BlackTrax Wiki

BlackTrax Wiki

1 of 298

5/14/2019

A Complete BlackTrax User Wiki

About Introduction

BlackTrax Wiki

2 of 298

5/14/2019

This wiki provides instructions for the installation, configuration and operation of the BlackTrax system.

This version is current as of May 2019.

© CAST Group of Companies Inc., 2002-2019 All rights reserved. BlackTrax, WYSIWYG, CAST Software,

and Autofocus are trademarks of the CAST Group of Companies Incorporated. All other trademarks and

logos are the property of their respective owners. Depending on your product/version, CAST incorporates

source code or libraries which are licensed to CAST and copyright protected. For more information, go to

http://cast-soft.com/third-party-libraries/.

A BlackTrax License will authorize the use of the BlackTrax system for a restricted number of output

connections based on the type of License that was purchased. For more information, go to Licensing.

About this Manual

BlackTrax Wiki

3 of 298

5/14/2019

Table of contents:

1 Introduction :

2 Text Conventions :

Text Conventions

BlackTrax Wiki

4 of 298

5/14/2019

The following text conventions are used in this wiki:

Instructions titles appear in Bold and Orange. For example, "To view a BTCamera’s video feed

in the visible spectrum"

Menus and menu commands appear in Bold and Navy. For example, “To open the window if

closed, go to the View menu and click Cameras.”

User interface elements such as buttons, tools, shortcuts, and dialog boxes appear in Italics and

Medium Blue. For example, “To close the project, click Yes.”

Keyboard keys are indicated in CAPITALS AND BLUE. For example, “To call up the save menu, enter

in the command CTRL+SHIFT+B.”

References to manuals appear in Italics Underlined in Blue. For example, “For an in depth

understanding on BTWYSIWYG and its capabilities, please refer to the WYSIWYG Reference Guide.”

Instructions to direct you to different features of the BTSystem or areas in the physical Space are

indicated by being Green and Underlined. For Example “In the Physical Space, take the BTBeacon.”

BlackTrax System Overview

BlackTrax Wiki

5 of 298

5/14/2019

1 BTSensor Installation :

1.1 Environment Considerations for BTSensor Installation :

1.2 Installing a BTSensor Lens :

1.3 BTSensor Placement and Orientation :

2 BTSystem Hardware Configuration :

2.1 BTSystem Configuration :

2.2 Optional Equipment Configuration :

3 BTSystem Components :

3.1 Standard System Components :

3.2 BTServer :

3.3 TimeKeeper :

3.4 BTRouter :

3.5 Ferrite Filter :

3.6 eSync 2 Controller :

3.7 BTSensors :

3.7.1 SLIM 13E :

3.7.2 PRIME 41 :

3.8 BTBeacon :

3.9 BT Smart Charger :

3.10 Calibration Kit :

3.10.1 Calibration Kit functions :

3.10.2 Wand Head :

3.10.3 Triangular Wand Holder :

3.10.4 Telescopic Wand Handle :

3.10.5 Ground Plane :

3.10.6 Hybrid Power Supply Unit (HPSU) :

3.10.7 Lighting Wand :

3.10.8 BTCalibration Kit Case :

3.11 Stringer :

3.12 Discontinued :

3.12.1 eSync Controller :

3.12.2 S250e Slim :

3.12.3 Power Supply Unit (PSU) :

3.12.4 BTServer (Legacy) :

3.12.5 TimeKeeper (Legacy) :

4 General System Information :

4.1 BTSystem Information Flow and Connections :

4.2 BTX Dongle :

4.3 Saved System Data :

4.4 FCC Information :

5 Not Included Mandatory Components :

5.1 Category 6 Ethernet Cabling :

5.2 Power Over Ethernet Gigabit Switch for BTSensors :

6 Optional Components :

6.1 DMX/Ethernet Node for Tracking with Moving Lights :

6.1.1 Compatible DMX/Ethernet nodes :

BlackTrax Wiki

6 of 298

5/14/2019

6.1.2 Luminex Node Settings :

6.1.3 Common ArtGate Node Setup Guide :

7 System Procedures :

7.1 Licensing :

7.2 Charging BTBeacons :

7.3 Replacing a BTBeacon's Lithium-Ion Battery :

7.4 Installing Third Party Software :

7.5 Server Failover :

BTSensor Installation

BlackTrax Wiki

7 of 298

5/14/2019

Table of contents:

Environment Considerations for BTSensor Installation

Installing a BTSensor Lens

BTSensor Placement and Orientation

Environment Considerations for

BlackTrax Wiki

8 of 298

5/14/2019

BTSensor Installation

The environment of the Space has a great impact on the capacity of BlackTrax to function as intended.

When you install the BTSystem, always remember the following precautions to limit interference and

make the ideal tracking environment.

Infrared interference: External infrared sources and reflections may cause interference with

BTSensors. For best results, ensure the venue is free from sunlight, lights which emit infrared

spectrum, infrared based devices, fire, and highly reflective materials. For infrared sources and

reflections which cannot be removed from the venue, there are provisions within the software to

mask out the affected areas of the BTSensor's field of view.

Note: Infrared interference is more critical during the BTSensor calibration than during

tracking operation. Since the BTSystem looks for a unique signal during tracking, there is

some tolerance for other infrared sources.

Reflective surfaces: Reflective materials that are present in a venue might reflect and mimic a

BTBeacon’s unique LED pulse, creating errors with tracking. Complex objects inside the tracking

area must be covered to block reflections. Reflective objects outside the tracking area can be

blocked out.

Cabling: Ethernet connected BTSensors are subject to the limitation of Ethernet communication

standards. The total Ethernet connection between any component to the BTServer can not be

longer than 91.44m for BlackTrax to function correctly. This range may be extended with a PoE

switch to link cables together.

Sensor stability: Ensure that the location where you choose to install BTSensors is stable, sturdy

and always stationary. Any movement of a BlackTrax sensor will require recalibration of the entire

sensor system.

Example: If a BTSensor is hung on a truss system which sways, the accuracy and

performance of the BTSystem will be affected. If the sway is small, you can decrease

accuracy in the system and may be able to track with lesser accuracy.

Sensor blocking: Ensure that BTSensors have an unimpeded view of the intended tracking area.

Multiple BTSensors need to see the same area at the same time for tracking to occur. Care should

be taken to ensure temporary objects do not obscure tracking.

Installing a BTSensor Lens

BlackTrax Wiki

9 of 298

5/14/2019

To install a BTSensor lens

Note: Only used on s250e and Slim 13E sensors.

Screw the lens onto the BTSensor with the included plastic lens tensioner between the M12 lens1.

adapter and the lens itself. Tighten until proper focus is achieved.

Once you achieve the desired focus, hold the lens in place while you tighten down the lens2.

tensioner.

Note: The s250e comes with a spring for the lens instead of a tensioner. No tightening is required for

this lens.

BTSensor Placement and Orientation

BlackTrax Wiki

10 of 298

5/14/2019

In order for tracking to function correctly, multiple BTSensors must be arranged to have overlapping

fields of view of the Space. A BTSensor's field of view is the part of the Space that is visible through the

BTSensor while the BTSensor is in a fixed position and orientation.

Attention: Sensors must not be installed closer than 1m apart to help ensure optimal sensor calibration.

Good sensor placement and orientation are absolutely critical to proper operation of the BTSystem!

BTSystem Hardware Configuration

BlackTrax Wiki

11 of 298

5/14/2019

Table of contents:

BTSystem Configuration

Optional Equipment Configuration

BTSystem Configuration

BlackTrax Wiki

12 of 298

5/14/2019

System Configuration Overview

Hardware modules that connect directly to the BTServer should be located in the same location outside

of the tracking area. BTSensors must be positioned where they will not be disturbed and have the best

unblocked view of the tracking area. TimeKeeper, BTRouter and eSync 2 Controller can be positioned

closer to the tracking space.

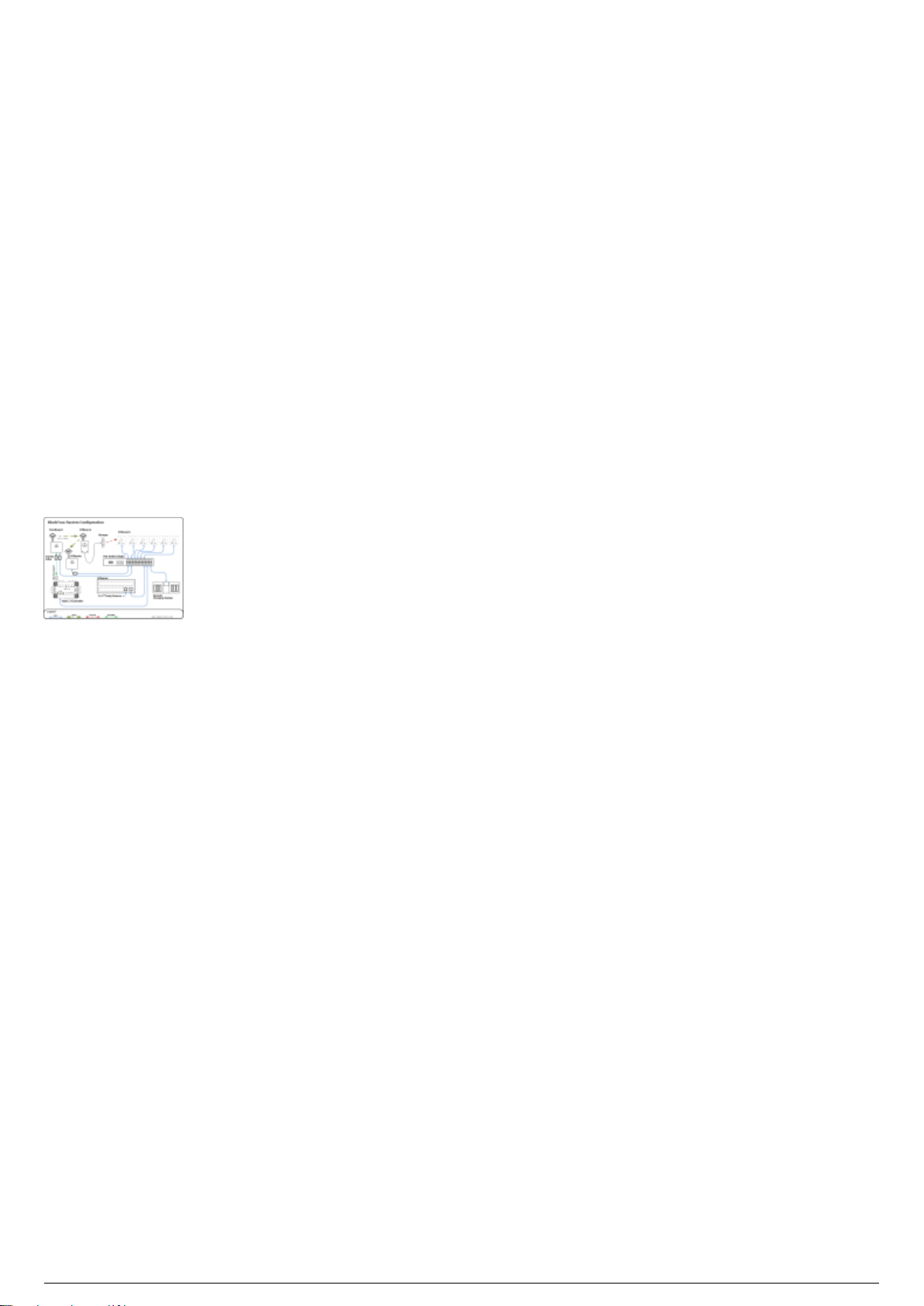

The following diagram outlines a typical hardware configuration and demonstrates how all BlackTrax

hardware modules are connected together.

