Page 1

www.blackanddecker.com

1

Page 2

Copyright Black & Decker

2

Page 3

10

4

1 23 5

6 7 8 9

A

911 8

B

3

Page 4

1218

6

12

13

C

4

7 9

8

Page 5

3mm

3 16

4

97

ED

F

5

5

G

5

Page 6

IH

17

J

6

K

Page 7

ML

18

N

11 8

19

7

Page 8

ENGLISH

CHAINSAW

Know your chainsaw

Warning! When using electric tools,

basic safety precautions should always be

taken to reduce the risk of fire, electric

shock and personal injury.

Read this user manual carefully, observing

all of the recommended safety instructions

before, during and after use of your

chainsaw. Maintain your chainsaw in good

working order. Familiarise yourself with the

controls on your chainsaw before attempting

to operate it, but above all, be sure you know

how to stop the tool in an emergency.

Retain this user manual and all other

literature supplied for future reference.

SAFETY INSTRUCTIONS

◆ Know your chainsaw. Please read this user

manual carefully and familiarise yourself with

your chainsaw, in particular with regard to the

sawing of round wood. We strongly recommend

that first time users practice sawing logs on a

saw horse or cradle.

◆ Avoid dangerous environments. Keep your

work area clean and remove clutter. Keep the

work area well lit. We strongly recommend the

use of a sawhorse or cradle whenever possible.

Do not saw wet wood or use your

chainsaw when it is raining.

◆ Keep people away while your chainsaw is in use.

Do not allow children, other people or animals

near your chainsaw while you are using it.

◆ Maintain your chainsaw when not in use.

Do not store your chainsaw for any length of

time without first removing the saw chain and

guide bar which should be kept immersed in

oil. Store all parts of your chainsaw in a dry,

secure place out of reach of children.

We recommend you drain the oil reservoir

prior to storage.

◆ Do not force your chainsaw. It will do the job

better and more safely at the rate for which it

was intended.

Protective clothing. Wear close fitting and

protective clothing including a safety

helmet with visor/goggles, ear protectors,

safety shoes, protective bib trousers and

strong leather gloves.

◆ Do not abuse the cable. Never carry a

chainsaw by the cable or jerk it to disconnect

the plug from the socket. Keep the cable away

from heat, oil or sharp edges. Check the cable

frequently for damage.

◆ Secure your work using clamps or chocks. Be

sure that you use both hands when operating

your chainsaw.

Remove the plug from the mains before

changing the work location, adjusting,

sharpening or cleaning, changing any

accessory such as the chain, or if the cord

becomes entangled or damaged.

◆ Adjusting wrenches. Form a habit of checking

to see that adjusting wrenches are removed

from your chainsaw before starting.

◆ Only use extension cable type HO7RN-F 2 x

1mm2, as a minimum only.

◆ Stay alert. Never operate your chainsaw when

you are tired.

◆ Check damaged parts. Before further use of

your chainsaw, a guard or other part that is

damaged should be carefully checked to

determine whether it will operate properly and

perform its intended function. Check for

alignment of moving parts, binding of moving

parts, breakage of parts, mounting and any

other conditions that may affect its operation.

A guard or other part that is damaged should

be properly repaired or replaced by an

authorised service agent. Do not use your

chainsaw if the switch does not turn it on and

off.

8

Page 9

ENGLISH

Warning! The use of an accessory or

attachment other than those recommended

in this user manual may present a risk of

personal injury.

◆ For all types of cutting, always hold the saw

firmly with both hands, with thumbs and fingers

encircling the saw handles. Do not release your

grip until your chainsaw has stopped moving.

◆ Be sure of your footing and pre-plan a safe exit

from a falling tree or branches.

◆ Use wedges to help control felling and prevent

binding the guide bar and saw chain in the cut.

◆ Keep all parts of your body and clothing away

from the saw chain when running your chainsaw.

Before you switch on make sure your chainsaw

is not contacting anything. Do not touch or try

to stop a moving saw chain with your hand.

◆ Carry your chainsaw carefully with the mains

supply disconnected and with the guide bar

and saw chain to the rear and the blade sheath

fitted.

◆ Keep your chainsaw clean. Do not allow dirt,

oil or sawdust to build up on your chainsaw.

Pay particular attention to the air inlet and

outlet slots; these must not become clogged.

Clean your chainsaw with a dry cloth but do

not use any solvents or cleaning fluids.

◆ Saw chain care. Keep the saw chain sharp and

snug on the guide bar. Ensure the saw chain

and guide bar are clean and well oiled.

Beware of kickback. Kickback is upward/

backward motion of the guide bar that

may occur when the nose of the saw chain

unexpectedly comes in contact with an

object. Hold your chainsaw firmly with

both hands when the motor is running.

Use a firm grip with thumbs and fingers

encircling the handles and watch carefully

what you cut.

Kickback can be caused by:

◆ Striking branches or other objects accidentally

with a tip of the saw while the saw chain is

moving.

◆ Striking metal, cement or any other hard

material near the wood, or buried in the wood.

◆ A dull or loose chain.

◆ Cutting above shoulder height.

◆ Lack of attention when holding or guiding

the saw while cutting.

