Page 1

IHSTBUCTION MANUAL

WARNING; FOR SAFE OPERATION

READ INSTRUCTION MANUAL.

IF YOU HAVE ANY QUESTIONS,

CALL US TOLL FREE:

800 762 6672

KEY INFORMATION

YOU SHOULD KNOW

Shaper/Router

POUR LE FRANÇAIS, VOIR LA

COUVERTURE ARRIÈRE.

VEA EL ESPAÑOL EN LA

CONTRAPORTADA.

Always make certain that material is fed

into the cutter rotation whether unit is

operating in forward or reverse.

Remove material from cuts in small

amounts and in multiple passes. This will

preserve both motor and cutter life and

provide the highest quality of cut. Always

use sharp cutters and bits.

Make certain that spindle and router bit

lock nuts are tightened snugly before

each use.

Page 2

WARNING: FOR YOUR OWN SAFETY, READ INSTRUCTION MANUAL BEFORE OPERATING SHAPER. ALWAYS WEAR EYE PROTECTION. DO NOT WEAR GLOVES,

NECKTIES, JEWELRY OR LOOSE CLOTHING. CONTAIN LONG HAIR. DO NOT OPERATE WITHOUT GUARDS IN PLACE. MAKE SURE CUTTER MEETS OR EXCEEDS SPEED

RATING OF TOOL. BE SURE SHAPER CUTTER IS PROPERLY SECURED, WITH KEYED WASHER DIRECTLY UNDER SPINDLE NUT, AND SPINDLE NUT TIGHT. DO NOT USE

AWKWARD HAND POSITIONS. KEEP FINGERS AWAY FROM REVOLVING CUTTER • USE FIXTURES WHEN NECESSARY. FEED WORKPIECE AGAINST ROTATION OF

CUTTER. DO NOT EXPO^ TO RAIN OR USE IN DAMP lOCATlOIS. SECURE TOOL PROPERLY TO PREVENT UNEXPEaED MOVEMENT. DO NOT OPERATE THIS MACHINE

WHILE UNDER THE INFLUENCE OF ALCOHOL OR DRUGS. FAILURE TO COMPLY WITH THESE WARNINGS MAY RESULT IN SERIOUS PERSONAL INJURY.

FORWARD/

RWfRSf SWITCH

OH/OFF SWITCH

WRENCHES

CUTTER DEPTH

HANDLE

ClEAlt FUSTIC GUARD

WODDEN FENCE BOARD

TABLE

MITER GAUGE

STORAGE

FENCE BRACKET

CENTER YOKE

SnOFICATIONS

l20Vohj

864 Worn

60 Hz

9Ami»

Page 3

IMPORTANT SAFETY INSTRUCTIONS

WARNING: When using electric tools, basic safety precautions should

always be followed to reduce risk of fire, electric shock, and personal

injury, including the following:

READ Aa INSTRUCTIONS

Double Insulation

Double insulated tools are constructed throughout with two separate

loyers of electrical insulation or one double thickness of insulation

between you and the tool's electrical system. Tools built with this

insulation system are not intended to be grounded. As a result, your

tool is equipped with a two prong plug which permits you to use

extension cords without concern for maintaining a ground connection.

NOTE: Double insulation does not take the place of normal safety

precautions when operating this tool. The insulation system is for

added protection againsf injury resulting from a possible electrical

insulation failure within the tool.

CAUTION: When servicing use only identical replacement parts.

Repair or replace damaged cords.

Polarized Plugs

Polarized plugs (one blade is wider than the other) are used on

equipment to reduce the risk of electric shock. When provided, this

plug will fit into a polarized outlet only one way. If the plug does not fit

fully in the outlet, reverse the plug. If It still does not fit, contact a

■ qualified electrician to install the proper outlet. Do not change the plug

in any way.

Safety Instructions For All Tools

• KEEP GUARD IN PLACE and in working order.

• REMOVE ADJUSTING KEYS AND WRENCHES. Form habit of

checking to see that keys and adjusting wrenches are removed from

spindle before turning tool on.

• KEEP WORK AREA CLEAN. Cluttered areas and benches

invite accidents.

DON'T USE IN DANGEROUS ENVIRONMENT. Don't use power

tools in damp or wet locations, or expose them to rain. Keep work

area well lignted.

KEEP CHILDREN AWAY. All visitors should be kept at a safe

distance from work area.