Attention: The Timekeeper and BTRouter Ethernet port are designed only to connect to a commercially

available Power over Ethernet (PoE) network switch. The TimeKeeper and BTRouter are not designed to

be a peripheral device to a Class B personal computer. As such, the Ethernet port shall not be connected

to a Class B personal computer in any operating configuration.

BlackTrax System Configuration Diagram

Optional Equipment Configuration

BlackTrax Wiki

13 of 298

5/14/2019

Optional Equipment Overview

Depending on your tracking needs, additional components must be connected with the BTSystem. The

following outlines how to connect this optional equipment with the BTSystem.

Tracking with Moving Light Fixtures Diagram

BTSystem Components

BlackTrax Wiki

14 of 298

5/14/2019

Table of contents:

Standard System Components

BTServer

TimeKeeper

BTRouter

Ferrite Filter

eSync 2 Controller

BTSensors

SLIM 13E

PRIME 41

BTBeacon

BT Smart Charger

Calibration Kit

Calibration Kit functions

Wand Head

Triangular Wand Holder

Telescopic Wand Handle

Ground Plane

Hybrid Power Supply Unit (HPSU)

Lighting Wand

BTCalibration Kit Case

Stringer

Discontinued

eSync Controller

S250e Slim

Power Supply Unit (PSU)

BTServer (Legacy)

TimeKeeper (Legacy)

Standard System Modules

BlackTrax Wiki

15 of 298

5/14/2019

List of Standard System Components

Note: The quantity of BTSensors, BTBeacons, BTSmart Chargers, and Stringers delivered with a

BTSystem are dependent on each user’s needs and on the individual sale.

(1) BTServer (pre-installed software below)

Hardware secured inside the server

BTX Dongle

Motive Dongle

Pre-installed software

BTWYSIWYG

Motive for BlackTrax

BlackTrax Software Suite

Device Manager

(1) BTRouter

(1) TimeKeeper

Ferrite filters

(1) eSync 2 Controller*

BNC/RCA Adapter

BTSensors

BTBeacons

Stringers

BTSmart Charger

(1) BTCalibration Kit

(1) BTCalibration Wand Head

(1) BTCalibration Triangular Wand Holder

(1) BTCalibration Telescopic Wand Handle

(1) BTCalibration Ground Plane

(1) BTCalibration Hybrid Power Supply Unit

(1) BTLighting Calibration Wand

(1) Carrying case

Attention: *The original eSync Controller is discontinued.

Not Included Mandatory Components

Category 6 Ethernet cable

Power over Ethernet (PoE) gigabit Switch

Optional Components

DMX/Ethernet Node (for tracking with moving lights)

Additional Power over Ethernet (PoE) gigabit Switches

BTServer

BlackTrax Wiki

16 of 298

5/14/2019

BTServer 2.0 (Rev 5)

Product ID

Model: BTServer 2.0 (Rev 5)

Physical Characteristics

Width: 48 cm (19")

Height: 9 cm (3.5")

Depth: 48.5 cm (19")

Weight: 15.2 kg (33.5 lb.)

Operating Temperature

0°C - 40°C

Technical Specifications

BTServer 2.0 (Rev 5):

(2x) Inter Xeon Silver 4110 @ 2.1GHz (3.00 GHz Turbo, 2400 MHz, 11M L3 Cache, 8 Core, 85W)

(2x) 2.5" 480GB SSD SATA in RAID1 on LSI MegaRAID SAS 9341-4i

32GB (8x4GB) RAM (DDR4, ECC, 2666 MHz)

Nvidia GeForce GTX1060 with 6GB GDDR5

100-240VAC, 800W redundant power supply with IEC

(2x) Intel I350 Quad-Port Gigabit Ethernet Controller (1 dedicated, 1 definable)

Windows 10 IoT Enterprise LTSB 2016

Default User Login

User name: btuser

Note: There is no password associated with the default user account for the BTServer

Default Network Address (Main)

Default Network Address (Backup)

BlackTrax Wiki

17 of 298

5/14/2019

Note:

The BTServer is built with 2 Network Interface Cards (NIC) with 4 ports on each card, and the

functions are: (see BlackTrax detailed system diagram)

Port 1: BTNet (PoE Switch - Tracking, BTSensors, BT Smart Chargers)

Port 2: RTTrPL and Lighting Input (Network Switch - Lighting)

Port 3: RTTrPM (Network Switch - 3rd Party)

Port 4: BTLink (links to BTServers)

Port 5-8: (User Defined)

Lighting Input and RTTrPL are combined into the RTTrPL port.

BTLink is the network connection link to the other BTServers.

Attention: Windows Remote Desktop Connection should not be used with a BlackTrax system. Security

measures on the BTX dongle installed in the BTServer will prevent it from working. Users should use

TeamViewer or VNC if remote access to a BTServer is required.

TimeKeeper

BlackTrax Wiki

18 of 298

5/14/2019

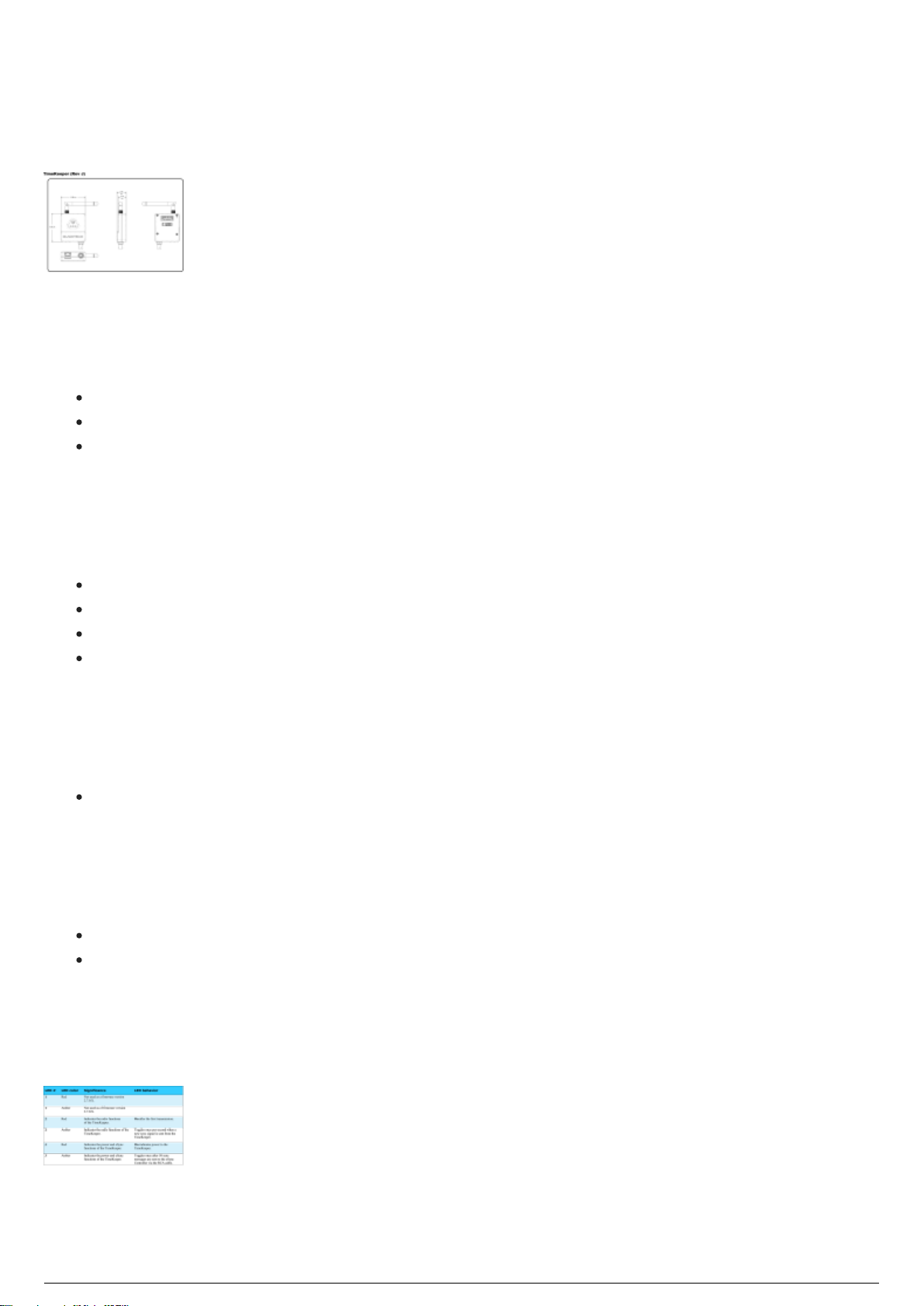

TimeKeeper (Rev J) Diagram

Product ID

FCC ID: RKT-BTTKV01

IC: 10858A-BTTKV01

Model number: BTTKV01

Physical Characteristics

Width: 6.46 cm (2.545")

Height: 7.50 cm (2.951")

Depth: 2.50 cm (0.968")

Weight: 86.64 g (3.056 oz)

Operating Temperature

0°C to +40°C (32°F to 104°F)

Input/Output & Power

Data: Ethernet, Radio 2.4(GHz) 10Hz

Power: 48VDC/15.6W from PoeE Network Switch via Ethernet port (No input power via USB port)

Status LEDs

Note: The Ethernet status lights on the TimeKeeper are not enabled while the TimeKeeper is in use.