◆ Over-reaching. Keep proper footing and

balance at all times and do not overreach.

◆ Do not try to insert into a previous cut, as this

could cause kickback. Make a fresh cut every time.

◆ We strongly recommend you do not attempt

to operate your chainsaw while in a tree, on a

ladder or on any other unstable surface. If you

decide to do so, be advised that these

positions are extremely dangerous.

◆ When cutting a branch that is under tension,

be alert for spring back so that you will not be

struck when the tension is released.

◆ Avoid cutting:

◆ Prepared timber.

◆ Into the ground.

◆ Into wire fences, nails, etc.

◆ Into small sized brush and saplings because

slender material may catch the saw chain and

be whipped towards you, or pull you off

balance.

◆ Do not use your chainsaw above shoulder height.

◆ Ensure someone is nearby (but at a safe distance)

in case of an accident.

◆ If for any reason you have to touch the chain,

make sure your chainsaw is disconnected from

the mains.

◆ The noise from this product can exceed 85 dB(A).

We therefore recommend you take appropriate

measures for the protection of hearing.

Warning symbols on your chainsaw

Read all of this manual carefully.

Do not use your chainsaw in wet

conditions or expose it to rain.

Always wear ear and eye protection.

Always remove the plug from the socket

before inspecting a damaged cable.

Be careful not to use your chainsaw if the

cable is damaged.

9

Page 10

ENGLISH

To ensure continued safe operation,

check the chain tension as described

in this manual after every 10 minutes

of use, and adjust back to 3 mm as

required.

Double insulation

Your chainsaw is double insulated.

This means that all external metal parts are

electrically isolated from the power supply.

This is achieved by placing an extra insulation

barrier between the electrical and mechanical

parts. Double insulation means greater

electrical safety and obviates the necessity

of having the machine earthed.

Electrical safety

◆ Make sure your chainsaw is correct for your

supply. The voltage can be found on the rating

plate.

Fuse replacement (UK & Ireland only)

If you need to replace the fuse on your extension

cable, please note the following:

◆ The plug should be fitted with a 13 amp fuse

which is the recommended fuse for your chainsaw.

◆ Only use replacement fuses which are

approved to BS1362.

◆ When changing the fuse in your plug, always

ensure the fuse cover is refitted.

If the fuse cover is missing or damaged do not

use the plug. Note: Fuses do not give personal

protection against electric shock.

Plug replacement (UK & Ireland only)

Insertion of a detatched plug into a 13 amp

socket outlet may result in electric shock.

◆ Only fit BS1363A approved plugs fitted with

the correctly rated fuse (1).

◆ The cable wire colours, or a letter, will be

marked at the connection points of most good

quality plugs. Attach the wires to their

respective points in the plug. Brown is for

„Live“ (L) (2) and blue is for „Neutral“ (N) (4).

◆ Before replacing the top cover of the mains

plug ensure that the cable restraint (3) is

holding the outer sheath on the cable firmly

and that the two leads are correctly fixed at the

terminal screws.

Warning! Never connect live or neutral

wires to the earth pin marked „E“ or .

Note: Do not wire an extension cable

directly into your chainsaw.

Increased safety can be obtained by having a

qualified electrician install a high sensitivity

(30 mA / 30mS) circuit breaker in the house wiring.

If you do not wish to have one installed, then we

strongly recommend that the electrical power to

your chainsaw be supplied through a high

sensitivity residual current device (RCD). The RCD

is designed to provide a high degree of personal

protection against harmful electric current should

fault conditions occur.

Warning! The use of an RCD or other

circuit breaker unit does not release the

operator of your chainsaw from the safety

instructions and safe working practices

given in this user manual.

We recommend that if your mains cable is cut or

requires replacement that you return your chainsaw

to a Black & Decker service agent. When repaired,

your chainsaw will be tested for electrical safety.

We strongly recommend the use of PVC or rubber

covered plugs or connectors with your chainsaw.

◆ Disconnect the plug from the supply.

◆ Cut off the plug and dispose of immediately.

10

Cable connection system (UK only)

Black & Decker continually makes every effort to

achieve the highest standards in performance,

quality and reliability. We recommend the use of a

new outdoor cable connection system,

which gives additional protection against the

possibility of water or moisture entering into the

cable connector during normal use.

Page 11

ENGLISH

The new connection system does not

release the operator of the tool from the

safety precautions and safe working

practices given in the manual. Particular

attention is drawn to the fact that this

connection system is ‚weather resistant‘,

but not suitable for immersion,

submersion or being subjected to water

jets. Take care to prevent the cable from

lying in or trailing through pools of water

or from splashing with hose pipes.

The following items are available:

A6615 20 m cable, socket, 13 Amp plug

A6616 20 m cable, socket, 13 Amp plug and

Cable Tidy frame

A6617 30 m cable, socket, 13 Amp plug and

Cable Tidy frame

A6613 40 m cable, socket, 13 Amp plug and

Cable Tidy reel

Existing cable systems

Your tool either comes with a cable attached

(the cat. no. ends with a C) or with a male connector

built into the tool. If you already own an outdoor

cable system with the old female connector shown

below, we recommend that you replace this

connector with the new female connector, which is

available from most major DIY outlets and from

Black & Decker service centres (cat. no. A6624S).

old female connector new female connector

Follow the instructions supplied with the connector.

