Page 1

GENERAL SAFETY RULES

WARNING:

Read and understand all instructions. Failure to follow all instructions listed

below may result in electric shock, fire and/or serious personal injury.

SAVE THESE INSTRUCTIONS

WORK AREA

• Keep your work area clean and well lit. Cluttered benches and dark areas invite

accidents.

• Do not operate power tools in explosive atmospheres, such as in the presence of

flammable liquids, gases, or dust. Power tools create sparks which may ignite the dust

or fumes.

• Keep bystanders, children, and visitors away while operating a power tool.

Distractions can cause you to lose control.

ELECTRICAL SAFETY

• Double Insulated tools are equipped with a polarized plug (one blade is wider than

the other). This plug will fit in a polarized outlet only one way. If the plug does not fit

fully in the outlet, reverse the plug. If it still does not fit, contact a qualified

electrician to install a polarized outlet. Do not change the plug in any way. Double

Insulation eliminates the need for the three wire grounded power cord and grounded

power supply system.

• Avoid body contact with grounded surfaces such as pipes, radiators, ranges and

refrigerators. There is an increased risk of electric shock if your body is grounded.

• Don’t expose power tools to rain or wet conditions. Water entering a power tool will

increase the risk of electric shock.

• Do not abuse the cord. Never use the cord to carry the tools or pull the plug from an

outlet. Keep cord away from heat, oil, sharp edges or moving parts. Replace

damaged cords immediately.Damaged cords increase the risk of electric shock.

• When operating a power tool outside, use an outdoor extension cord marked "W-A"

or "W". These cords are rated for outdoor use and reduce the risk of electric shock.

PERSONAL SAFETY

• Stay alert, watch what you are doing and use common sense when operating a power

tool. Do not use tool while tired or under the influence of drugs, alcohol, or medication. A moment of inattention while operating power tools may result in serious personal

injury.

• Dress properly. Do not wear loose clothing or jewelry. Contain long hair. Keep your

hair, clothing , and gloves away from moving parts. Loose clothes, jewelry, or long hair

can be caught in moving parts.

• Avoid accidental starting. Be sure switch is off before plugging in. Carrying tools with

your finger on the switch or plugging in tools that have the switch on invites accidents.

• Remove adjusting keys or wrenches before turning the tool on. A wrench or a key that

is left attached to a rotating part of the tool may result in personal injury.

• Do not overreach. Keep proper footing and balance at all times. Proper footing and bal-

ance enables better control of the tool in unexpected situations.

• Use safety equipment. Always wear eye protection. Dust mask, non-skid safety shoes,

hard hat, or hearing protection must be used for appropriate conditions.

TOOL USE AND CARE

• Use clamps or other practical way to secure and support the workpiece to a stable

platform. Holding the work by hand or against your body is unstable and may lead to loss

of control.

• Do not force tool. Use the correct tool for your application. The correct tool will do the

job better and safer at the rate for which it is designed.

• Do not use tool if switch does not turn it on or off. Any tool that cannot be controlled

with the switch is dangerous and must be repaired.

• Disconnect the plug from the power source before making any adjustments,

changing accessories, or storing the tool. Such preventive safety measures reduce the

risk of starting the tool accidentally.

• Store idle tools out of reach of children and other untrained persons. Tools are

dangerous in the hands of untrained users.

• Maintain tools with care. Keep cutting tools sharp and clean. Properly maintained

tools with sharp cutting edges are less likely to bind and are easier to control.

• Check for misalignment or binding of moving parts, breakage of parts, and any other

condition that may affect the tool’s operation. If damaged, have the tool serviced before

using. Many accidents are caused by poorly maintained tools.

• Use only accessories that are recommended by the manufacturer for your model.

Accessories that may be suitable for one tool may become hazardous when used on

another tool.

SERVICE

• Tool service must be performed only by qualified repair personnel. Service or

maintenance performed by unqualified personnel could result in a risk of injury.

• When servicing a tool, use only identical replacement parts. Follow instructions in

the Maintenance section of this manual. Use of unauthorized parts or failure to follow

Maintenance Instructions may create a risk of electric shock or injury.

SPECIFIC SAFETY RULES

• Accessories must be rated for at least the speed recommended on the tool warning

label. Wheels and other accessories running over rated speed can fly apart and cause

injury.

The label on your tool may include the following symbols.

V ..........................volts A..........................amperes

Hz ........................hertz W ........................watts

min........................minutes ......................alternating current

......................direct current

n

o........................no load speed

..........................

Class II Construction

........................earthing terminal

........................safety alert symbol .../min ..................revolutions or

reciprocations

per minute

ADDITIONAL SAFETY RULES F0R ROTARY TOOLS

ALWAYS WEAR EYE PROTECTION WHEN USING THIS TOOL!

• If accessory jams, turn tool off and disconnect from power supply before freeing

accessory from the jam.

• Hold tool by insulated gripping surfaces when performing an operation where the

cutting tool may contact hidden wiring or its own cord. Contact with a “live” wire will

make exposed metal parts of the tool “live” and shock the operator.

• When using cutoff wheels always have the work securely clamped. Never attempt to

hold the work with one hand while using any cutting accessory.

• Keep hands away from rotating accessories.

• Allow accessories and collets to cool before touching with bare hands. They will be

hot after using.

• Insure there are no foreign objects in the workpiece such as nails which if hit could

cause loss of control of unit.

• Always feed the cutter into the material in the same direction as the chips are being

thrown. Feeding the tool in the wrong direction can cause loss of control.

• Keep handles dry, clean, free from oil and grease. This will enable better control of the

tool.

• When cutting wood, extra care should be taken to avoid inhalation and minimize skin

contact.

• Wear ear protection. Noise level may be amplified when using tool in enclosed spaces.

• The RTX has an internal speed control, never use an external speed control on this

unit.

• Do not use worn accessories.

• Do not use grinding wheels that have cracks.

• When turning tool on, hold it away from your face, since a damaged accessory

could come apart.

CAT. NO. RTX FORM NO. 397438-00 Copyright©2000 Black &Decker (JUNE 00 -1) PRINTED IN CHINA

VEA EL ESPAÑOL EN LA CONTRAPORTADA.

SAVE THIS MANUAL FOR FUTURE REFERERENCE.

INSTRUCTIVO DE OPERACIÓN, CENTROS DE SERVICIO YPÓLIZA

DE GARANTÍA. ADVERTENCIA: LÉASE ESTE INSTRUCTIVO ANTES

DE USAR ELPRODUCTO.

INSTRUCTION MANUAL

KEY INFORMA TION YOU SHOULD KNOW :

• Do not tighten the collet nut without an accessory bit in place.

• Do not engage spindle lock until tool has come to a complete stop.

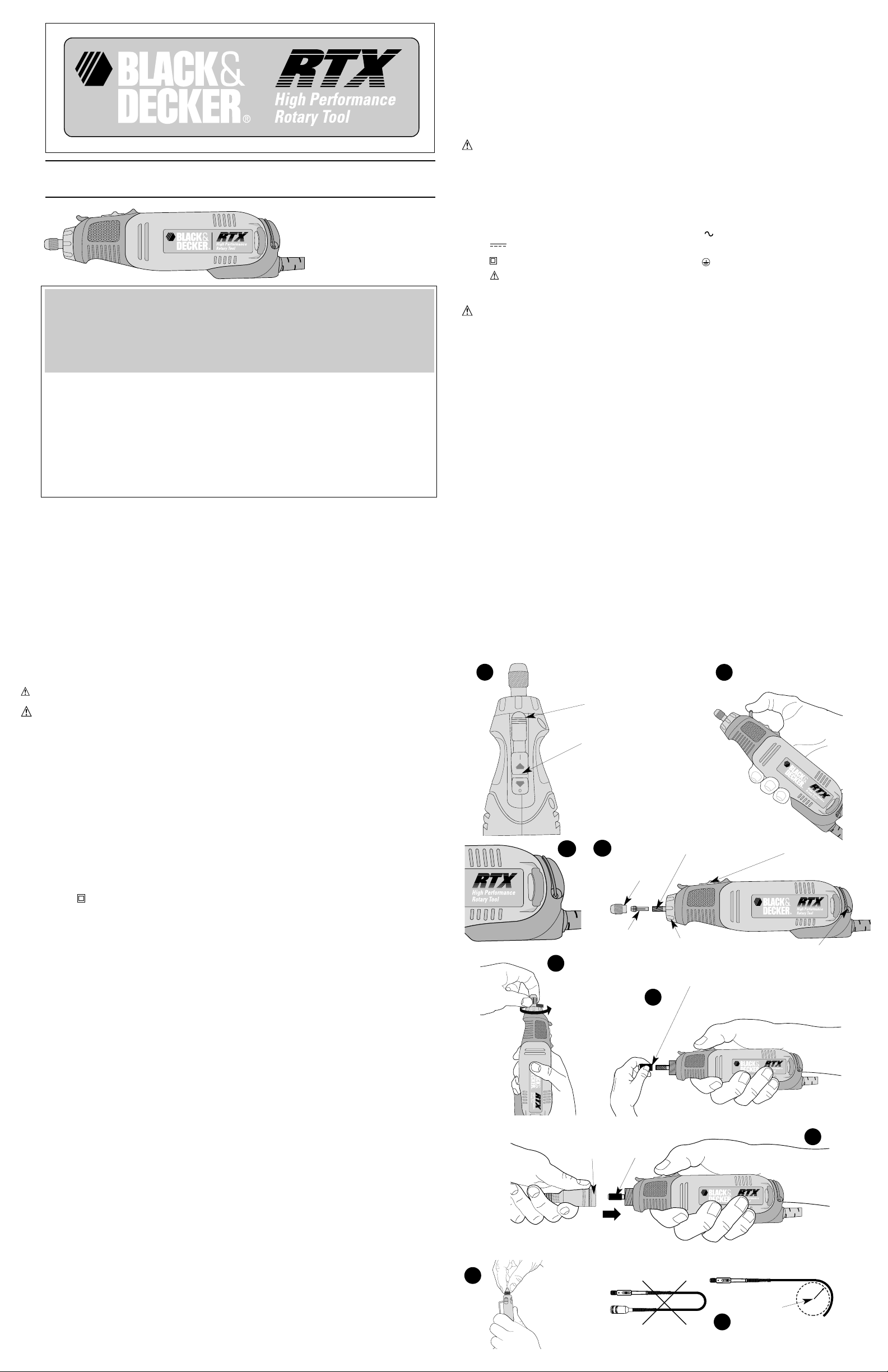

6

5

4

3

Collet nut

Écrou de la douille

Tuerca de la

mordaza

Collet

Douille

Mordaza

Spindle

Arbre

Flecha

6

5

4

1

Spindle Lock

Dispositif de verrouillage de l’arbre

Seguro de la flecha

On/Off Switch

Interrupteur

Interruptor de encendido y

apagado

On/Off Switch

Interrupteur

Interruptor de encendido y apagado

6

8

Driver Nut

Écrou de l'arbre

d'entraînement

Tuerca del mando

Flexible Shaft

Arbre flexible

Eje flexible

9

Driver Nut

Écrou de l'arbre

d'entraînement

Tuerca del mando

6 " (150mm)

150 mm 6 po

150 mm (6 pulg.)