TimeKeeper Functions

BlackTrax Wiki

19 of 298

5/14/2019

The TimeKeeper is a single wireless access point that uses a proprietary radio system running on the 2.4

Ghz frequencey to send data to all BTBeacons. Data sent includes a signal used to synchronize the

BTBeacons with the BTSensors and configuration commands sent to the eSync Controller via a BNC

cable.

TimeKeeper Transmitter Characteristics

BTRouter

BlackTrax Wiki

20 of 298

5/14/2019

BTRouter Diagram

Product ID

FCC ID: RKT-BTTKV01

IC: 10858A-BTTKV01

Model number BTTKV01

Physical Characteristics

Width: 5.7 cm (2.245")

Height: 7.11 cm (2.8")

Depth: 2.57 cm (1.013")

Weight: 125 g (4.41 oz)

Operating Temperature

0°C to +40°C (32°F to 104°F)

Input/Output & Power

Data: Ethernet, Radio 2.4(GHz) 10Hz

Power: 48VDC/15.6W from PoE Network Switch via Ethernet port (No input power via USB port)

Status LEDs

BTRouter Functions

BlackTrax Wiki

21 of 298

5/14/2019

The BTRouter is a single wireless access point that uses a proprietary radio system running on 2.4 Ghz

frequency to receive data from all BTBeacons. Data received includes BTBeacon button presses, battery

status, configuration details as well as inertial measurement unit (IMU) data. IMU data can be used to

calculate the BTBeacon’s orientation.

Note: Upon delivery of a new BTSystem shipment, the IMU on most of the Beacons included are disabled

by default, and the IMU of the Beacon with ID 1 will be switched on by default to help with Fixture

Calibration.

BTRouter Transmitter Characteristics

Ferrite Filter

BlackTrax Wiki

22 of 298

5/14/2019

Ferrite Filter Diagram

Product ID

Manufacturer: API

Model number: BF1835

Physical Characteristics

Width: 1.8 cm (0.709”)

Height: 1.96 cm (0.776”)

Depth: 3.48 cm (1.378”)

Center diameter: 0.89 cm (0.354”)

Weight: 15 g (.53 oz)

Operating temperature: 0°C to +40°C (32°F to 104°F)

Impedance: 172 Ohm

Ferrite Function

The ferrite filter is a cylindrical clamp fastened over cables to conform with regulatory standards. A

ferrite filter must be clamped over any cables connected to the TimeKeeper and BTRouter. Ferrite filters

should be fastened on any connected cables as close to the respective device as possible.

eSync 2 Controller

BlackTrax Wiki

23 of 298

5/14/2019

eSync 2 Controller Diagram

Physical Characteristics

Width: 13.89 cm (5.47”)

Height: 4.09 cm (1.61”)

Depth: 9.25 cm (3.64”)

Weight: 368.54 g (13 oz)

Operating temperature: 0°C to +40°C (32°F to 104°F)

Input/Output & Power

PoE: IEEE 802.3af-2003

Adapter: 12V @ 0.6A power supply

Data: Ethernet

Status LEDs

Per port activity status

Master time

External lock

Ethernet link status

Ethernet activity

eSync 2 Controller Functions

The eSync 2 Controller synchronizes BTSensors so that the shutters of BTSensors open and close

simultaneously and in synchronization with the pulsing of LED Stringers attached to BTBeacons.

eSync 2 Controller Connection to the TimeKeeper

The eSync 2 Controller connects to the TimeKeeper over RCA cable. A BNC/RCA adapter is used to plug

the RCA into input 3 of the eSync 2 Controller.

BTSensors

BlackTrax Wiki

24 of 298

5/14/2019

Table of contents:

SLIM 13E

PRIME 41

SLIM 13E

BlackTrax Wiki

25 of 298

5/14/2019

SLIM 13E Diagram

Product ID

Model number: CAM-CAM-S13

Physical Characteristics

Mounting: 0.635 cm (1/4”)-20 tripod thread

Operating temperature: 0°C to +51°C (32°F to 123.8°F)

Case: Aluminum and Polycarbonate

Width: 6.86 cm (2.7”)

Height: 6.86 cm (2.7”)

Depth: 2.3 cm (0.9”)

Weight: 320 g (11.29 oz)

Lens & Filter

Stock lens: 5.5 mm F#1.8 (wide band AR coated)

Horizontal FOV: 56°

Vertical FOV: 46°

Optional Lens: 8.0 mm F#1.8 (wide band AR coated)

Horizontal FOV: 42°

Vertical FOV: 34°

Optional Lens: 3.5 mm F#1.8 (wide band AR coated)

Horizontal FOV: 82°

Vertical FOV: 70°

Adjustable focus with wave spring assist

850nm band-pass filter

850nm (Infrared) / 700nm (Visible) Filter Switcher

Image Sensor

Resolution: 1280 × 1024

Frame Rate: 30–240 FPS (100 FPS average usage)

Accuracy: Sub-millimeter

BlackTrax Wiki

26 of 298

5/14/2019

Latency: 4.2 ms

Shutter type: global

Shutter speed:

Default: 0.5 ms (500 µs)

Minimum: 0.01 ms (10 µs)

Maximum: 3.9 ms (3,900 µs) at 240 FPS

Input/Output & Power

Data: Ethernet

Synchronization: Ethernet

Power: (PoE) 8.0 watts

Sensor Status

Front Light Status

The Slim Series sensors have a front LED status light to indicate their current state in relation to the

BTServer. The following table lists the default status light colors.

Back Light Status

The Slim Series sensors also have a status indicator on the back panel and indicates the state of the

sensor only. When updating the software on your BTServer, the sensor may need a firmware update in

order to communicate to the new version. Firmware updates are automatic when starting the connection

to the BTServer. If you revert back to an older version of the firmware as well. This process is automatic.

BTSensor Functions

BTSensors are used to view BTBeacon positions in the Space. A BTBeacon's position in 3 dimensions (X,

Y, and Z) can be determined when two or more BTSensors simultaneously have a direct line-of-sight to a

connected Stringer’s LED. This information is then sent to the BTServer.

Attention:

The switch must provide consistent power to every port simultaneously in order to power each

sensor.

Standard PoE switches must provide a full 15.4 watts to every port simultaneously.

BlackTrax Wiki

27 of 298

5/14/2019

Note that PoE Midspan devices or power injectors are not suitable for Ethernet camera systems.

PRIME 41

BlackTrax Wiki

28 of 298

5/14/2019

PRIME 41 Diagram

Product ID

Model number: CAM-CAM-P41

Physical Characteristics

Mounting: 0.635 cm (1/4")-20 tripod thread (x2)

Operating temperature: 0°C to +51°C (32°F to 123.8°F)

Case: Aluminum and Polycarbonate

Width: 12.6 cm (4.96”)

Height: 12.6 cm (4.96”)

Depth: 13.6 cm (5.34”)

Weight: 1.45 kg (3.2 lb)

Lens & Filter

Stock lens: 12 mm F#1.8 (wide band AR coated)

Horizontal FOV: 51°

Vertical FOV: 51°

Adjustable focus and f-stop

850nm band-pass filter

Image Sensor

Resolution: 2048 x 2048

Pixel Size: 5.5 µm x 5.5µm

Frame Rate: 30–180 FPS (adjustable)

Latency: 5.5ms

Shutter type: global

Shutter speed:

Default: 0.5 ms (500 µs)

Minimum: 0.01 ms (10 µs)

Maximum:

8.1ms (8100 µs) at 120 FPS

BlackTrax Wiki

29 of 298

5/14/2019

5.3 ms (5300 µs) at 180 FPS

Input/Output & Power

Data: GigE (1000BASE-T)

Synchronization: Ethernet

Power: PoE or PoE+¹

Attention:

The switch must provide consistent power to every port simultaneously in order to power each

sensor.

Standard PoE switches must provide a full 15.4 watts to every port simultaneously.

Note that PoE Midspan devices or power injectors are not suitable for Ethernet camera systems.

BTBeacon

BlackTrax Wiki

30 of 298

5/14/2019

BTBeacon Diagram

Product ID

FCC ID: RKT- BTBCV01

IC: 10858A- BTBCV01

Model: BTBCV01P

Physical Characteristics

Case: Plastic with Velcro strap attachments

Width: 4.94 cm (1.945”)

Height: 8.08 cm (3.18”)

Depth: 1.87 cm (.737”)

Weight: 70 g (2.5 oz)

Input/Output & Power

Data: USB, Radio 2.4 (GHz) 10Hz

Power: Rechargeable Lithium-ion Battery, charged by 5V USB

Watt hour: 4.44 Wh normal operation, 5.04 Wh while charging

Operating Temperature

0°C to +40°C (32°F to 104°F)

BTBeacon Status LEDs (During Operation)

Warning: If a BTBeacon experiences a charge error, there could be a potential issue with the Lithium-ion

battery. Discontinue use immediately. For more information about Lithium-ion battery safety see “Health

BlackTrax Wiki

31 of 298

5/14/2019

and Safety Information”. Alternately, no battery may be in the BTBeacon.

BTBeacon Status LEDs (During Boot

Loader Mode)

BTBeacon Functions

Each BTBeacon has three ports, each of which can power a single connected Stringer. When a Stringer is

connected to a BTBeacon’s LED port, the Stringer’s LED will emit infrared light in a unique pattern. These

infrared pulses create a unique ID used to identify BTBeacons. When the LED infrared pulse is seen by 2

or more BTSensors, the positional coordinates (XYZ) for the Stringer LED is calculated by the BTServer.

Position is based on the location of visible Stringer LEDs connected to a BTBeacon. Orientation data (roll,

pitch, yaw) is determined by an internal inertial measurement unit (IMU). The IMU also functions as a

backup for determining the BTBeacon's position. The IMU measures acceleration and rotation.

The BTBeacons have a red power and reset button, and two white auxiliary buttons. The auxiliary buttons

are used during fixture calibration.

The BTBeacon transmits the following data over radio to the BTRouter, which is relayed to the BTServer:

IMU data, button presses, battery status, configuration details, and Stringer IDs.

To enter the BTBeacon into Boot Loader Mode, turn the beacon off and hold A or B while inserting the

BTBeacon into the BTSmart Charger. This mode is used to update firmware.