If in doubt, consult a qualified electrician.

This adaptor is only suitable for products

rated up to 500 W. It is not recommended

for use with hover mowers, rotary mowers

with grass collection, chainsaws, shredders

and blower vacs. Please contact your local

service centre if you need further advice.

Fitting your own extension cable

◆ When making your own extension cable,

fit a 13 Amp plug to one end of the cable

(see „Mains plug replacement“) and a female

connector to the other end. For wiring

instructions, see those supplied with the

female connector.

◆ A male connector (see below) is already attached

to the power supply cable on your tool. It is

non-rewireable and should not be removed. If

the connector is damaged and needs

replacement, take the tool to a Black & Decker

service centre.

female connector male connector

Never wire an extension cable with

anything other than the female connector

supplied and a 13 Amp BS1363A

approved plug with the recommended

fuse. Never wire a male connector to the

extension cable. Never wire an extension

cable with a plug of any kind at each end

of the cable. This is extremely dangerous

and results in the pins being live, which

may cause a fatal electric shock.

Existing outdoor tools

To connect existing Black & Decker outdoor tools

to the new system, you will need an adaptor (see

below), which is available as an accessory from

most major DIY outlets and from Black & Decker

service centres (cat. no. A6623S).

Fitting the female connector

◆ To remove the cover, unscrew the fixing screw

until it is free of the nut which is located in the

hexagonal recess on the underside of the

connector. Take care not to lose the nut if it

falls out.

11

Page 12

ENGLISH

The extension cable contains two wires, which are

colour coded for easy identification: brown is for

Live (L), blue is for Neutral (N). The connector is

marked ‚L‘ for Live and ‚N‘ for Neutral.

These markings are located inside the body near

the terminal screws (see below).

◆ Lift out the cable protector.

◆ Pass the cable through from the narrow end of

the cable protector.

◆ Prepare the cable ends to the strip length

shown in the illustration.

◆ Remove the cable clamp.

◆ Loosen the terminal screws until you can enter

the stripped wires between the raised washer

and the terminal.

◆ Connect the brown lead to the terminal

marked ‚L‘ and the blue lead to the terminal

marked ‚N‘. Do not fix the wires directly under

the screw head.

◆ Locate the cable and cable protector into the

body.

◆ Fit the cable clamp over the outer sheath of

the cable. Tighten the screws until fully home.

◆ Make sure that the cable clamp is firmly

holding the outer sheath of the cable and that

the two leads are correctly fixed.

◆ Place the cover onto the connector body.

◆ Securely tighten the fixing screw.

◆ Check that the cable protector is secure and

that there are no gaps between the connector

body and the cover.

connector body

terminal screws

clamping washers

fixing screw

6 mm

30 mm

cable

clamp

a

cable

protector

bc

cover

Additional safety instructions for Australia and

New Zealand

◆ This appliance is not intended for use by

young or infirm persons without supervision.

Children must be supervised to ensure they do

not play with the appliance.

◆ If the supply cord is damaged, it must be replaced

by the manufacturer or an authorised

Black & Decker Service Centre in order to

avoid a hazard.