MAKE WORKSHOP KID PROOF with padlocks, master switches, or

by removing starter keys.

DON'T FORCE TOOL It will do the job better and be safer at the

rate for which it was designed.

USE RIGHT TOOL Don't force tool or attachment to do a job for

which it was not designed.

WEAR PROPER APPAREL No loose clothing, gloves, neckties, rings,

bracelets, or other jewelry to get caught in moving parts. Nonslip

footwear is recommended. Wear protective hair covering to contain

long hair.

ALWAYS WEAR SAFETY GLASSES. Also use face or dust mask if

cutting operation is dusty. Everyday eyeglasses have only impact

resistant lenses, they are NOT safely glasses.

DON'T OVERREACH. Keep proper footing and balance at all times.

MAINTMN TOOLS WITH CMtE. Keep tools sharp and clean for best

and safest performance. Follow inshbctions for lubricating and

changing accessories.

DISCONNECT TOOLS before servicing; when changing accessories

such as blades, bits, cutters, etc.

REDUCE THE RISK OF UNINTENTIONAL STARTING. Make sure

switch is in OFF position before plugging in. If a power failure

occurs and switch is left on, tool will start immediately when

power is restored.

USE RECOMMENDED ACCESSORIES. The use of improper

accessories may cause risk of injury to persons.

NEVER STAND ON TO^ Serious injury could occur if the tool is

tipped or if the cutting tool is unintentionally contocted.

CHECK DAMAGED PARTS. Before further use of the tool, a guard or

other part that is damaged should be corefully checked to o^rmine

that it will operate properly and perform its intended function—

check for alignment or moving parts, binding of moving parts.

Page 4

breakage of parts, mounting and any other conditions that may

affect its operation. A guard or other part that is damaged should

be properly repaired or replaced. Do not use tool if switch does not

turn it on and off.

• NEVER LEAVE TOOL RUNNING UNATTENDED. TURN POWER OFF.

Don't leave tool until it comes to a complete stop.

• DO NOT OPERATE ElEaRIC TOOLS NEAR FLAMAAABLE UQUIDS

OR IN GASEOUS OR EXPLOSIVE ATMOSPHERES. Motors in these

tools may spark and ignite fumes.

• EXTENSION CORDS. Make sure your extension cord is in good

condition. When using an extension cord, be sure to use one heavy

enough to carry the current your product will draw. An undersizeci

cord will cause a drop in fine voltage resulting in loss of power and

overheating. The table on page 2 snows the correct size to use

depending on cord length and nameplate ampere rating. If in

doubt, use the next heavier gage. The smaller the gage number, the

heavier the cord.

Volh Ibtei Ungth of Cord in Fm)

120V 0-25 26-50 5M00 101*150

240V

Ampere Rah'ng

More Noi more

Thon Than

Ô *

6 * 10 18 16

10 ■ 12 16 16 14 12

12 * 16

Minimum Gog« for Cord Seh

________

0*50 51*100 101*200 201*300

American Wire Goge

6 18 16 U

14 12

\4

14 12

Nol Recommended

• OUTDOOR USE EXTENSION CORDS. When tool is used outdoors,

use only extension cords intended for use outdoors and so marked.

• STAY ALERT, Watch what you are doing. Use common sense. Do

not operate tool when you are tired.

Additional Safety Rules for the Shoper/Router

• KEEP GUARDS in place and in working order.

• WARNING; Do not operate your shaper/router until it is completely

assembled and installed according to the instructions.

• MAKE SURE wiring codes and recommended electrical connections

are followed.

’ NEVER turn the Shaper/Router ON before clearing the table of all

objects (tools, scraps of wood, etc.).

' DO NOT process materials less than 12" (30 cm) in length or 4"

(10 cm) in width without special supporting fixtures.

' ALWAYS use a miter gage when edge shaping work less than

6" (15 cm) wide.

AVOID awkward hand positions where a sudden slip could allow

your hand to contact the cutter.

KEEP hands away from cutting tool.

NEVER run the stock between the fence and the cutter.

DO NOT feed material that is warped, cantains knots or is

embedded with foreign objects, such as nails or staples.

NEVER start the Shaper/Router with the stock in contact with

the cutter.

ALWAYS use auxiliary guard for any operation when the fence has

been removed.

NEVER perform layout, assembly or set-up work on the table while

the shaper is operating.

