Page 1

VEA EL ESPAÑOL EN LA CONTRAPORTADA.

SAVE THIS MANUAL FOR FUTURE REFERENCE.

INSTRUCTIVO DE OPERACIÓN, CENTROS DE SERVICIO YPÓLIZADE

GARANTÍA. ADVERTENCIA: LÉASE ESTE INSTRUCTIVO ANTES DE USAR EL

PRODUCTO.

CATALOG NUMBER - RS250

INSTRUCTION MANUAL

RR

RR

OO

OOTTTTAAAA

RR

RRYYYY SSSSAAAA

WW

WW

BEFORE RETURNING

THIS PRODUCT

FOR ANY REASON

PLEASE CALL

1 800 544 6986

IF YOU SHOULD EXPERIENCE

APROBLEM

WITH YOUR BLACK &DECKER

PRODUCT,

CALL 1 800 544 6986

BEFORE YOU CALL, HA VE THE

FOLLOWING INFORMATION AVAILABLE,

CATALOG No., TYPE No., AND DATE CODE

(e.g. 0130M). IN MOST CASES, ABLACK &

DECKER REPRESENTATIVE CAN

RESOLVE YOUR PROBLEM OVER THE

PHONE. IF YOU HA VE ASUGGESTION OR

COMMENT, GIVE US ACALL. YOUR

FEEDBACK IS VITALTO BLACK & DECKER.

611197-01 RS250 Rotary Tool 10/22/02 2:27 PM Page 1

Page 2

WARNING:Read and understand all

instructions. Failure to follow all

instructions listed below may result in

electric shock, fire and/or serious personal

injury.

SAVE THESE INSTRUCTIONS

Work Area

• Keep your work area clean and well

lit. Cluttered benches and dark areas

invite accidents.

• Do not operate power tools in

explosive atmospheres, such as in

the presence of flammable liquids,

gases, or dust. Power tools create

sparks which may ignite the dust or

fumes. Use in well ventilated areas only.

• Keep bystanders, children, and

visitors away while operating a power

tool. Distractions can cause you to lose

control.

Electrical Safety

• Double insulated tools are equipped

with a polarized plug (one blade is

wider than the other.) This plug will fit

in a polarized outlet only one way. If

the plug does not fit fully in the outlet,

reverse the plug. If it still does not fit,

contact a qualified electrician to

install a polarized outlet. Do not

change the plug in any way. Double

insulation eliminates the need for the

three wire grounded power cord and

grounded power supply system.

• Avoid body contact with grounded

surfaces such as pipes, radiators,

ranges and refrigerators. There is an

increased risk of electric shock if your

body is grounded.

• Don’t expose power tools to rain or

wet conditions. Water entering a power

tool will increase the risk of electric

shock.

• Do not abuse the cord. Never use the

cord to carry the tools or pull the plug

from an outlet. Keep cord away from

heat, oil, sharp edges or moving

parts. Replace damaged cords

immediately. Damaged cords increase

the risk of electric shock.

• When operating a power tool outside,

use an outdoor extension cord

marked "W-A" or "W ." These cords are

rated for outdoor use and reduce the risk

of electric shock.

Personal Safety

• Stay alert, watch what you are doing

and use common sense when

operating a power tool. Do not use

tool while tired or under the influence

of drugs, alcohol, or medication. A

moment of inattention while operating

power tools may result in serious

personal injury.

• Dress properly. Do not wear loose

clothing or jewelry. Contain long hair.

Keep your hair, clothing, and gloves

away from moving parts. Loose

clothing, jewelry, or long hair can be

caught in moving parts. Air vents cover

moving parts and should be avoided.

• Avoid accidental starting. Be sure

switch is off before plugging in.

Carrying tools with your finger on the

switch or plugging in tools that have the

switch on invites accidents.

• Remove adjusting keys or wrenches

before turning the tool on. Awrench or

key that is left attached to a rotating part

of the tool may result in personal injury.

• Do not overreach. Keep proper

footing and balance at all times.

Proper footing and balance enables

better control of the tool in unexpected

situations.

• Use safety equipment. Always wear

eye protection. Dust mask, non-skid

safety shoes, hard hat, or hearing

protection must be used for appropriate

conditions.

Tool Use and Care

• Use clamps or other practical way to

secure and support the workpiece to

a stable platform. Holding the work by

hand or against your body is unstable

and may lead to loss of control.

• Do not force tool. Use the correct tool

for your application. The correct tool

will do the job better and safer at the rate

for which it is designed.

• Do not use tool if switch does not

turn it on or off. Any tool that cannot be

controlled with the switch is dangerous

and must be repaired.

• Disconnect the plug from the power

source before making any

adjustments, changing accessories,

or storing the tool. Such preventative

safety measures reduce the risk of

starting the tool accidentally.

• Store idle tools out of reach of

children and other untrained

persons. Tools are dangerous in the

hands of untrained users.

• Maintain tools with care. Keep cutting

tools sharp and clean. Properly

maintained tools, with sharp cutting

edges are less likely to bind and are

easier to control.

• Check for misalignment or binding of

2

611197-01 RS250 Rotary Tool 10/22/02 2:27 PM Page 2

Page 3

3

moving parts, breakage of parts, and

any other condition that may affect

the tools operation. If damaged, have

the tool serviced before using. Many

accidents are caused by poorly

maintained tools.

• Use only accessories that are

recommended by the manufacturer

for your model. Accessories that may

be suitable for one tool, may become

hazardous when used on another tool.

Service

• Tool service must be performed only

by qualified repair personnel. Service

or maintenance performed by unqualified

personnel could result in a risk of injury.

• When servicing a tool, use only

identical replacement parts. Follow

instructions in the Maintenance

section of this manual. Use of

unauthorized parts or failure to follow

Maintenance Instructions may create a

risk of electric shock or injury.

Specific Safety Rules

• Hold tool by insulated gripping

surfaces when performing an

operation where the cutting tool may

contact hidden wiring or its own cord.

Contact with a "live" wire will make

exposed metal parts of the tool "live" and

shock the operator.

• The label on your tool may include the

following symbols.

V..............volts

A..............amperes

Hz............hertz

W ............watts

min ..........minutes

............alternating current

........direct current

no............no load speed

............Class II Construction

…/min......revolutions or reciprocation

................per minute

............earthing terminal

............safety alert symbol

WARNING: Some dust created by power

sanding, sawing, grinding, drilling, and other

construction activities contains chemicals

known to cause cancer, birth defects or

other reproductive harm. Some examples of

these chemicals are:

• lead from lead-based paints,

• crystalline silica from bricks and cement

and other masonry products, and

• arsenic and chromium from chemicallytreated lumber (CCA).

Your risk from these exposures varies,

depending on how often you do this type of

work. To reduce your exposure to these

chemicals: work in a well ventilated area,

and work with approved safety equipment,

such as those dust masks that are specially

designed to filter out microscopic particles.

• Avoid prolonged contact with dust

from power sanding, sawing, grinding,

drilling, and other construction

activities. Wear protective clothing

and wash exposed areas with soap

and water. Allowing dust to get into your

mouth, eyes, or lay on the skin may

promote absorption of harmful chemicals.

CAUTION: Wear appropriate hearing

protection during use. Under some

conditions and duration of use, noise

from this product may contribute to

hearing loss.

CAUTION: Do not touch the bit or

collet nut during or immediately after

cutting material. The bit and collet nut

may be hot enough to burn bare skin.

WARNING: After changing bits or

making any adjustments, make sure the

collet nut is securely tightened to avoid

injury.

WARNING: Do not press spindle lock

while motor is running. The operator may

lose control and drop the tool. Personal

injury or serious tool damage may result.

WARNING: Shut off all live electric

circuits to any areas where cut outs will be

made, to avoid fire or serious personal

injury.

• Always wear eye protection. Dust mask

or hearing protection must be used for

appropriate conditions. Using personal

safety devices is recommended. WORK

SAFE.

• Always operate the tool with the

depth guide in place. The guide keeps

the bit from plunging too deeply through

the material. A minimum of penetration

should be maintained to eliminate the

danger of cutting into electric wiring.

• Do not lay the tool down until the

motor has come to a complete stop.

The spinning motor may cause the tool

to roll off a table or into a piece of

material damaging the bit.