Technical data

Bar length 30 cm 35 cm 40 cm

Supply voltage (V) 230 230 230

Rated input (W) 1400/1600 1400/16001400/1600

Max. cutting length (cm) 30 35 40

Chain speed (no load m/s) 8 8 8

Weight (kg) 3.7 3.8 3.9

Oil capacity (ml) 180 180 180

Safety class II II II

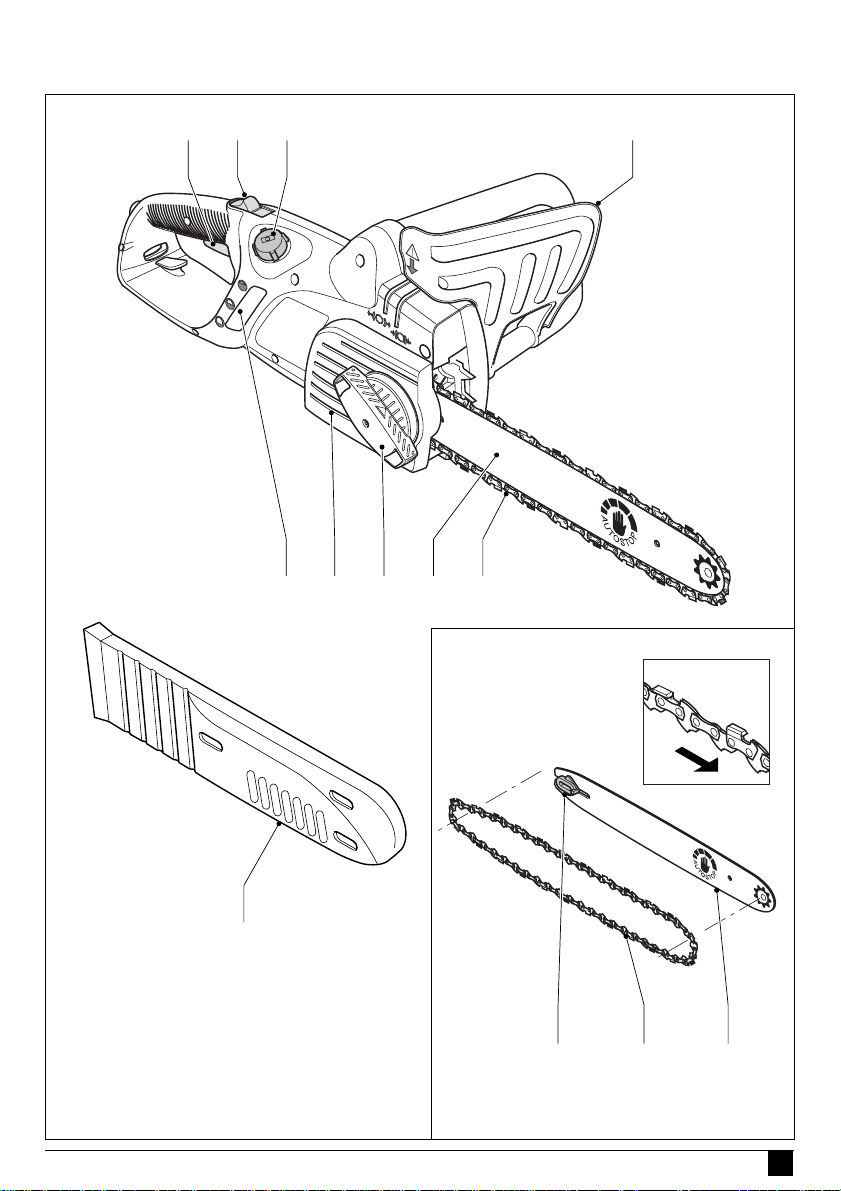

OVERVIEW (fig. A)

1. On/off switch

2. Lock-off button

3. Oil cap

4. Oil level indicator

5. Front guard/chain brake

6. Chain cover

7. Control knob

8. Guide bar

9. Chain

10.Chain sheath

ASSEMBLY

Before assembly, make sure that the tool

is switched off and unplugged.

Oiling the chain (fig. A)

◆ You must do this whenever you use a new

chain for the first time. Take the new chain out

of its plastic bag and soak it in chain oil for at

least an hour before using it. Use Black & Decker

chain oil (cat. no. A6027).

12

Page 13

ENGLISH

◆ We recommend that you use only one brand

of oil during the lifetime of your chainsaw

because mixtures of different oils could lead to

the oil becoming degraded, which can

drastically shorten the lifetime of the saw chain.

◆ Never use waste oil, thick oil or very thin

sewing machine oil. These may damage your

chainsaw.

