Page 1

Instruction Manual

Bedienungsanleitung

Manuel d’utilisation

Manuale di Istruzioni

Page 2

EN

Safety Precautions and Warnings

• Always keep a safe distance in all directions around your model to avoid

collisions or injury. This model is controlled by a radio signal subject to

interference from many sources outside your control. Interference can cause

momentary loss of control.

• Always operate your model in open spaces away from full-size vehicles, traffi c

and people.

• Always carefully follow the directions and warnings for this and any optional

support equipment (chargers, rechargeable battery packs, etc.).

• Always keep all chemicals, small parts and anything electrical out of the reach

of children.

• Always avoid water exposure to all equipment not specifi cally designed and

protected for this purpose. Moisture causes damage to electronics.

• Never place any portion of the model in your mouth as it could cause serious

injury or even death.

• Never operate your model with low transmitter batteries.

• Always keep aircraft in sight and under control.

• Always activate throttle hold at rotor strike.

• Always use fully charged batteries.

• Always keep transmitter powered on while aircraft is powered.

• Always remove batteries before disassembly.

• Always keep moving parts clean.

• Always keep parts dry.

• Always let parts cool after use before touching.

• Always remove batteries after use.

• Never operate aircraft with damaged wiring.

• Never touch moving parts.

Age Recommendation: Not for children under 14 years. This is not a toy.

WARNING: This is a large model helicopter with carbon fi ber blades that spin at very high RPM. Always use extreme caution and common sense when

maintaining and operating this product. If you are unsure about ANY function or procedure described in this manual, DO NOT operate. Contact Horizon

Product Support for assistance.

WARNING: Always ensure you are operating the helicopter a safe distance, 45 feet (13 meters), away from yourself and others.

WARNING: Read the ENTIRE instruction manual to become familiar with the features of the product before operating. Failure to operate the product

correctly can result in damage to the product, personal property and cause serious injury.

This is a sophisticated hobby product. It must be operated with caution and common sense and requires some basic mechanical ability. Failure to operate this

Product in a safe and responsible manner could result in injury or damage to the product or other property. This product is not intended for use by children without

direct adult supervision. Do not use with incompatible components or alter this product in any way outside of the instructions provided by Horizon Hobby, LLC. This

manual contains instructions for safety, operation and maintenance. It is essential to read and follow all the instructions and warnings in the manual, prior to assembly, setup or use, in order to operate correctly and avoid damage or serious injury.

The following terms are used throughout the product literature to indicate various levels of potential harm when operating this product:

WARNING: Procedures, which if not properly followed, create the probability of property damage, collateral damage, and serious injury OR create a high probability

of superfi cial injury.

CAUTION: Procedures, which if not properly followed, create the probability of physical property damage AND a possibility of serious injury.

NOTICE: Procedures, which if not properly followed, create a possibility of physical property damage AND a little or no possibility of injury.

NOTICE

All instructions, warranties and other collateral documents are subject to change at the sole discretion of Horizon Hobby, LLC. For up-to-date product literature,

visit horizonhobby.com and click on the support tab for this product.

Meaning of Special Language

2

Page 3

EN

To receive product updates, special offers and more, register your product at www.horizonhobby.com

Table of Contents

Length

38.6 in (980mm)

Main Rotor Diameter

43.1 in (1095mm)

Tail Rotor Diameter

9.1 in (232mm)

Components Needed to Complete ...................................................................... 3

Assembly Guide Legend ..................................................................................... 3

Tools Needed To Complete ................................................................................ 3

! BEFORE STARTING ASSEMBLY! ....................................................................... 4

Head Assembly ..................................................................................................4

Frame Assembly ................................................................................................5

Tail Assembly ................................................................................................... 11

Flight Controller Mounting ................................................................................15

Battery Installation ........................................................................................... 15

Helicopter Setup ..............................................................................................15

Main Rotor Alignment ......................................................................................16

Throttle Hold .................................................................................................... 16

Control Tests .................................................................................................... 16

Tail Rotor Blade Installation .............................................................................. 18

Main Rotor Blade Installation ...........................................................................18

Canopy Installation ..........................................................................................18

Flight Guidelines and Warnings ........................................................................ 19

Flying Your Fusion 480 ..................................................................................... 19

Blade Tracking ................................................................................................. 19

Post-Flight Inspection and Maintenance ...........................................................19

Troubleshooting Guide ..................................................................................... 20

Limited Warranty ............................................................................................. 20

Warranty and Service Contact Information .......................................................21

Exploded View ................................................................................................. 84

Parts List .........................................................................................................86

Recommended Components ............................................................................ 87

Optional Parts .................................................................................................. 87

Specifi cations

3

Recommended Component

Motor

Brushless Motor 4320-1300kV (BLH4953)

ESC

Talon 90-Amp 25V BL ESC W/20amp BEC (CSE010009700)

Battery

4400mAh 6S 22.2V 30C LiPo, 10AWG EC5 (EFLB44006S30)

Receiver

AR7210BX DSMX FBL Control System (SPMAR7210BX)

