Black & Decker GH710 TYPE 1 Owner’s Manual

TRIMMER / EDGER

iNSTRUCTiON MANUAL

Model Number GH710

PLEASE READ BEFORE RETURNING

THiS PRODUCT FOR ANY REASON:

Ifyou have a question or experience a problem with your

WWW.BLACKAN DDECKER.COM/INSTANTANSWERS

If you can't find the answer or do not have access to the internet,

call 1-800-544-6986 from 8 a.m. to 5 p.m. EST Mon. - Fri

Please have the catalog number available when you call.

SAVE THNSMANUAL FOR FUTURE REFERENCE.

VEA EL ESPANOL EN LA CONTRAPORTADA.

POUR LE FRAN(_AIS, VOIR LA COUVERTURE ARRIERE.

INSTRUCTIVO DE O.PERACION, CENTRO.S DE SERVICIO Y

POLIZA DE GARANTIA. ADVERTENCIA: LEASE ESTE

INSTRUCTIVO ANTES DE USAR EL PRODUCTO.

Black & Decker purchase, go to

for instant answers 24 hours a day.

to speak with an agent.

Model No. GH710

KEY INFORMATION YOU SHOULD KNOW:

o The guard must be installed before trimming or edging - if

not, the motor will overheat (page 5).

o When replacing the line, use only .065 inch diameter

ROUND line (B&D Model No. DF-065 is recommended) -

otherwise the tool will not function properly (page 8).

o Do not bump the feed head against the ground - it will

disrupt the feed mechanism.

o

Always use the cord retention feature (page 7).

1

SafetyGuidelines-Definitions.................................................2

ImportantSafetyWarningsandInstructions............................2

SafetyWarningsandInstructions:PolarizedPlugs.................4

SafetyWarningsandInstructions:ExtensionCords................4

Components.............................................................................5

Assembly/ Adjustment ............................................................ 5

Operating Instructions .............................................................. 7

Replacement Accessories ....................................................... 9

Maintenance ............................................................................ 10

Troubleshooting ....................................................................... 11

Service Information ....................................................................

Full Two-Year Home Use Warranty .......................................... 12

SAFETY GUIDELINES =DEFINITIONS

It is important for you to read and understand this manual. The

information it contains relates to protecting YOUR SAFETY and

PREVENTING PROBLEMS. The symbols below are used to help

you recognize this information.

z-_DANGER: Indicates an imminently hazardous situation

which, if not avoided, will result in death or serious injury.

ZLWARNING: Indicates a potentially hazardous situation which,

if not avoided, could result in death or serious injury.

ZLCAUTION: Indicates a potentially hazardous situation which,

if not avoided, may result in minor or moderate injury.

NOTICE: Used without the safety alert symbol indicates a

potentially hazardous situation which, if not avoided, may result in

property damage.

ZLWARNING: When using electric gardening appliances, basic

safety precautions should always be followed to reduce risk of fire,

electric shock, and personal injury, including the following.

Read All Instructions

• ALWAYS WEAR EYE PROTECTION - Wear safety spectacles

or goggles at all times when this tool is plugged in.

• GUARD - Do not use this tool without guard attached.

• DRESS PROPERLY - Do not wear loose clothing or jewelry.

They can be caught in moving parts. Rubber gloves and

substantial rubber soled footwear are recommended when

working outdoors. Don't operate the toot when barefoot or

wearing open sandals. Wear heavy long pants to protect your

legs. Wear protective hair covering to contain long hair.

• NYLON LINE - Keep face, hands and feet clear of rotating nylon

line at all times.

• THE ROTATING LINE PERFORMS A CUTTING FUNCTION -

Use care when trimming around screens and desirable plantings.

• KEEP ALL BYSTANDERS AWAY - at a safe distance from

work area, especially children.

• IMPORTANT WARNING - When being used as an Edger,

stones, pieces of metal and other objects can be thrown out at

high speed by the line. The toot and guard are designed to

reduce the danger. However, the following special precautions

should be taken:

• MAKE SURE that other persons and pets are at least 100 feet

(30m) away.

• TO REDUCE THE RISK of rebound (ricochet) injury, work going

away from any nearby solid object such as wall, steps, large

stone, tree, etc. Use great care when working close to solid

objects and where necessary, do edging or trimming by hand.

•AVOIDACCIDENTALLY STARTING - Don't carry plugged-in

tool with finger on trigger.

• DO NOT FORCE THE TOOL - at a rate faster than the rate at

which it is able to cut effectively.

• USE THE RIGHT TOOL - Do not use this tool for any job except

that for which it is intended.

• DON'T OVERREACH - Keep proper footing and balance at alltimes.

• DON'T ABUSE CORD - Don't yank cord from power supply.

Keep cord from heat, oil, and sharp edges.

• DAMAGE TO UNIT - If you strike or become entangled with a

foreign object, stop tool immediately, unplug, check for damage

and have any damage repaired before further operation is

attempted. Do not operate with a broken hub or spool.

• DAMAGE TO CORD - Keep power cord away from rotating line.

If you damage the cord, unplug it from the power supply before

moving the toot or examining the damage. A damaged cord must

be replaced before further use.

• DISCONNECT TOOL - when not in use, when replacing line, or

prior to cleaning.

• AVOID DANGEROUS ENVIRONMENTAL CONDITIONS - Do

not use electric tools in damp or wet locations. Follow all

instructions in this Instruction Manual for proper operation of your

tool. Don't use the tool in the rain.

• DO NOT OPERATE portable electric tools in gaseous or

explosive atmospheres. Motors in these tools normally spark, and

the sparks might ignite fumes.

• STORE IDLE TOOLS INDOORS - When not in use, tools

should be stored indoors in a dry, locked-up place out of reach of

children.

