Page 1

CORDLESS DRILL INSTRUCTION MANUAL

Catalog Numbers SS12D, SS14, SS18

Thank you for choosing Black & Deckert

Go to www.BlackandDecker.com/NewOwner

to register your new product.

PLEASE READ BEFORE RETURNING THIS

PRODUCT FOR ANY REASON:

Ifyouhaveaquestionorexperiencea problemwithyourBlack&Deckerpurchase,goto

HTTP://WWW.BLACKANDDECKER.COM/INSTANTANSWERS

forinstantanswers24hoursaday.

Ifyoucan'tfindtheanswerordonothaveaccesstotheinternet,

call1-800-544-6986from8a.m.to5 p.m.ESTMon.--Fri.tospeakwithanagent.

Pleasehavethecatalognumberavailablewhenyoucall.

VEA EL ESPAI_IOL EN LA CONTRAPORTADA.

INSTRUCTIVO DE OPERACION, CENTROS DE SERVIClO Y POLIZA DE GARANTiA.

ADVERTENClA" LEASE ESTE INSTRUCTIVO ANTES DE USAR EL PRODUCTO.

Page 2

General Power Tool Safety Warnings

z_WARNINGt Read all safety warnings and instructions. Failure to follow the

warnings and instructions may result in electric shock, fire and/or serious injury.

Save all warnings and instructions for future reference.

The term "power tool" in the warnings refers to your mains-operated (corded)

power tool or battery-operated (cordless) power tool.

1) Work area safety

a) Keep work area clean and well lit. Cluttered or dark areas invite accidents.

b) Do not operate power tools in explosive atmospheres, such as in the presence

of flammable liquids, gases or dust. Power tools create sparks which may ignite

the dust or fumes.

c) Keep children and bystanders away while operating a power tool. Distractions

can cause you to lose control

2) Electrical safety

a) Power tool plugs must match the outlet. Never modify the plug in any way. Do

not use any adapter plugs with earthed (grounded) power tools. Unmodified

plugs and matching outlets will reduce risk of electric shock.

b) Avoid body contact with earthed or grounded surfaces such as pipes,

radiators, ranges and refrigerators. There is an increased risk of electric shock if

your body is earthed or grounded.

c) Do not expose power tools to rain or wet conditions. Water entering a power tool

will increase the risk of electric shock.

d) Do not abuse the cord. Never use the cord for carrying, pulling or unplugging

the power tool. Keep cord away from heat, oil, sharp edges or moving parts.

Damaged or entangled cords increase the risk of electric shock.

e) When operating a power tool outdoors, use an extension cord suitable for

outdoor use. Use of a cord suitable for outdoor use reduces the risk of electric shock.

f) If operating a power tool in a damp location is unavoidable, use a ground fault

circuit interrupter (GFCl) protected supply. Use of a GFCI reduces the risk of

electric shock.

3) Personal safety

a) Stay alert, watch what you are doing and use common sense when operating a

power tool. Do not use a power tool while you are tired or under the influence

of drugs, alcohol or medication. A moment of inattention while operating power

tools may result in serious personal injury.

b) Use personal protective equipment. Always wear eye protection. Protective

equipment such as dust mask, non-skid safety shoes, hard hat, or hearing protection

used for appropriate conditions will reduce personal injuries.

c) Prevent unintentional starting. Ensure the switch is in the off-position before

connecting to power source and/or battery pack, picking up or carrying the

tool. Carrying power tools with your finger on the switch or energising power tools

that have the switch on invites accidents.

d) Remove any adjusting key or wrench before turning the power tool on. A

wrench or a key left attached to a rotating part of the power tool may result in

personal injury.

e) Do not overreach. Keep proper footing and balance at all times. This enables

better control of the power tool in unexpected situations.

f) Dress properly. Do not wear loose clothing or jewellery. Keep your hair,

clothing and gloves away from moving parts. Loose clothes, jewellery or long hair

can be caught in moving parts.

g) If devices are provided for the connection of dust extraction and collection

facilities, ensure these are connected and properly used. Use of dust collection

can reduce dust-related hazards.

4) Power tool use and care

a) Do not force the power tool. Use the correct power tool for your application.

The correct power tool will do the job better and safer at the rate for which it was

designed.

Page 3

b) Do not use the power tool if the switch does not turn it on and off. Any power

tool that cannot be controlled with the switch is dangerous and must be repaired.

c) Disconnect the plug from the power source and/or the battery pack from the

power tool before making any adjustments, changing accessories, or storing

power tools. Such preventive safety measures reduce the risk of starting the power

tool accidentally.

d) Store idle power tools out of the reach of children and do not allow persons

unfamiliar with the power tool or these instructions to operate the power tool.

Power tools are dangerous in the hands of untrained users.

e) Maintain power tools. Check for misalignment or binding of moving parts,

breakage of parts and any other condition that may affect the power tool's

operation. If damaged, have the power tool repaired before use. Many accidents

are caused by poorly maintained power tools.

f) Keep cutting tools sharp and clean. Properly maintained cutting tools with sharp

cutting edges are less likely to bind and are easier to control

g) Use the power tool, accessories and tool bits etc., in accordance with these

instructions, taking into account the working conditions and the work to be

performed. Use of the power tool for operations different from those intended could

result in a hazardous situation.

5) Battery tool use and care

a) Recharge only with the charger specified by the manufacturer. A charger that is

suitable for one type of battery pack may create a risk of fire when used with another

battery pack.

b) Use power tools only with specifically designated battery packs. Use of any

other battery packs may create a risk of injury and fire.

c) When battery pack is not in use, keep it away from other metal objects like

paper clips, coins, keys, nails, screws, or other small metal objects that can

make a connection from one terminal to another. Shorting the battery terminals

together may cause bums or a fire.

d) Under abusive conditions, liquid may be ejected from the battery, avoid

contact. If contact accidentally occurs, flush with water. If liquid contacts eyes,

additionally seek medical help. Liquid ejected from the battery may cause irritation

or bums.

6) Service

a) Have your power tool serviced by a qualified repair person using only identical

replacement parts. This will ensure that the safety of the power tool is maintained.

SPECIFIC SAFETY RULES

• Wear ear protectors with impact drills. Exposure to noise can cause hearing loss.

• Use auxiliary handles supplied with the tool. Loss of control can cause personal injury.

• Hold power tools by insulated gripping surfaces when performing an operation

where the cutting tool may contact hidden wiring or its own cord. Contact with a

"live" wire will make exposed metal parts of the toot "live" and shock the operator.

• When working on a ladder or on scaffolding be sure to lay the tool down on its side

when not in use. Some tools with large battery packs wilt stand upright but may be easily

knocked over.

• Use clamps or another practical way to secure and support the work piece to a

stable platform. Holding the work by hand or against your body leaves it unstable and

may lead to loss of control.

• Keep your hair, clothing, and gloves away from air vents. Air vents often cover

moving parts in which these items can be caught.

• Hold tool firmly with two hands. Use auxiliary handle if provided. If auxiliary handle

not provided, grip toot at bottom of battery. Loss of control can cause personal injury.

_WARNING: Some dust created by power sanding, sawing, grinding, drilling, and

other construction activities contains chemicals known to the State of California

to cause cancer, birth defects or other reproductive harm. Some examples of

these chemicals are:

• lead from lead-based paints,

• crystalline silica from bricks and cement and other masonry products, and

• arsenic and chromium from chemically-treated lumber.

Page 4

Yourriskfromtheseexposuresvaries,dependingonhowoftenyoudothistypeof

work.Toreduceyourexposuretothesechemicals:workinaweltventilatedarea,and

workwithapprovedsafetyequipment,suchasthosedustmasksthatarespecially

designedtofilteroutmicroscopicparticles.

• Avoid prolonged contact with dust from power sanding, sawing, grinding, drilling,

and other construction activities. Wear protective clothing and wash exposed

areas with soap and water. Allowing dust to get into your mouth, eyes, or lay on the

skin may promote absorption of harmful chemicals.

WARNING: Use of this tool can generate and/or disperse dust, which may cause

serious and permanent respiratory or other injury. Always use NIOSH/OSHA

approved respiratory protection appropriate for the dust exposure. Direct particles

away from face and body.

Z_WARNING: ALWAYS use safety glasses. Everyday eye glasses are NOT safety

glasses. Also use face or dust mask if cutting operation is dusty. ALWAYS WEAR

CERTIFIED SAFETY EQUIPMENT:

• ANSI Z87. 1 eye protection (CAN/CSA Z94.3)

• ANSI S12.6 (S3. 19) hearing protection

• NIOSH/OSHA/MSHA respiratory protection

SAFETY GUIDELINES - DEFINITIONS

It is important for you to read and understand this manual.

The information it contains relates to protecting YOUR SAFETY and PREVENTING

PROBLEMS. The symbols below are used to help you recognize this information.

Z_ DANGER: Indicates an imminently hazardous situation which, if not avoided, will

result in death or serious injury.

Z_ WARNING: Indicates a potentially hazardous situation which, if not avoided, could

result in death or serious injury.

Z_ CAUTION: Indicates a potentially hazardous situation which, if not avoided, may

result in minor or moderate injury.

CAUTION: Used without the safety alert symbol indicates a potentially hazardous

situation which, if not avoided, may result in property damage.

The label on your toot may include the following symbols.