• Be sure your cutting bits are sharp

611197-01 RS250 Rotary Tool 10/22/02 2:27 PM Page 3

Page 4

4

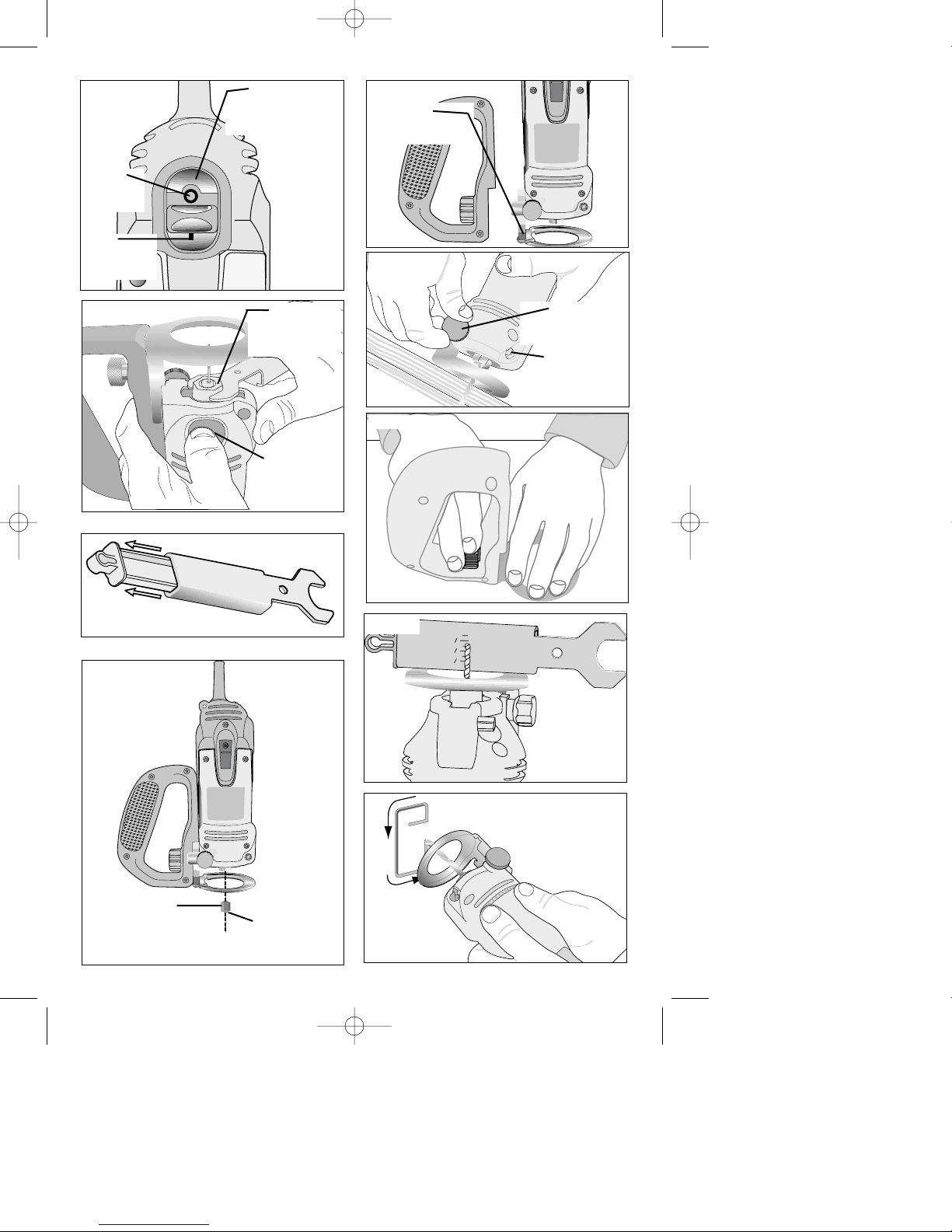

FIG. 1

OFF “O”

ARRÊT

APAGADO

ON “I”

MARCHE

ENCENDIDO

On/Off Switch (A)

Interrupteur de marche-arrêt

Interruptor de encendido y

apagado

Collet (D)

Douille de serrage (D)

Mordaza (D)

Collet nut (C)

Écrou de la douille de serrage (C)

Tuerca de mordaza (C)

Spindle Lock (B)

Bouton de verrouillage

de la broche (B)

Seguro de la flecha (B)

Collet nut (C)

Écrou de la douille de

serrage (C)

Tuerca de mordaza (C)

FIG. 3

FIG. 4

Depth Guide (E)

Guide de profondeur (E)

Guía de profundidad (E)

FIG. 5

FIG. 2

FIG. 6

Lock Knob (F)

Bouton de verrouillage (F)

Perilla de bloqueo (F)

FIG. 9

FIG. 8

FIG. 7

Dust Blower

Chasse-sciure

Soplador de polvo

611197-01 RS250 Rotary Tool 10/22/02 2:27 PM Page 4

3

4

1

2

1

4

Page 5

5

and in good condition. Damaged bits

can cause the tool to jump injuring the

operator.

•If your tool fails to function properly,

take it to an authorized service

center. There are no user serviceable

parts inside this tool and it should only

be opened by trained service

personnel.

TO MAINTAIN SAFE TOOL CONTROL

• Make sure the work surface is free of

nails or screws. Cutting into a nail or

screw may cause the tool to jump,

damaging the bit.

• Never operate the tool with one hand

while holding the workpiece with the

other hand. Always clamp the material

and guide the tool with both hands.

• Do not cut material lying on a hard

surface. Clearance behind material to be

cut must be allowed for protruding bit.

•

Disconnect plug from power supply

before making adjustments, changing

bits, or cleaning tool.

• Do not start the tool with bit

engaged in the material. The bit may

grab the material.

USE OF EXTENSION CORDS

Make sure the extension cord is in good

condition before using. Always use the

proper size extension cords with the tool –

that is, proper wire size for various lengths

of cord and heavy enough to carry the

current the tool will draw. Use of an

undersized cord will cause a drop in line

voltage resulting in loss of power and

overheating. For proper size cords see

chart.

MOTOR

Be sure your power supply agrees with

nameplate marking. 120 volts AC means

your tool may be operated only with

alternating current and never with direct

current.

SWITCH (FIG. 1)

To start the motor, slide the switch (A) to “I”

position. To stop the motor, slide the

switch to “O” position.

INSTALLING AND REMOVING THE BIT

(FIG. 2)

To change bits, FIRST turn off the tool and

disconnect from power supply.

1. To replace bit, depress and hold

spindle lock (B) and turn collet nut (C)

counter clockwise with the wrench

provided.

2. Remove old bit. CAUTION: Bit may

be hot.

3. Insert new bit.

WARNING: The bits are sharp and

should be handled with care.

CAUTION: When replacing bits, do

not insert cutting flutes into the collet.

This may result in broken bits.

4. While depressing spindle lock, turn the

collet nut clockwise with the wrench to

firmly tighten the collet.

CAUTION: Never tighten the collet

without a bit installed.

NOTE: Rotary saw accessory bits can be

stored in the wrench handle. See Fig. 3.

CHANGING THE COLLET (FIG. 4)

Some accessories require different sized

collets. The two collets used with

Black & Decker accessories are 1/8" and

1/4". The RS250 comes with both the 1/8”

and 1/4” collets as standard equipment.

TO CHANGE THE COLLET:

CAUTION: Collet may be hot.

1. Turn off tool, allow it to come to a

complete stop and disconnect from

power supply.

2. Depress and hold in spindle lock (B)

and turn collet nut (C) counterclockwise

with the wrench provided.

3. Remove the collet nut and collet from

the threaded spindle (see Fig. 4).

4. Thread the new collet nut and collet

onto the spindle.

5. Insert proper bit and securely tighten

collet nut with wrench.

CAUTION: Never tighten the collet

without a bit installed.

Minimum Gage for Extension Cords (AWG)

120 VAC Tools

Total Cord Length 0-25 26-50 51-100 101-150

Amp Rating AWG AWG AWG AWG

More than 0 18 16 16 14

Not More than 6

More than 6 18 16 14 12

Not More than 10

More than 10 16 16 14 12

Not more than 12

More than 12 14 12 Not

Not more than 16 Recomended

611197-01 RS250 Rotary Tool 10/22/02 2:27 PM Page 5

Page 6

6

DEPTH GUIDE (FIGS. 5,6,7)

CAUTION: Remove bit from collet

before installing or removing depth guide

or handle.

Keep depth guide ((E) Fig. 5) in place at all

times during operation of the tool. For best

results, adjust the guide using lock knob

((F) Fig. 6) to allow the bit to protrude a

minimum of 1/8" past the material to be

cut. Whenever the handle has been

removed and is being reattached, it is

recommended that the depth guide and

handle be aligned together. Loosely attach

handle to depth guide and place both on a

flat surface. Hold down the base of the

depth guide to keep it even with the flat

surface and tighten the knob of the handle

as shown in Figure 7.

Operation

GENERAL CUTTING

A handy scale on the wrench (Fig.8) can

be used to help determine the cutting

depth. When plunge cutting, hold the tool

firmly with both hands, insert the bit into

the material at a 45º angle. Slowly bring

the tool to a 90º angle to start the cut.

When cutting from the edge of the

workpiece, hold the tool 90º to the work

surface. With depth guide in contact with

work surface, slowly bring bit into contact

with edge. The depth guide should be kept

in contact with the material being cut at all

times. Move the tool in a clockwise

direction using slow steady pressure to

continue the cut. When the cut is

completed allow the tool to come to a

complete stop before lifting it from the

material.

DUST BLOWER

To aid visibility when cutting, your rotary

saw is equipped with a dust blower (Fig.6)

which can be used to keep the work area

clear of dust as you saw. It can also be

turned to block the air flow if desired.

CUTTING A HOLE FOR AN

ELECTRICAL OUTLET (FIG. 9)

WARNING: Shut off all live electric

circuits to any areas where cut outs will be

made.

Install the followpoint bit shown here. It is

designed specifically for use with cutting

out outlet boxes.

1. Push any wiring deeply into the outlet

box to avoid damage from the cutting

bit.

2. Before hanging the sheet covering the

outlet, mark the approximate location

of the center of the outlet on the wall

board. Check the cutting bit depth

against the side of the board to be

sure it will cut entirely through the

material.

3. Tack the sheet in place with a few

fasteners avoiding the stud holding

the outlet. This allows the wall board

to flex slightly around the protruding

fixture box.

4. Turn the rotary saw on. Holding the

tool firmly with both hands, (Fig. 9)

plunge the bit straight into the center

of the outlet.