• GROUND FAULT CIRCUIT INTERRUPTER (GFCl) protection

should be provided on the circuits or outlets to be used for the

gardening appliance. Receptacles are available having built in

GFCI protection and may be used for this measure of protection.

• SECURE EXTENSION CORD using the cord retainer shown in

Figure H.

• STAY ALERT - Do not operate this unit when you are tired, ill,

or under the influence of alcohol, drugs, or medication

MAINTAIN APPLIANCES WITH CARE - Follow instructions in

maintenance section. Inspect extension cords periodically and

replace if damaged. Keep handles dry, clean and free from oil and

grease.

• CHECK DAMAGED PARTS - Before further use of the

appliance, a guard or other part that is damaged should be

carefully checked to determine that it will operate properly and

perform its intended function. Check for alignment of moving

parts, binding of moving parts, breakage of parts, mounting, and

any other condition that may affect its operation. A guard or other

part that is damaged should be properly repaired or replaced by

an authorized service center unless otherwise indicated

elsewhere in this manual.

zLWARNING: Do not use toot if the switch trigger does not turn

the tool on or off. Any toot that can not be controlled with the switch

trigger is dangerous and must be repaired.

ZLWARNING: When servicing double insulated tools, USE

ONLY IDENTICAL REPLACEMENT PARTS. Replace or repair

damaged cords.

zLWARNING: To prevent electrical shock hazard, use only with

an extension cord suitable for outdoor use. Always connect extension

cords to a fused line or one protected by a circuit breaker.

• DO NOT immerse toot in water or squirt it with a hose. DO NOT

allow any liquid to get inside it.

• DO NOT store the toot on or adjacent to fertilizers or chemicals.

• DO NOT clean with a pressure washer.

SAVE THESE iNSTRUCTiONS

The label on your toot may include the following symbols. The

symbols and their definitions are as follows:

V .............. volts

Hz ............ hertz

min ............ minutes

- - -. ......... direct current

[] .............. Class II Construction

z_ ............safety alert symbol

A ................ amperes

W ................ watts

"_ .............. alternating current

no .............. no load speed

C_ ............ earthing terminal

.../min ...... revolutions or

reciprocations per minute

Z_WARNING: Some dust created by this product contains

chemicals known to the State of California to cause cancer, birth

defects or other reproductive harm. Some examples of these

chemicals are:

• compounds in fertilizers

• compounds in insecticides, herbicides and pesticides

• arsenic and chromium from chemically treated lumber

To reduce your exposure to these chemicals, wear approved safety

equipment such as dust masks that are specially designed to filter

out microscopic particles.

To reduce the risk of electric shock, this equipment has a polarized

plug (one blade is wider than the other) and wilt require the use of a

polarized extension cord. The appliance plug will fit into a polarized

extension cord only one way. If the plug does not fit fully into the

extension cord, reverse the plug. If the plug still does not fit, obtain

a correct polarized extension cord. A polarized extension cord will

require the use of a polarized wall outlet. This plug will fit into the

polarized wall outlet only one way. If the plug does not fit fully into

the wall outlet, reverse the plug. If the plug still does not fit, contact

a qualified electrician to install the proper walt outlet. Do not change

the equipment plug, extension cord receptacle, or extension cord

plug in any way.

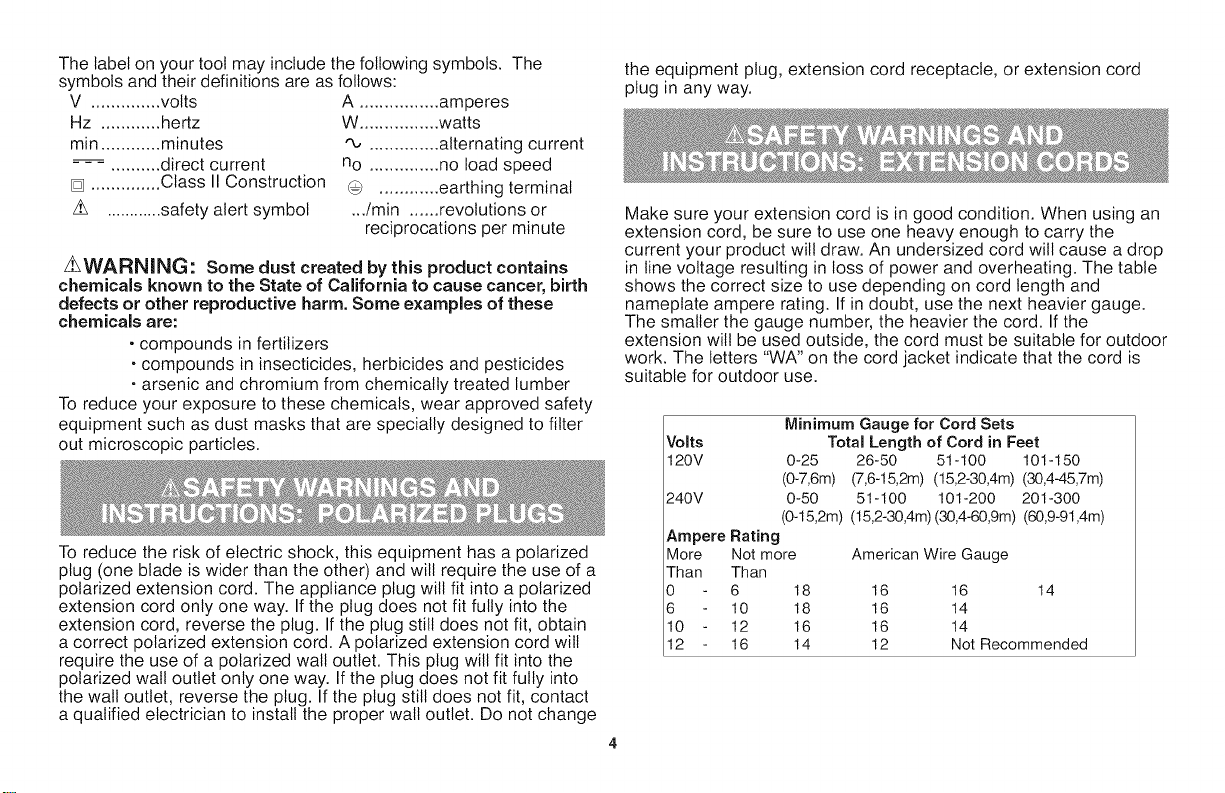

Make sure your extension cord is in good condition. When using an

extension cord, be sure to use one heavy enough to carry the

current your product will draw. An undersized cord will cause a drop

in line voltage resulting in loss of power and overheating. The table

shows the correct size to use depending on cord length and

nameplate ampere rating. If in doubt, use the next heavier gauge.

