Page 1

TRIMMER / EDGER

INSTRUCTION MANUAL

Model Number GH710

Thank youfor choosingBlack & Decker! Go

to www.BlackandDecker.com/NewOwner

to register your new product.

PLEASE READ BEFORE RETURNING

THIS PRODUCT FOR ANY REASON:

If you have a question or experience a problem with your

Black & Decker purchase, go to

WWW.BLACKANDDECKER.COM/INSTANTANSWERS

for instant answers 24 hours a day.

If you canʼt find the answer or do not have access to the internet,

call 1-800-544-6986 from 8 a.m. to 5 p.m. EST Mon. - Fri

to speak with an agent.

Please have the catalog number available when you call.

SAVE THIS MANUAL FOR FUTURE REFERENCE.

VEA EL ESPAÑOL EN LA CONTRAPORTADA.

POUR LE FRANÇAIS, VOIR LA COUVERTURE ARRIÈRE.

INSTRUCTIVO DE OPERACIÓN, CENTROS DE SERVICIO Y

PÓLIZADE GARANTÍA. ADVERTENCIA: LÉASE ESTE

INSTRUCTIVO ANTES DE USAR EL PRODUCTO.

Model No. GH710

KEY INFORMATION YOU SHOULD KNOW:

• The guard must be installed before trimming or edging - if

not, the motor will overheat (page 5).

• When replacing the line, use only .065 inch diameter

ROUND line (B&D Model No. DF-065 is recommended) otherwise the tool will not function properly (page 8).

• Do not bump the feed head against the ground - it will

disrupt the feed mechanism.

• Always use the cord retention feature (page 7).

1

Page 2

TABLE OF CONTENTS

Safety Guidelines - Definitions .................................................2

Important Safety Warnings and Instructions ............................2

Safety Warnings and Instructions: Polarized Plugs .................4

Safety Warnings and Instructions: Extension Cords ................4

Components.............................................................................5

Assembly / Adjustment ............................................................5

Operating Instructions ..............................................................7

Replacement Accessories .......................................................9

Maintenance ............................................................................10

Troubleshooting .......................................................................11

Service Information ..................................................................12

Full Two-Year Home Use Warranty..........................................12

SAFETY GUIDELINES - DEFINITIONS

It is important for you to read and understand this manual. The

information it contains relates to protecting YOUR SAFETY and

PREVENTING PROBLEMS. The symbols below are used to help

you recognize this information.

DANGER: Indicates an imminently hazardous situation

which, if not avoided, will result in death or serious injury.

WARNING: Indicates a potentially hazardous situation which,

if not avoided, could result in death or serious injury.

CAUTION: Indicates a potentially hazardous situation which,

if not avoided, may result in minor or moderate injury.

NOTICE: Used without the safety alert symbol indicates a

potentially hazardous situation which, if not avoided, may result in

property damage.

IMPORTANT SAFETY WARNINGS AND

INSTRUCTIONS

WARNING: When using electric gardening appliances, basic

safety precautions should always be followed to reduce risk of fire,

electric shock, and personal injury, including the following.

Read All Instructions

• ALWAYS WEAR EYE PROTECTION – Wear safety spectacles

or goggles at all times when this tool is plugged in.

• GUARD – Do not use this tool without guard attached.

• DRESS PROPERLY – Do not wear loose clothing or jewelry.

They can be caught in moving parts. Rubber gloves and

substantial rubber soled footwear are recommended when

working outdoors. Donʼt operate the tool when barefoot or

wearing open sandals. Wear heavy long pants to protect your

legs. Wear protective hair covering to contain long hair.

• NYLON LINE – Keep face, hands and feet clear of rotating nylon

line at all times.

• THE ROTATING LINE PERFORMS A CUTTING FUNCTION –

Use care when trimming around screens and desirable plantings.

• KEEP ALL BYSTANDERS AWAY – at a safe distance from

work area, especially children.

• IMPORTANT WARNING – When being used as an Edger,

stones, pieces of metal and other objects can be thrown out at

high speed by the line. The tool and guard are designed to

reduce the danger. However, the following special precautions

should be taken:

• MAKE SURE that other persons and pets are at least 100 feet

(30m) away.

• TO REDUCE THE RISK of rebound (ricochet) injury, work going

away from any nearby solid object such as wall, steps, large

stone, tree, etc. Use great care when working close to solid

objects and where necessary, do edging or trimming by hand.

2

Page 3

• AVOID ACCIDENTALLY STARTING – Donʼt carry plugged-in

tool with finger on trigger.

• DO NOT FORCE THE TOOL – at a rate faster than the rate at

which it is able to cut effectively.

• USE THE RIGHT TOOL – Do not use this tool for any job except

that for which it is intended.

• DON’T OVERREACH – Keep proper footing and balanceat all times.

• DON’T ABUSE CORD – Donʼt yank cord from power supply.

Keep cord from heat, oil, and sharp edges.

• DAMAGE TO UNIT – If you strike or become entangled with a

foreign object, stop tool immediately, unplug, check for damage

and have any damage repaired before further operation is

attempted. Do not operate with a broken hub or spool.

• DAMAGE TO CORD – Keep power cord away from rotating line.

If you damage the cord, unplug it from the power supply before

moving the tool or examining the damage. A damaged cord must

be replaced before further use.

• DISCONNECT TOOL – when not in use, when replacing line, or

prior to cleaning.

• AVOID DANGEROUS ENVIRONMENTAL CONDITIONS – Do

not use electric tools in damp or wet locations. Follow all

instructions in this Instruction Manual for proper operation of your

tool. Donʼt use the tool in the rain.

• DO NOT OPERATE portable electric tools in gaseous or

explosive atmospheres. Motors in these tools normally spark, and

the sparks might ignite fumes.

• STORE IDLE TOOLS INDOORS – When not in use, tools

should be stored indoors in a dry, locked-up place out of reach of

children.

• GROUND FAULT CIRCUIT INTERRUPTER (GFCI) protection

should be provided on the circuits or outlets to be used for the

gardening appliance. Receptacles are available having built in

GFCI protection and may be used for this measure of protection.

• SECURE EXTENSION CORD using the cord retainer shown in

Figure H.

• STAY ALERT – Do not operate this unit when you are tired, ill,

or under the influence of alcohol, drugs, or medication

• MAINTAIN APPLIANCES WITH CARE – Follow instructions in

maintenance section. Inspect extension cords periodically and

replace if damaged. Keep handles dry, clean and free from oil and

grease.

• CHECK DAMAGED PARTS – Before further use of the

appliance, a guard or other part that is damaged should be

carefully checked to determine that it will operate properly and

perform its intended function. Check for alignment of moving

parts, binding of moving parts, breakage of parts, mounting, and

any other condition that may affect its operation. A guard or other

part that is damaged should be properly repaired or replaced by

an authorized service center unless otherwise indicated

elsewhere in this manual.

WARNING: Do not use tool if the switch trigger does not turn

the tool on or off. Any tool that can not be controlled with the switch

trigger is dangerous and must be repaired.

WARNING: When servicing double insulated tools, USE

ONLY IDENTICAL REPLACEMENT PARTS. Replace or repair

damaged cords.

WARNING: To prevent electrical shock hazard, use only with

an extension cord suitable for outdoor use. Always connect extension

cords to a fused line or one protected by a circuit breaker.

• DO NOT immerse tool in water or squirt it with a hose. DO NOT

allow any liquid to get inside it.

• DO NOT store the tool on or adjacent to fertilizers or chemicals.

• DO NOT clean with a pressure washer.

SAVE THESE INSTRUCTIONS

3

Page 4

The label on your tool may include the following symbols. The

symbols and their definitions are as follows:

V ..............volts A ................amperes

Hz ............hertz W................watts

min............minutes ..............alternating current

..........direct current

..............

Class II Construction

............safety alert symbol .../min ......revolutions or

n

o ..............no load speed

............earthing terminal

reciprocations per minute

WARNING: Some dust created by this product contains

chemicals known to the State of California to cause cancer, birth

defects or other reproductive harm. Some examples of these

chemicals are:

• compounds in fertilizers

• compounds in insecticides, herbicides and pesticides

To reduce your exposure to these chemicals, wear approved safety

equipment such as dust masks that are specially designed to filter

out microscopic particles.

• arsenic and chromium from chemically treated lumber

SAFETY WARNINGS AND

INSTRUCTIONS: POLARIZED PLUGS

To reduce the risk of electric shock, this equipment has a polarized

plug (one blade is wider than the other) and will require the use of a

polarized extension cord. The appliance plug will fit into a polarized

extension cord only one way. If the plug does not fit fully into the

extension cord, reverse the plug. If the plug still does not fit, obtain

a correct polarized extension cord. A polarized extension cord will

require the use of a polarized wall outlet. This plug will fit into the

polarized wall outlet only one way. If the plug does not fit fully into

the wall outlet, reverse the plug. If the plug still does not fit, contact

a qualified electrician to install the proper wall outlet. Do not change

the equipment plug, extension cord receptacle, or extension cord

plug in any way.

SAFETY WARNINGS AND

INSTRUCTIONS: EXTENSION CORDS

Make sure your extension cord is in good condition. When using an

extension cord, be sure to use one heavy enough to carry the

current your product will draw. An undersized cord will cause a drop

in line voltage resulting in loss of power and overheating. The table

shows the correct size to use depending on cord length and

nameplate ampere rating. If in doubt, use the next heavier gauge.

The smaller the gauge number, the heavier the cord. If the

extension will be used outside, the cord must be suitable for outdoor

work. The letters “WA” on the cord jacket indicate that the cord is

suitable for outdoor use.