V .......................... volts

Hz ........................ hertz

min ........................ minutes

:_:: ...................... direct current

[] .......................... Class II Construction

z_ ........................ safety alert symbol

A .......................... amperes

W ........................ watts

...................... alternating

current

no ........................ no load speed

........................ earthing terminal

.../min .................. revolutions or

reciprocations

per minute

Page 5

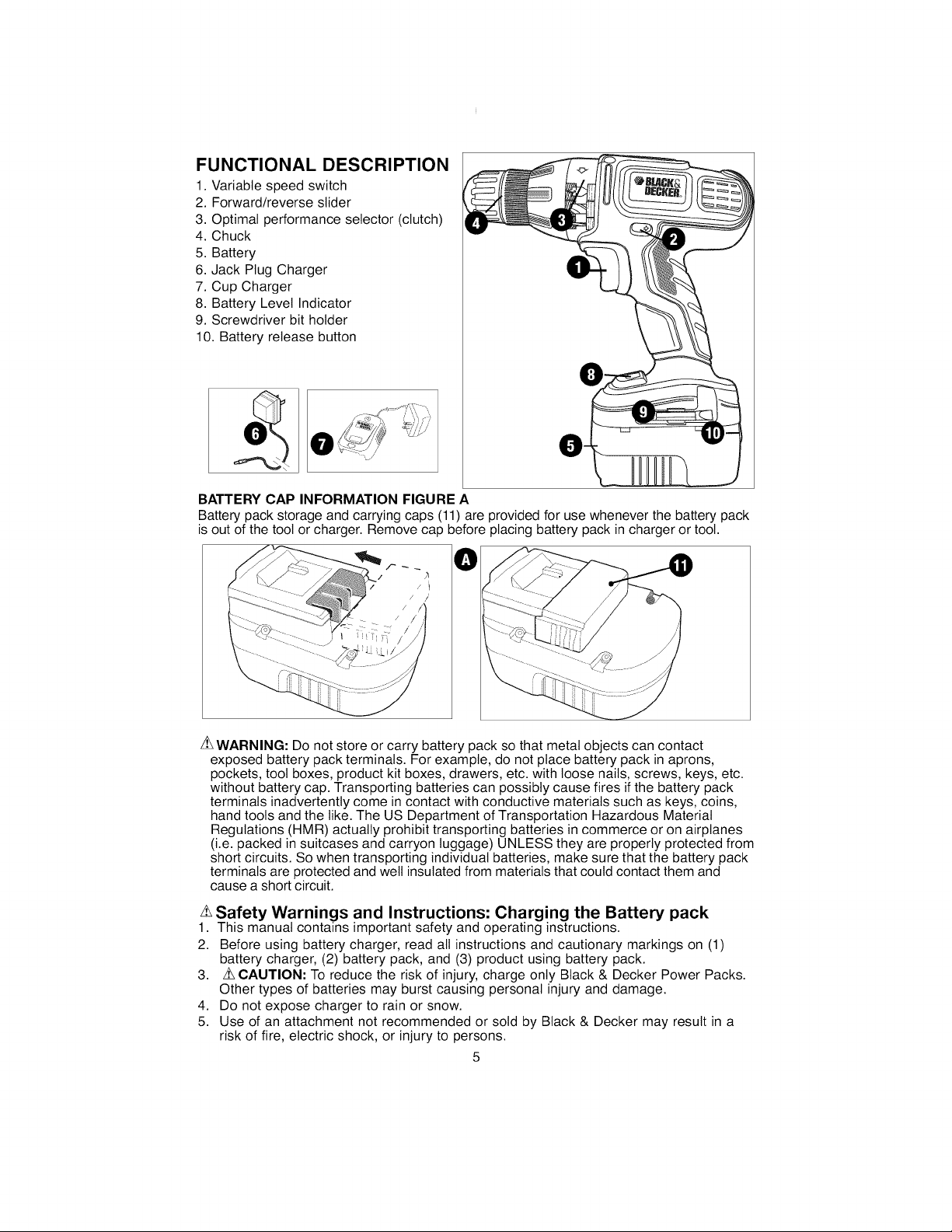

FUNCTIONAL DESCRIPTION

1. Variable speed switch

2. Forward/reverse slider

3. Optimal performance selector (clutch)

4. Chuck

5. Battery

6. Jack Plug Charger

7. Cup Charger

8. Battery Level Indicator

9. Screwdriver bit holder

10. Battery release button

/

BATTERY CAP INFORMATION FIGURE A

Battery pack storage and carrying caps (11) are provided for use whenever the battery pack

is out of the toot or charger. Remove cap before placing battery pack in charger or toot.

3

/ /

Z_WARNING: Do not store or carry battery pack so that metal objects can contact

exposed battery pack terminals. For example, do not place battery pack in aprons,

pockets, toot boxes, product kit boxes, drawers, etc. with loose nails, screws, keys, etc.

without battery cap. Transporting batteries can possibly cause fires if the battery pack

terminals inadvertently come incontact with conductive materials such as keys, coins,

hand tools and the like. The US Department of Transportation Hazardous Material

Regulations (HMR) actually prohibit transporting batteries in commerce or on airplanes

(i.e. packed in suitcases and carryon luggage) UNLESS they are properly protected from

short circuits. So when transporting individual batteries, make sure that the battery pack

terminals are protected and well insulated from materials that could contact them and

cause a short circuit.

Safety Warnings and Instructions: Charging the Battery pack

1. This manual contains important safety and operating instructions.

2. Before using battery charger, read all instructions and cautionary markings on (1)

battery charger, (2) battery pack, and (3) product using battery pack.

3. z_ CAUTION: To reduce the risk of injury, charge only Black & Decker Power Packs.

Other types of batteries may burst causing personal injury and damage.

4. Do not expose charger to rain or snow.

5. Use of an attachment not recommended or sold by Black & Decker may result in a

risk of fire, electric shock, or injury to persons.

Page 6

6. Toreduceriskofdamagetoelectricplugandcord,pullbyplugratherthancordwhen

disconnectingcharger.

7. Makesurecordislocatedsothatitwillnotbesteppedon,trippedover,orotherwise

subjectedtodamageorstress.

8. Anextensioncordshouldnotbeusedunlessabsolutelynecessary.Useofimproper

extensioncordcouldresultinariskoffire,electricshockorelectrocution.

a. Two-wirecordscanbeusedwith2-wireor3-wireextensioncords.Onlyround

jacketedextensioncordsshouldbeused,andwerecommendthattheybelistedby

UnderwritersLaboratories(U.L.).Iftheextensionistobeusedoutside,thecordmust

besuitableforoutdooruse.Anycordmarkedforoutdoorusecanalsobeusedfor

indoorwork.Theletters"W"or"WA"onthecordjacketindicatethatthecordis

suitableforoutdooruse.

b.Anextensioncordmusthaveadequatewiresize(AWGorAmericanWireGauge)for

safety,andtopreventtossofpowerandoverheating.Thesmallerthegaugenumber

ofthewire,thegreaterthecapacityofthecable;thatis,16gaugehasmorecapacity

than18gauge.Whenusingmorethanoneextensiontomakeupthetotallength,be

sureeachextensioncontainsatleasttheminimumwiresize.

CHART FOR MINIMUM WIRE SIZE (AWG)OF EXTENSION CORDS

Total Extension Cord Length (ft) 0-25 26-50 51-100 101-150

Wire Gauge 18 16 16 14

9. Use only the supplied charger when charging your drill. The use of any other charger

could damage the drill or create a hazardous condition.

10. Use only one charger when charging.

11. Do not attempt to open the charger or the drill. There are no customer serviceable

parts inside. Return to any authorized Black & Decker service center.

12. DO NOT incinerate the drill or battery packs even if they are severely damaged or

completely worn out. The batteries can explode in a fire.

13. A small leakage of liquid from the battery pack cells may occur under extreme usage,

charging or temperature conditions. This does not indicate a failure. However, if the

outer seal is broken and this leakage gets on your skin:

a. Wash quickly with soap and water.

b. Neutralize with a mild acid such as lemon juice or vinegar.

c. If the battery pack liquid gets in your eyes, flush them with clean water for a minimum

of 10 minutes and seek immediate medical attention. MEDICAL NOTE: The liquid is

a 25-35% solution of potassium hydroxide.

CHARGING THE POWER PACK

Your drill may use either a jack plug charger or a cup charger, both of which are described

below. Please follow the directions for the type of charger that you have. Chargers are

designed to use standard 120 volt AC, 60 Hz power. Do not use DC or any other voltage.

THE BATTERIES IN YOUR POWER PACK ARE NOT FULLY CHARGED AT THE

FACTORY. BEFORE ATTEMPTING TO CHARGE THEM, THOROUGHLY READ ALL OF

THE SAFETY INSTRUCTIONS.

INSTRUCTIONS FOR JACK PLUG CHARGERS:

1. Place the battery pack into the toot until it

"clicks" into place.

2. Insert the charger plug into the connector as

shown in figure B.

3. Plug the charger (6) into any standard 120

Volt 60 Hz electrical outlet and let the battery

pack charge initially for 12 hours. After the

initial charge, under normal usage, your

power pack should be fully charged in 6 to 12

hours.

4. _ WARNING: Fire Hazard. Disconnect the

charger from the outlet first, then disconnect

the charger from the toot. Do not use the toot

while it is connected to the charger.

NAMEPLATE RATING AMPS - 0 - 10.0

(0-7,6m) (7,6-15,2m)(15,2-30,4m)(30,4-4.5,7m)

6

Page 7

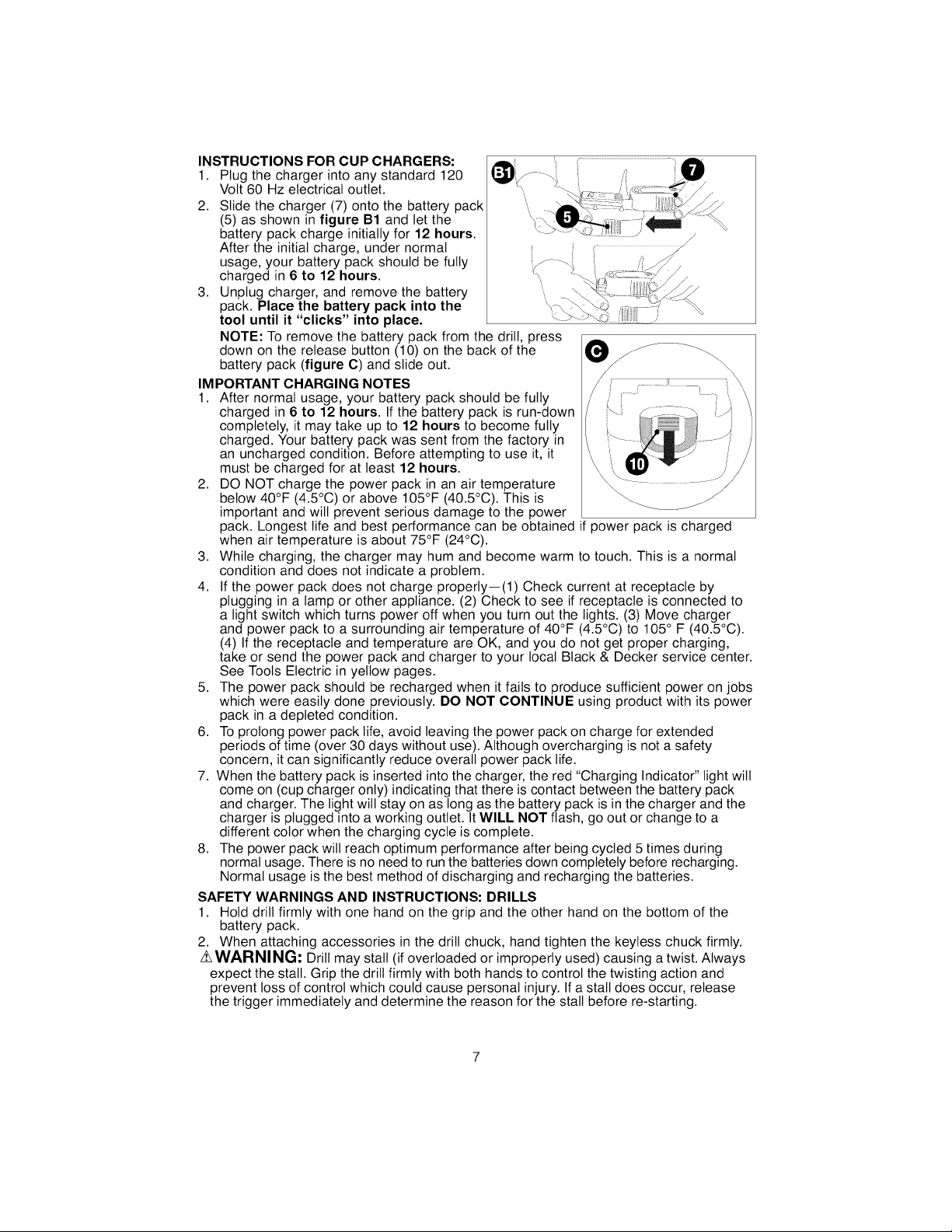

INSTRUCTIONS FOR CUP CHARGERS:

1. Plug the charger into any standard 120

Volt 60 Hz electrical outlet.