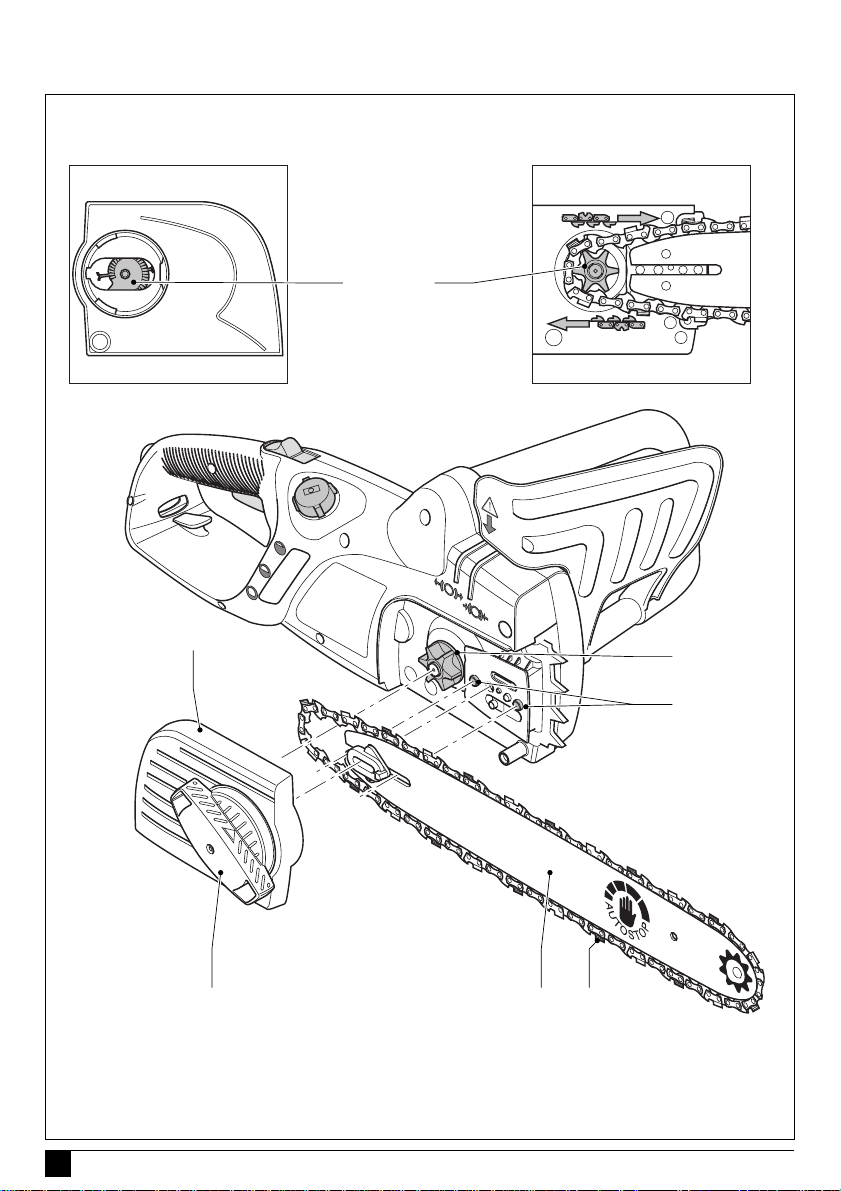

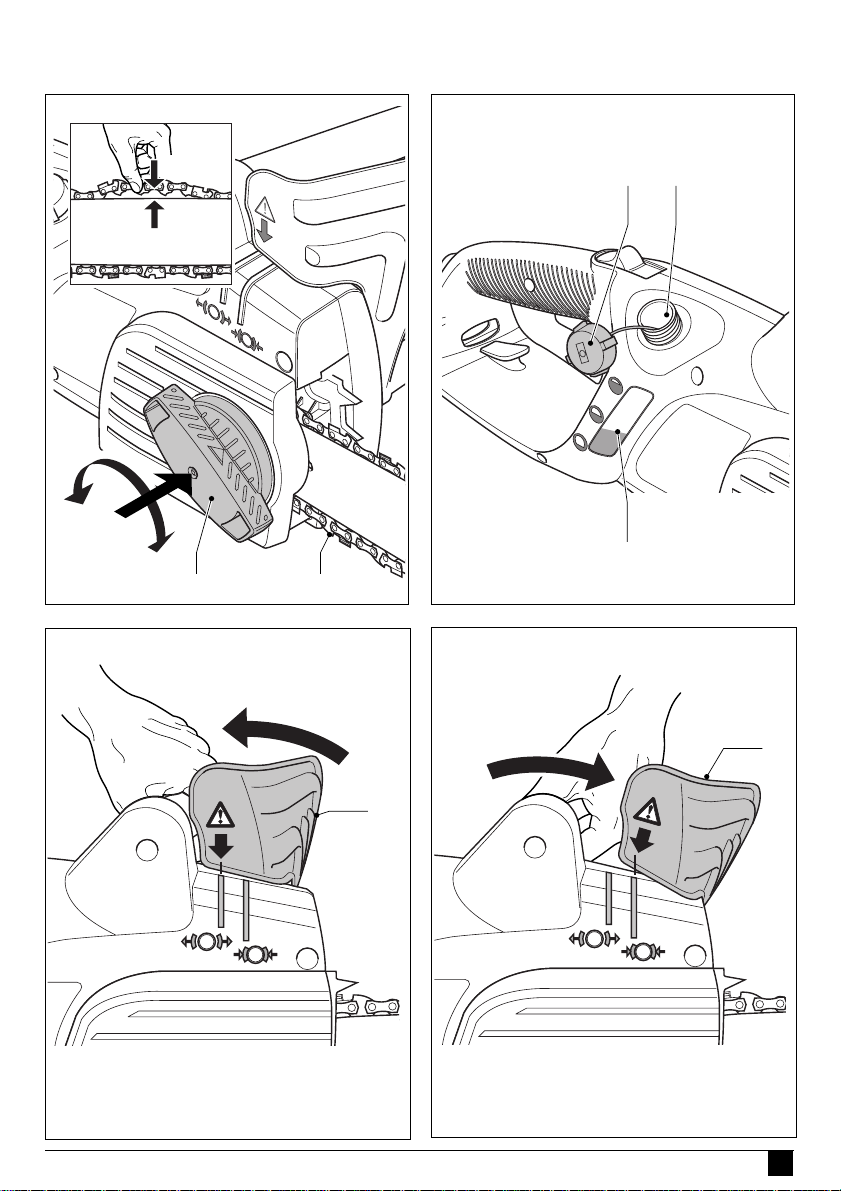

Fitting the guide bar and chain (fig. B & C)

Always wear protective gloves when

working on your chainsaw and ensure that

the plug is not in the electrical outlet.

◆ Fit the saw chain (9) over the guide bar (8),

making sure that the cutters are the right way

round and that the slider tensioner (11) is

facing towards you (fig. B).

◆ With the tool horizontal on a stable surface,

put the bar and chain onto the bar mounting

studs (13), ensuring the chain is around the

drive sprocket (12). Make sure that the cutters

on the upper part of the guide bar face

towards the front (fig. B).

◆ Before fitting the chain cover check that the

cam (18) is in the correct position.

If necessary, press and turn the control knob (7)

clockwise to rotate the cam into the correct

position.