Minimum Gauge for Cord Sets

Volts Total Length of Cord in Feet

120V 0-25 26-50 51-100 101-150

(0-7,6m) (7,6-15,2m) (15,2-30,4m) (30,4-45,7m)

240V 0-50 51-100 101-200 201-300

(0-15,2m) (15,2-30,4m) (30,4-60,9m) (60,9-91,4m)

Ampere Rating

More Not more American Wire Gauge

Than Than

0-6 18 16 16 14

6-10 18 16 14

10 - 12 16 16 14

12 - 16 14 12 Not Recommended

4

Page 5

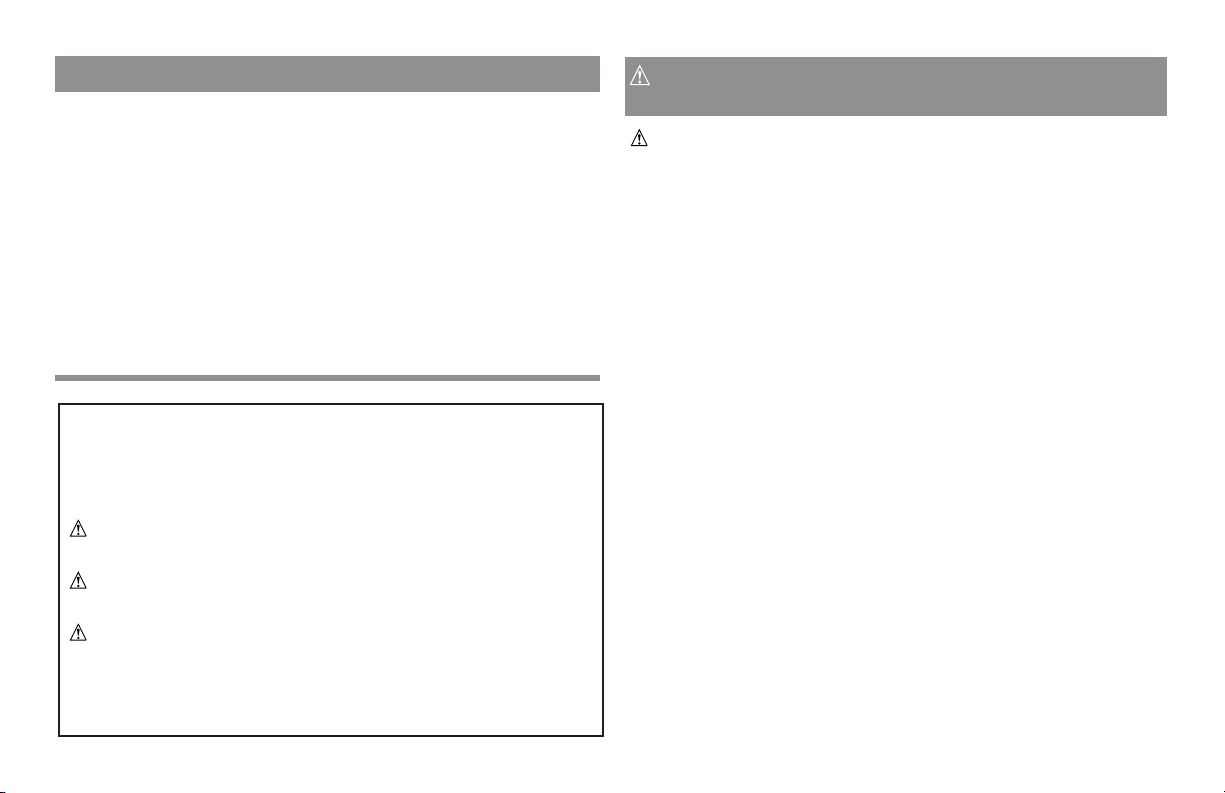

COMPONENTS

ASSEMBLY AND ADJUSTMENT

Figure A

1. Switch

2. Cord Retainer

3. Cord Receptacle

4. Auxillary Handle

5. Collar (to adjust

height and edge)

6. Motor Housing

7. Edge Guide

8. Guard

9. Spool

ASSEMBLY TOOLS REQUIRED (NOT SUPPLIED):

A

4

1

2

3

5

6

8

7

9

- Phillips Screwdriver

INSTALLING THE GUARD

WARNING: UNPLUG THE TOOL BEFORE ATTEMPTING TO

ATTACH THE GUARD, EDGE GUIDE OR HANDLE. NEVER

OPERATE TOOL WITHOUT GUARD FIRMLY IN PLACE. THE

GUARD MUST ALWAYS BE ON THE TOOL TOPROTECT THE USER.

B

• Turn the trimmer upside

down so that you are looking

down at the spool cap (1).

• Turn the guard (2) upside

down and slide it onto the

motor housing (3). Make

sure the tabs (4) on the

guard engage the ribs (5) on

the motor housing as shown.

• Continue to slide the guard

on until you hear it “snap” into

place.

• Using a phillips

screwdriver, remove the

screw from the guard.

• Insert the guard screw as

shown in figure C to

complete the guard

assembly.

• Once the guard is installed,

remove the covering from the

line cut-off blade, located on

the edge of the guard.

2

3

4

5

1

C

5

Page 6

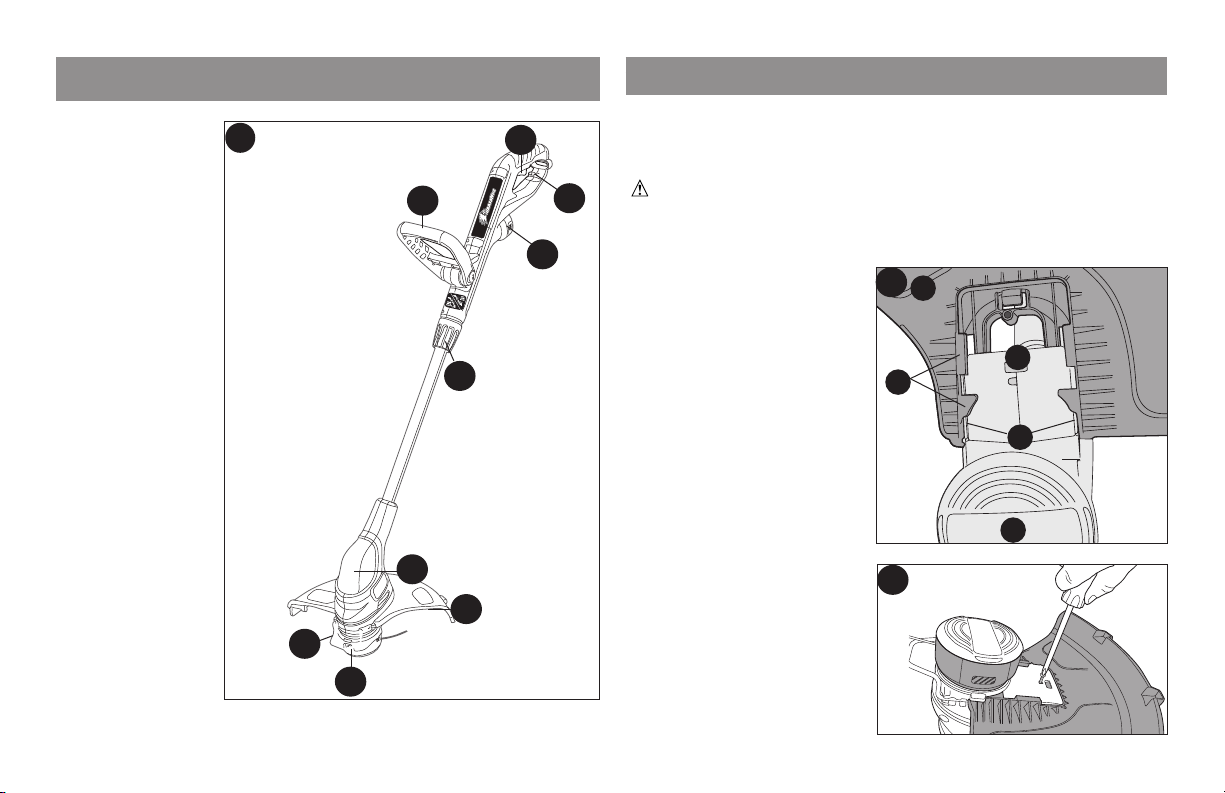

ATTACHING THE AUXILIARY HANDLE

• To attach the handle, press

in on the buttons (7) on both

sides of the upper housing as

shown in figure D.

• Position the handle as

shown in figure E (with the

Black & Decker logo facing

upward). Partially push the

handle on so that it will hold

the buttons in when you

release them with your hand.

D

E

• Push the handle

completely onto the housing

and position it slightly until it

“snaps” into place (figure F).

• To adjust the handle up or

down, press in on the button

(8) and raise or lower the

7

handle.

• The handle should be

adjusted so that your front

arm is straight when the

trimmer is in the working

position.

HEIGHT ADJUSTMENT

• The overall height of the

trimmer can be adjusted by

loosening the collar (9) and

rotating it in the direction of

the arrow shown in figure G.

• Move the upper housing

straight up or down. When

the desired height is

achieved, tighten the collar

by rotating it opposite of the

direction shown in figure G.