2. Slide the charger (7) onto the battery pack

(5) as shown in figure B1 and let the

battery pack charge initially for 12 hours.

After the initial charge, under normal

usage, your battery pack should be fully

charged in 6 to 12 hours.

3. Unplug charger, and remove the battery

pack. Place the battery pack into the

tool until it "clicks" into place.

NOTE: To remove the battery pack from the drill, press

down on the release button (10) on the back of the

battery pack (figure C) and slide out.

\

IMPORTANT CHARGING NOTES

1. After normal usage, your battery pack should be fully

charged in 6 to 12 hours. If the battery pack is run-down

completely, it may take up to 12 hours to become fully

charged. Your battery pack was sent from the factory in

an uncharged condition. Before attempting to use it, it

must be charged for at least 12 hours.

2. DO NOT charge the power pack in an air temperature

below 40°F (4.5°C) or above 105°F (40.5°C). This is

important and will prevent serious damage to the power

pack. Longest life and best performance can be obtained if power pack is charged

when air temperature is about 75°F (24°C).

3. While charging, the charger may hum and become warm to touch. This is a normal

condition and does not indicate a problem.

4. If the power pack does not charge propertyi(1) Check current at receptacle by

plugging in a tamp or other appliance. (2) Check to see if receptacle is connected to

a light switch which turns power off when you turn out the lights. (3) Move charger

and power pack to a surrounding air temperature of 40°F (4.5°C) to 105° F (40.5°C).

(4) If the receptacle and temperature are OK, and you do not get proper charging,

take or send the power pack and charger to your local Black & Decker service center.

See Tools Electric in yellow pages.

5. The power pack should be recharged when it fails to produce sufficient power on jobs

which were easily done previously. DO NOT CONTINUE using product with its power

pack in a depleted condition.

6. To prolong power pack life, avoid leaving the power pack on charge for extended

periods of time (over 30 days without use). Although overcharging is not a safety

concern, it can significantly reduce overall power pack life.

7. When the battery pack is inserted into the charger, the red "Charging Indicator" light wilt

come on (cup charger only) indicating that there is contact between the battery pack

and charger. The light will stay on as tong as the battery pack is in the charger and the

charger is plugged into a working outlet. It WILL NOT flash, go out or change to a

different color when the charging cycle is complete.

8. The power pack wilt reach optimum performance after being cycled 5 times during

normal usage. There is no need to run the batteries down completely before recharging.

Normal usage is the best method of discharging and recharging the batteries.

SAFETY WARNINGS AND INSTRUCTIONS: DRILLS

1. Hold drill firmly with one hand on the grip and the other hand on the bottom of the

battery pack.

2. When attaching accessories in the drill chuck, hand tighten the keytess chuck firmly.

z_WARNING: Drill may stall (if overloaded or improperly used) causing a twist. Always

expect the stall. Grip the drill firmly with both hands to control the twisting action and

prevent toss of control which could cause personal injury. Ifa stall does occur, release

the trigger immediately and determine the reason for the stall before re-starting.

Page 8

OPERATING INSTRUCTIONS

TRIGGER SWITCH & REVERSING BUTTON

The drill is turned ON and OFF by pulling

and releasing the trigger switch (1). The

farther the trigger is depressed, the higher

the speed of the drill.

A forward/reverse control button (2)

determines the direction of the toot and

also serves as a lock off button.

To select forward rotation, release the

trigger switch and depress the

forward/reverse control button to the left.

To select reverse, depress the

forward/reverse control button the

opposite direction.

NOTE: The center position of the control

button locks the toot in the off position.

When changing the position of the control

button, be sure the trigger is released.

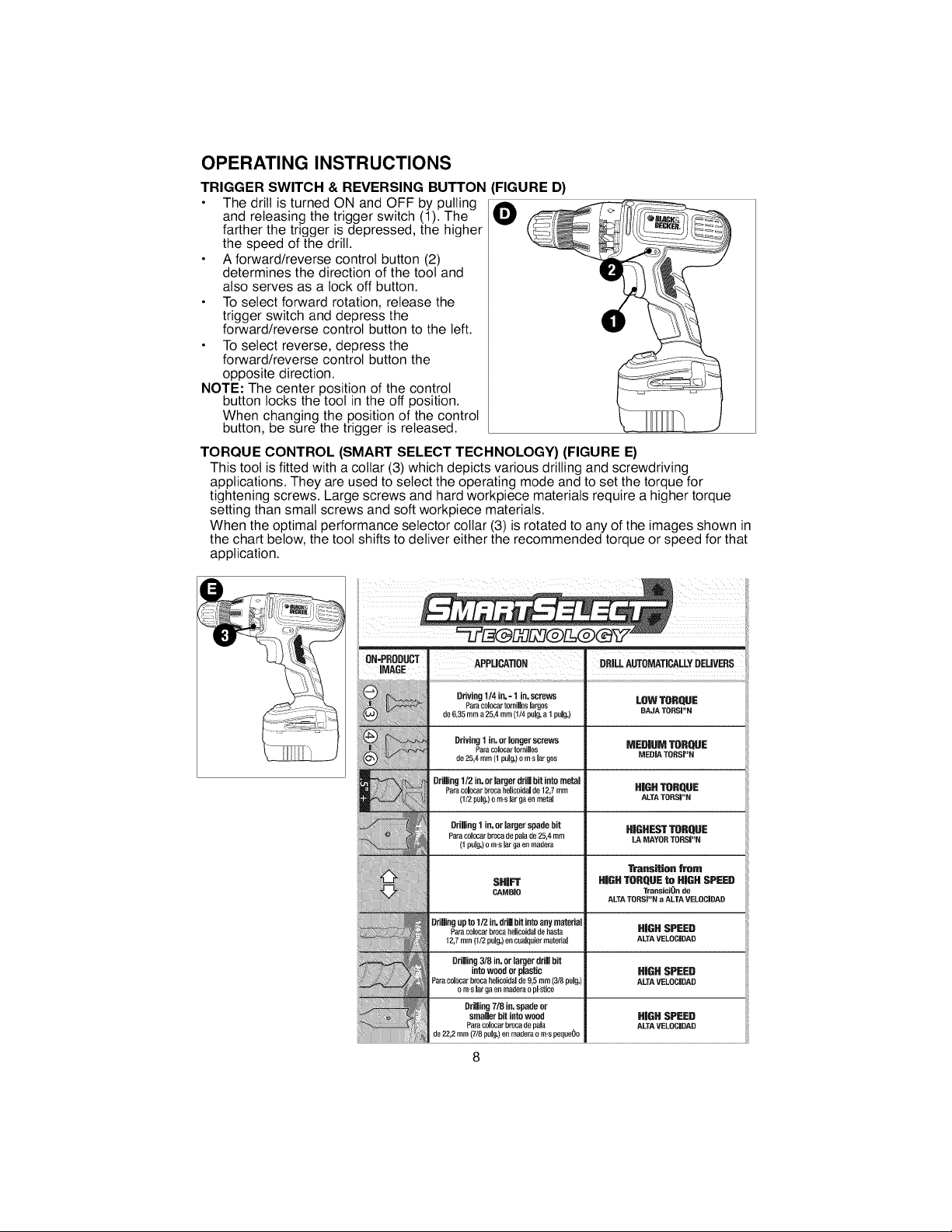

TORQUE CONTROL (SMART SELECT TECHNOLOGY) (FIGURE E)

This tool is fitted with a collar (3) which depicts various drilling and screwdriving

applications. They are used to select the operating mode and to set the torque for

tightening screws. Large screws and hard workpiece materials require a higher torque

setting than small screws and soft workpiece materials.

When the optimal performance selector collar (3) is rotated to any of the images shown in

the chart below, the toot shifts to deliver either the recommended torque or speed for that

application.

FIGURE D)

O

DRILLAUTOMATICALLYDEUVERS

Driving1/4 in. - 1 in, screws

ParacalocartareiUoslargos

de6,35mma25,4mm(1/4pulg.a1pulg.)

Driving 1 in,or longerscrews MEDIUM TDRQUE

Paracolocar tornilloe

de 25,4 mm (1 pulg.)o m.s Jar gee MEDIA TODSi"N

Drilling 1/2 in.or larger drillbit into metal

Para coJocar broca helicoidal de 12,7 mm HiGHTORQUE

(1/2 palg.)o rn.e Jarga en metal ALTA TORSI"N

Drilling 1 in. or larger spade bit HIGHEST TORQUE

Para ealocar broca de pala de 25,4 mm LA MAYOR TORSI"N

(I puIg,) o m,s lar ga en rnadera

SHIFT HiGH TORQUEto HiGH SPEED

CAMBBO Transici0n de

DdlJingupto 1/2 in. dri| bit into anymaterial

Para colocar broca helicoidalde hasta HiGHSPEED

12,7 i;lm (t/2 paiD.)en cealquier material ALTA VELOCIDAD

Ddiiing 3/8 in. or largerddil bit

intowood orplastic

Poracolocarbrocahelicoidalde9,5mm(3/5pul6.)