◆ Fit the chain cover by locating the bolt and

using the control knob (7) to tighten the chain

cover finger tight. To tension the chain, loosen

the control knob one full turn, press in firmly

and rotate clockwise. As the bar moves

forward make sure that the chain links feed

into the guide bar. When the control knob

stops rotating apply further light pressure.

Do not over-tension. Allow the control knob to

spring back to the „out“ position and rotate

further clockwise to tighten the guide bar.

Apply moderate pressure to tighten.

◆ Check the chain tension. The tension is correct

when the chain snaps back after being pulled

3 mm away from the chain bar with light force

from the middle finger and thumb.

There should be no „sag“ between the guide

bar and chain on the underside.

Note: Do not over-tension the chain as this will

lead to excessive wear and will reduce the life of

the bar and chain.

Note: When the chain is new, check the tension

frequently (after disconnecting from the mains)

during the first 2 hours of use as a new chain

stretches slightly.

USE

Let the tool work at its own pace.

Do not overload.

Filling oil into the reservoir (fig. E)

◆ Remove the oil cap (3) and fill the reservoir with

the recommended chain oil. You can see the oil

level in the indicator slot (4). Refit the oil cap.

◆ Periodically switch off and check the oil in the

indicator; if it is less than a quarter full,

disconnect your chainsaw from the mains and

refill with the correct oil.

Auto-stop chainbrake (fig. F & G)

This tool is fitted with an auto-stop chainbrake which

will stop the chain within 150 ms each time you

release the rear trigger, or if kickback should occur.

This brake should be tested before every use.

How to set the chainbrake

◆ Make sure that the tool is disconnected from

the mains supply.

◆ Pull the front guard (5) back into the „set“

position .

The tool is now ready to use.

How the anti-kickback chainbrake works

In the event of kickback, your left hand comes in

contact with the front guard, pushing it backwards,

and stops the tool within 150 ms.

How the inertia activated chainbrake works

The chainbrake is activated when the front hand

guard is pushed forward, either manually, by the

back of the users hand or by its own weight. The

advantage of the inertia brake is that it is activated

by a severe kickback, eg. when the chain hits metal,

even if the users hand does not contact the front

guard, ie. when the saw is in the felling position.

13

Page 14

ENGLISH

How to test the anti-kickback chainbrake

◆ Grip the tool firmly in both hands on a firm

surface - make sure the chain is clear of the

ground and switch on (see „How to switch your

chainsaw on“).

◆ Rotate your left hand forward around the front

handle so that the back of your hand comes in

contact with the front guard and pushes it

backwards (fig. G). The chain should stop

within a few fractions of a second.

To reset after the operation of the chainbrake

◆ Follow the instructions for setting the chainbrake.

Notes:

◆ It will not be possible to switch the tool on if

the front guard is not in the „set“ position.

◆ Avoid re-starting the tool until you hear the

motor come to a complete rest.

◆ If the chain does not come to rest immediately

then this indicates that it needs tensioning

(see „Fitting the guide bar and chain“).

How to switch the tool on (fig. A)

◆ Grip your chainsaw firmly with both hands.

Push the lock-off button (2) forward and then

push the on/off switch (1) to start.

◆ When the motor starts, remove your thumb

from the lock button and grip the handle firmly.

Do not force the tool - allow it to do the work.

It will do a better and safer job at the speed for

which it is designed. Excessive force will stretch

the chain.

If the saw chain or bar becomes jammed:

◆ Switch the tool off.

◆ Disconnect the tool from the mains supply.

◆ Open the cut with wedges to relieve the strain

on the guide bar. Do not try to wrench the saw

free. Start a fresh cut.