Swash Servos

H6050 Heli Cyclic Servo (SPMSH6050), metal gear servos required

Tail Servo

H6060 Heli Tail Servo (SPMSH6060), metal gear servo required

Charger

DC Li-Po Balancing Charger

Transmitter

DSM2

®

/DSMX® Compatible Transmitter

Components Needed to Complete Tools Needed To Complete

• Medium strength thread-locking compound

• High strength thread-locking compound

• 1.5mm, 2mm, 2.5mm, 3mm and 4mm hex drivers

• Ball link pliers

• Needle nose pliers

• Pitch gauge

• Metric ruler or calipers

Assembly Guide Legend

Apply NO Thread-locking Compound

Apply Medium Thread-locking Compound

Apply High Strength Thread-locking Compound

Loosely Tighten

Fully Tighten

Page 4

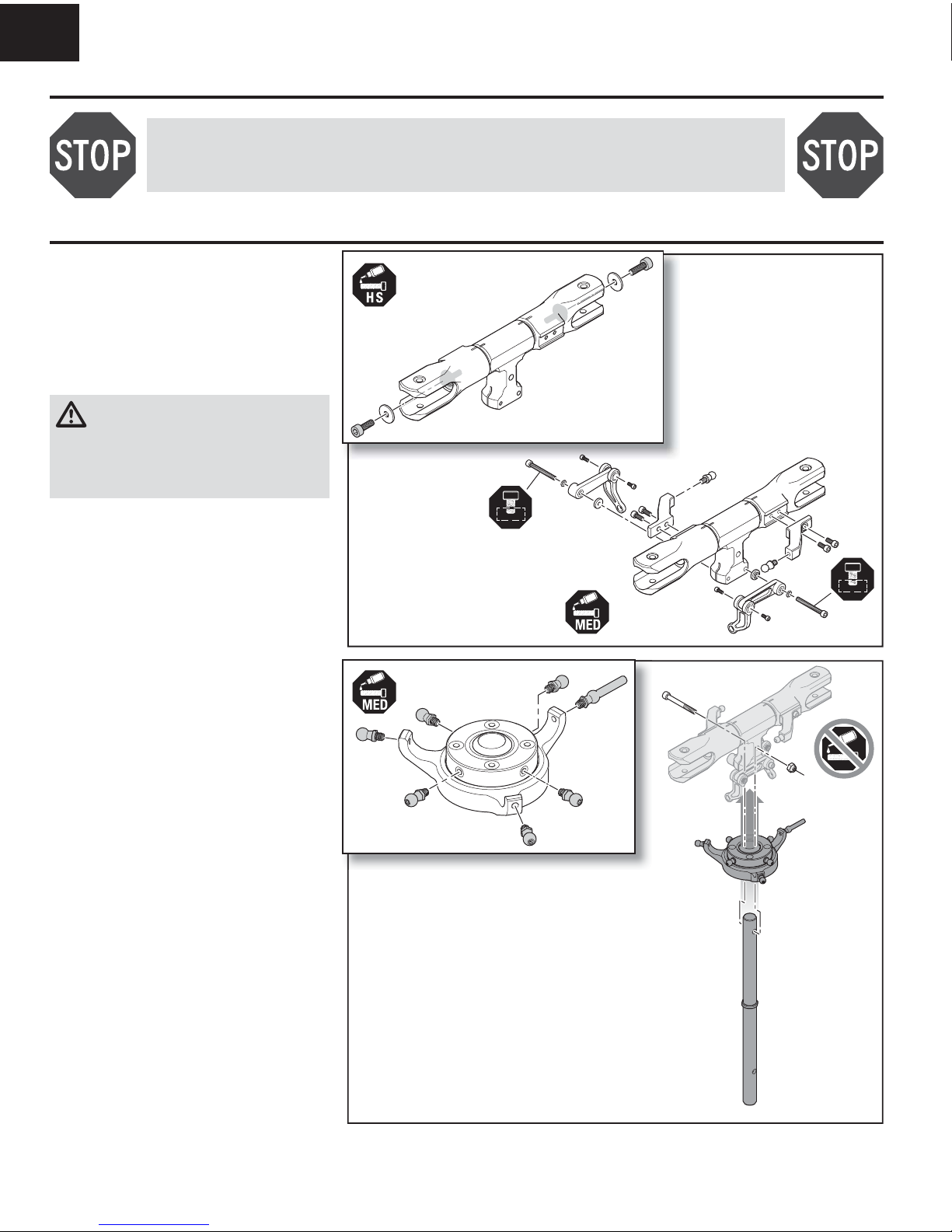

EN

4

Head Assembly (H)

! BEFORE STARTING ASSEMBLY!

Many of the major sub-assemblies of the Blade Fusion 480 kit have been pre-assembled at the factory. These sub-assemblies

were not assembled with thread-locking compound. Prior to beginning assembly of the kit, loosen any pre-assembled

screws which are threaded into metal components and apply thread-locking compound. Use only enough thread-locking

compound to moisten the threads. Check all pre-assembled components to ensure all fasteners are tight.

1. Remove the spindle bolts from the blade grips.

2. Clean the spindle threads and the threads of the

4x12mm spindle bolts with isopropyl alcohol.

3. Apply high strength thread-locking compound and

re-install the spindle bolts. Ensure the thread-locking

compound does not contact the blade grip bearings.

WARNING: Failure to apply high strength

thread-locking compound to the spindle bolts

may allow the spindle bolts to work free during

operation, which could cause the rotor blades to fl y

off. Projectile rotor blades pose a serious risk of

property damage and may cause severe bodily injury.

4. Remove the linkage balls from the main grip arms

and re-install them using medium thread-locking

compound.

5. Install the main grip arms to the blade grips using

two 3x10mm socket head caps crews per arm and

medium thread-locking compound.

6. Remove the 2x5mm socket head cap screws one

at a time from the follower arms and re-install with

medium thread-locking compound.

7. Install the follower arms to the head block using one

3x20mm socket head cap screw and two washers

per arm and medium thread-locking compound.

Ensure the thread-locking compound does not

contact the bearings of the follower arms. Do not

fully tighten at this time.

1. Remove the seven linkage balls from the swashplate

assembly one at a time and re-install them with

medium thread-locking compound.

2. Fit the swashplate over the main shaft.

3. Insert the main shaft into the head block and secure

it with a 4x20mm bolt and locknut. Before tightening

the bolt pull on the head block to verify the bolt

passes through the hole in the main shaft. Do not

use thread-locking compound on the head bolt

and locknut.

4. Fully tighten the two follower arm 3x20 socket head

cap screws installed in step 7 above.

Step H2

Step H1

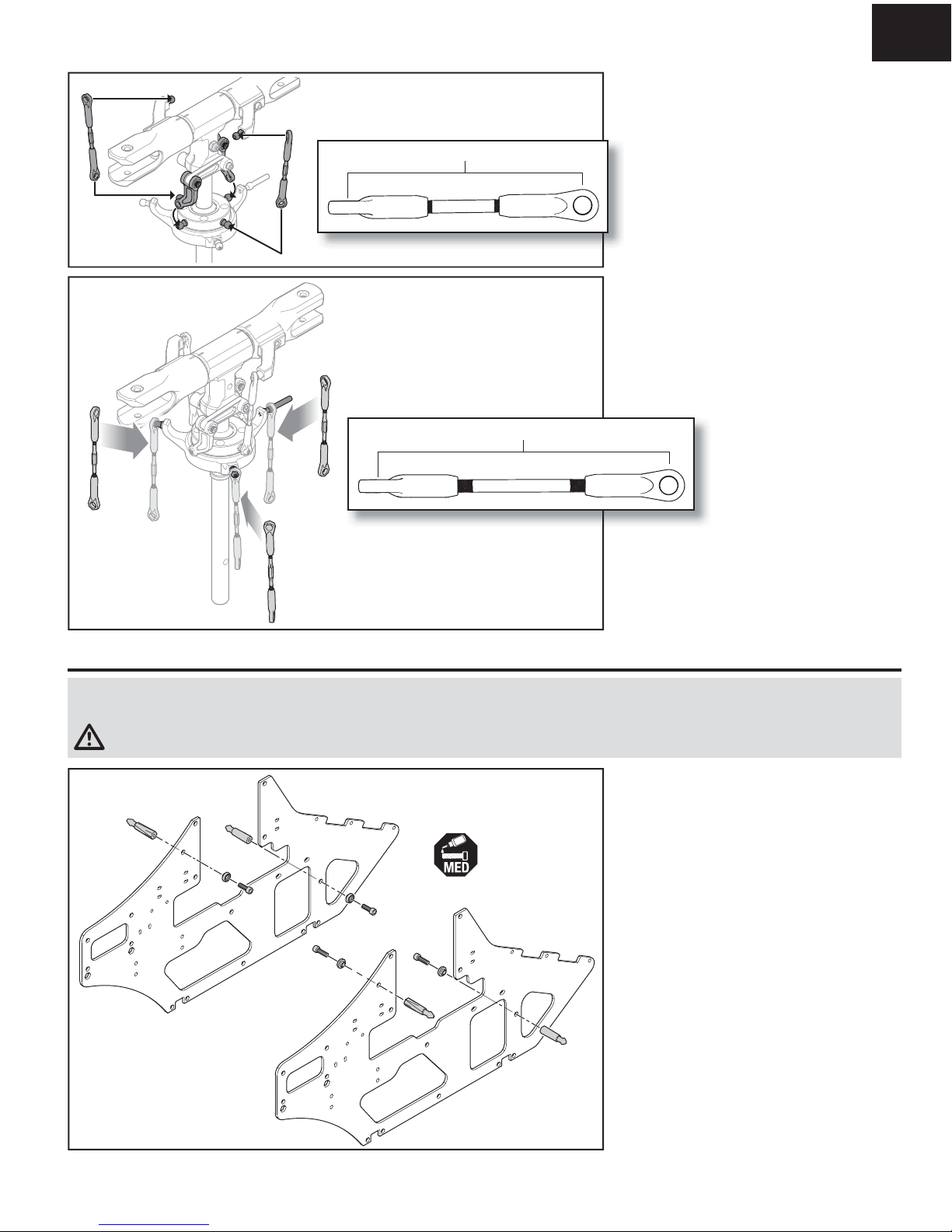

Page 5

EN

55mm

68mm

5

Frame Assembly (F)

NOTICE: Always plan your servo wire routing prior to assembly. If servo wires will pass through or cross the frame plates, use sandpaper or a fi le to smooth the

edges of the frame plate to prevent wire chafi ng. Damage to servo wires may result in loss of control.

CAUTION: Sanding or fi ling carbon fi ber, such as frame plates, may produce carbon dust. Always wear appropriate Personal Protection Equipment (PPE)

such as a dust mask, when there is a danger of carbon dust.

1. Snap the follower arms onto two opposite linkage

balls on the upper swashplate.

2. Adjust the length of the rotor head linkages to 55mm

from center to center of the link openings.

3. Snap the rotor head linkages onto the main grip

linkage balls.

4. Snap the other end of the linkages to the remaining

linkage balls of the upper swashplate.

1. Adjust the length of the rotor head linkages to 68mm

from center to center of the link openings.

2. Snap one end of the servo control linkages onto the

linkage balls on the lower swashplate.

Attach two canopy posts to each frame plate using

a 3x10mm screw, a machined washer and medium

thread-locking compound for each post. Assemble both

a left and right frame side as shown in the illustration.