F

8

G

9

6

Page 7

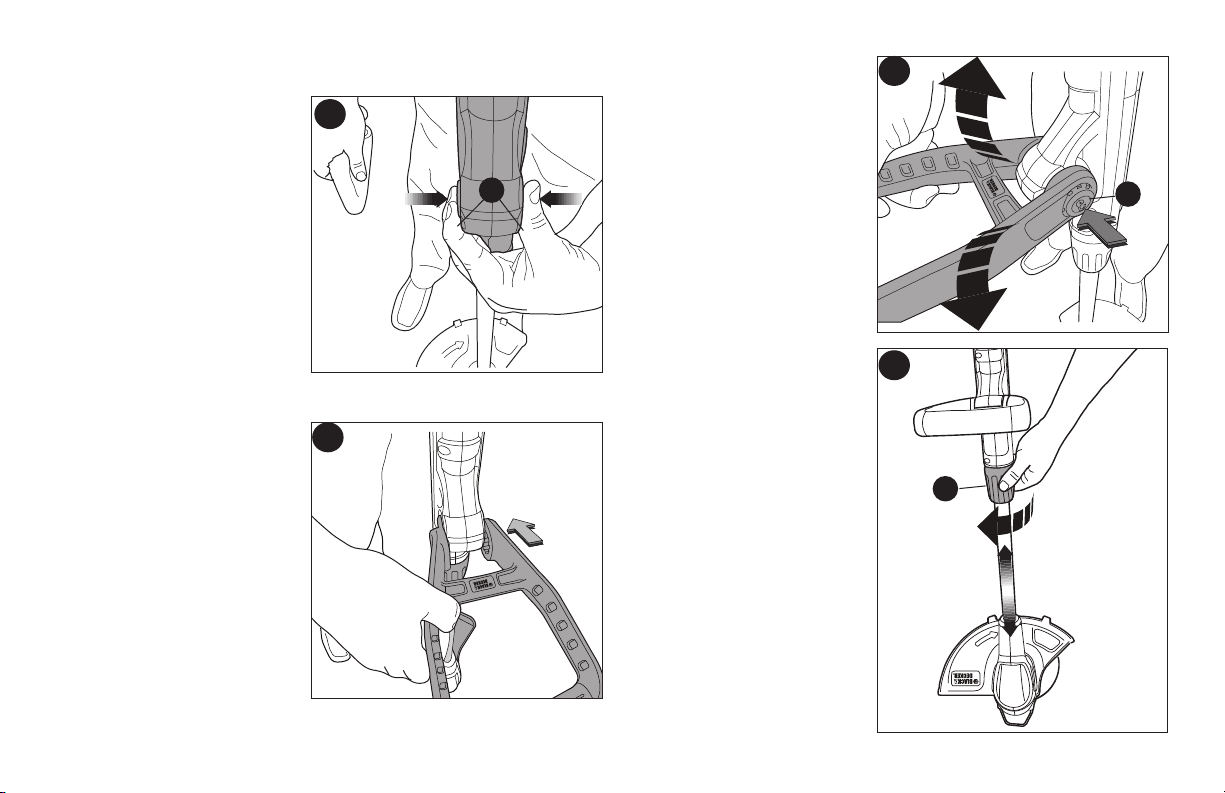

ATTACHING EXTENSION CORD

5O-10

O

• An extension cord retainer

(figure H) is built into the switch

handle that prevents the cord

from coming unplugged. To use

this feature, simply double the

extension cord about 8 inches

(203mm) from the end, and

insert it into the slot (10) in the

end of the handle area. Hook

the loop formed by doubling the

cord over the tab (11). Gently

tug on the cord to insure that it is

firmly retained in the trimmerʼs

handle. Plug the receptacle end of the extension cord into the

plug blades (12) in the trimmer.

10

H

11

12

OPERATING INSTRUCTIONS

WARNING: Always use proper eye protection that conforms

to ANSI Z87.1 (CAN/CSA Z94.3) while operating this power tool.

CAUTION: Inspect area to be trimmed and remove any wire,

cord, or string-like objects which could become entangled in the

rotating line or spool. Be particularly careful to avoid any wire which

might be bent outwardly into the path of the tool, such as barbs at the

base of a chain link fence.

SWITCHING ON AND OFF

• To switch the tool on, squeeze the trigger

lever.

• To switch the tool off, release the trigger

lever.

• With the unit on, angle unit and slowly

swing the trimmer side to side as shown in

figure I.

OPERATING THE TRIMMER

• Maintain a cutting angle of 5° to 10° as shown in figure J. Do

not exceed 10°(figure J1). Cut with the tip of the line. To keep

distance from hard surfaces use edge guide (7). Pull the guide out

until it snaps securely into place.

J

J1

I

7

Page 8

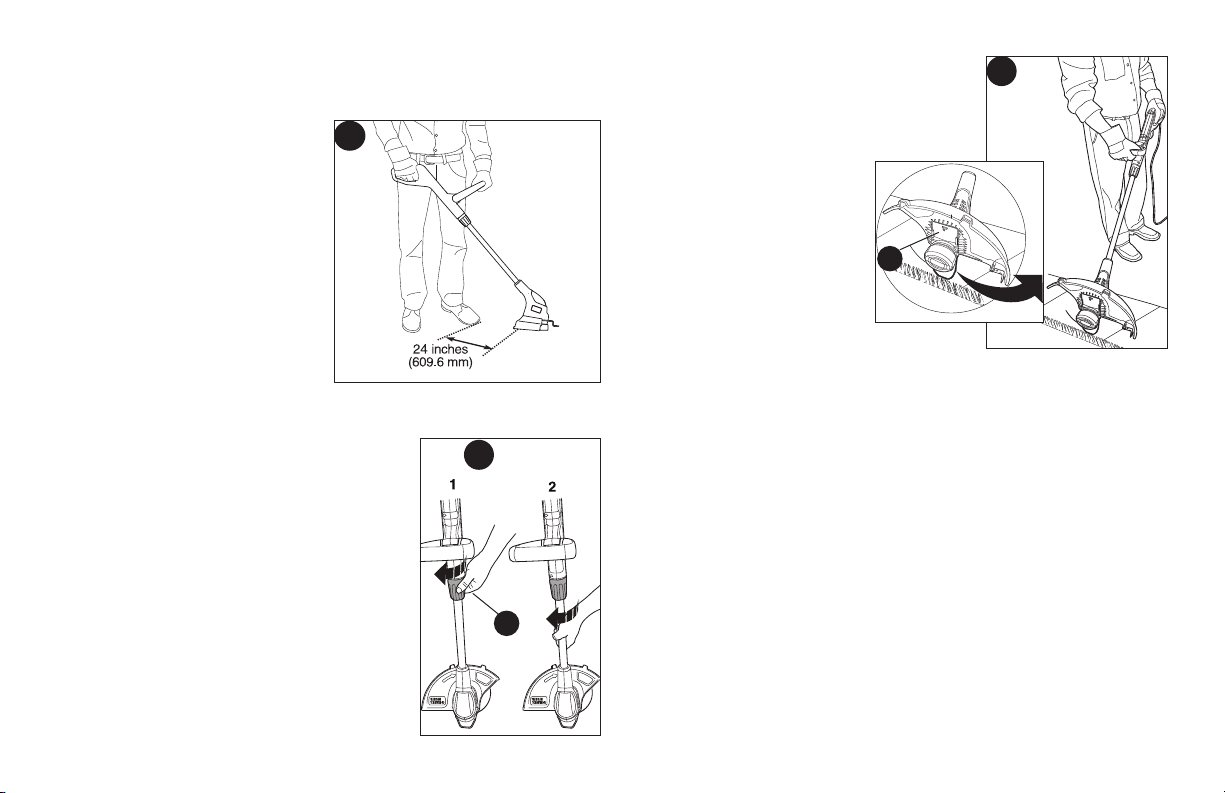

• Maintain a minimum distance of 24 inches (609.6 mm) between

the guard and your feet as shown in figure J2. To acheive this

distance adjust the overall height of the trimmer as shown in

figure G.

J2

CONVERT TO EDGING MODE

• To operate asa maintenance edger,turnthe

collar(9) as showninpart1 of figure K.

• Hold the metal shaft and rotate the lower

housing 180° as shown in part 2.

• Turn the collar (9) until tight.

K

9

• If desired, pull the wire edge guide (7)

out from the motor housing until it clicks

into the locked position as shown in figure

L and position the trimmer above the

surface as shown in figure L.

• Return to the trimming

position by loosening the

lock collar (9) and rotating

the lower housing back 180°.

The tool will lock in the

trimmer position. When using

the tool, retract the wire

edge guide to the original

position, out of the way.

HELPFUL CUTTING TIPS

• Use the tip of the string to do the cutting; do not force string

head into uncut grass. Use edge guide along such things as

fences, houses and flower beds for best practices.

• Wire and picket fences cause extra string wear, even breakage.

Stone and brick walls, curbs, and wood may wear string rapidly.

• Do not allow spool cap to drag on ground or other surfaces.

• In long growth cut from the top down and do not lift trimmer

head more than 12 inches (304.8 mm) from the ground.

• Keep trimmer tilted toward the area being cut; this is the best

cutting area.

• The trimmer cuts when passing the unit from the right to left.

This will avoid throwing debris at the operator.

• Avoid trees and shrubs. Tree bark, wood moldings, siding, and

fence posts can easily be damaged by the string.

7

L

8

Page 9

CUTTING LINE / LINE FEEDING

Your trimmer uses .065 inch (1.65 mm) diameter, ROUND

nylon line. During use, the tips of the nylon lines will become

frayed and worn and the special self feeding spool will

automatically feed and trim a fresh length of line. Cutting line will

wear faster and require more feeding if the cutting or edging is

done along sidewalks or other abrasive surfaces or heavier

weeds are being cut. The advanced automatic line feeding

mechanism senses when more cutting line is needed and feeds

and trims the correct length of line whenever itʼs required. DO

NOT BUMP unit on ground in attempt to feed line or for any other

purposes.

