Page 1

®

Instruction Manual

Bedienungsanleitung

Manuel d’utilisation

Manuale di Istruzioni

®

Page 2

NOTICE

All instructions, warranties and other collateral documents are subject to change at the sole discretion of Horizon Hobby, Inc. For up-to-date product literature, visit

horizonhobby.com and click on the support tab for this product.

Meaning of Special Language

The following terms are used throughout the product literature to indicate various levels of potential harm when operating this product:

The purpose of safety symbols is to atttract your attention to possible dangers. The safety symbols, and their explanations, deserve your careful attention and

understanding. The safety warnings do not by themselves eliminate any danger. The instructions or warnings they give are not substitutes for proper accident

prevention measures.

NOTICE: Procedures, which if not properly followed, create a possibility of physical property damage AND a little or no possibility of injury.

CAUTION: Procedures, which if not properly followed, create the probability of physical property damage AND a possibility of serious injury.

WARNING: Procedures, which if not properly followed, create the probability of property damage, collateral damage, serious injury or death OR create a high

probability of superfi cial injury.

Safety Alert: Indicates warning or caution. Attention is required in order to avoid serious personal injury.

WARNING: Read the ENTIRE instruction manual to become familiar with the features of the product before operating. Failure to operate the product correctly

can result in damage to the product, personal property and cause serious injury.

This is a sophisticated hobby product for advanced helicopter pilots with previous experience in the operation of CCPM helicopters (Cyclic Collective Pitch Mixing

or Collective Pitch Helicopter) such as the Blade SR, Blade mCP X or Blade 300 X. It must be operated with caution and common sense and requires some basic

mechanical ability. Failure to operate this product in a safe and responsible manner could result in injury or damage to the product or other property. This product is not

intended for use by children without direct adult supervision. Do not attempt disassembly, use with incompatible components or augment product in any way without

the approval of Horizon Hobby, Inc. This manual contains instructions for safety, operation and maintenance. It is essential to read and follow all the instructions and

warnings in the manual, prior to assembly, setup or use, in order to operate correctly and avoid damage or serious injury.

Age Recommendation: For advanced fl iers ages 14 and above. This is not a toy.

General Safety Precautions and Warnings

This model is controlled by a radio signal subject to interference from many sources outside your control. Interference can cause momentary

loss of control.

• Always ensure you fully understand the controls on your transmitter and how they affect the movement of the helicopter.

• Always operate your model outdoors in large, open spaces away from full-size vehicles, traffi c and people to avoid collisions or injury

• Always carefully follow the manufacturers directions and warnings for any related equipment (i.e., chargers, rechargeable battery packs, etc.).

• Always keep the product, related chemicals, small parts and electrical components out of the reach of children.

• Always keep children out of the vicinity of this product at all times.

• Always store this product well out of the reach of children.

• Always keep hair secured above your shoulders so it cannot get caught in the blades.

• Always avoid water exposure to all equipment not specifi cally designed and protected for this purpose. Moisture causes damage to electronics.

• Never maintain and operate this product at night, in rain or in inclement weather.

• Always ensure all fasteners are secure before use.

• Always store product in a dry, temperate, secure location

• Do not touch the motor as it can become extremely hot during use.

• Do not fl y this helicopter indoors

• Always ensure failsafe is properly set before fl ying. Do not exclusively rely on the safety mechanisms built into your transmitter and receiver.

• Always ensure you understand the product and how to operate it.

• Only use Horizon-approved replacement parts and accessories for this product.

• Never place any portion of the model in your mouth as it could cause serious injury.

• Never operate your transmitter or helicopter with low transmitter batteries.

• Never connect the battery unless using or testing the product. Do not perform maintenance with the battery installed.

• Never operate this product if you are tired, ill, taking any medications that impair judgment or are under the infl uence of alcohol or drugs.

• Never spray glass cleaner or any other liquid on this product.

• Always keep hair and dangling or loose items well away from the blades when the battery is connected.

NOTICE: Modifi cation with non-Horizon-approved components may result in refusal of service by Horizon.

WARNING: This is a large model helicopter with carbon fi ber blades that spin at very high RPM. Always use extreme caution and common sense when

maintaining and operating this product. If you are unsure about ANY function or procedure described in this manual, DO NOT operate. Contact Horizon

Product Support for assistance.

WARNING: Always ensure you are operating the helicopter a safe distance, 45 feet (13 meters), away from yourself and others.

EN

2

Page 3

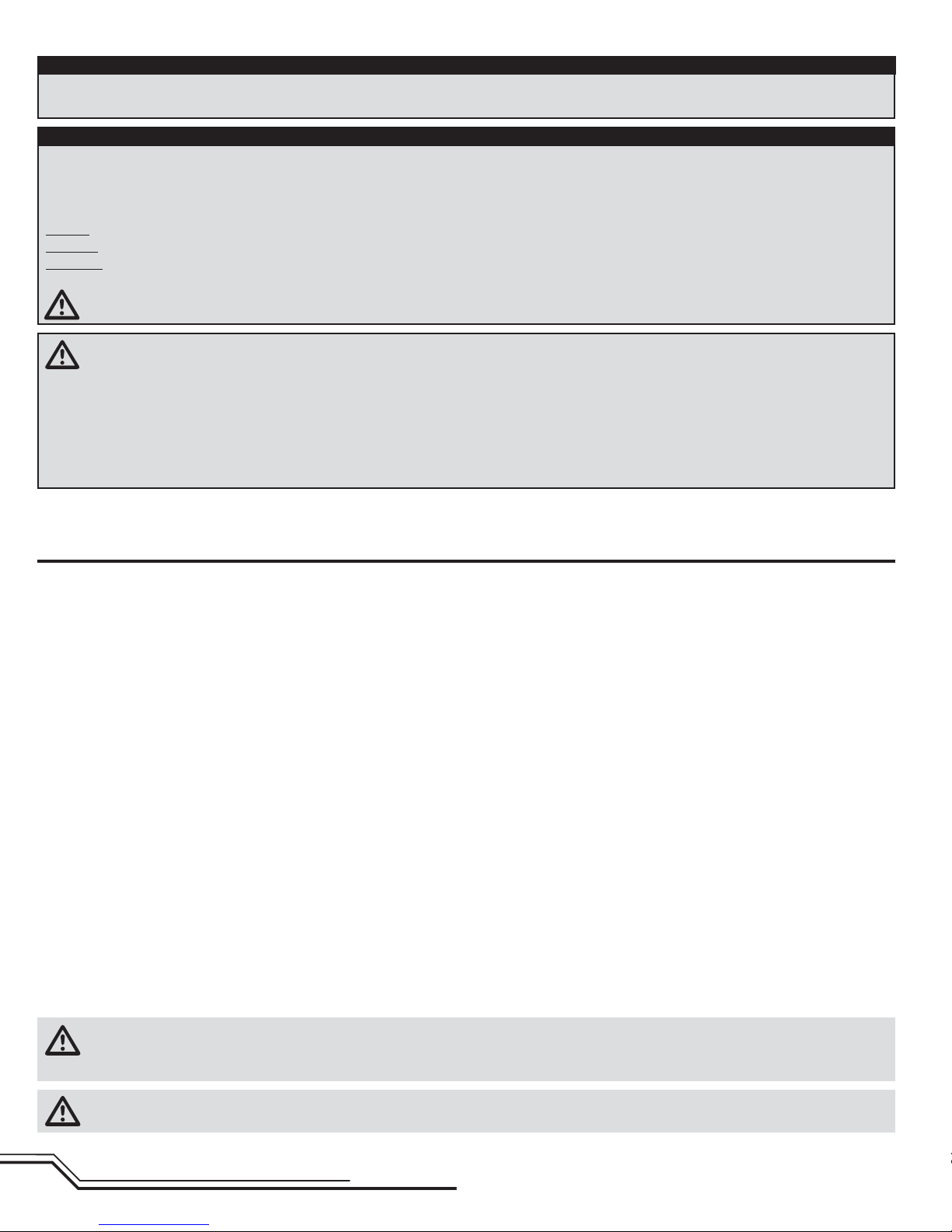

®

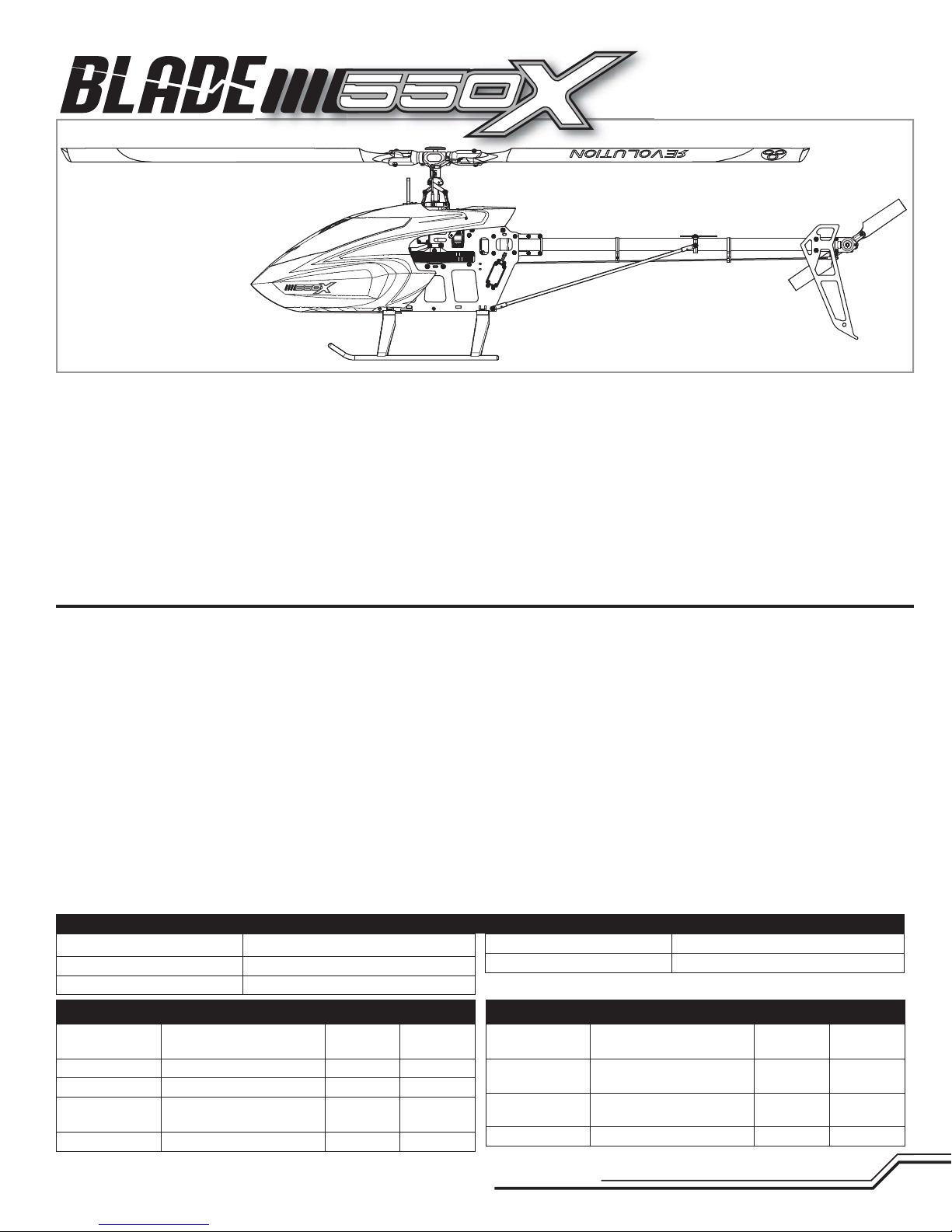

elcome to the world of Blade® Pro Series helicopter performance.

W

Over two decades of fl ying and design experience has gone into the

development of the Blade 550 X. Every part, down to the nuts and bolts,

has been chosen or designed with one goal in mind – giving you a nocompromise, 550-size 3D machine that is second to none.

Before you tear into the contents of this box, however, you must review

this manual. It’s been written and designed to make assembling the

Blade 550 X one of the most enjoyable, hassle-free building experiences

you’ll ever have. Every step is clearly illustrated and shows what parts

are needed to complete it. You’ll fi nd helpful building tips too.

Table of Contents

Tools Needed to Complete ..................................................................................4

Required Items ...................................................................................................4

Optional Items ....................................................................................................4

Assembly Guide ..................................................................................................4

Head Assembly (H) ..............................................................................................5

Frame Assembly (F) ............................................................................................7

Tail Assembly (T) ...............................................................................................10

Electronics Installation ......................................................................................13

Servo Arms and Links .......................................................................................15

Main Rotor Installation ......................................................................................15

Canopy Installation ...........................................................................................15

Programming Your Transmitter ..........................................................................16

Throttle Hold .....................................................................................................16

AR7200BX Setup ..............................................................................................17

AR7200BX Parameter Menu Tips ......................................................................17

Motor Direction Test ..........................................................................................17

If this is your fi rst helicopter building experience, there are a few things

you might want to get before you start unpacking parts. Many builders

prefer to lay out a towel or a rubber mat to prevent screws from bouncing off the worktable. It’s also a good idea to use small containers to

keep parts organized after you take them out of the bags.

Most importantly, take your time. Review every assembly step and make

sure you understand how the parts fi t before you start bolting things together. When you’re done, you’ll have a capable, smooth-fl ying helicopter

that fl ies exactly as it was designed to.

Control Test.......................................................................................................18

Low Voltage Cutoff ............................................................................................20

Flight Guidelines and Warnings .........................................................................20

Flying Your 550X ...............................................................................................20

Blade Tracking ..................................................................................................21

Adjusting the Rudder Gain.................................................................................21

Post Flight Inspection and Maintenance Checklist .............................................21

AR7200BX Fine-Tuning and Adjustment ............................................................21

Troubleshooting Guide ......................................................................................22

Limited Warranty ..............................................................................................23

Customer Service Information ...........................................................................24

Compliance Information for the European Union ................................................25

Exploded Views ......................................................................................... 98-100

Parts List / Ersatzteile / Pièces de rechange / Pezzi di ricambio ...............101-103

Optional Parts / Optionale Bauteile / Pièces optionnelles / Pezzi opzionali ...........103

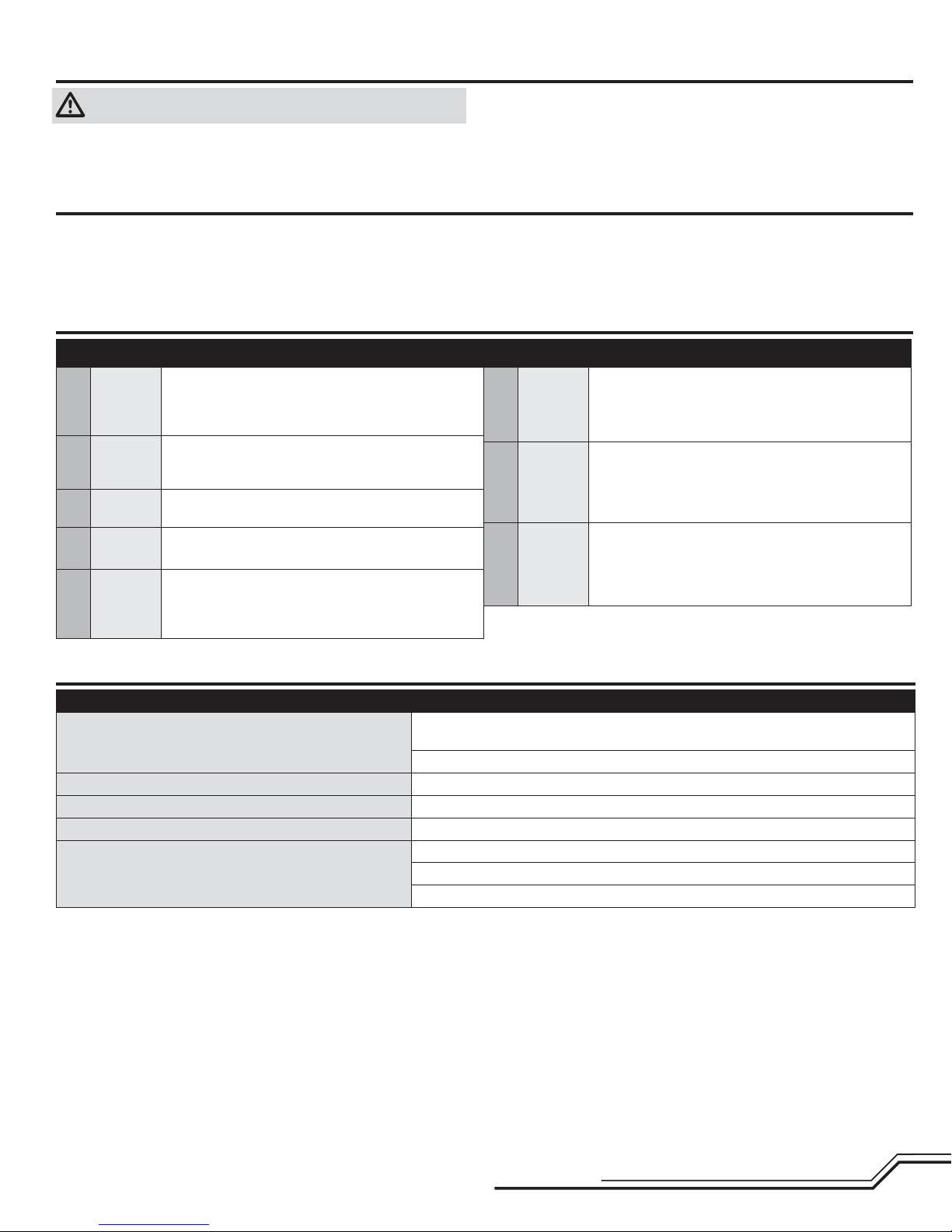

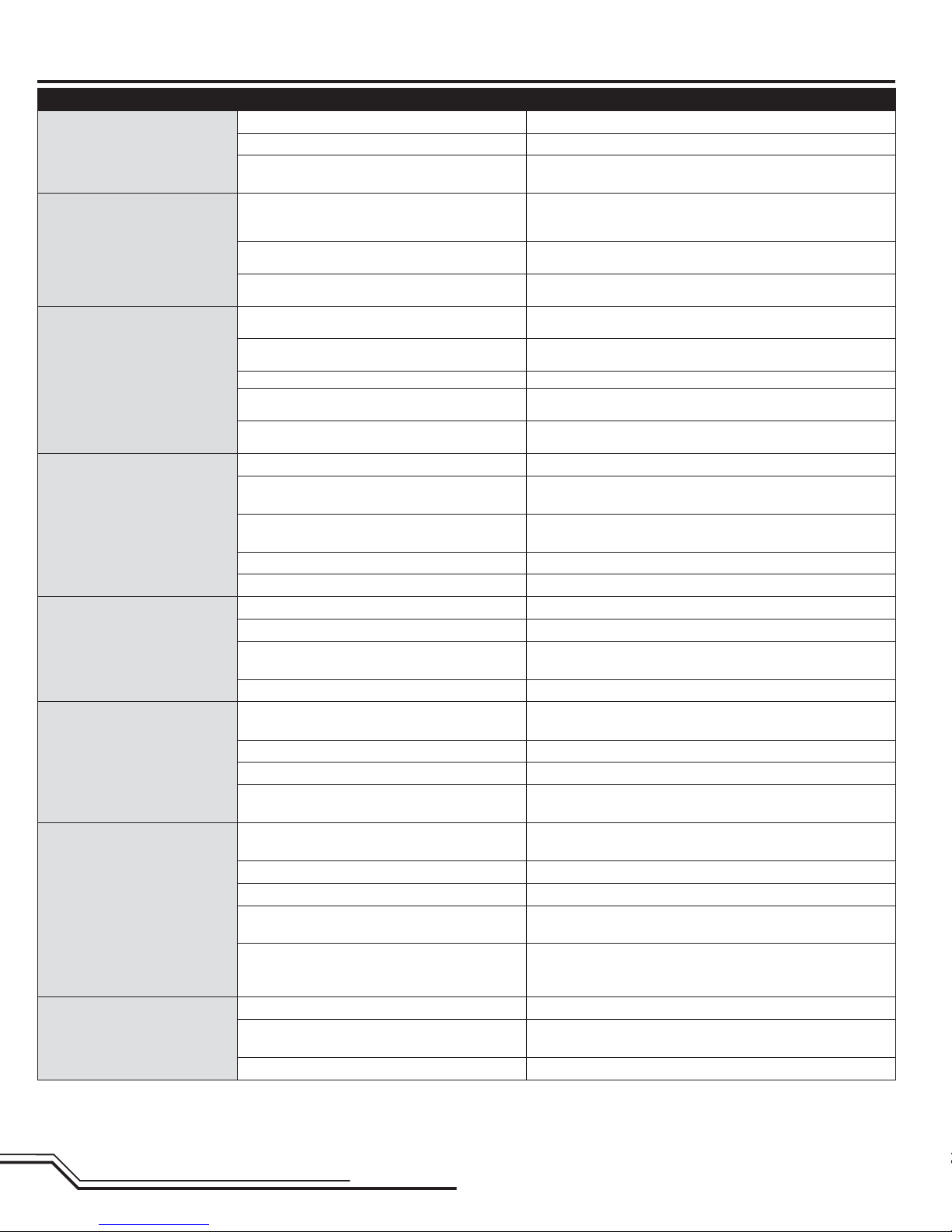

Length

Height

Main Rotor Diameter

Component Kit Combo

Motor

ESC

BEC

Battery

Charger

Heli 550 Brushless Outrunner

Motor, 1360Kv

130 Amp Brushless ESC included included

10 Amp BEC included included

6S 22.2V 5000mAh 30C + Li-Po required required

DC Li-Po Balancing Charger required required

44.5 in (1130mm)

