loose frontplate.

Diaphragm shaft seal failure.

Air valve system malfunction.

Valve ball not seating / partially obstructed.

Check carrier for freedom of movement. Clean, oil & replace.

Clean line or increase line size.

Remove obstruction.

Replace diaphragm.

Replace shaft seals.

Check all seals in valve chest assembly.

Re-connect to air inlet.

Replace diaphragm.

Check and remove obstruction.

Check and correct.

Replace diaphragm.

Replace shaft seals.

Check all seals in valve chest assembly.

Shorten suction line.

Check and correct.

Check and remove obstruction / replace.

Clear.

Replace diaphragm.

Replace diaphragm.

Re-Torque to manual specifications.

Shut-down pump. Remove air connection

into pump & introduce a small quantity of degreasing agent into air valve and replace

line. Run pump until clear.

Replace seals.

Check all seals in valve chest assembly.

Clear obstruction.

ATEX Certified units :- X2505..

These models are certified to :-

II 2 GD c

Non-electrical equipment for potentially explosive atmospheres,

: EN13463-1 : 2001, ‘c’ - Internal control of production.

Grounding the pump :-

WARNING!

Take action to prevent static sparking. Fire or

explosion can result, especially when handling

flammable liquids. The pump, piping, valves,

containers or other miscellaneous equipment

must be grounded.

The Atex approved units are supplied with a natural earth ground

cable. This cable is 2 meters in length and permanently connected

through a nut and bolt at the inner cover casting. The other end is free

to connect to the nearest available suitable point to provide a natural

earth ground. This must be done to reduce the risk of electro-static

sparking.

HG-CF-1197 Rev. 0 - 15.12.09 Page 7

HG-CF-1197

b25_HP_W1_manual-rev1210

Page 8

IMPORTANT!

Read these instructions

c o m p le t e l y, b ef o r e

installation and start-up. It

is the responsibility of the purchaser to

retain this manual for reference.

F a il u re t o c o m pl y w it h t h e

reco mmendat io ns s tated in this

manual will damage the pump, and

void factory warranty.

the valve system to malfunction.

Re -asse m ble the v a lve blo c k

assembly & re-torque in accordance

to the settings shown in the parts list.

In the event of a complete air-side

overhaul, the pump should be disassembled down to the centre

section assembly as described later

in the “Wet-Side Overhaul” section.

R E PL A C IN G D I AP HR AG M S

Remove both suction and discharge

manifolds as detailed in the previous

section, removing all ball valves,

seats and ‘O’ rings.

Loosen and remove both outer

covers from the pump assembly.

The orientation of the covers should

be noted so as to facilitate reassembly.

SERVICE

The following sections give a general

overview on how to service all

models of BLAGDON Diaphragm

Pumps. For details on individual part

numbers, quantities, materials, etc.,

please consult the parts list supplied

with the pump.

NOTE : Before commencing

any service or maintenance work

on the pump, ensure that the air

supply has been disconnected or

isolated.

AIR VALVE SYSTEMS

PNEUMATIC TYPE Remove the 4

screws securing the valve block to

the valve chest, together with any

associated gaskets or seals.

Remove slide valve plate & slide

valve from the valve block assembly.

Clean all parts thoroughly and

inspect for excessive wear, replacing

where necessary.

The slide valve and valve plate

contact faces should be flat and free

from scratches. A light polishing on a

flat surface with a fine abrasive paper

will remove most scratches.

If excessive wear is suspected in the

valve block bore or valve carrier,

remove the valve block plugs and

withdraw the valve carrier. Check

valve block plug o-rings for wear or

attack & replace where required.

Clean the valve carrier & valve block

bore with white spirits to remove any

oil films.

NOTE : T h e n o m i n a l

diametrical clearance between the

valve carrier and the valve block

block bore should be 0.05 -

0.09mm. A clearance in excess of

this will cause the valve system to

run erratically.

Apply a light grease to the valve

bl ock pl ug O- ring s whe n reassembling into the valve block bore.

Any damage to the O-ring may cause

With the valve block assembly

dismantled, remove the inner covers

where appropriate.

A careful note of the position of all

related seals and gaskets should be

made to facilitate re-assembly.

Remove diaphragm shaft bushes,

where appropriate, and check all

seals and ‘O’ rings for wear or

d a ma g e . I f w o r n , r e p la c e

immediately.

NOTE:- The integrity of the

diaphragm shaft seals is essential

for the correct functioning of all

pneumatically actuated valve

systems.

Check the diaphragm shaft for

excessive wear as this will result in

premature seal failure. Replace as

required. Lubricate all components

and re-assemble as detailed above,

in reverse order. Ensure the correct

position of all components detailed in

all sectional assembly drawings.

WET-SIDE OVERHAUL

REPL ACI N G B ALL VALVES

Remove discharge manifold from

pu mp as sembly to get her with

associated valve balls, seats and ‘O’

rings.

NOTE :- The orientation of the

valve seat relative to the valve ball

should be noted as incorrect

positioning may result in a

performance loss.