Housing Cap

Couvercle du boîtier

Tapa de la carcaza

Catalog Number RTX

Tool Hanger

Douille de serrage

Pinza portapiezas

5

4

2

7

6

5

4

BEFORE RETURNING THIS PRODUCT

FOR ANY REASON PLEASE CALL

1-800-54-HOW-TO

(544-6986)

IF YOU SHOULD EXPERIENCE A PROBLEM

WITH YOUR BLACK & DECKER PURCHASE,

CALL 1-800-54-HOW-TO (1-800-544-6986).

IN MOST CASES, A BLACK & DECKER REPRESENTATIVE

CAN RESOLVE YOUR PROBLEM OVER THE PHONE.

IF YOU HAVE A SUGGESTION OR COMMENT,

GIVE US A CALL. YOUR FEEDBACK IS VITAL

TO THE SUCCESS OF BLACK & DECKER'S QUALITY

IMPROVEMENT PROGRAM.

6

5

4

6

5

4

6

5

4

Page 2

WARNING:Some dust created by power sanding, sawing, grinding, drilling, and other

construction activities contains chemicals known to cause cancer, birth defects or other

reproductive harm. Some examples of these chemicals are:

• lead from lead-based paints,

• crystalline silica from bricks and cement and other masonry products, and

• arsenic and chromium from chemically-treated lumber. (CCA)

Your risk from these exposures varies, depending on how often you do this type of work. To

reduce your exposure to these chemicals: work in a well ventilated area, and work with

approved safety equipment, such as those dust masks that are specially designed to filter

out microscopic particles.

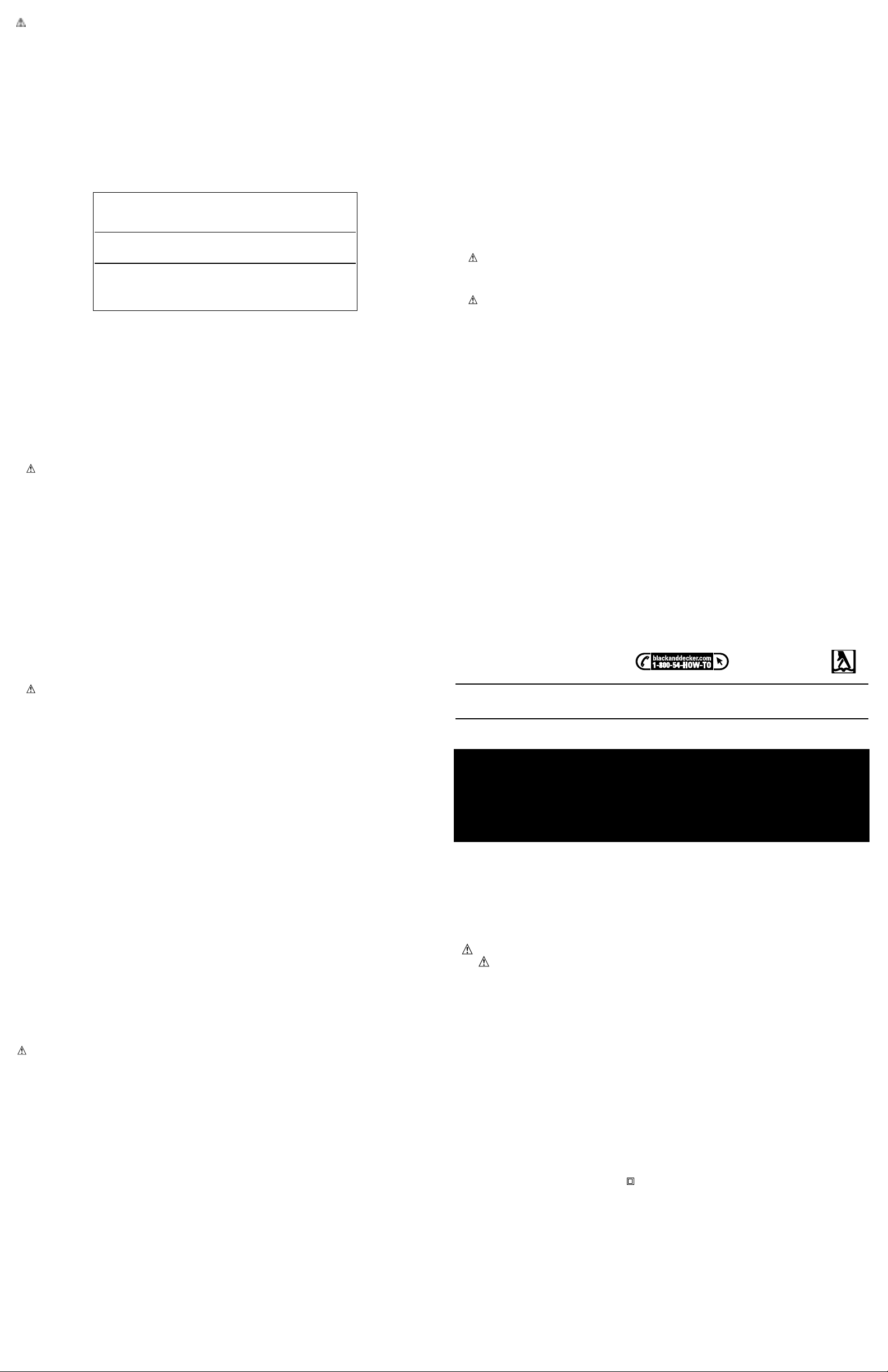

USE OF EXTENSION CORDS

Make sure the extension cord is in good condition before using. Always use the proper size

extension cords with the tool – that is, proper wire size for various lengths of cord and heavy

enough to carry the current the tool will draw. Use of an undersized cord will cause a drop in

line voltage resulting in loss of power and overheating. For proper size cords see chart

below.

SPINDLE LOCK LEVER

TURN OFF AND UNPLUG T OOLFROM POWER SUPPLY.

Fig.1 shows the ON/OFF switch and the spindle lock lever. To lock the spindle for changing

accessories, pull back on the spindle lock lever as shown in Figure 2. With the lever in the full

back position the spindle will lock. Install or remove the accessories as directed in this

manual. Release the spindle lock lever and you’re finished.

ON/OFF SWITCH

T o turn the tool ON, slide the switch button forward. The tool will immediately run at the speed

which is selected. Do not attempt to start tool with spindle lock engaged. It will not run.

SPEED SELECTION

To operate the tool, select the speed setting you wish with the speed wheel, shown in Fig 3,

and slide the ON/OFF switch forward. The speed setting can be adjusted either with the tool

on or off.

CAUTION: Because the RTX has a separate speed wheel for setting the speed (8,000 -

30,000 RPM), the tool will start at the speed where the speed wheel is set. Be sure switch is

fully OFF before plugging in.

The numbered positions,1 through 6 inscribed on the switch speed wheel, do not indicate

any precise speed but are good reference points. The higher the number, the higher the tool

speed.

The approximate speed at each setting is:

SPEED SETTING 1 2 3 4 5 6

APPROX. SPEED 8,000 12,000 19,000 24,000 28,000 30,000

(Actual RPM’s on your tool may vary .)

Be sure to select the proper speed for your rotary tool operation. The following chart

provides a speed guide for various operations.

If in doubt about the proper speed for your operation, test the performance at low speed

settings and gradually increase until a comfortable speed is found.

Cutting Metal . . . . . 5-6 Deburring . . . . . . . 4-5

Sanding Wood . . . . 5-6 Stripping Metal . . . 4-5

Sharpening. . . . . . . 3-5 Engraving Metal . . 4-5

Polishing . . . . . . . . 1-2 Drilling Holes. . . . . 4-5

Removing Rust. . . . 1-2

CAUTION: Never exceed the speed rating of the accessory being used.

CHANGING ACCESSORIES

Accessories are held in place by a collet and collet nut as shown in Figure 4.

To insert an accessory:

1. Turn off tool, allow it to come to a complete stop and disconnect from the power supply.

2. Pull back on the spindle lock lever (see Fig. 2) and grasp the collet nut.

3. Turn the collet nut counter-clockwise as shown in Fig. 5 until it is loose.

4. Insert the new accessory into the collet as far as it will go.

5. Tighten (clockwise) the collet nut securely. NOTE: The collet was designed to be hand

tightened and loosened only. Accessories naturally self tighten during use. A wrench is

provided with the tool for loosening. You should never need to tighten the collet nut with

the wrench. If a wrench is needed, use only the wrench provided. Do not use tools that

will mar the finish and could break the collet. Always ensure there is some accessory in

the collet before tightening. Tightening an empty collet can crack it.

