Black & Decker SS12C TYPE 2 Owner’s Manual

CORDLESS DRILL iNSTRUCTiON MANUAL

Catalog Number SS12

Thank you for choosing Black & Decker!

Go to www.BlackandDecker.com/NewOwner

to register your new product.

PLEASE READ BEFORE RETURNING THiS

PRODUCT FOR ANY REASON:

IfyouhaveaquestionorexperienceaproblemwithyourBlack&Deckerpurchase,goto

HTTP://WWW.BLACKANDDECKEB.C0M/INSTANTANSWERS

forinstantanswers24hoursa day.

Ifyoucan'tfindtheanswerordonothaveaccesstotheinternet,

call1-800-544-6986from8a.m.to5 p.m.ESTMon.-- Fri.tospeakwithanagent.

Pleasehavethecatalognumberavailablewhenyoucall.

VEA EL ESPA--OL EN LA CONTRAPORTADA.

INSTRUCTIVO DE.OPERACION, CENTROS DE SERVICIO Y POLIZA DE

ADVERTENClA: LEASE ESTE INSTRUCTIVO ANTES DE USAR EL PRODUCTO.

GARANTJA.

SAFETY GUiDELiNES = DEFiNiTiONS

Itis important for you to read and understand this manual. The information it contains relates to

protecting YOUR SAFETY and PREVENTING PROBLEMS. The symbols below are used to help

you recognize this information.

z_ DANGER: Indicates an imminently hazardous situation which, if not avoided, will

result in death or serious injury.

Z_ WARNING: Indicates a potentially hazardous situation which, if not avoided,

could result in death or serious injury.

z_ CAUTION: indicates a potentially hazardous situation which, if not avoided,

may result in minor or moderate injury.

NOTICE: Used without the safety alert symbol indicates potentially hazardous

situation which_sult in roert dama e.

General Power Tool Safety Warnings

zLWARNING: Read all safety warnings and all instructions. Failure to follow

the warnings and instructions may result in electric shock, fire and/or serious injury.

SAVE ALL WARNINGS AND INSTRUCTIONS

FOR FUTURE REFERENCE

he term, 'power, topl" i,n th,e warnings r#(ers t,_your mains,-operated

raea) power tool or oarrery-operarea (coraless) power tool.

SAVE THESE INSTRUCTIONS

1) WORK AREA SAFETY

• Keep work area clean and well lit. Cluttered or dark areas invite accidents.

. Do not operate power tools in explosive atmospheres, such as in the presence of

flammable liquids, gases or dust. Power tools create sparks which may ignite the dust or fumes.

• Keep children and bystanders away while operating a power tool. Distractions

can cause you to lose control.

2) ELECTRICAL SAFETY

a) Power tool plugs must match the outlet. Never modify the plug in any way. Do

not use any adapter plugs with earthed (grounded) power tools. Unmodified plugs

and matching outlets will reduce risk of electric shock:

b) Avoid body contact with earthed or grounded surfaces such as pipes, radiators,

ranges and refrigerators. There is an increased risk of electric shock ff your body is

earthed or grounded.

c) Do not expose power tools to rain or wet conditions. Water entering a power

tool will increase the risk of electric shock:

d) Do not abuse the cord. Never use the cord for carrying, pulling or unplugging

the power tool. Keep cord away from heat, oil, sharp edges or moving parts.

Damaged or entangled cords increase the risk of electric shock:

e) When operating a power tool outdoors, use an extension cord suitable for

outdoor use. Use of a cord suitable for outdoor use reduces the risk of electric shock:

f) if operating a power tool in a damp location is unavoidable, use a ground fault circuit

interrupter (GFCl) protected supply. Use of a GFCI reduces the risk of electric shock.

3) PERSONAL SAFETY

a) Stay alert, watch what you are doing and use common sense when operating

a power tool. Do not use a power tool while you are tired or under the influence

of drugs, alcohol or medication. A moment of inattention while operating power tools

may result in serious personal injury.

b) Use personal protective equipment. Always wear eye protection. Protective

equipment such as dust mask; nonskid safety shoes, hard hat, or hearing protection

used for appropriate conditions will reduce personal injuries.

c) Prevent unintentional starting. Ensure the switch is in the off position before

connecting to power source and/or battery pack, picking up or carrying the tool.

Carrying power tools with your finger on the switch or energizing power tools that have

the switch on invites accidents.

d) Remove any adjusting key or wrench before turning the power tool on. A wrench

or a key left attached to a rotating part of the power tool may result in personal injury.

e) Do not overreach. Keep proper footing and balance at all times. This enables

better control of the power tool in unexpected situations.

f) Dress properly. Do not wear loose clothing or jewelry. Keep your hair, clothing

and gloves away from moving parts. Loose clothes, jewelry or long hair can be

caught in moving parts.

g) if devices are provided for the connection of dust extraction and collection

facilities, ensure these are connected and properly used. Use of dust coflection

can reduce dust-related hazards.

4) POWER TOOL USE AND CARE

a) Do not force the power tool. Use the correct power tool for your application. The

correct power tool will do the job better and safer at the rate for which it was designed.

b) Do not use the power tool if the switch does not turn it on and off. Any power

tool that cannot be controfled with the switch is dangerous and must be repaired.

c) Disconnect the plug from the power source and/or the battery pack from the power

tool before making any adjustments, changing accessories, or storing power tools.

Such preventive safety measures reduce the risk of starting the power tool accidentally.

d) Store idle power tools out of the reach of children and do not allow persons

unfamiliar with the power tool or these instructions to operate the power tool.