Turn pump through 180

the suction manifold. Clean and

inspect the components. Check for

any wear or damage and replace as

required.

NOTE :- Ball or valve seat wear

may result in loss of performance

and suction lift.

Re-assemble the valve balls/seats

and ensure manifolds are adequately

torqued to the settings shown in the

parts list.

o

and remove

Holding one of the frontplates in a

vice, (‘soft jaws’ should be fitted), or

with an adjustable spanner, loosen

and remove the frontplate from the

opp o s i t e end . R e m ove t h e

diaphragm, backplate and bumpstop

from diaphragm shaft.

Carefully withdraw the diaphragm

shaft from the centre section and

hold the free end in a vice, holding

between the flats machined on the

end. Loosen and remove the

frontplate and remove the diaphragm

togeth e r wit h back p l a t e an d

bumpstop (where fitted).

NOTE :- Care should be taken with

all plastic, coated and hygienic

pumps, so that the surface of the

frontplate is not damaged.

Thoroughly clean all parts and check

for wear, damage, swelling, cracking,

delamination and chemical attack.

Replace components where required.

NOTE :- Rubber diaphragms

should be replaced if they are

worn to such an extent that the

fabric re-enforcing is evident on

the surface of the diaphragm.

Fo r p umps fit t ed with PTF E

diaphragms, a light coating of grease

should be applied to the back-up

diaphragm prior to re-assembly.

Before re-assembly, it is advisable to

check the condition of the diaphragm

shaft seal/’O’ rings for wear or attack.

If either is evident, it is recommended

that they be replaced.

Assemble the diaphragms onto the

shaft in a reverse sequence to their

removal. Care should be taken as to

the orientation of the diaphragm

relative to the front and back plates.

All diaphragms have “AIR SIDE”

mould ed onto o ne si de. The

backplate must be fitted adjacent to

the AIR SIDE of the diaphragm.

HG-CF-1197 Rev. 0 - 15.12.09 Page 8

HG-CF-1197

b25_HP_W1_manual-rev1210

Page 9

EXHAUST SAFETY WHEN PUMPING HAZARDOUS LIQUIDS

WARNING!

In the event of diaphragm rupture, pumped material may enter the air end of the pump, and be discharged into the atmosphere. If pumping

a product which is hazardous or toxic, the air exhaust must be piped to an appropriate area for safe disposition.

Flooded Suction Installation

Submerged Installation

Suction Lift Installation

Exhaust Safety :-

When a diaphragm fails during operation, pumped liquid can enter and contaminate the air side of the pump. If diaphragm failure is not

severe, i.e. a small split or hole, then the pump can continue to run, with air being forced into the product being pumped. If however the

failure is more serious, then the pump may stop, with fluid or fumes being expelled through the exhaust. Under these conditions it is

recommended that the exhaust is piped away to a safe area. In standard suction lift conditions this can simply be done by piping from the

exhaust connection to a safe area. Multiple installations can be piped to a common connection, then to a safe area. In flooded suction

conditions the exhaust must be taken to a point higher than the fluid level to prevent any siphoning away. In submerged conditions ensure

exhaust is piped away above fluid level.

In all conditions ensure exhaust outlet is not expelling across a non-conductive surface. The exhaust must not be placed less than 100mm

from any non-conductive surface, as this may generate a propagating brush discharge resulting in a possible ignition source.

HIGH TEMPERATURE INSTRUCTIONS

In situations where the temperature of the fluid to be pumped is likely to exceed 100°C, a high temperature pump

code must be specified. This is signified using an ‘X’ in the last part of the pump code as shown.

“XTS” in place of “TTS”.

This indicates the following specification amendments :All seals and o-rings will be changed from Buna-N to Viton and back-up diaphragms and any bump-stops will be

changed to Viton.

See table below for parts effected :- (refer to main table for quantities / pump)

These items are available in recommended spares kit :- ASK2505HT

HIGH TEMPERATURE SPECIFICATION

REF. NO 23 25 26 27 31

DESCRIPTION DIA. SHAFT

MATERIAL

VITON G536 G508 G533 G509 1A039

HG-CF-1197 Rev. 0 - 15.12.09 Page 9

SEAL

24

DIAPHRAGM

SHAFT BUSH

40-194

O-RING O-RING O-RING SUPPORT

DIAPHRAGM

HG-CF-1197

b25_HP_W1_manual-rev1210

Page 10

2

2

1

2

1

M5 x 14

4

1

M8

M8 x 40 4

1

1

2

2

8

- 8

POLYURETHANE QTY

-

- -

- -

-

-

1A358

SANTOPRENE

QTY

STEEL

STAINLESS

1A050 1A197

DELRIN

(ACETAL)

1A080

1

- -

- -

- -

PARTS LIST - cont.

Description Qty

Parts

Aluminium Common

Steel

Stainless

Cast Iron

Ref

No.

