Black & Decker Workmate 79-020 Owner's Manual

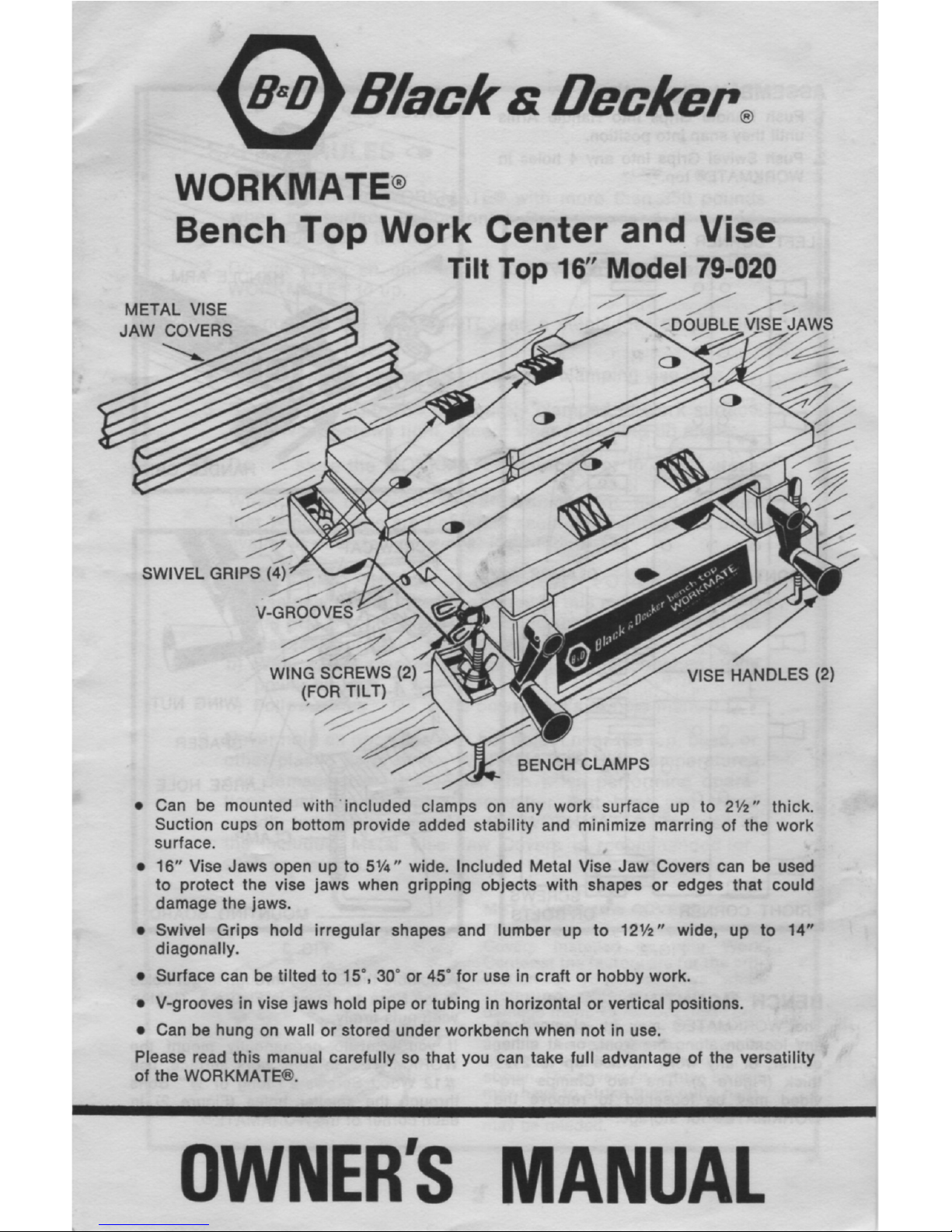

METAL VISE

JAW COVERS

SWIVEL GRIPS (4)

V-GROOVES

WING SCREWS (2)

(FOR TILT)

Black s Decker ,

WORKMATE®

Bench Top Work Center and Vise

Tilt Top 16" Model 79-020

-DOUBLE VISE JAWS

BENCH CLAMPS

VISE HANDLES (2)

• Can be mounted with included clamps on any work surface up to 21/2" thick.