KEEP cutting tools sharp and free from rust and pitch.

THE WOODEN FENCE BOARDS should be adjusted as close to the

clear plastic guard as possible.

ALWAYS lock fence hardware securely after making

fence adjustments.

MAKE CERTAIN cutting tools are properly secured before

starting machine.

WARNING: For your own safety, read instruction manual before

operating shaper.

a) Be sure keyed washer is directly under spindle nut and spindle

nut is tight.

b) Feed workpiece against rotation of cutter.

c) Use auxiliary guard when adjustable fence is not in place.

DO NOT perform any operation freehand. ALWAYS use fence for

straight shaping; miter gage for end shaping; and starting pin and

cutters with rub collars for curve shaping.

Page 5

• CAUTION: If a power failure occurs and the switch is left ON, the

tool will start immediately when power is restored.

> ALWAYS a collar or bearing guide must be used when cutting if the

fence assembly is removed.

■ ALWAYS use guards provided with the machine.

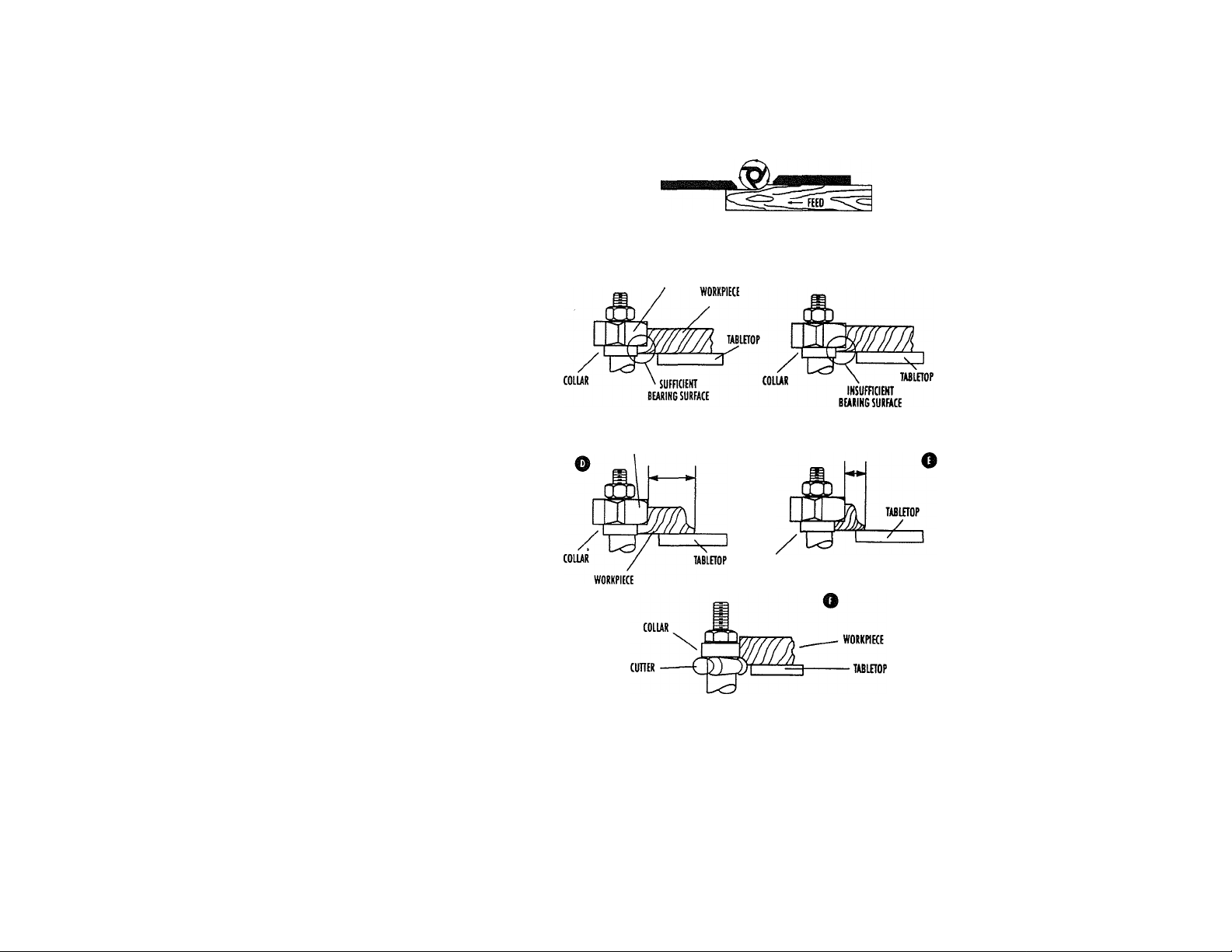

' ALWAYS feed against the cutter rotation, as shown in Figure A.