REPLACEMENT ACCESSORIES

Use Black & Decker replacement spool Model No. DF-065.

• USE ONLY .065 inch (1.65 mm) DIAMETER ROUND NYLON

LINE. Do not use heavier gauge line as it will overload the motor

and cause overheating. Do not use lighter gauge or serrated .065

inch (1.65 mm) line as it will cause overfeeding.

• Other replacement parts (guards, spool caps, etc.) are available

through Black & Decker service centers. To find your local service

location call: 1-800-544-6986 or visit www.blackanddecker.com.

WARNING: The use of any accessory not recommended by

Black & Decker for use with this tool could be hazardous.

REPLACING THE SPOOL (FIGURES M & N)

• Unplug the tool.

• Depress the tabs (a) and remove the spool cap (b) from the

spool housing (c) in the trimmer head (figure M).

• Replace spool with Black & Decker model # DF-065.

• Grasp empty spool (d) with one hand and spool housing with

other hand and pull spool out.

If lever (e)

(figure N) in base of housing

becomes dislodged, replace

in correct position before

inserting new spool into

housing.

• Remove any dirt and grass

from the spool and housing.

• Take the new spool and

push it onto the boss (f)

(figure N) in the housing.

Rotate the spool slightly until it

is seated.

• Unfasten the end of one of

the cutting lines and guide the

line into one of the eyelets (g).

figure N. The line should

protrude approximately 5-3/8

inches (136mm) from the

housing.

• Unfasten the end of the

other cutting line and guide

the line into the other eyelet.

The line should protrude

approximately 5-3/8 inches

(136mm) from the housing.

• Align the tabs on the spool

cap (a) withthe slots(h)in the

housing (figure M).

• Push the cap onto the

housing until it snaps

securely into place.

NOTICE: To avoid tool

damage, if the cutting lines

protrude beyond the trimming

blade (i), cut them off so that they

9

M

Replacement

spool

d

Model #

DF-065

b

b

a

h

N

g

f

c

i

d

a

e

b

Page 10

just reach the blade (figure M).

REWINDING SPOOLIF LINE UNRAVELS

(USE ONLY .065 IN. ROUND DIAMETER

LINE) (FIGURES O & P)

NOTE: Hand wound spools are likely to

become tangled more frequently than Black

& Decker factory wound spools. For best

results, factory wound spools are

recommended.

To rewind spools, follow the steps below:

• Unplug the tool.

• Remove the empty spool from the tool

as described in “REPLACINGTHE SPOOL”.

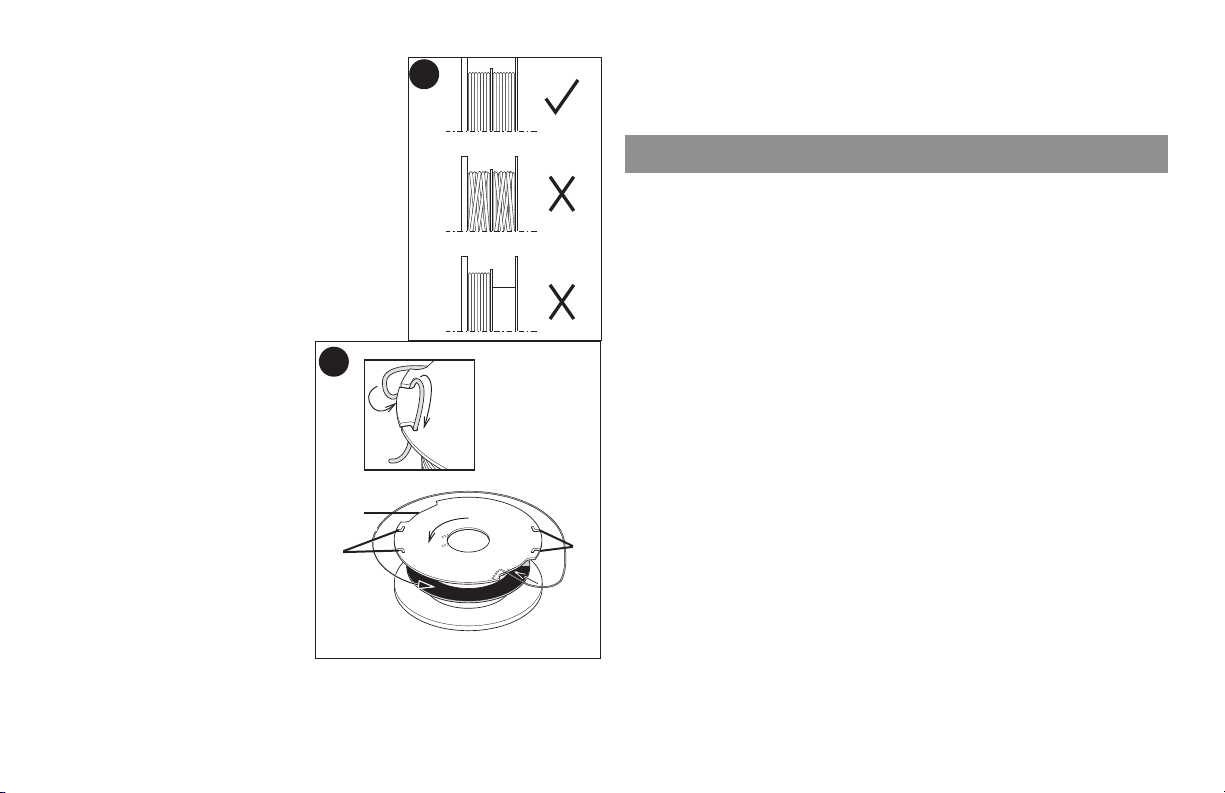

• Firstwindnew line onto theuppermost partof

the spool.

• Feed 3/4 inch (19mm) of

cutting line into one of the line

anchoring slots.

• Wind the cutting line onto

the spool in the direction of

the arrow on the spool. Make

sure to wind the line on

neatly and in layers. Do not

crisscross (figure O).

• When the wound cutting

line reaches the recesses (j),

cut the line. (figure P).

• Temporarily park the line in

the holding slots (k) on one side

of the spool as shown in the

inset in figure P.

• Repeat the above

procedure for the second

cutting line on the lower section of the spool.

• Fitthe spoolontothe tool as describedin“REPLACINGTHE SPOOL”.

P

j

k

O

CAUTION: Before you begin trimming, only use the

appropriate type of cutting line. Ensure that cutting line is present in

both sections of the spool (figure M).

MAINTENANCE

WARNING: To avoid serious injury, switch off and unplug the

tool before performing any maintenance.

1. Keepthe air intakeslotscleanto avoid overheating.

2. Your trimmer linecan dry out overtime.To keep yourlineintopcondition,

storespare pre-woundspoolsor bulkline ina plastic,sealablebagwith a

tablespoon ofwater.

3. Plastic parts may becleaned byusingamild soapandadamprag.

4.Theline cutteron the edge of theguardcandull overtime.It isrecommended

you periodically touch-upthesharpness ofthebladewith a file.

IMPORTANT: To assure product SAFETY and RELIABILITY,

repairs, maintenance and adjustment should be performed by

authorized service centers or other qualified service organizations,

always using identical replacement parts.

k

10

Page 11

TROUBLE SHOOTING GUIDE

PROBLEM

Tool runs slowly.

Automatic line feed does not

feed more line.

SOLUTION

• Check that the spool housing

can rotate freely. Carefully clean

it if necessary.

• Check that the cutting line

does not protrude more than

approximately 5-3/8 inches

(136mm) from the spool. If it

does, cut it off so that it just

reaches the line trimmingblade.

• If the tool still runs slowly, stop

using the tool and take it to a

service center.

• More line is fed when the line

shortens to approximately 3

inches (76.2mm). To determine if

the line is not feeding, let line

wear past this point.

• Keep the tabs depressed and

remove the spool from the spool

housing in the trimmer head.

• Ensure that the line is not

crisscrossed on the spool as

detailed in figure O. If it is,

unwind the cutting line, then

wind it back on the spool neatly

so that the lines do not cross.

• Inspect tracks at the bottom of

spool for damage. If damaged,

replace spool.

•Read thecodeonthe back of

spool.Ifitreads “PA66” call

customerservicefor a replacement.

Ifitreads“ABS” this is notthe issue.

PROBLEM

Automatic line feed does not

feed more line.

Overfeeding

11

SOLUTION

• Pull the cutting line until it

protrudes approximately 5-3/8

inches (136mm) from the spool.

If insufficient cutting line is left

on the spool, install a new spool

of cutting line.

• Align the tabs on the spoolcap

with the cutouts in the housing.

•Pushthe spoolcapontothehousing

until itsnapssecurelyintoplace.

• If the cutting line protrudes

beyond the trimming blade, cut

it off so that it just reaches the

blade. If the automatic line

feed still does not work or the

spool is jammed, try the

following suggestions:

• Carefully clean the spool

and housing.

• Remove the spooland checkif

the leverinthe spoolhousing can

movefreely.

• Remove the spool and

unwind the cutting line, then

wind it on neatly again.

Replace the spool into

the housing.

• Ensure you are cutting with

the tip of the line (5.25 inches

(133.4mm) from the spool).

Use the edge guide if needed to

ensure proper space is

maintained.

• Ensure you are not

exceeding a 10° angle as

shown in figure J1.

Page 12

PROBLEM

Line unravels when cap or spool

is removed.

SOLUTION

• Be sure to keep spool fully

seated in cap until lines are

parked in holding slots (K)

figure P before removing.