Step F1

Step H3

Step H4

Page 6

EN

6

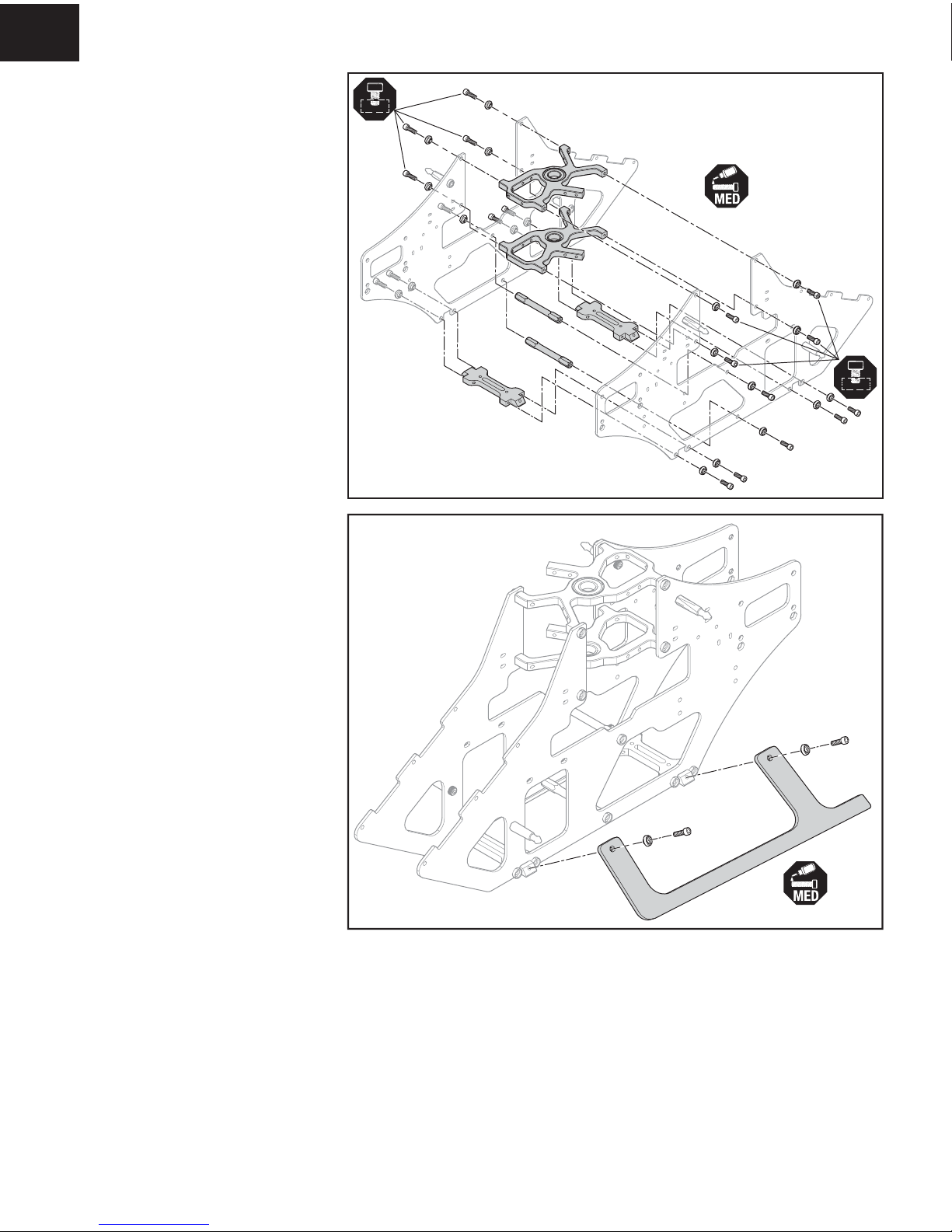

1. Attach the upper and lower bearing blocks to the

frame sides using 3x10mm screws, machined

washers and medium thread-locking compound.

The upper block has two threaded holes in the rear

of the block. Do not fully tighten the screws in the

bearing blocks at this time.

2. Slide the main shaft through both bearing blocks to

ensure the blocks are properly aligned with each

other.

3. Set the frame sides upright on a fl at surface, with

the bottom of both sides fully in contact with the

work surface.

4. Tighten all of the bearing block screws fully and

remove the main shaft from the bearing blocks.

5. Attach two landing gear mounts and two frame

posts to the frame sides using 3x10mm screws,

machined washers and medium thread-locking

compound.

Attach the landing gear to each side of the frame using

3x10mm screws, machined washers and medium

thread-locking compound.

Step F3

Step F2

Page 7

EN

7

Frame side removed for clarity

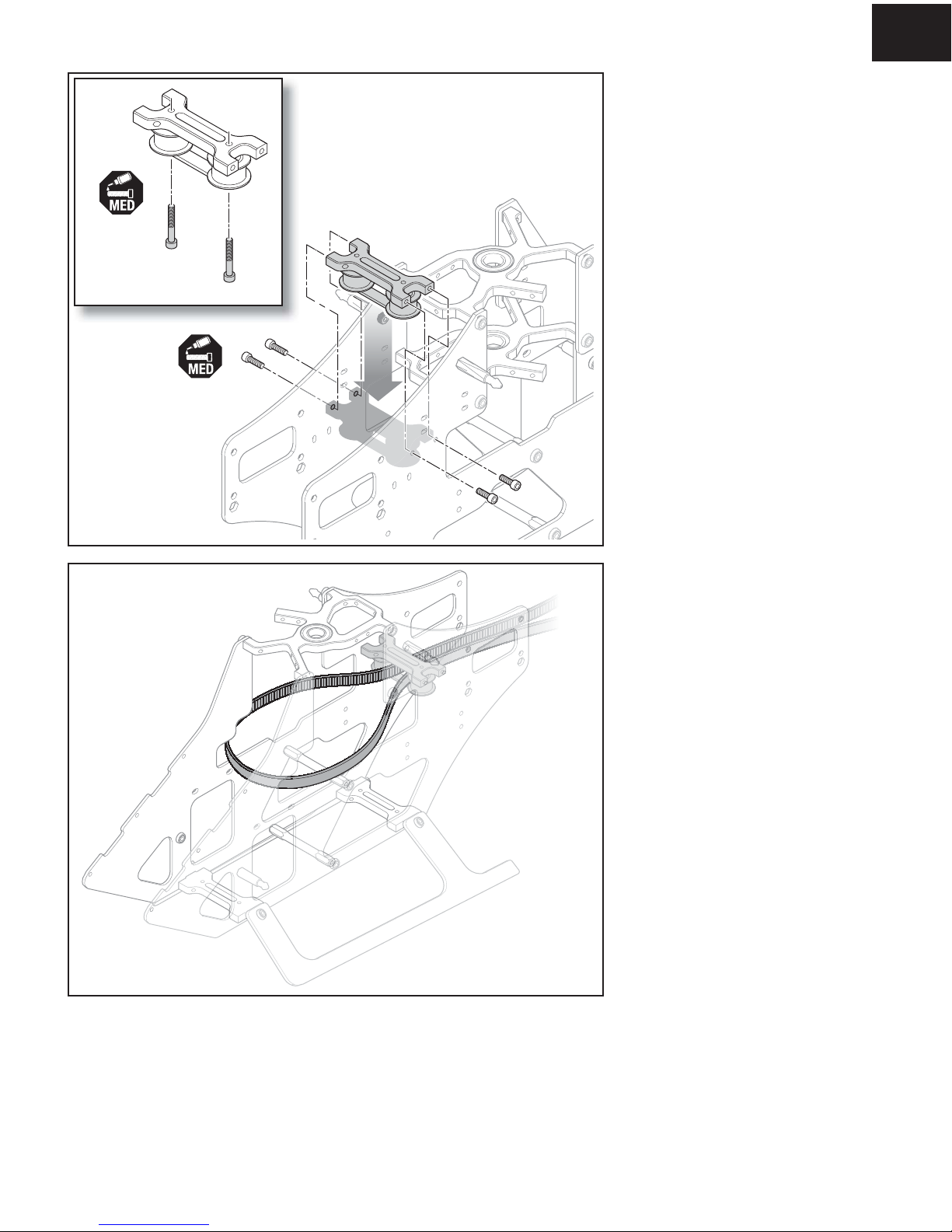

1. Remove the 3x18mm socket head cap screws of

the tail belt guide assembly and re-install them

using medium thread-locking compound. Ensure

the thread-locking compound does not contact the

bearings of the tail guide assembly.