5. Cut to the right until the edge of the

box is touched. Pull out just enough

for the bit to clear the edge of the box.

Plunge in again holding the bit gently

against the outside of the box.

6. Follow the outside of the box

(counterclockwise) as shown keeping

slight pressure against the box. This

will minimize wandering and give you

a clean precise cut.

NOTE: This is opposite of the

recommended clockwise direction for

general cutting.

7. Remove the waste and dust from the

outlet. Finish fastening the sheet of

wall board.

MAINTENANCE

The tool should be cleaned with a blast of

air often, to eject as much dust as

possible. This will increase the life of the

brushes and bearings inside the motor.

Always use appropriate safety equipment

when using compressed air to clean a tool.

The brushes in this tool are replaceable

and can be accessed through the panels

on either side of the tool housing. Black

and Decker recommends that brush

replacement be performed by a company

owned or authorized service center.

Although the tool’s plastic case is solvent

resistant, you should never use solvents

or harsh chemicals to clean it. Wipe the

non-metallic parts of the tool with a dry

cloth.

IMPORTANT: To assure product SAFETY

and RELIABILITY, repairs, maintenance

and adjustment should be performed by

authorized service centers or other

qualified service personnel, always using

identical replacement parts.

611197-01 RS250 Rotary Tool 10/22/02 2:27 PM Page 6

Page 7

7

LUBRICATION

All bearings are factory lubricated for the

life of the tool.

SERVICE INFORMATION

Black & Decker offers a full network of

company-owned and authorized service

locations throughout North America. All

Black & Decker Service Centers are

staffed with trained personnel to provide

customers with efficient and reliable power

tool service.

Whether you need technical advice, repair,

or genuine factory replacement parts,

contact the Black & Decker location

nearest you.

To find your local service location, refer to

the yellow page directory under “Tools—

Electric” or call: 1-800-544-6986

AVAILABLE BLACK AND DECKER

ACCESSORIES

Always use appropriate bit for the

application and material being cut. Do not

use this tool with drill and screwdriver

bits. Available bits are:

GENERAL PURPOSE BITS - for wood,

plywood, laminates and foam.

DRYWALL BITS - for use in drywall only.

Using on wood will rapidly dull the bit.

TILE BITS -for ceramic tile. Recommended accessories for use with your tool are

available from your local dealer or

authorized service center. If you need

assistance regarding accessories, please

call:1-800-544-6986

WARNING: The use of any accessory

not recommended for use with this tool

could be hazardous.

FULL TWO-YEAR HOME USE

WARRANTY

Black & Decker (U.S.) Inc. warrants this

product for two years against any defects

in material or workmanship. The defective

product will be replaced or repaired at no

charge in either of two ways.

The first, which will result in exchanges

only, is to return the product to the retailer

from whom it was purchased (provided

that the store is a participating retailer).

Returns should be made within the time

period of the retailer’s policy for

exchanges (usually 30 to 90 days after the

sale). Proof of purchase may be required.

Please check with the retailer for their

specific return policy regarding returns that

are beyond the time set for exchanges.

The second option is to take or send the

product (prepaid) to a Black & Decker

owned or authorized Service Center for

repair or replacement at our option. Proof

of purchase may be required. Black &

Decker owned and authorized Service

Centers are listed under “Tools-Electric” in

the yellow pages of the phone directory.

This warranty does not apply to

accessories. This warranty gives you

specific legal rights and you may have

other rights which vary from state to state

and province to province. Should you have

any questions, contact the manager of

your nearest Black & Decker Service

Center. This product is not intended for

commercial use

Imported by

Black & Decker (U.S.) Inc.,

701 E. Joppa Rd.

Towson, MD 21286 U.S.A.

611197-01 RS250 Rotary Tool 10/22/02 2:27 PM Page 7

Page 8

8

No de catalogue RS250

GUIDE D’UTILISATION

SSSSCCCCIIIIEEEE CCCCIIIIRR

RRCCCC

UU

UULLLLAAAAIIII

RR

RREEEE

AVANT DE RETOURNER

CE PRODUIT POUR

QUELQUE RAISON QUE

CE SOIT, APPELEZ

BLACK & DECKER AU

1 800 544-6986.

SI VOUS ÉPROUVEZ UN

PROBLÈME A VEC L ’OUTIL,

COMPOSEZ LE 1 800 544-6986.

A VANTD’APPELER, VEUILLEZ

VOUS ASSURER D’AVOIR

L’INFORMATION SUIVANTE À

PORTÉE DE LAMAIN : LE

NUMÉRO DE CA TALOGUE, LE

NUMÉRO DE PRODUIT ET LE

CODE DE DA TATION (P. EX.,

0130M). DANS LAMAJORITÉ

DES CAS, LE REPRÉSENT ANT

DE BLACK & DECKER SERAEN

MESURE DE RÉSOUDRE LE

PROBLÈME P AR TÉLÉPHONE.

VEUILLEZ NOUS FAIRE PART

DE VOS QUESTIONS OU DE

VOS COMMENT AIRES EN

COMPOSANT LE MÊME

NUMÉRO, CAR CEUX-CI

AIDENT À ASSURER LA

QUALITÉ DE NOTRE SERVICE.

611197-01 RS250 Rotary Tool 10/22/02 2:27 PM Page 8

Page 9

9

AVERTISSEMENT : lire, comprendre et

suivre toutes les directives précisées cidessous, y compris les consignes de

sécurité, afin d’éviter les risques de choc

électrique, d’incendie ou de blessure

grave.

CONSERVER CES DIRECTIVES

ZONE DE TRAVAIL

• Garder la zone de travail propre et

bien éclairée; les établis encombrés et

les endroits sombres sont propices aux

accidents.

• Ne pas utiliser les outils électriques

dans une atmosphère explosive,

comme à proximité de liquides, de

gaz ou de poussières inflammables;

le moteur peut créer des étincelles et

enflammer les vapeurs ou les

poussières environnantes. Utiliser

seulement dans des endroits bien aérés.

• Tenir les enfants, les visiteurs ou

toute autre personne à l’écart

lorsqu’on utilise un outil électrique;

les distractions peuvent faire perdre la

maîtrise de ce dernier.

MESURES DE SÉCURITÉ - ÉLECTRICITÉ

• Les outils à double isolation sont

munis d’une fiche polarisée (c’est-àdire que l’une des lames est plus

large que l’autre), laquelle ne peut

être raccordée qu’à une prise

polarisée et ce, dans un seul sens; on

doit l’inverser si on est incapable de

l’enfoncer complètement. Si la fiche

ne s’adapte toujours pas, on doit

demander à un électricien qualifié

d’installer la prise appropriée. On ne

doit jamais modifier la fiche. La

double isolation élimine le besoin

d’installer un cordon d’alimentation

trifilaire et un système d’alimentation

électrique pourvus d’une mise à la terre.

• Éviter tout contact entre le corps et

les éléments mis à la terre, comme

les tuyaux, les radiateurs, les

cuisinières et les réfrigérateurs, afin

de réduire les risques de choc

électrique.

• Ne pas utiliser l’outil électrique dans

des endroits mouillés, ni l’exposer à

la pluie; l’infiltration d’eau à l’intérieur de

l’outil augmente les risques de choc

électrique.

• Ne pas utiliser le cordon de manière

abusive; on ne doit pas transporter

l’outil en le tenant par le cordon, ou

utiliser ce dernier pour le débrancher.

On doit tenir le cordon à l’écart des

sources de chaleur, de l’huile, des

bords tranchants ou des pièces

mobiles. Remplacer immédiatement

les cordons endommagés, car ces

derniers augmentent les risques de choc

électrique.

• Lorsqu’on utilise un outil électrique à

l’extérieur, on ne doit utiliser que des

rallonges conçues pour cet usage,

comme celles de type W-A ou W, afin

de réduire les risques de choc

électrique.

SÉCURITÉ PERSONNELLE

• Rester vigilant en tout temps et faire

preuve de jugement lorsqu’on utilise

un outil électrique; ne pas utiliser

l’outil lorsqu’on est fatigué ou sous

l’influence de drogues, d’alcool ou de

médicaments, car un moment

d’inattention pourrait entraîner des

blessures graves.

• Porter des vêtements appropriés; ne

pas porter de vêtements amples ni de

bijoux. Couvrir ou attacher les

cheveux longs. Garder les cheveux,

les vêtements, les bijoux et les gants

éloignés des pièces mobiles, car

ceux-ci peuvent s’y coincer. Se tenir

éloigné des évents puisque ces derniers

pourraient camoufler des pièces

mobiles.

• Éviter les démarrages accidentels;

s’assurer que l’interrupteur est en

position d’arrêt avant de brancher

l’outil. Ne pas transporter l’outil en

laissant le doigt sur l’interrupteur ni le

brancher lorsque l’interrupteur est en

position de marche, car cela pourrait

causer un accident.

• Retirer les clés de réglage avant de

démarrer l’outil; une clé laissée sur

une pièce rotative pourrait entraîner des

blessures.

• Ne pas trop étendre les bras; les

pieds doivent rester ancrés

fermement au sol afin de maintenir

son équilibre en tout temps et de

mieux maîtriser l’outil dans des

situations imprévues.

• Utiliser le matériel de sécurité

approprié; toujours porter des

lunettes de protection. Porter un

masque anti-poussières, des

chaussures antidérapantes, un casque

de sécurité ou des protecteurs auditifs

lorsque la situation le requiert.