Suction cups on bottom provide added stability and minimize marring of the work

surface.

• 16" Vise Jaws open up to 51/4" wide. Included Metal Vise Jaw Covers can be used

to protect the vise jaws when gripping objects with shapes or edges that could

damage the jaws.

• Swivel Grips hold irregular shapes and lumber up to 121/2" wide, up to 14"

diagonally.

• Surface can be tilted to 15°, 30° or 45° for use in craft or hobby work.

• V-grooves in vise jaws hold pipe or tubing in horizontal or vertical positions.

• Can be hung on wall or stored under workbench when not in use.

Please read this manual carefully so that you can take full advantage of the versatility

of the WORKMATE®.

OWNER'S MANUAL

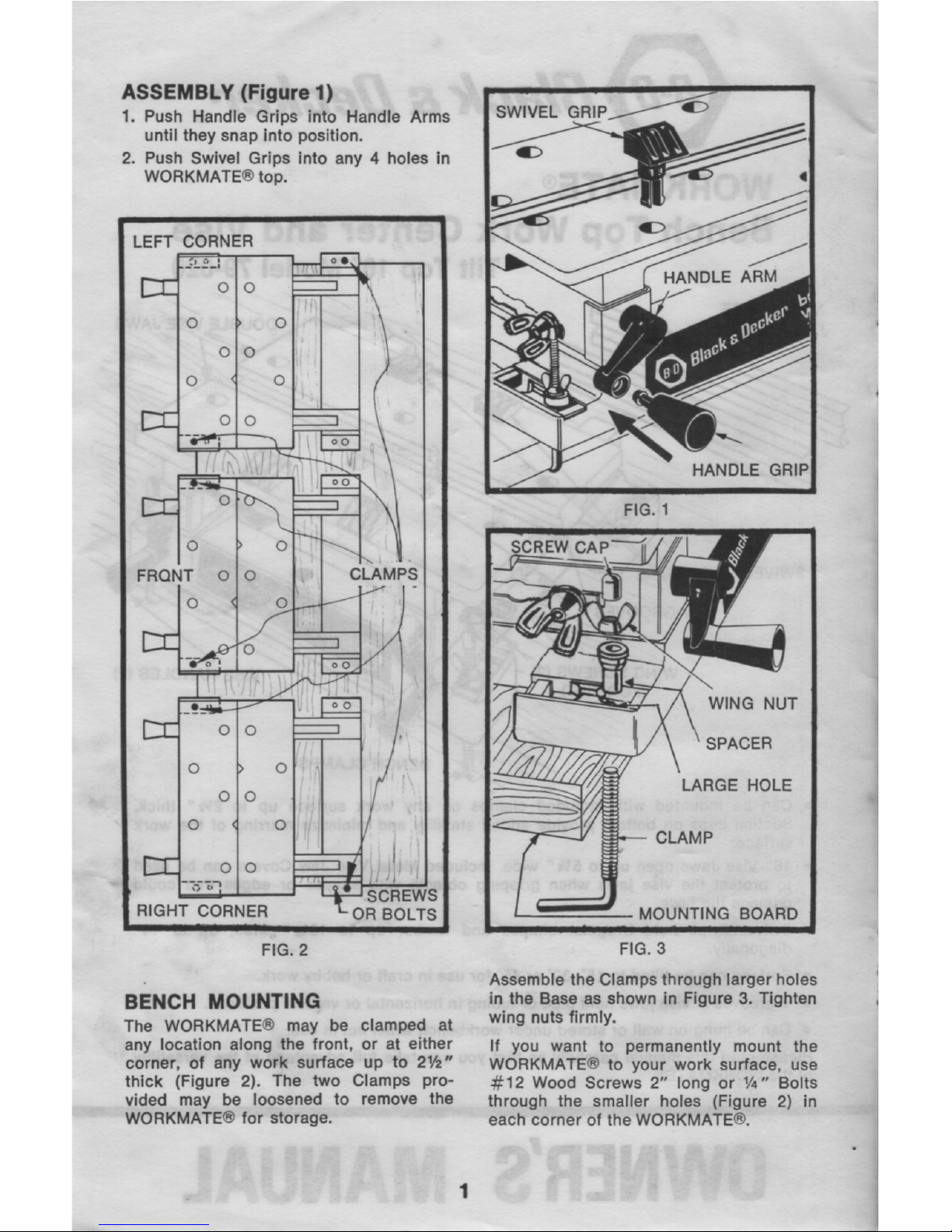

ASSEMBLY (Figure 1)

1. Push Handle Grips into Handle Arms

until they snap into position.

2. Push Swivel Grips into any 4 holes in

WORKMATE top.

LEFT CORNER

0

0

0

0

0

31_

0

0

FRONT 0

0 <

0

00

CLAMPSCLAMPS

I.

00

00

00

00

0

RIGHT CORNER OR SCREWS

0R BOLTS

FIG. 2

BENCH MOUNTING

The WORKMATE may be clamped at

any location along the front, or at either

corner, of any work surface up to 21/2"

thick (Figure 2). The two Clamps pro-

vided may be loosened to remove the

WORKMATE® for storage.

SWIVEL GRIP

SCREW CAP

HANDLE ARM

FIG. 1

HANDLE GRIP

WING NUT

SPACER

LARGE HOLE

CLAMP

MOUNTING BOARD

FIG. 3

Assemble the Clamps through larger holes

in the Base as shown in Figure 3. Tighten

wing nuts firmly.

If you want to permanently mount the