Power tools are dangerous in the hands of untrained users.

e) Maintain power tools. Check for misalignment or binding of moving parts,

breakage of parts and any other condition that may affect the power tool's

operation. If damaged, have the power tool repaired before use. Many accidents

are caused by poorly maintained power tools.

f) Keep cutting tools sharp and clean. Properly maintained cutting tools with sharp

cutting edges are less fikely to bind and are easier to control.

g) Use the power tool, accessories and tool bits, etc. in accordance with these

instructions, taking into account the working conditions and the work to be

performed. Use of the power tool for operations different from those intended could result

in a hazardous situation.

5) BATTERY TOOL USE AND CARE

a) Recharge only with the charger specified by the manufacturer. A charger that

is suitable for one type of battery pack may create a risk of fire when used with

another battery pack.

b) Use power tools only with specifically designated battery packs. Use of any

other battery packs may create a risk of injury and fire.

c) When battery pack is not in use, keep it away from other metal objects like

paper clips, coins, keys, nails, screws, or other small metal objects that can

make a connection from one terminal to another. Shorting the battery terminals

together may cause bums or a fire.

d) Under abusive conditions, liquid may be ejected from the battery, avoid contact. If

contact accidentally occurs, flush with water, if liquid contacts eyes, additionally

seek medical help. Liquid ejected from the battery may cause irritation or bums.

6) SERVICE

a) Have your power tool serviced by a qualified repair person using only identical

replacement parts. This will ensure that the safety of the power tool is maintained.

specific safety Rules

• Wear ear protectors with impact drills. Exposure to noise can cause hearing loss.

• Use auxiliary handles supplied with the tool. Loss of control can cause personal injury.

• Hold power tool by insulated gripping surfaces, when performing an operation

where the cutting accessory may contact hidden wiring. Cutting accessory

contacting a "live" wire may make exposed metal parts of the power tool "live" and

could give the operator an electric shock.

• When working on a ladder or on scaffolding be sure to lay the tool down on its side when

not in use. Some tools with large battery packswill stand upright but may be easily knocked over

• Use clamps or another practical way to secure and support the work piece to a

stable platform. Holding the work by hand or against your body leaves it unstable and

may lead to loss of control.

• Keep your hair, clothing, and gloves away from air vents. Air vents often cover

moving parts in which these items can be caught.

• Holdtoolfirmlywithtwohands.Useauxiliaryhandleifprovided.Ifauxiliaryhandle

notprovided,griptootatbottomofbattery.Lossofcontrolcancausepersonalinjury•

Z_WARNING:Somedust created by power sanding, sawing, grinding, drilling, and

other construction activities contains chemicals known to the State of

California to cause cancer, birth defects or other reproductive harm. Some

examples of these chemicals are:

• Avoid prolonged contact with dust from power sanding, sawing, grinding, drilling,

Z_WARNING: Use of this tool can generate and/or disperse dust, which may cause

z_WARNING: ALWAYS use safety glasses. Everyday eye glasses are NOT safety

WEAR CERTIFIED SAFETY EQUIPMENT:

• lead from lead-based paints,

• crystalline silica from bricks and cement and other masonry products, and

• arsenic and chromium from chemically-treated lumber.

Your risk from these exposures varies, depending on how often you do this type of

work. To reduce your exposure to these chemicals: work in a well ventilated area, and

work with approved safety equipment, such as those dust masks that are specially

designed to filter out microscopic particles.

and other construction activities. Wear protective clothing and wash exposed

areas with soap and water. Allowing dust to get into your mouth, eyes, or lay on the

skin may promote absorption of harmful chemicals•

serious and permanent respiratory or other injury. Always use NIOSH/OSHA

approved respiratory protection appropriate for the dust exposure• Direct particles

away from face and body•

glasses. Also use face or dust mask if cutting operation is dusty. ALWAYS

• ANSI Z87.1 eye protection (CAN/CSA Z94.3)

• ANSI S12.6 (S3.19) hearing protection

• N/OSH/OSHA/MSHA respiratory protection

The label on your tool may include the following symbols.