BTBeacon Transmitter Characteristics

BTBeacon Charging Information

A BTBeacon’s rechargeable lithium-ion battery is not fully charged when shipped. Please read the

following instructions carefully:

Never charge BTBeacon near heat or flammable objects.

BlackTrax Wiki

32 of 298

5/14/2019

The temperature range which the BTBeacon can be charged is 0°C to 40°C (32°F to 104°F).

Charging outside the recommended temperature range may automatically be blocked by the

protection circuitry of the device.

Do not charge or use the BTBeacon if any damage has occurred to the device.

The temperature range over which the BTBeacon’s battery can operate is 0°C to 40°C (32°F to

104°F). Operation outside of this temperature range may damage the performance of the battery

or may reduce its life expectancy.

Battery performance will naturally decay over time. If a battery can not maintain charge for long

periods, even when it is being charged correctly, this may indicate it is time to replace the battery.

BTBeacon Battery Replacement

After a period of time the battery of the BTBeacon will naturally decay through normal use and require

replacement. Contract your BTE for details on replacing the BTBeacon battery.

Attention: Any unauthorized modification to the BTBeacon or its battery will invalidate any warranty

claim and may damage the device.

BT Smart Charger

BlackTrax Wiki

33 of 298

5/14/2019

BTSmart Charger Diagram

Size and Weight

Case: Steel

Width: 15.5 cm (6.1”)

Height: 8.47 cm (3.33”)

Depth: 36 cm (14.17”)

Weight: 2440 g (86.07 oz)

Input/Output & Power

Data: Ethernet, USB

Power: 20 Watt

Voltage range: 100V - 240V

Note: BTSmart Charger Rev 6 is built with a momentary contact type power button with the blue LED

that will light up only after the "boot up" is complete. To turn the device power off, press the power

button, then wait until the blue LED light turns off before you disconnect from the power source.

BTSmart Charger Functions

The BTSmart Charger is a device used to recharge the battery of a BTBeacon. BTBeacons are connected

to the BTSmart Charger using the BTBeacon’s USB port. While connected, the BTSystem can read the

status of the battery, regulate charging and maximize battery life. The BTSmart Charger can hold a

maximum of 6 BTBeacons at one time.

BTSmart Charger Configurations

The BTSmart Charger can be configured to either be horizontal and sit flat on a desk, or be vertical and

be mounted on a wall.

Horizontal Configuration Diagram

BlackTrax Wiki

34 of 298

5/14/2019

Calibration Kit

BlackTrax Wiki

35 of 298

5/14/2019

Table of contents:

Calibration Kit functions

Wand Head

Triangular Wand Holder

Telescopic Wand Handle

Ground Plane

Hybrid Power Supply Unit (HPSU)

Lighting Wand

BTCalibration Kit Case

Calibration Kit functions

BlackTrax Wiki

36 of 298

5/14/2019

BlackTrax Calibration Kit Functions

The Calibration Kit is used for calibrating the BTSensors and Lighting Fixtures position in the Space. The

function of each equipment in the Kit are:

The Wand Head is attached to the Wand Handle and connected to the Power Supply Unit.1.

When you move the Wand Head inside the Space, the BTSensors look for active LEDs located on2.

the Wand Head.

When multiple BTSensors see the LEDs on the Wand Head, the BTSystem is able to generate a3.

measurement point for BTSensor calibration.

BTSensors use the measurement point data to determine their position relative to each other.4.

The Ground Plane is connected to the Power Supply Unit and placed in the designated origin of the5.

Space.

The Ground Plane LEDs are used in the BlackTrax system to calculate the BTSensor positions6.

relative to the origin and the orientation of the Cartesian axes.

The Lighting Calibration Wand is used for fixture calibration.7.

The Lighting Calibration Wand can be attached to a BTBeacon instead of a Stringer to extend the8.

range of a BTBeacon LEDs. This is used to calibrate fixtures in areas that are difficult to reach.

Wand Head

BlackTrax Wiki

37 of 298

5/14/2019

Wand Head

Size and Weight

Width: 105.92 cm (41.7”)

Height: 26.92 cm (10.6”)

Depth: 2.03 cm (0.8”)

Weight: 715 g (25.22 oz)

Triangular Wand Holder

BlackTrax Wiki

38 of 298

5/14/2019

Triangular Wand Holder

Size and Weight

Length: 24 cm (9.45”)

Height: 17.5 cm (6.89”)

Width: 4.45 cm (1.75”)

Weight: 420g (14.82 oz)

Telescopic Wand Handle

BlackTrax Wiki

39 of 298

5/14/2019

Telescopic Wand Handle

Size and Weight

Length: 2.03 cm (0.8”)

Height: 149.86 cm (59”)

Width: 2.03 cm (0.8”)

Weight: 365 g (12.86 oz)

Ground Plane

BlackTrax Wiki

40 of 298

5/14/2019

Ground Plane

Size and Weight

Width: 76.96 cm (30.3”)

Length: 98.04 cm (38.6”)

Depth: 5.08 cm (2”)

Weight: 1905 g (67.2 oz)

Hybrid Power Supply Unit (HPSU)

BlackTrax Wiki

41 of 298

5/14/2019

Hybrid Power Supply Unit (HPSU)

Size and Weight

Width: 1.35 cm (0.5")

Height: 0.45 cm (0.2")

Depth: 1.1 cm (0.4")

Power Run Time

High: 1:00

Med: 2:45

Low: 3:15

Notes

Most applications (comparable to the previous PSU) use Medium, depending on the size of the1.

venue and how far the sensors are. You may try out low or high to conserve power or boost the IR.

A USB port is available where you can use to charge an external Beacon. 2.

An External Beacon can be charged approximately 90% if the HPSU is fully charged, and the

Beacon Battery is completely out of charge. This assumes no Stringers are attached to the

Beacon.

The HPSU can also be used to extend the life of a Beacon Battery if it is required to run past

its normal usage time. A Beacon with 1 Stringer has approximately 7.5 hours of additional

usage time. Beacons with either 2 or 3 Stringers attached have approximately 1 hour of

additional usage time.

Changing Internal Batteries in the HPSU

Attention: Please use an anti-static mat while being grounded.

Tool Required: *1/16 hex bit key.

To add batteries to the second pack

Side A Side B

BlackTrax Wiki

42 of 298

5/14/2019

Remove the 4 screws from Side A using the 1/16 hex bit.1.

Once the screws are removed, pull the panel away to reveal the interior of the HPSU.2.

Remove the board half way to expose the attachment for the power switch.3.

Carefully remove the power switch pin. Pull the pin straight upwards. 4.

Attention: AVOID MOVING THE PIN IN THE DIRECTION SHOWN IN THE PICTURE WITH

ARROWS (below).

Once the pin is removed, push the board back into the HPSU.5.

Turn the HPSU to Side B and remove the screws.6.

Remove the HPSU all the way to expose the second battery pack.7.

Add the batteries.8.

Tighten the straps. 9.

Reattach the power switch on Side A. Carefully pushing down the pin until it is locked in place.10.

Push the board back into the case, making sure not to pinch any wires on Side B.11.

Close Side A.12.

To change the pre installed HPSU batteries

Remove the 4 screws from Side A using the 1/16 hex bit.1.

Once the screws are removed, pull the panel away to reveal the interior of the HPSU. 2.

Note: HPSU board slides into the bottom slot of the interior.

Carefully pull the board out from the HPSU. You only need to remove the board half way to replace3.

BlackTrax Wiki

43 of 298

5/14/2019

the batteries.

Once you have replaced the batteries, tighten the Velco straps on the batteries.4.

Slowly and carefully push the board back into the HPSU.5.

Lighting Wand

BlackTrax Wiki

44 of 298

5/14/2019

Lighting Wand

Size and Weight

Size: 2 m (6.56’)

Weight: 235 g (8.29 oz)

BTCalibration Kit Case

BlackTrax Wiki

45 of 298

5/14/2019

BTCalibration Kit Case

Outside dimensions: 134.6 x 40.6 x 15.5 cm (53” x 16” x 6.12”)

Weight: (with foam lining only): 11.6 kg (25.57 lbs.)

Stringer

BlackTrax Wiki

46 of 298

5/14/2019

Stringer Diagram

Physical Characteristics

Cable length: 1.37 m (4.5') Custom sizes are available

Cable thickness: 2.9 mm (0.11")

LED Diffuser diameter: 7.93 mm (5/16")

Strain relief: 30 mm (1.18")

Male SMA Connector: 9 mm x 8 mm (0.35" x 0.32")

Male SMA Connector diagram

Stringer Functions

When a Stringer is connected to a BTBeacon LED port, the LED portion of a Stringer will pulse that

BTBeacon’s unique ID signal. The pulse is viewed by BTSensors, sent to the BTServer and used to

calculate the BTBeacon position in the Space.

Discontinued

BlackTrax Wiki

47 of 298

5/14/2019

Table of contents:

eSync Controller

S250e Slim

Power Supply Unit (PSU)

BTServer (Legacy)

TimeKeeper (Legacy)

eSync Controller

BlackTrax Wiki

48 of 298

5/14/2019

eSync Controller Diagram

Physical Characteristics

Width: 13.89 cm (5.47”)

Height: 4.09 cm (1.61”)

Depth: 9.25 cm (3.64”)

Weight: 368.54 g (13 oz)

Operating temperature: 0°C to +40°C (32°F to 104°F)

Input/Output & Power

PoE: IEEE 802.3af-2003

Adapter: 12V DC and 3 Amps

Data: Ethernet

Status LEDs

Per port activity status

Master time

External lock

Ethernet link status

Ethernet activity

eSync Controller Functions

The eSync Controller synchronizes BTSensors so that the shutters of BTSensors open and close

simultaneously and in synchronization with the pulsing of LED Stringers attached to BTBeacons.

eSync Controller Connection to the TimeKeeper

The eSync Controller connects to the TimeKeeper over RCA cable. The RCA cable is plugged into the RCA

port of the eSync Controller.