• WHEN SHAPING with collars and starting pin, the collar MUST

have sufficient bearing surface against the workpiece to prevent

erosion, as shown in Figure B. Figure C, illustrates the wrong way

for this operation as the collar DOES NOT have sufficient

bearing surface.

WHEN SHAPING OR ROUTING with collars and starting pin, the

workpiece must be fairly wide in proportion to the cut being made

as shown in Figure D. UNDER NO CIRCUMSTANCES should short

workpieces of narrow material be shaped against the collars as

shown in Figure E. .

WHEN SHAPING with collars and starting pin, the cutter should be

positioned below the collar whenever possible, <

positioned below the collar whenever possible, os shown i

Figure F.

MAKE all adjustments with the power OFF.

KEEP cutter guards in place and in working order.

WEAR EAR PROTECTION when operating this tool.

YOUR HANDS MUST ALWAYS remain at a safe distance — at least

6" (15 cm) — away from the cutter to avoid making contact with

the cutter should loss of control occur.

USE an auxiliary or scrap piece to push the workpiece and use

auxiliary guides made from other scrap pieces clamped to the table

and/or fence, if necessory, to keep your hands safely away from

the cutter.

USE RECOMMENDED ACCESSORIES. The use of improper

accessories may cause risk of personal injury.

SAVE THESE INSTRUaiONS FOR FUTURE USE

o

CORRE0

CUTTiR

CUTTER CORRECT

CUITEIi

ROTATION

INCORRECT

INCORRECT

Page 6

Parts

a. (1) Auxiliary guard

b. (1) Vacuum adapter

c. (2) Wooden fence boords

d. (2) Wrenches

e. (1) Fence bracket

f. (1) Center Yoke

g. (11 Table Insert

h. (1) Miter gauge

HARDWARE BAG 1

i. (2) 23mm (0.9'

j. (21 ldmm(0.63'

k. (2) 30mm (1.2") knobs

l. (2) 8mm (0.32") Flat washers

m. (5) 6mm (0.24”) Flat washers

n. (4) Hex nuts

o. (4) Flathead screws

HARDWARE BAG 2

p. (1) Starting pin

q. (1) Shaper spindle

r. (1) Collet nut

s. (1) Shaper/spindie nut

t. (1) 1/2" (12.7mm) Collet

u. (1)1 /4" (6.35mm) Collet

V. (1) Cutter nut

w. (1) Keyed wosher

X. (2) 30mm x 6mm (1.2" x 0.24") Collars

y. (1) 32mm x 4mm (1.26" x 0.16") Collar

z. ¡1) 22mm (0.87") Spacer

A. (1) 20mm (0.79") Spacer

I clear guard lock knobs

I knobs

h.

x./y.

q-

t./u.

:./A.

Page 7

Shaper

ASSEMBUNG AND INSTALUNG THE FENCE

A cardbtxird box inside the tool carton contains the larger fence

parts. The hardware required for assembly is in two (2) plastic bags in

the cardboard box.

Select, from the cardboard box, the center yoke, the two wooden

fence boards and the fence bracket shown in Figure 1. Loosely install

the fence bracket, as shown in Figure 2, using one of the 23mm

(0.9") knobs and 6mm flat washers from the plastic bag. Use the four

hothead screws, 6mm washers and hex nuts from the plastic bag to

loosely install the wooden fence boards to the center yoke and the

fence bracket, as shown in Figure 3.

Using two 30mm (1.2") plastic knobs and (2) 8mm (0.32") Rat

washers from the plastic bag, install the fence to the table top, as

shown in Figure 4. Thread these knobs into the two threaded holes

closest to the rear of the-table. (The third threaded hole closer to the

front of the table is for the starting pin which will be discussed later.

Do not install it at this time.)

Use a straightedge to make the two wooden boards even with each

other and hold that position while you firmly tighten the four screws

and the plastic fence bracket knob, as shown in Figure 5. Move the

completed fence as necessary to make it roughly parallel to the rear

edge of the table fop. Securely tighten the two knobs to hold the

fence stationary.