6. Release the spindle lock lever and you’re finished.

7. If an accessory causes vibration it can usually be improved by loosening the collet nut,

pushing the accessory in as far as it will go and rotating it 1/4 turn then retightening the

collet.

CHANGING THE COLLET

Some accessories require different sized collets. The two collets used with Black & Decker

accessories are 1/8" (used for most accessories) and 3/32". Ensure your collet size

matches your accessory.

To change the collet:

1. Turn off tool, allow it to come to a complete stop and disconnect from power supply.

2. Pull back on the spindle lock lever (see Fig. 2) and grasp the collet nut.

3. Turn the collet nut counter-clockwise and remove the collet nut and the collet from the

threaded spindle (see Fig. 4).

4. Insert the new collet into the spindle.

5. Screw on the collet nut.

6. Release the spindle lock.

USING THE ROTARY TOOL

WARNING: Always wear eye protection.

When operating the tool be sure to hold it securely. For detail work, grip the contoured area

at the front of the tool, near the spindle. Before beginning a project, practice using the tool

on some scrap material until you get the "feel" of the tool. The rotary tool is small and easy to

use but don’t be fooled; it’s a real power tool and should be handled carefully and properly

as described in this manual. Don’t overload the tool. Performance is enhanced by letting the

tool do the work.

FLEXIBLE SHAFT RT5100 FLEXIBLE ROTARY TOOL EXTENDER

(Available as a separate accessory and included with catalog number RTX-2 only)

FLEXIBLE SHAFT INSTALLATION INSTRUCTIONS

1. Turn off tool, allow it to come to a complete stop and disconnect from power supply.

2. Remove the collet nut and collet from the tool by first pulling back on the spindle lock

lever and grasping the collet nut (Fig.2).

3. Turn the collet nut counter-clockwise and remove the collet nut and the collet from the

threaded spindle (see Fig. 4).Release the spindle lock.

4. Remove the silver housing cap (Fig.4) by turning counterclockwise.

5. Locate the driver nut and thread it onto the motor shaft (Fig. 6).

6. Screw the F

LEXIBLE SHAFT onto the rotary tool as shown in Fig. 7 insuring that the rotating

center core engages the square hole socket in the driver nut (Fig. 7). NOTE: Use caution

when screwing the metal housing of the shaft onto the threaded portion of the rotary tool.

Avoid cross threading.

7. The F

LEXIBLE SHAFT is now ready for use. To insert an accessory, Turn off tool, allow it to

come to a complete stop and disconnect from power supply. Place the provided lock pin

into the opening in the FLEXIBLE SHAFT hand piece and rotate collet nut until lockpin

engages hole in spindle (Fig. 8). With the shaft locked, turn the collet nut counter-clockwise to loosen. Insert the accessory completely into the collet to avoid wobbling. Tighten

collet nut securely by hand. Remove lock pin.

Minimum Gage for Cord Sets

Volts Total Length of Cord in Feet

120V 0-25 26-50 51-100 101-150

240V 0-50 51-100 101-200 201-300

Ampere Rating

More Not more American Wire Gage

Than Than

0-6 18 16 16 14

6 - 10 18 16 14 12

10 - 12 16 16 14 12

12 - 16 14 12 Not Recommended

8. The Flexible Shaft collet can be changed as described in the “Changing the Collet” section.

IMPORTANT: Avoid using the Flexible Shaft with a sharp bend as shown in Fig. 9. A radius

of 6" or larger is recommended. Atool hanger (Fig. 4) is provided to hang the tool when using

the flex shaft. The hanger secures the tool and helps avoid sharp bends on the flex shaft.

NOTE: The rotating center core can come out of the F

LEXIBLE SHAFT. This is not a problem.

Simply reinsert it into the FLEXIBLE SHAFT. If the center core gets dirty, wipe it off and apply a

very light film of high temperature grease. The square drive of the center core may not

engage the hand piece. To get it to engage, apply a light force to the tip of the center core

while rotating the handpiece collet nut.

MAINTENANCE

Use only mild soap and damp cloth to clean the tool. Never let any liquid get inside the tool;

never immerse any part of the tool into a liquid.

IMPORTANT: To assure product SAFETY and RELIABILITY, repairs, maintenance and

adjustment (other than those listed in this manual) should be performed by authorized

service centers or other qualified service organizations, always using identical replacement

parts. Unit contains no user serviceable parts inside.

ACCESSORIES

Black & Decker offers a large selection of accessories available at your local dealer or

authorized service center at extra cost. Only Black & Decker accessories are recommended

for use in the RTX or B&D Flexible Shaft.

If you need assistance regarding accessories, please call: 1-800-54-HOW TO (544-6986).

CAUTION: Use only those accessories rated at 30,000 RPM or greater. Exception: Do

not operate wire brushes, bristle brushes, diamond dome sander, or 1-1/4” diamond wheels

at speeds greater than 15,000 RPM (speed setting #2). Never exceed the speed rating of the

accessory being used.

WARNING: The use of any accessory not recommended for use with this tool could be

hazardous.

SERVICE INFORMA TION

Black & Decker offers a full network of company-owned and authorized service locations

throughout North America. All Black & Decker Service Centers are staffed with trained

personnel to provide customers with efficient and reliable power tool service.

Whether you need technical advice, repair, or genuine factory replacement parts, contact

the Black & Decker location nearest you.

To find your local service location, refer to the yellow page directory under "Tools–Electric"

or call: 1-800-54-HOW TO (544-6986).

FULL FIVE-YEAR HOME USE WARRANTY

Black & Decker (U.S.) Inc. warrants this product for five years against any defects in

material or workmanship. The defective product will be replaced or repaired at no charge in

either of two ways.

The first, which will result in exchanges only, is to return the product to the retailer from

whom it was purchased (provided that the store is a participating retailer). Returns should

be made within the time period of the retailer’s policy for exchanges (usually 30 to 90 days

after the sale). Proof of purchase may be required. Please check with the retailer for their

specific return policy regarding returns that are beyond the time set for exchanges.

The second option is to take or send the product (prepaid) to a Black & Decker owned or

authorized Service Center for repair or replacement at our option. Proof of purchase may be

required. Black & Decker owned and authorized Service Centers are listed under

"Tools–Electric" in the yellow pages of the phone directory.

This warranty does not apply to accessories. This warranty gives you specific legal rights

and you may have other rights which vary from state to state. Should you have any

questions, contact the manager of your nearest Black & Decker Service Center.

NOTE: This tool is designed, manufactured and tested to meet or exceed the needs of the

do-it-yourselfer in the execution of projects and repairs in and around the home. With proper

use it will provide the home owner with years of service. However, if you use tools for a living

and use this product or any of Black & Decker ’s other Consumer Home Use tools ON THE

JOBSITE you should know that they CANNOT BE COVERED UNDER OUR WARRANTY.

Modèle RTX

GUIDE D’UTILISATION

AVANT DE RETOURNER LE PRODUIT, PEU IMPORTE LA RAI-

SON PRIÈRE DE COMPOSER

1 800 544-6986

CONSERVER LE PRÉSENT GUIDE À TITRE DE RÉFÉRENCE.

See ‘Tools-Electric’

– Yellow Pages –

for Service & Sales

Imported by

Black & Decker (U.S.) Inc.,

701 E. Joppa Rd.

Towson, MD 21286 U.S.A.

RENSEIGNEMENTS IMPORT ANTS

• On ne doit jamais serrer l’écrou de la douille de serrage sans y avoir d’abord inséré

une mèche ou un autre accessoire.

• Attendre que l’outil se soit complètement immobilisé avant d’engager le dispositif de

verrouillage de la broche.

MESURES DE SÉCURITÉ

AVERTISSEMENT :Lire et comprendre toutes les directives. Le non-respect de toutes

les directives suivantes présente des risques de secousses électriques, d'incendie ou de

blessures graves.

CONSERVER CES MESURES.

ZONE DE TRAVAIL

• S'assurer que la zone de travail est propre et bien éclairée. Des établis encombrés et

des endroits sombres présentent des risques d'accidents.

• Ne pas utiliser des outils électriques en présence de vapeurs explosives (comme

celles dégagées par des liquides, des gaz ou des poussières inflammables). Les

étincelles générées par le moteur des outils électriques peuvent enflammer les poussières

ou les vapeurs.

• Éloigner les curieux, les enfants et les visiteurs de la zone de travail lorsqu'on utilise

un outil électrique. Une distraction peut entraîner la perte de maîtrise de l'outil.

MESURES DE SÉCURITÉ RELATIVES À L’ÉLECTRICITÉ

• Les outils à double isolation comportent une fiche polarisée (une lame plus large que

l'autre). La fiche n'entre que d'une façon dans une prise polarisée. Lorsque la fiche

n'entre pas à fond dans la prise, essayer de nouveau après avoir inversé les broches

de la fiche. Si la fiche n'entre toujours pas dans la prise, communiquer avec un

électricien certifié afin de faire installer une prise polarisée. Ne modifier en aucune

façon la fiche. La double isolation élimine le besoin d'un cordon trifilaire mis à la terre et

d'un système d'alimentation mis à la terre.

• Éviter de toucher à des surfaces mises à la terre comme des tuyaux, des radiateurs,

des cuisinières et des réfrigérateurs. Les risques de secousses électriques sont plus

élevés si le corps de l'utilisateur est mis à la terre.

• Protéger les outils électriques de la pluie ou des conditions mouillées. Une infiltration

d'eau dans l'outil augmente les risques de secousses électriques.

• Manipuler le cordon avec soin. Ne jamais se servir du cordon afin de transporter

l'outil ni tirer sur le cordon pour débrancher l'outil. Éloigner le cordon des sources de

chaleur, des flaques d'huile, des arêtes tranchantes et des pièces mobiles.