UTILISATION ET ENTRETIEN DE L’OUTIL

• Fixer et soutenir le matériel sur une

plate-forme stable au moyen d’une

bride de serrage ou de tout autre

dispositif semblable; le matériel est

instable lorsqu’on le retient

manuellement ou qu’on l’appuie contre

611197-01 RS250 Rotary Tool 10/22/02 2:27 PM Page 9

Page 10

10

le corps, ce qui peut faire perdre la

maîtrise de l’outil.

· Ne pas forcer l’outil ni l’utiliser pour

des travaux autres que ceux pour

lesquels il a été conçu. Pour obtenir de

meilleurs résultats et prévenir les risques

de blessure, laisser l’outil couper à la

vitesse pour laquelle il a été conçu.

· Ne pas utiliser l’outil lorsque

l’interrupteur marche-arrêt ne

fonctionne pas; tout outil qui ne peut être

commandé au moyen de l’interrupteur est

dangereux et doit être réparé.

· Débrancher l’outil avant d’effectuer

un réglage, de changer les accessoires

ou de ranger l’outil; ces mesures de

sécurité préventives réduisent les risques

de démarrage accidentel.

· Lorsqu’on n’utilise pas l’outil, le

ranger hors de la portée des enfants ou

des personnes non qualifiées; les outils

sont dangereux entre les mains de

personnes inexpérimentées.

· Bien entretenir l’outil et s’assurer

qu’il est toujours bien propre et

aiguisé; les outils bien entretenus et dont

les bords sont bien tranchants sont moins

susceptibles de rester coincés et sont plus

faciles à maîtriser.

· Vérifier les pièces mobiles afin de

s’assurer qu’elles sont bien alignées et

qu’elles ne restent pas coincées;

vérifier également les pièces afin de

s’assurer qu’il n’y a ni bris ni aucune

autre condition susceptible de nuire au

bon fonctionnement de l’outil; faire

réparer l’outil si ce dernier est

endommagé avant de s’en servir à

nouveau, car les accidents sont souvent

causés par des outils mal entretenus.

· N’utiliser que les accessoires

recommandés par le fabricant pour le

modèle concerné; un accessoire destiné

à un outil particulier peut devenir

dangereux lorsqu’il est utilisé avec un

autre.

ENTRETIEN

· L’outil doit être entretenu par le

personnel qualifié seulement; toute

maintenance effectuée par une personne

non qualifiée pourrait entraîner des

risques de blessure.

· Lors de l’entretien, n’utiliser que des

pièces de rechange identiques et

suivre les directives de la section

«Entretien» du présent guide afin de

prévenir les risques de choc électrique ou

de blessure.

RÈGLES DE SÉCURITÉ

PARTICULIÈRES

· Tenir l’outil par les surfaces isolées

prévues à cette fin lorsque l’outil risque

d’entrer en contact avec des fils cachés

ou le cordon, car de tels contacts

peuvent mettre les pièces métalliques de

l’outil sous tension, engendrant des

risques de choc électrique.

L’étiquette de l’outil peut comporter les

symboles suivants.

V ....................................volts

A ....................................ampères

Hz ..................................hertz

W ....................................watts

min..................................minutes

..................................courant

........................................alternatif

................................courant continu

n

o....................................sous vide

....................................

Construction de

........................................classe II

..................................borne de mise à

la ................................minute

..................................symbole

..................................d´avertissement

.../min..............................tours ou c

........................................ourses

à la minute

AVERTISSEMENT: certains outils

électriques, tels que les sableuses, les

scies, les meules, les perceuses ou

certains autres outils de construction,

peuvent produire de la poussière

contenant des produits chimiques

susceptibles d’entraîner le cancer, des

malformations congénitales ou pouvant

être nocifs pour le système reproductif.

Parmi ces produits chimiques, on retrouve

:

· le plomb dans les peintures à base de

plomb,

· la silice cristalline dans les briques et

le ciment et autres produits de

maçonnerie,

· l’arsenic et le chrome dans le bois de

sciage ayant subi un traitement chimique

(comme l’arséniate de cuivre et de

chrome).

Le risque associé à de telles expositions

varie selon la fréquence avec laquelle on

effectue ces travaux. Pour réduire

l’exposition à de tels produits, il faut

travailler dans un endroit bien aéré et

utiliser le matériel de sécurité approprié,

tel un masque anti-poussières

spécialement conçu pour filtrer les

particules microscopiques.

611197-01 RS250 Rotary Tool 10/22/02 2:27 PM Page 10

Page 11

11

· Éviter tout contact prolongé avec la

poussière soulevée par cet outil ou

autres outils électriques. Porter des

vêtements de protection et nettoyer les

parties exposées du corps avec de

l’eau savonneuse. S’assurer de bien se

protéger afin d’éviter d’absorber par la

bouche, les yeux ou la peau des produits

chimiques nocifs.

MISE EN GARDE : porter un

dispositif de protection personnel antibruit approprié durant l’utilisation.

Sous certaines conditions et pendant

toute la durée de l’utilisation, le bruit

émanant de ce produit pourrait

contribuer à la perte d’audition.

MISE EN GARDE : ne pas toucher à la

mèche ni à l’écrou de la douille de

serrage durant ou immédiatement

après la coupe, car ils peuvent être assez

chauds pour brûler la peau nue.

AVERTISSEMENT: dès qu’on a changé

la mèche ou effectué un réglage, s’assurer

que l’écrou de la douille de serrage est

bien serré afin d’éviter les blessures.

AVERTISSEMENT: ne pas appuyer sur

le bouton de verrouillage de la broche

lorsque le moteur est en marche afin

d’éviter de perdre la maîtrise de l’outil ou

de l’échapper, ce qui risque de

l’endommager ou de causer des

blessures.

AVERTISSEMENT: couper le courant

de tous les circuits électriques situés à

proximité de la zone où on prévoit

effectuer une coupe afin d’éviter les

risques d’incendie ou de blessure grave.

• Toujours porter des lunettes de

protection. Porter un masque antipoussières, ou des protecteurs auditifs

lorsque la situation le requiert. On

recommande d’utiliser des dispositifs de

sécurité personnelle. PENSONS

SÉCURITÉ!

• Toujours s’assurer que le guide de

profondeur est en place lorsqu’on

utilise l’outil. Ce dispositif empêche la

mèche de trop s’enfoncer dans le

matériau, éliminant les risques d’entrer

en contact avec un fil électrique.

• Attendre que le moteur s’arrête

complètement avant de déposer

l’outil sur une surface, afin d’éviter que

ce dernier tombe par terre ou qu’il

accroche une pièce, ce qui risque

d’endommager la mèche.

• S’assurer que les mèches sont bien

aiguisées et en bon état; elles risquent

de faire bondir l’outil et de blesser

l’opérateur si elles sont endommagées.

• Si l’outil ne fonctionne pas

correctement, on doit l’apporter dans

un centre de service autorisé. L’outil

ne comprend aucune pièce interne

destinée à être entretenue par

l’utilisateur et ne doit donc être ouvert

que par du personnel qualifié.

SÉCURITÉ ET MAÎTRISE DE L’OUTIL

• S’assurer que la surface de travail est

exempte de clou ou de vis; si l’outil

passe sur une ferrure de ce genre, cela

pourrait le faire sauter et endommager la

mèche.

• Ne jamais tenir l’outil d’une main et la

pièce de l’autre; la pièce doit être

maintenue au moyen de dispositifs de

serrage permettant ainsi de guider l’outil

des deux mains.

• Ne jamais couper un matériau

lorsque ce dernier est appuyé contre

une surface rigide; on doit prévoir

derrière le matériau un espace

suffisamment grand pour permettre à la

mèche de sortir librement.

• Toujours débrancher l’outil de la

source d’alimentation électrique

avant d’effectuer un réglage, de changer

une mèche ou de nettoyer l’outil.

• Ne jamais faire démarrer l’outil

lorsque la mèche est déjà engagée

dans une pièce; celle-ci pourrait

mordre dans le matériau.

RALLONGES

S’assurer que la rallonge est en bon état

avant de l’utiliser. Toujours utiliser une

rallonge qui convient à l’outil, c’est-à-dire

dont le calibre des fils, la longueur du

cordon et les valeurs nominales

correspondent à l‘outil alimenté. L’usage

d’une rallonge de calibre insuffisant

pourrait causer une chute de tension

entraînant une perte de puissance et une

surchauffe. Pour s’assurer qu’on utilise le

calibre approprié, consulter le tableau

indiqué ci-dessous.

MOTEUR

S’assurer que l’intensité nominale du

cordon d’alimentation correspond à celle

indiquée sur la plaque signalétique; sur

cette dernière, la mention «120 v c.a.»

signifie que l’outil ne doit être branché que

dans une prise de courant alternatif et non

pas dans une prise de courant continu.

611197-01 RS250 Rotary Tool 10/22/02 2:27 PM Page 11

Page 12

12

INTERRUPTEUR (FIG. 1)

Pour faire démarrer le moteur, faire glisser

l’interrupteur (A) jusqu’à la position «I»;

pour l’arrêter, le mettre à la position «O».

INSTALLATION ET RETRAIT DES

MÈCHES (FIG. 2)

AVANT de procéder, arrêter et

débrancher l’outil de la source

d’alimentation électrique.

1. Pour remplacer une mèche, enfoncer

le bouton de verrouillage de la broche (B)

sans le relâcher, puis tourner l’écrou de la

douille de serrage (C) vers la gauche au

moyen de la clé fournie.