2. Install the tail belt guide between the frame sides

using 3x10mm screws and medium thread-locking

compound.

Thread the tail belt through the belt guide with the teeth

of the belt facing inward. Pull enough of the belt through

the guide to form a large loop, as shown.

Be careful to not crimp the belt.

Step F4

Step F5

Page 8

EN

8

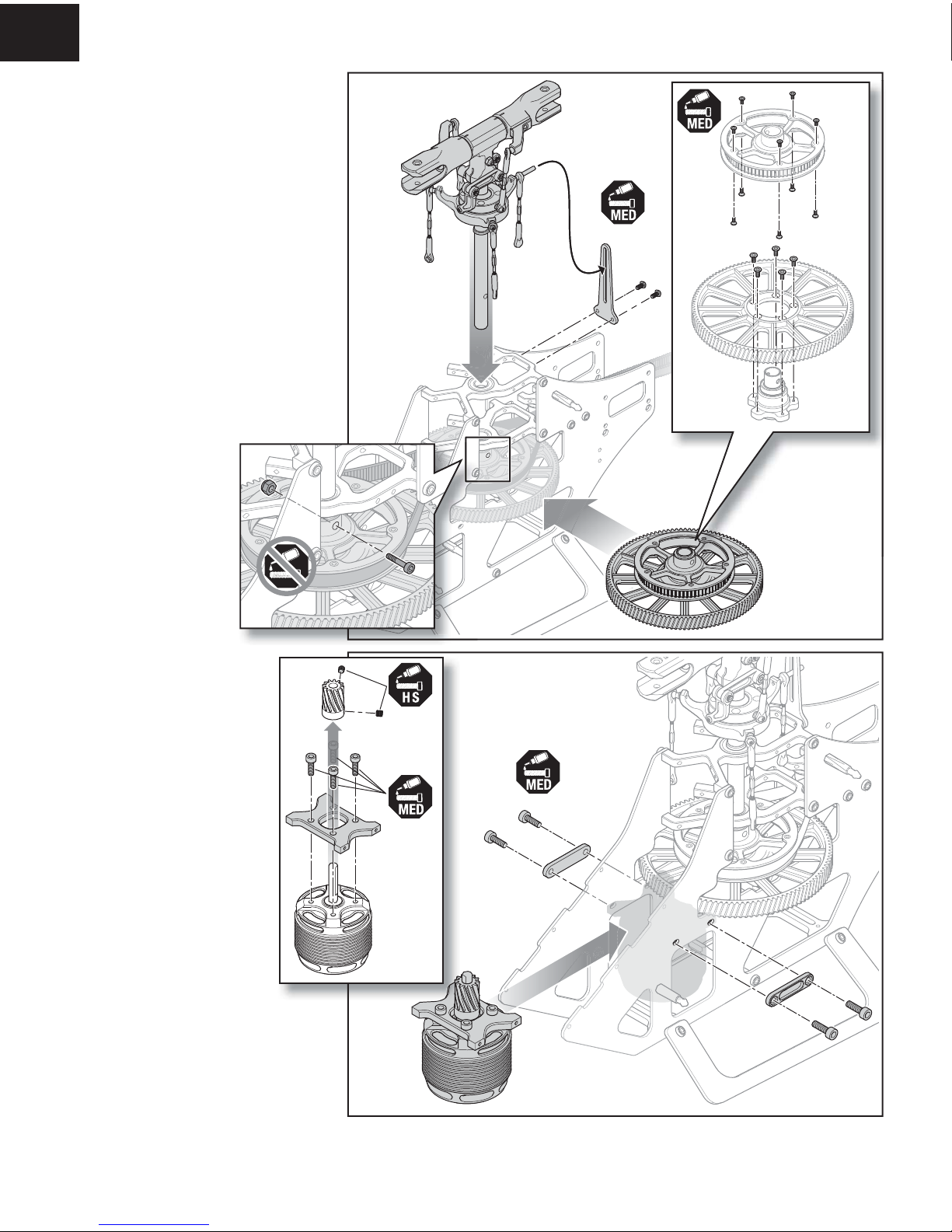

1. Pull the tail belt pulley off of the one-way bearing

sleave. Remove ten 2x4mm fl athead screws from

the tail drive pulley one at a time and re-install them

using medium thread-locking compound.

2. Remove fi ve 3x6mm fl athead screws one at a time

from the main gear and re-install them using medium

thread-locking compound. Re-install the tail belt pulley

on the one-way bearing sleave, ensuring the hole in the

pulley aligns with the holes in the sleave.

3. Slide the main gear assembly through the side of the

frame.

4. Place the tail belt around the upper gear as shown.

5. Slide the rotor head assembly down through both

bearing blocks and the main gear assembly.

6. Secure the main gear to the main shaft using a

4x20mm bolt and lock nut. Do not use thread-

locking compound on the bolt and lock nut.

7. Attach the anti-rotation bracket to the back of the

upper bearing block using two

M3x6mm button head screws

and medium thread-locking

compound. Ensure the antirotation pin is facing the rear

of the frame and is inserted in

the bracket before securing the

bracket to the bearing block.

8. Rotate the rotor head to ensure

it rotates freely.

1. Attach your chosen motor to the motor

mount using four 3x8mm screws and

medium thread-locking compound. The

motor leads should face toward the front

of the aircraft when installed.

2. Attach the pinion gear to the motor shaft

using two 4x4mm setscrews and high

strength thread-locking compound.

3. Prepare the motor leads for connecting

to the speed control. If using the

recommended speed control, solder the

large bullet connectors to the motor leads.

4. Attach the motor mount assembly

between the frame sides using

M3x10mm screws, machined frame

doublers and thread-locking compound.

Step F5

Step F6

Page 9

EN

9

1. If using the recommended speed control, attach the

speed control mount, included with the speed control,

to the bottom side of the battery plate. Secure a hook

and loop strap between the battery plate and the

speed control mount, as shown.

2. Clip the speed control in the speed control mount.

3. Connect the motor leads to the speed control.

4. Attach the battery mounting plate between the frame

sides using six 3x10mm screws and medium threadlocking compound. Place a second hook and loop

strap under the plate. The straps should exit through

the gaps in the frame sides.

Hook and

loop straps

Hook and

loop strap

Step F7

Page 10

EN

20mm

16mm

10

Prepare three cyclic servos as follows:

1. Center the servos using either your receiver or a

servo tester.

2. Attach the servo arm in the position shown,

perpendicular to the servo case, using the screw

provided with the servo and medium thread-locking

compound.

3. Attach the linkage ball to the outer servo arm

location using an M2 nut.

4. Attach the servos to the bearing blocks, in the

positions shown using 3x10mm button head screws

and medium thread-locking compound.

5. Press the bottom end of the servo linkages on the

servo arm linkage balls.

Prepare the tail servo as follows:

1. Center the servo using either your receiver or a

servo tester.

2. Attach the servo arm in the position shown,

perpendicular to the servo case, using the screw

provided with the servo and medium thread-locking

compound.

3. Attach the linkage ball to the middle servo arm

location, using an M2 nut.

4. Attach the tail servo mounts to the servo using

M3x8mm button head screws and thread-locking

compound. Do not fully tighten the servo mount

screws.

5. Attach the tail servo assembly to the inside of the

right frame side as shown, using four 3x10mm

screws, machined washers and medium threadlocking compound.

6. Fully tighten the servo mount screws.

Rotor head removed for clarity

Step F8

Step F9

Page 11

EN

11

Tail Assembly (T)

1. Slide two front tailboom mounts over the front of the

tail boom. The Blade

®

logo is towards the front of

the tailboom.

2. Attach the mounts to the tailboom using one

M3x6mm button head screw per mount and

medium thread-locking compound, into the holes in

the top of the tailboom.

3. Loosely insert a 3x12mm screw and locknut into the

bottom of each mount. Do not use thread-locking

compound. Do not fully tighten.

4. Insert the free end of the tail belt through the

tailboom.

5. Feed the belt through the boom as you slide the

boom mounts between the frame sides.

6. Attach the boom mounts to the frame sides using

3x10mm screws, machined washers and medium

thread-locking compund.