The smaller the gauge number, the heavier the cord. If the

extension will be used outside, the cord must be suitable for outdoor

work. The letters "WA" on the cord jacket indicate that the cord is

suitable for outdoor use.

Volts Total Length of Cord in Feet

120V 0-25 26-50 51-100 101-150

240V 0-50 51-100 101-200 201-300

Ampere Rating

More Not more American Wire Gauge

Than Than

0 6 18 16 16 14

6 10 18 16 14

10 12 16 16 14

12 16 14 12 Not Recommended

Minimum Gauge for Cord Sets

(0-7,6m) (7,6-15,2m) (15,2-30,4m) (30,4-4.5,7m)

(0-15,2m) (15,2-30,4m)(30,4-60,9m)(60,9-91,4m)

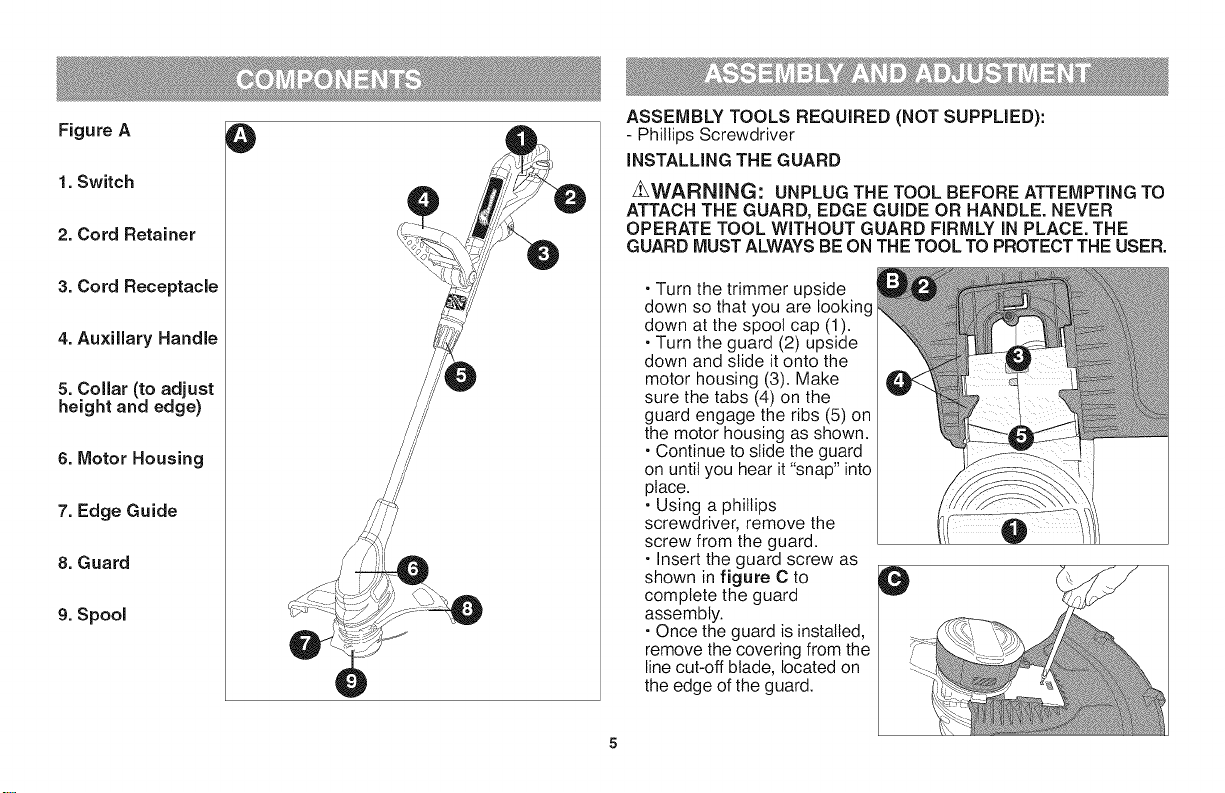

Figure A

1. Switch

2. Cord Retainer

O

ASSEMBLY TOOLS REQUIRED (NOT SUPPLIED):

- Phillips Screwdriver

INSTALLING THE GUARD

_WARNING: UNPLUG THE TOOL BEFORE ATTEMPTING TO

ATTACH THE GUARD, EDGE GUIDE OR HANDLE. NEVER

OPERATE TOOL WITHOUT GUARD FIRMLY IN PLACE. THE

GUARD MUST ALWAYS BE ON THE TOOL TO PROTECT THE USER.

3. Cord Receptacle

4. Auxiliary Handle

5. Collar (to adjust

height and edge)

6. Motor Housing

7. Edge Guide

8. Guard

9. Spool

• Turn the trimmer upside

down so that you are booking

down at the spool cap (1).

• Turn the guard (2) upside

down and slide it onto the

motor housing (3). Make

sure the tabs (4) on the

guard engage the ribs (5) on

the motor housing as shown.

