Page 1

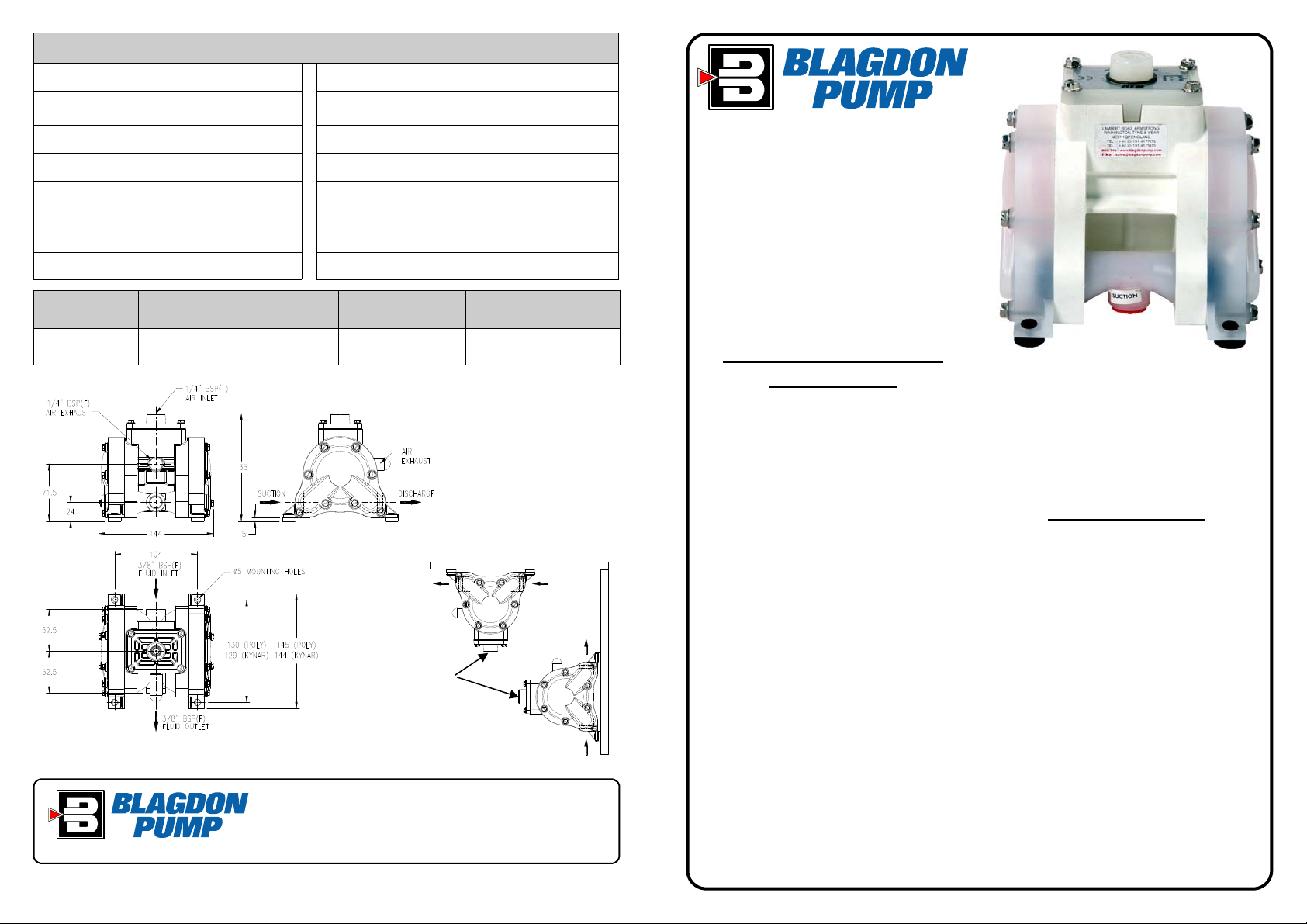

TECHNICAL DATA

Maximum Delivery: 26.5 Litres/min

Max. Working Pressure: 6.9 Bar (100 psi)

Max. Solid Particle Size: 1.5 mm (1/16”)

Air Inlet: 1/4” BSP(F)

Suction Lift (Dry): 3.05 M (10’)

Suction Lift (Wet): 6 M (20’)

FLUID

CONNECTIONS

3/8” BSP (F) 0 - 26.5 Liters/Minute

Installation Dimensions, All dimensions are +/- 1mm

CAPACITY MAX

(0 - 5.8 Gallons/Minute)

Accessories Included: Exhaust Air Silencer

Shipping Weight: 1.4 Kg (3.0 Lb) - Poly.