10.8 in (275mm)

49 in (1245mm)

Blade 550 X Specifi cations

included included

Tail Rotor Diameter

Flying Weight

Component Kit Combo

Transmitter

Receiver

Swash Servos

Tail Servo

To register your product online, visit www.bladehelis.com

DSM2®/DSMX® compatible

transmitter

AR7200BX 7CH DSMX

Flybarless Control System

Spektrum™ H6040 required included

Spektrum H6080G required included

7.4 –7.7 lb (3350 –3500 g)

3

9.45 in (240mm)

required required

required included

EN

Page 4

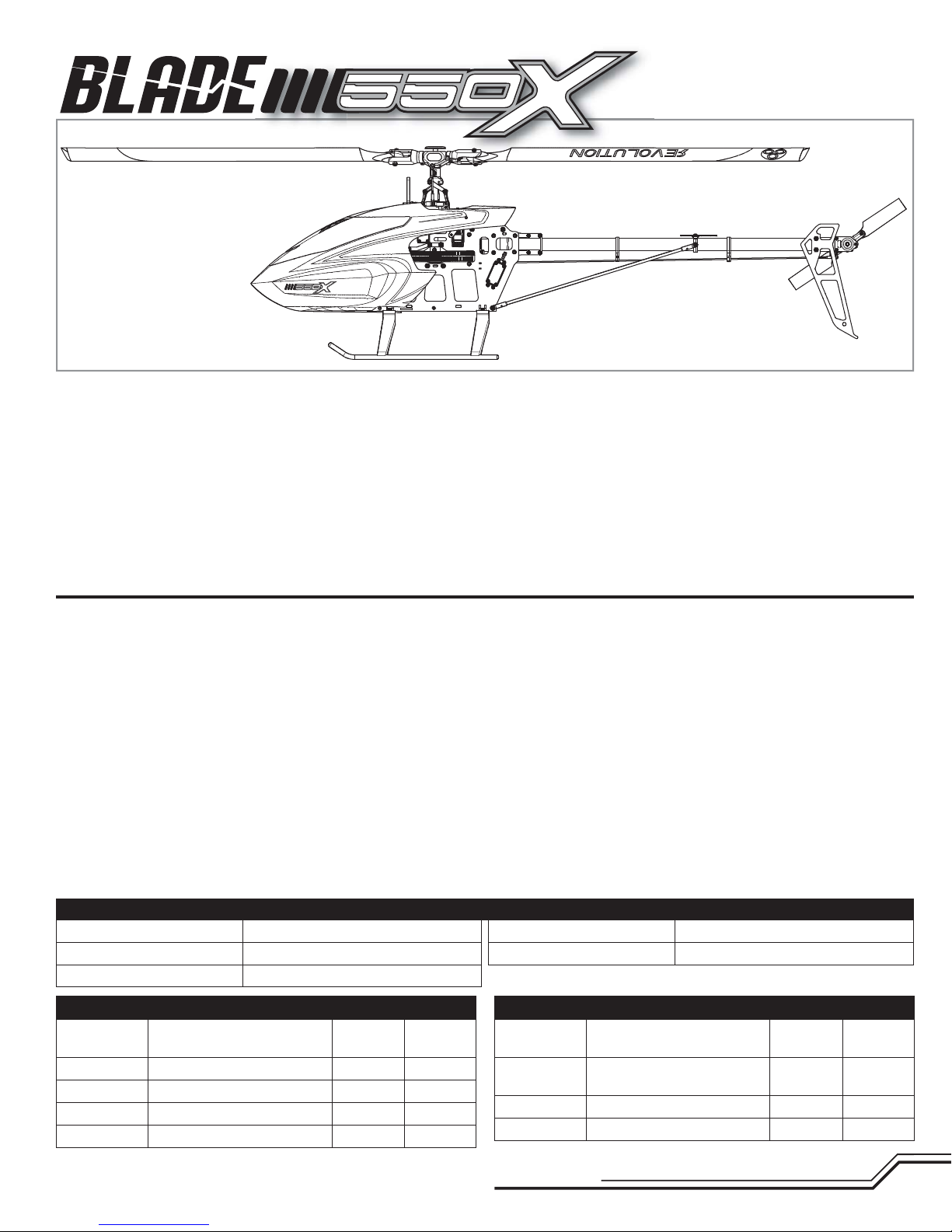

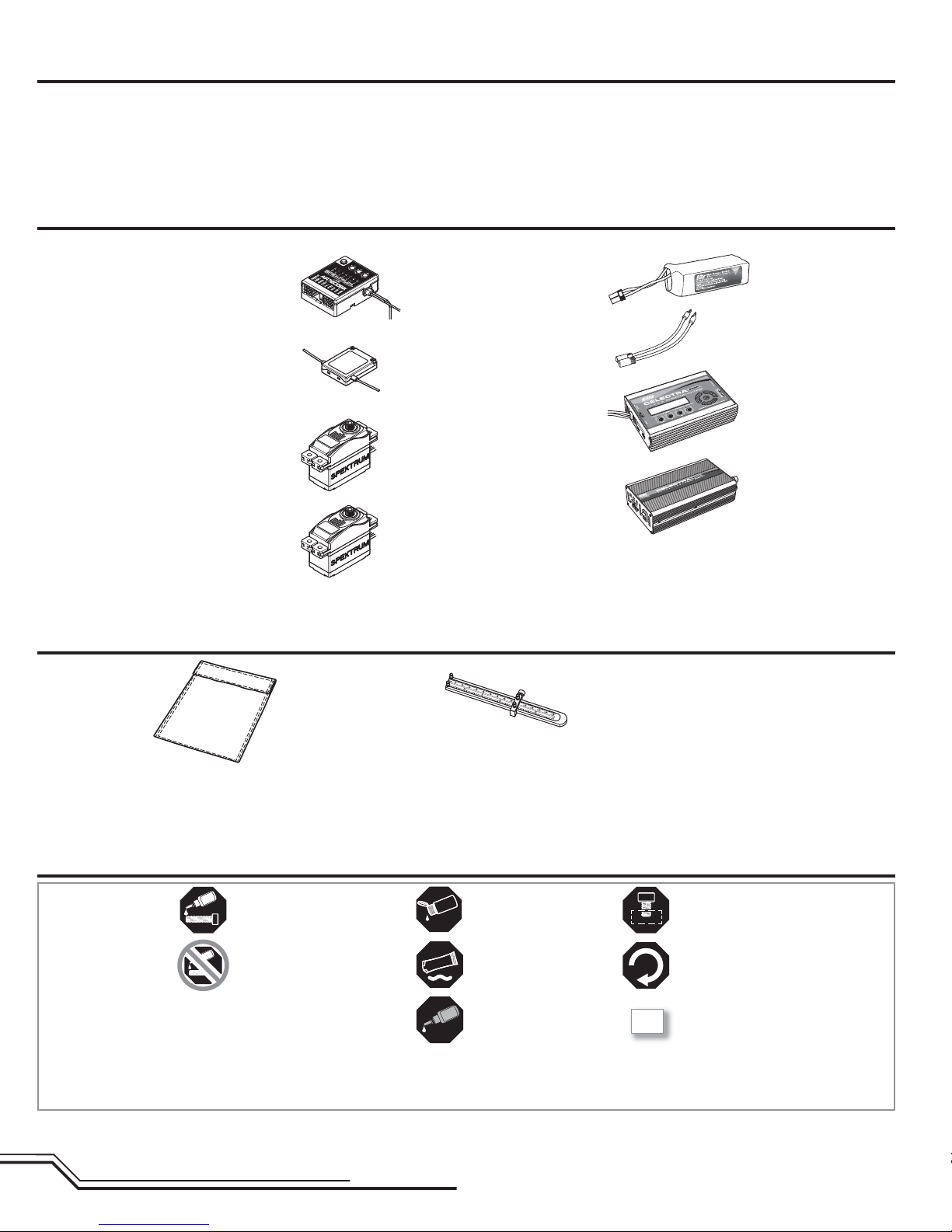

Tools Needed To Complete

• 1.5mm, 2mm, 2.5mm, and 3mm hex drivers

• Ball link pliers

• Needle nose pliers

• Phillips screwdriver

• Wire cutter

Required Items

• Pitch gauge

• Metric calipers

• Petroleum based, light viscosity lube

• Medium cyanoacrolate (CA)

• Receiver/Flybarless control unit

AR7200BX (SPMAR7200BX)

included with combo BLH5525C

• DSMX Remote Receiver (SPM9645)

included with combo BLH5525C

• 3 Servos

(3) H6040 servos (SPMSH6040)

included with combo BLH5525C

• 1 Tail servo

(1) H6080G servo (SPMSH6080G)

included with combo BLH5525C

Optional Items

• Dynamite

Protection Bag, Large

(DYN1405)

®

Li-Po Charge

• 5000mAh 6S 22.2V 30C LiPo,

10AWG with EC5™ connector

(EFLB50006S30)

®

• E-fl ite

• E-fl ite 200W charger (EFLC3020)

• Celectra™ 15VDC 250W

• DSM2

• Control Rod Set Up Tool

(RVO1004)

EC5 Device Charge

Lead with 6” Wire & Jacks,

12 AWG and EC5 connector

(EFLAEC512)

Power Supply (EFLC4010)

®

/DSMX® compatible DX6i 6 channel

transmitter or higher

Assembly Guide Legend

Apply BLUE Threadlock

Apply NO Threadlock

EN

Apply Petroleum based,

light viscosity lube

OIL

Apply Synthetic Grease

Apply MEDIUM CA

4

Loosely Tighten

Fully Tighten

Repeat Multiple Times

2X

Page 5

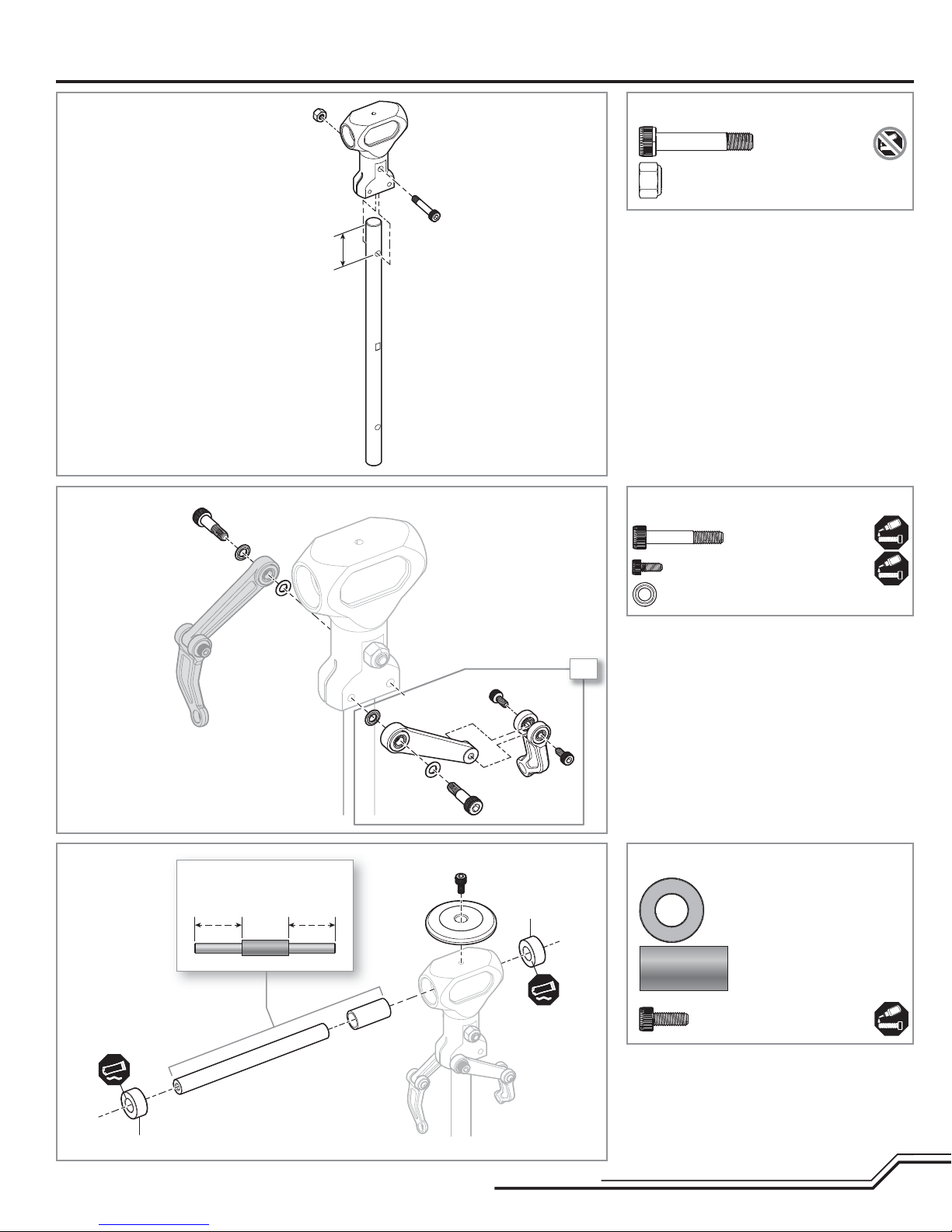

Head Assembly (H)

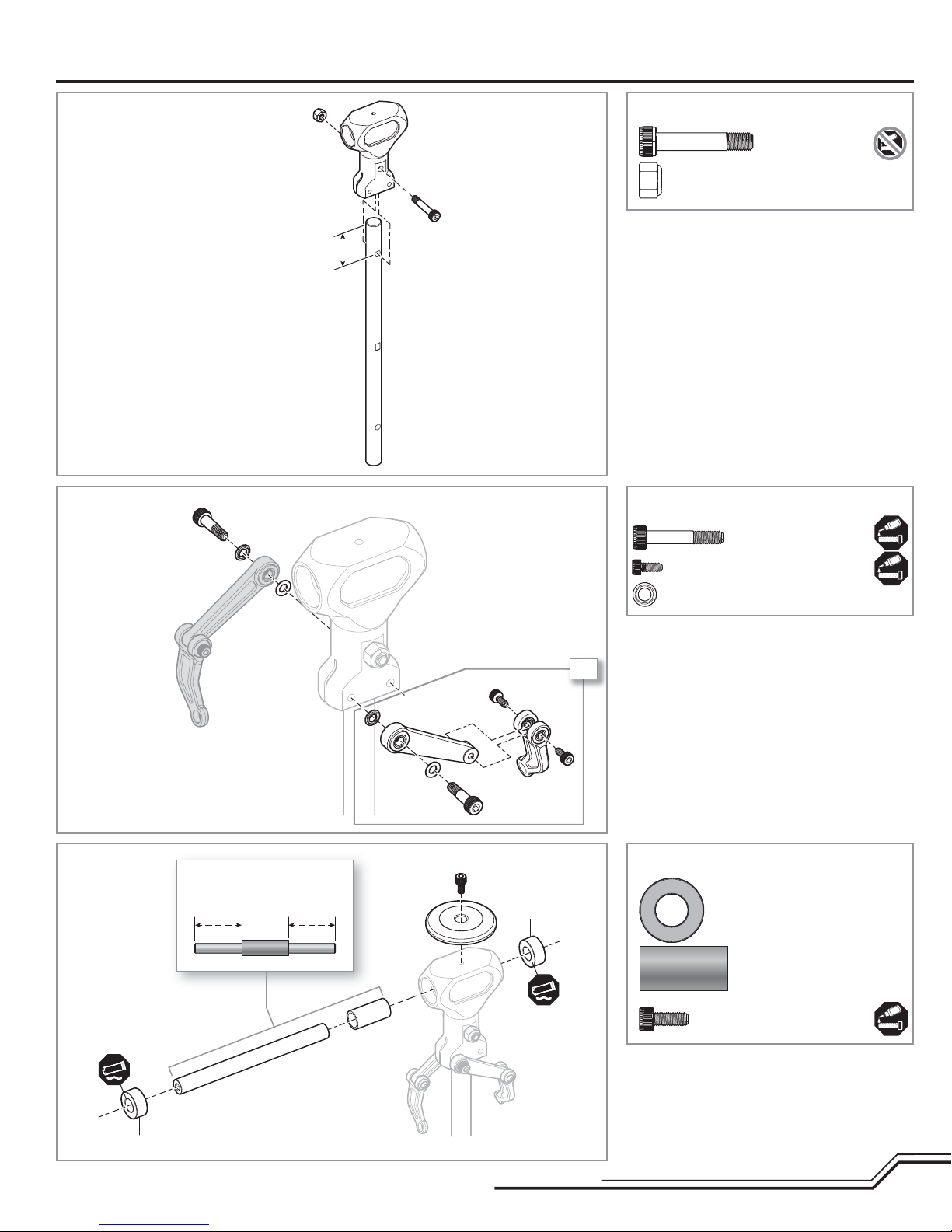

Step H1

Step H2

Step H1 parts (bags H1 and H2)

M4 X 22 cap head

shoulder bolt

M4 locknut

22mm

Step H2 parts (bag H1)

M3 X 18 cap head

shoulder bolt (x2)

M2 X 5 cap head bolt (x4)

Center sleeve

on the spindle

Damper

2X

Step washer (x4)

• The stepped sides of the washers should face the

radial bearings.