WORKMATE @ to your work surface, use

12 Wood Screws 2" long or 1/4" Bolts

through the smaller holes (Figure 2) in

each corner of the WORKMATE®.

1

SAFETY RULES

1. Do not load the WORKMATE® with more than 350 pounds

when top surface is horizontal. Do not exceed 40 pounds

when surface is tilted.

2. Do not apply an unbalanced load which could cause the

WORKMATE® to tip.

3. Do not use the WORKMATE® as a stepladder or standing

platform.

4. Avoid applying excessive force when clamping vise jaws.

5. Be sure WORKMATE® is securely clamped to work surface.

Keep Wing Screws tight, except when adjusting tilt angle.

6. Do not store the WORKMATE® outdoors or in damp areas.

7. When using the WORKMATE® with the top tilted, be sure

that Wing Screws are tightened securely in one of the three

available detented positions. (See Figure 17).

8. WHEN USING THE WORKMATE ® WITH POWER TOOLS:

a) Use only the methods described in this manual for mount-

ing power tools. Never mount power tools directly in the

vise jaws; pressure may damage tool.

b) Wear safety glasses or other eye protection when using

power tools.

c) Follow safety rules in the power tool's owners manual.

9. Never hold an open flame or hot object near the top, base, or

other plastic parts of the WORKMATE®. High temperatures

can damage these materials. Also when performing opera-

tions such as soldering, remember that heat can travel

rapidly through the metal to the WORKMATE®. The use of

the included Metal Vise Jaw Covers is recommended for

such operations.