Shipping Dimensions: 160 mm x 230 mm x 120 mm

Fluid Inlet/Outlet: 3/8” BSP(F)

Temperature Limits:

dB(A) Rating 78 dB(A)

SOLIDS

1.5 mm

(1/16”)

Page 8

Polypropylene :

MAX

DISCHARGE HEAD

70 Meters

(230 ft)

NOTE! PUMP DISCHARGE IS

ON SAME SIDE AS EXHAUST

PREFERRED MOUNTING ARRANGEMENTS FOR PUMP.

INVERTED

AIR INLET

INVERTED OR SIDE MOUNTING

ENSURES 100% VENTING FOR

MAXIMUM PERFORMANCE.

IDEX Pump Technologies (Ireland) Ltd.,

A Unit of IDEX Corporation,

R79, Shannon, Co Clare, IRELAND.

TEL. : +353 61 471933 FAX. : +353 61 475046

Web Site : www.blagdonpump.com

E-Mail : sales@blagdonpump.com

2.0 Kg (4.5 Lb) - Kynar.

Minimum 0

Maximum 79

Minimum -12

Kynar :

Maximum 107

DISPLACEMENT

/STROKE

0.034 Litres

(0.007 Gallons U.K.)

HG-CF-1106 Rev. H 10.12.09

0

C (320F)

0

C (1750F)

0

C (100F)

0

C (2250F)

SIDE

B10

AIR OPERATED

DOUBLE DIAPHRAGM PUMP

OWNERS OPERATING &

SAFETY MANUAL

PRINCIPLE OF PUMP

OPERATION

This spring loaded check valve pump is

powered by compressed air and is a 1:1 ratio

design. The inner side of one diaphragm

chamber is alternately pressurised while

simultaneously exhausting the other inner

chamber. This causes the diaphragms, which

are connected by a common rod, to move in a

reciprocating action. (As one diaphragm

performs a discharge stroke the other

diaphragm is pulled to perform the suction

stroke in the opposite chamber.) Air pressure is

applied over the entire inner surface of the

diaphragm while liquid is discharged from the

opposite side of the diaphragm. The diaphragm

operates in a balanced condition during the

discharge stroke which allows the pump to be

operated at discharge heads of over 230 feet

(70 meters) of water.

For maximum diaphragm life, keep the pump

as close to the liquid being pumped as

possible. Positive suction head in excess of 10

feet of liquid (3.048 meters) may require a back

pressure regulating device to maximize

diaphragm life.

Alternate pressurising and exhausting of the

diaphragm chamber is performed by an

internally mounted, pilot operated, 2 way type

distribution valve. When the spool shifts to one

end of the centre body, inlet pressure is applied

to one chamber and the other diaphragm

chamber exhausts. When the spool shifts to the

Page 1

opposite end of the centre body, the pressure

to the chambers is reversed.

The chambers are connected with rotatable

manifolds with a spring loaded suction and

discharge check valve for each chamber,

maintaining flow in one direction through the

pump.

INSTALLATION

Your installation will depend on the type of fluid

being pumped and your application needs. To

reduce the risk of serious bodily injury and

damage to property, never use fluids in this

pump which are not compatible with the wetted

components. Contact your local distributor or

the manufacturer for system design assistance

& compatibility if necessary.

The pump is fitted with spring loaded check

valves, as a result the pump can be mounted in

any position to suit the application needs.

Ensure the pump is securely mounted to avoid

movement and possible risk of bodily injury.

PRESSURE The pump delivers the same

pressure at the discharge outlet as the air

pressure applied at the air inlet.

NOTE: A Pressure Regulator should be

installed where air supply could exceed 100

psi.

Page 2

SAFETY

Your B10 pump is a high performance unit

capable of achieving

efficiencies. However, as is common with

pneumatic equipment, the pump efficiencies is

reliant upon the air being clean, dry and filtered.