SERVICE INFORMATION

All Black& DeckerService Centers arestaffedwithtrained personnel to

provide customerswithefficientand reliablepower toolservice.Whether you

needtechnicaladvice, repair, or genuine factory replacementparts,contact

the Black& Deckerlocationnearestyou.To findyourlocalservice location,

refer tothe yellowpagedirectory under "Tools—Electric" orcall: 1-800-544-

6986or visitwww.blackanddecker.com

FULL TWO-YEAR HOME USE WARRANTY

Black & Decker (U.S.) Inc.warrantsthisproduct for two years against

any defects inmaterialorworkmanship. Thedefectiveproduct willbe

replacedorrepairedat nochargeineitherof two ways.

The firstis toreturntheproductto the retailer from whom itwaspurchased

(provided that the storeisaparticipatingretailer). Returns should bemade

withinthe timeperiod ofthe retailerʼs policyfor exchanges (usually 30 to90

daysafter the sale). Proof ofpurchasemay berequired. Please checkwith

the retailerfortheir specific return policyregarding returnsthat arebeyond

the timeset forexchanges.

The second optionisto take orsend theproduct(prepaid)toa

Black & Deckerownedor authorizedServiceCenterfor repairor

replacementat our option.Proof ofpurchasemay berequired.

Black & Decker ownedandauthorizedService Centersare listedunder

"Tools-Electric"in theyellow pagesof thephone directory.

Thiswarranty doesnot applyto accessories.This warranty givesyou

specificlegal rightsand youmayhaveother rightswhichvaryfrom stateto

state orprovincetoprovince.Should youhave anyquestions, contactthe

manager ofyournearest Black & Decker ServiceCenter. This productis not

intendedfor commercial use.

FREEWARNING LABEL REPLACEMENT: Ifyour warninglabels become

illegible or are missing, call 1-800-544-6986for a free replacement.

LATINAMERICA: This warrantydoesnotapplytoproducts sold in

Latin America.Forproducts soldin LatinAmerica, checkcountry specific

warrantyinformation containedinthepackaging,callthe local company or

see the websiteforwarranty information.

12

Page 13

Black & Decker (U.S.) Inc.,

Imported by

701 E. Joppa Rd.

Towson, MD 21286 U.S.A.

See ‘Tools-Electric’

– Yellow Pages –

for Service & Sales

13

Page 14

TAILLE-BORDURE / COUPE-

BORDURE MODE D’EMPLOI

Numéro de modèle GH710

Merci d’avoir choisi Black & Decker!

Consulter le site Web

www.BlackandDecker.com/NewOwner

pour enregistrer votre nouveau produit.

A LIREAVANT DERETOURNER CE PRODUIT

POUR QUELQUE RAISON QUE CE SOIT :

Numéro de modèle GH710

Si des questions ou des problèmes surgissent après lʼachat dʼun produit

Black & Decker, consulter le site Web

HTTP://WWW.BLACKANDDECKER.COM/INSTANTANSWERS

pour obtenir des réponses instantanément 24 heures par jour.

Si la réponse est introuvable ou en lʼabsence dʼaccès à lʼInternet,

composer le 1-800-544-6986 de 8 h à 17 h HNE, du lundi au vendredi,

pour parler avec un agent.

Prière dʼavoir le numéro de catalogue sous la main lors de lʼappel.

CONSERVER CE MANUEL POUR UN USAGE ULTERIEUR.

VOICI DES RENSEIGNEMENTS IMPORTANTS

QU’IL VOUS FAUT CONNAÎTRE :

• Le pare-main doit être installé avant de débuter le taillage

ou la coupe sinon le moteur surchauffera (page 17).

• Utiliser seulement un fil ROND de 1,7 mm (0,065 po) de

diamètre lors du remplacement (modèle DF-065 de B&D

recommandé), sinon lʼappareil ne fonctionnera pas

correctement (page 20).

• Éviter de frapper la tête dʼalimentation contre le sol. En

effet, cela endommagera le mécanisme dʼalimentation.

• Toujours utiliser le dispositif de retenue du cordon (page 18).

14

Page 15

TABLE DES MATIÈRES

Directives de sécurité - définitions ...........................................15

Avertissements de sécurité et directives de première

importance ...............................................................................15

Avertissements de sécurité et directives : Fiches polarisées...17

Avertissements de sécurité et directives : Rallonges...............17

Composants.............................................................................18

Assemblage et réglage ............................................................19

Notice dʼutilisation ....................................................................21

Accessoires de rechange.........................................................22

Entretien...................................................................................23

Dépannage ..............................................................................24

Information sur les réparations ................................................25

Garantie complète de deux ans pour une

utilisation domestique ..............................................................25

LIGNES DIRECTRICES EN MATIERE DE

SECURITE - DEFINITIONS

Il est important que vous lisiez et compreniez ce mode dʼemploi.

Les informations quʼil contient concernent VOTRE SÉCURITÉ et

visent à ÉVITER TOUT PROBLÈME. Les symboles ci-dessous

servent à vous aider à reconnaître cette information.

DANGER : Indique une situation dangereuse imminente qui,

si elle nʼest pas évitée, causera la mort ou des graves blessures.

AVERTISSEMENT : Indique une situation potentiellement

dangereuse qui, si elle nʼest pas évitée, pourrait causer la mort

ou de graves blessures.

MISE EN GARDE : Indique une situation potentiellement

dangereuse qui, si elle nʼest pas évitée, pourrait causer des

blessures mineures ou modérées.

AVIS : Utilisé sans le symbole dʼalerte à la sécurité, indique une

situation potentiellement dangereuse qui, si elle nʼest pas

évitée, peut résulter en des dommages à la propriété.

AVERTISSEMENTS DE SÉCURITÉ ET

DIRECTIVES DEPREMIÈRE IMPORTANCE

AVERTISSEMENT : Lorsque des outils de jardinage

électriques sont utilisés, des précautions de base en matière de

sécurité doivent toujours être suivies afin de réduire le risque

dʼincendie, de choc électrique et de blessure corporelle,

notamment les suivantes.

Lire toutes les directives

• TOUJOURS PORTER UNE PROTECTION OCULAIRE - Porter

des lunettes ou des lunettes protectrices en tout temps lorsque cet

outil est branché.

• DISPOSITIF DE PROTECTION – Ne pas utiliser cet outil sans

les dispositifs de protection en place.

• S’HABILLER DE MANIÈRE APPROPRIÉE - Ne pas porter de

vêtements amples ni de bijoux. Ils peuvent sʼenchevêtrer dans les

pièces mobiles. Des gants en caoutchouc et des chaussures

adéquates à semelles en caoutchouc sont recommandés lors de

travaux à lʼextérieur. Ne pas utiliser lʼoutil avec les pieds nus ou

des sandales ouvertes. Porter des pantalons longs et épais pour

se protéger les jambes. Se couvrir les cheveux sʼils sont longs.

• FIL EN NYLON - Tenir le visage, les mains et pieds loin du fil de

nylon rotatif en tout temps.

• LE FIL EN ROTATION EXÉCUTE UNE COUPE - Être attentif

lors de taillage autour de grillages et de plates-bandes.

• TENIR ÉLOIGNÉ TOUS LES SPECTATEURS - À une distance

sécuritaire de lʼaire de travail, particulièrement les enfants.

• AVERTISSEMENT IMPORTANT : lorsque lʼoutil est utilisé

comme coupe bordure, des pierres, morceaux de métal et autres

objets peuvent être projetés à haute vitesse par le fil. Lʼoutil et le

dispositif de protection sont conçus pour réduire le risque.

Toutefois, les précautions spéciales suivantes doivent être prises :

15

Page 16

• S’ASSURER que toute personne et animaux sont éloignés dʼau

moins 30 m (100 pi).

• POUR RÉDUIRE LE RISQUE de blessures par ricochet,

travaillez en vous éloignant de tout objet solide tel un mur, des

marches, de grosses pierres, dʼarbres, etc. Soyez très prudent

lors de travaux près dʼobjetssolides et, le cas échéant, taillez ou coupez

manuellement.

• ÉVITER LES DÉMARRAGES ACCIDENTELS - Ne pas

transporter dʼoutil branché avec le doigt sur la détente.

• NE PAS FORCER L’OUTIL - à tourner à une vitesse plus rapide

que celle pour laquelle il est capable de couper efficacement.

• UTILISER LE BON OUTIL - Ne pas utiliser cet outil pour tout

autre type de travail sauf pour celui pour lequel il est prévu.

• NE PAS TROP TENDRE LES BRAS - Conserver son équilibre

en tout temps.

• NE PAS UTILISER LE CORDON DE FAÇON ABUSIVE - Ne

pas tirer sur le cordon dʼalimentation pour le débrancher. Tenir le

cordon éloigné de la chaleur, de lʼhuile et des bords tranchants.

• OUTIL ENDOMMAGÉ - Si vous frappez ou devenez enchevêtrer

dans un objet, arrêtez immédiatement lʼoutil, débranchez-le puis

inspectez pour toute trace de dommages qui devront être réparés

avant une autre utilisation. Ne pas utiliser avec un moyeu ou une

bobine brisés.

• CORDON D’ALIMENTATION ENDOMMAGÉ - Tenir éloigné le

cordon dʼalimentation du fil rotatif. En cas de dommages au

cordon dʼalimentation, débranchez-le de la prise avant de

déplacer lʼoutil ou dʼinspecter le dommage. Un cordon

endommagé doit être remplacé avant sa prochaine utilisation.

• DÉBRANCHER L’OUTIL – Lorsque inactif, lors de

remplacement de fil ou avant un nettoyage.