orn.slargaenmaderaopl-stico

Drilling7/8 in.spade or

smaller bit into wood

Paraeoloearbr_cadepala

de22,2mm(7/8paiD.)eemaderaorn.apeque0o

LOWTORQUE

BAJA TORSJ"N

Transition from

ALTA TORSI"N a ALTA VELOCiDAD

HiGHSPEED

ALTA VELOCJDAD

HiGHSPEED

ALTA VELOC|DAD

+i+i+i+i+

iiiiiiiii

iiiiiiiii

Page 9

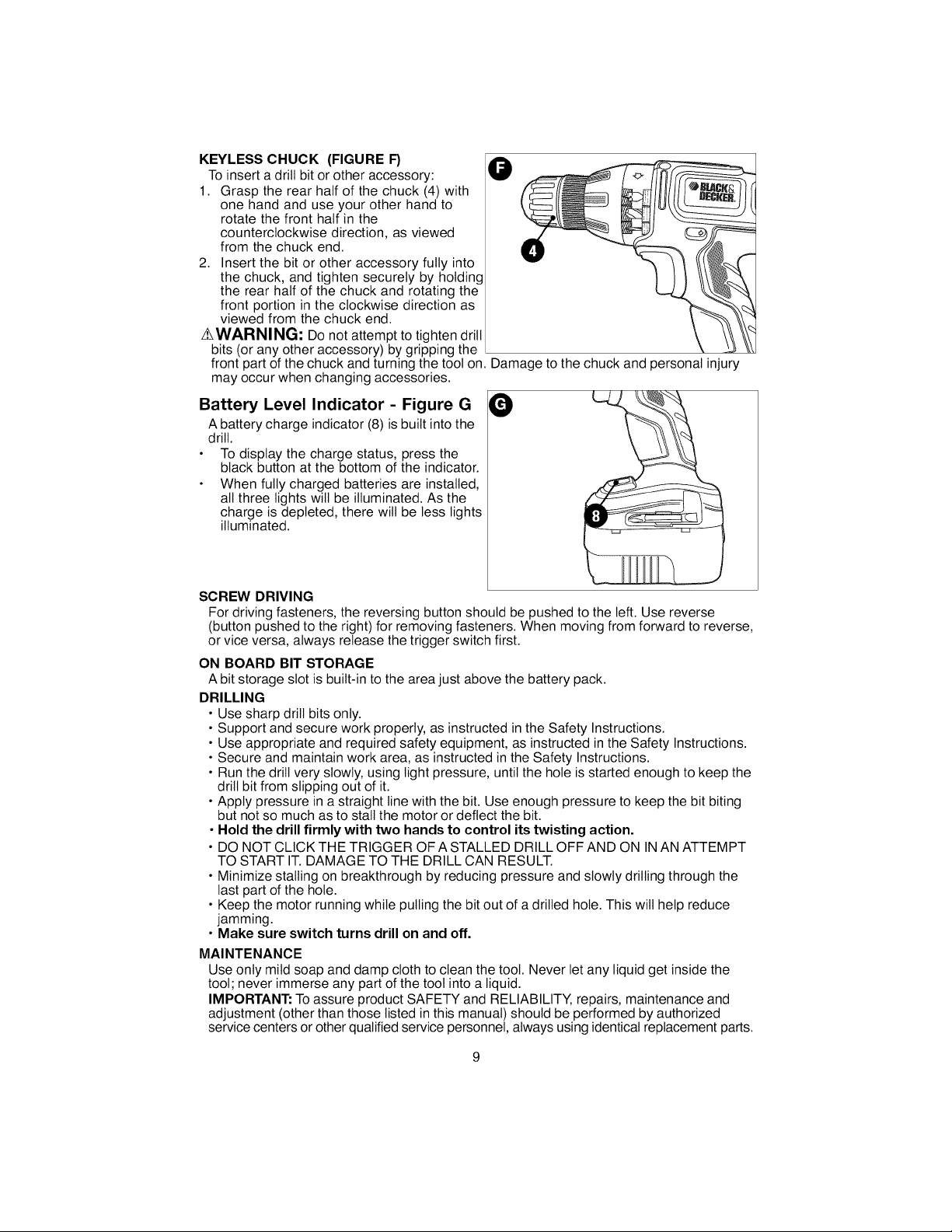

KEYLESS CHUCK (FIGURE F)

To insert a drill bit or other accessory:

1. Grasp the rear half of the chuck (4) with

one hand and use your other hand to

rotate the front half in the

counterclockwise direction, as viewed @

from the chuck end.

2. Insert the bit or other accessory fully into

the chuck, and tighten securely by holding

the rear half of the chuck and rotating the

front portion in the clockwise direction as

viewed from the chuck end.

IB

z_WARNING: Do not attempt to tighten drill

bits (or any other accessory) by gripping the

front part of the chuck and turning the toot on. Damage to the chuck and personal injury

may occur when changing accessories.

Battery Level Indicator - Figure G O

A battery charge indicator (8) is built into the

drill.

To display the charge status, press the

black button at the bottom of the indicator.

When fully charged batteries are installed,

all three lights will be illuminated. As the

charge is depleted, there will be less lights

illuminated.

SCREW DRIVING

For driving fasteners, the reversing button should be pushed to the left. Use reverse

(button pushed to the right) for removing fasteners. When moving from forward to reverse,

or vice versa, always release the trigger switch first.

ON BOARD BIT STORAGE

A bit storage slot is built-in to the area just above the battery pack.

DRILLING

• Use sharp drill bits only.

• Support and secure work properly, as instructed inthe Safety Instructions.

• Use appropriate and required safety equipment, as instructed in the Safety Instructions.

• Secure and maintain work area, as instructed in the Safety Instructions.

• Run the drill very slowly, using light pressure, until the hole is started enough to keep the

drill bit from slipping out of it.

• Apply pressure in a straight line with the bit. Use enough pressure to keep the bit biting

but not so much as to stall the motor or deflect the bit.

• Hold the drill firmly with two hands to control its twisting action.

• DO NOT CLICK THE TRIGGER OFA STALLED DRILLOFFAND ON IN AN ATTEMPT

TO START IT. DAMAGE TO THE DRILL CAN RESULT.

• Minimize stalling on breakthrough by reducing pressure and slowly drilling through the

last part of the hole.

• Keep the motor running while pulling the bit out of a drilled hole. This will help reduce

jamming.

• Make sure switch turns drill on and off.

MAINTENANCE

Use only mild soap and damp cloth to clean the toot. Never let any liquid get inside the

tool; never immerse any part of the toot into a liquid.

IMPORTANT: Toassure product SAFETY and RELIABILITY, repairs, maintenance and

adjustment (other than those listed in this manual) should be performed by authorized

service centers or other qualified service personnel, always using identical replacement parts.

Page 10

TROUBLESHOOTING

Problem

• Unitwill notstart.

• Batterypack will notcharge.

For assistance with your product, visit our website www.blackanddecker.com for the

location of the service center nearest you or call the BLACK & DECKER help line at

1-800-544-6986.

ACCESSORIES

Recommended accessories for use with your tool are available from your local dealer or

authorized service center. Ifyou need assistance regarding accessories, please call:

1-800-544-6986.

Possible Cause

• Batterypack not installedproperly.

• Batterypack not charged.

• Batterypack not inserted intocharger.

•Charger not plugged in.

•Surrounding airtemperature

too hotor too cold.

PossibleSolution

•Check battery pack

installation.

•Check battery pack charging

requirements.

• Insertbatterypackinto

charger until red LED

appears.

• Plugcharger intoa working

outlet. Referto"lmportant

ChargingNotes"formore

details.

• Movecharger andbattery

pack to a surrounding air

temperature of above 40

degrees F (4.5°C)or below

105degrees F (+40.5°C).

z_WARNING: The use of any accessory not recommended for use with this toot could be

hazardous.

The RBRC TM Seal

The RBRC TM (Rechargeable Battery Recycling Corporation)

Seat on the nickel-cadmium battery (or battery pack) indicates that the costs to

recycle the battery (or battery pack) at the end of its useful life have already been paid by

Black & Decker. In some areas, it is illegal to place spent nickel-cadmium batteries in the

trash or municipal solid waste stream and the RBRC program provides an environmentally

conscious alternative.

RBRC incooperation with Black & Decker and other battery users, has established

programs in the United States and Canada to facilitate the collection of spent nickel-

cadmium batteries. Help protect our environment and conserve natural resources by

returning the spent nickel-cadmium battery to an authorized Black & Decker service center

or to your local retailer for recycling. You may also contact your local recycling center for

information on where to drop off the spent battery, or call 1-800-8-BA'TrERY.

10

Page 11

Service Information

All Black & Decker Service Centers are staffed with trained personnel to provide

customers with efficient and reliable power toot service. Whether you need technical

advice, repair, or genuine factory replacement parts, contact the Black & Decker location

nearest you. To find your local service location, refer to the yellow page directory under

"Tools i Electric" or call: 1-800-544-6986 or visit www.blac kanddecker.corn

Full Two-Year Home Use Warranty

Black & Decker (U.S.) Inc.warrants this product for two years against any defects in

material or workmanship. The defective product will be replaced or repaired at no charge

in either of two ways.

The first, which will result in exchanges only, is to return the product to the retailer from

whom it was purchased (provided that the store is a participating retailer). Returns should

be made within the time period of the retailer's policy for exchanges (usually 30 to 90 days

after the sate). Proof of purchase may be required. Please check with the retailer for their

specific return policy regarding returns that are beyond the time set for exchanges.

The second option is to take or send the product (prepaid) to a Black & Decker owned or

authorized Service Center for repair or replacement at our option. Proof of purchase may

be required. Black & Decker owned and authorized Service Centers are listed under

"Tools-Electric" in the yellow pages of the phone directory and on our website

www.blackanddecker.com.

This warranty does not apply to accessories. This warranty gives you specific legal rights

and you may have other rights which vary from state to state or province to province.

Should you have any questions, contact the manager of your nearest Black & Decker

Service Center. This product is not intended for commercial use.

FREE WARNING LABEL REPLACEMENT: If your warning labels become illegible or are

missing, call 1-800-544-6986 for a free replacement.

Imported by See 'Tools-

Black & Decker (U.S.) Inc., Electric'

701 E. Joppa Rd. -Yellow Pages -

Towson, MD 21286 U.S.A. for Service &

11

Sales

Page 12

MODE D'EMPLOI DE LA PERCEUSE SANS FIL

N° de catalogue SS12D, SS14, SS18

Merci d'avoir choisi Black & Deckert

Consulter le site Web

www.BlackandDecker.com/NewOwner

pour enregistrer votre nouveau produit.

h. LIRE AVANT DE RETOURNER CE PRODUIT

POUR QUELQUE RAISON QUE CE SOIT :

SidesquestionsoudesproblemessurgissentapresI'achatd'unproduitBlack&Decker,

consulterlesiteWeb

HTTP://WWW.BLACKANDDECKER.COM/INSTANTANSWERS

pourobtenirdesreponsesinstantanement24heuresparjour.

SilareponseestintrouvableouenI'absenced'accesa Internet,composerle

1-800-544-6986de8ha17hHNE,dulundiauvendredi,pourparleravecunagent.

Priered'avoirlenumerodecataloguesouslamainIorsdeI'appel.

12

Page 13

Avertissements de sdcuritd gdndraux pour les outils

dlectriques

z_AVERTISSEMENT! Lire tous les avertissements de securit6 et toutes les

directives. Le non-respect des avertissements et des directives pourrait se

solder par un choc electrique, un incendie et/ou une blessure grave.

Conserver tousles avertissements et toutes les directives pour un usage

ulterieur.

Le terme <<outilelectrique,, cite dans les avertissements se rapporte & votre outil

electrique & alimentation sur secteur (avec ill) ou par piles (sans fil).

1) S_curit_ du lieu de travail

a) Tenir la zone de travail propre et bien _clair_e. Les endroits sombres sont souvent

des causes d'accidents.

b) Ne pas faire fonctionner d'outils _lectriques dans un milieu d_flagrant, soit en

presence de liquides inflammables, de gaz ou de poussi_re. Les outils

electriques produisent des etincelles qui peuvent enflammer la poussiere ou les vapeurs.

c) Eloigner les enfants et les curieux au moment d'utiliser un outil _lectrique. Une

distraction pourrait vous en faire perdre la maFtrise.

2) S_curite en mati_re d'_lectricit_

a) Les fiches des outils _lectriques doivent correspondre & la prise. Ne jamais

modifier la fiche en aucune fa£on. Ne jamais utiliser de fiche d'adaptation avec un

outil #lectrique mis a la terre. Le risque de choc #lectrique sera reduit par I'utilisation

de fiches non modifiees correspondant a la prise.

b) I_viter tout contact physique avec des surfaces mises & la terre comme des

tuyaux, des radiateurs, des cuisini_res et des r_frig_rateurs. Le risque de choc

electrique est plus #leve si votre corps est mis a la terre.

c) Ne pas exposer les outils _lectriques & la pluie ou _ d'autres conditions oil il

pourrait 6tre mouill& La p#n#tration de I'eau dans un outil #lectrique augmente le

risque de choc electrique.

d) Ne pas utiliser abusivement le cordon d'alimentation. Ne jamais utiliser le

cordon pour transporter, tirer ou d_brancher un outil _lectrique. Tenir le cordon

_loign_ de la chaleur, de I'huile, des bords tranchants ou des pi_ces mobiles.