Figure 6 illustrates clear plastic guard assembly. Insert the guard bar

into the guard holder on the rear position of the fence center yoke, and

install a 23mm (0.9") plastic knob into the side of the guard holder to

securely hold the guard in place, as shown in Figure 7.

Assembling Table Insert

The table insert is placed in the table, as shown in Figure 8.

Bench Mounting (See Figure on Following Page)

TURN OFF AND UNPLUG SHAPER/ROUTER.

The shaper/router must be mounted firmly to your workbench or other

anchored frame. Four holes are provided in the tool's feet for this

CEHTER

YOKE

immFIAT

WASHERS

HEX NUTS

FENG

luaEi

WOODEN FENCE

BOARDS

Page 8

6mm FIAT

WASHER

30mm PIASTIC KNOBS

CLEAR

PLASTIC

GUARD

Bench Mounting

TABLE

INSERT

CLEAR

Page 9

purpose. These holes should be used to anchor the shaper/router to

your workbench or other stationary rigid frame. Alternately, to

enhance portability, if can be mounted to a piece of wood that can be

"C" clamped to your work surface or Workmate® Workcenter.

CAUTION: Failure to permanently mount or "C" clamp the

shaper/router to the work surfoce con be hazardous.

When changing the direction of rotation, be sure to turn the cutter

over as necessary to assure that all cutting is done by feeding the work

against the rotation of the cutter. Be sure to close the plastic cover

before turning the tool on.

Only shaper bits which can be inverted can be used for left to right

cutting. Router bits can only cut from right to left.

Operating Controls and Adjustments

SWITCHES (FIGURES 9 AND 10)

We suggest that when the tool is not in use, the switch be locked in the

OFF position.

The switch is located on the Shaper/Router as shown in Figures 9

and 10. To turn the tool ON, flip the toggle upward. To turn the tool

OFF, flip the toggle down. The switch will stay in either position without

being held. For safety, the red switch toggle may be removed when the

switcn is in the locked OFF position. This will prevent unintentional

starting by others.

FORWARD/REVERSE SWITCH

The forward/reverse switch is provided for reversing the direction of

the cutter when it is desirable to work from left to right rather than right

to left. To reverse the cutter direction from counterclockwise (working

from right to left) to clockwise (working from left to right) or vice-verse,

turn the tool off and raise the plastic door over the forward/reverse

switch. Depress the left side of the switch for counterclockwise rotation

, and the right side for clockwise rotation.

Raising and Lowering the Spindle

The spindle can be raised or lowered on your machine for the

purposes of mounting and removing bits and cutters and for cutting at

various heights. To raise or lower the spindle, turn the handle end

counterclockwise to loosen it and then swing it to the right to raise the

spindle and left to lower it, as shown in Figure 11. When it has been

adjusted to the desired height, turn the handle end clockwise to lock it

into position.

Adjusting the Fence

Begin by positioning the fence so that the bit or cutter is located

directly between the wooden fence boards and that the boards are as

close to the guard as possible without touching it.

ctmiHG

e

FENCE

BRACKET

KNOB

WOODEN FENCE BOARDS

DEPTH

HANDLE

<D

0

Page 10

GUARD

(LAMPING

KNOB

16mm FUSTIC KNOB

ROUTER BIT

COLLET NUT

WRENCH STORAGE

CLEAR

FUSTIC

GUARD

STORAGE

DRAWER

BURING GUIDE

The left board on tbe fence is the moveable one. By loosening the

fence bracket knob on the fence bracket, the board can move forwards

or backwards, thus adjusting the position of the fence (see Figure 12).

Actual fence settings far various jobs are presented later in this manual.

Clear Plostic Guard

The clear plastic guard should always be used when cutting with the

fence. To set the guard for maximum effect, loosen the guard clamping

knob and slide the guard down between the wooden boards as far as

it will go without touching the work, as shown in Figure 13. Tighten the

knob securely.

When you are working without the fence an auxiliary guard is

provided which attaches to the rear edge of the table using the

(2) 16mm plastic knobs. It is adjusted and positioned just like the

guard that's mounted on the fence, as shown in Figure 14.