VALVE CARRIER

36 40-004 SLIDE VALVE

39 G512 O-RING 2

38 40-266 VALVE BLOCK PLUG

37 D391 SKT. CAP SCREW 4

1

40 40-192

2

1

8

SPRING WASHER

VALVE BLOCK

NEOPRENE POLYESTER

D337 SKT. CAP SCREW

C165

THE FOLLOWING PARTS ARE USED ON ATEX MODELS

44 G243 O-RING 2

45 1A089 SUPPORT DIAPHRAGM 1

43

41 40-264

42

1

2

SEE TABLE

46 1A071 DIAPHRAGM - PTFE 1

1

1

2

47 SA10288 GROUNDING LEAD 148 SP467 ATEX I/D TAG

30 40-240 SILENCER 1

6

2

2

2

ELASTOMER TABLE

SP473 TIE-LOK TIE

DESCRIPTION BUNA-N

No.

49

2

1

REF

1

2

1

G059

1A072 1A091

VALVE BALL 1A049 1A079

8

1

DIAPHRAGM 1A006 1A057 1A061 1A070 2

VALVE SEAT O-RING G057

3

6

8 VALVE BALL (W EIGHTED)

1

2

PTFE EPDM

ELASTOMER TABLE – Cont.

VITON

DESCRIPTION

REF

1

1

1

No.

- 1A092

1A002

VALVE SEAT O-RING G061 G058 G060

3

8 VALVE BALL 1A081

1

M8 x 25 8

6 DIAPHRAGM 1A039 SEE TABLE 1A040

8 VALVE BALL (WEIGHTED) 1A093

8

- These items are available in a recommended spares kit. Please refer to your local stockist / distributor for details.

- These items are available in a recommended spares kit - ASK2504 - Air side Kit - (All models).

- These items are available as a Sub-Assembly spare - SA10463, Valve Block Assy.

- All models are pre-lubricated, -LF options are only required for very dry air, or “clean room” applications.

8

1

24

M8

1

1

16

M8

Description Qty

Parts

Common

Aluminium

Steel

Stainless

OUTER COVER - WET SIDE

O-RING (VALVE SEAT)

1A205 VALVE SEAT - HEAVY DUTY

SEE TABLE

DIAPHRAGM

BACKPLATE

1A259

SEE TABLE

SA10104 SA10502 FRONTPLATE ASSEMBLY - FLUID SIDE

DIAPHRAGM SHAFT

DISCHARGE MANIFOLD

25-160

O-RING

O-RING

G367

G245

DIA. SHAFT SEAL (SEE NOTE )

O-RING

G189

25-103 SWIVEL ELBOW

G242 O-RING

VALVE CHEST

INNER COVER

MODELS)

1A210 BLANKING PLATE

SA10502 FRONTPLATE - AIR SIDE

1A211 - OUTER COVER - AIR SIDE

D310 SKT. CAP SCREW

25-214 AIR HOSE

25-213 SWIVEL ELBOW

SILENCER

G339 O-RING

PART NUMBER

WETTED COMPONENTS

Cast Iron

2

1 25-139 25-120 - SUCTION MANIFOLD

Ref

PARTS LIST

HG-CF-1197 Rev. 0 - 15.12.09 Page 10

No.

SA10104

3

6

7

5

4 1A075 1A035 1A005 -

9 25-140 25-121 -

8 SEE TABLE VALVE BALL

11 25-089 DIAPHRAGM SHAFT BUSH

10

14 25-091

12

13

17

18

16 25-206 INNER COVER - 2:1

15

19 40-259

22 1A006 AIR SIDE DIAPHRAGM (VITON, EPDM & PTFE

20 25-182

21

23 1A221 1A222

24

27

25

26

29 A181 A006 BOLT - HEX. HD. M8 x 40 16

30 40-047

28

31 A180 A005 BOLT - HEX. HD.

HG-CF-1197

b25_HP_W1_manual-rev1210

WASHER

C004

40-005 VALVE PLATE

C193

32 B179 B003 NUT

33

35

34 40-204 GASKET

Page 11

14

Refer to page 10, Parts List table for Item Ref. Nos.

Sectional General Assembly :- B25 & X2505 Metallic Pump

Inner Seals -

Lip faces in over, towards

Lip Seal Positions

Outer Seal -

11

Lip faces out over

HG-CF-1197 Rev. 0 - 15.12.09 Page 11

HG-CF-1197

b25_HP_W1_manual-rev1210

Page 12

IDEX Pump Technologies (Ireland) Ltd.,

A Unit of IDEX Corporation,

R79, Shannon, Co Clare,

IRELAND.

TEL. : +353 61 471933

FAX. : +353 61 475046

Web Site : www.blagdonpump.com

E-Mail : sales@blagdonpump.com

Date : December 01 2009

Des Monaghan,

Production & Technical Manager

HG-CF-223 (REV 5)

HG-CF-1197 Rev. 0 - 15.12.09 Page 12

HG-CF-1197

b25_HP_W1_manual-rev1210

Loading...

Loading...