V ........................... volts

Hz ......................... hertz

min........................ minutes

- - -. ..................... direct current

.......................... Class II Construction

z_ ......................... safety alert symbol

•../min ............... revolutions or

reciprocations per minute

A......................... amperes

W........................ watts

* ....................... alternating

current

no ....................... no load speed

........................ earthing terminal

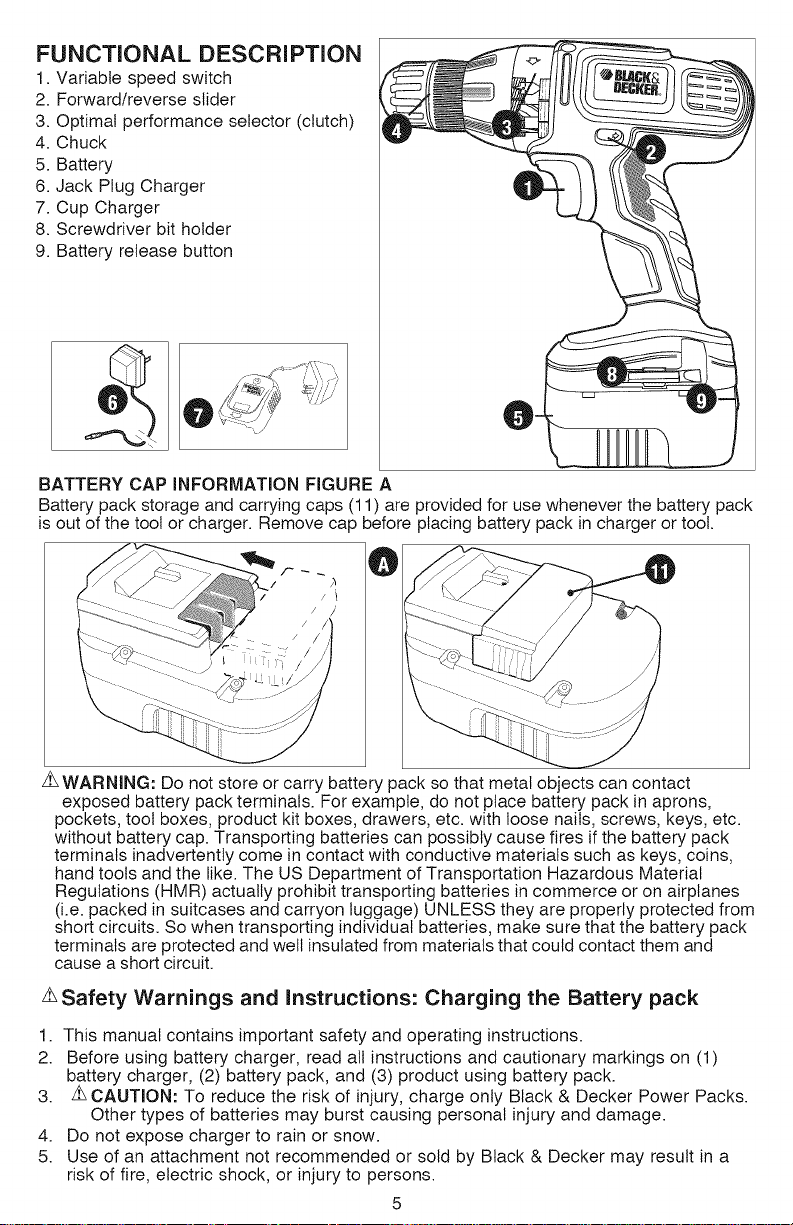

FUNCTIONAL DESCRiPTiON

1. Variable speed switch

2. Forward/reverse slider

3. Optimal performance selector (clutch)

4. Chuck

5. Battery

6. Jack Plug Charger

7. Cup Charger

8. Screwdriver bit holder

9. Battery release button

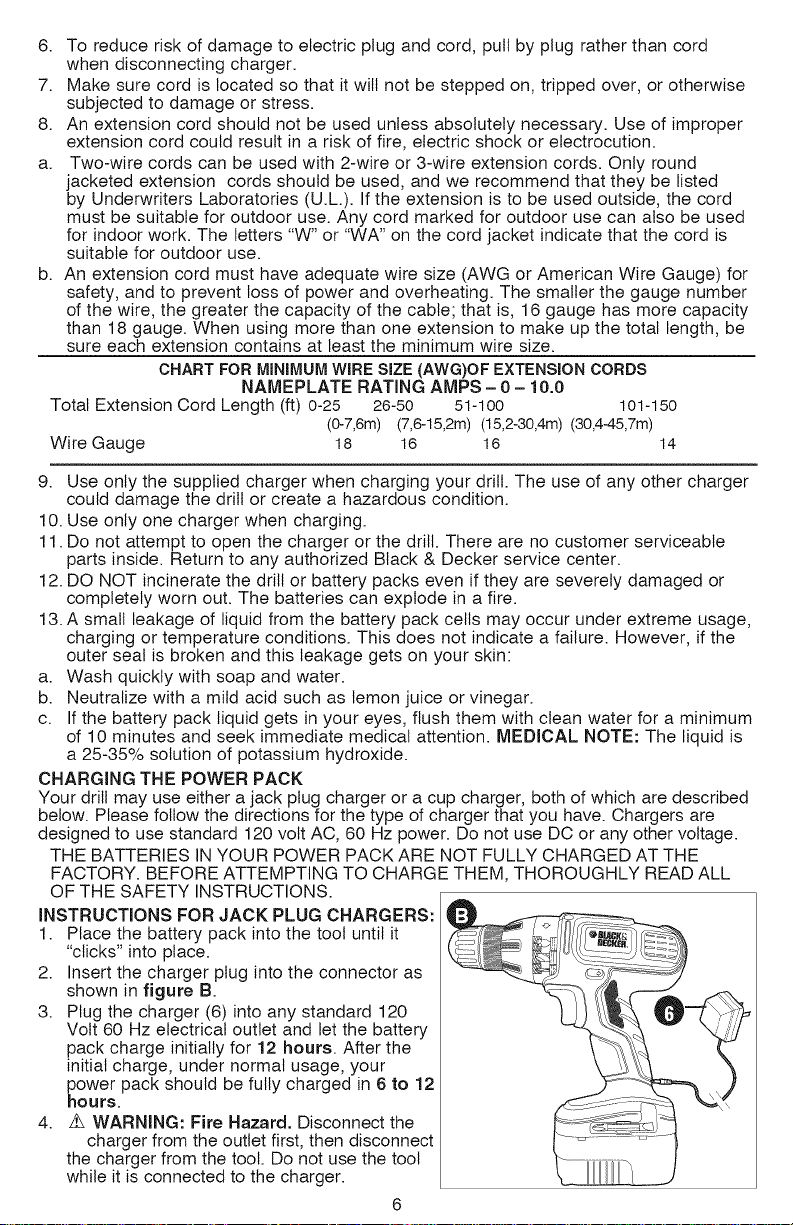

BATTERY CAP INFORMATION FIGURE A

Battery pack storage and carrying caps (11) are provided for use whenever the battery pack

is out of the toot or charger. Remove cap before placing battery pack in charger or tool.