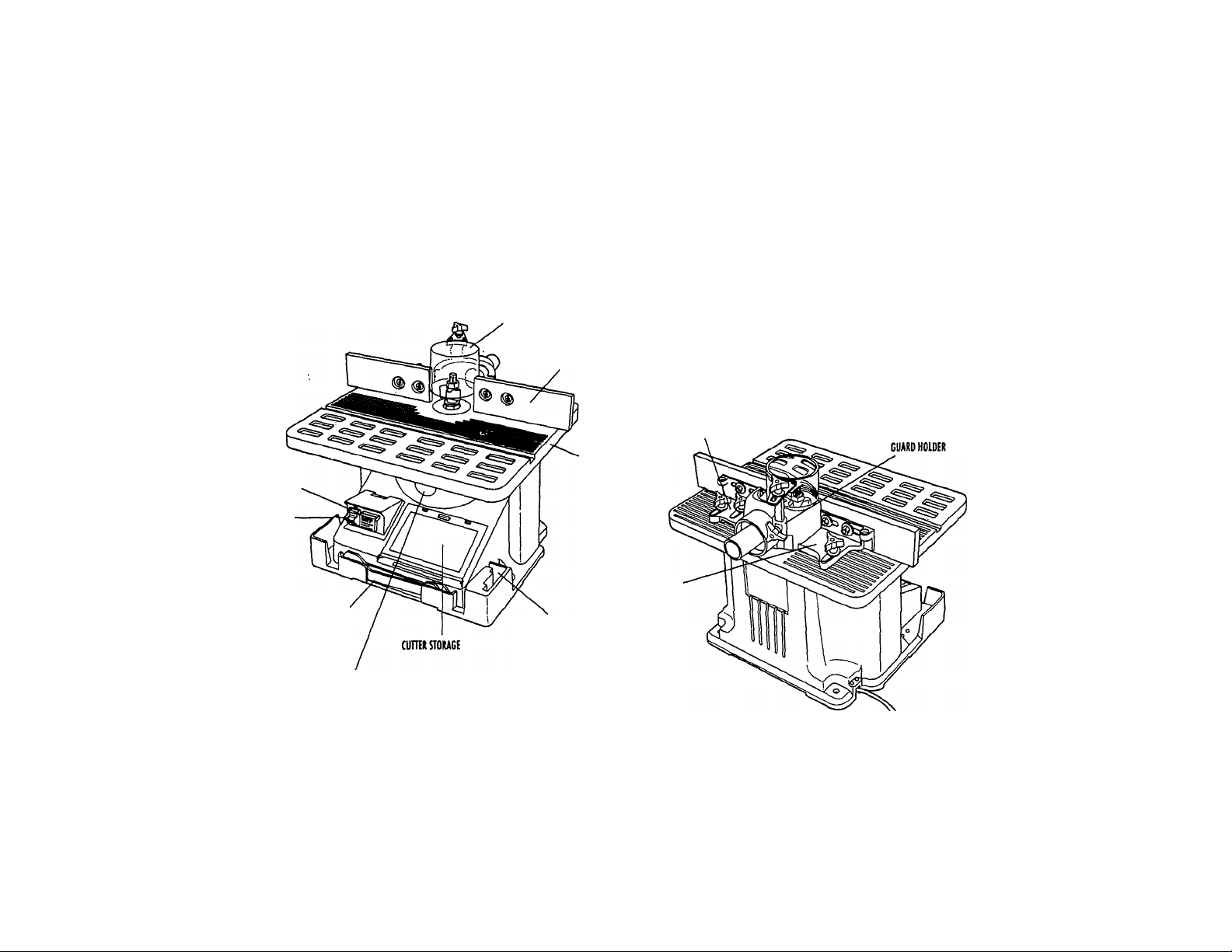

Wrench Storage

The Shaper/Router is supplied with two wrenches. When not in use,

the wrenches can be stored safely out of the way in the slot at the front

of the base. Also, extra cutters can be stored in the drawer shown in

Figure 15.

Installing Router Bits

1. Turn off machine and remove the switch toggle to lock switch off.

2. Install desired collet and collet nut as shown in Figure 16. Screw

collet nut (with collet inside it) down onto spindle. DO NOT

TIGHTEN THIS OR ANY COLLET WITHOUT A BIT IN PLACE. YOU

WILL CRACK THE COUfT.