• Do not over-tighten. The follower arms should move

freely.

Step H3 parts (bags H1 and H2)Step H3

Damper (x2)

Spindle sleeve

M3 X 8 cap head bolt

Damper

• Clean the threads in the spindle thoroughly with

alcohol before installation.

5

EN

Page 6

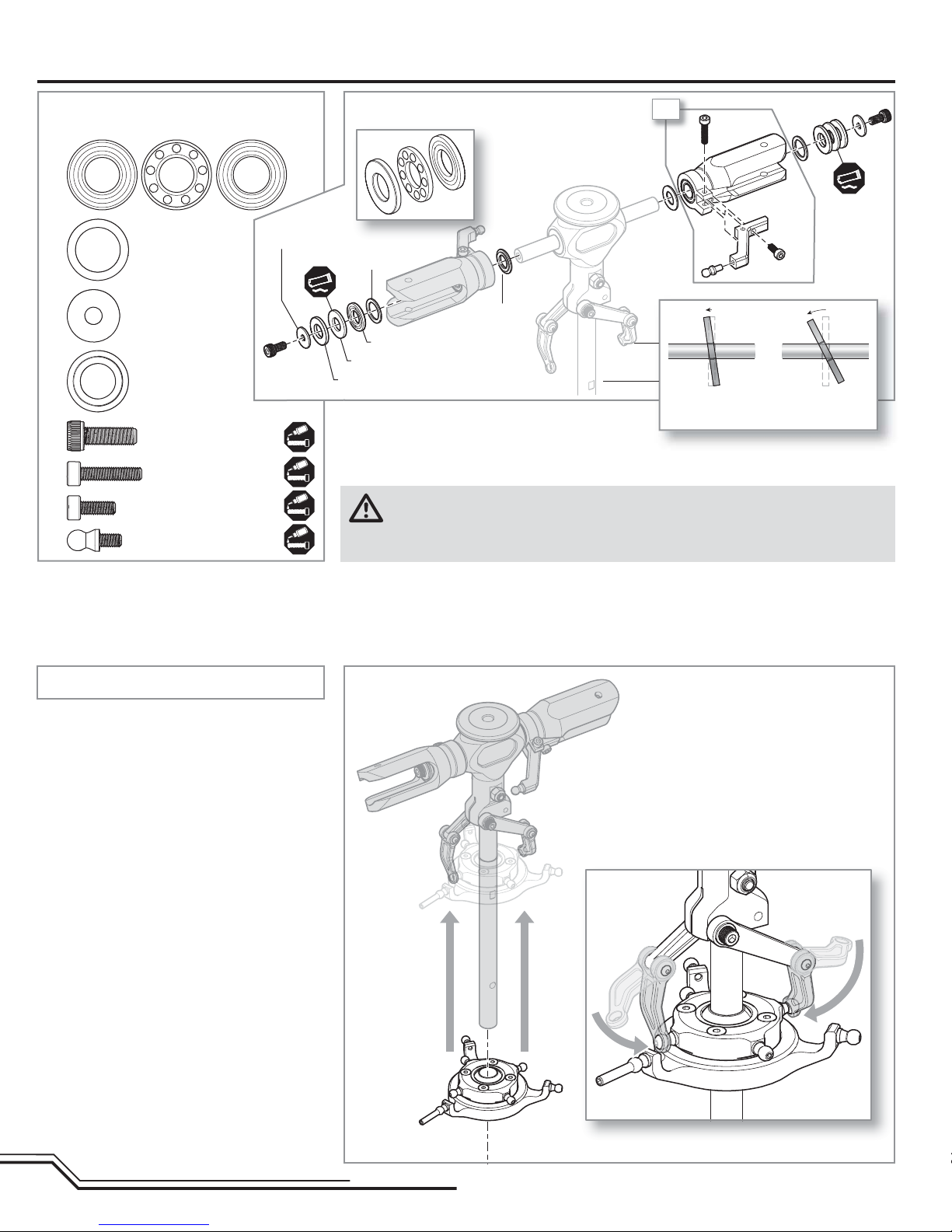

Head Assembly cont’d

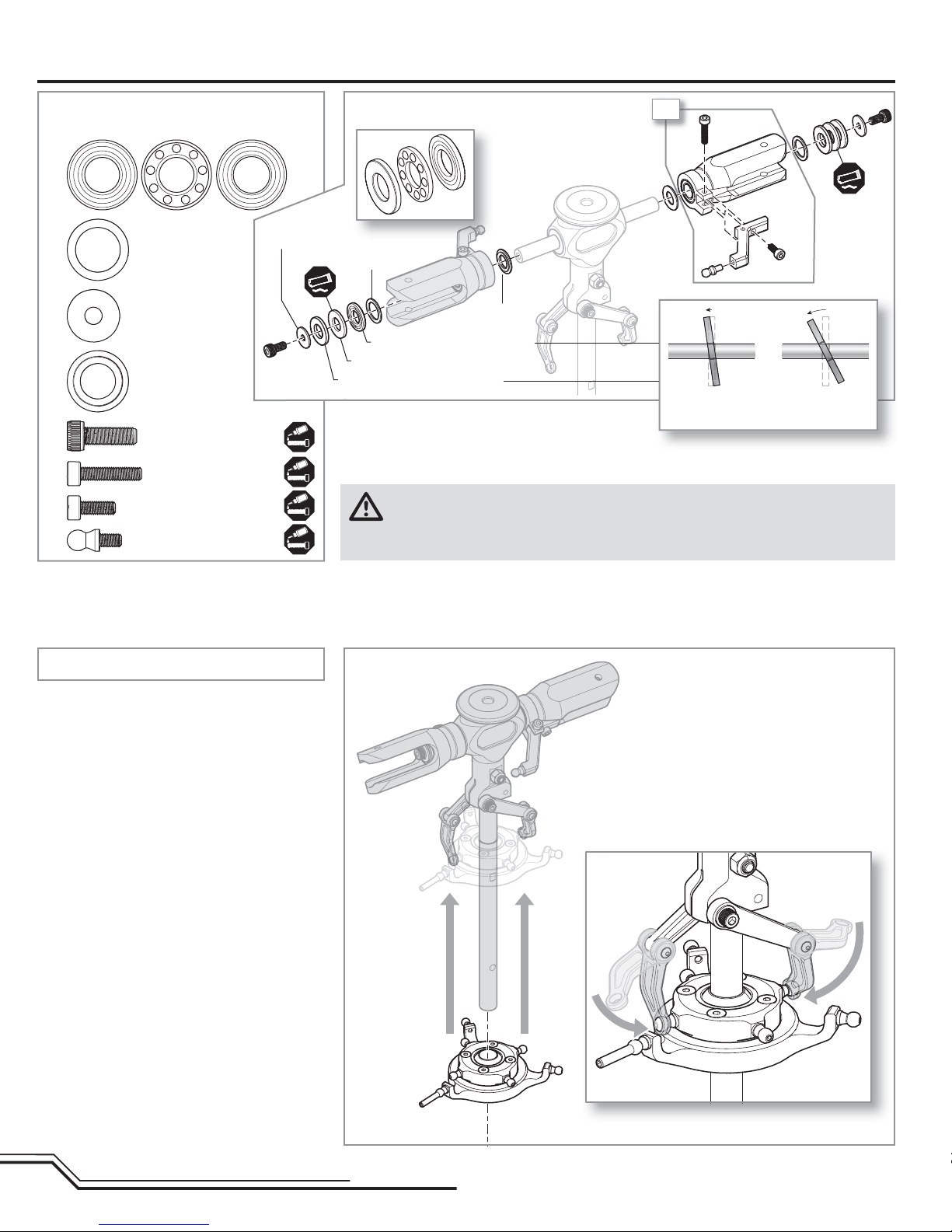

Step H4 parts (bag H3)

Thrust bearing (x2)

Thrust washer

10 X 14 X .8 (x2)

Spindle bolt washer

4 X 12 X 1 (x2)

Step washer (x2)

A

B

C

M4 X 12 bolt (x2)

M3 X 14 bolt (x2)

M3 X 8 bolt (x2)

Control ball (x2)

Spindle bolt washer

Thrust washer

A

Smaller I.D. thrust washer race

medium-strength threadlock to the bolts and allow time for the threadlock (about 4 to 6 hours) to dry

before attempting to fl y your helicopter.

Step H4

Step washer

Larger I.D. thrust washer race

Bearing cage

WARNING: Any time you loosen the spindle bolts, completely clean the bolts with denatured

alcohol making sure you have removed any residual oil. When putting bolts back on, apply

2X

B

Smaller inner

diameter (I.D.)

A

C

Larger inner

diameter (I.D.)

• Loosely install bolts B and C before tightening.

• The stepped washer faces the radial bearing in the

blade grip.

Step H5 parts (bag H4)

Step H5

EN

6

Page 7

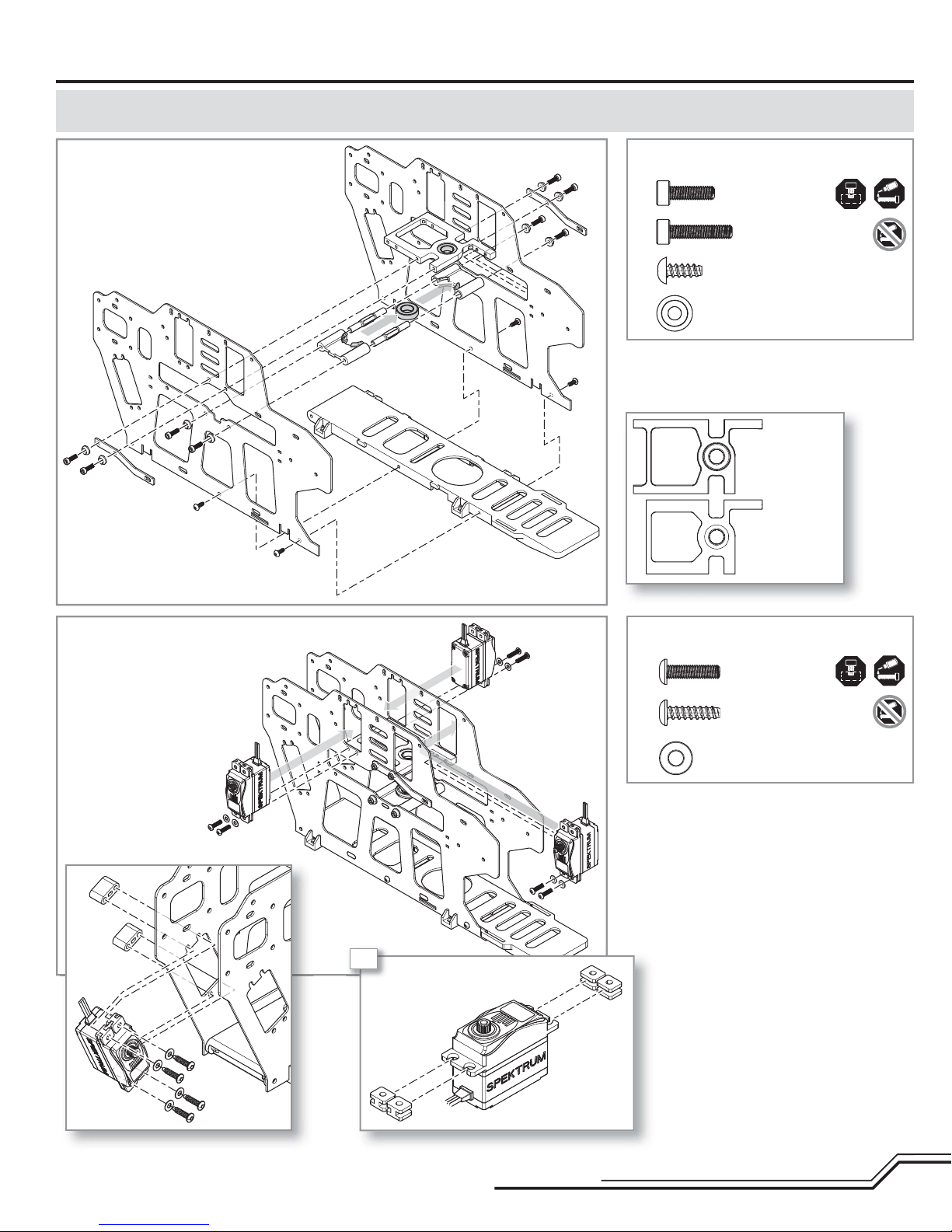

Frame Assembly (F)

ASSEMBLY NOTE: Before assembly, plan your wire routing for the servos. At any point where the servo wire is going to pass through or cross the frame plates,

use sandpaper to round the edge of the frame plate to prevent the wire from chafi ng.

Step F1

A

Step F1 parts (bags F1, F2, and F3)

A

A

B

C

C

B

C

C

B

C

• At this stage of the assembly, do not tighten

the bearing blocks or bottom plate screws.

Cap head bolt

M3 X 10 (x4)

Cap head bolt

M3 X 14 (x4)

Self tapping screw

M3 X 8 (x4)

M3 recessed washer (x8)

Top block

Middle block

Step F2

A

A

A

Step F2 parts (bag F5)

A

B

Button head screw

M3 X 12 (x6)

Self tapping screw

M3 X 12 (x4)

Servo washers (x10)

4X

B

B

7

EN

Page 8

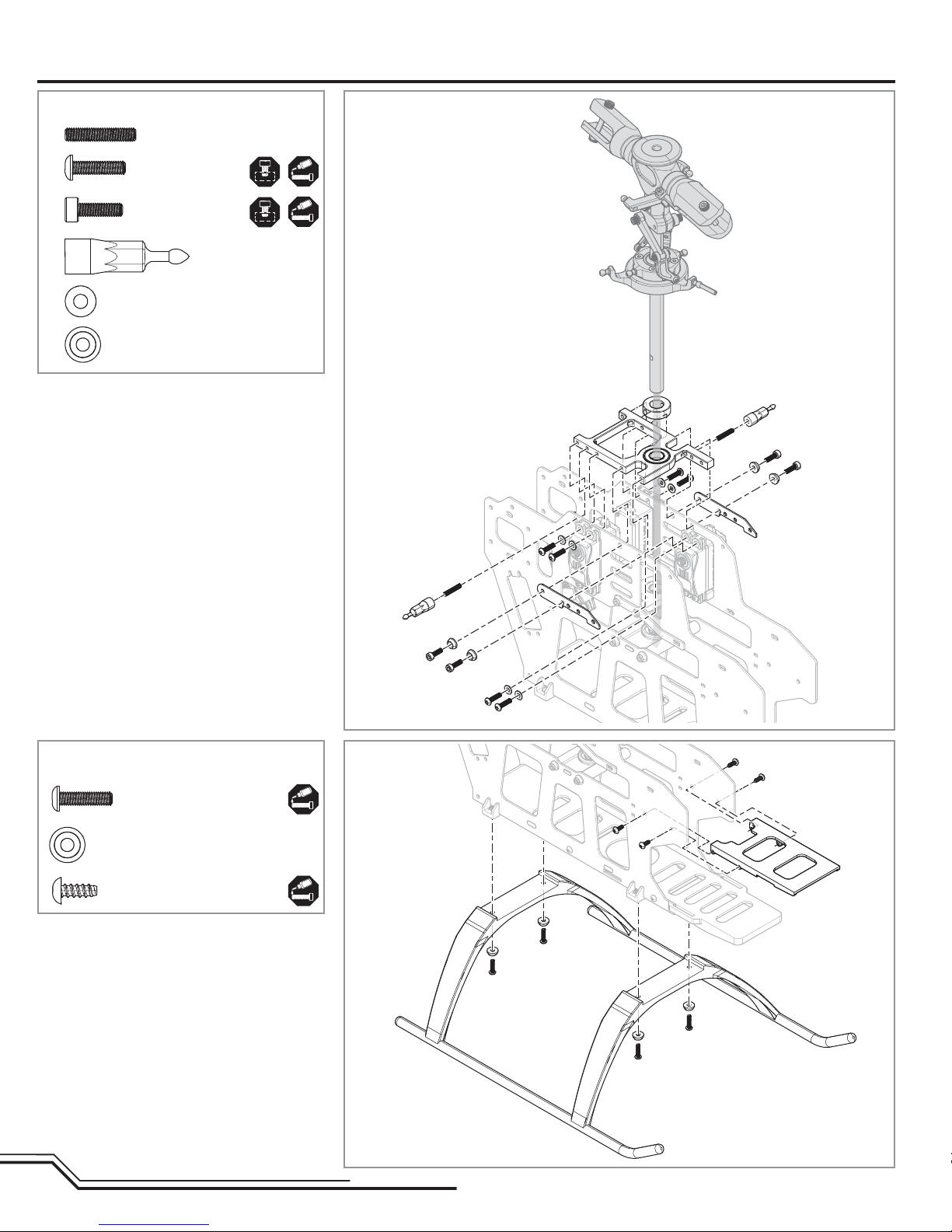

Frame Assembly cont’d

Step F3 parts (bags F3 and F5)

Setscrew

M3 X 11 (x2)

A

B

• Slide the mainshaft into position, then tighten all the

frame and servo screws.