Remplacer immédiatement les cordons endommagés. Les cordons endommagés

augmentent les risques de secousses électriques.

• Lorsqu'on utilise un outil électrique à l'extérieur, se servir d'un cordon de rallonge

prévu pour l'extérieur, portant la mention "W -A" ou "W". Ces cordons sont conçus pour

servir à l'extérieur et minimisent les risques de secousses électriques.

SÉCURITÉ PERSONNELLE

• Demeurer vigilant, prendre soin et faire preuve de jugement lorsqu'on utilise un outil

Page 3

électrique. Ne pas s'en servir lorsqu'on est fatigué ou affaibli par des drogues, de

l'alcool ou des médicaments. De graves blessures peuvent résulter d'un moment

d'inattention lors de l'utilisation d'un outil électrique

• Porter des vêtements appropriés. Éviter de porter des vêtements amples ou des

bijoux. Recouvrir la chevelure si elle est longue. Éloigner les cheveux, les vêtements et

les bijoux des pièces en mouvement qui peuvent les happer.

• Éviter les démarrages accidentels. S'assurer que l'interrupteur est en position hors

tension avant de brancher l'outil. Afin d'éviter les risques de blessures, ne pas transporter

l'outil avec le doigt sur l'interrupteur ni brancher un outil dont l'interrupteur est en position

sous tension.

• Enlever les clés de réglage avant de mettre l'outil sous tension. Une clé qui est laissée

sur une pièce rotative de l'outil présente des risques de blessures.

• Ne pas dépasser sa portée. Garder son équilibre en tout temps. On s'assure d'une

meilleure maîtrise de l'outil dans des situations imprévues grâce à une position stable et un

bon équilibre.

• Porter de l'équipement de sécurité. Toujours porter des lunettes de sécurité. Dans

certaines conditions, il faut porter des masques respiratoires, des chaussures

antidérapantes, un casque de sécurité ou des protège-tympans..

UTILISATION ET ENTRETIEN DE L’OUTIL

• Utiliser des pinces de serrage ou de tout autre moyen pratique afin de fixer et de

soutenir la pièce à ouvrer sur une plate-forme stable. La pièce est instable lorsqu'elle est

retenue par la main ou le corps de l'utilisateur. Cela présente des risques de perte de

maîtrise de l'outil.

• Ne pas forcer l'outil. Utiliser l'outil approprié à la tâche. L'outil approprié fonctionne

mieux et sûrement lorsqu'on s'en sert à son rendement nominal.

• Ne pas se servir de l'outil lorsque l'interrupteur est défectueux. Le cas échéant, l'outil

est dangereux et il faut le réparer.

• Débrancher l'outil de la source d'alimentation avant de le régler, d'en remplacer les

accessoires ou de le ranger. On minimise de la sorte le risque de démarrage accidentel de

l'outil.

• Ranger l'outil hors de portée des enfants et de toute autre personne qui n'en connaît

pas le fonctionnement. L'outil est dangereux entre les mains de ces personnes.

• Prendre soin des outils. S'assurer que les outils de coupe sont tranchants et propres.

Des outils bien entretenus à arêtes tranchantes ont moins tendance à se coincer et ils se

maîtrisent mieux.

• Vérifier l'alignement et les attaches des pièces mobiles, le degré d'usure des pièces

ainsi que tout autre facteur susceptible de nuire au bon fonctionnement de l'outil.

Faire réparer un outil endommagé avant de s'en servir. Des outils mal entretenus sont la

cause de nombreux accidents.

• Utiliser seulement les accessoires recommandés par le fabricant. Des accessoires qui

conviennent à un outil peuvent présenter des risques avec un autre outil.

ENTRETIEN

• Confier l'entretien de l'outil seulement à du personnel qualifié. Le non-respect de la

présente directive présente des risques de blessures.

• Lors de l'entretien de l'outil, utiliser seulement des pièces de rechange identiques.

Respecter les consignes relatives à l'entretien du présent guide d'utilisation. Il y a

risque de secousses électriques ou de blessures lorsqu'on utilise des pièces non autorisées

ou lorsqu'on ne respecte pas les consignes relatives à l'entretien.

MESURES DE SÉCURITÉ SPÉCIFIQUES

• Les accessoires doivent pouvoir fonctionner au moins à la vitesse nominale

recommandée sur l’étiquette de l’outil. Les meules et tout autre accessoire utilisés à des

vitesses supérieures risquent d’éclater et de provoquer des blessures.

L’étiquette de l’outil peut comporter les symboles suivants.

V ....................................volts A..........................ampères

Hz ..................................hertz W ........................watts

min..................................minutes ......................courant alternatif

................................courant continu

n

o........................sous vide

....................................

construction de classe II

........................borne de terre

..................................symbole d´avertissement .../min ..................tours ou courses

RÈGLES DE SÉCURITÉ ADDITIONNELLES CONCERNANT LES OUTILS

ROTATIFS

TOUJOURS PORTER DES LUNETTES DE PROTECTION LORSQU’ON UTILISE CET

OUTIL!

• Si un accessoire reste bloqué, arrêter l’outil et le débrancher de l’alimentation électrique

avant de tenter de débloquer l’accessoire.

• Tenir l’outil par les surfaces isolées prévues à cette fin lorsque l’outil risque d’entrer en

contact avec des fils cachés ou son propre cordon, car de tels contacts peuvent mettre les

pièces métalliques sous tension, engendrant des risques de choc électrique.

• Lorsqu’on utilise une lame circulaire, toujours s’assurer que l’ouvrage soit fixé solidement.

Ne jamais tenter de tenir ce dernier d’une main et de manipuler un outil de coupe de l’autre.

• Tenir les mains éloignées de tout accessoire rotatif.

• Attendre que l’accessoire et la douille de serrage se soient refroidis avant de les toucher;

ces accessoires sont chauds après avoir fonctionné.

• S’assurer que l’ouvrage soit exempt de tout corps étrangers, comme des clous, car si l’outil

entre en contact avec ces derniers, on risque d’en perdre la maîtrise.

• Toujours pousser l’organe de coupe dans le même sens que celui dans lequel les copeaux

sont éjectés; autrement, on risque de perdre la maîtrise de l’outil.

• T enir les poignées sèches, propre et exemptes d’huile ou de graisse afin de mieux maîtriser

l’outil.

• Lorsqu’on coupe du bois, on doit prendre des précautions supplémentaires pour éviter

d’inhaler la poussière et pour réduire autant que possible tout contact avec la peau.

• Porter des protège-oreilles; l’utilisation de l’outil dans un espace clos amplifie davantage le

niveau de bruit.

• Le modèle RTX est doté d’une commande de réglage interne de vitesse; ne jamais utiliser

une commande de vitesse externe avec cet outil.

• Ne pas utiliser d’accessoires usés.

• Ne pas utiliser de meules fissurées.

• Lorsqu’on met l’outil en marche, le tenir éloigné du visage, car il existe un risque qu’un

accessoire endommagé soit projeté.

AVERTISSEMENT : certains outils électriques, tels que les sableuses, les scies, les

meules, les perceuses ou certains autres outils de construction, peuvent soulever de la

poussière

contenant des produits chimiques susceptibles d’entraîner le cancer, des malformations congénitales ou pouvant être nocifs pour le système reproductif. Parmi ces produits chimiques

(arséniate de cuivre et de chrome) on retrouve :

• le plomb dans les peintures à base de plomb;

• la silice cristalline dans les briques et le ciment et autres produits de maçonnerie;

• l’arsenic et le chrome dans le bois de sciage ayant subi un traitement chimique (CCA).

Le risque associé à de telles expositions peut varier selon la fréquence avec laquelle on

effectue ces travaux. Pour réduire l’exposition à de tels produits, il faut travailler dans un endroit

bien ventilé et utiliser l’équipement de sécurité approprié tel un masque anti-poussières spé-

cialement conçu pour filtrer les particules microscopiques.

RALLONGES

Le cas échéant, s’assurer que la rallonge soit en bon état avant de l’utiliser . Toujours utiliser une

rallonge qui convient à l’outil, c’est-à-dire dont le calibre des fils, la longueur du cordon et les

valeurs nominales correspondent à l‘outil alimenté. L’usage d’une rallonge de calibre insuffisant

pourrait causer une chute de tension entraînant une perte de puissance et une surchauffe. Pour

s’assurer qu’on utilise le calibre approprié, consulter le tableau ci-dessous.

DISPOSITIF DE VERROUILLAGE DE LA BROCHE

ARRÊTER ET DÉBRANCHER L’OUTIL.

La figure 1 illustre l’interrupteur de marche-arrêt et le dispositif de verrouillage de la broche.

Pour verrouiller la broche en vue de changer un accessoire, tirer sur le dispositif de

verrouillage, tel qu’illustré à la figure 2; une fois le dispositif complètement retiré vers l’arrière,

la broche est verrouillée. Installer ou retirer l’accessoire en suivant les directives contenues

dans ce manuel. Relâcher ensuite le dispositif de verrouillage de la broche

.

INTERRUPTEUR DE MARCHE-ARRÊT

Pour mettre l’outil en marche, glisser l’interrupteur vers l’avant; l’outil se mettra

immédiatement en marche à la vitesse sélectionnée. Ne pas tenter de démarrer l’outil

lorsque le dispositif de verrouillage de la broche est engagé; l’outil ne pourra pas démarrer.

SÉLECTON DE LA VITESSE

Avant d’utiliser l’outil, sélectionner la vitesse voulue au moyen de la commande de réglage

de vitesse (fig. 3), puis glisser l’interrupteur de marche-arrêt vers l’avant. On peut régler la

vitesse lorsque l’outil est en position de marche ou d’arrêt.

MISE EN GARDE : le modèle RTX est muni d’une commande de réglage de vitesse

distinct variant entre 8 000 et 30 000 t / min; comme l’outil démarre à la vitesse sélectionnée,

on doit s’assurer que l’interrupteur soit bien placé en position d’arrêt («OFF») avant de

brancher l’outil.