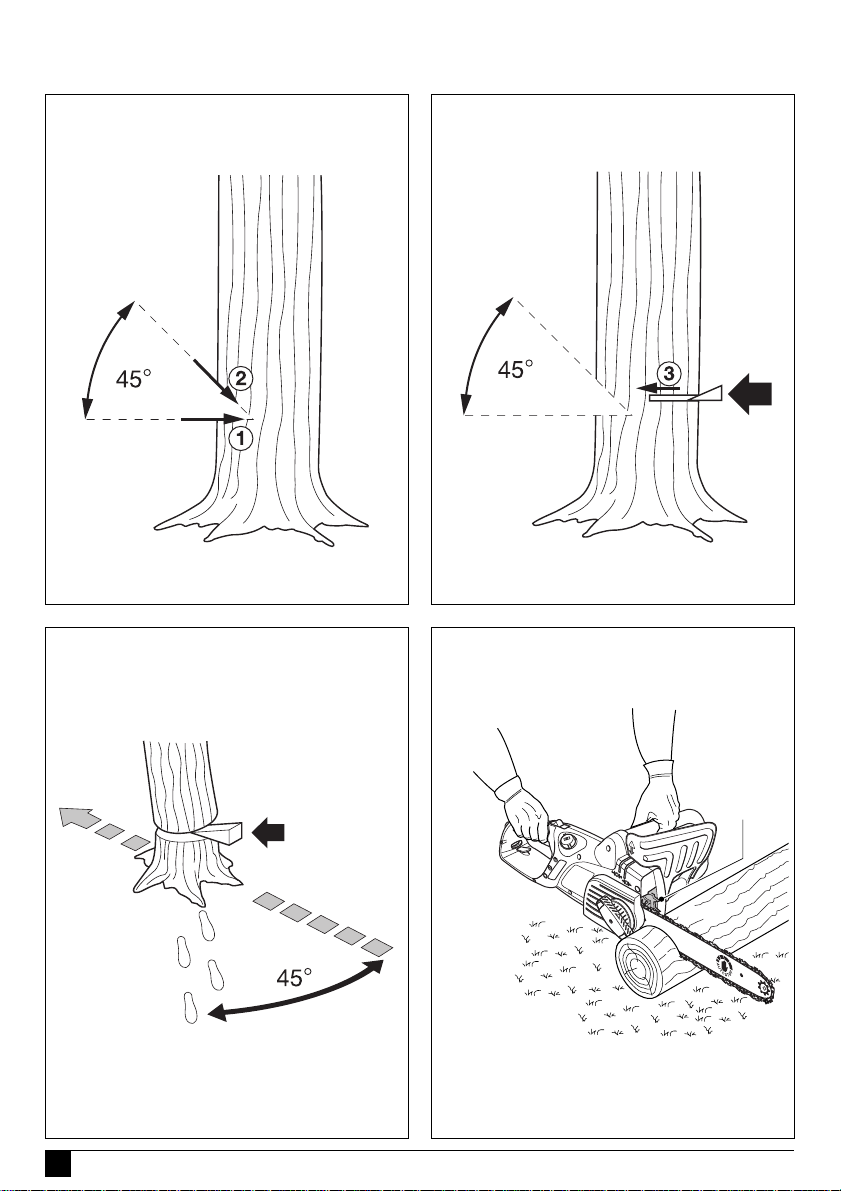

Felling (fig. H - J)

◆ Pre-plan a safe exit from falling trees or branches.

◆ Cut one third of the diameter of the tree (Fig. H).

Then cut down from above to make a notch of

about 45°. This way you will avoid pinching the

saw.

14

◆ Make a single felling cut from the other side

but stop before you cut through to the notch

(fig. I).

◆ Drive a wedge or wedges into the felling cut to

open it and drop the tree (fig. J).

Logging (fig. K - M)

How you should cut depends on how the log is

supported. Use a saw horse whenever possible.

Always start a cut with the chain running and the

spiked bumper (17) in contact with the wood (fig. K).

To complete the cut use a pivoting action of the

spiked bumper against the wood.

When supported along its whole length

◆ Make a downward cut, but avoid cutting the

earth as this will blunt your saw quickly.

When supported at both ends

◆ First, cut one third down to avoid splintering

and second, cut again to meet the first cut.

When supported at one end

◆ First, cut one third up to avoid splintering and

second, cut down to prevent splintering.

When on a slope (fig. L)

◆ Always stand on the uphill side.

When using a saw horse (fig. M)

This is strongly recommended whenever possible.

◆ Position the log in a stable position. Always cut

on the outside of the saw horse arms.

MAINTENANCE (fig. N)

Regular maintenance ensures a long effective life

for the tool. We recommend you make the

following checks on a regular basis.

Oil level

The level in the reservoir should not be allowed to

fall below a quarter full.

Chain and guide bar

◆ After every few hours of use, remove the guide

bar and chain and clean thoroughly.

◆ Ensure the hole between the tensioning/oil

hole (18) and the bar groove is clear.

Page 15

ENGLISH

◆ On reassembling, the guide bar should be

turned through 180° and the sprocket nose

greased via the sprocket lubrication hole (19).

This ensures an even distribution of wear

around the guide bar rails.

◆ To turn the guide bar through 180°, remove

the small screw from the slider and re-fasten to

the opposite side of the bar.

Saw chain sharpening

If you are to get the best possible performance

from the tool it is important to keep the teeth of

the saw chain sharp. Guidance for this procedure

is found on the sharpener package. For this purpose

we recommend the purchase of the Black & Decker

saw chain sharpening kit (available from

Black & Decker service agents and selected dealers).

Replacing worn out chains

Replacement chains are available through retailers

or Black & Decker service agents. Always use

genuine spare parts.

Saw chain sharpness

The cutters will blunt immediately if they touch the

ground or a nail whilst cutting.

Saw chain tension

◆ Regularly check the chain tension.

Oil level

◆ Top up if low.

What to do if your chainsaw needs repair

Your chainsaw is in accordance with the relevant

safety requirements. Repairs should only be

carried out by a qualified persons using original

spare parts, otherwise this may result in considerable

danger to the user. We recommend you keep this

user manual in a safe place.

ACCESSORIES

Cat. no. Description

A6154 300 mm / 12" chain

A6155 350 mm / 14" chain

A6156 400 mm / 16" chain

A6039 Sharpening kit

A6027 0.5 l chain oil

PROTECTING THE ENVIRONMENT

Black & Decker provides a facility for

recycling Black & Decker products once

they have reached the end of their

working life. This service is provided free

of charge. To take advantage of this

service please return your product to any

authorised repair agent who will collect

them on our behalf.