S250e Slim

BlackTrax Wiki

49 of 298

5/14/2019

S250e SLIM diagram

Product ID

Model Number: BT-S250-15

Physical Characteristics

Mounting: 0.635 cm (1/4”)-20 tripod thread

Operating temperature: 0°C to +51°C (32°F to 123.8°F)

Case: Aluminum and Polycarbonate

Width: 8.1 cm (3.19”)

Height: 8. cm (3.16”)

Depth: 6.76 cm (2.66”)

Weight: 430.91 g (15.2 oz)

Lens & Filter

Stock lens: 5.5 mm F#1.8 (wide band AR coated)

Horizontal FOV: 56°

Vertical FOV: 46°

Optional lens: 8 mm F#1.8 (wide band AR coated)

Horizontal FOV: 42°

Vertical FOV: 34°

M12 Lens Mount

Adjustable focus with wave spring assist

800nm IR long pass filter with Filter Switcher

Image Sensor

Resolution: 832 × 832

Frame Rate: 30–250 FPS (100 FPS average usage)

Accuracy: Sub-millimeter

Latency: 4 ms

BlackTrax Wiki

50 of 298

5/14/2019

Shutter Type: global

Shutter Speed:

Default: 0.5 ms (500 µs)

Minimum: 0.01 ms (10 µs)

Maximum: 3.8 ms (3,800 µs) at 100 FPS

Input/Output & Power

Data: Ethernet

Synchronization: Ethernet

Power: (PoE) 15.4 watts

Power Supply Unit (PSU)

BlackTrax Wiki

51 of 298

5/14/2019

Power Supply Unit (PSU)

Size and Weight

Width: 10.5 cm (4.1”)

Height: 9.8 cm (3.8”)

Depth: 4.57 cm (1.8”)

Weight: 335 g (11.82 oz)

Power

Power: 10 Watt

BTServer (Legacy)

BlackTrax Wiki

52 of 298

5/14/2019

BTServer (Rev 1-4) Diagram

Physical Characteristics

Technical Specifications

BTServer Rev 4:

(2x) Intel Xeon Processor E5-2620 v4 (8C, 2.1GHz, 3.0GHz Turbo, 2133MHz, 20MB, 85W)

(2x) 2.5" 512GB SSD SATA in RAID 1

16GB (4x4GB) 2400MHz DDR4 RDIMM ECC

NVidia GeForce GTX 1060

Dual, Hot-plug, Redundant Power Supply (1+1), 1100W

Integrated Intel I350 (4x1Gbit) Quad Port Network Card + Additional Intel I350 Quad-Port Gigabit

Ethernet Controller

Windows Embedded 8.1 Industry Pro

BTServer Rev 3:

(2x) Intel Xeon Processor E5-2620 v3 (6C, 2.4GHz, 3.2GHz Turbo, 1866MHz, 15MB, 85W)

(2x) 2.5" 512GB SSD SATA in RAID 1 -or- (2x) 2.5" 500GB HDD SATA in RAID 1

64GB (8x8GB) 2400MHz DDR4 RDIMM ECC

NVidia GeForce GTX 1060 -or- NVidia GeForce GTX 960 -or- Earlier

Dual, Hot-plug, Redundant Power Supply (1+1), 1100W

Integrated Intel I350 (4x1Gbit) Quad Port Network Card + Additional Broadcom BCM5719 Quad-Port

Gigabit Ethernet Controller

DVD-ROM Optical Disk Drive

Newer Systems: Windows 8.1 Pro; Legacy Systems: Windows 7 Professional

BTServer Rev 2:

(2x) Intel Xeon Processor E5-2620 v2 (6C, 2.1GHz, 2.6GHz Turbo, 1600MHz, 15MB, 80W)

(2x) 2.5" 500GB HDD SATA in RAID 1

16GB (4x4GB) 1866MHz DDR3 ECC RDIMM

NVidia GeForce GTX 760 -or- Earlier

Dual, Hot-plug, Redundant Power Supply (1+1), 1100W

Intel X520-T2 Dual Port 10GbE Network Interface Card

DVD-ROM Optical Disk Drive

Windows 7 Professional

BlackTrax Wiki

53 of 298

5/14/2019

BTServer Rev 1:

(2x) Intel Xeon Processor E5-2620 v2 (6C, 2.1GHz, 2.6GHz Turbo, 1600MHz, 15MB, 80W)

(2x) 3.5" 500GB HDD SATA in RAID 1

4GB RDIMM, 1600MT/s, Low Volt, Single Rank, x8 Data Width

NVidia GeForce GTX 760 -or- Earlier

Dual, Hot-plug, Redundant Power Supply (1+1), 1100W

Broadcom 5720 Quad Port 1Gb Network Interface Card

DVD-ROM Optical Disk Drive

Windows 7 Professional

TimeKeeper (Legacy)

BlackTrax Wiki

54 of 298

5/14/2019

TimeKeeper (Rev G) Diagram

Product ID

FCC ID: RKT-BTTKV01

IC: 10858A-BTTKV01

Model number: BTTKV01

Physical Characteristics

Width: 5.7 cm (2.245")

Height: 7.11 cm (2.8")

Depth: 2.57 cm (1.013")

Weight: 125 g (4.41 oz)

Operating Temperature

0°C to +40°C (32°F to 104°F)

Input/Output & Power

Data: Ethernet, Radio 2.4(GHz) 10Hz

Power: 48VDC/15.6W from PoeE Network Switch via Ethernet port (No input power via USB port)

Status LEDs

Note: The Ethernet status lights on the TimeKeeper are not enabled while the TimeKeeper is in use.

TimeKeeper Functions

BlackTrax Wiki

55 of 298

5/14/2019

The TimeKeeper is a single wireless access point that uses a proprietary radio system running on the 2.4

Ghz frequencey to send data to all BTBeacons. Data sent includes a signal used to synchronize the

BTBeacons with the BTSensors and configuration commands sent to the eSync Controller via an RCA

cable.

TimeKeeper Transmitter Characteristics

General System Information

BlackTrax Wiki

56 of 298

5/14/2019

Table of contents:

BTSystem Information Flow and Connections

BTX Dongle

Saved System Data

FCC Information

BTSystem Information Flow and

BlackTrax Wiki

57 of 298

5/14/2019

Connections

Introduction

The following diagram outlines how the components of the BTSystem are connected and how data flows

between the different modules of the system.

BlackTrax Detailed System Diagram

BTX Dongle

BlackTrax Wiki

58 of 298

5/14/2019

Embedded inside each BTServer is a BTX dongle which serves two principal uses. The primary function of

a dongle is to act as a key. The dongle is the only way that BlackTrax software will open and operate. The

dongle has dynamic embedded information that controls the level of the software you can open/use, as

well as the expiry date of the Membership Period. A BTX Dongle grants the server access to the

BlackTrax software package as well as a custom version of WYSIWYG for BlackTrax. The expiry date for

the BTX dongle is set for April, 2021.

Secondly, a dongle is a security device used by CAST to prevent unauthorized use of the software and

protects an End User's work as well as their investment in the Product.

Attention: Windows Remote Desktop Connection should not be used with a BlackTrax system. Security

measures on the BTX dongle will prevent it from working. Users should use TeamViewer or VNC if remote

access to a BTServer is required.

Saved System Data

BlackTrax Wiki

59 of 298

5/14/2019

In BlackTrax, when system information is saved, the information is saved to a general folder on the

BTServer. Information saved this way includes configuration files and system lists from sub-processes.

By default this folder can be found at the following location, depending on your server version and

BlackTrax release version:

All BlackTrax Servers running v2.0.0 or later - C:\bt_run_time

FCC Information

BlackTrax Wiki

60 of 298

5/14/2019

Important FCC Information

These devices comply with Part 15 of the FCC Rules. Operation is subject to the following conditions:

This device must not cause harmful, interference, and1.

This device must accept any interference received, including interference that may cause2.

undesired operation.

This equipment has been tested and found to comply with the limits for a Class B digital device, pursuant

to Part 15 of the FCC Rules. These limits are designed to provide reasonable protection against harmful

interference. This equipment generates, uses and can radiate radio frequency energy and, if not installed

and used in accordance with the instructions, may cause harmful interference to radio communications.

Certificate Numbers

Model BTTKV01: Radio Cert. No.: IC: 10858A-BTTKV01

Model BTBCV01P: Radio Cert. No.: IC: 10858A-BTBCV01

Not Included Mandatory Components

BlackTrax Wiki

61 of 298

5/14/2019

Attention: BlackTrax requires additional components to function which are not included with purchase

of the BTSystem.

Category 6 Ethernet Cabling

Power Over Ethernet Gigabit Switch for BTSensors

Category 6 Ethernet Cabling

BlackTrax Wiki

62 of 298

5/14/2019

All Ethernet cabling used to connect the system components together must be of Category 6 (Cat6)

quality or greater. Cat6 is necessary for the transmission of data at gigabit speeds, which is required by

BlackTrax. The amount of cable needed will vary depending on the Space dimensions and user needs.

Attention: The maximum allowed length of a Cat6 cable is 91.44 meters. Cat6 standards should be

followed when connecting modules together to ensure the BTSystem operates as intended. This range

can be extended by using Gigabit switches to connect Cat6 cable of 91.44 meter length or less.

Power Over Ethernet Gigabit Switch for

BlackTrax Wiki

63 of 298

5/14/2019

BTCameras

BlackTrax requires a dedicated Power over Ethernet (PoE) gigabit switch or dedicated virtual local area

network (VLAN) to connect all the BTSensors with the rest of the system. The switch should have the

following:

A PoE gigabit switch.

A PoE port for each BTSensor, plus 4 extra to connect to the TimeKeeper, BTRouter, eSync

Controller and BTServer.

PoE switches must support 15.4 watts per Ethernet port.

Optional Components

BlackTrax Wiki

64 of 298

5/14/2019

Depending on the purpose of tracking, you may need additional hardware components that are not

included with the BTSystem.

DMX/Ethernet Node for Tracking with Moving Lights

Compatible DMX/Ethernet nodes

Luminex Node Settings

Common ArtGate Node Setup Guide

DMX/Ethernet Node for Tracking with

BlackTrax Wiki

65 of 298

5/14/2019

Moving Lights

Table of contents:

Compatible DMX/Ethernet nodes

Luminex Node Settings

Common ArtGate Node Setup Guide

Merging Channel:

The merging channel is a single DMX channel that is patched into your lighting console to

enable the control of moving fixtures from BlackTrax.

The merging channel can be a dimmer channel that controls intensity fading between BlackTrax

and the lighting console, or as a simple non-dim On/Off control.

The merging channel must be patched in your console and set as the trigger channel in your merge

node.

When the merging channel is at full (100%) intensity, BlackTrax has complete control over the

channels connected to the BlackTrax project. When the merging channel is at zero (0) intensity, the

lighting console has full control over the channels in the BlackTrax project.

In the Project Properties widget in BlackTrax, you can activate and set the monitoring of the Merge

Channel that was set in your merge node.