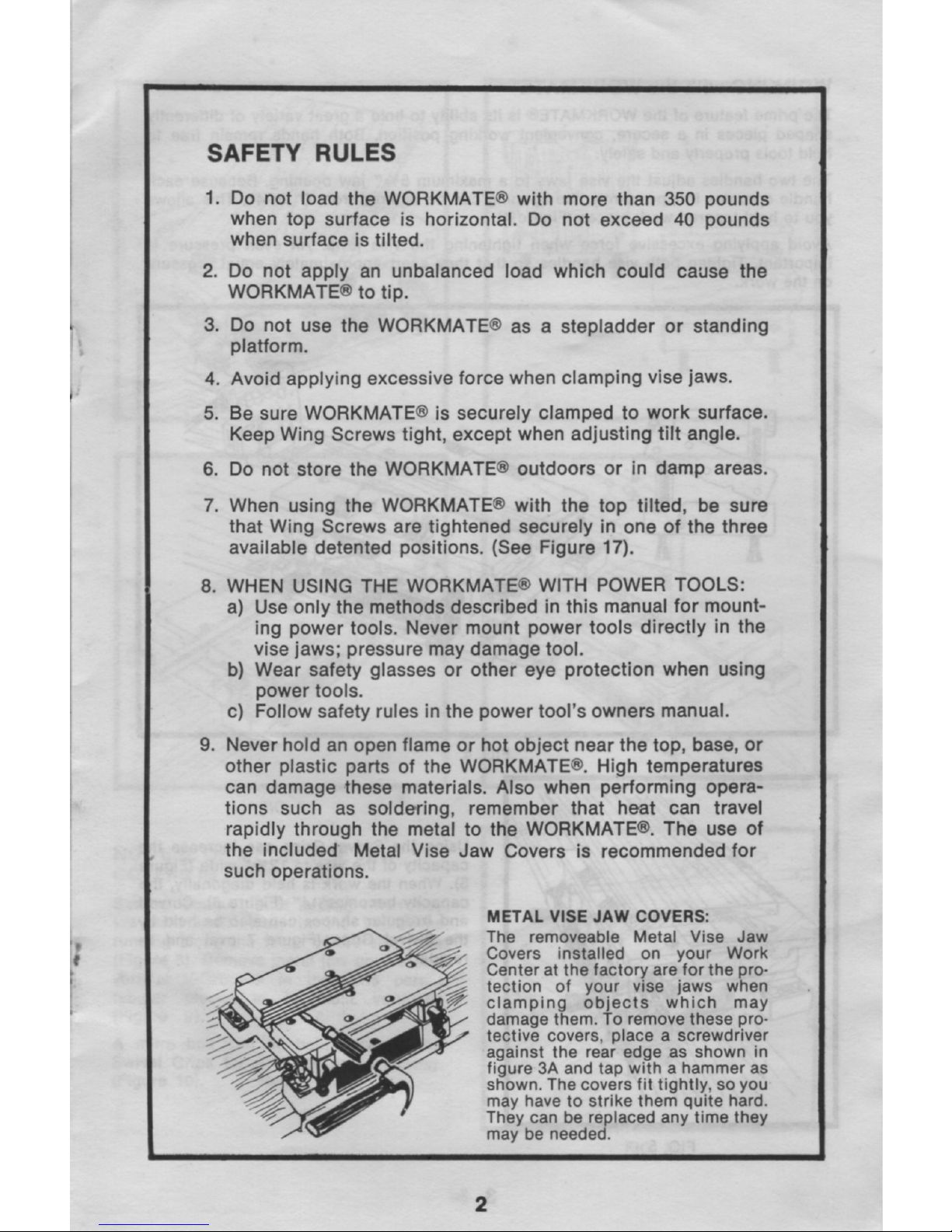

METAL VISE JAW COVERS:

The removeable Metal Vise Jaw

Covers installed on your Work

Center at the factory are for the pro-

tection of your vise jaws when

clamping objects which may

damage them. To remove these pro-

tective covers, place a screwdriver

against the rear edge as shown in

figure 3A and tap with a hammer as

shown. The covers fit tightly. so you

may have to strike them quite hard.

They can be replaced any time they

may be needed.

2

Loading...

Loading...