Button head screw

M3 X 12 (x6)

Cap head bolt

M3 X 10 (x4)

Canopy

mounting post (x2)

M3 Washer (x6)

M3 Recessed

washer (x4)

Step F3

B

A

Step F4 parts (bag F3)

Button head screw

M3 X 12 (x4)

M3 Recessed washer (x6)

Self tapping screw

M3 X 8 (x4)

A

B

A

Step F4

EN

8

Page 9

Frame Assembly cont’d

Step F5

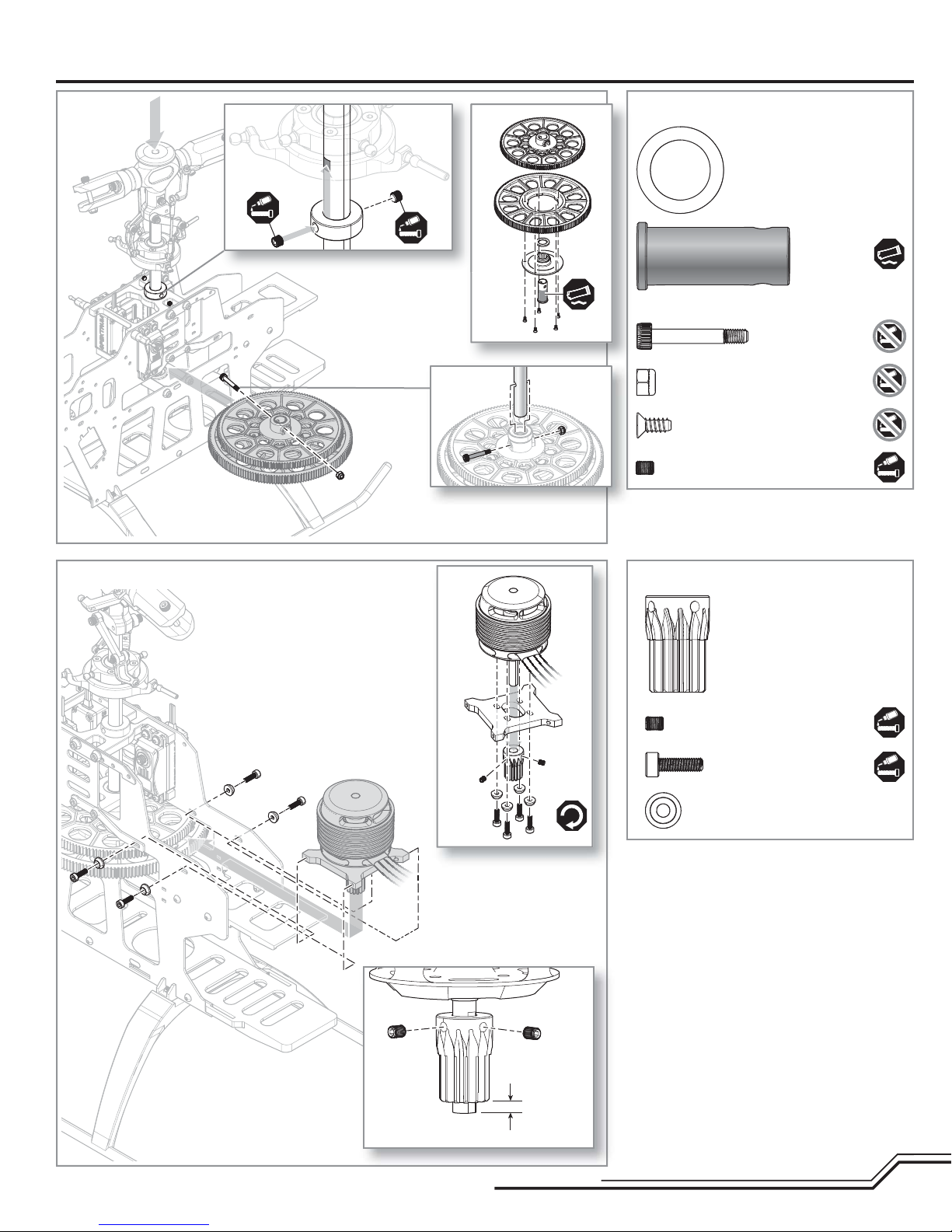

Step F5 parts (bag M1)

Washer (x1)

One way sleeve (x1)

Shoulder cap head bolt

M4 X 22

M4 Lock nut

Counter sunk self tapping

screw M3 X 8 (x5)

Setscrew M3 X 4 (x2)

Step F6

Step F6 parts (bag F6)

6mm, 14 tooth pinion gear

Setscrew M3 X 4 (x2)

Cap head bolt M3 X 10 (x8)

M3 Recessed washer (x8)

3mm

9

EN

Page 10

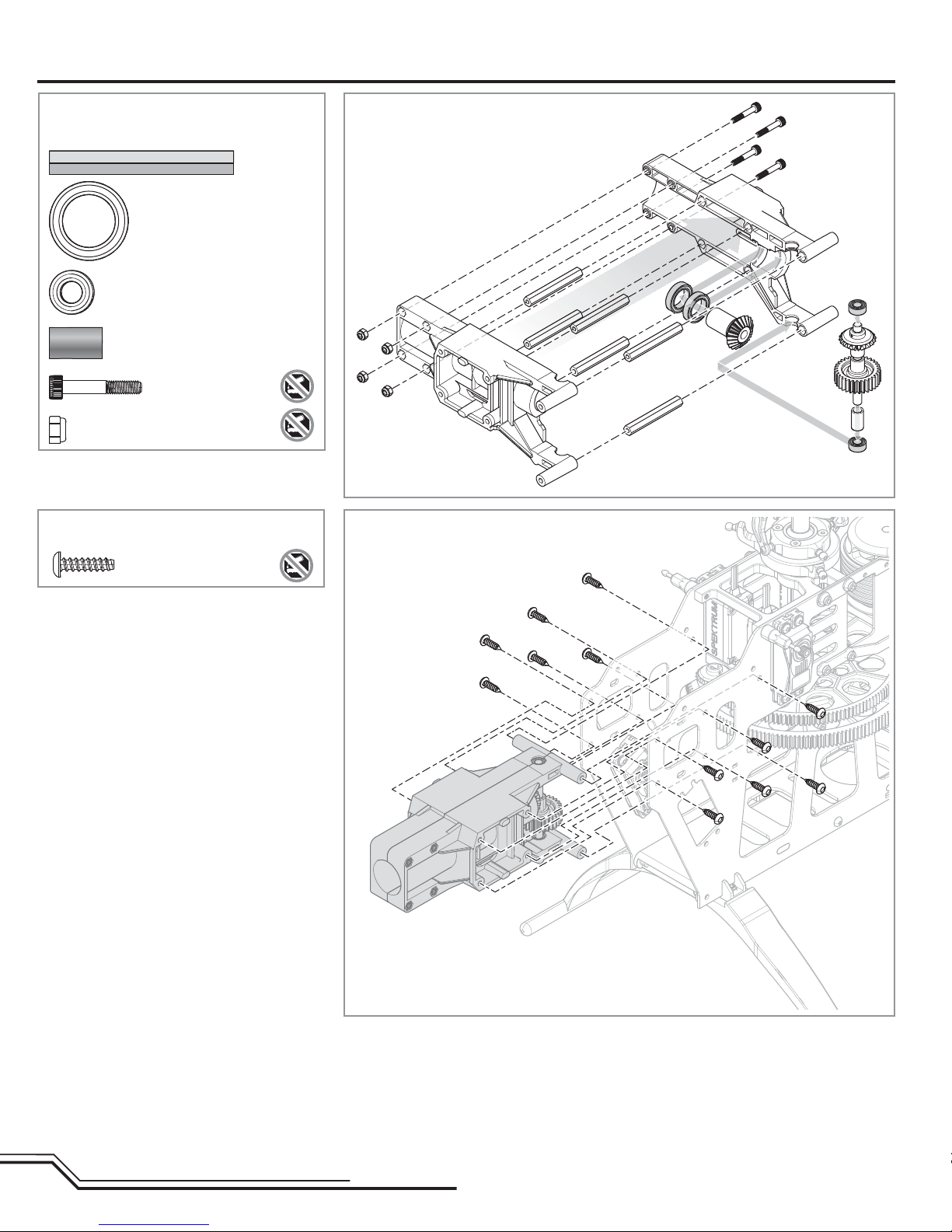

Tail Assembly (T)

Hexagonal posts (x6)

Radial bearing

12 X 18 X 4 (x2)

Radial bearing

5 X 10 X 4 (x2)

Brass spacer

Cap head shoulder

bolt M3 X 18 (x4)

M3 Lock nut (x4)

Step T1Step T1 parts (bag T1)

Step T2 parts (bag T1) Step T2

Button head self tapping

screw M3 X 16 (x12)

EN

10

Page 11

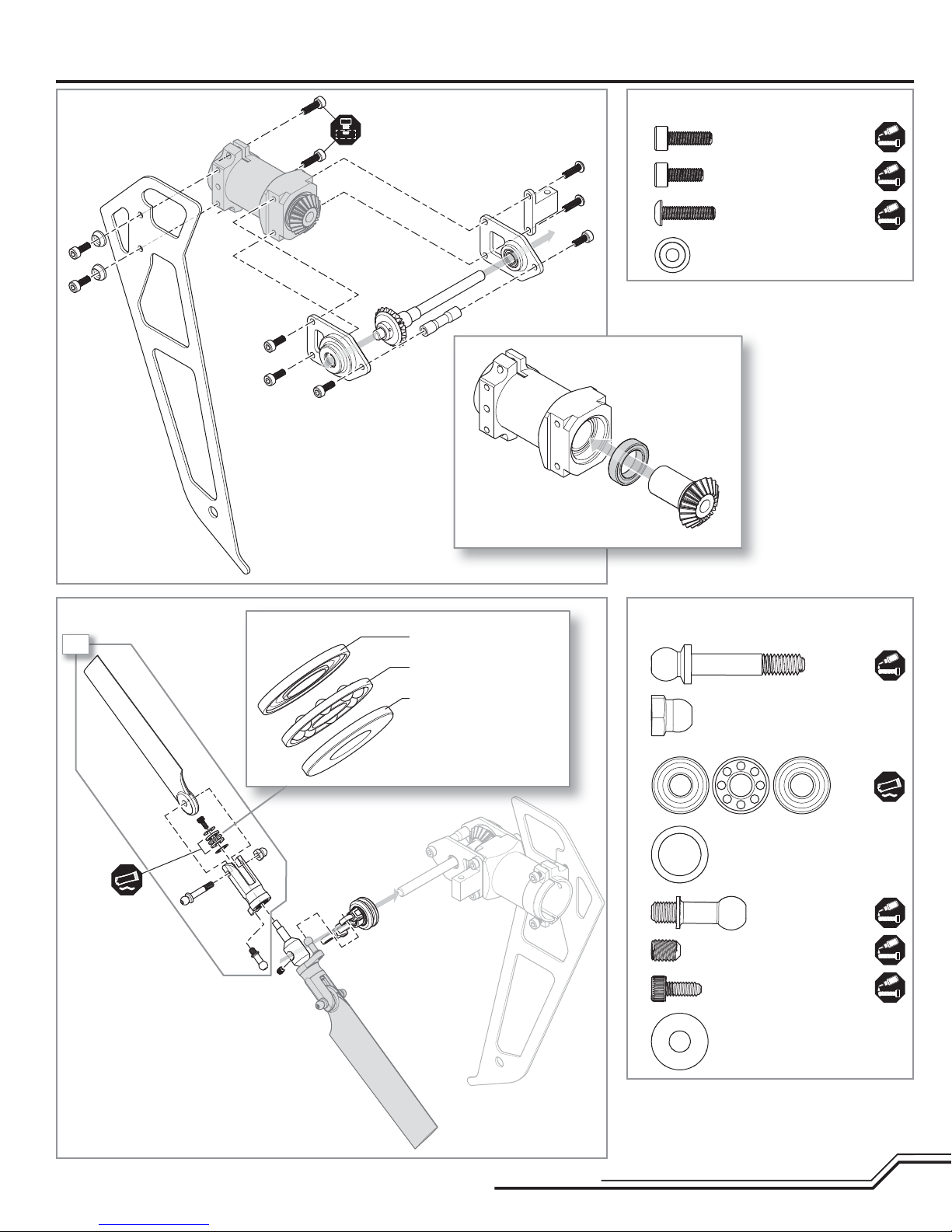

Tail Assembly cont’d

Step T3

B

Step T3 parts (bags T2 and T3)

A

C

B

B

B

A

B

C

Cap head bolt M3 X 10 (x2)

Cap head bolt M3 X 8 (x4)

Button head screw

M3 x 10 (x2 )

M3 Recessed washer (x2)

Step T4

2X

Step T4 parts (bags T4 and T5)

Small inner diameter race

Bearing cage

Large inner diameter race

B

A

A

B

Tail blade bolt (x2)

Tail blade nut (x2)

Thrust bearing (x2)

Thrust washer (x2)

Control ball (x2)

M4 x 3 Set screw

M3 X 8 Cap head

bolt (x2)

M3 Washer (x2)

11

EN

Page 12

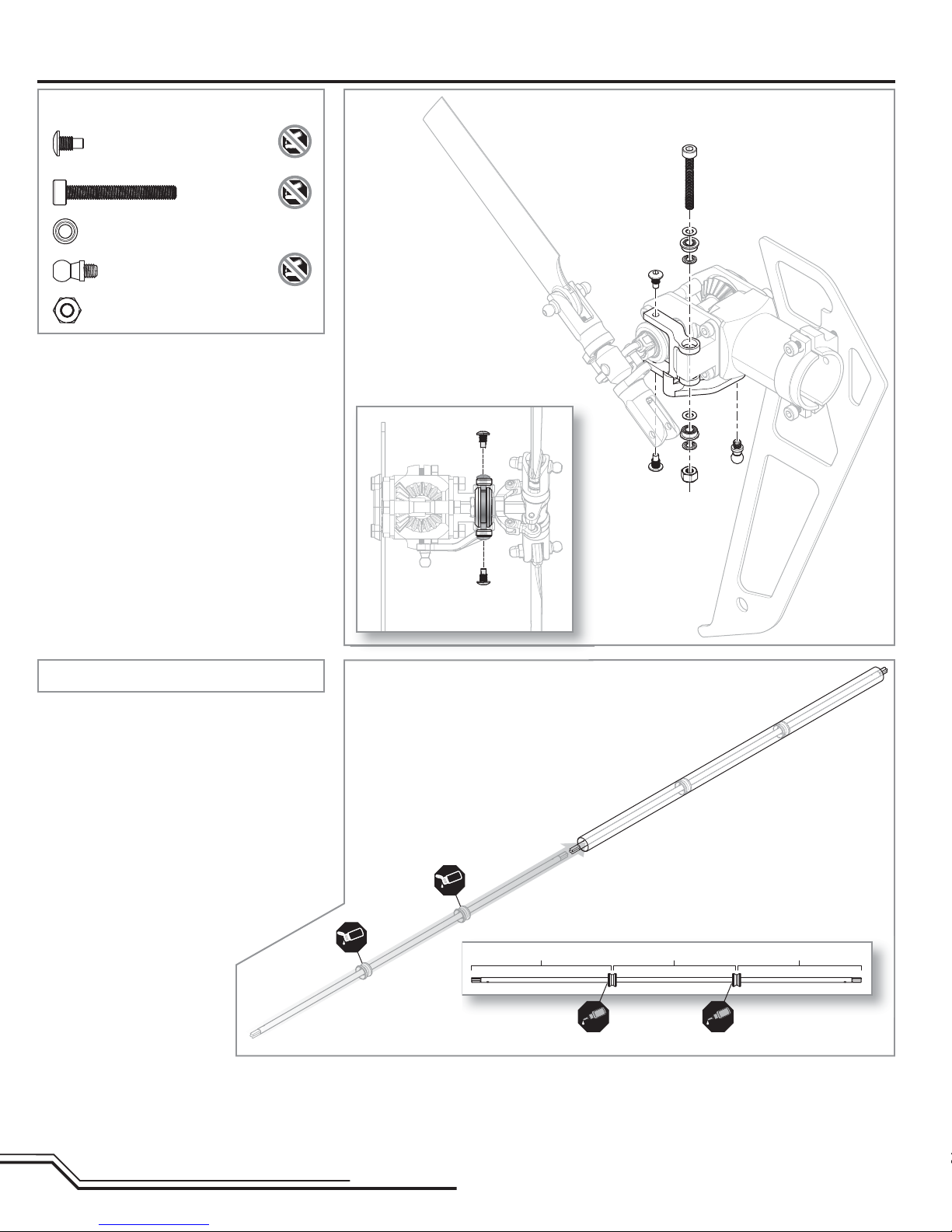

Tail Assembly cont’d

Button head screw

M3 X 5 (x2)

Cap head bolt M3 X 25

M3 Step washer (x4)

Control ball

M3 Lock nut

• The stepped side of the washer faces the radial

bearing.

Step T5Step T5 parts (bag T6)

Tail rotor blade

removed for clarity

Step T6a parts (bag T7)

• Glue the torque tube bearings in place by placing a

thin bead of CA on the torque tube at the given locations (200mm, 200mm), then slide the bearings onto

the CA. Do not allow CA to get into the bearings.

• Use oil on the outside of the torque tube bearing

holders to ease installation into the boom.

Step T6a

OIL

viewed from back

OIL

214 mm 200 mm 200 mm

EN

12

Page 13

Tail Assembly cont’d

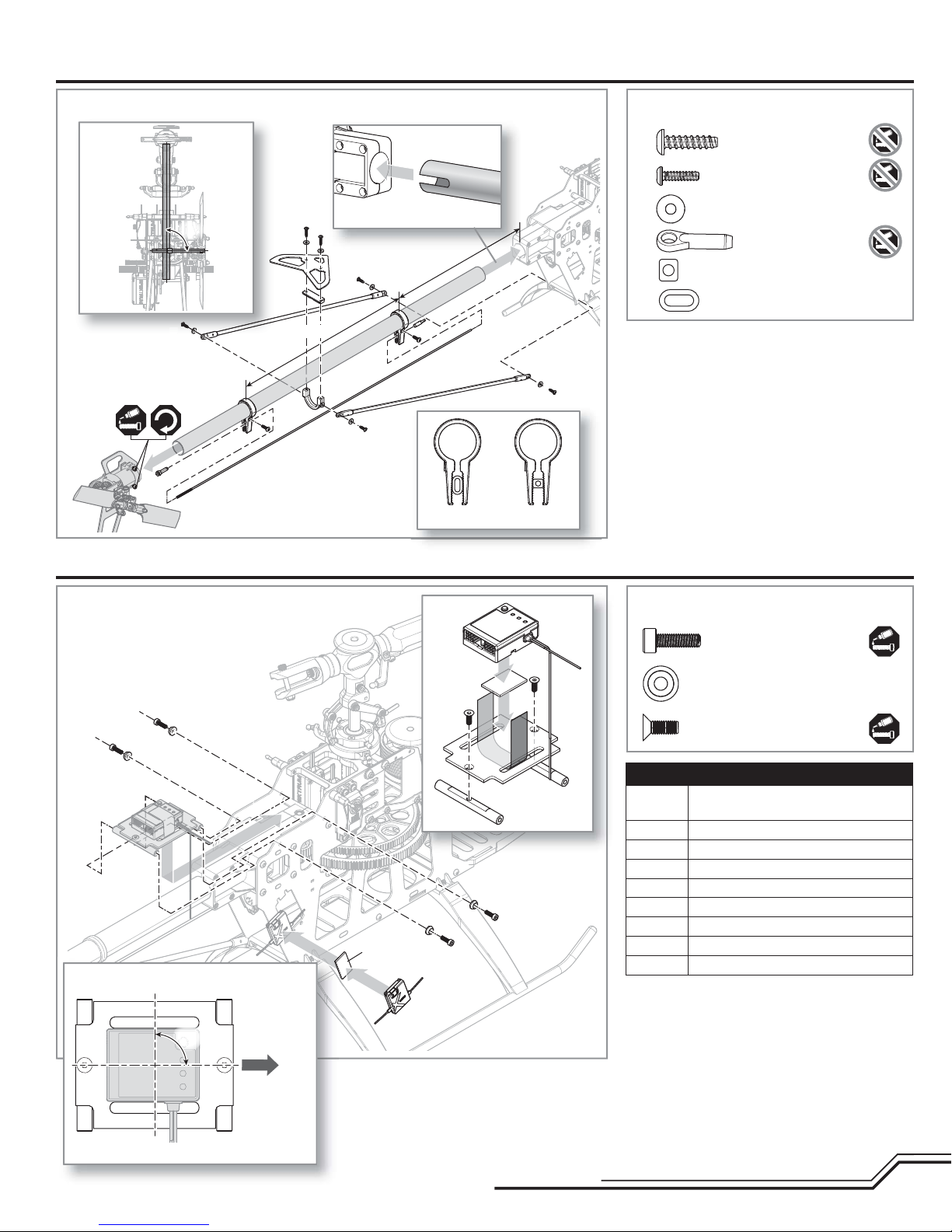

Step T6b Step T6b parts (bags T8 and T3)

viewed

from back

90°

A

B

Electronics Installation (E)

230 mm

B

viewed from left

A

A

A

B

120 mm

A

B

A

Front Rear

Self tapping screw

M3 X 12 (x4)

Self tapping screw

M2.5 X 8 (x2)

M3 Recessed washer (x6)

Ball link (x2)

Rear pushrod guide insert

Front pushrod guide insert

Flybarless Control Unit and Remote Receiver

Double-sided

foam tape

AR7200BX Alignment

90°

Step E1 parts (bag E1)

Cap head

M3 X 10 (x4)

Recessed washer (x4)

Counter sunk screw

M3 X 8 (x2)

AR7200BX servo connections

BIND/DAT Bind plug, telemetry module or data

logger (optional)

AUX2 BEC

AUX3 BEC

THRO Speed control

Rx L Remote receiver

ELEV Center swashplate servo

AILE Left swashplate servo

AUX1 Right swashplate servo

RUDD Tail servo

TIP: Connect the remote receiver before plugging in the

servo leads.