7. Fully tighten the 3x12mm boom mount screws and

locknuts installed in Step 3 above.

8. When the boom is fully seated in place, the tail

belt should extend from the back of the boom as

shown. Rotate the rear loop of the belt 90° counterclockwise from horizontal, when viewed from the

rear of the aircraft. Ensure the belt is not twisted

inside the boom.

Step T1

Viewed from the rear of the helicopter

Page 12

EN

12

Tail Assembly (T)

1. Slide the tail pushrod guide onto the tailboom. The

guide should be located approximately in the center

of the tailboom.

1. Remove the 3x16mm socket head cap screw and

linkage ball from the tail pitch lever assembly

and re-install them using medium thread-locking

compound. Ensure the thread-locking compound

does not contact the lever assembly bearings.

2. Attach the tail rotor pitch lever assembly to the

right side tail plate using two 2.5x8mm button head

screws and medium thread-locking compound.

3. Attach the right tail plate assembly to the tailboom

mounts using four 3x10mm socket head capscrews,

machined washers and medium thread-locking

compound. Do not fully tighten.

4. Attach the left side tail plate/fi n to the tailboom

mounts using four 3x10mm socket head capscrews,

machined washers and medium thread-locking

compound. Do not fully tighten.

5. Insert the tail belt guide bearing between the tail

plates and attach with two 2.5x8mm socket head

capscrews and medium thread-locking compound.

6. Insert the rear spacer post between the tail

plates and attach with two 3x10mm socket head

capscrews, machined washers and medium threadlocking compound.

2. Slide two rear tailboom mounts over the tailboom.

3. Attach the mounts using two 3x6mm button head

screws per mount and medium thread-locking

compound, into the holes on either side of the tailboom.

4. Loosely insert one 3x10mm socket head capscrew

with medium thread-locking compound in the top of

each mount as shown.

Step T2

Step T3

Page 13

EN

13

Tail Assembly (T)

1. Remove the tail grip retention screws and linkage

balls and re-install them using medium threadlocking compound. Ensure the thread-locking

compound does not contact the tail grip bearings.

2. Insert the tail shaft into the tail rotor hub assembly.

3. Lock the tail shaft into place with a M4x4mm

setscrew and high strength thread-locking

compound. Ensure the setscrew contacts the fl at

area machined into the tail shaft.

4. Remove the linkage ball from the pitch slider assembly

and re-install using medium thread-locking compound.

5. Slide the pitch slider assembly over the tail shaft and

snap the ball links onto the tail grip linkage balls.

1. Remove four 2x16mm cap head screws from the

tail pulley one at a time and re-install using medium

thread-locking compound.

2. Insert the tail pulley into the loop created by the tail

belt, as shown.

3. Slide the tail shaft in from the right side, through the

tail pulley and into the left side tail plate bearing. As

you slide the tail shaft in, insert the linkage ball of

the tail pitch slider into the nylon bushing of the tail

rotor bell crank.

4. The tail shaft should extend out of the left side plate

bearing by approximately 1mm.

5. Secure the tail pulley to the tail shaft using two

4x4mm setscrews and medium thread-locking

compound. Ensure the setscrews are in contact with

the fl at areas machined into the tail shaft.

Check the rotation of the tail pulley. The tail pulley

should rotate as shown when the main rotor is rotated

clockwise, when viewed from above. If the tail gear

does not rotate as shown, remove the tail shaft and tail

pulley, rotate the tail belt loop 180° and re-assemble.

Sight down the tail boom and ensure the tail belt is

not twisted more than 90° inside the tail boom.

Step T4

Step T5

Page 14

EN

14

Tail Assembly (T)

1. Check the belt tension just behind the main gear at

the rear of the side plate opening. Push inward on

the belt from the side with moderate pressure. The

belt should not defl ect more 4mm.

2. Set the tail belt tension by applying pressure against

both tail side plates towards the rear of the aircraft.

Fully tighten the eight 3x10mm screws holding the

tail side plates to the rear boom mounts.

1. Insert the metal sleeve of the tail pushrod into the

pushrod guide.

2. Secure the pushrod guide with a socket head cap

screw.

3. Snap the front tail pushrod linkage onto the tail

servo arm.

4. Snap the rear pushrod linkage onto the tail rotor

pitch lever.

Step T6

Step T7

Page 15

EN

15

Flight Controller Mounting

Battery Installation

1. Route the servo and throttle wires to the fl ight

controller mounting area of the frame. Small holes are

provided in the frame side plates to allow for securing

the servo wires with small plastic cable ties. When

routing the wires, be very careful to avoid any moving

parts and sharp edges of the carbon fi ber plates.

2. Attach the fl ight controller mounting plate to the top

of the front tail boom mounts using four M3x6mm

fl athead screws and thread-locking compound.

3. Secure your chosen fl ybarless fl ight controller to

the mounting plate per the mounting instructions

included with your fl ight controller.

4. Connect the servo and throttle wires to the fl ight

controller.

1. Apply the loop side of adhesive backed hook and loop

material to the fl ight battery.

2. Apply the hook side to the battery plate.

3. Attach the fl ight battery to the battery plate.

4. Secure the battery with the hook and loop straps.

CAUTION: Always disconnect the Li-Po

battery from the electronic speed control

when not fl ying to avoid over-discharging the battery.

Batteries discharged to a voltage lower than the

lowest approved voltage may become damaged,

resulting in loss of performance and potential fi re

when batteries are charged.

Loop

material

Hook

material

Hook and

loop straps

Helicopter Setup

The following are optimal settings for the Blade Fusion 480, obtained through extensive fl ight testing. Refer to your fl ybarless fl ight controller and transmitter manuals for

proper setup.

Head Speed

Flight Mode 11t Pinion

Optional 12t Pinion

(only recommended for 65C batteries)

Normal 2100 2100

Stunt 1 2350 2550

Stunt 2 2550 2750

Collective Pitch Range

Normal, -12 degrees to +12 degrees

(adjust to suit your preferences)

Page 16

EN

Throttle Hold

Control Tests

16

Main Rotor Alignment

Activating and using the Throttle Hold (TH HOLD) function in your chosen

transmitter is highly recommended. Throttle hold only cuts power to the motor on

an electric helicopter. Pitch and direction control are maintained.

WARNING: If your transmitter has throttle hold, always engage throttle

hold before approaching the helicopter for any reason.

The blades will spin if TH HOLD is OFF. For safety, turn TH HOLD ON any time you

need to touch the helicopter or check the direction controls.

Additionally, turn TH HOLD ON to cut power to the motor if the helicopter is out of

control, in danger of crashing, or both.

With the servos centered and arms level, the

swashplate should be level and the 0 degree collective

indication marks on top of the blade grips and

headblock should align, as shown. Adjust the lengths

of the blade grip linkages and servo linkages until

everything is aligned properly.

Cyclic Sensor Test

From the back of the helicopter:

1. Tilt the helicopter forward. The swashplate should tilt backward.

2. Tilt the helicopter backward. The swashplate should tilt forward.

3. Roll the helicopter left. The swashplate should roll right.

4. Roll the helicopter right. The swashplate should roll left.

5. If the swashplate does not move in the correct direction, you will need to

reverse the cyclic sensor direction or sensor orientation setting. Refer to the

fl ight controller manual for information.

CAUTION: You must complete the Rudder and Cyclic tests prior to attempting fl ight. Failure to ensure the sensor directions are not reversed can cause the

helicopter to crash, resulting in property damage and injury.

Rudder

1. Power on the transmitter.

2. Turn TH HOLD ON and set the fl ight mode to NORMAL.

3. Connect the helicopter battery to the ESC and allow the fl ight controller to

fully initialize.

4. Rudder channel test:

Move the rudder stick to the right. The tail pitch slider should move towards

the tail boom.

Move the rudder stick to the left. The tail pitch slider should move away from

the tail boom.

If the slider does not move in the desired direction, refer to your fl ight

controller manual for instructions to correct the issue.

5. Flight controller sensor test:

Release the rudder control. Manually turn the helicopter counterclockwise when

viewed from above. The tail pitch slider should move towards the tail boom.

Manually turn the helicopter nose clockwise. The tail pitch slider should move

away from the tail boom.

If the slider does not react in the proper direction, refer to your fl ight controller

manual for information on reversing the tail sensor direction.