Les chiffres 1 à 6 apparaissant sur la commande de réglage de vitesse ne sont inscrits qu’à

titre indicatif; plus le chiffre est haut, plus la vitesse est élevée. Les chiffres correspondent

approximativement aux vitesses suivantes:

RÉGLAGE 1 23456

VITESSE APPROXIMATIVE 8,000 12,000 19,000 24,000 28,000 30,000

(t / min) (Les tours-minute réels peuvent varier.)

On doit s’assurer de choisir une vitesse appropriée à l’usage de l’outil. Le tableau suivant

indique les vitesses recommandées selon les travaux à effectuer .

En cas de doute, sélectionner une faible vitesse et augmenter graduellement le réglage

jusqu’à l’obtention de la vitesse appropriée.

Coupe du métal 5-6 Ébavurage 4-5

Ponçage du bois 5-6 Décapage du métal 4-5

Aiguisage 3-5 Gravure du métal 4-5

Polissage 1-2 Perçage de trous 4-5

Élimination de rouille 1-2

MISE EN GARDE : ne jamais utiliser une vitesse supérieure à celle recommandée pour

l’accessoire utilisé.

CHANGEMENT D’ACCESSOIRES

Les accessoires sont retenus dans une douille de serrage au moyen d’un écrou, tel

qu’illustré à la figure 4.

Pour insérer un accessoire, on doit:

1.Arrêter l’outil, attendre qu’il se soit complètement immobilisé, puis le débrancher de

l’alimentation électrique.

2.Tirer sur le dispositif de verrouillage de la broche (fig. 2) et saisir l’écrou de la douille de

serrage.

3.Tourner l’écrou vers la gauche, tel qu’illustré à la figure 5, pour desserrer cette dernière

complètement.

4.Insérer l’accessoire voulu dans la douille de serrage et l’enfoncer jusqu’au fond.

5.Serrer fermement l’écrou de la douille de serrage (en le tournant vers la droite).

REMARQUE: la douille doit toujours être serrée et desserrée manuellement; les

accessoires se serrent automatiquement durant l’usage. La clé fournie avec cet outil n’est

destinée qu’à desserrer des accessoires; on ne doit jamais utiliser la clé pour serrer l’écrou.

Ne jamais utiliser une clé autre que celle fournie avec cet outil, ni d’autres instruments qui

risquent d’endommager le fini de l’outil ou d’endommager la douille de serrage. Toujours

s’assurer d’avoir inséré un accessoire dans la douille avant de serrer celle-ci, car le serrage

d’une douille vide peut fendre cette dernière.

6.Relâcher le dispositif de verrouillage de la broche.

7.Si un accessoire semble causer la vibration de l’outil, on peut généralement rectifier le

problème en desserrant l’écrou de la douille de serrage, en enfonçant complètement

l’accessoire dans la douille et en le tournant d’un quart de tour, puis en resserrant la douille.

CHANGEMENT DE LA DOUILLE DE SERRAGE

Certains accessoires requièrent des douilles de serrage de différentes grandeurs; les douilles

convenant aux accessoires Black & Decker mesurent 0,32 cm ou 1/8 po (plus généralement

utilisées) et 0,24 cm (3/32 po). S’assurer que la dimension de la douille choisie corresponde

à l’accessoire utilisé.

POUR CHANGER LA DOUILLE DE SERRAGE, ON DOIT:

1.Arrêter l’outil, attendre qu’il se soit complètement immobilisé, puis le débrancher de

l’alimentation électrique.

2.Tirer sur le dispositif de verrouillage de la broche (fig. 2) et saisir l’écrou de la douille de

serrage.

3.Tourner l’écrou vers la gauche, puis retirer ce dernier , ainsi que la douille de la broche filetée

(fig. 4).

4.Insérer la douille voulue dans la broche.

5.Visser de nouveau l’écrou de la douille de serrage.

6.Relâcher le dispositif de verrouillage de la broche.

UTILISATION DE L’OUTIL ROTA TIF

AVERTISSEMENT : toujours porter des lunettes de protection.

On doit tenir l’outil fermement lorsqu’on l’utilise. Pour les travaux de précision, saisir la

section profilée à l’avant de l’outil, près de la broche. Avant de débuter un travail, il est

préférable de pratiquer sur des retailles jusqu’à ce qu’on se sente bien à l’aise avec l’outil.

Bien que cet outil rotatif soit petit et facile à utiliser, il s’agit tout de même d’un outil électrique

qu’on doit manipuler en tout temps avec précaution et de manière appropriée, conformément

aux directives contenues dans le présent manuel. Ne pas forcer l’outil; on peut en augmenter

le rendement en le laissant fonctionner à la vitesse pour laquelle il est destiné.

ARBRE FLEXIBLE DE RALLONGE RT5100 POUR OUTIL ROTATIF

(Vendu séparément ou fourni avec le numéro de catalogue R TX-2 seulement.)

DIRECTIVES D’INSTALLATION DE L’ARBRE FLEXIBLE

1.Arrêter l’outil, attendre qu’il se se soit complètement immobilisé, puis le débrancher de

l’alimentation électrique.

2.Retirer l’écrou et la douille de serrage en tirant sur le dispositif de verrouillage de la broche,

puis en saisissant l’écrou (fig. 2).

3.Tourner l’écrou vers la gauche, puis retirer ce dernier , ainsi que la douille de la broche filetée

(fig. 4). Relâcher le dispositif de verrouillage de la broche.

4. Retirer le couvercle du boîtier argenté (fig. 4) en le tournant vers la gauche.

5.Localiser l’écrou du dispositif d’entraînement et le fileter sur l’arbre moteur (fig. 6).

6.Visser l’arbre flexible sur l’outil rotatif, tel qu’illustré à la figure 7, en s’assurant que le noyau

central rotatif force le manchon carré de l’écrou dans le dispositif d’entraînement (fig. 7).

REMARQUE: lorsqu’on visse le carter métallique de l’arbre sur la section filetée de l’outil,

s’assurer de respecter le filetage.

7.L’ARBRE FLEXIBLE est maintenant prêt à être utilisé. Pour y insérer un accessoire, arrêter

l’outil, attendre qu’il se soit complètement immobilisé, puis le débrancher de l’alimentation

électrique. Mettre la goupille de sécurité dans l’ouverture de la pièce à main de l’ARBRE

FLEXIBLE et tourner l’écrou de la douille de serrage jusqu’à ce que la goupille engage

l’orifice dans la broche (fig. 8). Une fois l’arbre verrouillé, desserrer l’écrou de la douille de

serrage en le tournant vers la gauche, puis insérer l’accessoire dans la douille et l’enfoncer

jusqu’au fond afin de l’empêcher d’osciller . Serrer fermement l’écrou de la douille de serrage

à la main, puis retirer la goupille de sécurité.

8.On peut changer la douille de serrage de l’arbre flexible en suivant les directives dans la

section «Changement de la douille de serrage» du présent manuel.

IMPORTANT: éviter d’utiliser un arbre flexible courbé, comme celui illustré à la figure 9; on

Calibre minimal des cordons de rallonge

Tension Longueur totale du cordon en pieds

120 V De 0 à 25 De 26 à 50 De 51 à 100 De 101 à 150

240 V De 0 à 50 De 51à 100 De 101 à 200 De 201 à 300

Intensité (A)

Au Au Calibre moyen de fil (AWG)

moins plus

0-6 18 16 16 14

6 - 10 18 16 14 12

10 - 12 16 16 14 12

12 - 16 14 12 Non recommandé

Page 4

recommande d’utiliser un arbre ayant un rayon de 15,2 cm (6 po) ou plus. Un crochet de

suspension (fig. 4) est fourni pour permettre d’immobiliser l’outil lorsqu’on utilise un arbre

flexible et pour empêcher les courbures trop prononcées de se former.

REMARQUE: il peut arriver que le noyau central rotatif sorte de l’arbre flexible; si tel est le

cas, on n’a qu’à le réinsérer. Au besoin, nettoyer le noyau en l’essuyant au moyen d’un linge

et y appliquer une fine pellicule de graisse haute température. Il se peut que le dispositif

d’entraînement carré du noyau central ne bloque pas la pièce à main; si cela se produit,

appliquer une légère pression sur l’extrémité du noyau tout en tournant l’écrou de la douille

de serrage de la pièce à main.

ENTRETIEN

Nettoyer l’outil au moyen d’un savon doux et d’un linge humide seulement. Ne jamais laisser

de liquide s’infiltrer à l’intérieur de l’outil ni tremper ce dernier dans un liquide quelconque.

IMPORTANT: pour assurer la SÉCURITÉ et la FIABILITÉ de cet outil, toutes les opérations

de réparation, d’entretien et de réglage (autres que celles décrites aux présentes) doivent

être effectuées par un centre de service autorisé ou qualifié; seules des pièces de rechange

identiques doivent être utilisées. L’outil ne comprend aucune pièce interne destinée à être

entretenue par l’utilisateur.

ACCESSOIRES

Black & Decker offre une vaste sélection d’accessoires vendus séparément chez les

dépositaires locaux ou les centres de service autorisés. On ne doit utiliser que les

accessoires Black & Decker recommandés pour le modèle RTX ou l’arbre flexible.

Pour obtenir de l’aide concernant l’achat d’un accessoire, composer le 1 800 544-6986.

MISE EN GARDE : n’utiliser que les accessoires ayant une vitesse de rotation de 30 000

t / min ou plus, à l’exception de ce qui suit: ne pas utiliser de brosse en métal ou en soie, de

ponceuse avec dôme au diamant ni de meule au diamant de 3,18 cm (1-1/4 po) à des

vitesses supérieures à 15 0000 t / min. (réglage no 2). Ne jamais dépasser la vitesse

recommandée pour l’accessoire utilisé.