3. Insert the desired router bit as far as it will go. Then pull it out about

1/16" (1.6mm) and tighten the collet nut firmly using the wrenches

provided, in order to tighten the collet nut, two flats have been

provided on the spindle. These flats are accessible only through the

spindle height adjustment slot below the table. Adjust the spindle

height to maximum by sliding the adjustment handle to the right as

far as it will go. Put one wrench through the slot and onto the flats

and the other on the collet nut, as shown in Figure 17.

Page 11

HINT; To best see the flats and your wrench, remove the table insert

and view through the top of the table. Reinstall table insert before use.

Starting Pin

A starting pin is supplied with your Shaper/Router and is used to

support the workpiece ot the start of the cut when using the

Shaper/Router without the fence. Install the starting pin as shown in

Figure 18. Make sure auxiliary guard is in place furore use.

Installing the Shaper Spindle and Shaper Cutter (Figure 19)

An accessory 1 /2" (12.7mrh) shaper cutter spindle that

accommodates 1 /2" (12.7mmj bore shaper cutters is supplied for

use with your Shaper/Router and can be installed as follows:

1. MAKE CERTAIN THE MACHINE IS DISCONNECTED FROM THE

POWER SOURCE.

2. Raise tool spindle as far as it will go and lock the cutting

depth handle.

3. Select shaper spindle and shaper spindle nut. Thread shaper

spindle into small diameter threads in shaper spindle nut.

4. Screw shaper spindle into shaper spindle nut until the shaper

spindle shoulder protrudes approximately 1 /16" (1.6mm) above

the face of the shaper spindle nut, as shown in Fig. 19B. Maintain

this position as you install the shaper spindle to the tool spindle.

5. Insert tapered end of shaper spindle into tapered end of

tool spindle.

6. Tighten the nut securely to tool spindle using the same means you

used for tightening the collet nut.

7. Install the desired cutter. The cutter must have a 1 /2“ (12.7mm)

hole or bushings (supplied by cutter manufacturer) to reduce the

hole to 1/2" (12.7mm). When installing the shaper cutter use the

appropriate combination of supplied spacers to raise or lower the

shaper cutter. Use the appropriate collar for your cutter when

shaping without the fence. The cutting depth handle can also be

used to adjust the height.

For detailed instructions on cutter Installation, refer to instructions

provided by cutter manufacturer.

piu

0

Page 12

0

BOTH Of CUT

CUiriNGCInaf

Operation

The following is an example of the setup and operational procedures

when using the fence, collars and starting pin. Please review this

information carefully before turning on the power to avoid damage to

the machine or personal injury.

m

0

COlUR

OUTFEED FENCE

CORREa

WORKPIECE

TABLETOP

INFEED FENCE

INCORREa

CUTTER

WORK

Shoping or Routing When Using the Fence as a Guide

Using the fence is the safest and most satisfactory method of shaping

and routing and this method should always be used when the work

permits. Almost all straight work con be shaped using the fence as follows:

1. For average work, where a portion of the original edge of the work

is not touched by the cutter, both the front and rear fences are in a

straight line, as shown in Figure 20.

2. When the operation removes the entire edge of the work, e.g., in

jointing or making a full bead, the shaped edge will not be

supported by the rear fence when both fences are in line, as shown

in Figure 21. In this case, the work should be advanced to the

position shown in Figure 21 and stopped. Then turn the machine off.

3. The outfeed fence and infeed fence should then be adjusted to

contact the work, as shown in Figure 22. The outfeed fence will

then be in line with the cutting circle. Refer to Figure 12 which

illustrates "Adjusting the Fence."

NOTE; When cutter rotation is reversed from that shown in

Figures 20, 21 and 22, feed direction will also be reversed

and infeed and outfeed fence identification will reverse.

4. Avoid heavy cuts. Begin by positioning cutter and fence to remove

only a small portion of the final cutter form. Increase cutter

exposure with each successive pass by moving fence and/or cutter

height until desired form is cut on workpiece. After gaining

experience with a particular cutter, you will learn how many passes

with accompanying fence and cutter adjustments are necessary to

produce a safe and satisfactory result. Remember, taking loo great

a cut or feeding the workpiece too fast can cause damage to the

piece and loss of control with possible injury.

5. When beginning the shaping operation, apply most pressure to that

portion of the workpiece supported by the infeed fence taking care

to keep your hands safely away from the cutter. When more than

to

Page 13

half of the workpiece has passed the cutter, transfer most pressure

to that portion now supported by the outfeed fence. Never apply

pressure to the workpiece in the area between fences. This will

prevent the workpiece from kicking in toward the cutter when its

trailing edge leaves the infeed fence and prevent loss of control and

possible injury.