Front

viewed from top

13

EN

Page 14

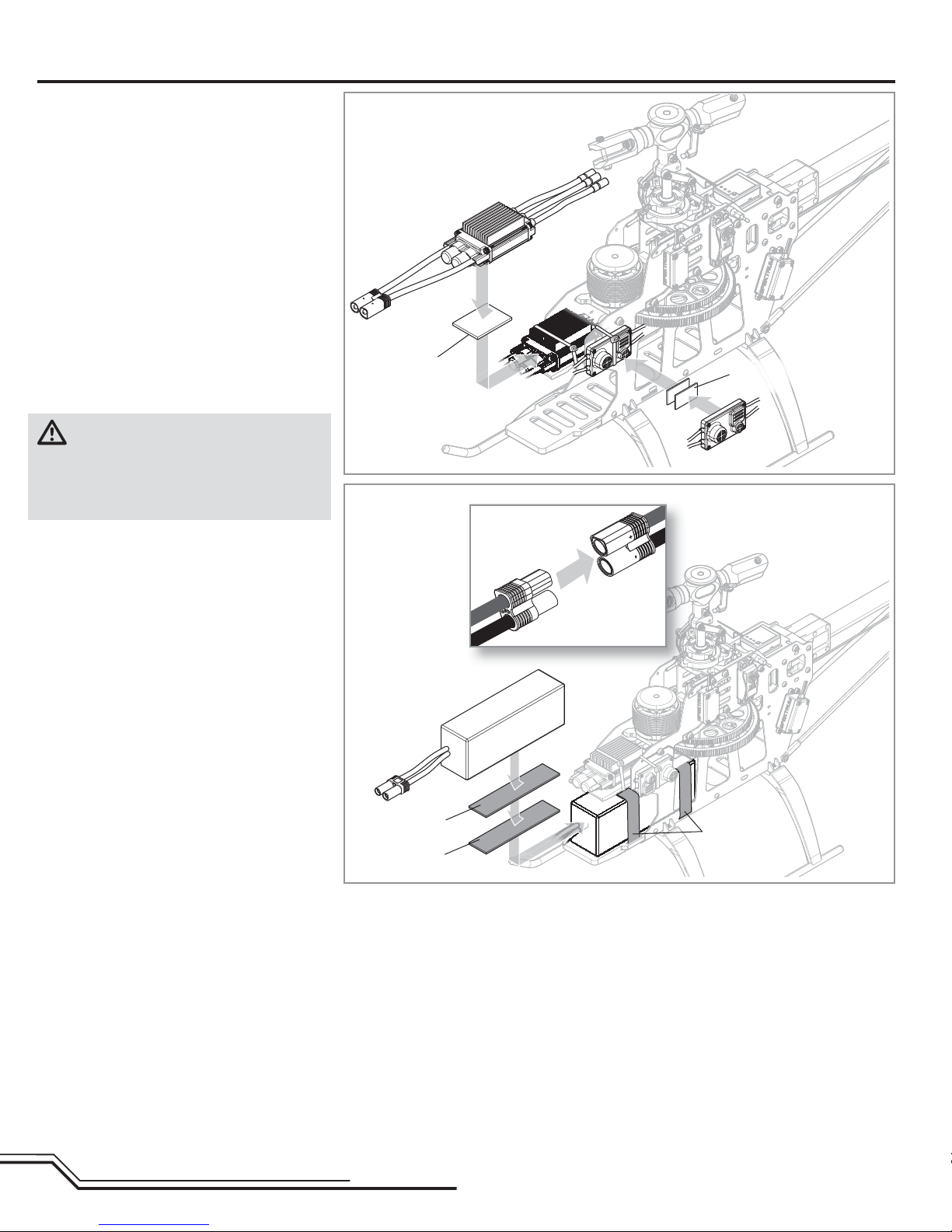

Electronics Installation cont’d

AR7200BX Arming

1. Lower the throttle.

2. Power on the transmitter.

3. Center the throttle trim.

4. Turn throttle hold ON.

5. Attach hook material to the helicopter frame and

loop material to the battery.

6. Install the fl ight battery on the helicopter frame.

Secure the fl ight battery with a hook and loop

strap.

7. Connect the battery cable to the ESC.

8. Do not move the helicopter until the AR7200BX

initializes. The swashplate will move up and down,

indicating that the unit is ready. The AR7200BX will

also emit a solid BLUE Status LED when it is ready

9. The helicopter motor will emit a series of tones,

indicating the ESC is armed.

CAUTION: Always disconnect the Li-Po battery

from the aircraft receiver when not in use to

avoid over-discharging the battery. Batteries discharged to a voltage lower than the lowest approved

voltage may become damaged, resulting in loss of performance and potential fi re when batteries are charged.

Speed control and BEC

Double-sided foam tape

Flight battery

Hook and loop

material

EN

Loop material

Hook material

Hook and loop

strap

14

Page 15

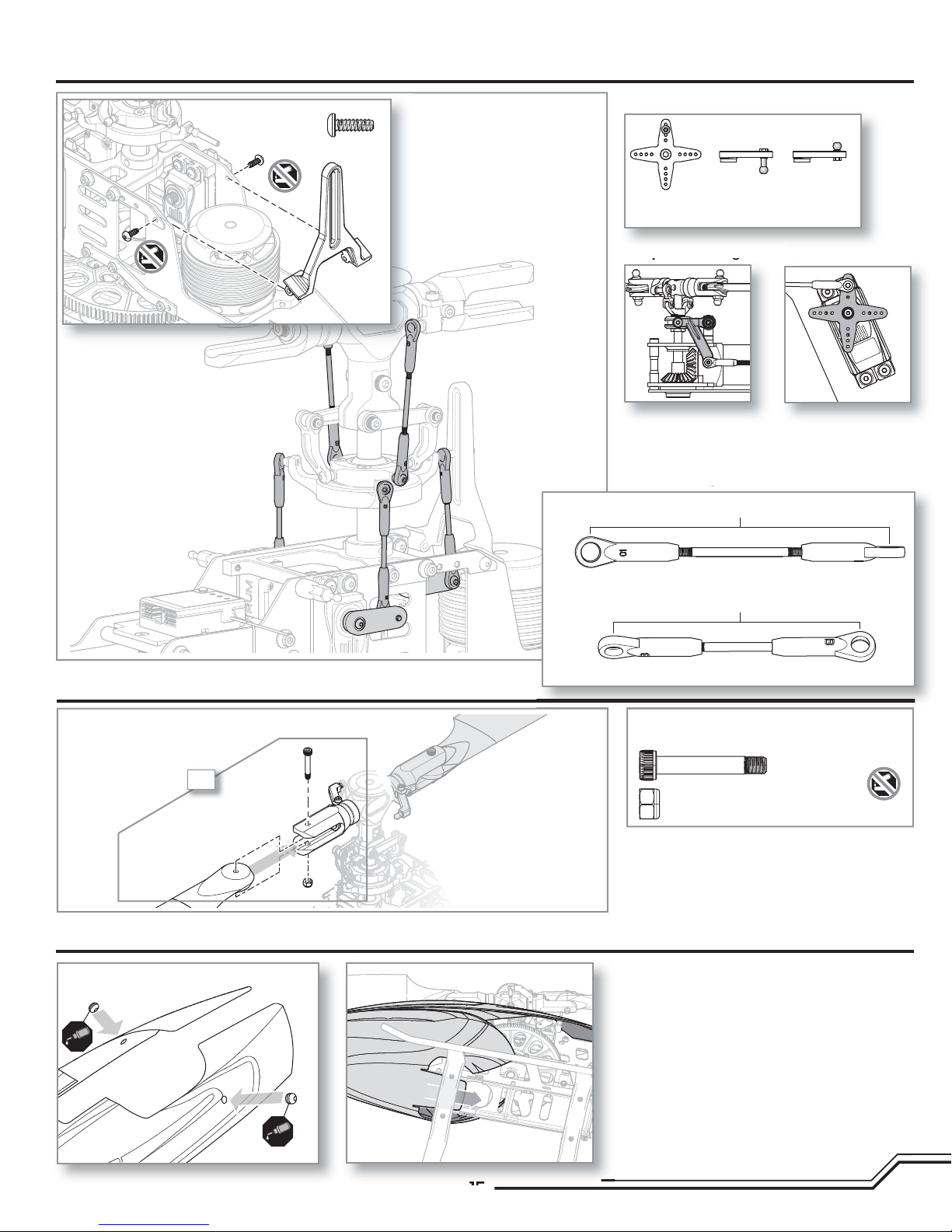

Servo Arms and Links Installation

pg

g

Self tapping screw

M3 X 8 (x2)

B

Servo ball link placement

Tail servo Rear swash

servos (x2)

Front swash

servo

Tail pushrod alignment

A

A

Tail pitch bellcrank

neutral position

(viewed from the bottom)

Tail servo arm

neutral position

(viewed from the right side)

Pushrod lengths

B

68mm

Main Rotor Installation

Main Rotor Blades

2X

Canopy Installation

Canopy Grommets

A

B

B

Swash to blade grip link, 68mm (x2)

56mm

Servo to swash link, 56mm (x3)

Main Rotor Blade parts

Main blade shoulder bolt M4 X 30 (x2)

M4 Lock nut (x2)

• The rotor blades should be tight enough to hold their

position if you hold the helicopter sideways, but loose

enough to swing freely if you move the helicopter

and stop abruptly.

15

EN

Page 16

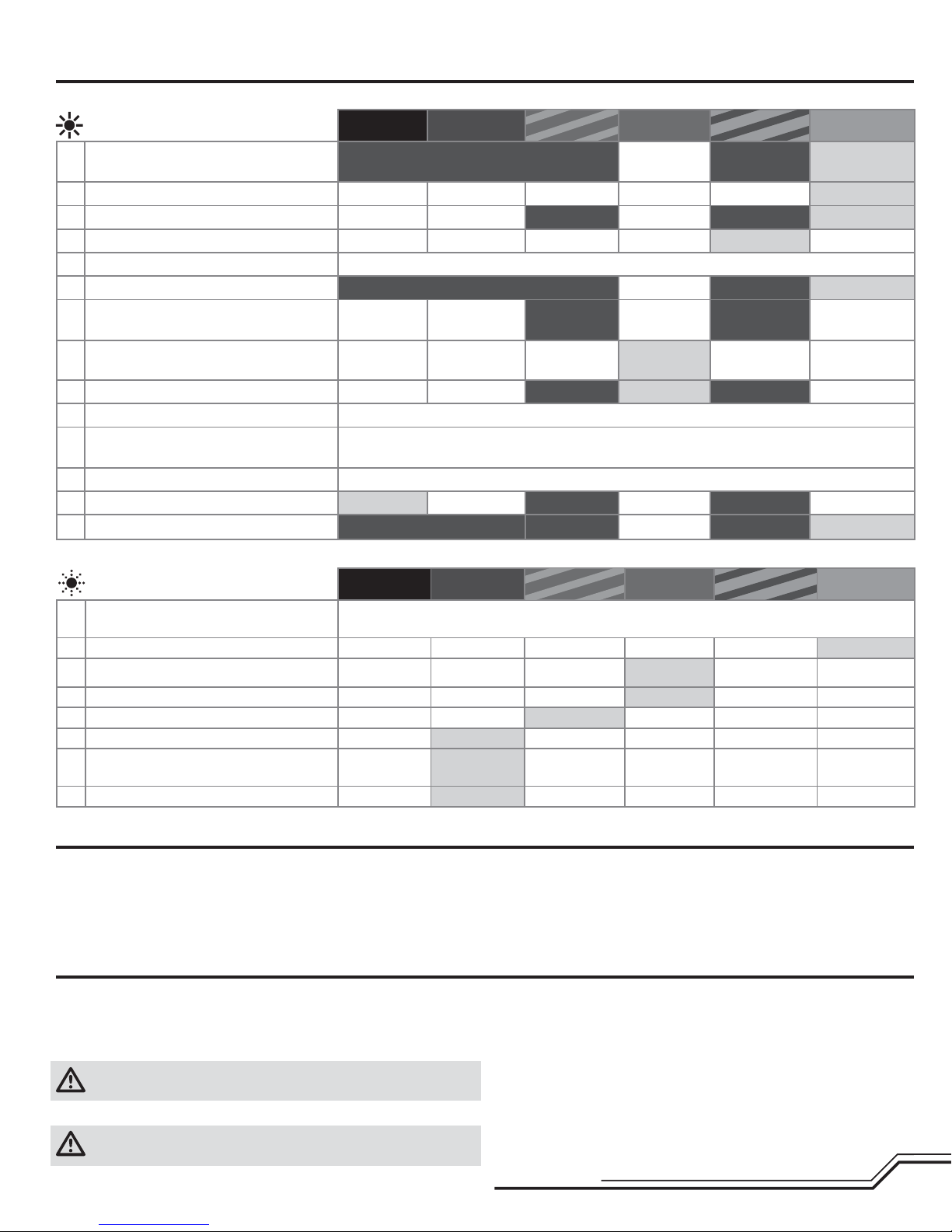

Programming Your Transmitter

Program your transmitter before attempting to bind or fl y the helicopter. Transmitter programming values are shown below for the Spektrum DX6i, DX7/DX7se,

DX7s, DX8, and DX18. The fi les for models using SpektrumTM transmitters with AirWare™ software are also available for download online in the Spektrum Community.

DX6i

SETUP LIST

Model Type

HELI

Reverse

THRO N

AILE R

ELEV R

RUDD N

GYRO N

PITC R

Swash Type

1 Servo 90

Timer

4:00

DX7s/DX8/DX18

SYSTEM SETUP

Model Type

HELI

Swash Type

1 Servo Normal

F-Mode Setup

Flight Mode: F Mode

Hold: Hold

Frame Rate

11ms

DSMX

ADJUST LIST

D/R & Expo

0-AILE 100% 30%

0-ELEV 100% 30%

0-RUDD 100% INH

1-AILE 85% 30%

1-ELEV 85% 30%

1-RUDD 85% INH

Thro Curve

NORM 0% 40% 80% 80% 100%

STUNT 100% 100% 100% 100% 100%

HOLD 10% 10% 10% 10% 10%

Pitc Curve

NORM 30% 40% 50% 75% 100%

STUNT 0% 25% 50% 75% 100%

HOLD 0% 25% 50% 75% 100%

Travel Adj

THRO 100%

AILE 100%

ELEV 100%

RUDD 100%

GYRO 100%

PITC 100%

FUNCTION LIST

D/R & Expo

0-AILE 100% 30%

0-ELEV 100% 30%

0-RUDD 100% 0%

1-AILE 85% 30%

1-ELEV 85% 30%

1-RUDD 85% 0%

2-AILE 85% 30%

2-ELEV 85% 30%

2-RUDD 85% 0%

SERVO SETUP

Travel

THRO 100%

AILE 100%

ELEV 100%

RUDD 100%

GEAR 100%

PIT. 100%

Gyro

Rate SW-F. Mode

NORM 84%

STUNT 84%

Throttle Curve

NORM 0% 40% 60% 80% 100%

ST-1 80% 80% 80% 80% 80%

ST-2 (DX8/18 only) 100% 100% 100% 100% 100%

HOLD 0% 0% 0% 0% 0%

Pitch Curve

NOR 30% 40% 50% 75% 100%

ST-1 0% 25% 50% 75% 100%

ST-2 (DX8/18 only) 0% 25% 50% 75% 100%

HOLD 0% 25% 50% 75% 100%

Reverse

THRO N

AILE R

ELEV R

RUDD N

GEAR N

PIT. N

Timer

MODE Countdown

TIME 4:00 Tone/Vibe

START Throttle Out

POS 25

DX7/DX7se

SYSTEM LIST

Model Type

HELI

Swash Type

1 Servo 90

Gyro

SW F Mode

CH Gear

NORMAL/POS 0 68%

STUNT 1/POS 1 68%

STUNT 2/POS 2 68%

HOLD 68%

FUNCTION MODE

D/R & EXP

0-AILE 100% 30%

0-ELEV 100% 30%

0-RUDD 100% INH

1-AILE 85% 30%

1-ELEV 85% 30%

1-RUDD 85% INH

Thro Curve

NORM 0% 40% 60% 80% 100%

ST-1 80% 80% 80% 80% 80%

ST-2 100% 100% 100% 100% 100%

HOLD 0% 0% 0% 0% 0%

Pitc Curve

NORM 30% INH 50% INH 100%

ST-1 0% INH 50% INH 100%

ST-2 0% INH 50% INH 100%

HOLD 0% INH 50% INH 100%

Travel Adj

THRO 100%

AILE 100%

ELEV 100%

RUDD 100%

GEAR 100%

PIT. 100%

Reversing SW

THRO N RUDD N

AILE R GEAR N

ELEV R PIT. N

Gyro SENS

AUTO F.MODE

STNT 84%

HOLD 84%

Timer

4:00

Throttle Hold

When you move the throttle hold switch to the ON position, the helicopter motor

turns off. You will still have control of the helicopter cyclic and rudder commands.

The blades spin if throttle hold is OFF. For safety, turn throttle hold ON any time

you need to touch the helicopter or check the direction controls.

EN

You should also turn throttle hold ON to minimize damage if the helicopter is out

of control or in danger of crashing.

See your transmitter manual for more information on programming throttle hold.

16

Page 17

AR7200BX Recommended Blade 550 X Setup

Firmware version 3.X.X

SETUP MENU Menu LED solid

Status-LED: OFF Purple Red Flashing Red Solid Blue Flashing Blue Solid

A Mounting orientation

B Swashplate servo - frequency User defi ned 50 Hz 65 Hz 120 Hz 165 Hz 200 Hz*

C Tail servo - center position pulse length User defi ned 960 μs 760 μs 1520 μs*

D Tail servo - frequency User defi ned 50 Hz 165 Hz 270* Hz 333 Hz 560 Hz

E Tail servo - rotor endpoints Tail stick - move to right endpoint and wait/left endpoint and wait

F Tail - sensor direction normal reversed*

G Swashplate - servo centering

H Swashplate - mixer User defi ned mechanical 90° 120°* 140° 140° (1=1)

I Swashplate - servo directions nor|rev|rev nor|nor|rev* nor|rev|nor nor|nor|nor

J Swashplate - cyclic pitch geometry Aileron stick – adjust 6° cyclic pitch on the roll axis (blades aligned with fuselage)

K Collective pitch range

L Swashplate - cyclic limit Move aileron, elevator and pitch sticks – adjust max limits with tail stick

M Swashplate - sensor directions rev | rev rev | nor nor | rev nor | nor*

N Pirouette optimization direction normal reversed*

Reference

position

Collective stick on max and min position and use tail stick to adjust desired pitch.