Page 17

EN

Cyclic and Collective Control Test

Turn TH HOLD ON when conducting the control tests. Increasing Collective Pitch while TH HOLD is off will cause the motor to engage and the rotors to spin.

Elevator, Forward and Back Cyclic

Aileron, Left and Right Cyclic

Rear ViewRear View

Collective Pitch

Left Side View Left Side View

Left Side View Left Side View

17

Motor Direction Test

Place the helicopter outdoors on a clean, fl at and level surface (concrete or asphalt) free of obstructions. Always stay clear of rotating parts.

1. Power on the transmitter. Make sure TH HOLD is ON and the fl ight mode

switch is set to NORMAL.

WARNING: The motor and rotors will spin when throttle is increased

and THHOLD is OFF.

2. Lower the throttle completely.

3. Connect the Li-Po battery to the ESC.

4. Turn TH HOLD OFF. Slowly increase the throttle until the drive train begins

to turn. The main rotor should spin clockwise when viewing the helicopter

from the top. The tail rotor should spin counterclockwise when viewing the

helicopter from the right side.

NOTICE: If the drive train does not turn with the motor or the main rotor

spins counterclockwise, turn TH HOLD ON. Disconnect the battery from the

helicopter and reverse any two motor wire connections to the ESC and repeat

the motor control test.

Thoroughly review your chosen fl ight control system manual to ensure the system is confi gured properly, per the manufacturer’s recommendations.

WARNING: Disconnect the motor from the electronic speed control or ensure the transmitter throttle hold function is properly confi gured and ON prior to

performing the cyclic and collective control tests. Failure to do so will allow the motor to start unexpectedly and may cause serious property damage or

bodily injury.

Page 18

EN

18

Main Rotor Blade Installation

Canopy Installation

Install the main rotor blades in the orientation shown

using 4x30mm bolts, plastic blade shims and locknuts.

Do not apply thread lock compound to the bolt and

lock nut.

Do not over-tighten.

• The rotor blades should be tight enough to hold their

position if you hold the helicopter sideways and

remain in position even if the helicopter is shaken

abruptly. The exact tension is not as important as

ensuring both blades are at the same tension.

Tail Rotor Blade Installation

Install the tail blades in the orientation shown using

3x12mm bolts and locknuts. Do not apply thread lock

compound to the bolt and lock nut.

1. Install the four canopy grommets into the canopy

from the inside.

2. Install the canopy by sliding the canopy grommets

over the corresponding canopy posts as shown.

Page 19

EN

Flight Guidelines and Warnings

• Always keep aircraft in sight and under control.

• Always keep people and pets at least 45 feet (13 meters) away when the

battery is connected.

• Keep children out of the vicinity of this product at all times.

• Always turn on throttle hold prior to a rotor strike.

• Always use fully charged batteries.

• Always keep transmitter powered on while the aircraft is powered on.

• Always remove batteries before disassembly.

• Always keep moving parts clean.

• Always keep parts dry.

• Always let parts cool after use before touching.

• Always remove batteries after use.

• Always have a fi rst aid kit with you.

• Always have an appropriate fi re extinguisher with you.

• Never operate aircraft with damaged wiring.

• Never touch moving parts.

Post-Flight Inspection and Maintenance

Ball Links

Make sure the plastic ball link holds the control ball, but is not tight (binding) on the ball. When a link is too loose on the ball, it can separate

from the ball during fl ight and cause a crash. Replace worn ball links before they fail.

Cleaning Make sure the battery is not connected before cleaning. Remove dust and debris with a soft brush or a dry lint-free cloth.

Bearings Replace bearings when they become notchy (sticky in places when turning) or draggy.

Wiring Make sure wiring does not block moving parts. Replace damaged wiring and loose connectors.

Fasteners

Make sure there are no loose screws, other fasteners or connectors. Do not over tighten metal screws in plastic parts. Tighten screws so

parts are mated together, then turn screw only 1/8th of a turn more.

Rotors

Make sure there is no damage to rotor blades and other parts which move at high speed. Damage to these parts includes cracks, burrs, chips

or scratches. Replace damaged parts before fl ying.

Flight Controller

Make sure the fl ight controller is securely attached to the frame. Replace the double-sided tape when necessary. The helicopter will crash if

the fl ight controller separates from the helicopter frame.

Gear

Make sure the gears are all in good condition. Watch for chipped teeth or excessive wear. Dust around gears is an indication of excess wear.

Replace damaged gears before fl ying.

19

CAUTION: The Blade Fusion 480 is intended for pilots with experience

fl ying aerobatic, collective pitch helicopters. The Blade Fusion 480 is more

responsive than other Blade helicopters. If you are not an experienced 3D or

collective pitch helicopter pilot, do not attempt to fl y this product.

NOTICE: To minimize damage, always activate throttle hold prior to or during

a crash.

WARNING: Only use Blade Fusion 480 approved carbon fi ber main

blades. Do not use wooden main blades with the Blade Fusion 480.

Using wooden main blades may cause injury or property damage.

Consult local laws and ordinances before choosing a location to fl y your

aircraft.

Select a large, open area away from people and objects. Your fi rst fl ights should

be outdoors in low-wind conditions. Always stay at least 45 feet (13 meters)

away from the helicopter when it is fl ying.

Do not attempt to fl y the Blade Fusion 480 indoors.

Flying Your Fusion 480

Blade Tracking

WARNING: Always maintain a safe distance of at least 13 meters

(45feet) when checking the main rotor blade tracking.

WARNING: Always wear protective safety glasses when checking the

main rotor blade tracking.

To check the blade tracking:

1. Put the helicopter in a hover at an altitude near eye height.

2. Watch the movement at the blade tips. Both blades should travel in the same plane.

3. If one blade tip appears to be higher than the other, land the helicopter,

disconnect the fl ight battery and adjust the blade linkages.

4. Repeat Steps 1 through 3 until both blades are moving in the same plane.

WARNING: Disconnect and remove the fl ight battery prior to performing any troubleshooting or maintenance. Failure to do so may cause serious injury if

the motor starts unexpetedly or if the battery or ESC connections are shorted.

Page 20

EN

Troubleshooting Guide

Problem Possible Cause Solution

Helicopter power is lacking

Flight battery has low voltage Fully charge the fl ight battery

Flight battery is old or damaged Replace the fl ight battery

Flight battery cells are unbalanced Fully charge the fl ight battery, allowing the charger time to balance the cells

Helicopter will not lift off

Transmitter settings are not correct Check throttle and pitch curve settings and pitch control direction

Flight battery has low voltage Fully charge the fl ight battery

Main rotor blades are installed backwards Install the main rotor blades with the thicker side as the leading edge

The helicopter tail spins

out of control

Rudder control and/or sensor direction reversed Make sure the rudder control and the rudder sensor are operating in the correct direction

Tail servo is damaged Check the rudder servo for damage and replace if necessary

Tail drive gears are damaged Replace damaged gears.

Inadequate control arm throw Check the rudder control arm for adequate travel and adjust if necessary

The helicopter wobbles in fl ight

Cyclic gain is too high Decrease gain on the fl ight controller

Headspeed is too low

Increase the helicopter's head speed via your transmitter settings

and/or using a freshly charged fl ight pack

What this Warranty Covers

Horizon Hobby, LLC, (Horizon) warrants to the original purchaser that the product

purchased (the “Product”) will be free from defects in materials and workmanship at

the date of purchase.

What is Not Covered

This warranty is not transferable and does not cover (i) cosmetic damage, (ii)

damage due to acts of God, accident, misuse, abuse, negligence, commercial use, or

due to improper use, installation, operation or maintenance, (iii) modifi cation of or to

any part of the Product, (iv) attempted service by anyone other than a Horizon Hobby

authorized service center, (v) Product not purchased from an authorized Horizon

dealer, (vi) Product not compliant with applicable technical regulations, or (vii) use

that violates any applicable laws, rules, or regulations.