Shaping or Routing With Collars and Starting Pin

A collar or bearing guide must be used when cutting if the fence

assembly is removed. The following rules must always be followed for

good work and safety in operation.

1. Collars MUST be smooth and free of all gum or other substances.

2. The edge of the work to be shaped MUST be smooth, as any

irregularity in the surface which rides against the collar will be

duplicated on the moulded surface.

3. A portion of the edge of the work MUST remain untouched by the

cutters in order that the collar will have sufficient bearing surface.

Figure 23 illustrates the right way for the operation while

Figure 24 illustrates the wrong way.

4. The workpiece MUST be fairly wide in proportion to the cut being

made as shown in Figure 25. Under NO circumstances should short

workpieces of narrow material be shaped against the collars as

shown in Figure 26.

5. when routing with collars and starting pin, the overhead cutter

guard, supplied with your machine, should always be used.

POSITION OF COLLARS

1. The collars may be used in any of the following positions: above,

below or between two cutters.

■2. When the collar is used below the cutter, as shown in Figure 27, the

progress of the cut can be observed at all times. However, any

accidental lifting of the work will gouge the wood and ruin

the workpiece.

3. When the collar is used above the cutter as shown in Figure 28, the

cut cannot be seen, yet this method offers some advantage in that

the cut is not affected by slight variations in the thickness of

the stock.

STARTING PIN

2ND POSITION

3RD POSITION

Page 14

4. The collar behveen cutters method, as shown in Figure 29, has both

the odvantages of the first two methods and is frequently used

where both edges of the work are to be shaped.

Starting Pin

1. Your machine is supplied with a starting pin which is used as a

support when starting the cut. The starting pin is placed into the

threaded hole in the table.

2. The work should be placed in the first position using the starting pin

as a support, as shown in Figure 30. Then swing the work into the

cutter as shown in the second position. The work will now be

supported by the collar and starting pin as shown in Figure 30.

3. After the cut has been started, the work is swung free of the starting

pin and rides only against the collar as shown in the third position

Figure 31.

ALWAYS FEED AGAINST THE ROTATION OF THE CUTTER.

IMPORTANT; If the work would be advanced to the cutter without the

side support of the starting pin, it would invariably be kicked back.

Accessories

Recommended accessories for use with your tool are available at

extra cosf from your local dealer or authorized service center.

CAUTION: The use of any accessory not recommended for use with

this tool could be hazardous. Use only cutters that are rated above

10,000 RPM and equal to or less than 2-1/2" (63.5mm) diameter.

If you need assistance in locating any accessory, please contact:

Black & Decker (U.S.) Inc.

Consumer Service Dept.

626 Hanover Pike, P.O. Box 618

Hampstead, MD 21074-0618

Phone: 1-800-762-6672

To purchase Black & Decker bench tool accessories, which are not

available at your local retailer, please call Black & Decker Teleservice

at 1-800-258-6003.

Important

To assure product SAFETY and REUABIUTY, repairs, maintenance and

adjustment (including brush inspection and replacement) should be

performed by authorized service centers or other qualified service

organizations, always using identical replacement parts.

Full Two-Year Home Use Warranty

Black & Decker (U.S.) Inc. warrants this product for two years against

any defects thot are due to faulty material or workmanship. Please

return the complete unit, transportation prepaid, to the seller (if a

participating retailer) for free replacement (proof of purchase may be

required). This unit may also be returned to a Black & Decker service

center or authorized service station, listed under "Tools-Electric" in the

yellow pages for free replacement or repair at our option. This

warranty does not apply to accessories. This warranty gives you

specific legal rights and you may have other rights which vary from

state to state. Should you have any questions, contact your nearest

Block & Decker service center manager.

This product is not intended for commercial use.

Every Black & Decker tool is of the highest quality. If you wish to

contact us regarding this product, please call toll free between

8:00 a.m. and 8:00 p.m. ET, seven days a week.

1-800-762-6672

Imported by

Black & Decker (U.S.) Inc.,

701 E. Joppa Ro.

Tovrson, MD 21286 U.S.A.

Sm'Tool»-EI*ctrlc'

- Yellow Peges -

Tor Service 1 Selee

12

Loading...

Loading...