Stock settings provide +/- 14 degrees of collective pitch.

ELE center pos. AIL center pos. PIT center pos.

Refer to the Spektrum AR7200BX manual for specifi c details.

upright

(vertical)

fl at (horizontal)*

PARAMETER MENU Menu LED is fl ashing quickly

Status-LED:

A Swashplate -

cyclic center adjustment

B Control behavior User defi ned normal sport* pro extreme transmitter

C Swashplate - pitching up behavior

D Tail - HeadingLock gain User defi ned very low low medium* high very high

E Stick deadband User defi ned 12* 34 5

F Tail - torque precompensation IX) User defi ned off* low - nor high - nor low - rev high - rev

G Cyclic response

H Pitch boost User defi ned off* low medium high very high

OFF Purple Red Flashing Red Solid Blue Flashing Blue Solid

Aileron and elevator stick – reset with tail stick

User defi ned very low low medium* high very high

User defi ned normal*

slightly

increased*

increased high very high

AR7200BX Parameter Menu Tips

Refer to the Spektrum AR7200BX manual to fi ne tune the Blade 550 X to your

fl ying and control style via the AR7200BX parameter menu.

If you would like to change the control behavior of the fl ybarless system to a

pre-defi ned behavior in the AR7200BX, adjust parameter B (default behavior is

transmitter).

If you would like to have the cyclic behavior to feel more linear OR more like

a fl ybarred helicopter, increase the cyclic response by adjusting parameter G

(default is ‘normal’).

Refer to the Spektrum AR7200BX manual for specifi c details on each

parameter.

Motor Direction Test

Place the helicopter outdoors on a clean, fl at and level surface (concrete or

asphalt) free of obstructions. Always stay clear of moving rotor blades.

1. Power on the transmitter. Make sure TH HOLD is ON and the fl ight mode

switch is in the normal position.

WARNING: The motor will spin when throttle is increased

and TH HOLD is OFF.

2. Lower the throttle completely.

WARNING: Stay at least 45 feet (13 meters) away from

the helicopter when the motor is running.

3. Connect the Li-Po battery to the ESC.

4. Turn TH HOLD OFF. Slowly increase the throttle until the drive train begins to

turn. The main blades spin clockwise when viewing the helicopter from the top.

The tail rotor blades spin counterclockwise when viewing the helicopter from

the right-hand side.

NOTICE: If the drive train does not turn with the motor or spins counterclockwise,

turn TH HOLD ON. Disconnect the battery from the helicopter and reverse any

two motor wire connections to the ESC and repeat the motor control test.

17

EN

Page 18

Control Tests

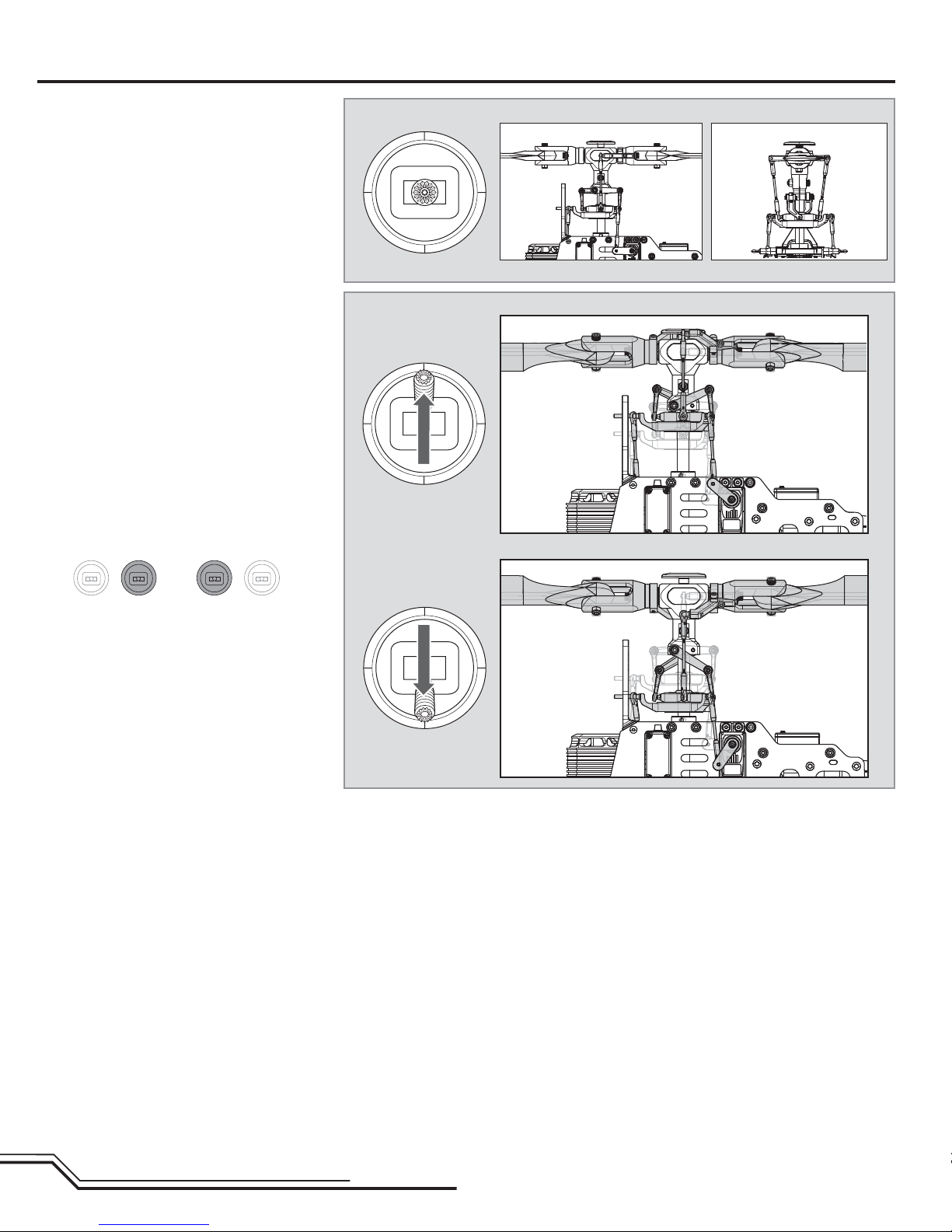

Swashplate set to 0° (Neutral)

Neutral (Viewed from left) Neutral (Viewed from back)

Positive pitch (Viewed from left)

Collective pitch

Mode 1

Mode 2

Negative pitch (Viewed from left)

EN

18

Page 19

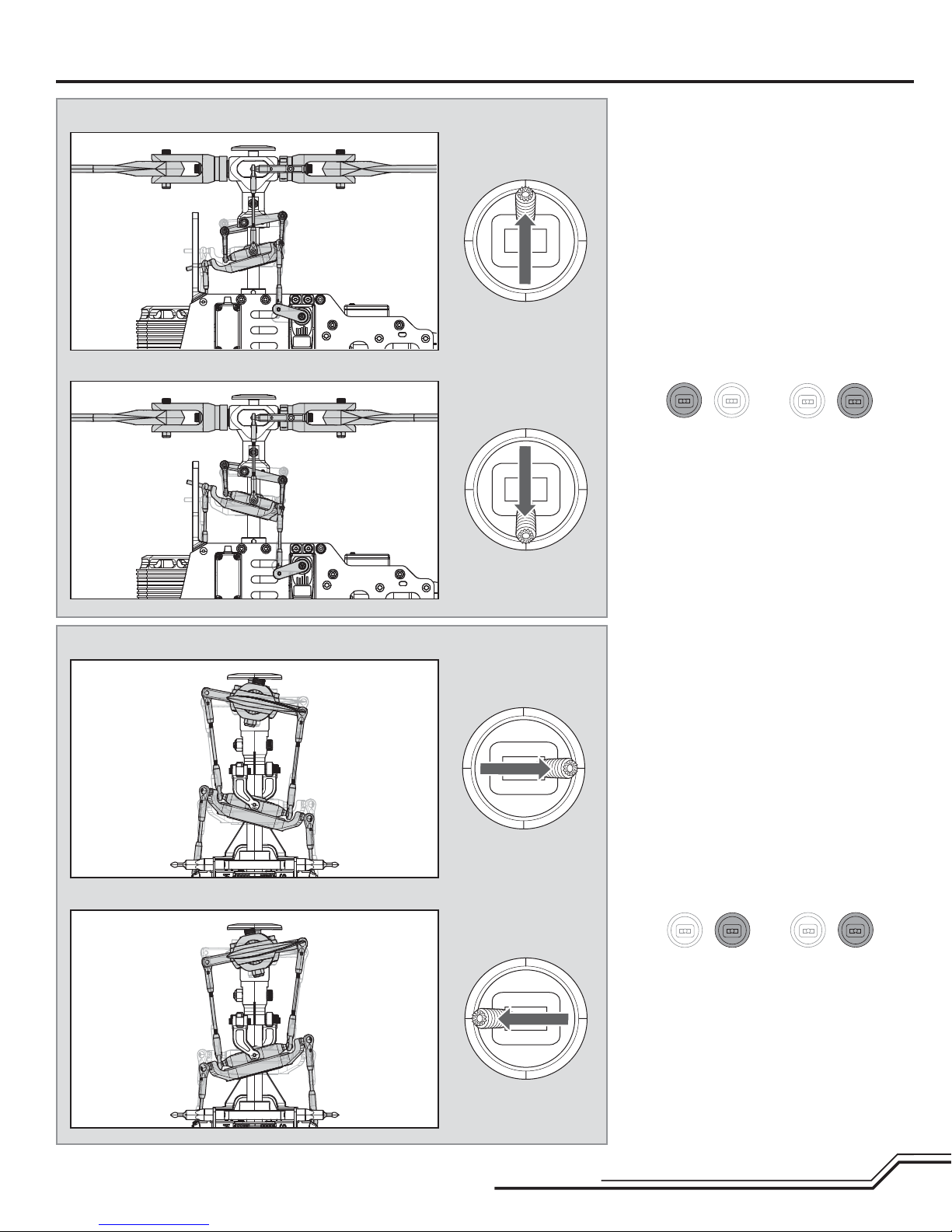

Forward elevator (Viewed from left)

Back elevator (Viewed from left)

Elevator

Mode 1

Mode 2

Right aileron (Viewed from back)

Left aileron (Viewed from back)

Aileron

Mode 1

Mode 2

19

EN

Page 20

Low Voltage Cuto (LVC)

Low voltage cutoff (LVC) protects the Li-Po battery from overdischarge in fl ight

and activates when the battery reaches 3V per cell under load.

Set your transmitter timer for 4 minutes and land when the timer expires.

Repeatedly activating LVC damages the fl ight battery and you will need to

replace the battery.

Flight Guidelines and Warnings

• Always keep aircraft in sight and under control.

• Always keep people and pets at least 45 feet (13 meters) away when the

battery is connected.

• Keep children out of the vicinity of this product at all times.

• Always turn on throttle hold at rotor strike.

• Always use fullly charged batteries.

• Always keep transmitter powered on while aircraft is powered.

• Always remove batteries before disassembly.

Flying Your 550X

Crash damage and battery damage are not covered under warranty.

Always disconnect and remove the Li-Po battery from the aircraft after each

fl ight. Charge your Li-Po battery to about half capacity before storage. During

storage, make sure battery charge does not fall below 3V per cell. A connected

battery will result in trickle discharge.

• Always keep moving parts clean.

• Always keep parts dry.

• Always let parts cool after use before touching.

• Always remove batteries after use.

• Always have a fi rst aid kit with you.

• Always have an appropriate fi re extinguisher with you.

• Never operate aircraft with damaged wiring.

• Never touch moving parts.

Consult local laws and ordinances before choosing a location

to fl y your aircraft.

Select a large, open area away from people and objects. Your fi rst fl ights should

be outdoors in low-wind conditions. Always stay at least 45 feet

(13 meters) away from the helicopter when it is fl ying.

Do not attempt to fl y the Blade 550 X indoors.

CAUTION: The Blade 550 X is intended for pilots with experience fl ying

aerobatic, collective pitch helicopters. The Blade 550 X is more responsive

than other Blade helicopters. If you are not an experienced 3D or collective pitch

helicopter pilot, do not attempt to fl y this product.

Takeoff

Gradually increase the throttle, allowing the rotors time to come up to speed.

CAUTION: Do not give any aileron, elevator or rudder commands before the

helicopter lifts off. Any control inputs prior to liftoff could cause a crash.

The helicopter will lift off the ground when the rotor head reaches a suitable

speed and you apply collective pitch. Once airborne, establish a low-level hover

to verify everything is functioning properly. DO NOT use trim to assist in holding

the Blade 550X in a desired position. The AR7200BX Flybarless Stabilization

System renders trim unnecessary by working to keep the helicopter in whatever

attitude you command with the control sticks.

Flying

This aircraft is extremely sensitive to control inputs. We recommend you fl y at

low rate settings for the fi rst few fl ights until you are familiar with its response.

For pilots new to collective pitch helicopters, familiarize yourself with your Blade

550 X in normal mode and at low rate.

CAUTION: Always fl y the helicopter with your back to the sun and wind to

prevent loss of fl ight control.

Landing

Establish a low level hover. Deliberately lower the throttle until the helicopter

lands. Make only small control corrections during this time to avoid rotor blade

strikes or other damage.

When the helicopter is in stunt mode:

• The rotor head speed is constant.

• The main rotor will increase negative pitch as the throttle/collective stick is

moved from the middle stick position to the low stick position. Negative pitch

allows the helicopter to fl y upside down and perform aerobatics.

Change between stunt and normal modes in a hover with the throttle near the

hovering stick position.

The helicopter may go up or down when you change between modes due to the

difference in the throttle and pitch curves.

NOTICE: To minimize damage, always activate throttle hold in preparation for or

during a crash.

WARNING: Only use Blade 550 X approved carbon fi ber main blades.

Do not use wooden main blades with the Blade 550 X. Using wooden

main blades may cause injury or property damage.

As you become more familiar with the helicopter’s response, adjust the rates,

expo, pitch and throttle curves to suit your fl ying style.

EN

20

Page 21

Blade Tracking

WARNING: Always maintain a safe distance of at least 15 meters

(45 feet) when checking the main rotor blade tracking.

To check the blade tracking:

1. Put the helicopter in a hover at an altitude near eye height.

Adjusting the Rudder Gyro Gain

• If the tail wags or oscillates, lower the gain on the gyro.

On your transmitter’s gyro menu, decrease the gyro gain values a small amount

at a time until the helicopter is stable within a particular fl ight mode

Post-Flight Inspection and Maintenance Checklist

√

Make sure the plastic ball link holds the control ball, but

Ball Links

Cleaning

Bearings

Wiring

Fasteners

is not tight (binding) on the ball. When a link is too loose

on the ball, it can separate from the ball during fl ight and

cause a crash. Replace worn ball links before they fail.

Make sure the battery is not connected before cleaning.

Remove dust and debris with a soft brush or a dry lint-free

cloth.

Replace bearings when they become notchy (sticky in

places when turning) or draggy.

Make sure wiring does not block moving parts. Replace

damaged wiring and loose connectors.

Make sure there are no loose screws, other fasteners or

connectors. Do not over tighten metal screws in plastic

parts. Tighten screw so parts are mated together, then turn

screw only 1/8th of a turn more.

2. Watch the movement at the blade tips. Both blades should travel in the

same plane.

3. If one blade tip appears to be higher than the other, land the helicopter,

disconnect the fl ight battery and adjust the blade linkages.

4. Repeat Steps 1 through 3 until both blades are moving in the same plane.

• If the tail is drifting while hovering, increase the gain on the gyro.

On your transmitter, increase the gyro gain values a small amount at a time until

the tail starts to wag/oscillate. Afterwards, reduce the gain until the tail stops

wagging/oscillating within a particular fl ight mode.

√

Make sure there is no damage to rotor blades and other

Rotors

Gyro

Gearing

parts which move at high speed. Damage to these parts

includes cracks, burrs, chips or scratches. Replace damaged parts before fl ying.

Make sure the AR7200BX is securely attached to the

frame. Replace the double-sided tape when necessary. The

helicopter will crash if the AR7200BX separates from the

helicopter frame.

Make sure gears are all in good condition. Watch for

chipped teeth or excessive wear. White dust around gears

is an indication of excess wear. Replace damaged gears

before fl ying.

AR7200BX Fine-tuning and Adjustment

Observed Behavior Suggested Adjustment

Cyclic response is too slow or too fast Adjust end points to fi t your fl ying style. Refer to your transmitter instruction

Control inputs feel delayed Increase Dial 2 on the AR7200BX

The helicopter seems to overshoot control input and then return Decrease Dial 2 on the AR7200BX

The helicopter tail stops too abruptly Decrease Dial 3 on the AR7200BX

The helicopter tail does not stop precisely Increase the rudder gain in your transmitter

manual for more information

Adjust the control behavior parameter in the AR7200BX to fi t your fl ying style.

Increase Dial 3 on the AR7200BX

Adjust the rudder heading lock gain parameter in the AR7200BX

21

EN

Page 22

Blade 550 X Troubleshooting Guide

Problem Possible Cause Solution

The helicopter was moved during initialization Lay the helicopter on its side during initialization if windy

AR7200BX will not initialize

LED on receiver fl ashes rapidly and

aircraft will not bind to transmitter

(during binding)

LED on receiver fl ashes rapidly and

aircraft will not respond to transmitter (after binding)

Helicopter will not respond to the

throttle but responds to other controls

Helicopter power is lacking

Helicopter will not lift off

The helicopter tail spins out of

control

The helicopter wobbles in fl ight

The transmitter is powered off Power on the transmitter

Controls are not centered

Transmitter is too near aircraft during binding process

Bind switch or button was not held while transmitter

was powered on

Aircraft or transmitter is too close to large metal object, wireless source or another transmitter

Less than a 5-second wait between fi rst powering on

transmitter and connecting fl ight battery to aircraft

Aircraft is bound to a different model memory

(ModelMatch

Flight battery/transmitter battery charge is too low Replace/recharge batteries

Transmitter may have been bound to a different model

(or with a different DSM Protocol)

Aircraft or transmitter is too close to large metal object, wireless source or another transmitter

Throttle not at idle and/or throttle trim is too high Lower the throttle stick and lower the throttle trim

The transmitter is not in normal mode or throttle hold

is on

The motor is not connected to the ESC or the motor

wires are damaged

Flight battery charge is too low Replace or recharge fl ight battery

Throttle channel is reversed Reverse the throttle channel on the transmitter

Flight battery has low voltage Fully charge the fl ight battery

Flight battery is old or damaged Replace the fl ight battery

Flight battery cells are unbalanced

Excessive current is being drawn through the BEC Check all servos and the helicopter motor for damage

Main rotor head is not spinning in the correct direc-

tion

Transmitter settings are not correct Check throttle and pitch curve settings and pitch control direction

Flight battery has low voltage Fully charge the fl ight battery

Main rotor blades are installed backwards

Rudder control and/or sensor direction reversed

Tail servo is damaged Check the rudder servo for damage and replace if necessary

Tail drive gears are damaged Replace damaged gears.

Inadequate control arm throw

Torque tube is not fully engaged in tail gears.