• Continue to slide the guard

on until you hear it "snap" into

place.

• Using a phillips

screwdriver, remove the

screw from the guard.

• Insert the guard screw as

shown in figure C to

complete the guard

assembly.

• Once the guard is installed,

remove the covering from the

line cut-off blade, located on

the edge of the guard.

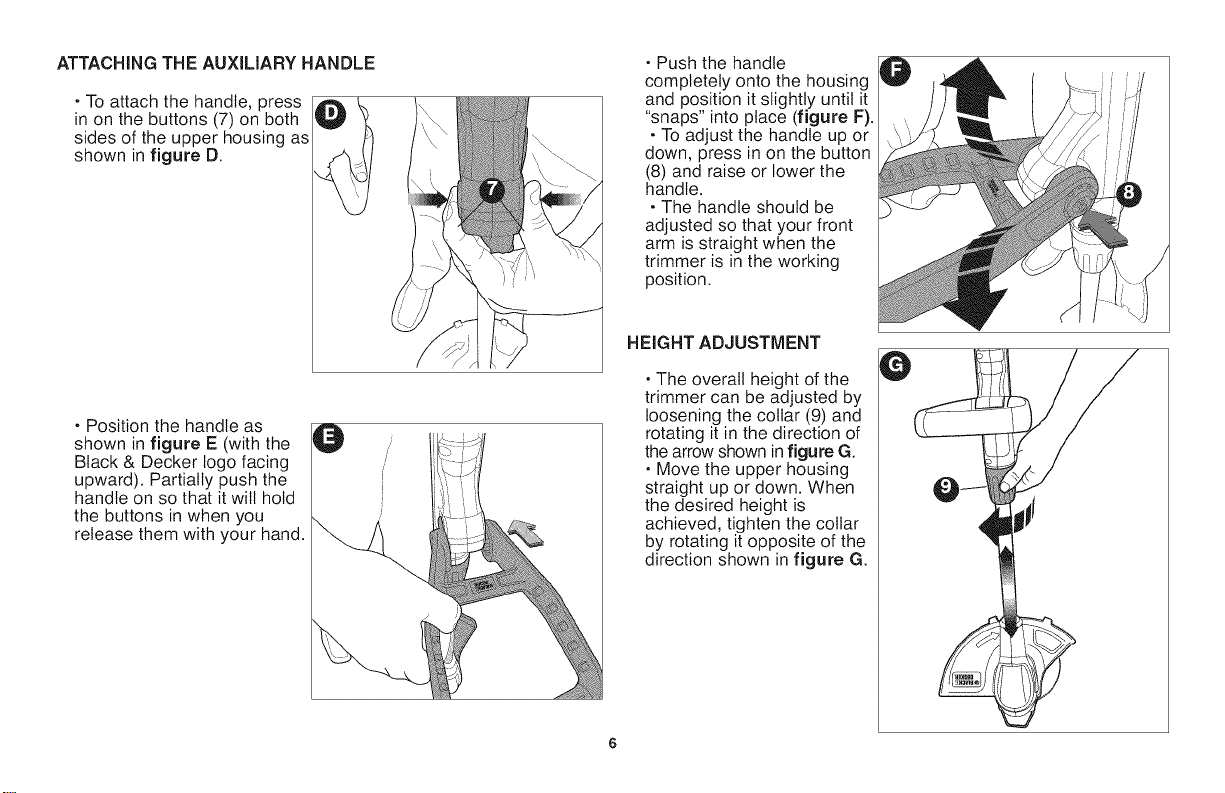

ATTACHING THE AUXiLiARY HANDLE

• To attach the handle, press

in on the buttons (7) on both

sides of the upper housing as

shown in figure D.

• Position the handle as

shown in figure E (with the

Black & Decker logo facing

upward). Partially push the

handle on so that it will hold

the buttons in when you

release them with your hand.

• Push the handle

completely onto the housing

and position it slightly until it

"snaps" into place (figure F).

• To adjust the handle up or

down, press in on the button

(8) and raise or lower the

handle.

• The handle should be

adjusted so that your front

arm is straight when the

trimmer is in the working

position.

HEIGHT ADJUSTMENT

• The overall height of the

trimmer can be adjusted by

loosening the collar (9) and

rotating it in the direction of

the arrow shown in figure G.

• Move the upper housing

straight up or down. When

the desired height is

achieved, tighten the collar

by rotating it opposite of the

direction shown in figure G.