2. Retirer la mèche. MISE EN GARDE

:la mèche peut être chaude.

3. Insérer la nouvelle mèche.

AVERTISSEMENT : les mèches sont

coupantes et doivent donc être

manipulées avec soin.

MISE EN GARDE : s’assurer de ne

pas insérer les cannelures tranchantes

de la mèche dans la douille de serrage;

cela pourrait briser la mèche.

4. Le bouton de verrouillage de la broche

étant toujours enfoncé, tourner l’écrou de

la douille de serrage vers la droite au

moyen de la clé fournie afin de bien la

serrer.

MISE EN GARDE : ne jamais serrer la

douille sans y avoir d’abord inséré une

mèche.

REMARQUE : les mèches peuvent être

rangées dans la poignée de la clé (voir la

fig. 3).

REMPLACEMENT DE LA DOUILLE DE

SERRAGE (FIG. 4)

Les accessoires requièrent des douilles de

dimensions diverses; ceux de Black &

Decker doivent être utilisés avec les

douilles de serrage de 3,2 mm (1/8 po) ou

de 6,4 mm (1/4 po); ces deux douilles

standard sont fournies avec le modèle

RS250.

REMPLACEMENT DE LA DOUILLE :

MISE EN GARDE : la douille peut être

chaude.

1. Arrêter l’outil, puis attendre qu’il s’arrête

complètement avant de le débrancher de

la source d’alimentation électrique.

2. Enfoncer le bouton de verrouillage de la

broche (B) sans le relâcher, puis tourner

l’écrou de la douille de serrage (C) vers la

gauche au moyen de la clé fournie.

3. Retirer l’écrou et la douille de la broche

filetée (fig. 4).

4. Fileter la nouvelle douille et l’écrou dans

la broche.

5. Insérer la mèche voulue, puis bien

serrer l’écrou au moyen de la clé.

MISE EN GARDE : ne jamais serrer la

douille sans y avoir d’abord inséré une

mèche.

GUIDE DE PROFONDEUR (fig. 5, 6 et 7)

MISE EN GARDE : retirer la mèche de

la douille avant d’installer ou de retirer le

guide de profondeur ou la poignée.

Toujours s’assurer que le guide de

profondeur (fig. 5E) est en place lorsqu’on

utilise l’outil. Remarque : il n’est toutefois

pas nécessaire de l’utiliser avec l’arbre

flexible. Pour obtenir les meilleurs

résultats possibles, régler le guide au

moyen du bouton prévu à cet effet (fig.

6F), de manière à laisser dépasser la

mèche d’environ 3 mm (1/8 po) derrière la

pièce. Si on a retiré la poignée et qu’on

veut la fixer de nouveau, on recommande

de l’aligner d’abord avec le guide de

profondeur. Fixer la poignée au guide de

profondeur, sans la serrer, et placer

Calibres minimaux des rallonges (AWG)

Outils de 120 V c.a.

Longueur totale de la rallonge (en pieds) 0 à 25 26 à 50 51 à 100101 à 150

Intensité (en ampères) AWG AWG AWG AWG

Plus de 0

Pas plus de 6 18 16 16 14

Plus de 6

Pas plus de 10 18 16 14 12

Plus de 10

Pas plus de 12 16 16 14 12

Plus de 12

Pas plus de 16 14 12 Non recommandé

611197-01 RS250 Rotary Tool 10/22/02 2:27 PM Page 12

Page 13

13

l’ensemble sur une surface plane. Retenir

la base du guide vers le bas afin de le

maintenir de niveau avec la surface, puis

serrer le bouton de la poignée, tel

qu’illustré à la figure 7.

FONCTIONNEMENT

COUPES ORDINAIRES

La clé est munie d’une échelle pratique

(fig. 8) qui aide à déterminer la profondeur

de coupe. Pour réaliser une coupe en

plongée, tenir fermement l’outil des deux

mains, puis insérer la mèche dans le

matériau à un angle de 45 º. Ramener

lentement l’outil à un angle de 90 º afin

d’amorcer la coupe. Lorsqu’on coupe le

matériau à partir du bord de la pièce, on

doit tenir l’outil à un angle de 90 º par

rapport à la surface de travail. En

maintenant le guide de profondeur appuyé

contre le matériau, exercer une légère

pression afin que la mèche entre en

contact avec le bord de la pièce. Le guide

de profondeur doit resté appuyé contre le

matériau en tout temps. Déplacer l’outil

vers la droite en exerçant une légère

pression uniforme. Une fois la coupe

terminée, attendre que l’outil s’arrête

complètement avant de le soulever hors

du matériau.

CHASSE-SCIURE

Pour améliorer la visibilité durant la coupe,

la scie est munie d’un chasse-sciure (fig.

6) qu’on peut utiliser pour éliminer à

mesure les débris sur la ligne de coupe.

On peut aussi le régler de manière à

bloquer la circulation d’air, au besoin.

DÉCOUPE D’UN TROU POUR UNE

PRISE ÉLECTRIQUE (fig. 9)

AVERTISSEMENT : couper le courant

de tous les circuits électriques situés à

proximité de la zone où on prévoit

effectuer une telle coupe.

Installer la mèche illustrée ci-dessus; elle

est spécialement conçue pour la coupe de

boîtes électriques.

1. Pousser les fils électriques au fond de

la boîte à prises afin d’éviter de les

endommager, le cas échéant.

2. Avant d’installer le panneau de plâtre

sur la boîte à prises, indiquer

l’emplacement approximatif du centre de

la boîte sur le panneau. Vérifier

l’épaisseur du matériau afin de s’assurer

que la mèche utilisée est suffisamment

longue pour le traverser complètement.

3. Fixer le panneau au moyen de

quelques attaches, en prenant soin

d’éviter le montant auquel est fixée la

boîte à prises, afin de permettre au

panneau de plâtre de fléchir légèrement

autour de la boîte en saillie.

4. Mettre l’outil en marche puis, en le

tenant fermement des deux mains (fig. 9),

enfoncer la mèche directement au centre

de la boîte à prises.

5. Diriger la mèche vers la droite, jusqu’à

ce qu’elle atteigne le côté de la boîte;

retirer la mèche suffisamment pour passer

par-dessus la boîte, puis l’enfoncer de

nouveau dans le matériau en l’accotant

légèrement sur l’extérieur de la boîte.

6. Suivre le contour de la boîte (vers la

gauche), tel qu’illustré, en exerçant une

légère pression contre celle-ci afin d’éviter

de faire dévier l’outil et de s’assurer

d’obtenir une coupe précise.

REMARQUE : il s’agit du sens contraire à

celui recommandé (vers la droite) pour les

coupes ordinaires.

7. Retirer les retailles et la poussière de la

boîte. Fixer le panneau de plâtre de façon

définitive.

ENTRETIEN

L’outil doit être souvent nettoyé au moyen

d’un jet d’air comprimé de manière à en

retirer le plus de poussière possible et

d’améliorer la durée de vie des balais et

des roulements du moteur. On doit

toujours porter le matériel de sécurité

approprié lorsqu’on nettoie un outil à l’air

comprimé. Les balais peuvent être

remplacés; on peut y avoir accès par les

panneaux situés de chaque côté du boîtier

de l’outil. Black & Decker recommande de

faire remplacer les balais dans un de ses

centres de service ou dans un centre

autorisé. Bien que le boîtier en plastique

de l’outil soit résistant aux solvants, ne

jamais utiliser ce produit, ni toute autre

solution chimique, pour le nettoyer.

Essuyer les pièces non métalliques de

l’outil au moyen d’un linge sec.

IMPORTANT :pour assurer la SÉCURITÉ

et la FIABILITÉ de ce produit, toutes les

opérations de réparation, d’entretien et de

réglage doivent être effectuées dans un

centre de service autorisé ou par du

personnel qualifié; on ne doit utiliser que

des pièces de rechange identiques.

611197-01 RS250 Rotary Tool 10/22/02 2:27 PM Page 13

Page 14

14

LUBRIFICATION

Tous les roulements ont été lubrifiés en

usine pour la durée de vie de l’outil.

INFORMATION SUR LES SERVICES

Black & Decker dispose d’un réseau

complet composé de centres de service et

de centres autorisés situés partout en

Amérique du Nord. Tous les centres de

service Black & Decker sont dotés de

personnel qualifié en matière d’outillage

électrique; ils sont donc en mesure d’offrir

à leur clientèle un service efficace et

fiable.

Pour obtenir un conseil technique ou une

pièce d’origine ou pour faire réparer un

outil, on peut communiquer avec le centre

Black & Decker le plus près.

Pour obtenir le numéro de téléphone,

consulter les pages jaunes sous la

rubrique «Outils - électriques» ou

composer le 1 800 544-6986.

ACCESSOIRES OFFERTS PAR BLACK

& DECKER

Toujours utiliser la mèche qui convient aux

travaux à effectuer et au matériau à

couper. Ne pas utiliser cet outil avec des

mèches de perceuses ou de tournevis.

Les mèches offertes sont les suivantes :

MÈCHES UNIVERSELLES : bois,

contreplaqué, stratifié et mousse

MÈCHES POUR PLACOPLÂTRE :

cloisons sèches seulement; ne pas utiliser

pour couper le bois afin d’éviter d’user

prématurément la mèche.

MÈCHES POUR TUILES : tuiles en

céramique

ACCESSOIRES

Les accessoires recommandés pour

chaque outil sont vendus séparément

chez les dépositaires locaux ou dans les

centres de service autorisés. Pour obtenir

plus d’information sur les accessoires,

composer le 1 800 544-6986.