Les cordons endommag#s ou emm#les augmentent les risques de choc #lectrique.

e) Pour I'utilisation d'un outil _lectrique _ rexterieur, se servir d'une rallonge

convenant _ une telle utilisation. L'utilisation d'une rallonge con_ue pour I'exterieur

reduit les risques de choc #lectrique.

f) S'il est impossible d'_viter I'utilisation d'un outil _lectrique darts un endroit

humide, brancher I'outil darts une prise ou sur un circuit d'alimentation dotes

d'un disjoncteur de fuite _ la terre (GFCl). L'utilisation de ce type de disjoncteur

reduit les risques de choc electrique.

3) S_curit_ personnelle

a) #tre vigilant, surveiller le travail effectu_ et faire preuve de jugement Iorsqu'un

outil _lectrique est utilis& Ne pas utiliser d'outil _lectrique en cas de fatigue ou

sous I'influence de drogues, d'alcool ou de m_dicaments. Un simple moment

d'inattention en utilisant un outil electrique peut entraFner des blessures corporelles

graves.

b) Utiliser des _quipements de protection individuelle. Toujours porter une

protection oculaire. L'utilisation d'equipements de protection comme un masque

antipoussiere, des chaussures antiderapantes, un casque de s#curite ou des

protecteurs auditifs Iorsque la situation le requiert reduira les risques de blessures

corporelles.

c) Emp_cher les d_marrages intempestifs. S'assurer que I'interrupteur se trouve

la position d'arr6t avant de relier I'outil _ une source d'alimentation et/ou

d'ins_rer un bloc-piles, de ramasser ou de transporter I'outil. Transporter un outi/

electrique alors que le doigt repose sur I'interrupteur ou brancher un outil electrique

dont I'interrupteur est a la position de marche risque de provoquer un accident.

d) Retirer toute cl_ de r_glage ou cl_ standard avant de d_marrer I'outil. Une cle

standard ou une cle de reglage attach#e a une partie pivotante peut causer des

blessures.

e) Ne pas trop tendre les bras. Conserver son _quilibre en tout temps. Cela permet

de mieux maFtriser Ibutil electrique dans les situations imprevues.

13

Page 14

f) S'habiller de mani_re appropri_e. Ne pas porter de v_tements amples ni de

bijoux. Garder los cheveux, los v_tements et los gants _ I'_cart des pi_ces

mobiles. Les v#tements amples, les bijoux ou les cheveux longs risquent de rester

coinces dans los pieces mobiles.

g) Si des composants sont fournis pour le raccordement de dispositifs de

depoussi_rage et de ramassage, s'assurer que ceux-ci sont bien raccord_s et

utilis_s. L'utilisation d'un dispositif de depoussierage pout reduire los dangers

engendres par los poussieres.

4) Utilisation et entretien d'un outil _lectrique

a) Ne pas forcer un outil _lectrique. Utiliser I'outil _lectrique appropri_

I'application. L butil #lectrique appropri# effectuera un meilleur travail, de fagon

plus s_re eta la vitesse pour laquelle il a #to congu.

b) Ne pas utiliser un outil _lectrique dont I'interrupteur est d_fectueux. Tout outil

electrique dont I'interrupteur est defectueux est dangereux et doit #tre repar&

c) D_brancher la fiche du secteur ou le bloc-piles de I'outil _lectrique avant de

faire tout r_glage ou changement d'accessoire, ou avant de ranger I'outil

_lectrique. Cos mesures preventives reduisent los risques de demarrage accidentel

de Ibutil electrique.

d) Ranger les outils _lectriques hors de la pottle des enfants, et ne permettre

aucune personne n'_tant pas famili_re avec un outil _lectrique (ou son

manuel d'instruction) d'utiliser ce dernier. Los outi/s e/ectriques deviennent

dangereux entre les mains d'utilisateurs inexperimentes.

e) Entretenir los outils _lectriques. V_rifier los pi_ces mobiles pour s'assurer

qu'elles sont bien align_es et tournent librement, qu'elles sont en bon _tat et

ne sont affectees par aucun trouble susceptible de nuire au bon

fonctionnement de routil _lectrique. En cas de dommage, faire r_parer I'outil

_lectrique avant toute nouvelle utilisation. Beaucoup d'accidents sont causes par

des outils electriques mal entretenus.

f) S'assurer que los outils de coupe sont aiguis_s et propres. Los outils de coupe

bien entretenus et affOtes sont moins susceptibles de se coincer et sont plus faciles

contrOler.

g) Utiliser I'outil _lectrique, los accessoires, los forets, etc. conform_ment aux

pr_sentes directives en tenant compte des conditions de travail et du travail

effectuer. L'utilisation d'un outil #lectrique pour toute operation autre que cello pour

laquelle il a #to congu est dangereuse.

5) Utilisation et entretien du bloc-piles

a) Ne recharger I'outil qu'au moyen du chargeur pr_cis_ par le fabricant.

L'utilisation d'un chargeur qui convient a un type de bloc-piles risque de provoquer un

incendie s'il est utilise avec un autre type de bloc-piles.

b) Utiliser los outils _lectriques uniquement avec los blocs-piles con_us _ cot

effet. L'utilisation de tout autre bloc-piles risque de causer des blessures ou un

incendie.

c) Lorsque le bloc-piles n'est pas utilis_, le tenir _loigne des objets m_talliques,

notamment des trombones, de la monnaie, des cl_s, des clous, des vis, etc.,

qui peuvent _tablir une connexion entre los deux bornes. Le court-circuit des

bomes du bloc-piles risque de provoquer des #tincelles, des br_lures ou un incendie.

d) En cas d'utilisation abusive, le liquide pout gicler hors du bloc-piles, _viter tout

contact. Si un contact accidentel se produit, laver _ grande eau. Sile liquide

entre en contact avec los yeux, obtenir des soins m_dicaux. Le liquide qui gicle

hors du bloc-piles pout provoquer des irritations ou des br_lures.

6) R_paration

a) Faire r_parer I'outil _lectrique par un r_parateur professionnel en n'utilisant

que des pi_ces de rechange identiques. Cola permettra de maintenir une

utilisation securitaire de Ibutil electrique.

14

Page 15

RI GLES DE SC:CURIT¢: SPC:CIFIQUES

• Porter des protecteurs auditifs si une perceuse a percussion est utilis_e. Une

exposition au bruit peut entrafner une perte auditive.

• Utiliser les poign_es auxiliaires fournies avec I'outil. Une perte de maftrise de I'outil

peut entrafner des blessures corporelles.

• Saisir I'outil _lectrique par ses surfaces de prises isol_es Iorsque I'outil peut entrer

en contact avec des fils caches ou son cordon. En cas de contact avec un fil sous

tension, les pieces metalliques de I'outil seront sous tension et l'utilisateur subira des

secousses electriques.

• Lorsqu'on est install_ sur une _chelle ou un _chafaudage pour travailler, on doit

d_poser I'outil sur le cSt_ Iorsqu'on ne s'en sert plus. Bien que certains outils munis

d'un gros bloc-piles puissent 6tre places & la verticale, dans cette position, ils peuvent

facilement 6tre renverses.

• Utiliser des brides de fixation ou un autre dispositif de fixation permettant de fixer

solidement et de soutenir la piece sur une plateforme stable. Tenir la piece avec la

main ou contre son corps la rend instabte et risque de provoquer une perte de maftrise de

I'outil.

• Tenir les cheveux, les v6tements et les gants loin des _vents. En effet, les events

cachent souvent des pieces mobiles qui risquent de happer ces articles.

• Tenir fermement I'outil a deux mains. Utiliser ta poignee auxiliaire si I'outit en est

muni. Sinon, saisir l'outil par le bas du bloc-piles. Une perte de maftrise de l'outil peut

entrafner des blessures.

_AVERTISSEMENT : certains outils _lectriques, tels que los sableuses, los scies,

los meules, los perceuses ou certains autres outils de construction, peuvent

produire de la poussi_re contenant des produits chimiques reconnus par I'Etat

de la Californie comme _tant susceptibles d'entrainer le cancer, des

malformations cong_nitales ou pouvant _tre nocifs pour le syst_me reproductif.

Parmi cos produits chimiques, on retrouve :

• le ptomb dans les peintures &base de plomb,

• la silice cristalline dans les briques et le ciment et autres produits de magonnerie,

• t'arsenic et le chrome dans te bois de sciage ayant subi un traitement chimique.

Le risque associe b.de teltes expositions varie selon la frequence avec laquelle on

effectue ces travaux. Pour reduire l'exposition &de tels produits, il faut travailler dans un

endroit bien aer6 et utiliser le materiel de securit6 approprie, tel un masque anti-

poussieres specialement congu pour filtrer les particutes microscopiques.

• leviter tout contact prolong_ avec la poussi_re soulev_e par cot outil ou autres

outils _lectriques. Porter des v_tements de protection et nettoyer los parties

expos_es du corps avec de I'eau savonneuse. S'assurer de bien se proteger afin

d'eviter d'absorber par la bouche, les yeux ou ta peau des produits chimiques nocifs.

_AVERTISSEMENT : Cot outil pout produire et r_pandre de la poussi_re

susceptible de causer des dommages s_rieux et permanents au syst_me

respiratoire. Toujours utiliser un appareil respiratoire anti-poussieres approuve par le

NIOSH ou I'OSHA. Diriger les particutes dans le sens oppose du visage et du corps•

_AVERTISSEMENT : TOUJOURS porter des lunettes de s_curit& Los lunettes de

vue ne constituent PAS des lunettes de s_curit& Utiliser _galement un masque

facial ou anti-poussi_re si I'op_ration de d_coupe g_n_re de la poussibre.

TOUJOURS PORTER UN EQUIPEMENT DE PROTECTION HOMOLOGUE :

•protection oculaire conforme a la norme ANSI Z87.1 (CAN/CSA Z94.3);

•protection auditive ANSI S12.6 (S3.19);

•protection des voies respiratoires conformes aux normes NIOSH/OSHA/MSHA.

15

Page 16

LIGNES DIRECTRICES EN MATII_RE DE SI_CURITI_ - DI_FINITIONS

IIest important que vous lisiez et compreniez ce mode d'emploi. Les inform.ations qu'it

contient concernent VOTRE SECURITE et visent a EVlTER TOUT PROBLEME. Les

symbotes ci-dessous servent a vous aider a reconnaTtre cette information.

z_ DANGER : Indique une situation dangereuse imminente qui, si erie n'est pas evit6e,

causera la mort ou des graves btessures.

Z_ AVERTISSEMENT : Indique une situation potentiellement

dangereuse qui, si erie n'est pas evit6e, pourrait causer la mort ou de graves btessures.

Z_ MISE EN GARDE : Indique une situation potentiellement dangereuse qui, si erie n'est

)as evit6e, pourrait causer des btessures mineures ou moder6es.