3

/i

/ /

/ /

Z_WARNING: Do not store or carry battery pack so that metal objects can contact

exposed battery pack terminals. For example, do not place battery pack in aprons,

pockets, toot boxes, product kit boxes, drawers, etc. with loose nails, screws, keys, etc.

without battery cap. Transporting batteries can possibly cause fires if the battery pack

terminals inadvertently come in contact with conductive materials such as keys, coins,

hand tools and the like. The US Department of Transportation Hazardous Material

Regulations (HMR) actually prohibit transporting batteries in commerce or on airplanes

(i.e. packed in suitcases and carryon luggage) UNLESS they are properly protected from

short circuits. So when transporting individual batteries, make sure that the battery pack

terminals are protected and well insulated from materials that could contact them and

cause a short circuit.

z_Safety Warnings and instructions: Charging the Battery pack

1. This manual contains important safety and operating instructions.

2. Before using battery charger, read all instructions and cautionary markings on (1)

battery charger, (2) battery pack, and (3) product using battery pack.

3. z_ CAUTION: To reduce the risk of injury, charge only Black & Decker Power Packs.

Other types of batteries may burst causing personal injury and damage.

4. Do not expose charger to rain or snow.

5. Use of an attachment not recommended or sold by Black & Decker may result in a

risk of fire, electric shock, or injury to persons.

6. Toreduceriskofdamagetoelectricplugandcord,puttbyplugratherthancord

whendisconnectingcharger.

7. Makesurecordislocatedsothatitwillnotbesteppedon,trippedover,orotherwise

subjectedtodamageorstress.

8. Anextensioncordshouldnotbeusedunlessabsolutelynecessary.Useofimproper

extensioncordcouldresultinariskoffire,electricshockorelectrocution.

a. Two-wirecordscanbeusedwith2-wireor3-wireextensioncords.Onlyround

jacketedextensioncordsshouldbeused,andwerecommendthattheybelisted

byUnderwritersLaboratories(U.L).Iftheextensionistobeusedoutside,thecord

mustbesuitableforoutdooruse.Anycordmarkedforoutdoorusecanalsobeused

forindoorwork.Theletters"W"or"WA"onthecordjacketindicatethatthecordis

suitableforoutdooruse.

b. Anextensioncordmusthaveadequatewiresize(AWGorAmericanWireGauge)for

safety,andtopreventlossofpowerandoverheating.Thesmallerthegaugenumber

ofthewire,thegreaterthecapacityofthecable;thatis,16gaugehasmorecapacity

than18gauge.Whenusingmorethanoneextensiontomakeupthetotallength,be

sureeachextensioncontainsatleasttheminimumwiresize.

CHARTFORMiNiMUMWiRE SIZE (AWG)OF EXTENSION CORDS

NAMEPLATE RATING AMPS -0 - 10.0

Total Extension Cord Length (ft) 0-25 26-50 51-100 101-150

Wire Gauge 18 16 16 14

9. Use only the supplied charger when charging your drill. The use of any other charger

could damage the drill or create a hazardous condition.

10. Use only one charger when charging.

11. Do not attempt to open the charger or the drill. There are no customer serviceable

parts inside. Return to any authorized Black & Decker service center.

12. DO NOT incinerate the drill or battery packs even if they are severely damaged or

completely worn out. The batteries can explode in a fire.

13. A small leakage of liquid from the battery pack cells may occur under extreme usage,

charging or temperature conditions. This does not indicate a failure. However if the

outer seal is broken and this leakage gets on your skin:

a. Wash quickly with soap and water.

b. Neutralize with a mild acid such as lemon juice or vinegar.

c. Ifthe battery pack liquid gets in your eyes, flush them with clean water for a minimum

of 10 minutes and seek immediate medical attention. MEDICAL NOTE: The liquid is

a 25-35% solution of potassium hydroxide.

CHARGING THE POWER PACK

Your drill may use either a jack plug charger or a cup charger, both of which are described

below. Please follow the directions for the type of charger that you have. Chargers are

designed to use standard 120 volt AC, 60 Hz power. Do not use DC or any other voltage.

THE BATTERIES IN YOUR POWER PACK ARE NOT FULLY CHARGED AT THE

FACTORY. BEFORE ATTEMPTING TO CHARGE THEM, THOROUGHLY READ ALL

OF THE SAFETY INSTRUCTIONS.