MISE EN GARDE : l’usage d’un

accessoire non recommandé peut

présenter un danger.

GARANTIE COMPLÈTE DE DEUX ANS

POUR USAGE RÉSIDENTIEL

Black & Decker (U.S.) Inc. garantit ce

produit pour une période de deux ans

contre tout défaut de matériel ou de

fabrication. Le produit défectueux sera

remplacé ou réparé sans frais, suivant

l’une des deux méthodes suivantes.

La première méthode consiste en un

échange seulement. On doit retourner le

produit au détaillant qui l’a vendu (pourvu

qu’il s’agisse d’un détaillant participant),

en respectant les délais stipulés dans sa

politique relative aux échanges

(normalement de 30 à 90 jours après la

vente). Une preuve d’achat peut être

requise. On doit vérifier la politique de

retour du détaillant pour tout produit

retourné après le délai prescrit pour les

échanges.

La deuxième méthode consiste à apporter

ou à envoyer le produit (prépayé) à un

centre Black & Decker ou à un centre de

service autorisé aux fins de réparation ou

de remplacement, selon notre choix. Une

preuve d’achat peut être requise. Les

centres Black & Decker et les centres de

service autorisés sont répertoriés dans les

pages jaunes sous la rubrique «Outils électriques».

Cette garantie ne s’applique pas aux

accessoires. Elle confère des droits

légaux particuliers à l’acheteur, mais celuici pourrait aussi bénéficier d’autres droits

variant d’un territoire à l’autre.

Toute question doit être adressée au

gérant du centre Black & Decker le plus

près. Ce produit n’est pas destiné à un

usage commercial.

Imported by / Importé par

Black & Decker Canada Inc.

100 Central Ave.

Brockville (Ontario) K6V 5W6

Voir la rubrique “Outils électriques”

des Pages Jaunes

pour le service et les ventes.

611197-01 RS250 Rotary Tool 10/22/02 2:27 PM Page 14

Page 15

15

NÚMERO DE CATÁLOGO – RS2500

MANUAL DE INSTRUCCIONES

SSSSIIIIEEEERR

RR

RR

RRAAAA

RR

RR

OO

OOTTTTAAAATTTT

OO

OO

RR

RRIIIIAAAA

ANTES DE DEVOLVER

ESTE PRODUCTO

POR CUALQUIER

MOTIVO, FAVOR

LLAMAR AL

1-800-544-6986

DE TENER ALGÚN

PROBLEMACON SU

PRODUCTO BLACK & DECKER,

FAVOR LLAMAR AL

1-800-544-6986

ANTES DE LLAMAR, TENGALA

SIGUIENTE INFORMACIÓN

DISPONIBLE. NO. DE

CA TALOGO, TIPO NO., Y

CÓDIGO DE FECHA

(P.EJ.0130M). EN LAMAYORÍA

DE LOS CASOS, UN

REPRESENT ANTE DE BLACK

& DECKER LE PUEDE

RESOL VER SU PROBLEMA

TELEFÓNICAMENTE. SI TIENE

UNASUGERENCIA O

COMENT ARIO, LLÁMENOS. SU

APORTE ES VITAL PARA

BLACK & DECKER.

611197-01 RS250 Rotary Tool 10/22/02 2:27 PM Page 15

Page 16

16

ADVERTENCIA: Lea y entienda todo el

instructivo. El no seguir todas las

instrucciones enumeradas a continuación

puede resultar en electrochoque, fuego

y/o seria lesión personal.

GUARDE ESTAS INSTRUCCIONES

ÁREA DE TRABAJO

• Mantenga su área de trabajo limpio y

bien iluminado. Bancos de trabajo

abarrotados de cosas y áreas oscuras

son una invitación a los accidentes.

• No opere herramientas eléctricas en

atmósferas explosivas, donde hay

presencia de líquidos, gases, o polvos

inflamables. Las herramientas eléctricas

crean chispas que podrían encender el

polvo o los gases.

• Mantenga a los transeúntes, niños, y

visitantes alejados mientras opera una

herramienta eléctrica. Las distracciones

podrían causar la pérdida de control.

SEGURIDAD ELÉCTRICA

• Las herramientas con doble aislamiento

están equipadas con un enchufe

polarizado (una clavija es más ancha

que la otra.) Este enchufe encajará en

un tomacorriente polarizado de una sola

manera. Si el enchufe no encaja bien en

el tomacorriente, invierta el enchufe. Si

todavía no encaja, contacte a un

electricista competente para que instale

un tomacorriente polarizado. No cambie

el enchufe. El aislamiento doble elimina

la necesidad de un cable eléctrico a

tierra de tres alambres y un sistema de

alimentación eléctrica puesto a tierra.

• Evite que su cuerpo haga contacto con

superficies a tierra tales como tuberías,

radiadores, cocinas, y refrigeradoras.

Existe un mayor riesgo de

electrochoque si su cuerpo está en

contacto a tierra.

• No exponga las herramientas eléctricas

a la lluvia o condiciones húmedas. La

penetración de agua a una herramienta

eléctrica incrementará el riesgo de

electrochoque

• No maltrate el cable. No lo use nunca

para acarrear las herramientas o halar el

enchufe de un tomacorriente. Mantenga

el cable alejado del calor, aceite, bordes

afilados o partes en movimiento.

Reemplace inmediatamente los cables

dañados. Los cables dañados

incrementan el riesgo de electrochoque.

• Al operar una herramienta eléctrica a la

intemperie, use un cable de extensión

para exteriores marcado “W-A” o “W.”

Estos cables están hechos para uso

exterior y reducen el riesgo de

electrochoque.

SEGURIDAD PERSONAL

• Manténgase alerta, observe lo que está

haciendo y use sentido común al usar

una herramienta eléctrica. No la use

cuando esté cansado o bajo la influencia

de drogas, alcohol, o medicinas. Un

instante de inatención mientras opera

herramientas eléctricas puede resultar

en serias lesiones personales.

• Vístase adecuadamente. No use

vestimenta suelta o joyas. Mantenga el

cabello largo sujeto. Mantenga su

cabello, vestimenta y guantes apartados

de piezas en movimiento. La vestimenta

suelta, las joyas o el cabello largo

podrían quedar atrapados en las partes

en movimiento. Los huecos de

ventilación cubren partes en movimiento

y debe ser evitados.

• Evite un arranque accidental. Asegúrese

de apagar la herramienta antes de

enchufarla. El cargar las herramientas

con el dedo en el interruptor o enchufar

herramientas que tienen el interruptor

activado es una invitación a los

accidentes.

• Quite las llaves de ajuste antes de

activar la herramienta. Una llave que se

deja anexada a una parte giratoria de la

herramienta puede resultar en lesión

personal.

• No se extralimite. Mantenga la pisada

firme y el balance apropiado todo el

tiempo. El pié bien afincado y el balance

apropiado permite un mejor control de la

herramienta en situaciones

inesperadas.

• Utilice equipo de seguridad. Use

siempre protección ocular. Se deberá

usar máscara contra el polvo, calzado

protector antirresbalante, casco, o

protector de oído en las condiciones que

los justifican.

USO Y CUIDADO DE HERRAMIENTAS

• Utilice tornillos de banco u otra forma

práctica para sujetar y apoyar la pieza

de trabajo a una plataforma estable.

Sujetar la pieza manualmente o contra

su cuerpo es inestable y puede llevar a

la pérdida de control.

• No fuerce la herramienta. Use la

herramienta correcta para la aplicación.

La herramienta correcta hará una labor

mejor y más segura, con la energía

nominal para la cual fue diseñada.

• No use la herramienta si el interruptor no

prende y apaga. La herramienta que no

se puede controlar con el interruptor es

peligrosa y debe ser reparada.

611197-01 RS250 Rotary Tool 10/22/02 2:27 PM Page 16

Page 17

17

• Desconecte el enchufe de la toma de

corriente antes de efectuar cualquier

ajuste, cambio de accesorios, o guardar

la herramienta. Estas medidas de

seguridad preventivas reducen el riesgo

a que la herramienta arranque

accidentalmente.

• Mantenga herramientas que no estén en

uso fuera del alcance de los niños y

otras personas no entrenadas. Las

herramientas son peligrosas en manos

de usuarios no entrenados.

• Las herramientas deben recibir un

mantenimiento cuidadoso. Mantenga las

herramientas para corte afiladas y

limpias. Las herramientas bien cuidadas

con bordes de corte afilados son menos

susceptibles a trabarse y más fáciles de

controlar.

• Revise si hay desalineamiento o traba

en las partes movibles, partes rotas u

otra condición que pueda afectar la

operación de la herramienta. De estar

dañada, dar servicio a la misma antes

de utilizarla. Muchas veces la causa de

accidentes se debe a herramientas con

poco mantenimiento.

• Use solamente los accesorios que el

fabricante recomienda para su modelo.

Los accesorios adecuados para una

herramienta, pueden resultar peligrosos

cuando se usa en otra.

SERVICIO

• El servicio a la herramienta debe ser

efectuado por personal de reparación

calificado únicamente. El servicio o

mantenimiento realizado por personal

no calificado puede provocar riesgos de

lesiones.

• Cuando se efectúe el mantenimiento de

una herramienta, utilice únicamente

accesorios originales. Siga las

instrucciones presentadas en la sección

Mantenimiento, de este manual. El

empleo de piezas no autorizadas o el no

seguir las instrucciones de

mantenimiento, puede originar riegos de

electrochoque o lesiones.