• ÉVITER LES CONDITIONS ENVIRONNEMENTALES

DANGEREUSES - Ne pas utiliser dʼoutils électriques dans des

lieux humides ou mouillés. Suivre toutes les directives de ce mode

dʼemploi pour une utilisation adéquate de votre outil. Ne pas

utiliser lʼoutil sous la pluie.

• NE PAS UTILISER dʼoutils électriques portatifs dans un milieu

gazeux ou déflagrant. Les moteurs de ces outils produisent

normalement des étincelles qui pourraient enflammer des vapeurs.

• RANGER LES OUTILS INUTILISÉS À L’INTÉRIEUR –

Lorsquʼils ne sont pas utilisés, les outils doivent être rangés à

lʼintérieur, dans un endroit sec et verrouillé, hors de portée des

enfants.

• UN DISJONCTEUR DE FUITE DE TERRE doit être installé pour

protéger les circuits ou prises utilisés pour cet appareil électrique

de jardin. Des prises avec fonction de disjoncteur de fuite de terre

intégrées sont aussi disponibles et peuvent être utilisées comme

mesures de protection.

• FIXER LE CORDON D’ALIMENTATION à lʼaide du dispositif de

retenu de celui-ci tel quʼillustré à la figure H.

• ÊTRE VIGILANT – Ne pasutiliserlʼappareil en cas defatigue ou de

maladie ousouslʼinfluence dʼalcool, de droguesoudemédicaments.

• PRENDRE SOIN DES OUTILS ÉLECTRIQUES – Suivre les

directives figurant à la section Entretien. Inspecter régulièrement

les rallonges électriques et remplacer si endommagées. Maintenir

les poignées sèches, propres et exemptes dʼhuile et de graisse.

• VÉRIFIER LES PIÈCES ENDOMMAGÉES – Avant toute

utilisation ultérieure de lʼappareil électrique, un dispositif de

protection endommagé, ou toute autre pièce endommagée, doit

être examiné soigneusement afin dʼassurer un fonctionnement

adéquat selon sa fonction prévue. Vérifier lʼalignement des pièces

mobiles, la présence de grippage des pièces mobiles, de rupture

de pièces, la fixation et tout autre problème pouvant nuire au

fonctionnement de lʼoutil. Un dispositif de protection endommagé,

ou toute autre pièce endommagée, doit être réparé ou remplacé

adéquatement par un centre de réparation autorisé à moins dʼun

avis contraire indiqué dans le présent mode dʼemploi.

AVERTISSEMENT : Ne pas utiliser lʼoutil si la détente ne

fonctionne pas. Tout outil qui ne peut être réglé par la détente est

dangereux et doit être réparé.

AVERTISSEMENT : Pour réparer tout outil à double isolation,

VEUILLEZ UTILISER DES PIÈCES DE RECHANGE IDENTIQUES.

Remplacer ou réparer les cordons endommagés.

16

Page 17

AVERTISSEMENT : Pour prévenir un choc électrique ou une

électrocution, se servir uniquement dʼune rallonge convenant à une

utilisation à lʼextérieur. Toujours brancher les rallonges à une prise

avec fusible ou protégée par un disjoncteur.

• NE PAS immerger lʼoutil dans lʼeau ou lʼarroser au boyau.

ÉVITER la pénétration de tout liquide dans lʼoutil.

• NE PAS ranger lʼoutil sur des engrais ou des produits chimiques

ou près de ceux-ci.

• NE PAS nettoyer avec un nettoyeur à pression.

CONSERVER CES MESURES.

Lʼétiquette apposée sur votre outil pourrait comprendre les symboles

suivants. Les symboles et leurs définitions sont indiqués ci-après :

V ..............volts A ................ampères

Hz ............hertz W................watts

min............minutes ..............courant alternatif

..........courant continue non ............régime à vide

..............

AVERTISSEMENT : Certaines poussières produites par cet

util contiennent des produits chimiques reconnus par l’État de

la Californie comme pouvant causer le cancer, les anomalies

congénitales et d’autres dangers pour la reproduction. Voici

quelques exemples de ces produits chimiques :

Pour réduire votre exposition à ces produits chimiques, porter un

équipement de sécurité approuvé comme un masque anti-poussières

conçu spécialementpour filtrer lesparticulesmicroscopiques.

Construction classe II

............symbole dʼalerte à la .../min ........révolutions ou

sécurité alternance par minute

• composés présents dans les engrais

• composés présents dans les insecticides, herbicides et

pesticides

• arsenic et chrome provenant de bois traité chimiquement

............

borne de terre

AVERTISSEMENTS DE SÉCURITÉ ET

DIRECTIVES : FICHES POLARISÉES

Pour réduire le risque de chocs électriques, cet équipement

comporte une fiche polarisée (une broche est plus large que lʼautre)

et exigera lʼutilisation dʼune rallonge polarisée. La fiche de lʼoutil

électrique ne se branchera que dʼune seule façon dans une rallonge

polarisée. Si la fiche ne sʼinsère pas totalement dans la rallonge,

renversez-la. Si la prise ne sʼinsère toujours pas, rechercher une

rallonge polarisée appropriée. Une rallonge polarisée exigera

lʼutilisation dʼune prise murale polarisée. Cette fiche ne se

branchera que dʼune seule façon dans une prise murale polarisée.

Si la fiche ne sʼinsère pas totalement dans la prise murale,

renversez-la. Si elle ne sʼinsère toujours pas dans la prise,

demandez à un électricien compétent dʼinstaller une prise murale

polarisée. Ne modifiez en aucun cas la fiche de lʼappareil, la prise

ou la fiche de la rallonge.

AVERTISSEMENTS DE SÉCURITÉ ET

DIRECTIVES : RALLONGES ÉLECTRIQUES

Sʼassurer que la rallonge est en bon état. Lorsque quʼune rallonge

électrique est utilisée, sʼassurer dʼen utiliser une de calibre

suffisamment élevé pour assurer le transport du courant nécessaire

au fonctionnement de votre appareil. Un cordon de calibre inférieur

causera une chute de tension de ligne et donc une perte de

puissance et une surchauffe. Le tableau indique le calibre approprié

à utiliser selon la longueur du cordon et lʼintensité nominale de la

plaque signalétique. En cas de doute, utiliser le calibre suivant le

plus gros. Plus le numéro de calibre est petit, plus le cordon est

lourd. Si la rallonge est utilisée à lʼextérieur, elle doit être prévue à

cet effet. Les lettres « WA » marquées sur lʼenveloppe du cordon

indiquent que le cordon convient à un usage extérieur.

17

Page 18

Tension Longueur totale du cordon en pieds

Calibre minimal des cordons de rallonge

120V 0-25 26-50 51-100 101-150

(0-7,6m) (7,6-15,2m) (15,2-30,4m) (30,4-45,7m)

240V 0-50 51-100 101-200 201-300

(0-15,2m) (15,2-30,4m) (30,4-60,9m) (60,9-91,4m)

Intensité (A)

Au Au Calibre moyen des fils (AWG)

moins plus

0-6 18 16 16 14

6-10 18 16 14 12

10 - 12 16 16 14 12

12 - 16 14 12 Non recommandé

1. Détente

2. Dispositif de

retenue du cordon

3. Logement pour

cordon

4. Poignée auxiliaire

5. Collier (pour

régler la hauteur et

le bord)

6. Boîtier du moteur

7. Guide de coupe

8. Pare-main

9. Bobine

COMPOSANTS

A

7

1

4

2

3

5

6

8

18

9

Page 19

ASSEMBLAGE ET RÉGLAGE

OUTILS REQUIS POUR L’ASSEMBLAGE (NON FOURNIS) :

- Tournevis cruciforme

POSE DU PARE-MAIN

AVERTISSEMENT : DEBRANCHER L’OUTIL AVANT

D’ESSAYER DE FIXER LE PARE-MAIN, LE GUIDE DE COUPE OU

LA POIGNEE. NE JAMAIS UTILISER L’OUTIL SANS LE PAREMAIN SOLIDEMENT FIXÉ. LE PARE-MAIN DOIT TOUJOURS

ETRE EN PLACE SUR L’OUTIL POUR PROTEGER L’OPERATEUR.

• Mettre le taille-bordure à lʼenvers de manière à voir le couvercle

de la bobine (1).

• Mettre le pare-main (2) à

lʼenvers et le glisser sur le

boîtier du moteur (3).

Sʼassurer que les pattes (4)

du dispositif de protection

engagent les nervures (5)

du boîtier du moteur comme

dans lʼillustration.

• Continuer de glisser le

pare-main jusquʼà ce quʼil «

sʼenclenche » en position.

B

2

3

4

5

1

• Utiliser un tournevis

cruciforme, retirer la vis de la

garde.

• Insérer la vis du pare-main

comme lʼillustre la figure 2

pour terminer lʼassemblage

du pare-main.

• Une fois le pare-main

installé, retirer lʼenveloppe

de la lame, pour la coupe du

fil, située sur le bord du pare-main.

FIXATION DE LA POIGNEE

AUXILIAIRE

• Pour fixer la poignée,

enfoncer les boutons (7) des

deux côtés du boîtier

supérieur comme le montre

la figure D.

C

D

7

19

Page 20

• Positionner la poignée

comme le montre la figure E

(le logo Black & Decker

étant positionné vers le

haut). Pousser partiellement

la poignée. Ainsi, les

boutons seront maintenus

enfoncés au moment de

les relâcher.

• Pousser la poignée

complètement sur le boîtier

et la positionner légèrement

de manière à ce quʼelle

« sʼenclenche » en place

(figure F).

• Pour régler la poignée

vers le haut ou le bas,

appuyer sur le bouton (8),

puis relever ou abaisser la

poignée.