_IISE EN GARDE : Utilise sans le symbole d'aterte b.ta securit6, indique une situation

potentiettement dangereuse qui, si erie n'est pas evit6e, peut resulter en des dommages

la propriet6.

SYMBOLES

L'etiquette de I'outil peut comporter les symboles suivants.

V ................ volts

Hz .............. hertz

min .............. minutes

_;or_;_:............ courant continu

[] .............. Construction de classe II

z_ .............. symbole d'avertissement

DESCRIPTION FONCTIONNELLE

1. Detente b.vitesse variable

2. Dispositif de gtissement avant/arriere

3. Setecteur d'optimisation du rendement

(embrayage)

4. Mandrin

5. Bloc-piles

6. Chargeur a fiche

7. Chargeur cuvette

8. Indicateur de niveau de charge

9. Porte-embout de vissage

10. Bouton de degagement du bloc-piles

A .............. amperes

W.............. watts

............ courant alternatif

no.............. sous vide

.............. borne de mise a la minute

.../min ........tours a la minute

16

Page 17

INFORMATION CONCERNANT LE CAPUCHON DU BLOC-PILE (FIGURE A)

Un capuchon (8) est fourni avec te bloc-pile en vue d'6tre utilise chaque fois qu'on retire

ce dernier de l'outil ou du chargeur en vue de le ranger ou de te transporter; enlever le

capuchon avant de remettre le bloc-pile dans te chargeur ou dans I'outil.

_AVERTISSEMENT : S'assurer, au moment de ranger ou de transporter un bloc-pile ou

une pile, qu'aucun objet metallique n'entre en contact avec leurs bornes a decouvert de

celui-ci. Par exempte, it faut eviter de placer un bloc-pile ou une pile sans capuchon darts

un tabtier, une poche, une boTte a outits ou un tiroir (etc.) contenant des objets tels que

des clous, des vis ou des ctes, car tout contact entre les bornes a decouvert et un objet

metattique comme une cte, une piece de monnaie, un outit a,main. etc. pourrait causer un

incendie. En effet, les reglements americains Hazardous Material Regulations (HMR) du

US Department of Transportation interdisent le transport d'un bloc-pile ou d'une pile darts

tout moyen de transport commercial ou aeronef (que ce soit darts une valise ou le

bagage de cabine) SAUF s'its sont bien proteg6s contre tes courts-circuits. On doit donc

s'assurer, torsqu'on transporte un bloc-pile ou une pile separ6ment, de bien proteger et

isoler les bornes contre tout materiau qui risque d'entrer en contact avec eux et de causer

un court-circuit.

DIRECTIVES ET CONSlGNES DE SI_CURITI_ CONCERNANT LE

CHARGEMENT

1. Le present guide comprend d'importantes directives, dont un mode d'emptoi et des

consignes de securit6.

2. Avant d'utiliser le chargeur, lire routes les directives et tes etiquettes de mise en garde

apposees sur (1) le chargeur, (2) ta pile et (3) le produit utilisant la pile.

3. _ MISE EN GARDE : afin de reduire tes risques de btessure, ne charger que des

blocs-piles Black & Decker, car les autres peuvent eclater et entraTner des btessures

ou des dommages materiels.

4. Ne pas exposer te chargeur a la ptuie ou a ta neige.

5. L'utilisation d'un accessoire n'etant ni recommande ni vendu par Black & Decker peut

entraTner des risques d'incendie, de choc electrique ou de blessure.

6. Afin de reduire les risques de dommage a la fiche ou au cordon electrique,

debrancher le chargeur en saisissant la fiche, non le cordon.

7. S'assurer que le cordon est place de maniere a eviter qu'il ne subisse des dommages

ou des contraintes ou que les personnes s'y prennent les pieds et trebuchent.

8. Ne pas utiliser de ratlonge a moins que cela ne soit absotument necessaire, car

I'usage d'une ratlonge ayant une puissance inadequate pourrait causer des risques

d'incendie, de choc electrique ou d'electrocution.

a) Bien qu'on puisse utiliser un cordon bifilaire avec une rallonge bifilaire ou trifilaire, on

ne doit utitiser qu'une rallonge a cordon; on recommande que cetle-ci soit approuvee

par l'organisme americain Underwriters Laboratories (UL). Lorsqu'on utilise un outil

electrique a I'exterieur, on ne doit utitiser que des rallonges congues pour cet usage,

comme cettes de type W-A ou W. Toute rallonge congue pour un usage exterieur peut

aussi 6tre employee a t'interieur.

b) Afin d'eviter une perte de puissance ou une surchauffe et d'assurer la securit6 de

I'utitisateur, la ratlonge doit 6tre de calibre AWG approprie. Plus le calibre est petit,

plus la capacite est grande; autrement dit, une rallonge de calibre 16 est plus

17

Page 18

puissantequ'unerattongedecalibre18.Lorsqu'onutiliseplusieursraltongespour

obtenirlaIongueurvoutue,s'assurerquechacuned'ellespresentelesvaleurs

minimalesrequises.

Tableau des calibres de fils minimums (AWG) pour les rallonges

Valeur nominale de la plaque signal_tique A - 0 - 10,0

Longueur de rallonge totale (pi) 0 a 25 26 & 50 51 & 100 101 & 150

Calibre du fit 18 16 16 14

9. Utitiser seulement le chargeur fourni pour charger votre batterie. L'utilisation de tout

autre chargeur risque d'endommager ta batterie ou de creer une condition dangereuse.

10. N'utiliser qu'un seut chargeur durant le chargement.

11. Ne pas tenter d'ouvrir te chargeur. Aucune piece a I'interieur ne peut 6tre repar6e par

le client. Retourner le produit a tout centre de reparation Black & Decker autorise.

12. N'INClN#REZ PAS le bloc de batteries m6me s'il est serieusement endommage ou

completement usa. Les piles peuvent exptoser dans un feu.

13. Les celtutes peuvent subir une fuite leg6re par suite d'un usage extr6me, du

chargement ou d'une exposition a.certaines temperatures; cela n'indique pas un

probleme. Cependant, si le sceltant externe est perce et le liquide entre en contact

avec la peau, on dolt :

a. se laver rapidement ta partie du corps touchee avec de t'eau savonneuse;

b. neutratiser l'effet au moyen d'un acide doux tel que du jus de citron ou du vinaigre;

c. si les yeux sont touches, les rincer b.fond avec de t'eau propre pendant au moins

10 minutes et consulter immediatement un medecin.

REMARQUE AUX FINS MleDICALES : ce liquide contient une solution composee de

25 b.35 % d'hydroxyde de potassium.

CHARGEMENT DU BLOC-PILES

La perceuse utilise un chargeur &fiche ou un chargeur cuvette. Les deux modetes sont

decrits ci-dessous. Respecter les directives pour le type de chargeur utilis& Its sont congus

pour une alimentation standard & 120 V c.a., 60 Hz. Ne pas utiliser un courant continu ou

toute autre tension.

LES BLOC-PILES NE SONT PAR COMPLE,TEMENT CHARGE,S A LEUR SORTIE DE

L'USINE. AVANT DE LES CHARGER, LIRE ATTENTIVEMENT TOUTES LES

DIRECTIVES DE SECURITE.

DIRECTIVES POUR LES CHARGEURS .&FICHE :

1. Inserer le bloc-piles dans t'outil jusqu'& ce

qu'it s'enclenche en position.

2. Inserer la fiche du chargeur (6) dans te

connecteur comme montre b. ta figure B.

3. Brancher le chargeur dans toute prise

electrique standard de 120 volts b. 60 Hz puis

laisser le bloc-piles se charger pendant 12

heures la premiere fois. Apres ta premiere

charge, dans le cas d'une utilisation normale,

le bloc-piles devrait se charger

entierement en 6 _ 12 heures.

4. Z_ AVERTISSEMENT : Risque d'incendie

Debrancher d'abord le chargeur de ta prise

secteur puis degager I'outit du chargeur. Ne

pas utiliser I'outil Iorsqu'il est branche au

chargeur.

(0 & 7,6 m) (7,6 & 15,2 m) (15,2 & 30,4 m) (30,4&45,7m)

18

Page 19

DIRECTIVES POUR LES CHARGEURS

CUVETTES :

i

1. Brancher le chargeur dans une prise

etectrique standard de 120 volts, 60 Hz.

2. Gtisser le chargeur (7) sur te bloc-piles (5)

comme montre a la figure B1 puis laissez

le bloc-piles se charger durant 12 heures

pour la premiere fois. Apres ta premiere

charge, dans le cas d'une utitisation

normate, le bloc-piles devrait se recharger ....

entierement entre 6 et 12 heures.

3. Debrancher le chargeur, puis entever le

bloc-piles. Inserer le bloc-piles dans I'outil jusqu'a ce qu'it

s'enclenche en position.

REMARQUE : pour retirer le bloc-piles de la perceuse,

\

enfoncer te bouton (10) de degagement au dos du bloc-

piles (figure C), puis le tirer hors de l'outil.

NOTES IMPORTANTES RELATIVES AU

CHARGEMENT

1. A la suite d'une utilisation normale, le bloc-pile devrait

prendre de 6 _ 12 heures pour se charger comptetement,

et jusqu'a 12 heures s'it est comptetement decharg6. Le

bloc-pile n'est pas charge au moment de quitter t'usine;

on dolt donc le charger pendant au moins 12 heures

avant de l'utiliser.

2. Afin d'eviter d'endommager le bloc-pile, il est important de NE PASte charger a des

temperatures inferieures a 4.5 °C (40 °F) ou superieures a.40.5 °C (105 °F). Pour

augmenter ta duree de vie du bloc-pile et optimiser son rendement, le charger a une

temperature d'environ 24°C (75 °F).

3. Le chargeur peut emettre un bourdonnement ou devenir chaud au toucher durant le

chargement. Cela est normal et n'indique pas la presence d'un probleme.

4. Si le bloc-pile ne se charge pas normalement, it faut : (1) verifier I'alimentation de la

prise en y enfichant une tampe ou un appareit, (2) s'assurer que la prise n'est pas

raccordee a un interrupteur qui coupe le courant lorsqu'on eteint tes tumieres, (3)

placer te chargeur et le bloc-pile dans un endroit oQ la temperature ambiante est

environ 4.5 °C (40 °F) a 40.5 °C (105 °F) ou, si le probteme persiste, (4) retourner te

bloc-pile et le chargeur au centre de service Black & Decker le plus pros (les centres

de service autorises sont repertori6s dans les pages jaunes sous la rubrique ,<Outils -

61ectriques,,).

5. Le bloc-pile dolt 6tre recharge Iorsqu'it ne produit pas suffisamment de courant pour

permettre b.t'utilisateur de travailler normalement. On dolt CESSER d'utiliser la

perceuse dans de telles conditions.

6. On peut prolonger ta duree de vie du bloc-pile en evitant de te taisser dans le chargeur

pendant de Iongues periodes (plus de 30 jours torsqu'on ne l'utilise pas). Bien que la

surcharge du bloc-pile ne soit pas un probteme au niveau de la securit6, cette pratique

peut reduire de fagon appreciable sa duree de vie.