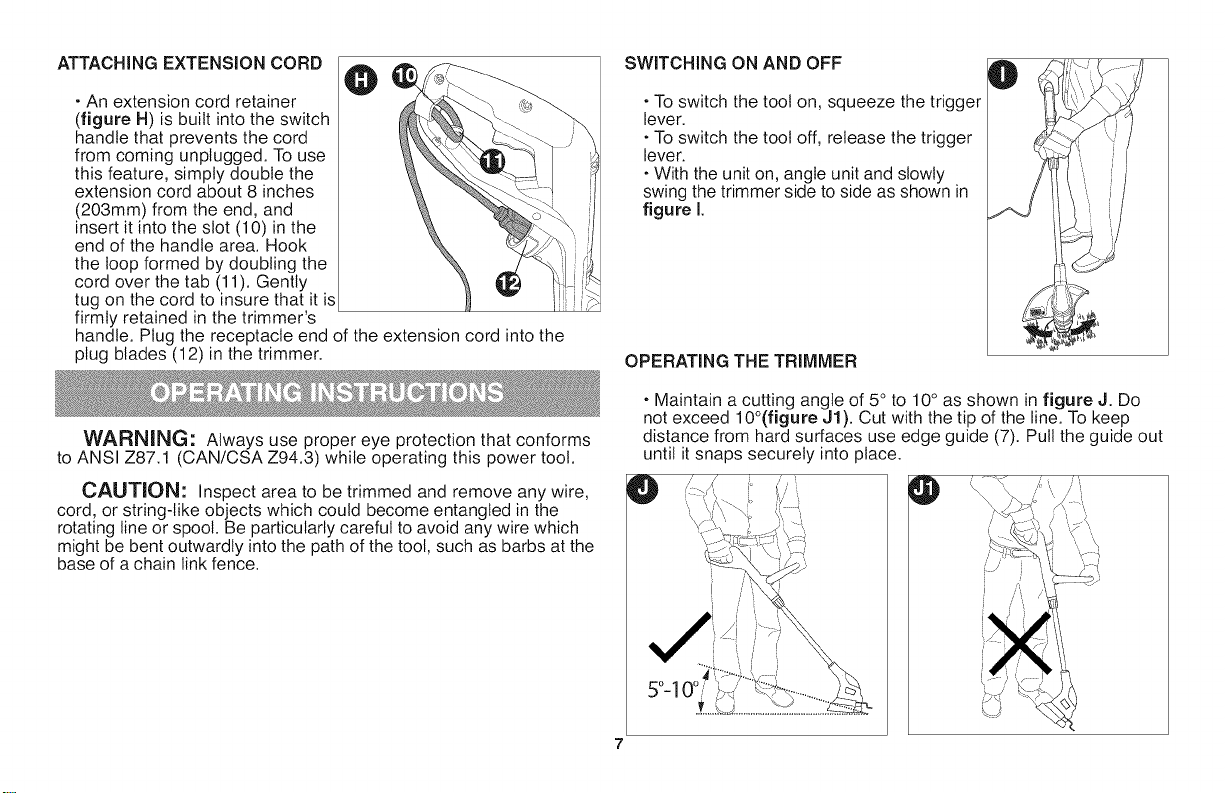

ATTACHINGEXTENSIONCORD

•Anextensioncordretainer

(figureH)isbuiltintotheswitch

handlethatpreventsthecord

fromcomingunplugged.Touse

thisfeature,simplydoublethe

extensioncordabout8inches

(203mm)fromtheend,and

insertitintotheslot(10)inthe

endofthehandlearea.Hook

theloopformedbydoublingthe

cordoverthetab(11).Gently

tugonthecordtoinsurethatitis

firmlyretainedinthetrimmer's

handle.Plugthereceptacleendoftheextensioncordintothe

plugblades(12)inthetrimmer.

WARNING: Always use proper eye protection that conforms

to ANSI Z87.1 (CAN/CSA Z94.3) while operating this power tool.

CAUTION: Inspect area to be trimmed and remove any wire,

cord, or string-like objects which could become entangled in the

rotating line or spool. Be particularly careful to avoid any wire which

might be bent outwardly into the path of the tool, such as barbs at the

base of achain link fence.

SWITCHINGON ANDOFF

• To switch the tool on, squeeze the trigger

lever.

• To switch the tool off, release the trigger

lever.

• With the unit on, angle unit and slowly

swing the trimmer side to side as shown in

figure I.

OPERATING THE TRIMMER

• Maintain a cutting angle of 5° to 10° as shown in figure J. Do

not exceed lO°(figure J1). Cut with the tip of the line. To keep

distance from hard surfaces use edge guide (7). Pull the guide out

until it snaps securely into place.

/, /

iJ _ )'/ ',

• Maintain a minimum distance of 24 inches (609.6 ram) between

the guard and your feet as shown in figure J2. To acheive this

distance adjust the overall height of the trimmer as shown in

figure G.