AVERTISSEMENT :l’usage d’un accessoire non recommandé peut présenter un danger.

INFORMATION SUR LES SER VICES

Black & Decker dispose d’un réseau complet composé de centres de service et de centres

autorisés situés partout en Amérique du Nord. Tous les centres de service Black & Decker

sont dotés de personnel qualifié en matière d’outillage électrique; ils sont donc en mesure

d’offrir à leur clientèle un service ef ficace et fiable.

Pour obtenir un conseil technique ou une pièce d’origine ou pour faire réparer un outil, on

peut communiquer avec le centre Black & Decker le plus près de chez soi. Pour obtenir le

numéro de téléphone, consulter les pages jaunes sous la rubrique «Outils - électriques» ou

composer le 1 800 544-6986.

RENSEIGNEMENTS RELATIFS AU SERVICE

Black & Decker exploite un réseau complet de centres de service et d'ateliers d'entretien

autorisés par toute l'Amérique du Nord. Le personnel de tous les centres de service Black &

Decker a reçu la formation voulue pour assurer l'entretien efficace et fiable des outils

électriques.

Pour obtenir des renseignements d'ordre technique, des conseils relatifs aux réparations ou

des pièces de rechange d'origine, communiquer avec le centre de service Black & Decker de

la région.

On peut trouver l'adresse du centre de service de la région dans l'annuaire des Pages

Jaunes à la rubrique «Outils électriques» ou en composant le numéro suivant :

1 (800) 544-6986.

GARANTIE COMPLÈTE DE CINQ ANS POUR USAGE RÉSIDENTIEL

Black & Decker (U.S.) Inc. garantit ce produit pour une période de cinq ans contre tout défaut

de matériel ou de fabrication. Le produit défectueux sera remplacé ou réparé sans frais,

suivant l’un des deux modes suivants.

Le premier mode consiste en un échange seulement. On doit retourner le produit au

détaillant qui l’a vendu (pourvu qu’il s’agisse d’un détaillant participant), en respectant les

délais stipulés dans sa politique relative aux échanges (normalement de 30 à 90 jours après

la vente). Une preuve d’achat peut être requise. On doit vérifier la politique de retour du

détaillant pour tout produit retourné après le délai prescrit pour les échanges.

Le deuxième mode consiste à emporter ou à envoyer le produit (prépayé) à un centre Black

& Decker ou à un centre de service autorisé aux fins de réparation ou de remplacement,

selon notre choix. Une preuve d’achat peut être requise. Les centres Black & Decker et les

centres de service autorisés sont répertoriés dans les pages jaunes sous la rubrique «Outils

- électriques». Cette garantie ne s’applique pas aux accessoires. Elle confère des droits

légaux particuliers à l’acheteur, mais celui-ci pourrait aussi bénéficier d’autres droits différant

d’un territoire à l’autre.

Toute question doit être adressée au gérant du centre Black & Decker le plus près de chez

soi.

REMARQUE: cet outil est conçu, fabriqué et vérifié afin de satisfaire – et même surpasser –

les besoins des bricoleurs qui effectuent des travaux ou des réparations à la maison. Utilisé

convenablement, cet outil peut offrir de nombreuses années de service. Cependant, cet outil,

comme tous les autres produits pour usage résidentiel de Black & Decker destinés aux

consommateurs, n’est pas conçu pour un usage professionnel en chantier; l’utiliser ainsi

ANNULE DONC TOUTE GARANTIE.

Imported by / Importé par

Black & Decker Canada Inc.

100 Central Ave.

Brockville (Ontario) K6V 5W6

Voir la rubrique “Outils électriques”

des Pages Jaunes

pour le service et les ventes.

MANUAL DE INSTRUCCIONES

Númerode catálogoRTX

INFORMACIÓN CLA VE QUE SE DEBE SABER:

· No apriete la cabeza de la pinza de portapiezas

· No accione la manecilla de fijación hasta que la herramienta pare completamente

ANTES DE DEVOLVER ESTE PRODUCTO POR CUALQUIER

RAZON POR FAVOR LLAME

326-7100

CONSERVE ESTE MANUAL PARA REFERENCIAS FUTURAS

• Evite el contacto corporal con superficies aterrizadas tales como tuberías,

radiadores, hornos y refrigeradores. Hay un gran riesgo de choque eléctrico si su cuerpo

hace tierra.

• No exponga las herramientas eléctricas a la lluvia o a condiciones de mucha

humedad. El agua que se introduce en las herramientas aumenta el riesgo de descargas

eléctricas.

• No maltrate el cable. Nunca tome el cable para transportar una herramienta ni para

desconectarla de la toma de corriente. Consérvelo alejado de calor aceite, bordes

afilados o piezas móviles. Cambie inmediatamente los cables dañados. Los cables

dañados aumentan el riesgo de choque eléctrico.

• Cuando opere una herramienta eléctrica a la intemperie, utilice una extensión

marcada "W-A" o "W". Estas extensiones están clasificadas para uso a la intemperie y

para reducir el riesgo de choques eléctricos.

SEGURIDAD PERSONAL

• Esté alerta, concéntrese en lo que está haciendo. Recurra al sentido común cuando

opere una herramienta eléctrica. No opere ninguna herramienta si se encuentra

fatigado o bajo la influencia de drogas, alcohol o medicamentos. Un momento de

desatención mientras se operan herramientas eléctricas puede ocasionar lesiones graves.

• Vístase de manera adecuada. No tenga puestas ropas o artículos de joyería flojos.

Cubra su cabello si lo tiene largo. Conserve su cabello, sus ropas y guantes alejados

de las piezas móviles. Las piezas de vestir flojas, las joyas y el cabello largo pueden

resultar atrapados por las piezas móviles.

• Evite el encendido accidental. Asegúrese que el interruptor esté en posición de

apagado antes de conectar. Sostener una herramienta con el dedo en el interruptor o

conectarla sin fijarse si el interruptor está en posición de encendido propicia los accidentes.

• Retire las llaves de ajuste antes de encender la herramienta. Una llave que se deja en

una pieza giratoria puede ocasionar lesiones personales.

• No se sobreextienda. Conserve siempre los pies bien apoyados, al igual que el

equilibrio. La posición correcta de los pies y el equilibrio permiten controlar mejor la

herramienta en situaciones inesperadas.

• Utilice equipo de seguridad. Siempre utilice protección en los ojos. Se deben utilizar

mascarillas contra polvo, zapatos antiderrapantes, casco o protectores para los oídos para

tener las condiciones apropiadas.

USO Y CUIDADOS DE LAHERRAMIENTA

• Utilice prensas u otros medios prácticos para asegurar y apoyar la pieza de trabajo en

una plataforma estable. Sujetar las piezas con la mano o contra su cuerpo es inestable y

puede originar la pérdida de control.

• No fuerce la herramienta. utilice la herramienta apropiada para su aplicación. La

herramienta apropiada hará el trabajo mejor y de manera más segura bajo las

especificaciones para las que se diseñó.

• No utilice la herramienta si el interruptor no enciende y apaga. Cualquier herramienta

que no pueda controlarse por medio del interruptores peligrosa y debe reemplazarse.

• Desconecte la clavija de la toma de corriente antes de hacer cualquier ajuste, cambio

de accesorios o de guardar la herramienta. Tales medidas de seguridad preventivas

reducirán el riesgo de que la herramienta se encienda accidentalmente.

• Guarde las herramientas fuera del alcance de los niños y de otras personas no

capacitadas. Las herramientas son peligrosas en manos de personas no capacitadas.

• Cuide sus herramientas. Conserve las herramientas de corte afiladas y limpias. Las

herramientas que reciben un mantenimiento adecuado, con piezas de corte afiladas,

difícilmente se atascan y son más fáciles de controlar.

• Verifique la alineación de las piezas móviles, busque fracturas en las piezas y

cualesquiera otras condiciones que puedan afectar la operación de las herramientas.

Si está dañada, lleve su herramienta a servicio antes de usarla de nuevo. Muchos

accidentes se deben a herramientas con mantenimiento pobre.

• Solamente use accesorios que el fabricante recomiende para su modelo de

herramienta. Los accesorios que estén diseñados para una herramienta, pueden volverse

peligrosos cuando se emplean con otra.

SERVICIO

• El servicio a las herramientas lo debe efectuar únicamente personal calificado. El

servicio o mantenimiento realizado por personal no calificado puede originar riesgos de

lesiones.

• Cuando efectúe servicio a una herramienta, utilice únicamente refacciones idénticas.

Siga las instrucciones de la sección de Mantenimiento de este manual. El empleo de

piezas no autorizadas o no seguir las instrucciones de mantenimiento puede originar riegos

de choque eléctrico o lesiones.

REGLAS ESPECIFICAS DE SEGURIDAD

• Los accesorios deberán estar clasificados para al menos la velocidad recomendada

en la etiqueta de advertencia de la herramienta. Los discos y otros accesorios que

funcionen a una velocidad mayor pueden salir despedidos con el consiguiente riesgo de

lesiones.

La etiqueta de su herramienta puede incluir los siguientes símbolos.

V ..........................volts A..........................amperes

Hz ........................hertz W ........................watts

min........................minutos ......................corriente alterna

......................corriente directa

n

o........................velocidad sin carga

..........................construcción clase II

........................erminales de

conexión a tierre

........................símbolo de alerta seguridad .../min ..................revoluciones o

reciprocaciones por

minuto

REGLAS ADICIONALES DE SEGURIDAD PARA HERRAMIENTAS

ROTATORIAS

¡SIEMPRE USE PROTECCIÓN PARALOS OJOS CUANDO USE ESTAHERRAMIENTA!

• Si el accesorio se atasca, apague la herramienta y desconéctela antes de liberar el

accesorio del atasco.