Failure to comply with these requirements may

lead to loss of performance and reduced

component life and in extreme cases, permanent

damage to the pump.

To avoid leaks, ensure that all fluid connections

are tight. The use of PTFE thread tape correctly

applied should be used to ensure 100% leakproof

connections.

Failure to ensure 100% sealability of the

suction connection could adversely affect

suction performance.

If you are pumping hazardous fluids, or operating

the pump in an enclosed area, it is essential that

the exhaust from the pump is piped away to a

safe location. When pumping hazardous fluids

the above instructions must be adhered to in

order to ensure safe operating procedures.

(Under certain operating conditions the failure of

internal components can lead to the pumped fluid

being exhausted via the pump exhaust outlet).

high outputs at high

WARNING

NEVER place your hands over or near the

pump suction inlet. Powerful suction could

cause serious bodily injury.

FLUSH THE PUMP This pump was

tested with clean water. If this solution could

contaminate or react with the fluid you are

pumping, flush the pump thoroughly with a

solvent/detergent to clean internal components.

The solvent/detergent must be compatible with

the pump materials of construction. Care should

be taken to flush the pump each time it is

disassembled for maintenance or repair.

CAUTION Ensure that only the

recommended grade of lubricating oil is used.

BLAGDON PUMPS do not require any dedicated

lubrication system, however a periodical

application of an SAE 10 lubricating oil will help to

prolong seal life. Other grades of oil may cause

the Air Logic System to operate intermittently,

Page 2

thereby causing a loss of output and failure to

operate.

If the pump accelerates or is running too fast due

to a lack of fluid, then stop it immediately by

shutting off the air supply. A dry pump will

accelerate to a high speed causing wear to

elastomers.

If the fluid you are pumping tends to dry up or set

when it is not moving, then flush the pump as

often as necessary to prevent the fluid from

drying in the pump. Drain the pump thoroughly

before storing. If feasible, invert pump to allow

any fluid to drain from the non-return valves

.

IMPORTANT!

Read these instructions completely, before

installation and start-up. It is the

manual for reference. Failure to comply with the

recommendations stated in this manual will damage the

pump, and void factory warranty.

responsibility of the purchaser to retain this

WARNING!

Before maintenance or repair, shut off the

compressed air line, bleed the pressure,

The discharge line may be pressurized and must be bled

of its pressure.

and disconnect the air line from the pump.

WARNING!

Take action to prevent static sparking. Fire

or explosion can result, especially when

piping, valves, containers or other miscellaneous

equipment must be grounded.

handling flammable liquids. The pump,

IMPORTANT!

This pump is pressurized internally with air

pressure during operation. Always make

and that all of the correct bolting is reinstalled during

assembly.

certain that all bolting is in good condition

WARNING!

When used for toxic or aggressive fluids,

the pump should always be flushed clean

prior to disassembly.

Performance Curve

All figures based on pumping clean water at ambient temperature

/HR

3

CFM

1 1.7

3 5.1

5 8.5

40 psi

5

(4.1 bar)

20 psi

(2.8 bar)

(1.4 bar)

6427890

Capacity in LitersPer Minute

Capacity in U.S. GallonsPer Minute

Capacity in Liters per Minute

Capacity in U.K. Gallons per Minute

D is p lacem en tPer S troke , 0.009 Gal . (0.0 34 L)

AIR CONSUMPTION IN CFM

(7 bar)

100 psi

R ecommended O perating Area

80 psi

(5.5 bar)

3

SCFM M

60 psi

5 101520253035

Displacement Per Stroke, 0.007 Gal. (UK) (0.034 L)

153

0.8 1.7 2.5 3.3 4.2 5 5.8 6.7 7.5

1

0

90

80

70

60

50

40

30

100

240

220

200

180

160

140

120

100

80

20

Discharge Head in PSI

60

75706560555045403530252015

40

10

10

20

5

0

0

Feet

0

Meters Feet

These items are available as a recommended Air Side Kit, ASK1001P, see page three for details.

These items are available as a recommended Wet Side Kit, see page three for Part Nos.

For any further information regarding available kits, please contact your local stockist / distributor.