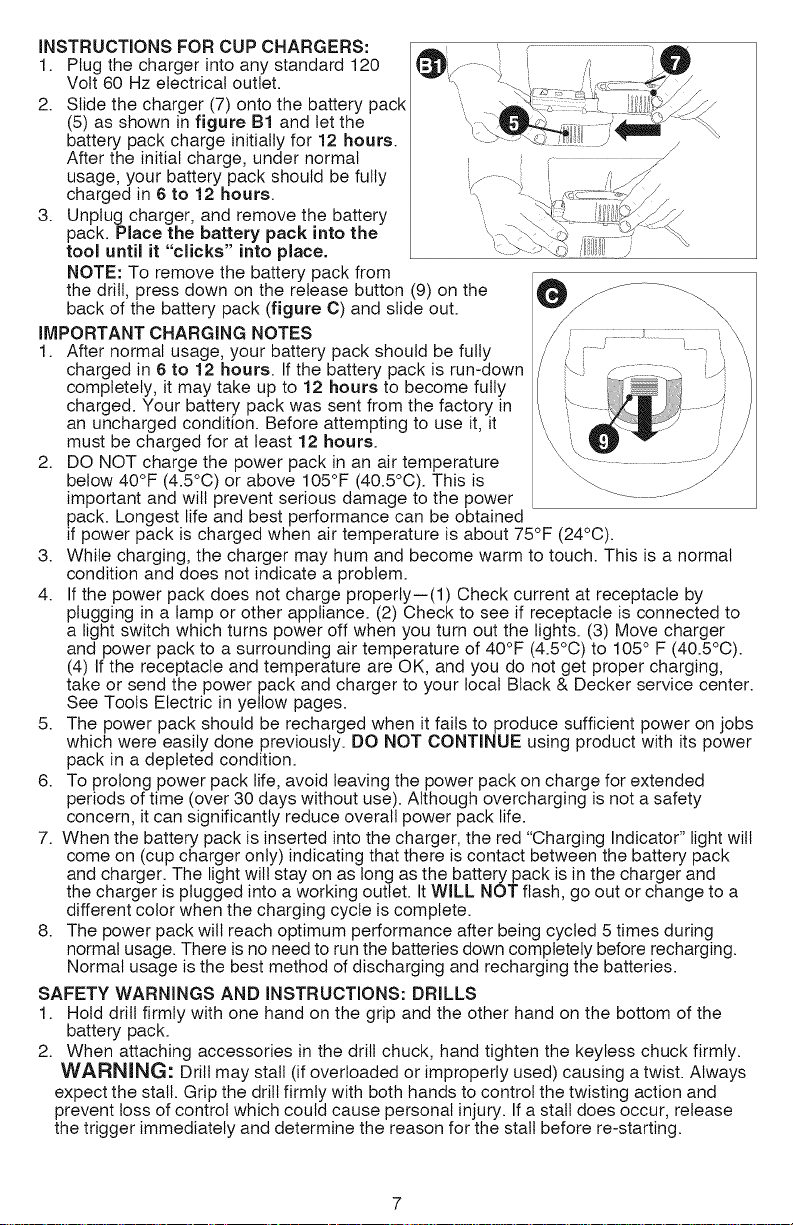

INSTRUCTIONS FOR JACK PLUG CHARGERS:

1. Place the battery pack into the tool until it

"clicks" into place.

2. Insert the charger plug into the connector as

shown in figure B.

3. Plug the charger (6) into any standard 120

Volt 60 Hz electrical outlet and let the battery

pack charge initially for 12 hours. After the

initial charge, under normal usage, your

power pack should be fully charged in 6 to 12

hours.

4. Z_ WARNING: Fire Hazard. Disconnect the

charger from the outlet first, then disconnect

the charger from the tool. Do not use the tool

while it is connected to the charger.

(0-7,6m) (7,6-15,2m)(15,2-30,4m)(30,4-45,7m)

INSTRUCTIONSFORCUPCHARGERS:

1. Plugthechargerintoanystandard120

Volt60Hzelectrical outlet.

2. Slide the charger (7) onto the battery pack

(5) as shown in figure B1 and let the

battery pack charge initially for 12 hours.

After the initial charge, under normal

usage, your battery pack should be fully

charged in 6 to 12 hours.

3. Unplug charger, and remove the battery

pack. Place the battery pack into the

tool until it "clicks" into place. "

NOTE: To remove the battery pack from

the drill, press down on the release button (9) on the

back of the battery pack (figure C) and slide out.

IMPORTANT CHARGING NOTES

1. After normal usage, your battery pack should be fully

charged in 6 to 12 hours. Ifthe battery pack is run-down

completely, it may take up to 12 hours to become fully

charged. Your battery pack was sent from the factory in

an uncharged condition. Before attempting to use it, it

must be charged for at least 12 hours.

2. DO NOT charge the power pack in an air temperature

below 40°F (4.5°C) or above 105°F (40.5°C). This is

important and will prevent serious damage to the power

pack. Longest life and best performance can be obtained

if power pack is charged when air temperature is about 75°F (24°C).

3. While charging, the charger may hum and become warm to touch. This is a normal

condition and does not indicate a problem.

4. If the power pack does not charge properly--(1) Check current at receptacle by

plugging in a lamp or other appliance. (2) Check to see if receptacle is connected to

a light switch which turns power off when you turn out the lights. (3) Move charger

and power pack to a surrounding air temperature of 40°F (4.5°C) to 105 ° F (40.5°C).

(4) If the receptacle and temperature are OK, and you do not get proper charging,

take or send the power pack and charger to your local Black & Decker service center.

See Tools Electric in yellow pages.

5. The power pack should be recharged when it fails to produce sufficient power on jobs

which were easily done previously. DO NOT CONTINUE using product with its power

pack in a depleted condition.

6. To prolong power pack life, avoid leaving the power pack on charge for extended

periods of time (over 30 days without use). Although overcharging is not a safety

concern, it can significantly reduce overall power pack life.

7. When the battery pack is inserted into the charger, the red "Charging Indicator" light will

come on (cup charger only) indicating that there is contact between the battery pack

and charger. The light will stay on as long as the battery pack is in the charger and

the charger is plugged into a working outlet. It WILL NOT flash, go out or change to a

different color when the charging cycle is complete.