Compatible DMX/Ethernet nodes

BlackTrax Wiki

66 of 298

5/14/2019

To connect BlackTrax downstream to a lighting console, a DMX to Ethernet/Ethernet to DMX node is

required. The following nodes have been tested and are approved to work with BlackTrax:

Luminex

Luminex Ethernet-DMX2/Truss MkII

Luminex Ethernet-DMX4 MkII

Luminex Ethernet-DMX4/ Truss MkII

Luminex Ethernet-DMX8 MkII

Luminex Ethernet-DMX8/ Truss MkII

Sundrax

Sundrax ArtGate Pro

Sundrax ArtGate DIN

Sundrax ArtGate Board

Sundrax ArtGate Compact

Sundrax ArtGate Solid

Sundrax ArtGate Arma

Sundrax ArtJet Pro

Luminex Node Settings

BlackTrax Wiki

67 of 298

5/14/2019

The Luminex Ethernet DMX nodes must be configured to work with your BlackTrax system.

Attention: The following guide outlines how each variable should be set for use with BlackTrax. Each

BlackTrax event is unique. There are circumstances where these settings need to be modified based on

factors such as the rig, cabling, and patching.

Setup the node through the web interface. Please ensure your IP settings match that of the node(s) you

wish to configure. There are 2 ways to configure your node to work with BlackTrax:

To merge RTTrPL with an Art-Net or sACN universe via the 5-pin DMX ports.1.

To have the merged data be rerouted to another universe over the network (for example, when2.

other nodes are being used downstream of your Luminex nodes).

To configure a node to merge and send data via the DMX ports

To navigate to the web interface, enter the IP address of the node in your browser window.1.

Under Setup, click on the desired node you wish to configure.2.

Note: The 8 port nodes will appear as multiple 4 port nodes in the interface.

For the desired ports, choose Output as the Direction, and Custom for IP Merging.3.

Result: A blue box appears beside the number for the output after IP Merging is set to

Custom.

Click on this blue box beside the number for the output.4.

Result: The Config Outlet window for that output appears.

Set the universes you wish to merge. Source one chooses the DMX protocol, with a universe, and5.

source two chooses the RTTrPL universe.

Notes:

RTTrPL universes start from universe 0 instead of 1.

RTTrPL must be source 2.

Change the Mode to be X-Fade, set the trigger channel to be the same as your merging channel,6.

and then click Set default mode.

Click Submit Changes.7.

Result: That output will be configured as expected. If you select Show table, you should see

the channels have all changed to X-Fade, with a trigger of the specified channel.

Repeat the above for all outputs you wish to configure on the node.8.

Click Submit Changes.9.

Navigate to the Global tab under Setup. Set Enable Trigger to DMX, and the universe to whichever10.

universe your Merging Channel is patched to, with the desired DMX protocol.

To configure a node to reroute merged data to send to other DMX nodes

BlackTrax Wiki

68 of 298

5/14/2019

Note: It is recommended that the reroute is done to a universe which is different than the universes from

the console and BlackTrax. For example, if you are merging sACN universe 1, with RTTrPL universe 1, you

might re route the merged data to sACN universe 101.

To navigate to the web interface, enter the IP address of the node in your browser window.1.

Under Setup, click on the desired node you wish to configure.2.

Note: The 8 port nodes will appear as multiple 4 port nodes in the interface.

For the desired ports, choose Output as the Reroute, and Custom for IP Merging.3.

Result: A blue box appears beside the number for the output after IP Merging is set

to Custom.

Result: The port will now have an arrow leading to a box to specify the new universe to

reroute the merged data on.

Click on this blue box beside the number for the output.4.

Result: The Config Outlet window for that output appears.

Set the universes you wish to merge. Source one chooses the DMX protocol, with a universe, and5.

source two chooses the RTTrPL universe.

Notes:

RTTrPL universes start from universe 0 instead of 1.

RTTrPL must be source 2.

Change the Mode to be X-Fade, set the trigger channel to be the same as your merging channel,6.

and then click Set default mode.

Click Submit Changes.7.

Result: That output will be configured as expected. If you select Show table, you should see

the channels have all changed to X-Fade, with a trigger of the specified channel.

Repeat the above for all outputs you wish to configure on the node.8.

Click Submit Changes.9.

Navigate to the Global tab under Setup. Set Enable Trigger to DMX, and the universe to whichever10.

universe your Merging Channel is patched to, with the desired DMX protocol.

Common ArtGate Node Setup Guide

BlackTrax Wiki

69 of 298

5/14/2019

DMX nodes of the ArtGate family of models must be configured to work with your BlackTrax system.

Attention: The following guide outlines how each variable should be set for use with BlackTrax. Each

BlackTrax event is unique. There are circumstances where these settings need to be modified based on

factors such as the rig, cabling and patching.

Setup the node through a web interface, or setup the node through a BlackTrax server. Please ensure

your IP settings match that of the node(s) you wish to configure.

To configure a node

To navigate to the ArtGate model's web interface, enter the IP address of the node in your browser1.

window.

Result: The Main Settings window of the ArtGate model appears.

On the Main tab, scroll down to the Ports section.2.

For each DMX port that you want to use:3.

Set Mode/merging column to Out/ComXFade.1.

Set Pri.unv.protocol column to the desired protocol (Art-Net or sACN).2.

Set the Pri.unv.number column to the desired universe.3.

Set the Sec.unv.protocol to RTTrPL.4.

Set the Sec.unv.number to the corresponding RTTrPL universe.5.

Click Save Settings at the bottom of the page.4.

Click the Advanced tab on the main toolbar at the top of the page.5.

Result: The Advanced port settings window appears.

Notes:

Scroll down to the Advanced Port Settings section.6.

For each DMX port that you set on the Main tab:7.

Set the Trigger/XFade unv.protocol column to the desired protocol for the merge channel1.

(Art-Net or sACN).

Set the Trigger/XFade unv.number column to the universe which contains the merge2.

channel.

Set the Common Trigger/XFade control channel to the chosen DMX merge channel in the3.

above universe.

Click Save Settings at the bottom of the page.8.

RTTrPL universes start from universe 0 instead of 1.

Information updated as per ArtGate Pro firmware version 4.06.

System Procedures

BlackTrax Wiki

70 of 298

5/14/2019

Table of contents:

Licensing

Charging BTBeacons

Replacing a BTBeacon's Lithium-Ion Battery

Installing Third Party Software

Server Failover

Licensing

BlackTrax Wiki

71 of 298

5/14/2019

Licensing Overview

BlackTrax includes a licensing security system to authorize hardware devices on the BlackTrax Network.

Unrecognized devices on the BlackTrax Network are not compatible with the software. An unrecognized

device is any device on the BlackTrax Network that was not sold directly to you by CAST Software.

A BlackTrax License will authorize the use of the BlackTrax system for a restricted number of output

connections based on the type of License that was purchased. The number of output connections allowed

for each type of License varies from a minimum of 1 output connection and up to a maximum of 12

output connections, or the non-restricted Unlimited License.

The number of output connections that is authorized with the BlackTrax License is indicated in the About

BlackTrax dialog box.

Notes:

The default License Folder location is: C:\bt_run_time\license. Licenses can be downloaded from the

BlackTrax Members Only Downloader which can be found at this link.

You need to update your license if you have added new hardware devices to the network and

received an error message in BlackTrax.

You need to upgrade your license if you want to add output connections for additional unicast

outputs.

Attention: BlackTrax Licenses purchased before BlackTrax Release Version 2.2.3 will automatically

convert to the Unlimited License.

Charging BTBeacons

BlackTrax Wiki

72 of 298

5/14/2019

Charging Overview

BTBeacons are charged using the BTSmart Charger. BTBeacons can be connected to the BTSmart

Charger using the Mini USB port found on the side of the BTBeacon.

Attention:

The Mini USB port of the BTBeacon is not designed to be a peripheral device to a Class B personal

computer. As such, a user shall not connect the USB port to a Class B personal computer during

normal operation.

The sole power source of the BTBeacon is the internal 3.7V rechargeable Lithium-ion battery. The

BTBeacon does not require a connection at the Mini USB port to operate.

To charge a BTBeacon using the BTSmart Charger

Connect the BTBeacon to the charge station via the Mini USB port found on the side of the BTBeacon.

Result: The BTBeacon is charging. To determine when the BTBeacon is fully charged, see BTBeacon

status LEDs (During operation).

Replacing a BTBeacon's Lithium-Ion

BlackTrax Wiki

73 of 298

5/14/2019

Battery

BTBeacon Lithium-ion Battery Overview

After extensive use the lithium-ion battery in a BTBeacon may no longer operate and be unable to power

the BTBeacon. The lithium-ion battery’s life cycle is at its end if the lithium-ion battery will not hold a

charge and the BTBeacon will not power on. When this occurs, it is recommended that the lithium-ion

battery inside the BTBeacon be carefully replaced with a new lithium-ion battery.

Attention:

Only use lithium-ion batteries supplied by CAST. It is recommended that batteries be changed

every 6 months to ensure optimal performance.

The following are required when replacing a BTBeacon’s battery:

Replacement battery

3/8” Hex key

Adhesive tape

To replace a BTBeacon’s battery

On the BTBeacon, hold down the red Power button for 2 seconds.1.

Result: The BTBeacon will power off. No lights on the unit will be on.

Turn the BTBeacon over. Using a hex key, remove the 3/8” screws holding the case together.2.

Carefully separate the two halves of the BTBeacon case. There is a ribbon cable connecting the3.

motherboard in one half of the case, to the lithium-ion battery in the other half of the case.

Disconnect the ribbon cable from the motherboard.4.

The lithium-ion battery is attached to the case with adhesive tape. Gently remove the battery free5.

from the case.

Attention: When removing the battery, use soft tools and take care to not puncture or

damage the battery casing.

Properly dispose of the old battery.6.

Take a new battery and adhere it to the inside of the case.7.

Note: The adhesive tape must be heat resistant to function properly.

Connect the ribbon of the new battery to the motherboard.8.

Join the halves of the BTBeacon case and close the unit.9.

Fasten screws to the back of the BTBeacon case, sealing it.10.

Press the Power button down.11.

Result: The lights of the BTBeacon will flash and the unit will turn on. The BTBeacon’s

battery has successfully been replaced.