Page 7

Page 3

Parts List

Item Description Qty. Standard: Polypropylene

1 Centre Section

2 Valve Gasket

3 Valve Insert

4 Air Diverter

5 End Cap

6 End Cap O-Ring

7 Valve Screw

8 Valve Body

9 Valve Spool

10 Valve Spool U-Cup

11 Main & Pilot Shaft O-Ring

12 Pilot Shaft Spacer

13 Shaft Retainer

14 Pilot Shaft

15 Pilot Shaft Snap Ring

16 Shaft Retainer Screw

POLY / SANTOPRENE PUMPS KYNAR / PTFE PUMPS

17 Valve Seat

18 Spring

19 Valve Stem

20 Valve Seat Seal

21 Water Chamber Bolt (Short)

22 Water Chamber Bolt (Long)

23 Water Chamber

24 Foot Pad

25 Outer Diaphragm Plate

26 Diaphragm

27 Inner Diaphragm Plate

28 Main Shaft

29 Manifold

30 Muffler

1 E801A

1 E800J

1 E500H

1 10-075

2 E800D

2 E500E

4 10-050

1 10-048

1 E500B

2 P98-104A

8 E503B

5 E503C

2 E801B

1 E803A

2 E503D

4 E501C

4 10-022(Poly) 10-039(Kynar)

4 10-030 10-030

4 10-005 10-038

8 10-073

12 10-051 10-051

4 10-052 10-052

2 10-002 10-036

4 10-035 10-035

2 10-023(poly) 10-023(poly)

10-040(kynar) 10-040(kynar)

2 10-032(R) 10-044

2 C126 C126

1 10-028 10-028

2 10-003 10-037

1 06-034 06-034

Santoprene Option

AIR VALVE

ASSEMBLY

(items 2 - 10)

PILOT VALVE

ASSEMBLY

PTFE Option

E800

10-045

WARNING!

Before doing any maintenance on the

pump, be certain all pressure is completely

vented from the pump, suction, discharge,

piping, and all other openings and connections. Be

certain the air supply is locked out or made

non-operational, so that it cannot be started while work

is being done on the pump. Be certain that approved eye

protection and protective clothing are worn all times in

the vicinity of the pump. Failure to follow these

recommendations may result in serious injury or death.

fasteners to prevent leakage. Follow recommended

torques stated in this manual.

CAUTION!

Before pump operation, inspect all

gasketed fasteners for looseness caused

by gasket creep. Re-torque loose

WARNING!

Airborne particles and loud noise hazards.

Wear ear and eye protection.

WARNING!

In the event of diaphragm rupture, pumped

material may enter the air end of the

phere. If pumping a product which is hazardous or toxic,

the air exhaust must be piped to an appropriate area for

safe disposition.

pump, and be discharged into the atmos-

encourage pump users to recycle worn out parts and

pumps whenever possible, after any hazardous pumped

fluids are thoroughly flushed.

RECYCLING

Many components of BLAGDON air

operated double diaphragm pumps are

made of recyclable materials. We

TYPICAL ORDER CODE = B10. 01. P P. R P P

MODEL - B10

DESIGN LEVEL

WETTED COMPONENTS

P : POLYPROPYLENE

K : PVDF (KYNAR)

NON - WETTED COMPONENTS

P : POLYPROPYLENE

SPARES KITS :- REFER TO TABLE & DRAWING ON PAGES 4,5 & 6

ASK1001P - AIR SIDE KIT WETTED END KITS

ITEM DESCRIPTION QTY PART NUMBER

2 VALVE GASKET 1 E800J

3 VALVE INSERT 1 E500H

4 AIR DIVERTER 1 10-075

6 END CAP O-RING 2 E500E

10 VALVE SPOOL U-CUP 2 P98-104A

11 PILOT SHAFT O-RING 6 E503B

11 MAIN SHAFT O-RING 2 E503B

PART NO. DESCRIPTION

SA10RPP POLY./SANTOPRENE

SA10TPP POLY./PTFE

SA10RKK KYNAR/SANT.

SA10TKK KYNAR/PTFE

Note. These descriptions refer to the Pump body

and Diaphragm materials.

VALVE SEATS

P : POLYPROPYLENE

K : PVDF (KYNAR)

VALVE STEMS

P : POLYPROPYLENE

K : PVDF (KYNAR

DIAPHRAGMS

R : SANTOPRENE

T : PTFE

Page 6

Page 3

Page 4

Page 4 Page 5

Loading...

Loading...