Cyclic gain is too high Decrease Dial 1 on the AR7200BX

Headspeed is too low

Dampers are worn Replace the main rotor head dampers

TM

radios only)

Center elevator, aileron and rudder controls. Make sure the throttle

is at idle

Power off transmitter, move transmitter a larger distance from aircraft, disconnect and reconnect fl ight battery to aircraft and follow

binding instructions

Power off transmitter and repeat bind process

Move aircraft and transmitter to another location and attempt binding

again

Leaving transmitter on, disconnect and reconnect fl ight battery to

aircraft

Select correct model memory on transmitter and disconnect and reconnect fl ight battery to aircraft

Select the right transmitter or bind to the new one

Move aircraft and transmitter to another location and attempt con-

necting again

Make sure the transmitter is in normal mode and throttle hold is off

Connect the motor wires to the ESC and check motor wires for damage

Fully charge the fl ight battery, allowing the charger time to balance

the cells

Make sure the main rotor head is spinning clockwise. Refer to the

motor control test

Install the main rotor blades with the thicker side as the leading

edge

Make sure the rudder control and the rudder sensor are operating in

the correct direction

Check the rudder control arm for adequate travel and adjust if necessary

Ensure the tail boom and tail gear box are fully seated. Confi rm tail

pushrod length and tail settings on AR7200BX are correct after making any changes.

Increase the helicopter's head speed via your transmitter settings

and/or using a freshly charged fl ight pack

EN

22

Page 23

Limited Warranty

What this Warranty Covers

Horizon Hobby, Inc. (“Horizon”) warrants to the original purchaser that the product

purchased (the “Product”) will be free from defects in materials and workmanship at

the date of purchase.

What is Not Covered

This warranty is not transferable and does not cover (i) cosmetic damage, (ii)

damage due to acts of God, accident, misuse, abuse, negligence, commercial use, or

due to improper use, installation, operation or maintenance, (iii) modifi cation of or to

any part of the Product, (iv) attempted service by anyone other than a Horizon Hobby

authorized service center, (v) Product not purchased from an authorized Horizon

dealer, or (vi) Product not compliant with applicable technical regulations.

OTHER THAN THE EXPRESS WARRANTY ABOVE, HORIZON MAKES NO OTHER

WARRANTY OR REPRESENTATION, AND HEREBY DISCLAIMS ANY AND ALL IMPLIED

WARRANTIES, INCLUDING, WITHOUT LIMITATION, THE IMPLIED WARRANTIES

OF NON-INFRINGEMENT, MERCHANTABILITY AND FITNESS FOR A PARTICULAR

PURPOSE. THE PURCHASER ACKNOWLEDGES THAT THEY ALONE HAVE

DETERMINED THAT THE PRODUCT WILL SUITABLY MEET THE REQUIREMENTS OF

THE PURCHASER’S INTENDED USE.

Purchaser’s Remedy

Horizon’s sole obligation and purchaser’s sole and exclusive remedy shall be that

Horizon will, at its option, either (i) service, or (ii) replace, any Product determined by

Horizon to be defective. Horizon reserves the right to inspect any and all Product(s)

involved in a warranty claim. Service or replacement decisions are at the sole

discretion of Horizon. Proof of purchase is required for all warranty claims. SERVICE

OR REPLACEMENT AS PROVIDED UNDER THIS WARRANTY IS THE PURCHASER’S

SOLE AND EXCLUSIVE REMEDY.

Limitation of Liability

HORIZON SHALL NOT BE LIABLE FOR SPECIAL, INDIRECT, INCIDENTAL OR

CONSEQUENTIAL DAMAGES, LOSS OF PROFITS OR PRODUCTION OR COMMERCIAL

LOSS IN ANY WAY, REGARDLESS OF WHETHER SUCH CLAIM IS BASED IN

CONTRACT, WARRANTY, TORT, NEGLIGENCE, STRICT LIABILITY OR ANY OTHER

THEORY OF LIABILITY, EVEN IF HORIZON HAS BEEN ADVISED OF THE POSSIBILITY

OF SUCH DAMAGES. Further, in no event shall the liability of Horizon exceed the

individual price of the Product on which liability is asserted. As Horizon has no

control over use, setup, fi nal assembly, modifi cation or misuse, no liability shall be

assumed nor accepted for any resulting damage or injury. By the act of use, setup or

assembly, the user accepts all resulting liability. If you as the purchaser or user are

not prepared to accept the liability associated with the use of the Product, purchaser

is advised to return the Product immediately in new and unused condition to the

place of purchase.

Law

These terms are governed by Illinois law (without regard to confl ict of law principals).

This warranty gives you specifi c legal rights, and you may also have other rights

which vary from state to state. Horizon reserves the right to change or modify this

warranty at any time without notice.

WARRANTY SERVICES

Questions, Assistance, and Services

Your local hobby store and/or place of purchase cannot provide warranty support

or service. Once assembly, setup or use of the Product has been started, you

must contact your local distributor or Horizon directly. This will enable Horizon

to better answer your questions and service you in the event that you may need

any assistance. For questions or assistance, please visit our website at www.

horizonhobby.com, submit a Product Support Inquiry, or call 877.504.0233 toll free

to speak to a Product Support representative.

Inspection or Services

If this Product needs to be inspected or serviced and is compliant in the country

you live and use the Product in, please use the Horizon Online Service Request

submission process found on our website or call Horizon to obtain a Return

Merchandise Authorization (RMA) number. Pack the Product securely using a

shipping carton. Please note that original boxes may be included, but are not

designed to withstand the rigors of shipping without additional protection. Ship via a

carrier that provides tracking and insurance for lost or damaged parcels, as Horizon

is not responsible for merchandise until it arrives and is accepted at our facility.

An Online Service Request is available at http://www.horizonhobby.com/content/_

service-center_render-service-center. If you do not have internet access, please

contact Horizon Product Support to obtain a RMA number along with instructions

for submitting your product for service. When calling Horizon, you will be asked to

provide your complete name, street address, email address and phone number

where you can be reached during business hours. When sending product into

Horizon, please include your RMA number, a list of the included items, and a brief

summary of the problem. A copy of your original sales receipt must be included for

warranty consideration. Be sure your name, address, and RMA number are clearly

written on the outside of the shipping carton.

NOTICE: Do not ship LiPo batteries to Horizon. If you have any issue with a

LiPo battery, please contact the appropriate Horizon Product Support offi ce.

Warranty Requirements

For Warranty consideration, you must include your original sales receipt

verifying the proof-of-purchase date. Provided warranty conditions have been

met, your Product will be serviced or replaced free of charge. Service or replacement

decisions are at the sole discretion of Horizon.

Non-Warranty Service

Should your service not be covered by warranty, service will be completed

and payment will be required without notifi cation or estimate of the

expense unless the expense exceeds 50% of the retail purchase cost. By

submitting the item for service you are agreeing to payment of the service without

notifi cation. Service estimates are available upon request. You must include this

request with your item submitted for service. Non-warranty service estimates will be

billed a minimum of ½ hour of labor. In addition you will be billed for return freight.

Horizon accepts money orders and cashier’s checks, as well as Visa, MasterCard,

American Express, and Discover cards. By submitting any item to Horizon for service,

you are agreeing to Horizon’s Terms and Conditions found on our website http://

www.horizonhobby.com/content/_service-center_render-service-center.

ATTENTION: Horizon service is limited to Product compliant in the country

of use and ownership. If received, a non-compliant Product will not be

serviced. Further, the sender will be responsible for arranging return

shipment of the un-serviced Product, through a carrier of the sender’s

choice and at the sender’s expense. Horizon will hold non-compliant

Product for a period of 60 days from notifi cation, after which it will be

discarded.

23

EN

Page 24

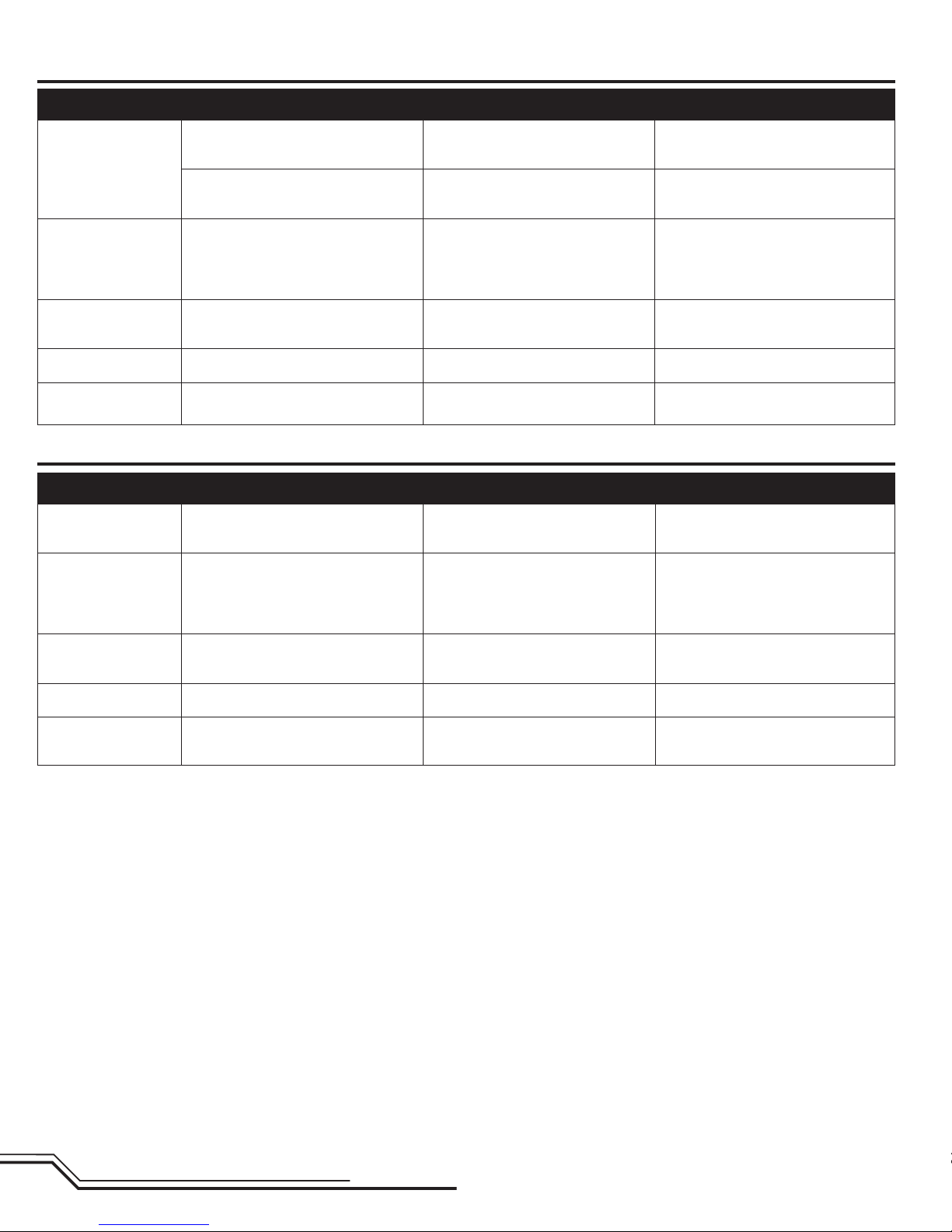

Warranty and Service Contact Information

Country of Purchase Horizon Hobby Address Phone Number/Email Address

Horizon Service Center

(Electronics and engines)

United States of America

Horizon Product Support (All other products)

United Kingdom Horizon Hobby Limited

Germany Horizon Technischer Service

France Horizon Hobby SAS

China Horizon Hobby – China

4105 Fieldstone Rd

Champaign, Illinois

61822 USA

4105 Fieldstone Rd

Champaign, Illinois

61822 USA

Units 1-4 Ployters Rd

Staple Tye

Harlow, Essex

CM18 7NS

United Kingdom

Christian-Junge-Straße 1

25337 Elmshorn

Germany

11 Rue Georges Charpak

77127 Lieusaint, France

Room 506, No. 97 Changshou Rd.

Shanghai, China 200060

877-504-0233

Online Repair Request:

visit www.horizonhobby.com/service

877-504-0233

productsupport@horizonhobby.com

+44 (0) 1279 641 097

sales@horizonhobby.co.uk

+49 (0) 4121 2655 100

service@horizonhobby.de

+33 (0) 1 60 18 34 90

infofrance@horizonhobby.com

+86 (021) 5180 9868

info@horizonhobby.com.cn

Customer Service Information

Country of Purchase Horizon Hobby Address Phone Number/Email Address

United States of America Sales

United Kingdom Horizon Hobby Limited

Germany Horizon Hobby GmbH

France Horizon Hobby SAS

China Horizon Hobby – China

4105 Fieldstone Rd

Champaign, Illinois

61822 USA

Units 1-4 Ployters Rd

Staple Tye

Harlow, Essex

CM18 7NS

United Kingdom

Christian-Junge-Straße 1

25337 Elmshorn

Germany

11 Rue Georges Charpak

77127 Lieusaint, France

Room 506, No. 97 Changshou Rd.

Shanghai, China 200060

(800) 338-4639

sales@horizonhobby.com

+44 (0) 1279 641 097

sales@horizonhobby.co.uk

+49 (0) 4121 2655 100

service@horizonhobby.de

+33 (0) 1 60 18 34 90

infofrance@horizonhobby.com

+86 (021) 5180 9868

info@horizonhobby.com.cn

EN

24

Page 25

Compliance Information for the European Union

Declaration of Conformity

(in accordance with ISO/IEC 17050-1)

No. HH2012101407

Product(s): BLH 550 X Pro Kit

Item Number(s): BLH5525

The object of declaration described above is in conformity with the requirements of the specifi cations

listed below, following the provisions of the European EMC Directive 2004/108/EC:

EN55022:2010 + AC:2011

EN55024:2010

Signed for and on behalf of:

Horizon Hobby, Inc.

Champaign, IL USA

Oct 14, 2012

Executive Vice President and Chief Operating Offi cer

International Operations and Risk Management

Steven A. Hall

Horizon Hobby, Inc.

Declaration of Conformity

(in accordance with ISO/IEC 17050-1)

No. HH2012122101

Product(s): Blade 550X Pro Combo

Item Number(s): BLH5525C

The object of declaration described above is in conformity with the requirements of the specifi cations

listed below, following the provisions of the European R&TTE directive 1999/5/EC and EMC Directive

2004/108/EC:

EN301 489-1 V1.7.1: 2006

EN301 489-17 V1.3.2: 2008

EN55022:2010 + AC:2011

EN55024:2010

Signed for and on behalf of:

Horizon Hobby, Inc.

Champaign, IL USA

Dec 21, 2012

Executive Vice President and Chief Operating Offi cer

International Operations and Risk Management

Steven A. Hall

Horizon Hobby, Inc.

Instructions for disposal of WEEE by users in the European Union

This product must not be disposed of with other waste. Instead, it is the user’s responsibility to dispose of their waste equipment by handing it over

to a designated collections point for the recycling of waste electrical and electronic equipment. The separate collection and recycling of your waste

equipment at the time of disposal will help to conserve natural resources and ensure that it is recycled in a manner that protects human health and the

environment. For more information about where you can drop off your waste equipment for recycling, please contact your local city offi ce, your household waste disposal service or where you purchased the product.

25

EN

Page 26

HINWEIS

Allen Anweisungen, Garantien und anderen zugehörigen Dokumenten sind Änderungen nach Ermessen von Horizon Hobby, Inc. vorbehalten. Aktuelle Produktliteratur fi nden Sie auf horizonhobby.com im Support-Abschnitt für das Produkt.

Spezielle Bedeutungen

Die folgende Begriffe werden in der gesamte Produktliteratur verwendet, um die Gefährdungsstufen im Umgang mit dem Produkt zu defi nieren:

Der Zweck der Sicherheitssymbole ist es Ihre Aufmerksamkeit auf mögliche Gefahren zu lenken. Die Symbole und ihre Erklärungen erfordern ihre sorgfältige Aufmerksamkeit und Verstehen. Die Symbole eliminieren nicht die Gefahr. Die Anweisungen und Warnungen ersetzen nicht angemessene und korrekte Unfallverhütungsmaßnahmen.

HINWEIS: Verfahren können bei nicht ordnungsgemäßer Durchführung womöglich Schäden an physischem Eigentum UND geringfügige oder keine Verletzungen verursachen.

ACHTUNG: Verfahren können bei nicht ordnungsgemäßer Durchführung womöglich Schäden an physischem Eigentum UND schwere Verletzungen verursachen.

WARNUNG: Verfahren können bei nicht ordnungsgemäßer Durchführung möglicherweise Schäden an Eigentum, Kollateralschäden UND schwere Verletzungen bis zum

Tot ODER höchstwahrscheinlich oberfl ächliche Verletzungen verursachen.

Sicherheitsalarm: Zeigt eine Warnung oder Vorsichtmaßregel an. Hier ist Aufmerksamkeit erforderlich um ernste Körperverletzungen zu vermeiden.

WARNUNG: Lesen Sie die GESAMTE Bedienungsanleitung, um sich vor Inbetriebnahme mit den Funktionen des Produkts vertraut zu machen. Eine nicht ordnungs-

gemäße Bedienung des Produkts kann das Produkts und persönliches Eigentum schädigen und schwere Verletzungen verursachen.

Dieses ist ein anspruchvolles Hobby Produkt für den fortgeschrittenen Hubschrauberpiloten mit Erfahrung von Pitchgesteuerten (CCPM) Hubschraubern ((Cyclic Collective

Pitch Mixing oder Collective Pitch Helicopter) wie zum Beispiel dem Blade SR oder dem Blade mCP X. Es muss mit Vorsicht und Umsicht bedient werden und erfordert

einige mechanische Grundfertigkeiten. Dies ist ein hoch entwickeltes Produkt für den Hobbygebrauch. Es muss mit Vorsicht und Umsicht bedient werden und erfordert

einige mechanische Grundfertigkeiten. Wird das Produkt nicht sicher und umsichtig verwendet, so könnten Verletzungen oder Schäden am Produkt oder anderem Eigentum

entstehen. Dieses Produkt ist nicht für den Gebrauch durch Kinder ohne direkte Aufsicht eines Erwachsenen vorgesehen. Versuchen Sie nicht, das Produkt ohne Zustimmung von Horizon Hobby, Inc. zu zerlegen, mit nicht-kompatiblen Komponenten zu verwenden oder beliebig zu verbessern. Dieses Handbuch enthält Sicherheitshinweise

sowie Anleitungen zu Betrieb und Wartung. Es ist unerlässlich, dass Sie alle Anleitungen und Warnungen in diesem Handbuch vor dem Zusammenbau, der Einrichtung oder

der Inbetriebnahme lesen und diese befolgen, um eine korrekte Bedienung zu gewährleisten und Schäden bzw. schwere Verletzungen zu vermeiden.

Alters Empfehlung: Nicht für Anfängerpiloten unter 14 Jahren. Das ist kein Spielzeug.

Zusätzliche Sicherheitsmaßnahmen und Warnungen

Dieses Modell wird über ein Funksignal gesteuert. Funksignale können von außerhalb gestört werden, ohne dass Sie darauf Einfl uss nehmen können. Dies kann zu einem

vorübergehenden Verlust der Steuerungskontrolle führen.

• Stellen Sie immer sicher, dass Sie vollständig die Kontrollen des Senders und Ihren Einfl uß auf die Bewegung des Hubschrauber verstanden haben.

• Betreiben Sie Ihr Modell stets auf offenen Geländen, weit ab von Automobilen, Verkehr und Menschen.