REGLAS DE SEGURIDAD

ESPECÍFICAS

• Cuando realice una operación en la cual

la herramienta pueda hacer contacto

con cables escondidos, sujétela por las

partes con aislamiento antideslizante. El

contacto con un cable con corriente hará

que las partes metálicas de la

herramienta puedan transmitir una

descarga eléctrica al operario..

ADVERTENCIA: El polvo creado al lijar,

aserrar, pulir, taladrar o realizar otras

actividades de la construcción, contiene

substancias químicas que se sabe

producen cáncer, defectos de nacimiento

u otros defectos del sistema reproductor.

Algunos ejemplos de esos productos

químicos son:

• El plomo de las pinturas a base de

plomo,

• La sílice cristalina de los ladrillos, del

cemento y de otros productos de

albañilería, y

• El arsénico y el cromo de la madera

tratada químicamente (CCA).

El riesgo que se corre a causa del

contacto con esos productos varía según

la frecuencia con que usted realice este

tipo de trabajos. Con el fin de reducir su

exposición a esas substancias químicas,

trabaje en un área bien ventilada y utilice

un equipo de seguridad reglamentario, tal

como una máscara contra el polvo

especialmente diseñada para filtrar

partículas microscópicas.

• Evite el contacto prolongado con el

polvo proveniente del lijado, aserrado,

amolado y taladrado eléctrico y otras

actividades de construcción. Use

vestimenta protectora y lave todas las

áreas expuestas con agua y jabón. De

entrar polvo en sus ojos, boca, o que

este permanezca sobre su piel puede

promover la absorción de químicos

dañinos.

ATENCIÓN: Use protección auditiva

apropiada cuando usa la herramienta.

Bajo ciertas condiciones y el tiempo que

se usa la herramienta, el ruido

proveniente de este producto podría

contribuir a pérdida auditiva.

ATENCIÓN: No tocar la broca o la

tuerca de mordaza durante o

inmediatamente después de cortar el

material. La broca y la tuerca de mordaza

podrían ser lo suficientemente calientes

como para quemar la piel.

ADVERTENCIA: Después de cambiar

las brocas o efectuar ajustes, asegúrese

de que la tuerca de mordaza esté bien

apretada para evitar lesiones.

ADVERTENCIA: No presione el seguro

de la flecha mientras el motor está en

marcha. El operador puede perder el

control y dejar caer la herramienta. Esto

podría ocasionar lesión personal o daño a

la herramienta.

ADVERTENCIA: Apague todos los

circuitos eléctricos activos de toda área

611197-01 RS250 Rotary Tool 10/22/02 2:27 PM Page 17

Page 18

18

donde se harán cortes para evitar

incendio o lesiones graves.

• Use siempre protección ocular. Se

deben usar las mascarillas contra el

polvo o protección auditiva de acuerdo a

las condiciones de trabajo. Se

recomienda usar aparatos de seguridad

personal. TRABAJE CON SEGURIDAD.

• Siempre opere la herramienta con la

guía de profundidad en su lugar. La

guía no permite que la broca se hunda

con demasiada profundidad a través del

material. Se debe mantener un mínimo

de penetración para eliminar el peligro

de cortar el cableado eléctrico.

• No coloque la herramienta sobre

alguna superficie hasta que el motor

se haya detenido completamente. La

rotación del motor podría hacer que la

herramienta ruede al piso o dentro de

alguna pieza de material que dañaría la

broca.

• Asegúrese de que las brocas de corte

estén afiladas y en buenas

condiciones. Brocas dañadas pueden

hacer saltar la herramienta y lesionar al

operador.

• Si su herramienta no funciona

correctamente, llévela a un centro de

servicio autorizado. Dentro de esta

herramienta no hay piezas que puedan

repararse. La misma sólo debe ser

abierta por personal de servicio

entrenado.

P

ARA MANTENER UN CONTROL

SEGURO SOBRE HERRAMIENTA

• Asegúrese que la superficie de

trabajo esté libre de clavos o

tornillos. Hacer cortes donde se

encuentra un clavo o tuerca puede

hacer que la herramienta salte, dañando

la broca.

• No opere la herramienta con una

mano mientras sujeta la pieza de

corte con la otra. Fije siempre el

material y guíe la herramienta con

ambas manos.

• No corte material que reposa sobre

una superficie dura. Debe dejar

espacio detrás del material para que la

broca pueda sobresalir.

• Desconecte el enchufe del

tomacorriente antes de hacer ajustes,

cambios de broca, o limpieza de la

herramienta.

• No ponga a funcionar la herramienta

con la broca metida en el material. La

broca puede engarzar el material.

USO DE CABLES DE EXTENSIÓN

Asegúrese que el cable de extensión esté

en buenas condiciones antes de usar. Al

utilizar un cable de extensión, asegúrese

de que sea del tamaño correspondiente a

la herramienta, o sea, lo suficientemente

“pesado” como para transportar la

corriente que la herramienta va a extraer.

Un cable de tamaño insuficiente causará

una caída en la línea de voltaje resultando

en pérdida de energía y recalentamiento.

Para el tamaño correcto vea la tabla

siguiente.

Calibre mínimo para cables de extensión (AWG)

Herramientas de 120 VAC

Largo total del cable 0-25 26-50 51-100 101-150

Amp nominal AWG AWG AWG AWG

Más de 0

No más de 6 18 16 16 14

Más de 6

No más de 10 18 16 14 12

Más de 10

No más de 12 16 16 14 12

Más de 12

No más de 16 14 12 No recomendado

611197-01 RS250 Rotary Tool 10/22/02 2:27 PM Page 18

Page 19

19

MOTOR

Verifique que su suministro de corriente

concuerde con el marcaje de la placa de

datos. 120 Voltios de corriente alterna

(AC) solo indica que su herramienta

operará con corriente alterna y nunca con

corriente directa.

INTERRUPTOR (FIG. 1)

Para prender el motor, deslice el

interruptor (A) a la posición “I”. Para

pararlo, deslice el interruptor a la posición

“O”.

INSTALACIÓN Y REMOCIÓN DE LA

BROCA (FIG. 2)

Para cambiar brocas, PRIMERO

apague la herramienta y desconéctela

del tomacorriente.

1.Para cambiar la broca, oprima y

mantenga el seguro de la flecha hacia

abajo (B) y gire la tuerca de mordaza (C)

en sentido antihorario con la llave

suministrada.

2.Saque la broca vieja. ATENCIÓN: La

broca puede estar caliente.

3.Inserte la broca nueva

ADVERTENCIA: Las brocas son

afiladas y deben manejarse con gran

cuidado.

ATENCIÓN: Al cambiar brocas, no

insertar en la mordaza las brocas para

corte. Esto puede ocasionar su rotura.

4.Mientras oprime el seguro de la flecha,

gire la tuerca de mordaza en sentido

horario con la llave, a fin de que la

mordaza quede bien apretada.

ATENCIÓN: Nunca apriete la mordaza

sin la broca instalada.

NOTA:Las brocas para accesorios de la

sierra rotatoria se pueden guardar en el

mango de la llave. Ver Fig. 3.

CAMBIO DE MORDAZAS (FIG. 4)

Algunos accesorios requieren mordazas

de distinto tamaño. Las dos mordazas que

se usan con accesorios Black & Decker

son de 1/8" y 1/4". La RS250 viene con

mordazas de 1/8” y 1/4” como equipo

estándar.

PARACAMBIAR LA MORDAZA:

ATENCIÓN: La mordaza puede estar

caliente.

1.Apague la herramienta, deje que la

misma se haya detenido por completo y

desconéctela del tomacorriente.

2.Oprima y mantenga el seguro de la

flecha (B) hacia dentro y gire la tuerca

de mordaza (C) en sentido antihorario

con la llave suministrada.

3.Saque la tuerca de mordaza y la

mordaza de la flecha roscada (vea Fig.

4).

4.Ensarte la nueva tuerca de mordaza y

mordaza en la flecha.

5.Inserte la broca adecuada y mediante la

llave, apriete muy bien la tuerca de

mordaza con la llave.

ATENCIÓN: Nunca apretar la

mordaza sin la broca instalada.

GUÍA DE PROFUNDIDAD (FIGS. 5,6,7)

ATENCIÓN: Remueva la broca de la

mordaza antes de instalar o quitar la guía

de profundidad o el mango.

Mantenga la guía ((E) Fig. 5) en su lugar

durante todo el tiempo que opera la

herramienta. Nota: No se requiere usar

con el eje flexible. Para mejor resultado,

ajuste la guía usando la perilla de bloqueo

((F) Fig. 6) para permitir que la broca

sobresalga un mínimo de 1/8" más allá del

material a cortar. Cuando el mango se

haya removido y se vuelve a poner, se

recomienda alinear la guía de profundidad

con el mango. Unir sin apretar el mango

con la guía de profundidad y coloque

ambos sobre una superficie plana.

Mantenga la base de la guía hacia abajo

para que quede uniforme con la superficie

plana y apriete la perilla del mango como

se ilustra en la Figura 7.