OTHER THAN THE EXPRESS WARRANTY ABOVE, HORIZON MAKES NO OTHER

WARRANTY OR REPRESENTATION, AND HEREBY DISCLAIMS ANY AND ALL IMPLIED

WARRANTIES, INCLUDING, WITHOUT LIMITATION, THE IMPLIED WARRANTIES

OF NON-INFRINGEMENT, MERCHANTABILITY AND FITNESS FOR A PARTICULAR

PURPOSE. THE PURCHASER ACKNOWLEDGES THAT THEY ALONE HAVE

DETERMINED THAT THE PRODUCT WILL SUITABLY MEET THE REQUIREMENTS OF

THE PURCHASER’S INTENDED USE.

Purchaser’s Remedy

Horizon’s sole obligation and purchaser’s sole and exclusive remedy shall be that

Horizon will, at its option, either (i) service, or (ii) replace, any Product determined by

Horizon to be defective. Horizon reserves the right to inspect any and all Product(s)

involved in a warranty claim. Service or replacement decisions are at the sole

discretion of Horizon. Proof of purchase is required for all warranty claims. SERVICE

OR REPLACEMENT AS PROVIDED UNDER THIS WARRANTY IS THE PURCHASER’S

SOLE AND EXCLUSIVE REMEDY.

Limitation of Liability

HORIZON SHALL NOT BE LIABLE FOR SPECIAL, INDIRECT, INCIDENTAL OR

CONSEQUENTIAL DAMAGES, LOSS OF PROFITS OR PRODUCTION OR COMMERCIAL

LOSS IN ANY WAY, REGARDLESS OF WHETHER SUCH CLAIM IS BASED IN

CONTRACT, WARRANTY, TORT, NEGLIGENCE, STRICT LIABILITY OR ANY OTHER

THEORY OF LIABILITY, EVEN IF HORIZON HAS BEEN ADVISED OF THE POSSIBILITY

OF SUCH DAMAGES. Further, in no event shall the liability of Horizon exceed the

individual price of the Product on which liability is asserted. As Horizon has no

control over use, setup, fi nal assembly, modifi cation or misuse, no liability shall be

assumed nor accepted for any resulting damage or injury. By the act of use, setup or

assembly, the user accepts all resulting liability. If you as the purchaser or user are

not prepared to accept the liability associated with the use of the Product, purchaser

is advised to return the Product immediately in new and unused condition to the

place of purchase.

Law

These terms are governed by Illinois law (without regard to confl ict of law principals).

This warranty gives you specifi c legal rights, and you may also have other rights

which vary from state to state. Horizon reserves the right to change or modify this

warranty at any time without notice.

WARRANTY SERVICES

Questions, Assistance, and Services

Your local hobby store and/or place of purchase cannot provide warranty support

or service. Once assembly, setup or use of the Product has been started, you

must contact your local distributor or Horizon directly. This will enable Horizon

to better answer your questions and service you in the event that you may need

any assistance. For questions or assistance, please visit our website at www.

horizonhobby.com, submit a Product Support Inquiry, or call the toll free telephone

number referenced in the Warranty and Service Contact Information section to speak

with a Product Support representative.

Inspection or Services

If this Product needs to be inspected or serviced and is compliant in the country

you live and use the Product in, please use the Horizon Online Service Request

submission process found on our website or call Horizon to obtain a Return

Merchandise Authorization (RMA) number. Pack the Product securely using a

shipping carton. Please note that original boxes may be included, but are not

designed to withstand the rigors of shipping without additional protection. Ship via a

carrier that provides tracking and insurance for lost or damaged parcels, as Horizon

is not responsible for merchandise until it arrives and is accepted at our facility.

An Online Service Request is available at http://www.horizonhobby.com/content/

service-center_render-service-center. If you do not have internet access, please

contact Horizon Product Support to obtain a RMA number along with instructions

for submitting your product for service. When calling Horizon, you will be asked to

provide your complete name, street address, email address and phone number

where you can be reached during business hours. When sending product into

Horizon, please include your RMA number, a list of the included items, and a brief

summary of the problem. A copy of your original sales receipt must be included for

warranty consideration. Be sure your name, address, and RMA number are clearly

written on the outside of the shipping carton.

NOTICE: Do not ship LiPo batteries to Horizon. If you have any issue with a LiPo

battery, please contact the appropriate Horizon Product Support offi ce.

Warranty Requirements

For Warranty consideration, you must include your original sales receipt verifying the

proof-of-purchase date. Provided warranty conditions have been met, your Product

will be serviced or replaced free of charge. Service or replacement decisions are at

the sole discretion of Horizon.

Limited Warranty

20

Page 21

EN

Warranty and Service Contact Information

Non-Warranty Service

Should your service not be covered by warranty, service will be completed and

payment will be required without notifi cation or estimate of the expense unless the

expense exceeds 50% of the retail purchase cost. By submitting the item for service

you are agreeing to payment of the service without notifi cation. Service estimates

are available upon request. You must include this request with your item submitted

for service. Non-warranty service estimates will be billed a minimum of ½ hour of

labor. In addition you will be billed for return freight. Horizon accepts money orders

and cashier’s checks, as well as Visa, MasterCard, American Express, and Discover

cards. By submitting any item to Horizon for service, you are agreeing to Horizon’s

Terms and Conditions found on our website http://www.horizonhobby.com/content/

service-center_render-service-center.

ATTENTION: Horizon service is limited to Product compliant in the

country of use and ownership. If received, a non-compliant Product will

not be serviced. Further, the sender will be responsible for arranging

return shipment of the un-serviced Product, through a carrier of the

sender’s choice and at the sender’s expense. Horizon will hold noncompliant Product for a period of 60 days from notifi cation, after which it

will be discarded.

10/15

Country of Purchase Horizon Hobby Contact Information Address

United States of America

Horizon Service Center

(Repairs and Repair Requests)

servicecenter.horizonhobby.com/RequestForm/

1608 Interstate Drive

Champaign, IL 61822

Horizon Product Support

(Product Technical Assistance)

productsupport@horizonhobby.com

877-504-0233

Sales

websales@horizonhobby.com

800-338-4639

European Union

Horizon Technischer Service service@horizonhobby.eu

Hanskampring 9

D 22885 Barsbüttel, Germany

Sales: Horizon Hobby GmbH +49 (0) 4121 2655 100

21

Page 22

Exploded View / Explosionszeichnung / Vue éclatée / Vista esplosa

17

9

12

15

16

47

47

46

11

8

10

7

1

2

2

3

3

1

5

5

6

7

8484

Page 23

Exploded View / Explosionszeichnung / Vue éclatée / Vista esplosa

13

22

25

14

29

18

18

27

27

18

28

49

26

24

30

34

35

32

36

37

38

41

43

45

44

44

42

39

39

33

31

40

24

24

24

21

21

19

20

48

23

8585

Page 24

Parts List / Ersatzteile / Pièces de rechange / Pezzi di ricambio

8686

# Part # English Deutsch Français Italiano

1

BLH4901 480mm CF Main Rotor Blades (2) 480mm CF Hauptrotorblätter (2) Pales du rotor principal 480mm CF (2) Pale rotore principale 480 mm CF (2)

2

BLH4902 Main Rotor Grip Hauptrotorhalter Poignée du rotor principal Fermo rotore principale

3

BLH4903 Grip Arm Halterarm Poignée Braccio fermo

4

BLH4904 Spindle Spindel Axe Fuso

5

BLH4905 Dampener Set Stoßdämpfersatz Ensemble d’amortisseur Set ammortizzatori

6

BLH4906 Aluminum Head Block Aluminium-Kopfblock Bloc de tête en aluminium Blocco di testa in alluminio

7

BLH4907 Follower Arm Folgerarm Bras suiveur Braccio elevatore

8

BLH4908 Rotor Head Linkage Rotorkopf-Verbindung Tringlerie de tête du rotor Giunzione di testa del rotore

9

BLH4909 Swashplate Assembly Taumelscheibenbaugruppe Ensemble de plateau cyclique Gruppo piatto ciclico

10

BLH4910 Servo Linkage Set Servo-Verbindungssatz Ensemble de tringlerie de servo Set giunzione servo

11

BLH4911 Servo Arm Set Servoarm-Satz Ensemble de bras de servo Set braccio servo

12

BLH4912 Main shaft Hauptwelle Arbre principal Albero principale

13

BLH4913 Upper Servo Mount Obere Servohalterung Support de servo supérieur Supporto superiore servo

14

BLH4914 Lower Servo Mount Untere Servohalterung Support de servo inférieur Supporto inferiore servo