• Ajuster la poignée de façon

à avoir le bras avant

complètement droit lorsque

le taille-bordure est en

position de fonctionnement.

E

F

8

REGLAGE DE LA HAUTEUR

• La hauteur totale du taillebordure peut être réglée en

desserrant le collier (9) et en

le tournant dans le sens de

la flèche illustrée dans la

figure G.

• Monter ou baisser le boîtier

supérieur en ligne droite.

Lorsque la hauteur désirée

est atteinte, serrer le collier

en le tournant dans le sens

opposé à celui illustré à la

figure G.

FIXATION DE LA RALLONGE

• Un dispositif de retenue de

rallonge (figure H) est

intégré à la poignée de la

détente pour empêcher le

débranchement de la

rallonge. Pour utiliser ce

dispositif, replier simplement

la rallonge en deux à environ

203 mm (8 po) de lʼextrémité,

puis lʼinsérer dans lʼencoche

(10) logée à lʼextrémité de la

poignée. Fixer la boucle ainsi

formée en repliant la rallonge

sur la patte (11). Tirer

délicatement sur la rallonge afin

de sʼassurer que celle-ci est

fermement retenue par la

poignée du taille-bordure.

Brancher la prise femelle de la

rallonge sur la fiche (12) du

taille-bordure.

20

G

9

10

H

11

12

Page 21

DIRECTIVES D’UTILISATION

5O-10

O

AVERTISSEMENT : Toujours utiliser une protection oculaire

appropriée conformeà la norme ANSI Z87.1(CAN/CSAZ94.3) lors de

lʼutilisation de cetoutilélectrique.

MISE EN GARDE :Inspecter la zone quisera

taillée etretirertoutmorceau defil métallique,decorde ou

dʼobjetssimilairesqui pourraient sʼenchevêtrer dans le fil

rotatif ouavecla bobine. Être spécialementattentif et

éviter, sur le parcours delʼoutil, tout filmétallique courbé

verslʼextérieurcomme les filsaupied dʼuneclôture à

mailles losangées.

MISEEN MARCHE ETARRET

• Pour mettre lʼoutil en marche, appuyer sur le

levier de déclenchement.

• Pour éteindre lʼoutil, relâcher le levier de

déclenchement.

• Le moteurétant en marche,incliner lʼappareiletbalancer lentement le

taille-borduredʼuncôtéà lʼautretel quelʼindique lafigure I.

FONCTIONNEMENTDUTAILLE-BORDURES

•Maintenirun angle decoupeentre5° et10° comme lemontrelafigure J1.

Nepasexcéder10°(figureJ1). Couper aveclebout dufil. Pourse tenir à

distance dessurfacesdures, utiliser le guide decoupe(7). Sortirle guidede

manièreà bienlʼenclencheren place.

•Maintenirune distance minimale de609,6mm(24po) entreledispositifde

protectionetvospieds, commelemontre lafigure J2.Pourobtenircettedistance,

régler lahauteurglobaledutaille-bordurescomme lemontrela figure G.

CONVERTIR AU MODE COUPE-BORDURE

• Pour utiliser lʼappareil comme coupe-bordure dʼentretien, tourner

le collier (9) comme lʼindique la partie 1 de la figure K.

• Tenir la tige de métal et tourner le boîtier inférieur de 180° comme

lʼillustre la partie 2.

• Tourner lecollier(9) jusquʼà ce quʼilsoitserré.

J1

J1

J2

I

K

9

• Au besoin, tirer le guide de coupe avec fil métallique (7) du

boîtier du moteur de manière à ce quʼil sʼenclenche en position

verrouillée comme le montre la figure K, puis positionner le taillebordure au-dessus de la surface comme le montre la figure K.

• Pour retourner à la position de taille-bordure, desserrer le collier

de blocage (9) et tourner le boîtier inférieur de 180°. Lʼoutil se

verrouillera en position de taille-bordure. Lors de lʼutilisation de

lʼoutil, mettre le guide de coupe avec fil métallique dans sa

position dʼorigine, hors du parcours.

21

7

L

Page 22

CONSEILSUTILES ENMATIÈRE DECOUPE

• Utiliser le bout du fil pour effectuer la coupe; ne pas forcer la

tête du fil dans le gazon non coupé. Utiliser le guide de coupe le

long des clôtures, des maisons et des massifs de fleurs pour

adopter les pratiques exemplaires.

• Les clôtures en fil de fer et à montants peuvent user davantage

le fil, voire le briser. Les murs de pierre et de brique, les bordures

de trottoir et le bois peuvent user rapidement le fil.

• Ne pas laisser le capuchon de bobine traîner sur le sol ou

dʼautres surfaces.

• Si le gazon est long, couper de haut en bas et ne pas excéder

une hauteur de 304,8 mm (12 po).

• Maintenir le taille-bordures incliné vers la zone à couper; cʼest la

meilleure zone de coupe.

• Le taille-bordures coupe par passage de droite à gauche. De

cette façon, les débris ne seront pas envoyés vers lʼopérateur.

• Éviter les arbres et les arbustes. Lʼécorce dʼarbre, les moulures

en bois, le parement et les piquets de clôture peuvent facilement

être endommagés par le fil.

FIL TRANCHANT / AVANCE DUFIL

Votretaille-bordureutilise unfil de nylon ROND de 1,7mm(0,065po) de

diamètre. Encoursdʼutilisation,les extrémitésdes fils de nylon

sʼeffilocherontet sʼuseront. Labobine spécialeà avance automatique de fil

fourniraetcoupera automatiquementune nouvelle longueur defil.Lefil

tranchant sʼusera plus rapidementetexigeraune plus grande quantité de

fil si la coupe ou le taillagesʼeffectue lelongdetrottoirsou dʼautres

surfacesabrasives ou si desbroussailles épaisses sont coupées. Le

mécanisme évoluédʼalimentation automatisée dufil perçoitlademande

accruedefil,fournit etcoupe la bonne longueur defil dèsquʼelleest

nécessaire.NE PAS FRAPPER lʼappareil sur le solpour alimenter

lʼappareil oupourtoute autre raison.

ACCESSOIRES DE RECHANGE

Utiliser labobinederechange modèleDF-065deBlack & Decker.

• UTILISERUNIQUEMENTUN FILENNYLON ROND DE1,7 mm(0,065

po) DEDIAMÈTRE. Nepas utiliserla ligneplus épaiscar il vasurchargerle

moteur etprovoquer unesurchauffe.Ne

pas utiliserplus léger jaugeou dentelées

0,065pouce(1,65mm) enligne carcela

fera unesuralimentation.

•Dʼautres piècesderechange(pare-mains,

couverclesde bobine,etc.)sont offertesaux

centresderéparationBlack & Decker. Pour

trouverlecentre deréparationdevotre

région,composerle: 1-800-544-6986ou

consulterwww.blackanddecker.com.

d

b

AVERTISSEMENT:Lʼutilisationde

tout accessoirenonrecommandéparBlack &

Decker,avec cetoutil,pourraitsʼavérer

dangereuse.

REMPLACER LA BOBINE (FIGURES

M ET N)

• Débrancher lʼoutil.

• Enfoncer leslanguettes (a) etretirer le

couvercle delabobine (b)duboîtier de la bobine (c)logédanslatêtedu

taille-bordure(figure M).

• Pour obtenirdes résultats

optimaux, remplacer labobine par

une bobine de modèle DF-065 de

Black & Decker.

• Tenirlabobinevide(d) dʼunemain

etleboîtierdebobinedelʼautre, puis

sortirlabobineentirantdessus.

• Si le levier (e) (figure N) situéà la

baseduboîtier se détache, le

remettreà la bonnepositionavant

dʼinsérer labobine neuvedansle

boîtier.

• Retirerlʼherbe etles saletés

présentes danslabobine etle

boîtier.

• Prendrelabobineneuve et

22

a

h

N

g

f

M

Bobine de

rechange

N°demodèle

DF-065

b

c

i

d

a

e

b

Page 23

lʼenfoncer sur lasaillie(f) (figureM)duboîtier. Faire pivoterlégèrement la

bobinejusquʼà cequʼellesoitbieninstallée.

• Détacherlʼextrémitédelʼundes filsde coupe,puisinsérerle fil danslʼun des

œillets(g),figureM. Lefildoitsortirdʼenviron136mm (53/8po)duboîtier.

• Détacher lʼextrémité delʼautre fil de coupeetlefaire passer dans lʼautre

œillet. Lefil doit sortir dʼenviron136 mm (5 3/8po) duboîtier.

• Alignerles languettes, situées surlecouvercle dela bobine(a) surles

encoches(h) duboîtier(figure M).

• Enfoncerlecouverclesurleboîtierdemanièreàcequʼilsʼenclenchebienenplace.

AVIS : Si les fils de coupe dépassent la lame du taille-bordure (i),

les couper de sorte quʼils atteignent à peine la lame (figure L)

pour éviter dʼendommager lʼoutil.

REMBOBINER LA BOBINE SI LE FIL SE DÉROULE

(UTILISER UNIQUEMENT UN FIL ROND DE 1,7 MM (0,065 PO)

DE DIAMETRE) (FIGURES O, P)

REMARQUE : Le filen vrac des bobines

enroulées à la main est susceptiblede

sʼenchevêtrer plus souvent que le fildes

bobines enroulées dans une usine Black &

Decker. Ilest recommandé dʼutiliser des

bobines embobinées à lʼusine.

Suivre les étapes ci-dessous pour installer

du fil en vrac :

• Débrancher lʼoutil.

• Retirer la bobine vide de lʼoutil comme

le décrit la section

« REMPLACER LA BOBINE »

• Enrouler dʼabord le fil neuf en

commençant par la partie supérieure de

la bobine.