Operación

CORTES EN GENERAL

En la llave (Fig.8) se encuentra una escala

conveniente que se puede utilizar para

determinar la profundidad del corte. En

pasadas penetrantes, mantenga la

herramienta firme sujetándola con las dos

manos, e inserte la broca en el material a

un ángulo de 45º. Lleve la herramienta

lentamente hasta un ángulo de 90º para

comenzar el corte. Al cortar desde el

borde de la pieza, mantenga la

herramienta a 90º respecto a la superficie

de la pieza. Con la guía de profundidad en

contacto con la superficie de la pieza,

aproxime la broca lentamente hasta hacer

contacto con el borde. La guía de

profundidad debe mantenerse en todo

momento en contacto con el material que

se está cortando. Mueva la herramienta

en dirección horaria mediante presión

lenta y continua para seguir cortando. Al

finalizar el corte, deje que la herramienta

se detenga completamente antes de

levantarla del material.

611197-01 RS250 Rotary Tool 10/22/02 2:27 PM Page 19

Page 20

20

SOPLADOR DE LA LÍNEADE CORTE

Para fomentar la visibilidad mientras

ejecuta el corte, su sierra rotatoria viene

equipada con un soplador de la línea de

corte (Fig. 6) que puede usarse para

mantener el área de trabajo libre de polvo

mientras ejecuta el aserrado. También se

puede girar para bloquear el flujo de aire si

se desea.

CORTE DE HUECO PARA UNA CAJA

DE TOMACORRIENTE (FIG. 9)

ADVERTENCIA: Apague todos los

circuitos eléctricos activos en el área

donde se van a cortar los huecos.

Instale la broca para seguimiento de

puntos de corte aquí. Está diseñado

específicamente para usarse con cortes

de huecos para cajas de salida.

1.De haberlo, empuje el cableado lo más

profundo dentro de la caja de la toma de

corriente para evitar dañarla con la

broca cortante.

2.Antes de colgar la lámina que cubre la

caja, marque la ubicación aproximada

del centro de la caja en la lámina de

cartón de yeso o fibra prensada.

Verifique la profundidad de corte de la

broca contra el lado de la lámina para

asegurar que ésta cortará por completo

a través del material.

3.Fije la lámina en su lugar con algunos

sujetadores evitando el del entramado

que sujeta la caja. Esto permite que la

lámina pueda flexionarse un poco

alrededor de la caja haciéndola

sobresalir.

4.Encienda la sierra rotatoria. Sujetando

firmemente la herramienta con ambas

manos, (Fig. 9) penetre la broca en

forma recta en el centro de la caja.

5.Corte hacia la derecha hasta tocar el

borde de la caja. Saque la broca lo justo

para que ésta quede apenas sin tocar el

borde de la caja. Húndala otra vez

manteniendo la broca suavemente

contra la parte exterior de la caja.

6.Siga la parte exterior de la caja (sentido

antihorario) según se ilustra,

manteniendo una leve presión contra la

caja. Esto minimizará el desplazamiento

y le dará un corte limpio y preciso.

NOTA: Esto es lo opuesto a la

recomendación para cortes en general,

de cortar en sentido horario.

7.Quite los desechos y el polvo de la caja.

T ermine la fijación de la lámina de cartón

de yeso o fibra prensada.

IMANTENIMIENTO

Se debe limpiar la herramienta soplando

aire a menudo, a fin de expeler el máximo

posible de polvo. Esto aumentará la vida

de las escobillas y rolineras dentro del

motor. Use siempre el equipo de

seguridad apropiado al usar aire

comprimido para limpiar una herramienta.

Las escobillas de esta herramienta son

reemplazables y se pueden llegar hasta

ellas a través de los paneles de cualquier

lado de la envoltura de la herramienta.

Black and Decker recomienda que el

cambio de escobillas sea hecho por un

centro de servicio de la compañía o centro

autorizado. Aunque la cubierta de plástico

es resistente a los disolventes, evite usar

estos o químicos fuertes para limpiarla.

Limpie las partes no metálicas de la

herramienta con un paño seco.

IMPORTANTE: para garantizar la

SEGURIDAD y CONFIABILIDAD del

producto, toda reparación, mantenimiento

y ajuste debe efectuarse en los centros de

servicio autorizados u otras

organizaciones de servicio calificados,

utilizando siempre repuestos idénticos.

LUBRICACIÓN

Todas las rolineras vienen lubricadas de

fábrica para su buena conservación.

INFORMACIÓN DE SERVICIO

Black & Decker ofrece una red completa

de centros de servicio y centros

autorizados en toda Norteamérica. Todos

los centros de servicio Black & Decker

disponen de personal entrenado para dar

un servicio eficiente y confiable a las

herramientas eléctricas de sus clientes.

De necesitar orientación técnica,

reparación o repuestos originales de

fábrica, diríjase al centro Black & Decker

local.

Para hallar la ubicación del centro de

servicio más cercano, busque en las

páginas amarillas de la guía telefónica

bajo "Herramientas—Eléctricas" o llame a:

1-800-544-6986

611197-01 RS250 Rotary Tool 10/22/02 2:27 PM Page 20

Page 21

ACCESORIOS BLACK AND DECKER

DISPONIBLES

Use siempre la broca apropiada para la

aplicación y el material a cortar. No use

esta herramienta con brocas de taladro y

de atornillar. Las brocas disponibles son:

BROCAS DE USO GENERAL – para

madera, madera contrachapada,

laminados y espuma.

BROCAS DE “DRYWALL” (mampostería

en seco) – sólo para “drywall”. Si se usa

en madera la broca se desafila

rápidamente.

BROCAS DE BALDOSA – para baldosas

de cerámica.

BROCAS BURILADORAS CON GUÍA –

para aplicar un borde decorativo a

maderas, contrachapados y laminados.

ACCESORIOS

Los accesorios que se recomiendan usar

con su herramienta están disponibles en

su centro de servicio local o centro de

servicio autorizado. Si necesita ayuda

para obtener un accesorio, favor llamar

al:1-800-544-6986

ADVERTENCIA: Puede ser peligroso

usar cualquier accesorio no recomendado

GARANTÍA COMPLETA DE DOS AÑOS

PARAUSO DOMÉSTICO

Black & Decker (U.S.) Inc. garantiza este

producto por dos años contra todo defecto

de material y fabricación. El producto

defectuoso será reemplazado o reparado

sin costo en una de las dos formas

siguientes.

La primera opción, que resultará en

intercambio solamente, será devolviendo

el producto al minorista donde fue

comprado (siempre que la tienda sea un

minorista participante). Las devoluciones

deberán hacerse dentro del período de

intercambio que el minorista tiene por

política (generalmente de 30 a 90 días

después de la venta). La prueba de

compra podrá ser requerida. Favor

informarse con el minorista sobre la

política específica de devolución en

cuanto a devoluciones hechas en fecha

posterior a la fijada para intercambios.

La segunda opción es llevar o enviar el

producto (pre-pagado) a un centro de

servicio Black & Decker o un centro

autorizado para reparaciones o

reemplazo, a nuestra discreción. La

prueba de compra podrá ser requerida.

Los centros de servicio Black & Decker o

centros autorizados se anuncian bajo

"Herramientas - Eléctricas" en las páginas

amarillas de la guía telefónica.

Esta garantía no aplica a los accesorios.

Esta garantía le otorga a usted derechos

legales específicos y otros derechos que

pueden variar de estado en estado y de

provincia a provincia. Si tiene alguna

pregunta, comuníquese con el gerente de

su centro de servicio Black & Decker más

cercano.

Este producto no está destinado al uso

comercial.

611197-01 RS250 Rotary Tool 10/22/02 2:27 PM Page 21

Page 22

22

PARAREPARACION Y SERVICIO DE SUS HERRAMIENTAS ELECTRICAS FAVOR

DE DIRIGIRSE AL CENTRO DE SERVICIO MAS CERCANO

CULIACAN A v. Nicolas Bravo #1063 Sur (56 77) 12 42 10

GAUDALAJARA Av . La Paz #1770 (33 38) 26 69 78

LEON Polara #32 (47 77) 13 14 56

MEXICO Sonora #134 Hiprodromo Condesa (55 55) 53 99 79

MERIDA Calle 63 #459 (99 99) 23 54 90

MONTERREY Av . Francisco I. Madero Pte. 1820-A (81 83) 72 11 25

PUEBLA 17 Norte #2057 (22 22) 46 90 20

QUERETARO Av. Madero 139 Pte. (44 22) 14 60 60

SAN LOUIS POTOSI Pedro Moreno #408 Fracc. la Victoria (44 48) 14 25 67

TORREON Blvd. Independencia, 96 pte. (87 17) 16 52 65

VERACRUZ Prolongación Diaz Miron #4280 (29 99) 21 70 18

VILLAHERMOSA Zaragoza #105 (99 33) 12 53 17

PARAOTRAS LOCALIDADES LLAME AL: (55) 5326-7100

IMPORTADO: BLACK & DECKER S.A. DE C.V.

BOSQUES DE CIDROS ACCESO RADIATAS NO. 42

COL. BOSQUES DE LAS LOMAS.

05120 MÉXICO, D.F

TEL. 3-26-71-00

ESPECIFICACIONES

Tension de alimentación:

Potencia nominal: 279 W

Frecuencia de operación: 60 Hz

Consumo de corriente: 2.5 A

611197-01 RS250 Rotary Tool 10/22/02 2:27 PM Page 22

120V

Page 23

23

611197-01 RS250 Rotary Tool 10/22/02 2:27 PM Page 23

Page 24

24

Cat. # RS250 Part # 611197-01 (OCT-02-1) Copyright © 2002 Black & Decker Printed in U.S.A.

611197-01 RS250 Rotary Tool 10/22/02 2:27 PM Page 24

Loading...

Loading...