Opening the case to remove the battery

Disconnecting the ribbon cable

BlackTrax Wiki

74 of 298

5/14/2019

Adding new double sided tape, and insert new battery

Reconnecting the ribbon cable

Closing the case

Installing Third Party Software

BlackTrax Wiki

75 of 298

5/14/2019

The BTServer is a closed system. Circumventing the security measures in place on the BTSystem for any

reason, including the installation of third party software on the BTServer, is explicitly not permitted.

Circumventing the security of the BTSystem will immediately void the warranty.

This policy is in effect to protect the performance and stability of the BTSystem. Having third party

software installed might adversely affect the BTSystem.

Note: If third party software must absolutely be installed on the BTSystem, please contact CAST or your

local BTE for a possible solution. If a BTE or CAST deems the software acceptable, they may arrange to

install it for you.

Server Failover

BlackTrax Wiki

76 of 298

5/14/2019

In the event a user needs to switch from their main BT Server, to a backup BT Server, the following

procedure should be followed.

Note: Users should keep a backup of their related show files in the event they need to switch servers

during operation. Users can easily do this using BTBackup on their servers, or by manually copying the

files to a USB stick.

Only 1 instance of Motive, as well as BTEngine should be present on the network at any given time.1.

Therefore, the backup server should not have these modules open, or be disconnected from all

networks until needed.

The BlackTrax GUI, and BTWYG can be opened, with their files loaded on both servers at the

same time.

In the event of needing to switch servers, ensure the main BTServer has been disconnected from2.

it's associated networks.

On the Backup server, Launch Motive, with the correct file.3.

In the BTGUI launch BTEngine and Apply Changes.4.

From this point the show should be running as expected from the Backup Machine. Optionally, users

could have all modules and files running on the Backup Machine, with it completely disconnected from all

networks until the time of failover.

BTWYSIWYG For BlackTrax

BlackTrax Wiki

77 of 298

5/14/2019

Table of contents:

1 Preparing the BTWYG file :

1.1 Introduction :

1.2 Creating a BTWYSIWYG Project :

1.3 Saving the BTWYSIWYG Project :

1.4 Requirements for Creating the Space in BTWYSIWYG :

1.5 Defining a Common Origin in BTWYSIWYG :

1.6 Creating the Venue in BTWYSIWYG :

1.7 Creating Trackables in BTWYSIWYG :

1.8 Patching Trackables in BTWYSIWYG :

1.9 Hanging Moving Fixtures in BTWYSIWYG :

1.10 Best Practices for Moving Fixture Placement :

1.11 Patching and Assigning an ID to Fixtures in BTWYSIWYG :

1.12 Patching DMX Universes to a Console :

1.13 Patching Universes to BlackTrax :

1.14 Applying BTX information to BlackTrax from BTWYSIWYG :

2 Optional .BTX Information :

2.1 BlackTrax Zones :

3 Planning BTSensor Placement :

3.1 Introduction :

3.2 BTSensor Placement :

4 BlackTrax Visualization :

4.1 Introduction :

4.2 Using BTWYSIWYG as a Tracking Visualizer :

4.3 Using Calibration Data to Adjust Visualization in BTWYSIWYG :

4.4 Using Stick Beams for Fixtures in BTWYSIWYG :

4.5 Shaded View Camera Control :

Preparing the BTWYG file

BlackTrax Wiki

78 of 298

5/14/2019

Table of contents:

Introduction

Creating a BTWYSIWYG Project

Saving the BTWYSIWYG Project

Requirements for Creating the Space in BTWYSIWYG

Defining a Common Origin in BTWYSIWYG

Creating the Venue in BTWYSIWYG

Creating Trackables in BTWYSIWYG

Patching Trackables in BTWYSIWYG

Hanging Moving Fixtures in BTWYSIWYG

Best Practices for Moving Fixture Placement

Patching and Assigning an ID to Fixtures in BTWYSIWYG

Patching DMX Universes to a Console

Patching Universes to BlackTrax

Applying BTX information to BlackTrax from BTWYSIWYG

BTWYG Introduction

BlackTrax Wiki

79 of 298

5/14/2019

BTWYSIWYG is an award-winning program that offers lighting designers a customized 3D CAD, reporting

and pre-visualization application which is included in the BlackTrax software suite. Using BTWYSIWYG will

let you create a virtual representation of the Space.

BTWYSIWYG exports this information as a .btx file, which is then used by BlackTrax as a blueprint for

tracking in the Space. If you are tracking with moving fixtures, fixture position and patching must also be

included in the .btx file.

When connected to BlackTrax, BTWYSIWYG can act as a visualizer for what is happening in the Space.

Trackable and fixture movement can be fully simulated, using information from BlackTrax or other data

sources.

The following section on BTWYSIWYG covers only the features directly related to BlackTrax. For an indepth understanding of BTWYSIWYG and its full capabilities, please refer to the current WYSIWYG

Reference Guide.

Tip: A registered BlackTrax Expert can be consulted to assist with any portion of a BlackTrax project,

including transferring information from BTWYSIWYG to BlackTrax.

Creating a BTWYSIWYG Project

BlackTrax Wiki

80 of 298

5/14/2019

Creating a BTWYSIWYG Project from BlackTrax

When a new BlackTrax project is launched from the Portfolio Manager for the first time, a new

BTWYSIWYG project associated with the launched BlackTrax project is automatically created and opens

by default.

When a new BTWYSIWYG project is created from BlackTrax, all necessary settings and configurations are

automatically applied to that new BTWYSIWYG project. These template projects simplify the setup

process for BTWYSIWYG on new installations.

Creating and launching the new BTWYSIWYG project from the BlackTrax Portfolio Manager will

automatically start BTWYSIWYG in a state that is ready for BlackTrax use.

In the Editing section of the System Configuration widget in BlackTrax, you can set the BTWYSIWYG file

to automatically open after the associated BlackTrax file launches from the Portfolio Manager.

See Editing section for more details.

Notes:

We recommend creating and launching the new BTWYSIWYG project from the BlackTrax Portfolio

Manager which is more convenient than having to manually create the new project and settings in

BTWYSIWYG.

The BTWYSIWYG file associated with a BlackTrax project can also be launched via the BTWYG

option under the Modules menu.

Creating a New BTWYSIWYG Project

in BTWYSIWYG

The New command creates a new show document and will be saved as a ".wyg" file.

To create a new BTWYSIWYG project

In BTWYSIWYG, on the Welcome Screen, click File to choose New.1.

Result: The BTWYSIWYG opens a new show file in CAD.

BTWYG Welcome Screen

Saving the BTWYSIWYG Project

BlackTrax Wiki

81 of 298

5/14/2019

Once you have all the information on the Space that was created in BTWYSIWYG, the information must

be saved as a BTWYSIWYG project file (.wyg). Save will save the open BTWYSIWYG project to the same

file name and location under which it was previously saved. If you are saving the project for the first

time, this command will perform Save As..., which will save the current project with a new file name

and/or a new destination.

To save the BTWYSIWYG project using Save

In BTWYSIWYG, from the File menu, choose Save.1.

Result: The Save as window appears.

In the window, navigate to where you want to save the project file.2.

In the File name field type in the name of the project.3.

Click Save.4.

To save the BTWYSIWYG project using Save As...

In BTWYSIWYG, from the File menu, choose Save As.1.

Result: The Save as window appears.

In the window, navigate to where you want to save the project file.2.

In the File name field type in the name of the project.3.

Click Save.4.

Requirements for Creating the Space in

BlackTrax Wiki

82 of 298

5/14/2019

BTWYSIWYG

To use BlackTrax you are required to create a virtual representation of the Space in BTWYSIWYG. This

virtual Space will possess vital information that BlackTrax requires as follows: what the dimensions and

tracking area of the Space are, what objects or people you want BlackTrax to follow (Trackables), and

information on devices in use (e.g., fixtures). This section will guide you on creating the Space in

BTWYSIWYG and aspects that must be included.

To create the BTWYSIWYG file for tracking with moving fixtures in BlackTrax, follow these

mandatory steps

Define a common origin position in the Space. (Default set in template file.)1.

Create and patch Trackables to a motion universe and assign avatars. (Default set in2.

template file.)

Hang moving fixtures approximately where they will be in the venue with the correct orientation.3.

Patch fixtures to DMX universe and assign Spot IDs.4.

Patch DMX universes to console. (Default set in template file.)5.

Patch all created universes to BlackTrax. (Default set in template file.)6.

Save the BTWYSIWYG project. 7.

Export the BTWYSIWYG project for use with BlackTrax. (Default set in template file.)8.

Tip: Some of the required steps are set by default when the BlackTrax Template file is used in

creating a BlackTrax Portfolio, or from the Templates section in BTWYSIWYG.

To create the BTWYSIWYG file NOT for tracking with moving fixtures, follow these mandatory

steps

Define a common origin position in the Space. (Default set in template file.)1.

Create and patch Trackables to a motion universe and assign avatars. (Default set in2.

template file.)

Patch all created universes to BlackTrax. (Default set in template file.)3.

Save the BTWYSIWYG project.4.

Export the BTWYSIWYG project for use with BlackTrax. (Default set in template file.)5.

Tip: Some of the required steps are set by default when the BlackTrax Template file is used in

creating a BlackTrax Portfolio, or from the Templates section in BTWYSIWYG.

BTWYG file with patched fixtures and a trackable

Defining a Common Origin in

BlackTrax Wiki

83 of 298

5/14/2019

BTWYSIWYG

Origin Introduction

Most objects in BTWYSIWYG are drawn as 3D objects, with width, depth, and height values using the

Cartesian coordinate system of 3 working axes, X, Y, and Z. The point where the 3 axes meet is called

the origin and the value of X, Y, and Z is 0 respectively (0,0,0).

By default, the origin will be in the center of the WYSIWYG project. This default origin is called the

Document Origin. It is possible to move the origin from its default location to a new position. This origin is

called the User Origin.

CAD mode with a frame representing the default origin

Origin Requirements

The location of the origin is recommended to be inside the Space.

The origin should be easy to see and determine in the Physical Space.

The origin in the Physical Space needs to be visible to at least 2 BTSensors for BTSensor calibration

to function.

The location of the origin needs to be consistent. The origin needs to be the same in the

BTWYSIWYG virtual Space, in Motive, in the Physical Space and any Third Party Programs

connected to BlackTrax. Inconsistencies will cause errors in the BTSystem and any connected

downstream technologies.

The alignment of the ground plane in relation to the axes needs to be the same in the BTWYSIWYG

virtual Space, in Motive, and in the Physical Space. It is recommended that the following

conventions are followed when aligning the origin:

The +Y axis directed Upstage.

The +X axis is directed Stage Left.