8. The power pack will reach optimum performance after being cycled 5 times during

normal usage. There is no need to run the batteries down completely before recharging.

Normal usage is the best method of discharging and recharging the batteries.

SAFETY WARNINGS AND INSTRUCTIONS: DRILLS

1. Hold drill firmly with one hand on the grip and the other hand on the bottom of the

battery pack.

2. When attaching accessories in the drill chuck, hand tighten the keyless chuck firmly.

WARNING: Drill may stall (if overloaded or improperly used) causing a twist. Always

expect the stall. Grip the drill firmly with both hands to control the twisting action and

prevent loss of control which could cause personal injury. If a stall does occur, release

the trigger immediately and determine the reason for the stall before re-starting.

OPERATING iNSTRUCTiONS

TRIGGER SWITCH & REVERSING BUTTON FIGURE D)

The drill is turned ON and OFF by pulling ,_L

and releasing the trigger switch (1). The

farther the trigger is depressed, the higher

the speed of the drill.

A forward/reverse control button (2)

determines the direction of the tool and

also serves as a lock off button.

To select forward rotation, release the

trigger switch and depress the forward/

reverse control button to the left.

To select reverse, depress the forward/

reverse control button the opposite

direction.

NOTE: The center position of the control

button locks the tool in the off position.

When changing the position of the control

button, be sure the trigger is released.

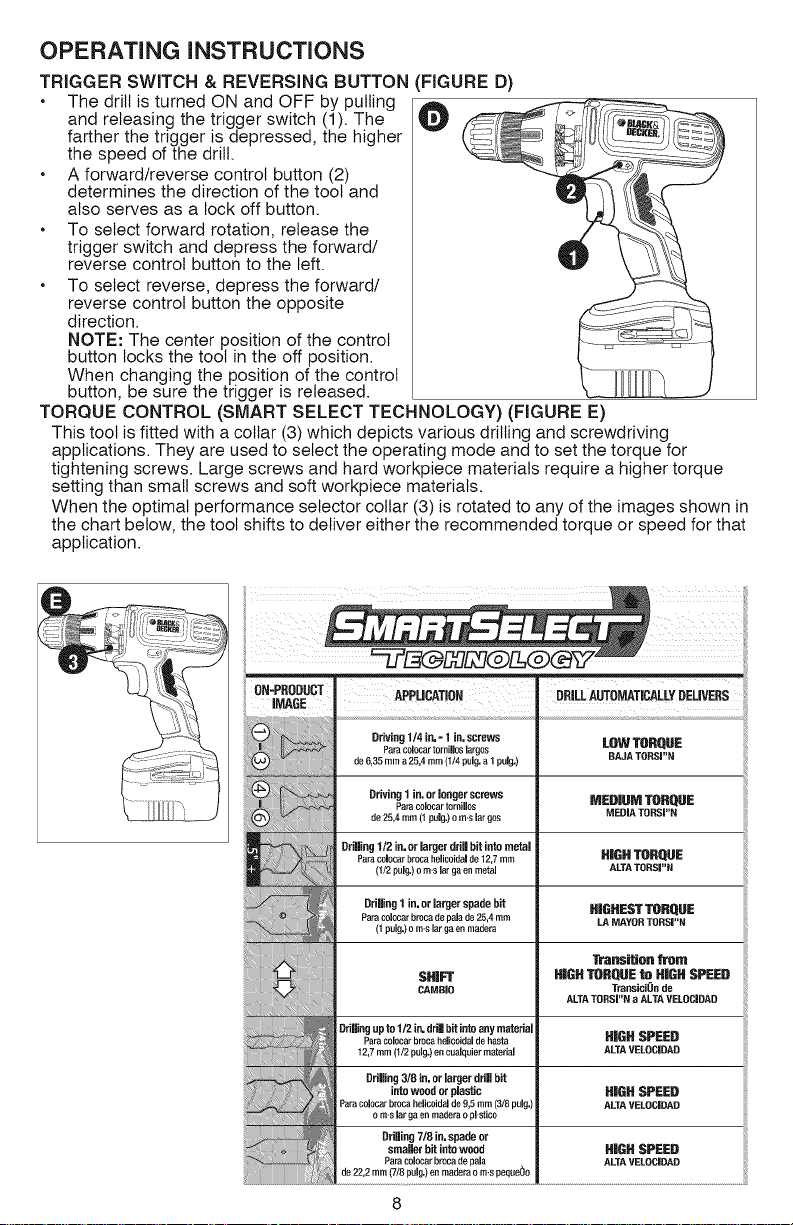

TORQUE CONTROL (SMART SELECT TECHNOLOGY) (FIGURE E)

This tool is fitted with a collar (3) which depicts various drilling and screwdriving

applications. They are used to select the operating mode and to set the torque for

tightening screws. Large screws and hard workplace materials require a higher torque

setting than small screws and soft workpiece materials.

When the optimal performance selector collar (3) is rotated to any of the images shown in

the chart below, the toot shifts to deliver either the recommended torque or speed for that

application.