• Sostenga la herramienta por las superficies con aislamiento para agarrar cuando haga un

trabajo en que la herramienta de cortar pueda entrar en contacto con alambres escondidos o

con su propio cordón. El contacto con un hilo con electricidad puede hacer que las partes

metálicas de la herramienta se electrifiquen y le den un golpe de corriente al operador.

• Cuando use una rueda de recortar siempre engrape con seguridad el objeto de trabajo.

Nunca intente sostener el objeto con una mano mientras use algún accesorio cortante.

• Aleje las manos de todos los accesorios rotatorios.

• Deje que los accesorios y pinzas portapiezas se enfríen antes de tocarlos con las manos

descubiertas. Se calientan al usarse.

• Asegúrese de que no hayan objetos extraños en la pieza de trabajo tales como clavos; si se

llegaran a tocar podrían hacerle perder el control sobre la unidad.

• Siempre introduzca la cuchilla en el material en la misma dirección en que se arrojan las

astillas. Si se introduce la cuchilla en la dirección equivocada podría causar pérdida del

control.

• Mantenga las manillas secas, sin aceite ni grasa. Eso le permitirá tener un mejor control

sobre la herramienta.

• Cuando corte madera, debe tener mayor cuidado para evitar inhalar y minimizar el contacto

de partículas con la piel.

• Use protección para los oídos. El ruido puede ser amplificado cuando una herramienta se

usa en espacios cerrados.

• El RTX tiene un control interno de la velocidad, nunca use un control externo de la velocidad

en esta unidad.

• No use accesorios gastados.

• No use muelas abrasivas que tengan quebraduras.

• Al encender la herramienta, sosténgala lejos de su cara, ya que podría saltar un accesorio

dañado.

ADVERTENCIA : Parte del polvo producido al lijar, aserruchar, perforar y otras

actividades de construcción contiene sustancias químicas que se sabe producen cáncer,

defectos congénitos u otras lesiones al sistema reproductivo. Algunos ejemplos de esas

sustancias químicas son:

• plomo de pinturas a base de plomo,

• sílice cristalino de ladrillos y cemento y otros productos de albañilería, y

• arsénico y cromo de la madera tratada químicamente (CCA).

El riesgo que usted corre al exponerse a esas sustancias varía, según la frecuencia que

REGLAS GENERALES DE SEGURIDAD

ADVERTENCIA: Lea y comprenda todas las instrucciones. No seguir todas las

instrucciones enlistadas a continuación puede resultar en choque eléctrico, incendio y(o)

lesiones personales de gravedad.

CONSERVE ESTAS INSTRUCCIONES

AREA DE TRABAJO

• Conserve su área de trabajo limpia y bien iluminada. Las bancas amontonadas y las

zonas oscuras propician los accidentes.

• No opere herramientas eléctricas en atmósferas explosivas, como en presencia de

líquidos, gases o polvos inflamables. Las herramientas eléctricas producen chispas que

pueden originar la ignición de los polvos o los vapores.

• Conserve a observadores, niños y visitantes alejados mientras opera una

herramienta eléctrica. Las distracciones pueden ocasionar que pierda el control.

SEGURIDAD ELECTRICA

• Las herramientas con doble aislamiento están equipadas con una clavija polarizada

(con una pata más ancha que la otra.) Esta clavija se acoplará únicamente en una

toma de corriente polarizada de una manera. Si la clavija no se acopla al contacto,

inviértala. Si aún así no se ajusta, comuníquese con un electricista calificado para

que le instalen una toma de corriente polarizada apropiada. El doble aislamiento

elimina la necesidad de cables con tres hilos y sistemas de alimentación con conexión a

tierra.

Page 5

haga ese tipo de trabajo. Para reducir la exposición a eas sustancias químicas: trabaje en

espacios bien ventilados y hágalo con equipos de seguridad aprobados, tales como

máscaras contra el polvo especialmente diseñadas para filtrar las partículas microscópicas.

USO DE CORDONES ALARGADORES

Antes de usar cordones alargadores asegúrese de que estén en buen estado. Siempre use

los alargadores del tamaño adecuado para la herramienta -- es decir, que los hilos tengan el

calibre apropiado para los distintos largos de cordón y suficientemente pesados para llevar

la corriente que la herramienta requiera. El uso de un cordón de tamaño menor causará la

caída de voltaje en la línea resultando en la pérdida de poder y calentamiento excesivo.

Consulte el cuadro de abajo para ver el tamaño apropiado de cordones.

MANECILLA DE FIJACIÓN DEL HUSILLO

APAGUE YDESCONECTE LAHERRAMIENT ADEL ENCHUFE.

La ilustración 1 muestra el interruptor y la manecilla de fijación del husillo. Para fijar el husillo

a fin de cambiar de accesorio, eche hacia atrás la manecilla de fijación del husillo tal como

se muestra en la ilustración 2. Con la manecilla totalmente hacia atrás el husillo queda

fijado. Instale o saque los accesorios tal como se instruya en este manual. Libere la

manecilla de fijación del husillo y ya lo habrá hecho.

INTERRUPTOR DE ENCENDIDO/AP AGADO

Para encender la herramienta, apriete el botón interruptor hacia adelante. La herramienta

empezará a funcionar de inmediato a la velocidad seleccionada. No intente hacer arrancar

la herramienta con la manecilla de fijación del husillo apretado. No funcionará.

SELECCIÓN DE LA VELOCIDAD

Para operar la herramienta, seleccione la velocidad que usted desee en la rueda de

velocidades, como se muestra en la ilustración 3, y apriete el interruptor hacia adelante. La

velocidad se puede ajustar ya esté la herramienta funcionando o esté apagada.

AVISO : Dado que el RTX tiene una rueda de velocidades aparte para fijar la velocidad

(8.000 - 30.000 RPM), la herramienta empezará a la velocidad que se haya fijado en la

rueda de velocidades. Asegúrese de que el interruptor esté en posición de apagado antes

de enchufar.

Las posiciones numeradas, del 1 al 6 en la rueda de velocidades, no indican una velocidad

precisa pero son buenos puntos de referencia. Mientras mayor sea el número, mayor la

velocidad de la herramienta.

La velocidad aproximada de cada punto es:

VEL.SELEC 123456

VEL. APROX 8,000 12,000 19,000 24,000 28,000 30,000

(Las RPM efectivas en su herramienta pueden ser diferentes)

Seleccione la velocidad adecuada para el funcionamiento de su herramienta rotatoria. El

cuadro siguiente entrega orientación sobre la velocidad para los diversos trabajos.

Si tiene alguna duda sobre la velocidad apropiada para su trabajo, ensaye el

funcionamiento a velocidades bajas y auméntela paulatinamente hasta encontrar una

velocidad conveniente.

Cortar metal 5-6 Desbarbado 4-5

Lijar madera 5-6 Desmontaje de metal 4-5

Afilar 3-5 Gravado de metal 4-5

Pulir 1-2 Perforar agujeros 4-5

Sacar herrumbre 1-2

AVISO : Nunca emplee un accesorio a una velocidad superior de la requerida para ese

accesorio.

CAMBIO DE ACCESORIOS

Los accesorios son sostenidos en su lugar por una pinza portapiezas y la cabeza de la

pinza portapiezas tal como se muestra en la ilustración 4.

Para insertar un accesorio:

1. Apague la herramienta, deje que se pare completamente y desconéctela del enchufe.

2. Tire hacia atrás la manecilla de fijación del husillo (véase ilust. 2) y tome la cabeza de la

pinza portapiezas.

3. Gire la cabeza de la pinza portapiezas en sinistrorso (a izquierdas) tal como se muestra

en la Ilust. 5 hasta soltarla.

4. Inserte el nuevo accesorio en la pinza portapiezas hasta el fondo.

5. Apriete bien, en el sentido de las manecillas del reloj (a derechas), la cabeza de la pinza

portapiezas. NOTA: La pinza portapiezas fue diseñada para ser apretada o ser soltada

a mano solamente. Los accesorios se aprietan naturalmente en el uso. Se provee una

llave inglesa con la herramienta para soltarla. Nunca debería necesitar apretar la cabeza

de la pinza portapiezas con la llave inglesa. Si necesita usar la llave inglesa, use solamente la que se provee. No use herramientas que vayan a dañar el acabado y podrían

quebrar la pinza portapiezas. Asegúrese de que hay algún accesorio en la pinza portapiezas antes de apretar. Si se aprieta una pinza portapiezas vacía puede romperse.

6. Suelte la manecilla de fijación del husillo y está terminado.

7. Si un accesorio causa vibración puede normalmente mejorarse soltando la cabeza de la

pinza portapiezas, empujando el accesorio hasta el fondo y rotándolo 1/4 de vuelta y

volviendo a apretar la cabeza de la pinza portapiezas.

CAMBIO DE LA PINZAPORTAPIEZAS

Algunos accesorios requieren pinzas portapiezas de diferentes tamaños. Las dos pinzas

portapiezas usadas en los accesorios de Black & Decker son de 1/8 de pulgada (usada

para la mayoría de los accesorios) y 3/32 de pulgada. Asegúrese de que el tamaño de

la pinza portapiezas corresponde al accesorio utilizado.

PARACAMBIAR LA PINZA PORTAPIEZAS

1. Apague la herramienta, deje que se pare completamente y desconéctela del enchufe.

2. Tire hacia atrás la manecilla de fijación del husillo (véase ilust. 2) y tome la cabeza de la

pinza portapiezas.

3. Gire la cabeza de la pinza portapiezas en sinistrorso (a izquierdas), saque la cabeza de

la pinza portapiezas y la pinza portapiezas del husillo con rosca (véase ilust. 4).

4. Inserte la nueva pinza portapiezas en el husillo.

5. Atornille la cabeza de la pinza portapiezas.

6. Suelte la manecilla de fijación del husillo.

USO DE LA HERRAMIENT AROTA TORIA

ADVERTENCIA : Siempre use protección para los ojos.