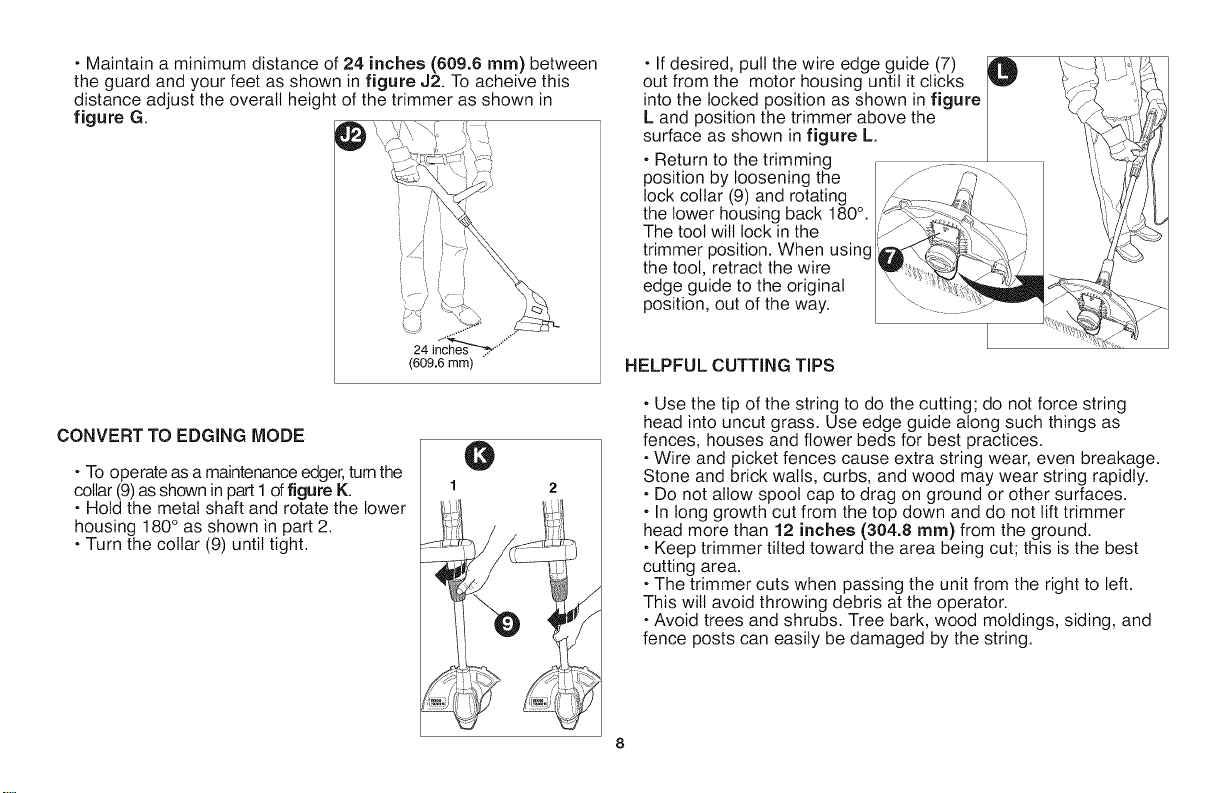

CONVERT TO EDGING MODE

• To operate as amaintenance edger,turn the

collar (9)asshown in part 1of figure K.

• Hold the metal shaft and rotate the lower

housing 180° as shown in part 2.

• Turn the collar (9) until tight.

• If desired, pull the wire edge guide (7)

out from the motor housing until it clicks

into the locked position as shown in figure

L and position the trimmer above the

surface as shown in figure L.

• Return to the trimming

position by loosening the

lock collar (9) and rotating

the lower housing back 180°.

The tool will lock in the

trimmer position. When using

the tool, retract the wire

edge guide to the original

position, out of the way.

HELPFUL CUTTING TIPS

• Use the tip of the string to do the cutting; do not force string

head into uncut grass. Use edge guide along such things as

fences, houses and flower beds for best practices.

• Wire and picket fences cause extra string wear, even breakage.

Stone and brick walls, curbs, and wood may wear string rapidly.

• Do not allow spool cap to drag on ground or other surfaces.

• In long growth cut from the top down and do not lift trimmer

head more than 12 inches (304.8 rnm) from the ground.

• Keep trimmer tilted toward the area being cut; this is the best

cutting area.

• The trimmer cuts when passing the unit from the right to left.

This will avoid throwing debris at the operator.

• Avoid trees and shrubs. Tree bark, wood moldings, siding, and

fence posts can easily be damaged by the string.

CUTTINGLINE / LINE FEEDING

Your trimmer uses .065 inch (1.65 ram) diameter, ROUND

nylon line. During use, the tips of the nylon lines wilt become

frayed and worn and the special self feeding spool will

automatically feed and trim a fresh length of line. Cutting line will

wear faster and require more feeding if the cutting or edging is

done along sidewalks or other abrasive surfaces or heavier

weeds are being cut. The advanced automatic line feeding

mechanism senses when more cutting line is needed and feeds

and trims the correct length of line whenever it's required. DO

NOT BUMP unit on ground in attempt to feed line or for any other

purposes.

Use Black & Decker replacement spool Model No. DF-065.

• USE ONLY .065 inch (1.65 mm) DIAMETER ROUND NYLON

LINE. Do not use heavier gauge line as it will overload the motor

and cause overheating. Do not use lighter gauge or serrated .065

inch (1.65 mm) line as it will cause overfeeding.

• Other replacement parts (guards, spool caps, etc.) are available

through Black & Decker service centers. To find your local service

location call: 1-800-544-6986 or visit www.biackanddecker.com.

WARNING: The use of any accessory not recommended by

Black & Decker for use with this tool could be hazardous.