0N-PRODUCT APPLiCATiON DRILLAUTOMATiCALLYDELIVERS

IMAGE

Driving1/4 in.- 1in, screws LOW TORQUE

ParecolocartarniU0slargos

de 6,35 mm a 25,4 mm (1/4 paiD. a1 palg.) BAJA TORSi"N

Driving1in.orlongerscrews MEDIUM TORQUE

Paracolcoar torniiios

de 25,4 mm (1 palg.) o m's JarDos MEDIA TORSi"N

gdUing !/2 in. or Jargerddllbit into metal

Para cal0car broca helicoidal de 12,7 mm HIGHTORQUE

(1/2 polo.)o m,s Jarga eft metal ALTA TORSI"N

Drilling1in, or larger spade bit HIGHEST TORQUE

Para eolcoar broca de pala de 25,4 mm LA MAYOR TORSJ"N

(I polo.) o m-s lar ga on madera

SHIFT HIGH TORQUEto HIGH SPEED

CAMBBO Transict0n de

Drilling upto 1/2 in. dd| bit into any material

Para colcoar broca helicoidalde hasta HIGHSPEED

12,7 mm (1/2 puIg.)eo eualquier material ALTA VELOC|DAD

Drilling 3/8 in. or largerdrillbit

intowood or plastic

Paracolocarbrcoahelicoidalde9,5mm(3/8puig.)

om-sJargaenmadamopl.stico

Drilling7/8 in,spade or

srealler bitintowood

Paracolcoarbrcoadepala

de22,2mm(7/8paiD.)enmadera0m.speque00

_a.siUon from

ALTA TDRSJ'_N a ALTA VELOCJDAD

HiGHSPEED

ALTA VELOCJDAD

HIGHSPEED

ALTA VELOC|DAD

iiiiiiiii

iiiiiiiii

iiiiiiiii

iiiiiiiii

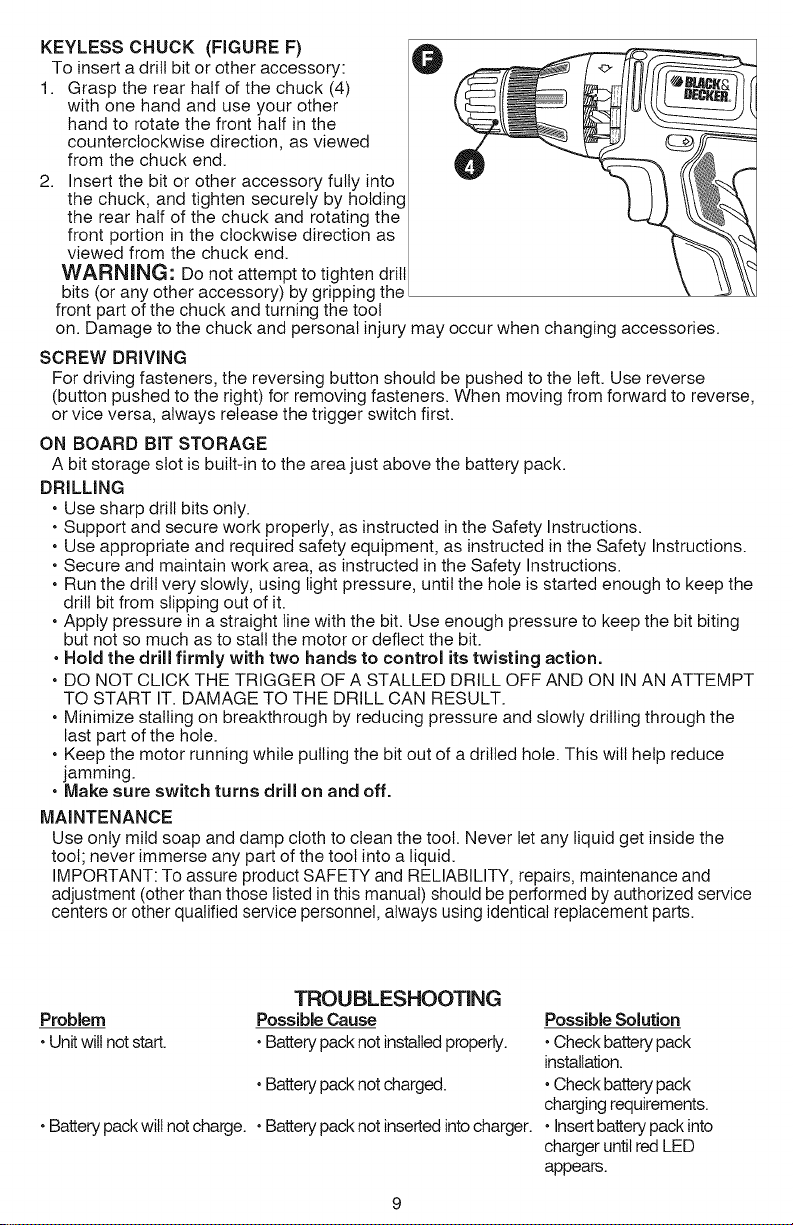

KEYLESS CHUCK (FIGURE F)

To insert a drill bit or other accessory:

1. Grasp the rear hatf of the chuck (4)

with one hand and use your other

hand to rotate the front half in the

counterclockwise direction, as viewed

from the chuck end.

2. Insert the bit or other accessory fully into

the chuck, and tighten securely by holding

the rear half of the chuck and rotating the

front portion in the clockwise direction as

viewed from the chuck end.

O

WARNING: Do not attempt to tighten drill

bits (or any other accessory) by gripping the

front part of the chuck and turning the tool

on. Damage to the chuck and personal injury may occur when changing accessories.