Cuando trabaje con la herramienta sosténgala firmemente. Para hacer trabajo detallado,

agarre la superficie curva en la parte delantera de la herramienta, cerca del husillo. Antes de

comenzar un proyecto, practique usando la herramienta en algún material de desecho

hasta que capte el modo de funcionar de la herramienta. La herramienta rotatoria es

pequeña y fácil de usar pero no se equivoque; es una verdadera herramienta motorizada y

se debe manejar con cuidado y en forma adecuada tal como se describe en este manual.

No recargue la herramienta. El rendimiento mejora al dejar que la herramienta haga el

trabajo.

EXTENSOR FLEXIBLE DE HERRAMIENTAROTA T ORIART5100 DE BARRAFLEXIBLE

(Disponible como accesorio separado e incluido en el catálogo con el número RTX-2)

INSTRUCCIONES PARAINSTALACIÓN DE BARRAFLEXIBLE

1. Apague la herramienta, deje que pare completamente y desconéctela del enchufe.

2. Saque la cabeza de la pinza portapiezas y la pinza misma de la herramienta tirando

primero hacia atrás la manecilla de fijación del husillo y tomando la cabeza de la pinza

portapiezas (ilust. 2).

3. Gire la cabeza de la pinza portapiezas en sinistrorso (a izquierdas), saque la cabeza de

la pinza portapiezas y la pinza portapiezas del husillo con rosca (véase ilust. 4). Libere

la manecilla del husillo.

4. Saque la tapa de la envuelta plateada (ilust. 4) dándole vuelta en sinistrorso (a izquier-

das).

CCalibre mínimo para cordones de extensión

Volts Longitud total del cordón en metros

120V 0-7,6 7,6-15,2 15,2-30,4 30,4-45,7

240V 0-15,2 15,2-30,4 30,4-60,9 60,9-91,4

Amperje

Más No más Calibre del cordón AWG

de de

0-6 18 16 16 14

6 -10 18 16 14 12

10 -12 16 16 14 12

12 -16- 14 12 No recomendado

5. Ubique la tuerca y rósquela en la barra del motor (ilust. 6).

6. Atornille la Barra flexible en la herramienta rotatoria tal como se muestra en la ilust. 7, asegurándose de que el núcleo central rotatorio haya encajado en el agujero cuadrado en la

punta impulsora (ilust. 7). NOTA: Use cautela al atornillar la envuelta de metal de la barra

a la porción con rosca de la herramienta rotatoria. Evite estropear la rosca.

7. La BARRAFLEXIBLE está ahora lista para ser usada. Para insertar un accesorio, apague

la herramienta, deje que pare completamente y desconéctela del enchufe. Ponga el

pasador provisto en la abertura de la manilla de la BARRA FLEXIBLE y haga rotar la

cabeza de la pinza portapiezas hasta que el pasador se conecte al agujero del husillo

(ilust. 8). Después de que la barra esté trabada, gire la pinza portapiezas sinestrorso (a

izquierdas) para soltarla. Inserte el accesorio completamente en la pinza portapiezas

para evitar oscilaciones irregulares. Apriete bien la cabeza de la pinza portapiezas con la

mano. Saque el pasador.

8. La pinza portapiezas de Barra flexible puede cambiarse en la forma descrita en la sección

"Cambio de pinza portapiezas".

IMPORTANTE: Evite usar la barra flexible con una curva acentuada tal como la que se

muestra en la ilust. 9. Se recomienda un radio de 6 pulgadas o más. Se suministra un

colgador de herramientas (ilust. 4) para colgar la herramienta cuando use la barra flexible. El

colgador salvaguarda la herramienta y ayuda a evitar las curvas acentuadas en la barra

flexible.

NOTA: El eje rotatorio puede salirse de la barra flexible. Eso no es problema. Simplemente

reinsértelo en la barra flexible. Si el eje central se ensucia, límpielo y aplique un capa fina de

grasa de alta temperatura.. La cabeza cuadrada del eje no puede contactar la pieza de

mano. Para que conecte, aplique una fuerza ligera en la punta del núcleo central al mismo

tiempo que haga rotar la cabeza de la pinza portapiezas de mano.

SERVICIO

Use sólo jabón suave y un paño húmedo para limpiar la herramienta. Nunca deje que ningún

líquido penetre la herramienta; nunca sumerja ninguna parte de la herramienta en un líquido.

IMPORTANTE: Afin de asegurar la SEGURIDAD y CONFIABILIDAD , las reparaciones, el

servicio y ajustes (que no sean los enumerados en este manual) deben ser realizados por

centros de servicio autorizados o por organizaciones de servicio calificadas, siempre usando

repuestos idéntico. La unidad no contiene piezas de cuyo servicio pueda encargarse el

usuario.

ACCESORIOS

Black and Decker ofrece una gran selección de accesorios que se pueden obtener en el

concesionario local o en los centros de servicio autorizados sin costo extra. Se recomienda

usar sólo accesorios de Black and Decker en el RTX y el B&D Barra flexible.

Si necesita asistencia respecto de los accesorios, llame al teléfono: 1-800-544-6986.

AVISO : Use sólo los accesorios para 30.000 RPM o más. Excepción: No emplee

brochas de alambres, brochas de cerdas, lijador de diamante convexo, o ruedas de

diamantes de 1-1/4 pulgada a velocidades de más de 15.000 RPM (velocidad número 2).

Nunca exceda la velocidad en que deba funcionar un accesorio.

ADVERTENCIA : Puede ser peligroso usar accesorios no recomendados para ser

usados en esta herramienta.

INFORMACIÓN SOBRE EL SERVICIO

Black & Decker ofrece una red completa de centros de servicio propiedad de la compañía y

autorizados en toda América del Norte. Todos los centros de servicio de Black & Decker

cuentan con personal entrenado para proporcionarles a los clientes un servicio eficiente y

seguro de sus herramientas.

Ya sea que usted necesite asesoría técnica, o respuestos genuinos de fábrica, contacte el

centro de Black & Decker más cercano.

Para encontrar el centro de servicio local, vea las páginas amarillas de la guía telefónica bajo

el encabezamiento "Herramientas-eléctricas" o llame: 1-800-544-6986.

GARANTÍA DE CINCO AÑOS POR USO EN ELHOGAR

Black & Decker (U.S.) Inc. garantiza este producto por cinco años contra todo defecto en

material o factura. El producto defectuoso será reemplazado o reparado sin costo en una de

dos formas.

La primera, que resultará en intercambio solamente, es devolver el producto al comerciante

minorista donde usted lo compró (siempre que la tienda sea un comerciante que participe).

Las devoluciones se deben hacer en el plazo establecido en la política de intercambios del

comerciante (normalmente 30 a 90 días después de la venta). Puede exigirse un

comprobante de compra. Por favor, consulte al comerciante respecto a su política específica

de devolución con respecto a las devoluciones que se deseen hacer después de haber

vencido el plazo de intercambios.

La segunda opción es tomar o enviar el producto (prepagado) a un Centro de servicio de

propiedad de Black & Decker o autorizado por la compañía para repararlo o reemplazarlo,

según sea su decisión. Puede exigirse un comprobante de compra. Los centros de servicio

de propiedad de Black & Decker o autorizados por la compañia aparecen en las páginas

amarillas de la guía telefónica bajo el encabezamiento de "herramientas-eléctricas".

Esta garantía no se aplica a los accesorios. Esta garantía le da a usted derechos legales

específicos y usted puede tener otros derechos que varían de un estado a otro. En caso de

que tenga preguntas, contacte al gerente del Centro de servicio de Black & Decker más

cercano.

NOTA: Esta herramienta ha sido diseñada, fabricada y probada para cumplir o exceder las

necesidades de las personas que les gusta trabajar por su cuenta en la ejecución de

proyectos y reparaciones en la casa. Si se usa en forma apropiada le proveerá al dueño de

casa años de servicio. No obstante, si usa las herramientas para ganarse la vida y usa este

producto en el lugar de trabajo, o cualquier otra herramienta de Black & Decker

específicamente diseñada para uso del consumidor en casa, debe usted tomar conocimiento

de que NO ESTÁN CUBIERTAS POR NUESTRAGARANTÍA.

PARAREPARACION YSERVICIO DE SUS HERRAMIENTAS ELECTRICAS FAVOR DE

DIRIGIRSE ALCENTRO DE SERVICIO MAS CERCANO

CULIACAN

Av . Nicolas Bravo #1063 Sur (91 671) 242 10

GAUDALAJARA

Av . La Paz #1779 (91 3) 826 69 78.

MEXICO

Eje Lázaro Cárdenas No. 18 Local D, Col. Obrera 588-9377

MERIDA

Calle 63 #459-A (91 99) 23 54 90

MONTERREY

Av . Francisco I. Madero Pte. 1820-A (91 83) 72 11 25

PUEBLA

17 Norte #205 (91 22) 46 37 14

QUERETARO

Av . Madero 139 Pte. (91 42) 14 16 60

SAN LOUIS POTOSI

Pedro Moreno #100 Centro (91 48) 14 25 67

TORREON

Blvd. Independencia, 96 pte. (91 17) 16 52 65

VERACRUZ

Prolongación Diaz Miron #4280 (91 29) 21 70 16

VILLAHERMOSA

Constitucion 516-A (91 93) 12 53 17

PARAOTRAS LOCALIDADES LLAME AL: 326 7100

BLACK & DECKER S.A. DE C.V.

BOSQUES DE CIDROS ACCESO RADIATAS NO. 42

COL. BOSQUES DE LAS LOMAS.

05120 MÉXICO, D.F

TEL. 3-26-71-00

Para servicio y ventas consulte

“HERRAMIENTAS ELECTRICAS”

en la sección amarilla.

ESPECIFICACIONES

Tensión de alimentación: 120 V~

Potencia nominal: 223 W

Frecuencia de operacion: 60 Hz

Consumo de corriente: 2A

Loading...

Loading...