7. Lorsqu'on insere le bloc-pile dans le chargeur, le temoin rouge s'atlume pour indiquer

(echargeurs cuvettes seutement) que le contact entre te bloc-pile et le chargeur s'est

tabti; cetui-ci reste atlume tant que te bloc-pile est dans le chargeur et que ce dernier

est enfiche dans une prise sous tension. Le temoin NE CMGNOTERA PAS, ne

s'eteindra pas et ne changera pas de couteur une fois la periode de charge terminee.

8. Le bloc-pile atteindra son rendement optimal apres avoir termine cinq cycles de charge

et de decharge au cours d'une utilisation normale. I1n'est pas necessaire de decharger

comptetement le bloc-pile avant de le recharger. Le meitleur moyen de charger et de

decharger le bloc-pile est de I'utiliser normalement.

AVERTISSEMENTS DE SleCURITle ET DIRECTIVES : PERCEUSES

1. Tenir fermement ta perceuse en saisissant ta poignee d'une main et en ptagant

I'autre main sur la partie inferieure du bloc-piles.

2. Lorsqu'on utilise un mandrin sans cte, on dolt te serrer fermement a la main.

Z_AVERTISSEMENT : La perceuse peut caler (a la suite d'une surcharge ou d'un

mauvais usage) et causer un mouvement de torsion; on dolt toujours prevoir un tel

19

Page 20

incident.Saisirlaperceusefermementafindemaftriserlatorsiondecettederniereet

d'eviterdeperdrelamaTtrise,cequipourraitentraTnerdesbtessures.Silaperceusecate,

relb.cherimmediatementlagb.chetteetendeterminerlacauseavantderedemarrerI'outit.

DIRECTIVES D'UTILISATION

DC:TENTE ET BOUTON INVERSEUR (FIGURE D)

• Laperceuse est mise en positions de

MARCHE et d'ARRC:T en tirant et en relb.chant

la detente (1). Plus on enfonce ta detente,

plus ta vitesse de ta perceuse augmente.

• Un bouton de commande marche

avant/marche arriere (2) determine te sens de

I'outil et sert aussi de bouton de verrouillage.

• Pour choisir une rotation en marche avant,

rel&cher la detente et abaisser le bouton de

commande marche avant/marche arriere vers

la gauche.

• Pour choisir la marche arriere, abaisser le

bouton de commande marche avant/marche

arriere en direction opposee.

REMARQUE : la position du centre du bouton

de commande verrouilte t'outil en position

d'arr6t. Toujours relb.cher la detente avant de

changer la position du bouton de commande.

CORRECTEUR DE COUPLE (TECHNOLOGIE SMART SELECT) (FIGURE E)

L'outit est muni d'une bague (3) qui illustre diverses applications de per_age et de

vissage. Ils sont utilises pour selectionner le mode de fonctionnement et pour regler le

couple de serrage des vis. Les grosses vis etles pieces en matiere dure exigent un

couple de serrage plus elev6 que les petites vis etles pieces de matieres plus souptes.

Lorsque la bague (3) du selecteur d'optimisation du rendement pivote sur une des

images itlustrees

dans le tableau ci-

dessous, I'outil passe

alors au couple ou au

regime recommande

pour I'application.

FOURNiPARLAPERCEOSE

Vissa6e : vis de 6,35 mm FAJBLECOUPLE

a 25,4 mm (1\4_ 1 po)

Vissage : vis de 25,4 mm

(1 pc) ou pies COUPLE MOYEN

Pert;age(ionslem_tol:

foret de 12,7 mm (1_ pc} ou plus COUPLE ELEVE

Per(_:aoe dons le bois :

foret _ trois pointus de 25,4 mm COUPLE ELEVE MAXIMAL

(1 pc) ou pies ou scie cloche

CHANGEMENT Transition du COUPLE ]ELEVI_AU REGJlVIEt_LEV

Pet,;age dons le bois :

forat _ trois pointcs de 6,36 mm REGIME _LEVIE

a 25,4 mm (1\4_ 1 pc)

Portage densle bois oole plastique:

toret de 12,7 mm (1_2 pc) ou plus REGIME ELEVt_

Perr_egedoristout mat_riau :

furor de 12,7 mm (1\2 pc) maximum REGIME ELEVE

2O

Page 21

MANDRIN SANS CLI_ (FIGURE F)

Pour inserer une meche ou autre accessoire " V

1. Saisir la partie inferieure du mandrin (4)

avec une main et utiliser t'autre pour faire

tourner la partie superieure du mandrin en

sens antihoraire, si vous regardez la (_

perceuse par le mandrin.

2. Inserer completement la meche ou tout

autre accessoire dans te mandrin et

resserrer fermement en retenant la partie

inferieure du mandrin et en faisant tourner

sa partie superieure en sens horaire, si

vous regardez la perceuse, par le mandrin.

2_AVERTISSEMENT : ne pas essayer

de resserrer les meches (ou tout autre accessoire) en saisissant ta partie avant du mandrin

et en mettant I'outil en marche. Lors du changement d'accessoires, it y a risque

d'endommager le mandrin et d'entraTner des blessures corporelles.

Indicateur de niveau de charge

(figure G)

Un indicateur de niveau de charge du bloc-

piles (8) est integr6 b.ta perceuse.

Pour afficher I'etat de la charge, appuyer

sur le bouton noir au bas de t'indicateur.

Lorsque le bloc-piles inser6 est

completement charge, les trois voyants

s'ittuminent. Au fur eta mesure de

I'utitisation du bloc-piles, les voyants

s'eteignent un a la fois.

VISSAGE

Pour visser des attaches, pousser te bouton de marche arriere vers la gauche. Utiliser ta

marche arriere (te bouton pousse a droite) pour retirer les attaches. Lors de la permutation

entre la marche avant et la marche arriere, ou vice versa, s'assurer de rel&cher d'abord ta

detente.

RANGEMENT INTleGRle DES Mi=CHES

I1existe une rainure pour le rangement des meches juste au-dessus du bloc-piles.

O

Pergage

N'utiliser que des forets bien aff0tes.

Veitler ace que la piece a percer soit sotidement retenue ou fixee en place, selon les

mesures de securit6.

Porter t'equipement de securit6 approprie et requis, seton les mesures de securit6.

Rendre ta zone de travail sore et en assurer I'entretien, seton les mesures de securit6.

Actionner la perceuse a basses vitesses en exergant une pression minimale jusqu'a ce

que le trou soit suffisamment perce afin d'emp6cher te glissement du foret hors du trou.

Toujours exercer la pression en ligne directe avec le foret. N'user que de ta force

necessaire pour que te foret continue de percer; eviter de trop forcer, ce qui pourrait faire

etouffer le moteur ou devier le foret.

Bien saisir la perceuse afin de maitrise son effet de torsion.

NE PAS ACTIONNER ,ik PLUSIEURS REPRISES LA DI_TENTE D'UNE PERCEUSE

BLOQUC:E DANS LE BUT DE LA DI_COINCER AU RISQUE DE L'ENDOMMAGER.

Reduire la pression exercee sur t'outil et le foret vers la fin de la course afin d'eviter que

le moteur ne cale en traversant le materiau.

Laisser le moteur en marche Iorsqu'on retire le foret du trou afin d'en prevenir le

coincement.

Utitiser de l'huile de coupe pour percer darts tes metaux, saul la fonte et te laiton qui se

percent b.sec. Les huiles de coupe les plus efficaces sont l'huile sutfurisee ou l'huile de

lard; la graisse de bacon est parfois suffisante.

21

Page 22

Lesforetshelicofdaux&metalpeuventservir&percerlebois,maisilfautlesretirer

souventdutroupourchasserlescopeauxetrognuresdesgoujures.

•. S'assurer que I'interrupteur met I'outil en marche et qu'il I'arr6te.

/X_AVERTISSEMENT • I1est essentiel de bien soutenir la piece & ouvrer et de saisir

fermement ta perceuse afin de prevenir la perte de maftrise de I'outil qui pourrait

occasionner de graves btessures. Pour obtenir de plus amptes renseignements relatifs au

bon fonctionnement de I'outit, composer le : 1 800 544-6986.

ENTRETIEN

Nettoyer I'outil seutement & I'aide d'un savon doux et d'un linge humide. Ne laisser aucun

liquide s'infiltrer dans l'outil et ne jamais immerger I'outil.

IMPORTANT • Pour assurer ta SFCURITP D'EMPLOI et la FIABILITF de I'outil, n'en confier

la reparation, I'entretien et tes rajustements qu'& un centre de service ou & un atelier

d'entretien autorise n'utilisant que des pieces de rechange identiques.

DC:PANNAGE

Probl_me

• L'appareil refuse de

demarrer.

• Le bloc-piles ne se

charge pas.

Pour de I'aide avec I'outil, consulter notre site Web www.blackanddecker.com pour

I'emplacement du centre de reparation le plus pros ou communiquer avec I'assistance

BLACK & DECKER au 1-800-544-6986.

Cause possible

• Mauvaise installation du

bloc-piles.

• Bloc-piles non chargee.

• Bloc-piles non inser6e dans le

chargeur.

• Chargeur non branche.

• Temperature ambiante

trop chaude ou froide.

Accessoires

Les detaitlants et te centre de service de la region vendent les accessoires recommandes

pour I'outil. Pour trouver un accessoire, composer le 1 800 544-6986.

i_AVERTISSEMENT : L'utilisation de tout accessoire non recommande pour I'outil peut

6tre dangereuse.

Sceau RBRC Mc

Le sceau RBRC de ta Rechargeable Battery Recycling Corporation appose

sur la pile au nickel-cadmium (ou le bloc-pile) indique que les coQts de

recyctage de ce dernier & la fin de sa vie utile ont dej& et6 payes par Black &

Decker. En certains endroits, la mise au rebut ou aux ordures municipales des piles au

nickel-cadmium est iltegate; le programme de -RBRC,, constitue donc une solution des

plus pratiques et ecotogiques.

La -RBRC,,, en collaboration avec Black & Decker et d'autres utilisateurs de piles, a mis

sur pied des programmes aux t_tats-Unis et au Canada dans te but de faciliter la cottecte

des piles decharg6es. Black & Decker encourage ses utilisateurs b.participer & son

programme de protection de t'environnement et de conservation des ressources natureltes

en retournant tes piles usagees & un centre de service Black & Decker ou chez un

depositaire local afin qu'etles puissent 6tre recyctees. On peut en outre se renseigner

aupres d'un centre de recyclage local pour connaftre d'autres sites les acceptant, ou

composer le 1 800 8-228-8379 pour obtenir de I'information sur le recyclage de ces piles

dans sa region.

22

Solution possible

• Verifier I'installation du

bloc-piles.

• Verifier les exigences de

charge pour le bloc-piles.

• Inserer te bloc-piles dans le

chargeur de sorte que le

voyant DEL rouge

apparaisse.

•Brancher le chargeur dans

une prise qui fonctionne. Se

reporter & la rubrique

- Remarques importantes

de chargement ,, pour plus

de renseignements.

• Deplacer le chargeur

et l'outil &une temperature

ambiante de plus de 4.5 °C

(40 °F) ou sous les 40.5 °C

(105 °F).