• Befolgen Sie die Anweisungen und Warnungen für dieses Produkt und jedwedes optionales Zubehörteil (Ladegeräte, wiederaufl adbare Akkus etc.) stets sorgfältig.

• Halten Sie sämtliche Chemikalien, Kleinteile und elektrische Komponente stets außer Reichweite von Kindern.

• Halten Sie dieses Produkt immer aus der Reichweite von Kindern.

• Halten Sie dieses Produkt stets ausser Reichweite von Kindern. Lagern Sie dieses Produkt immer ausserhalb der Reichweite von Kindern.

• Halten Sie stets ihr Haar über den Schultern gesichert, dass es sich nicht in den Blättern verfangen kann.

• Feuchtigkeit beschädigt die Elektronik. Vermeiden Sie den Wasserkontakt aller Komponenten, die dafür nicht speziell ausgelegt und entsprechend geschützt sind.

• Betreiben und warten Sie dieses Produkt immer bei Tageslicht.

• Stellen Sie vor dem Betrieb immer sicher dass alle Befestigungen gesichert sind.

• Lagern Sie dieses Produkt immer an einem sicheren trockenen Ort.

• Berühren Sie nicht den Motor, da er während des Betriebes extrem heiß werden kann.

• Fliegen Sie den Hubschrauber nicht Indoor (in Räumen, Gebäuden oder Hallen).

• Vertrauen Sie nicht ausschließlich auf die Sicherheitsmechanismen die im Sender und Empfänger eingebaut sind. Versichern Sie sich immer, dass Sie das Produkt und wie

es zu betreiben ist verstehen.

• Versichern Sie sich immer, dass Sie das Produkt und wie es zu betreiben ist verstehen.

• Verwenden Sie für dieses Produkt nur von Horizon zugelassene Teile und Zubehör.

• Nehmen Sie niemals ein Element des Modells in Ihren Mund, da dies zu schweren Verletzungen oder sogar zum Tod führen könnte.

• Betreiben Sie Ihr Modell niemals mit Senderbatterien.

• Schließen Sie kein Akku an wenn Sie das Produkt nicht testen oder in Betrieb nehmen.

• Betreiben Sie dieses Produkt nicht wenn Sie müde sind, sich unwohl fühlen, Medikamente nehmen die ihre Reaktionsfähigkeit beeinfl ussen, oder unter dem Einfl uß von

Drogen oder Alkohol stehen.

• Sprühen Sie niemals Glasreiniger oder andere Flüssigkeiten auf dieses Produkt.

• Bei der Wartung oder dem Betrieb des Produkt dürfen Sie keine hängende oder lose Gegenstände an ihrer Person haben.

HINWEIS:

Bei der Verwendung von Komponenten, die von Horizon nicht zugelassen sind, kann eine mögliche Serviceleistung abgelehnt werden.

WARNUNG: Das ist großer Hubschrauber mit Rotorblättern die mit hoher Drehzahl drehen. Seien Sie extrem aufmerksam und benutzen ihren gesunden

Menschenverstand wenn Sie dieses Produkt warten oder nutzen. Sollte Ihnen eine beliebige Funktion oder Vorgang der in dieser Anleitung beschrieben

wird nicht klar sein betreiben Sie das Produkt NICHT. Kontaktieren Sie den technischen Service von Horizon zur Unterstützung.

WARNUNG: Halten Sie mit dem Hubschrauber mindestens 13 Meter Abstand zu sich selbst und anderen.

DE

26

Page 27

®

illkommen in der Welt der Blade Pro Serie Helikopter Performance.

Über 20 Jahre Erfahrung in Flug und Konstruktion sind in die Ent-

W

wicklung des Blade 550X gefl ossen. Jedes Teil bis zur kleinsten Mutter

wurde nur mit einem Ziel entwickelt oder ausgewählt, um Ihnen damit

einen unvergleichlichen 550 3D Hubschrauber anbieten zu können.

Bevor Sie sich sich auf den Boxinhalt stürzen ist es allerdings notwendig,

dass Sie bitte diese Bedienungsanleitung lesen. Die wurde geschrieben

damit Ihnen die Montage des Hubschraubers Freude macht und zu

einem der besten Bauprojekte wird, die Sie jemals durchgeführt haben.

Jeder Schritt ist klar abgebildet und zeigt Ihnen welche Teile zur Montage

benötigt werden. Sie fi nden in der Anleitung auch hilfreiche Bautipps.

Inhaltsverzeichnis

Benötigtes Werkzeug .......................................................................................28

Erforderliche Teile ............................................................................................ 28

Optionales Zubehör ..........................................................................................28

Erklärung der Montagesymbole .......................................................................28

Rotorkopfmontage (H) ...................................................................................... 29

Chassismontage (F) .........................................................................................31

Heckmontage (T) .............................................................................................34

Einbau der Elektronik ....................................................................................... 37

Servoarm und Anlenkungen ............................................................................. 39

Montage Hauptrotorkopf ..................................................................................39

Montage der Kabinenhaube .............................................................................39

Programmieren des Senders ............................................................................40

Throttle Hold (Gas aus) .................................................................................... 40

AR7200 Standard Blade 550 X Setup ............................................................... 41

Tipps zum AR7200BX-Parametermenü ............................................................41

Test der Motorsteuerung .................................................................................. 42

Sollte dieses ihr erstes Hubschrauberprojekt sein, gibt es noch ein paar

Dinge die Sie benötigen bevor Sie mit dem Auspacken beginnen. Viele

Modellbauer nutzen ein Handtuch oder eine Gummimatte als Unterlage

auf dem Arbeitstisch, damit keine Schrauben herunterfallen. Kleine Kästchen sind für Organisation und Aufbewahrung der Teile nützlich wenn

Sie aus der Packung genommen wurden.

Eines der wichtigsten Dinge ist es aber sich Zeit zu nehmen und sicher

zu stellen, dass Sie verstehen wie die Teile montiert werden. Haben Sie

das gemeistert fl iegt ihr Hubschrauber genauso präzise wie er entwickelt

wurde.

Test der Kontrollen ......................................................................................42-43

Niederspannungsabschaltung (LVC) ................................................................. 44

Warnungen und Richtlinien zum Fliegen...........................................................44

Fliegen Ihres 550X ........................................................................................... 44

Blattspurlauf .................................................................................................... 45

Einstellen der Heckverstärkung (Gain) .............................................................. 45

Kontrollen nach dem Flug und Wartung - Checkliste ........................................45

AR7200BX Feinabstimmung und Anpassung ....................................................45

Blade 550 X Leitfaden zur Fehlerbehebung ...................................................... 46

Garantieeinschränkungen ................................................................................ 47

Garantie und Service Kontaktinformationen......................................................47

Kundendienstinformationen ............................................................................. 47

Konformitätserklärung für die EU .....................................................................48

Explosionzeichnung ..................................................................................98-100

Parts List / Ersatzteile / Pieces de rechange / Pezzi di ricambio ...............101-103

Optional Parts / Optionale Bauteile / Pieces optionnelles / Pezzi opzionali ..........103

Länge

Höhe

Hauptrotordurchmesser

Komponenten Kit Combo

Motor

Regler/ESC

BEC

Akku

Ladegerät

Heli 550 Brushless Outrunner Motor, 1360Kv

130 Amp Brushless ESC Inklusive Inklusive

10 Amp BEC Inklusive Inklusive

6S 22.2V 5000mAh

30C + Li-Po

DC Li-Po Balancing Charger Erforderlich Erforderlich

Blade 550 Spezifi kationen

1130mm

275mm

1245mm

Inklusive Inklusive

Erforderlich Erforderlich

Heckrotordurchmesser

Fluggewicht

Komponenten Kit Combo

Sender

Empfänger

Taumelscheibenservos

Heckservo

Sie können Ihr Produkt online unter www.bladehelis.com registrieren.

DSM2 / DSMX kompatibler

Sender

AR7200BX 7CH DSMX

Flybarless Kontrolleinheit

Spektrum H6040 Erforderlich Inklusive

Spektrum H6080G Erforderlich Inklusive

240mm

3350–3500 g

Erforderlich Erforderlich

Erforderlich Inklusive

27

DE

Page 28

Benötigtes Werkzeug

• Inbusschlüssel: 1.5mm, 2mm, 2.5mm und 3mm

• Kugelkopfzange

• Spitzzange

• Phillips Schraubendreher

• Seitenschneider

Erforderliche Teile

• Pitchlehre

• Schiebelelehre

• Petroleumbasierendes leichtes Öl

• Sekundenkleber mittel

• Empfänger/Flybarless Kontrolleinheit

AR7200BX Empfänger/Flybarless Kontrolleinheit

(SPMAR7200BX)

In dem Set ist BLH5525C enthalten

• DSMX Satellitenempfänger (SPM9645)

In dem Set ist BLH5525C enthalten

• 3 Servos

(3) H6040 Servos (SPMSH6040)

In dem Set ist BLH5525C enthalten

• 1 Heckrotor-servo

(1) H6080G Heckrotor-servo (SPMSH6080G)

In dem Set ist BLH5525C enthalten

Optionales Zubehör

• Dynamite

Protection Bag, Gross

(DYN1405)

®

Li-Po Charge

• Gestängeeinstellwerkzeug

(RVO1004)

• 5000mAh 6S 22.2V 30C LiPo,

10AWG mit EC5 Anschluss

(EFLB50006S30)

• E-fl iteR EC5 Ladestecker

(EFLAEC512)

• E-fl ite 200W Ladegerät

(EFLC3020)

• Celectra 15VDC 250W

Netzteil (EFLC4010)

• DSM2/DSMX

Sender oder größer

®

kompatibler DX6i 6 Kanal

Erklärung der Montagesymbole

Schraubensicherungslack

blau verwenden

KEINEN Schraubensicherungslack

verwenden

DE

Petroleumbasierendes

leichtes Öl verwenden

OIL

Synthetisches Fett

verwenden

Mittelfl üssigen Sekundenkleber verwenden

28

leicht anziehen

fest anziehen

wie angezeigt wiederholen

2X

Page 29

Rotorkopfmontage (H)

Schritt H1

Schritt H2

Schritt H1 Teile (Beutel H1, H2)

M4 x 22 Bolzen mit

Inbuskopf

M4 Stopmutter

22mm

Schritt H2 Teile (Beutel H1)

M3 x 18 Inbusschraube

M2 x 5

Halbrundschraube (4)

Bundscheibe

Zentrieren Sie die Lagerbu-

chse auf der Blattlagerwelle

Dämpfer

2X

• Die Bundseite der Bundscheibe soll in die Radiallager

zeigen.

• Überdrehen Sie die Befestigung nicht, die Taumelscheibenmitnehmer sollten sich frei bewegen können.

Schritt H3 Teile (Beutel H1, H2)Schritt H3

Dämpfer (x2)

Lagerbuchse Blattlagerwelle

M3 x 8 Inbusschraube

• Reinigen Sie die Gewinde der Blattlagerwelle sorgfältig

mit Alkohol bevor Sie sie einbauen.

Dämpfer

29

DE

Page 30

Rotorkopfmontage (H) Fortsetzung

Schritt H4 Teile (Beutel H3)

Drucklager (x2)

Unterlegscheibe

Drucklager 10 X 14

X .8 (x2)

Unterlegscheibe

Blattlagerwelle 4 X

12 X 1 (x2)

Bundscheibe (x2)

A

B

C

M4 X 12 Bolzen (x2)

M3 X 14 Bolzen (x2)

M3 X 8 Bolzen (x2)

Kugelkopf (x2)

Schritt H4

Unterlegscheibe Blattlagerwelle

Drucklager

Unterlegscheibe mit größerem Innendurchmesser

A

Lagerkäfi g

Unterlegscheibe mit kleinerem Innendurchmesser

WARNUNG: Reinigen Sie immer die Blattlagerwellenschrauben nach dem lösen mit denaturi-

ertem Alkohol um sicher zu stellen, dass sich kein Öl mehr an den Schrauben befi ndet. Geben

Sie bei dem Einschrauben mittelfesten Schraubensicherungslack auf die Schrauben und lassen diesen

trocknen (ca. 4 bis 6 Stunden) bevor Sie den Hubschrauber fl iegen.

Bundscheibe

2X

B

kleiner

Innendurchmesser

A

C

großer

Innendurchmesser

• Montieren Sie die Bolzen B und C lose bevor Sie sie

festziehen.

• Die Bundseite der Bundscheibe zeigt in den Blatthalter

Schritt H5 Teile (Beutel H4)

Schritt H5

DE

30

Page 31

Chassismontage (F)

MONTAGEHINWEIS: Planen Sie vor der Montage die Kabelführung der Servos. Schleifen Sie an jeder Kante an der ein Servokabel durchgeführt wird die Kante

so, dass das Kabel nicht durch scheuern beschädigt werden kann.

Schritt F1

A

Schritt F1 Teile (Beutel F1, F2, F3)

A

A

B

C

C

B

C

C

B

C

• Ziehen Sie zu diesem Zeitpunkt nicht die Lagerblöcke

oder unteren Chassisplatten-schrauben fest.

Inbusschraube

M3 x 10 (x4)

Inbusschraube

M3 x 14 (x4)

Selbstschneidene Schraube

M3 x 8 (x4)

Unterlegscheibe m. kleinem

Loch M3 (x8)

Lagerblock oben

Lagerblock mitte

Schritt F2

A

A

A

Schritt F2 Teile (Beutel F5)

A

B

Halbrundschraube

M3 x 12 (x6)

Selbstschneidene Schraube

M3 x 12 (x4)

Servo Unterlegscheiben (x10)

4X

B

B

31

DE

Page 32

Chassismontage (F) Fortsetzung

Schritt F3 Teile (Beutel F3, F5)

Madenschraube

M3 x 11 (x2)

A

B

• Schieben Sie die Hauptrotorwelle in Position und

ziehen dann die Chassis- und Servoschrauben an.

Halbrundschraube

M3 x 12 (x6)

Inbusschraube

M3 x 10 (x4)

Kabinenhaubenhalter

(x2)

M3 Unterlegscheibe (x6)

Unterlegscheibe m.

kleinem Loch M3 (x4)

Schritt F3

B

A

Schritt F4 Teile (Beutel F3)

Halbrundschraube

M3 x 12 (x4)

Unterlegscheibe m.

kleinem Loch M3 (x4)

Selbstschneidene

Schraube M3 x 8 (x4)

A

B

A

Schritt F4

DE

32

Page 33

Chassismontage (F) Fortsetzung

Schritt F5

Schritt F5 Teile (Beutel M1)

Unterlegscheibe (x1)

Freilauf (x1)

Inbusbolzen M4 X 22

M4 Stopmutter

Senkkopfschraube

selbstschneidend M3 x8 (x5)

Madenschraube M3 x 4 (2)

Schritt F6

Schritt F6 Teile (Beutel F6)

Ritzel 6mm, 14 Zähne

Madenschraube M3 x 4 (2)

Inbusschraube M3 x 10 (x8)

Unterlegscheibe m. kleinem

Loch M3 (x8)

33

3mm

DE

Page 34

Heckmontage (T)

Sechskantstifte (x6)

Radiallager 12 X 18 X 4

(x2)

Radiallager

5 x10 x 4 (x2)

Blechdistanzstück

Inbusbolzen

M3 x18 (x4)

M3 Stopmutter (x4)

Schritt T1Schritt T1 (Beutel T1)

Schritt T2 (Beutel T1) Schritt T2

Selbstschneidene

Schraube M3 x 16 (x12)

DE

34

Page 35

Heckmontage Fortsetzung

Schritt T3

B

Schritt T3 Teile (Beutel T2, T3)

A

C

B

B

B

A

B

C

IInbusschraube

M3 x 10 (x2)

Inbusschraube

M3 x 8 (x4)

Halbrundschraube

M3 x 10 (x2)

Unterlegscheibe m.

kleinem Loch M3 (x4)

Schritt T4

2X

Schritt T4 Teile (Beutel T4, T5)

Kleiner Innendurchmesser

Lagerkäfi g

Grosser Innendurchmesser

B

A

A

B

Heckrotorblattbolzen (x2)

Mutter Heckrotorblattbolzen

(x2)

Drucklager (x2)

Unterlegscheibe für

Drucklager (x2)

Kugelkopfbolzen (x2)

Madenschraube

M3 x 4 (2)

M3 x 8 Inbusschraube

(x2)

M3 Unterlegscheibe (x2)

35

DE

Page 36

Heckmontage Fortsetzung

Halbrundschraube

M3 x 5 (x2)

Inbusschraube M3 x 25

M3 Bundscheibe (x2)

Kugelkopf

M3 Stopmutter

• Die Bundseite der Bundscheibe zeigt in das Lager.

Schritt T5Schritt T5 Teile (Beutel T6)

Heckrotorblatt für

bessere Erkennbarkeit

nicht dargestellt

Schritt T6a Teile (Beutel T7)

• Kleben Sie die Lager der Heckwelle mit etwas

Sekundenkleber in die Positionen im Führungsrohr

(200mm, 200mm) und schieben dann die Heckwelle

ein. Bitte achten Sie darauf nicht die Welle im Lager

zu verkleben.

• Verwenden Sie etwas Öl um das Führungsrohr

einfacher im Heckausleger zu montieren.

Schritt T6a

OIL

Ansicht von hinten

OIL

214 mm 200 mm 200 mm

DE

36

Page 37

Heckmontage Fortsetzung

Schritt T6b Schritt T6b Teile (Beutel T8, T3)

Ansicht

von hinten

90°

A

B

Einbau der Elektronik (E)

230 mm

B

Ansicht von links

A

A

A

B

120 mm

A

B

A

Front Heck

Selbstschneidene Schraube

M3 x 12 (x6)

Selbstschneidene

Schraube M2.5 x 8 (x2)

Unterlegscheibe m. kleinem

Loch M3 (x4)

Kugelkopfanschluss

(x 2)

Gestängeführung Heck

Gestängeführung Front

Flybarless Kontroll-Einheit und

Satellitenempfänger

Ausrichtung AR7200BX

90°

Doppelseitiges

Schaumklebeband

Schritt E1 Teile (Beutel E1)

Inbusschraube

M3 x 10 (x4)

Unterlegscheibe m.

kleinem Loch (x4)

Senkkopfschraube

M3 x 8 (x2)

AR7200BX Servoanschlüsse

BIND/DAT Bindestecker, Telemetriemodul oder

Datenlogger (optional)

AUX2 BEC

AUX3 BEC

THRO Regler

Rx L Satellitenempfänger

ELEV Taumelscheibenservo Mitte

AILE Taumelscheibenservo links

AUX1 Taumelscheibenservo rechts

RUDD Heckservo

HINWEIS: Schließen Sie den Satellitenempfänger an

bevor Sie die Servokabel einstecken.

Vorne

Ansicht von oben

37

DE

Page 38

Einbau der Elektronik Fortsetzung

Armieren des AR7200BX

1. Stellen Sie das Gas auf Leerlauf / Motor aus.

2. Schalten Sie den Sender ein.

3. Zentrieren Sie die Gastrimmung.

4. Schalten Sie Throttle Hold auf ON (EIN).

5. Kleben Sie das Klettband auf den Akkuträger des

Hubschrauber und die andere Seite auf den Akku.

6. Setzen Sie den Flugakku auf den Akkuträger auf

dem Helikopterrahmen. Sichern Sie den Flugakku

mit den Klettschlaufen.