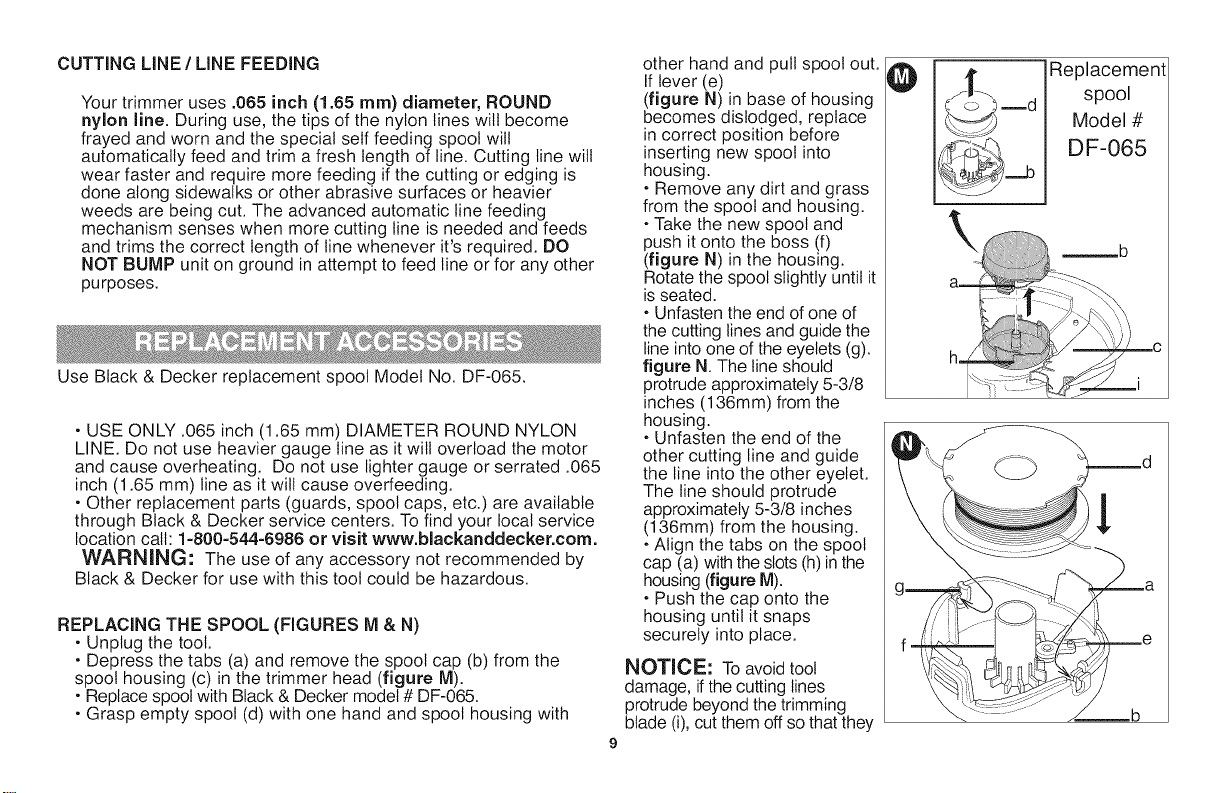

REPLACING THE SPOOL (FIGURES M & N)

• Unplug the toot.

• Depress the tabs (a) and remove the spool cap (b) from the

spool housing (c) in the trimmer head (figure M).

• Replace spool with Black & Decker model # DF-065.

• Grasp empty spool (d) with one hand and spool housing with

other hand and pull spool out.

If lever (e)

(figure N) in base of housing

becomes dislodged, replace

in correct position before

inserting new spool into

housing.

• Remove any dirt and grass

from the spool and housing.

• Take the new spool and

push it onto the boss (f)

(figure N) in the housing.

Rotate the spool slightly until it

is seated.

• Unfasten the end of one of

the cutting lines and guide the

line into one of the eyelets (g).

figure N. The line should

protrude approximately 5-3/8

inches (136mm) from the

housing.

• Unfasten the end of the

other cutting line and guide

the line into the other eyelet.

The line should protrude

approximately 5-3/8 inches

(136mm) from the housing.

• Align the tabs on the spool

cap (a) with the slots (h) inthe

housing (figure M).

• Push the cap onto the

housing until it snaps

securely into place.

NOTICE: Toavoid tool

damage, if thecutting lines

protrude beyond the trimming

blade (i), cut them off so that they

@

Replacement

spool

Model #

DF-065

just reach the blade (figure M).

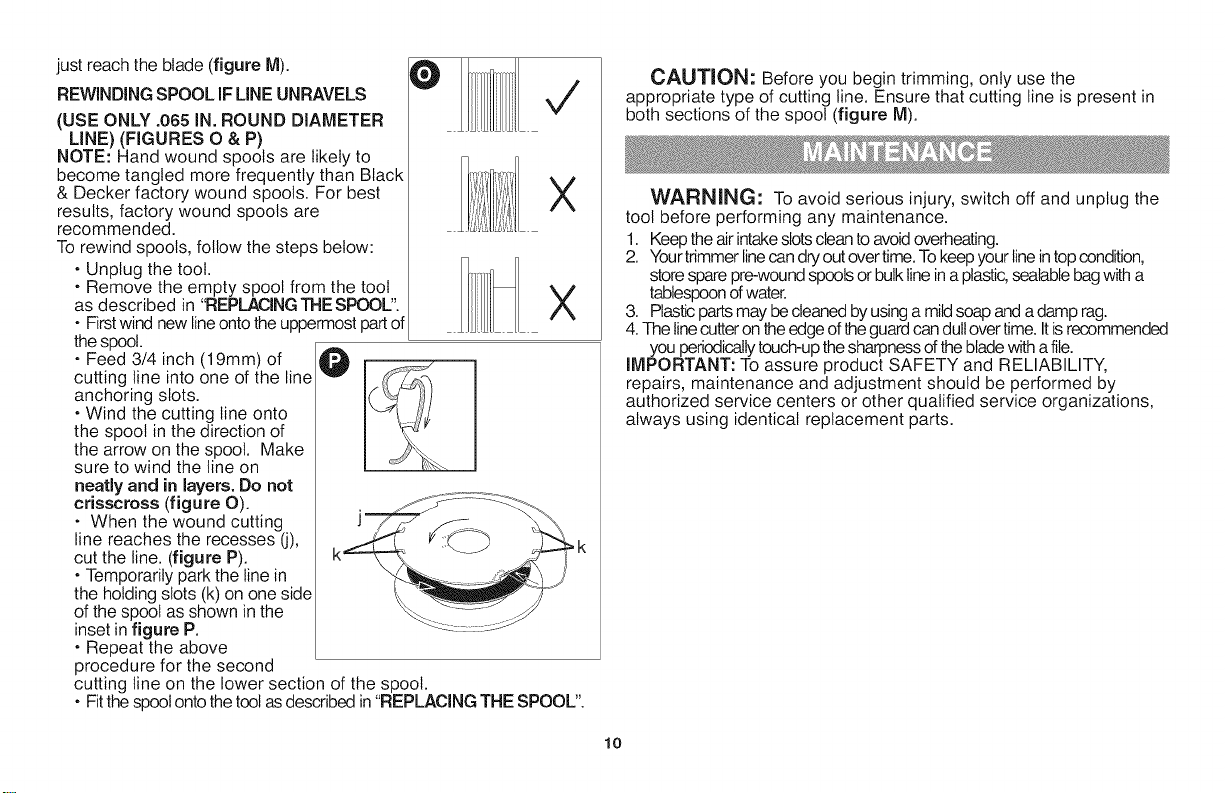

REWINDING SPOOL IF LINE UNRAVELS

(USE ONLY .065 IN. ROUND DIAMETER

LINE) (FIGURES 0 & P)

NOTE: Hand wound spools are likely to

become tangled more frequently than Black

& Decker factory wound spools. For best

results, factory wound spools are

recommended.

To rewind spools, follow the steps below:

• Unplug the toot.

• Remove the empty spool from the tool

as described in "REPLACINGTHESPOOL".