The +Z axis is directed vertically towards the ceiling.

Ruler Tool

The Ruler Tool helps you design your show file in the Wireframe views of the CAD mode, providing a

visual aid for coordinate reference and measurement. By default, the ruler is aligned with the document

origin and displays coordinate information along the top and left side of the view. Its scale matches the

default grid scale. The ruler has different colors to represent different axes (X=Red, Y=Green, Z=Blue).

X Axis Ruler

Y Axis Ruler

BlackTrax Wiki

84 of 298

5/14/2019

Z Axis Ruler

Ruler Icons

Document Origin: The document origin icon appears when the Ruler’s zero position (origin) is aligned

with the Document Origin, which is set by default to be the center point of the BTWYSIWYG venue

defined for the event.

Document Origin Icon

User Origin: The user origin icon appears when you have set a new User Origin for the file.

User Origin Icon

Creating the Venue in BTWYSIWYG

BlackTrax Wiki

85 of 298

5/14/2019

Using the tools in BTWYSIWYG’s CAD mode, create an accurate scale representation the venue Space is

in. The suggested minimum level of detail is that it contains the floor, the walls and any pipes, trusses or

structural frames in which BTSensors or moving fixtures will be attached. The more detailed the venue,

the better looking and accurate the visualization will be.

Attention: Fixtures need to be attached to pipe or truss to be inserted. You may also insert fixtures on

the floor, but you won't be able to spin them using Fixture Properties.

Note: Due to the complexity of recreating an accurate representation of a venue, refer to the WYSIWYG

Reference Guide’s chapter on The CAD environment for a thorough understanding.

Creating Trackables in BTWYSIWYG

BlackTrax Wiki

86 of 298

5/14/2019

Trackables are objects or people that are to be tracked. A Trackable can be represented by a library

object from the Library Browser, or on a drawn object like a sphere or riser. Trackables are created on

the Trackables/Motion layer by default.

Important Notes:

Trackables are automatically named and patched when created.

By default, when a New Portfolio is launched from BlackTrax, BTWYSIWYG opens with 12

Trackables.

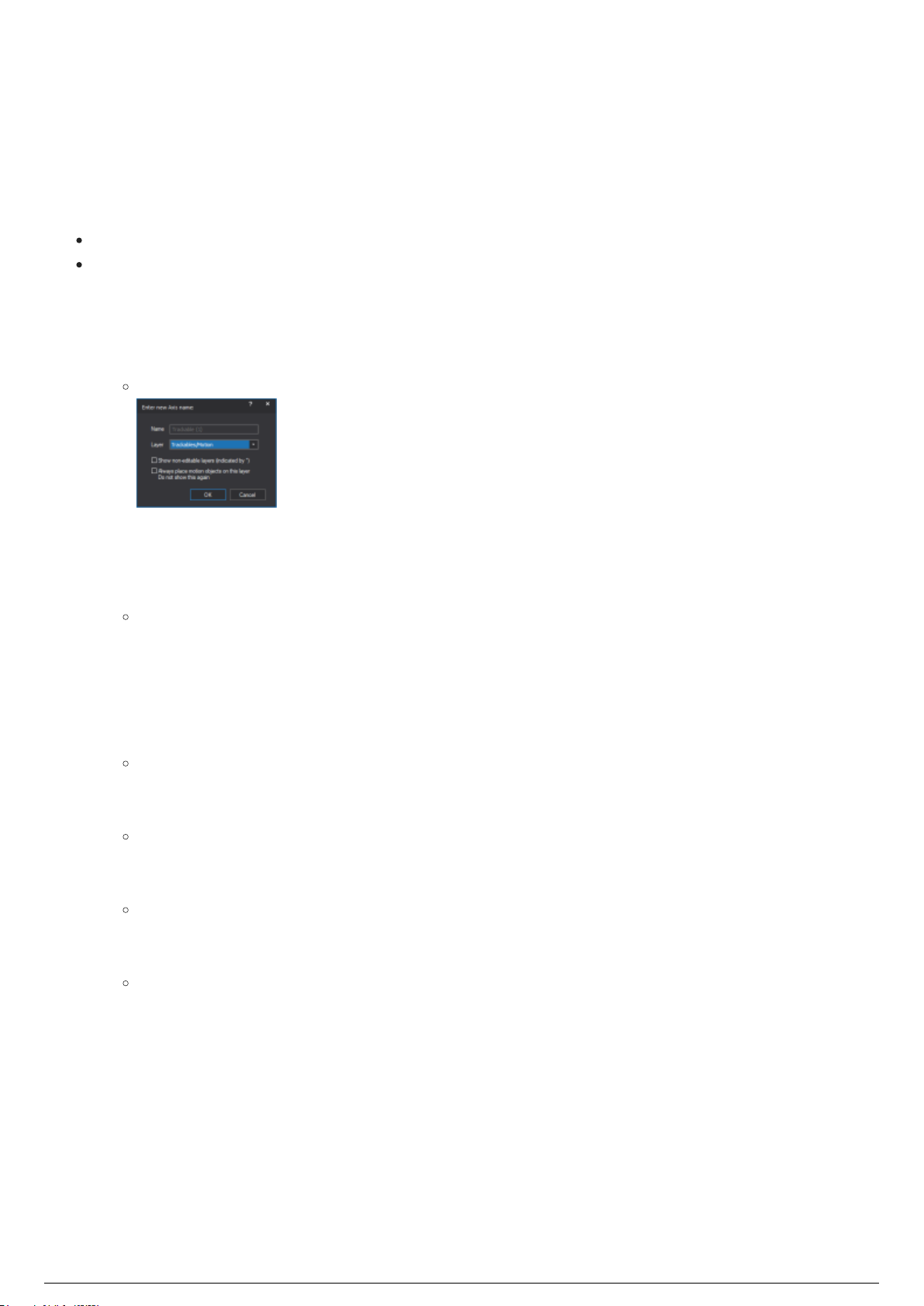

To create a trackable in BTWYSIWYG

In BTWYSIWYG CAD mode, from the BlackTrax menu, choose BT Trackable.1.

Result: The Enter new Axis name window appears.

In the Enter new Axis name window, click the layer for the Trackable from the Layer drop-down list.2.

You can also select the checkboxes to enable the other options for the layer display.3.

Click OK.4.

On your drawing, click where you wish to place your Trackable.5.

Result: A Trackable object appears where the mouse was clicked. The Trackable object is

represented as a Cartesian axis.

To add a library object to your trackable

In BTWYSIWYG CAD mode, at the bottom of the screen, click the Wireframe view tab.1.

From the LIBRARY menu, choose Browse Library.2.

Result: The Library Browser window appears.

At the bottom of the Library Browser window, click the Library items tab to display the contents.3.

Navigate to the desired object you wish to represent a Trackable.4.

Note: The actual look of the Trackable is purely cosmetic and will only represent the

Trackable's position in the visualization.

At the top of the Library Browser, click the Insert tool.5.

Tip: You can also double-click the object name.

To insert the object, click on your drawing to place the object where you want in relation to the6.

Trackable.

Tip: You should place the object relative to the drawn Trackable where the stringers will be

on your physical tracked object. The object will then move and rotate around the centroid of

the Trackable.

To stop inserting the object, right-click on the drawing and select Finish Library Item from the7.

menu that appears.

Right-click on the Trackable object you inserted on the drawing.8.

From the menu that appears, select Properties.9.

On the General tab, from the Attach to Axis drop-down list, select the Trackable object you wish to10.

assign the Library object to.

Click OK.11.

Result: The Trackable is represented as the inserted object and its motion is associated with the

BTTrackable.

BlackTrax Wiki

87 of 298

5/14/2019

Trackable object with a person attached

Note: The BlackTrax Template file has one Trackable and avatar created and patched by default. It is

possible to create multiple Trackables at once using the array tool in BTWYSIWYG, and this created

Trackable. See the Array section in the WYSIWYG Reference Guide for more information.

Patching Trackables in BTWYSIWYG

BlackTrax Wiki

88 of 298

5/14/2019

Patching Trackables Introduction

Important Note: As of BlackTrax v2.2, the Quick Motion Patch Tool is no longer required to patch

Trackables because Trackables are automatically named and patched when inserted.

Trackables that are created need to be patched to a Motion Universe. The patch allows the visualization

of Trackable movement in BlackTrax. This section shows how to easily patch Trackables using the Quick

Motion Patch Tool, as well as the manual way to patch each Trackable.

Note: Read the WYSIWYG Reference Guide’s chapter on Data mode for a complete understanding of

patching manually assigned Trackables.

Quick Motion Patch Tool

Patching Trackables Using Quick Motion Patch Tool

To patch all trackables using the quick motion patch tool

From the Tools menu, choose Quick Tools and then choose Quick Motion Patch Tool.1.

Under the Auto-Patch Motion section, ensure that All Trackable/Axes is selected.2.

Click Patch.3.

Note: If the motion universe BT-Trackables does not yet exist in the file, BTWYSIWYG will

ask in a dialog box if you wish to create it. In the dialog box, click Yes to create the motion

universe.

Result: The Trackables are patched to the motion universe. The total number of Trackables

patched will be reported at the bottom of the window.

Click Close.4.

To patch only selected trackables using the quick motion patch tool

Select all Trackables you wish to patch in one of the wireframe views.1.

Tip: Remember that the Trackable is the Cartesian axis associated with the Trackable, not

the Trackable object itself.

From the Tools menu, choose Quick Tools and then choose Quick Motion Patch Tool.2.

Under the Auto-Patch Motion section, ensure that Only Selected Trackable/Axes is selected.3.

Click Patch.4.

Note: If the motion universe BT-Trackables does not yet exist in the file, BTWYSIWYG will

ask in a dialog box if you wish to create it. In the dialog box, click Yes to create the motion

universe.

Result: The Trackables are patched to the motion universe. The total number of Trackables

patched will be reported at the bottom of the window.

Click Close.5.

To clear all trackables' patch using the quick motion patch tool

From the Tools menu, choose Quick Tools and then choose Quick Motion Patch Tool.1.

BlackTrax Wiki

89 of 298

5/14/2019

Under the Clear Motion Patch section, ensure that All Trackable/Axes is selected.2.

Click Clear.3.

Result: All Trackables are unpatched from the motion universe. The total number of patched

Trackables removed will be reported at the bottom of the window.

Click Close.4.

To clear only selected trackables' patch using the quick motion patch tool

Select all trackables you wish to clear patch info for in one of the Wireframe views.1.