SCREW DRIVING

For driving fasteners, the reversing button should be pushed to the left. Use reverse

(button pushed to the right) for removing fasteners. When moving from forward to reverse,

or vice versa, always release the trigger switch first.

ON BOARD BIT STORAGE

A bit storage slot is built-in to the area just above the battery pack.

DRILLING

• Use sharp drill bits only.

• Support and secure work properly, as instructed in the Safety Instructions.

• Use appropriate and required safety equipment, as instructed in the Safety Instructions.

• Secure and maintain work area, as instructed in the Safety Instructions.

• Run the drill very slowly, using light pressure, until the hole is started enough to keep the

drill bit from slipping out of it.

• Apply pressure in a straight line with the bit. Use enough pressure to keep the bit biting

but not so much as to stall the motor or deflect the bit.

• Hold the drill firmly with two hands to control its twisting action.

• DO NOT CLICK THE TRIGGER OF A STALLED DRILL OFF AND ON IN AN ATTEMPT

TO START IT. DAMAGE TO THE DRILL CAN RESULT.

• Minimize stalling on breakthrough by reducing pressure and slowly drilling through the

last part of the hole.

• Keep the motor running while pulling the bit out of a drilled hole. This will help reduce

jamming.

• Make sure switch turns drill on and off.

MAINTENANCE

Use only mild soap and damp cloth to clean the toot. Never let any liquid get inside the

tool; never immerse any part of the tool into a liquid.

IMPORTANT: To assure product SAFETY and RELIABILITY, repairs, maintenance and

adjustment (other than those listed in this manual) should be performed by authorized service

centers or other qualified service personnel, always using identical replacement parts.

TROUBLESHOOTING

Problem Possible Cause Possible Solution

•Unit will notstart. •Battery pack not installedproperly. •Check battery pack

•Battery pack notcharged. •Check battery pack

•Battery pack willnot charge. •Battery pack not insertedinto charger. •Insert battery pack into

installation.

charging requirements.

charger untilred LED

appears.

•Chargernotpluggedin.

•Plugchargerintoaworking

outlet.Referto"Important

ChargingNotes"formore

details.

•Surroundingairtemperature

toohotortoocold.

•Movechargerandbattery

packtoasurroundingair

temperatureofabove40

degreesF(4.5°C)orbelow

105degreesF(+40.5°C).

Forassistancewithyourproduct,visitourwebsitewww.blackanddecker.comforthe

locationoftheservicecenternearestyouorcalltheBLACK&DECKERhelplineat

1=800=544=6986.

ACCESSORIES

Recommended accessories for use with your tool are available from your local dealer or

authorized service center. Ifyou need assistance regarding accessories, please call:

1-800-544-6986.

WARNING: The use of any accessory not recommended for use with this toot could

be hazardous.

The RBRC TM Seal

The RBRC TM (Rechargeable Battery Recycling Corporation) Seal on the

nickel-cadmium battery (or battery pack) indicates that the costs to recycle

the battery (or battery pack) at the end of its useful life have already been paid

by Black & Decker. In some areas, it is illegal to place spent nickel-cadmium

batteries in the trash or municipal solid waste stream and the RBRC program

provides an environmentally conscious alternative.

RBRC incooperation with Black & Decker and other battery users, has established

programs in the United States and Canada to facilitate the collection of spent nickel-

cadmium batteries. Help protect our environment and conserve natural resources by

returning the spent nickel-cadmium battery to an authorized Black & Decker service center

or to your local retailer for recycling. You may also contact your local recycling center for

information on where to drop off the spent battery, or call 1=800=8=BATTERY.

Service Information

All Black & Decker Service Centers are staffed with trained personnel to provide

customers with efficient and reliable power tool service. Whether you need technical

advice, repair, or genuine factory replacement parts, contact the Black & Decker location

nearest you. To find your local service location, refer to the yellow page directory under

"Tools--Electric" or call: 1=800=544=6986 or visit www.blackanddecker.com

10

Full Two=Year Home Use Warranty

Black & Decker (U.S.) Inc. warrants this product for two years against any defects in

material or workmanship. The defective product will be replaced or repaired at no charge

in either of two ways.

The first, which will result in exchanges only, is to return the product to the retailer from

whom it was purchased (provided that the store is a participating retailer). Returns should

be made within the time period of the retailer's policy for exchanges (usually 30 to 90 days

after the sate). Proof of purchase may be required. Please check with the retailer for their

specific return policy regarding returns that are beyond the time set for exchanges.

The second option is to take or send the product (prepaid) to a Black & Decker owned

or authorized Service Center for repair or replacement at our option. Proof of purchase

may be required. Black & Decker owned and authorized Service Centers are listed under

"Tools-Electric" in the yellow pages of the phone directory and on our website www.

blackanddecker.com.

This warranty does not apply to accessories. This warranty gives you specific legal rights

and you may have other rights which vary from state to state or province to province.

Should you have any questions, contact the manager of your nearest Black & Decker

Service Center. This product is not intended for commercial use.

FREE WARNING LABEL REPLACEMENT: If your warning labels become illegible or are

missing, call 1-800-544-6986 for a free replacement.

LATIN AMERICA: This warranty does not apply to products sold in Latin America. For

products sold in Latin America, check country specific warranty information contained in

the packaging, call the local company or see the website for warranty information.

Imported by

Black & Decker (U.S.) Inc.,

701 E. Joppa Rd.

Towson, MD 21286 U.S.A.

See 'Tools=

Electric'

- Yellow Pages -

for Service &

Sales

11

Loading...

Loading...