Page 23

Accessoi res

Les detaittants et te centre de service de la region vendent tes accessoires recommandes

Jr I'outit. Pour trouver un accessoire, composer le 1 800 544-6986.

AVERTISSEMENT : L'utilisation de tout accessoire non recommande pour I'outil peut

6tre dangereuse.

Information sur les reparations

Tous tes centres de reparation Black & Decker sont dotes de personnel qualifie en

matiere d'outillage electrique; ils sont doric en mesure d'offrir a leur clientele un service

efficace et fiable. Que ce soit pour un avis technique, une reparation ou des pieces de

rechange authentiques installees en usine, communiquer avec t'etablissement Black &

Decker te plus pros de chez vous. Pour trouver t'etabtissement de reparation de votre

region, consulter le repertoire des Pages jaunes a ta rubrique ,, Outits electriques ,_ou

composer le numero suivant : 1-800-544-6986 ou consulter le site

www.blackanddecker.com

Garantie complete de deux ans pour une utilisation domestique

Black & Decker (E.-U.) Inc. garantit ce produit pour une duree de deux arts contre tout

defaut de materiau ou de fabrication. Le produit defectueux sera remplace ou repar0 sans

frais de l'une des deux fagons suivantes :

La premiere fagon consiste en un simple echange chez te detaillant qui l'a vendu (pourvu

qu'it s'agisse d'un detaillant participant). Tout retour dolt se faire durant la periode

correspondant a ta politique d'echange du detaillant (habitueltement, de 30 a 90 jours

apres t'achat). Une preuve d'achat peut 6tre requise. Verifier aupres du detaillant pour

connaftre sa potitique concernant les retours hors de la periode definie pour les

echanges.

La deuxieme option est d'apporter ou d'envoyer te produit (transport paye d'avance) a un

centre de reparation autorise ou a un centre de reparation de Black & Decker pour faire

reparer ou echanger le produit, a notre discretion. Une preuve d'achat peut 6tre requise.

Les centres Black & Decker et les centres de service autorises sont repertori0s darts tes

pages jaunes, sous ta rubrique ,, Outils electriques ,_.

Cette garantie ne s'apptique pas aux accessoires. Cette garantie vous accorde des droits

legaux specifiques et vous pourriez avoir d'autres droits qui varient d'un Etat ou d'une

province a l'autre. Pour route question, communiquer avec le directeur du centre de

reparation Black & Decker le plus pros de chez vous. Ce produit n'est pas destine a un

usage commercial.

REMPLACEMENT GRATUlT DES I_TIQUE'rFES D'AVERTISSEMENT :si les etiquettes

d'avertissement deviennent itlisibles ou sont manquantes, composer le 1-800-544-6986

pour en obtenir le remplacement gratuit.

Imported by / Importe par

Black & Decker Canada Inc.

100 Central Ave.

Brockvitle (Ontario) K6V 5W6

Voir la rubrique

"Outils _lectriques"

des Pages Jaunes

pour le service et les ventes.

23

Page 24

MANUAL DE INSTRUCCIONES DEL TALADRO

INALAMBRICO

Cat&logo N° SS12D, SS14, SS18

Gracias por elegir Black & Deckert

Visite

www.Blackand Decker.com/NewOwner

para registrar su nuevo producto.

LEA EL MANUAL ANTES DE DEVOLVER

ESTE PRODUCTO POR CUALQUIER MOTIVO:

SitieneunaconsultaoalgOninconvenienteconsuproductoBlack&Decker,visite

HTTP://WWW.BLACKANDDECKER.COM/INSTANTANSWERS

paraobtenerrespuestasinstanta.neaslas24horasdeldia.

Sinoencuentralarespuestao notieneaccesoaInternet,Ilameal1-800-544-6986de

lunesaviernesde8a.m.a5p.m.horadelEsteparahablarconunagente.

CuandoIlame,tengaamanoelnOmerodecata.logo.

24

Page 25

Advertencias generales de seguridad para herramientas

eldctricas

_ADVERTENCIA: Lea todas las advertencias de seguridad e instrucciones Et

incumplimiento de las advertencias e instrucciones puede provocar descargas

electricas, incendios o lesiones graves.

Conserve todas las advertencias e instrucciones para futuras consultas.

El termino "herramienta electrica" incluido en las advertencias hace referencia a

las herramientas electricas operadas con corriente (con cable electrico) o alas

herramientas electricas operadas con baterias (inal&mbricas).

1) Seguridad en el _rea de trabajo

a) Mantenga el _rea de trabajo limpia y bien iluminada. Las areas abarrotadas y

oscuras propician accidentes.

b) No opere herramientas eldctricas en atmosferas explosivas, como ambientes

donde se encuentran liquidos, gases o polvo inflamables. Las herramientas

electricas originan chispas que pueden encender el polvo o los vapores.

c) Mantenga a los ni5os y espectadores alejados de la herramienta eldctrica en

funcionamiento. Las distracciones pueden provocar la perdida de control.

2) Seguridad eldctrica

a) Los enchufes de la herramienta eldctrica deben adaptarse al tomacorriente.

Nunca modifique el enchufe de ninguna manera. No utilice ningdn enchufe

adaptador con herramientas eldctricas con conexion a tierra. Los enchufes no

modificados y que se adaptan a los tomacorrientes reduciran el riesgo de descarga

electrica.

b) Evite el contacto corporal con superficies puestas a tierra, como por ejemplo

tuberias, radiadores, rangos y refrigeradores. Existe mayor riesgo de descarga

electrica si su cuerpo esta puesto a tierra.

c) No exponga las herramientas eldctricas a la Iluvia o a condiciones de humedad.

Si ingresa agua a una herramienta electrica, aumentara el riesgo de descarga electrica.

d) No maltrate al cable. Nunca utilice el cable para transportar, tirar o

desenchufar la herramienta eldctrica. Mantenga el cable lejos del calor, aceite,

bordes afilados o piezas moviles. Los cables dadados o enredados aumentan el

riesgo de descarga electrica.

e) AI operar una herramienta eldctrica en el exterior, utilice un cable

prolongador adecuado para tal uso. Utilice un cable adecuado para uso en

exteriores a fin de reducir el riesgo de descarga electrica.

f) Si el uso de una herramienta el_ctrica en un lugar ht_medo es imposible de

evitar, utilice un suministro protegido con un interruptor de circuito por falla a

tierra (GFCl). El uso de un GFCI reduce el riesgo de descargas electricas.

3) Seguridad personal

a) Permanezca alert& controle Io que est_ haciendo y utilice el sentido com_n

cuando emplee una herramienta el_ctrica. No utilice una herramienta electrica si

esta cansado o bajo el efecto de drogas, alcohol o medicamentos. Un momento de

descuido mientras se opera una herramienta electrica puede provocar lesiones

personales graves.

b) Utilice equipos de proteccion personal. Siempre utilice proteccion para los

ojos. En las condiciones adecuadas, el uso de equipos de proteccion, como

mascaras para polvo, calzado de seguridad antideslizante, cascos o proteccion

auditiva, reducira las lesiones personales.

c) Evite el encendido por accidente. Asegerese de que el interruptor est_ en la

posicion de apagado antes de conectarlo a la fuente de energia o paquete de

baterias, o antes de levantar o transportar la herramienta. Transportar

herramientas electricas con el dedo apoyado en el interruptor o enchufar herramientas

electricas con el interruptor en la posicion de encendido puede propiciar accidentes.

d) Retire las clavijas de ajuste o Ilaves de tuercas antes de encender la

herramienta el_ctrica. Una Ilave de tuercas o una clavija de ajuste que se deje

conectada a una pieza giratoria de la herramienta electrica pueden provocar

lesiones personales.

e) No se estire. Conserve el equilibrio adecuado y mant_ngase parado

25

Page 26

correctamente en todo momento. Esto permite un mejor control de la

herramienta el#ctrica en situaciones inesperadas.

f) Use la vestimenta adecuada. No use ropas holgadas ni joyas. Mantenga el

cabello, la ropa y los guantes alejados de las piezas en movimiento. Las ropas

holgadas, las joyas o el cabello largo pueden quedar atrapados en las piezas en

movimiento.

g) Si se suministran dispositivos para la conexion de accesorios con fines de

recoleccion y extraccion de polvo, asegt_rese de que est_n conectados y que

se utilicen correctamente. El uso de dispositivos de reco/eccion de po/vo puede

reducir los peligros relacionados con el polvo.

4) Uso y mantenimiento de la herramienta el_ctrica

a) No fuerce la herramienta el_ctrica. Utilice la herramienta el_ctrica correcta

para el trabajo que realizar_. La herramienta el#ctrica correcta hara el trabajo

mejor y mas seguro a la velocidad para la que fue dise#ada.

b) No utilice la herramienta el_ctrica si no puede encenderla o apagarla con el

interruptor. Toda herramienta electrica que no puede ser controlada mediante el

interruptor es peligrosa y debe ser reparada.

c) Desconecte el enchufe de la fuente de energia y/o el paquete de baterias de la

herramienta el_ctrica antes de realizar ajustes, cambiar accesorios o

almacenar herramientas el_ctricas. Estas medidas de seguridad preventivas

reducen el riesgo de encender la herramienta electrica en forma accidental

d) Guarde las herramientas el_ctricas que no est&n en uso fuera del alcance de

los ni_os y no permite que otras personas no familiarizadas con ella o con

estas instrucciones operen la herramienta. Las herramientas electricas son

peligrosas en las manos de usuarios no entrenados.

e) Mantenimiento de las herramientas el_ctricas. Controle que no haya piezas

moviles mal alineadas o trabadas, piezas rotas y toda otra situacion que

pueda afectar el funcionamiento de las herramientas el_ctricas. Si encuentra

dahos, haga reparar la herramienta el_ctrica antes de utilizarla. Se producen

muchos accidentes a causa de las herramientas electricas que carecen de un

mantenimiento adecuado.

f) Mantenga las herramientas de corte afiladas y limpias. Las herramientas de

corte con mantenimiento adecuado, con los bordes de corte afilados son menos

propensas a trabarse y son mas faciles de controlar.

g) Utilice la herramienta el_ctrica, los accesorios y las brocas de la herramienta,

etc. de acuerdo con estas instrucciones y teniendo en cuenta las condiciones

de trabajo y el trabajo que debe realizarse. El uso de la herramienta electrica para

operaciones diferentes de aquellas para las que fue dise#ada podria originar una

situaci6n peligrosa.

5) Uso y mantenimiento de la herramienta con baterias

a) Recargue solamente con el cargador especificado pot el fabricante. Un cargador

adecuado para un tipo de paquete de baterias puede originar riesgo de incendio si se

utiliza con otro paquete de baterias.

b) Utilice herramientas el_ctricas solo con paquetes de baterias especificamente

disehados. El uso de cualquier otro paquete de baterias puede producir riesgo de

incendio y lesiones.

c) Cuando no utilice el paquete de baterias, mantengalo lejos de otros objetos

metblicos como sujetapapeles, monedas, Ilaves, clavos, tornillos u otros

objetos metblicos pequehos que puedan realizar una conexion desde un

terminal al otro. Los cortocircuitos en los terminales de la bateria pueden provocar

quemaduras o incendio.