• Firstwind new line onto the uppermost partof

the spool.

• Feed 3/4 inch (19mm) of

cutting line into one of the line

anchoring slots.

• Wind the cutting line onto

the spool in the direction of

the arrow on the spool. Make

sure to wind the line on

neatly and in layers. Do not

crisscross (figure 0).

• When the wound cutting

line reaches the recesses (j),

cut the line. (figure P).

• Temporarily park the line in

the holding slots (k) on one side

of the spool as shown in the

inset in figure P.

• Repeat the above

procedure for the second

cutting line on the lower section of the spool.

• Fitthe spool onto the tool as described in"REPLACING THE SPOOL".

CAUTION: Before you begin trimming, only use the

appropriate type of cutting line. Ensure that cutting line is present in

both sections of the spool (figure M).

WARNING: To avoid serious injury, switch off and unplug the

tool before performing any maintenance.

1. Keepthe airintakeslotscleanto avoidoverheating.

2. Yourtrimmer Finecandry outover time. Tokeep your line intop condition,

storespare pre-woundspools or bulk linein a plastic,sealablebagwith a

tablespoonofwater.

3. Plasticpartsmay becleaned by usinga mildsoap and a damp rag.

4.The linecutteron the edgeofthe guardcandullovertime. Itis recommended

you periodicallytouch-upthesharpnessofthe blade with a file.

iMPORTANT: To assure product SAFETY and RELIABILITY,

repairs, maintenance and adjustment should be performed by

authorized service centers or other qualified service organizations,

always using identical replacement parts.

lO

PROBLEM

SOLUTION

PROBLEM

Tool runs slowly.

Automatic line feed does not

feed more line.

SOLUTION

Check that the spool housing

can rotate freely. Carefully clean

it if necessary.

• Check that the cutting line

does not protrude more than

approximately 5-3/8 inches

(136mm) from the spool. If it

does, cut it off so that it just

reaches the line trimmingblade.

• If the toot still runs stov_ty,stop

using the tool and take it to a

serwce center.

More line is fed when the line

shortens to approximately 3

inches (76.2mm). Todetermine if

the line is not feeding, letline

wear past this point.

• Keep the tabs depressed and

remove the spool from the spool

housing in the trimmer head.

• Ensure that the line is not

crisscrossed on the spool as

detailed in figure O. If it is,

unwind the cutting line, then

wind it back on the spool neatly

so that the lines do not cross.

• Inspect tracks at the bottom of

spool for damage. If damaged,

replace spool.

•Read the code on the back of

spool. Ifit reads"PA66"call

customer service for a replacement.

Ifit reads "ABS"thisis notthe issue.

Automatic line feed does not

feed more line.

Overfeeding

11

• Pull the cutting line until it

protrudes approximately 5-3/8

inches (136mm) from the spool.

If insufficient cutting line is left

on the spool, install a new spool

of cutting line.

• Align the tabs on the spool cap

with the cutouts in the housing.

•Push thespoolcap ontothe housing

untilitsnapssecurelyintoplace.

• If the cutting line protrudes

beyond the trimming blade, cut

it off so that it just reaches the

blade. If the automatic line

feed still does not work or the

spool is jammed, try the

following suggestions:

• Carefully clean the spool

and housEng.

• Remove the spool and check if

the lever in the spoolhousing can

move freely.

• Remove the spool and

unwind the cutting line, then

wind it on neatly again.

Replace the spootinto

the housing.

• Ensure you are cutting with

the tip of the line (5.25 inches

U 33.4mm) from the spool).

se the edge guide if needed to

ensure proper space is

maintained.

• Ensure you are not

exceeding a 10° angle as

shown infigure J1.

PROBLEM

SOLUTION

Line unravels when cap or spool

is removed.

• Be sure to keep spool fully

seated in cap until lines are

parked in holding slots (K)

figure P before removing.

All Black & Decker Service Centers arestaffedwithtrained personnel to

provide customers withefficient and reliablepowertool service.Whether you

need technical advice, repair,orgenuine factoryreplacement parts,contact

the Black & Decker locationnearestyou. Tofindyour localservice location,

refertothe yellowpage directoryunder "Toots--Electric or call:1=800=544-

6986 or visitvvvvw.blackanddecker.corn

Black & Decker (U.S.) Inc. warrants this product for two years against

any defects inmaterialor workmanship. The defectiveproductwill b6

replacedor repairedat no chargein eitherof twoways.

The first isto returnthe productto theretailerfrom whom itwas purchased

(providedthatthe store isa participatingretailer).Returnsshould be made

withinthe time periodof theretailer'sp6ticyfor exchanges (usually30 to90

days afterthe sale). Proofof purchase may berequired.Pleasecheckwith

the retailerfor theirspecificreturn policy regardingreturnsthat arebeyond

the time set for exchanges.

The second optionis to takeor sendthe product (prepaid)toa

Black &Decker owned or authorizedServiceCenter for repairor

replacement at ouroption. Proof ofpurchase maybe requtred.

Black &Decker owned and authorized Service Centers arelistedunder

"Tools-Electrid'inthe yellow pages ofthe phonedirectory.

This warrantydoes notapply to accessories. This warranty givesyou

specificlegafrights andyou may haveother rightswhich vary from stateto

stateor provinceto prownce.Shouldyou naveany questions,contact the

manager ofyour nearestBlack & Decker ServiceCenter.This product is not

intendedfor commercial use.

FREE WARNING LABEL REPLACEMENT: Ifyourwarning labels become

illegibleor are missing,call 1-800-544-6986 for a free replacement.

LATIN AMERICA: Thiswarranty doesnot apply toproductssold in

LatinAmerica. Forproductssold in LatinAmerica,check country specific

warranty informationcontained inthe packaging, call thelocalcompany or

see the websitefor warranty information.

12

Loading...

Loading...