15

BLH4915 Tail Drive Pulley, 75T Heckriemenscheibe, 75T

Poulie d’entraînement

d’empennage, 75T

Puleggia azionamento coda, 75T

16

BLH4916 Main Gear, 112T Hauptgetriebe, 112T Train principal, 112T Ingranaggio principale, 112T

17

BLH4917 Autorotation Hub Autorotationsnabe Moyeu d’autorotation Mozzo rotazione automatica

18

BLH4919 Motor Mount Motorhalterung Support moteur Supporto motore

19

BLH4921 Gyro Tray Kreiselhalterung Plateau de Gyro Piatto giroscopio

20

BLH4922 Tailboom Mount Heckauslegerhalterung Support de poutre de queue Supporto tubo di coda

21

BLH4923 Main Frame Hauptrahmen Châssis principal Telaio principale

22

BLH4924 Swashplate Guide Taumelscheibenführung Guide de plateau cyclique Guida piatto ciclico

23

BLH4926 Battery Tray Akkuhalterung Support de batterie Vassoio portabatteria

24

BLH4927 Body Mounts (4) Gehäusehalterung (4) Supports de carrosserie(4) Supporti scocca (4)

25

BLH4928 Tail Belt Front Heckriemen vorn Courroie d’empennageavant Parte anteriore cinghia di coda

26

BLH4929 Frame Spacer (2) Rahmenabstandshalter (2) Entretoise de châssis (2) Distanziatore telaio (2)

BLH4930 Frame Screw Set (10) Rahmen-Schraubensatz (10) Jeu de vis du châssis (10) Set viti telaio (10)

27

BLH4931 Skid Set (2) Kufensatz (2) Ensemble de patin (2) Set staffa di arresto (2)

28

BLH4932 Skid Mount (2) Kufenhalterung (2) Support de patin (2) Supporto staffa di arresto (2)

29

BLH4933 Tail Servo Mounts Heckservohalterungen Support de servo d’empennage Supporti servo coda

30

BLH4934 Tailboom Heckausleger Poutre de queue Tubo di coda

31

BLH4935 Tailrotor Pushrod Heckrotorgestänge Barre de liaison du rotor d’empennage Asta di comando del rotore di coda

32

BLH4936 T/RPushrod Guide Heckrotorgestängeführung

Guide de la barre de liaison du rotor

d’empennage

Guida asta di comando T/R

33

BLH4937 Tail Case Mount Heckgehäusehalterung Support du boîtier de queue Supporto contenitore coda

34

BLH4938 Tail Fin Heckfl osse Aileron caudal Aletta coda

35

BLH4939 Tail Case Heckgehäuse Boîtier de queue Contenitore coda

36

BLH4940 Tail Belt Guide Heckriemenführung Guide de courroie d’empennage Guida cinghia di coda

37

BLH4941 Tail Case Standoff Heckgehäuseabstand Entretoise du boîtier de queue Staffa contenitore coda

38

BLH4942 Tail Shaft Heckwelle Arbre de queue Albero coda

39

BLH4943 Tail Shaft Bearing Heckwellenlager Roulement d’arbre de queue Cuscinetto albero coda

40

BLH4944 Bell Crank Mount Winkelhebelhalterung Support de levier coudé Supporto biella a campana

41

BLH4945 Tail Bell Crank Heckwinkelhebel Levier coudé d’empennage Biella a campana coda

42

BLH4946 Tail Pitch Slider Heckschiebehülse Curseur d’inclinaison arrière Cursore beccheggio coda

43

BLH4947 Tail Rotor Hub Heckrotornabe Moyeu du rotor d’empennage Mozzo rotore di coda

44

BLH4948 Tail Rotor Grip Heckrotorhalter Poignée du rotor d’empennage Fermo rotore di coda

45

BLH4949 CF Tail Blades CF Heckblätter Pales d’empennage CF Pale coda CF

46

BLH4951 Fiberglass Canopy Glasfaser-Kanzel Verrière en fi bre de verre Capottina in vetroresina

47

BLH4952 Canopy Grommets Kanzelhülsen Passe-fi ls de verrière Guarnizioni capottina

48

BLH4954 Tail Pulley Umlenktrommel Poulie d’empennage Puleggia coda

49

BLH4958 11t Pinon 11T Ritzel Pignon 11t Pignone 11t

BLH4961 Tail Belt Heckriemen Courroie d’empennage Cinghia di trasmissione coda

Page 25

Recommended Components / Empfohlene Komponenten / Composants recommandés / Componenti raccomandati

Optional Parts / Optionale Bauteile / Pièces optionnelles / Pezzi opzionali

8787

Part # English Deutsch Français Italiano

BLH4953 Brushless Motor 4320-1300kV

Bürstenloser Motor 4320-1300kV

Moteur sans balais 4320-1300kV Motore brushless 4320-1300 kV

CSE010009700 Talon 90 Heli ESC 010-0097-00

Talon 90 HubschrauberGeschwindigkeitsregler 010-0097-00

Variateur ESC Talon 90 Heli 010-0097-00

Talon 90 elicottero ESC 010-0097-00

EFLB44006S30

4400mAh 6S22.2V 30C LiPo, 10AWG EC5

4400mA 6S 22,2V 30C LiPo, 10AWG EC5

4400mAh 6S 22,2V 30C Li-Po,

10AWG EC5

4400 mAh 6S 22,2V 30C LiPo, 10AWG

EC5 (EFLB44006S30)

SPMAR7210BX AR7210BX DSMX FBL Control Sys

AR7210BX DSMX FBL-Steuersystem

Système de commande AR7210BX

DSMX FBL

Sistema di controllo AR7210BX

DSMX FBL

SPMSH6050 H6050 H-T M-S Heli Cyclic Servo

H6050 H-T M-S Hubschrauber-Steuerservo

Servo cyclique H6050 H-T M-S Heli Servo ciclico H6050 H-T M-S elicottero

SPMSH6060 H6060 M-T U-S Heli Tail Servo

H6060 M-T M-S Hubschrauber-Heckservo

Servo d’empennage H6060 M-T U-S Heli

Servo coda H6060 M-T U-S elicottero

Part # English Deutsch Français Italiano

KXSB40006S40 F-Tek 4000mAh 6S 40C, EC5, LED F-Tek 4000mA 6S 40C, EC5, LED F-Tek 4000mAh 6S 40C, EC5, LED F-Tek 4000mAh 6S 40C, EC5, LED

BLH4918 12t Pinon: Fusion 480 12T Ritzel: Fusion480 Pignon 12t: Fusion 480 Pignone 12t: Fusion 480

BLH4920 BLS Motor: 4020-1350Kv Bürstenloser Motor: 4020-1350kV Moteur sans balais: 4020-1350Kv Motore brushless: 4020-1350Kv

BLH4962 11t Pinion 5mm Shaft: Fusion 480 11T Ritzel 5mm Welle: Fusion480

Arbre de 5mm du Pignon 11t:

Fusion 480

Pignone 11t Albero 5 mm: Fusion 480

SPMSH6050 H6050 H-T M-S Heli Cyclic Servo

H6050 H-T M-S Hubschrauber-Steuerservo

Servo cyclique H6050 H-T M-S Heli Servo ciclico H6050 H-T M-S elicottero

SPMSH6060 H6060 M-T U-S Heli Tail Servo

H6060 M-T M-S Hubschrauber-Heckservo

Servo d’empennage H6060 M-T

U-S Heli

Servo coda H6060 M-T U-S elicottero

SPMSH6350 H6350 U-T / H-S Heli Cyclic Ser

H6350 U-T/H-S Hubschrauber-Steuerservo

Servo cyclique H6350 U-T / H-S Heli

Servo ciclico H6350 U-T / H-S elicottero

SPMSH6360 H6360 M-T / U-S Heli Tail Servo

H6060 M-T/U-S Hubschrauber-Heckservo

Servo d’empennage H6360 M-T /

U-S Heli

Servo coda H6360 M-T U-S elicottero

Page 26

©2018 Horizon Hobby, LLC.

Blade, the Blade logo, EC5, DSM, DSM2, DSMX and the Horizon Hobby logo

are trademarks or registered trademarks of Horizon Hobby, LLC.

The Spektrum trademark is used with permission of Bachmann Industries, Inc.

Created 5/18 50111 BLH4925

Loading...

Loading...