TROUBLESHOOTING

If the tool does not operate correctly, check the following.

Fault Possible cause Action

Tool will not start. Blown fuse. Replace fuse.

Tripped RCD. Check RCD.

Mains lead not connected. Check mains supply.

Tool will not start

button will not slide. Front guard in the brake position Reset front guard.

Chain does not stop instantly

when the tool is switched off. Chain tension is too slack. Check chain tension.

Bar/chain appear hot/smoking. Oil tank empty. Check oil tank level.

Chain tension is too tight. Check chain tension.

Guide bar sprocket nose needs greasing.

15

Page 16

ENGLISH

You can check the location of your nearest

authorised repair agent by contacting your local

Black & Decker office at the address indicated in

this manual. Alternatively, a list of authorised

Black & Decker repair agents and full details of our

after-sales service and contacts are available on

the Internet at: www.2helpU.com.

Guarantee

Black & Decker is confident of the quality of its

products and offers an outstanding guarantee.

This guarantee statement is in addition to and in

no way prejudices your statutory rights.

The guarantee is valid within the territories of the

Member States of the European Union and the

European Free Trade Area.

If a Black & Decker product becomes defective

due to faulty materials, workmanship or lack of

conformity, within 24 months from the date of

purchase, Black & Decker guarantees to replace

defective parts, repair products subjected to fair

wear and tear or replace such products to ensure

minimum inconvenience to the customer unless:

◆ The product has been used for trade,

professional or hire purposes;

◆ The product has been subjected to misuse or

neglect;

◆ The product has sustained damage through

foreign objects, substances or accidents;

◆ Repairs have been attempted by persons other

than authorised repair agents or Black & Decker

service staff.

EC DECLARATION OF CONFORMITY

GK1640T/GK1635T/GK1630T series

Black & Decker declares that these

products conform to:

98/37/EC, 89/336/EEC, 73/23/EEC,

EN 50144, EN 55014,

2000/14/EC, Chainsaw ≤ 1600 W, Annex V

Level of sound pressure, measured according to

2000/14/EC:

LpA(sound pressure) dB(A) 88

LWA(acoustic power) dB(A) 101

LWA(guaranteed) dB(A) 103

Always wear ear protection if the sound

pressure exceeds 85 dB(A).

Hand/arm weighted vibration value according to

EN 50144:

2

3.5 m/s

TÜV Rheinland

Cert. No.

BM981084801

To claim on the guarantee, you will need to submit

proof of purchase to the seller or an authorised

repair agent. You can check the location of your

nearest authorised repair agent by contacting your

local Black & Decker office at the address indicated

in this manual. Alternatively, a list of authorised

Black & Decker repair agents and full details of our

after-sales service and contacts are available on

the Internet at: www.2helpU.com.

16

Kevin Hewitt

Director of Consumer Engineering

Spennymoor, County Durham DL16 6JG,

United Kingdom

Page 17

GK1430 GK1435 GK1440 GK1630 GK1635

GK1640 GK1330 GK1630T GK1635T GK1640T

TYP

4

149

147

146

149

158

145

152

135

112

168

149

111

103

121

133

156

102

163

119

167

101

120

149

155

107

118

149

141

139

138

142

140

135

144

144

143

148

110

111

137

104

108

123

124

149

161

162

115

153

151

150

113

116

114

117

154

125

149

127

128

129

130

131

132

GK1630T GK1635T GK1640T

E13317

134

157

164

165

136

127

130

159

GK1430 GK1435

GK1440 GK1630

GK1635 GK1640 GK1330

WWW.2helpU.com

126

846

04 - 03 - 02

17

Page 18

Australia DEWALT Industrial Power Tool Company Tel. 03 9895 9200

7 Clarice Road Fax 03 9899 7465

Box Hill, Victoria 3128

New Zealand Black & Decker Tel. 09 579 7600

81 Hugo Johnson Drive Fax 09 579 8200

Penrose, Auckland, New Zealand

South Africa Black & Decker South Africa (Pty) Ltd Tel. (011) 653-1400

Physical address: Fax (011) 653-1499

39 Commerce Crescent

Eastgate, ext. 12, Sandton, Kramerville 2148

Postal address:

Postnet Suite 107, Private Bag X65

Halfway House 1685

United Kingdom Black & Decker Tel. 01753 511234

210 Bath Road Fax 01753 551155

Slough, Berkshire SL1 3YD Helpline 01753 574277

18

374860-13

Page 19

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

✁

Yes

No

Data protection act:

Tick the box if you prefer not to receive further information.

Dealer address Date of purchase

.................................................................................................................

Was this tool bought as a replacement?

Name: ......................................................................................................

Address: ...................................................................................................

Town: .......................................................................................................

.................................................................................................................

Dealer address: ........................................................................................

Yes

No

Postal code: .............................................................................................

Was this tool a gift?

Yes

No

Was this tool your first purchase?

19

Page 20

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

✁

Please complete this section immediately after the purchase of your tool and send it to Black & Decker in your

country. If you live in Australia or New Zealand, please register by using the alternative guarantee card

supplied.

GUARANTEE CARD

20

374860-13

Loading...

Loading...