• Insérer 19 mm (3/4 po) de fil de coupe dans lʼune des encoches

dʼancrage.

• Prendresoindʼenrouler lefil defaçonnette et ordonnée par couches

successives. Nepas entrecroiserle fil (figureO).

• Couper le fil de coupe enroulé lorsquʼil atteint les encoches (j).

(figure P).

• Placertemporairement le fil dans lʼunedesencochesde retenue(k)sur

O

lʼundescôtés delabobine,comme

lemontre lʼencadréde la figureP.

• Répéter la procédure

précédente pour le second fil

de coupe sur la partie

inférieure de la bobine.

• Ajuster la bobine sur lʼoutil

comme le décrit la section «

REMPLACER LA BOBINE »

MISE EN GARDE : Avant

de procéder autaillage,sʼassurer

dʼutiliser uniquementletypedefil de

coupe adéquat. Vérifierque le filde

coupe estprésent dans lesdeux

parties dela bobine(figure N).

P

j

k

ENTRETIEN

AVERTISSEMENT : Pour éviter des blessures graves, éteindre et

débrancher lʼoutil avantdʼeffectuer toute opérationdʼentretien.

1. Maintenir les orifices de ventilation dégagés pour éviter la surchauffe.

2. Votre fil rotatif peut sécher avec le temps. Pour tenir votre fil en

excellente condition, entreposer les bobines de rechange de fil

pré-enroulé ou le fil en vrac dans un sac en plastique scellé

contenant lʼéquivalent dʼune cuillerée dʼeau.

3. Les pièces en plastique se nettoient avec un savon doux et un

chiffon humide.

4. Le coupe-fil sur le bord du dispositif de protection peut sʼémousser

avec le temps. Il est recommandé de sʼassurer régulièrement

que la lame est bien tranchante en utilisant une lime.

IMPORTANT : Pour garantir la SÉCURITÉ et la FIABILITÉ du

produit, les réparations, lʼentretien et le réglage doivent être réalisés

par un centre de réparation autorisé ou tout autre centre de

réparation professionnel, et des pièces de rechange identiques

doivent être utilisées.

23

k

Page 24

DEPANNAGE

PROBLÈME

Lʼoutil fonctionne lentement.

Laalimentación automática decuerda

noalimenta más cuerda.

SOLUTION

Vérifier que le boîtier de la bobine

peut tourner librement. Le nettoyer

avec précaution si nécessaire.

• Sʼassurer que le fil de coupe

sort dʼau plus 136 mm (5 3/8

po) de la bobine. Le cas

échéant, le couper afin que sa

longueur atteigne juste la lame

de coupe pour le fil.

• Si l'outil s'exécute toujours

lentement, arrêtez d'utiliser l'outil et

le prendre à un centre de service.

• Enlever le capuchon de la bobine.

• Tirer sur le fil de coupe de

manière à ce quʼil sorte dʼenviron

136 mm (5 3/8 po) de la bobine. Si

la longueur de fil restant sur la

bobine est insuffisante, installer une

nouvelle bobine de fil.

• Sʼassurer que lefil nʼestpas entrecroisé

sur la bobine commelʼillustre la figure

U. Si cʼest le cas, dérouler le fil de

coupe, puis lʼenrouler de nouveau

sur la bobine de façonordonnée, de

manièreànepas entrecroiserles fils.

• Aligner les languettes, logées sur

le couvercle de la bobine, sur les

fentes pratiquées dans le boîtier.

•Enfoncer labobinesurleboîtierdemanièreà

ce quʼelle sʼenclenche bienenplace.

•Inspecterlesrainures pratiquéessousla

bobineà larecherchededommages. Encas

de dommages,remplacerlabobine.

PROBLÈME

Laalimentación automática decuerda no

alimenta máscuerda.

Alimentation excédentaire

Le fil se déroule lorsque la bobine ou

le capuchon est enlevé.

SOLUTION

•Lire lecodeinscrit àlʼendosdelabobine.Sile

codeest«PA66»,appelerleserviceàla

clientèlepourfaireremplacerlabobine.Sile code

indiquéest«ABS»,cenʼestpas leproblème.

• Silefil de coupedépasse la lame

decoupe,lecouperdefaçon à ce

quʼil atteigneseulementlalame. Si

lʼalimentationautomatiquedefil ne

fonctionne toujourspas ou sila

bobine sebloque,procédercomme suit :

• Nettoyer avec précaution la bobine

et son boîtier.

• Retirer la bobine, puis vérifier si le

levier, situé dans le boîtier de la

bobine, peut se déplacer librement.

• Retirer la bobine et dérouler le fil

decoupe, puis lʼenrouler à nouveau

de façon ordonnée. Remettre la

bobine dans le boîtier.

• Sʼassurer decouper avec leboutdufil

(133,3 mm[5.25 po] de labobine).

Utilisele guide decoupesi nécessaire

pourmaintenirlabonne distance.

• Sʼassurer denepas excéderunangle

de10° commelemontrelafigureJ1.

• Sʼassurer defixer les fils dans les

encoches de retenue(K) (figure P)avant

leretrait.

24

Page 25

INFORMATION SUR LES REPARATIONS

Tous les centres de réparation Black & Decker sont dotés de

personnel qualifié en matière dʼoutillage électrique; ils sont

donc en mesure dʼoffrir à leur clientèle un service efficace et

fiable. Que ce soit pour un avis technique, une réparation ou

des pièces de rechange authentiques installées en usine,

communiquer avec lʼétablissement Black & Decker le plus

près de chez vous. Pour trouver lʼétablissement de réparation

de votre région, consulter le répertoire des Pages jaunes à la

rubrique « Outils électriques » ou composer le numéro suivant

: 1-800-544-6986 ou consulter le site

www.blackanddecker.com

GARANTIE COMPLETE DE DEUX ANS

POUR UNE UTILISATION DOMESTIQUE

Black & Decker (É.-U.) Inc. garantit ce produit pour une durée

de deux ans contre tout défaut de matériau ou de fabrication.

Le produit défectueux sera remplacé ou réparé sans frais de

lʼune des deux façons suivantes :

La première façon consiste en un simple échange chez le

détaillant qui lʼa vendu (pourvu quʼil sʼagisse dʼun détaillant

participant). Tout retour doit se faire durant la période

correspondant à la politique dʼéchange du détaillant

(habituellement, de 30 à 90 jours après lʼachat). Une preuve

dʼachat peut être requise. Vérifier auprès du détaillant pour

connaître sa politique concernant les retours hors de la

période définie pour les échanges. La deuxième option est

dʼapporter ou dʼenvoyer le produit (transport payé dʼavance) à

un centre de réparation autorisé ou à un centre de réparation

de Black & Decker pour faire réparer ou échanger le produit, à

notre discrétion. Une preuve dʼachat peut être requise. Les

centres Black & Decker et les centres de service autorisés

sont répertoriés dans les pages jaunes, sous la rubrique «

Outils électriques ».

Cette garantie ne sʼapplique pas aux accessoires. Cette garantie

vous accorde des droits légaux spécifiques et vous pourriez avoir

dʼautres droits qui varient dʼun État ou dʼune province à lʼautre. Pour

toute question, communiquer avec le directeur du centre de

réparation Black & Deckerle plus près de chez vous. Ce produitnʼest

pasdestiné à un usage commercial.

REMPLACEMENT GRATUIT DES ETIQUETTES

D’AVERTISSEMENT : si les étiquettes dʼavertissement deviennent

illisibles ou sont manquantes, composer le

1-800-544-6986 pour en obtenir le remplacement gratuit.

Imported by / Importé par

Black & Decker Canada Inc.

100 Central Ave.

Brockville (Ontario) K6V 5W6

Voir la rubrique “Outils électriques”

25

des Pages jaunes

pour le service et les ventes.

Page 26

PODADORA / BORDEADORA

MANUAL DE INSTRUCCIONES

Modelo N° GH710

Gracias por elegir Black & Decker!

Visite

www.BlackandDecker.com/NewOwner

para registrar su nuevo producto.

LEA EL MANUAL ANTES DE DEVOLVER

ESTE PRODUCTO POR CUALQUIER MOTIVO:

Si tiene una consulta o algún inconveniente con su producto

Black & Decker, visite

HTTP://WWW.BLACKANDDECKER.COM/INSTANTANSWERS

para obtener respuestas instantáneas las 24 horas del día.

Si no encuentra la respuesta o no tiene acceso a Internet, llame al

1-800-544-6986 de lunes a viernes de 8 a. m. a 5 p. m. hora del Este

para hablar con un agente.

Cuando llame, tenga a mano el número de catálogo.

CONSERVE ESTE MANUAL PARA FUTURAS CONSULTAS

Modelo N° GH710

INFORMACION CLAVE QUE DEBE SABER:

El protector debe instalarse antes de podar o bordear. De

lo contrario, el motor se sobrecalentará (página 28).

• Al reemplazar la cuerda, utilice sólo una cuerda REDONDA

de 1,7 mm (0,065 pulgada) de diámetro (Se recomienda el

modelo Nº DF-065 de B&D). De lo contrario, la unidad no

funcionará correctamente (página 31).

• No golpee el cabezal de alimentación contra el piso. Esto

interrumpirá el mecanismo de alimentación.

• Utilice siempre el dispositivo de retención del cable (página

30).

26

Page 27

ÍNDICE DE TEMAS

Normas de seguridad - Definiciones ........................................27

Instrucciones y advertencias de seguridad importantes ..........27

Instrucciones y advertenciasde seguridad:Enchufes polarizados..29

Instrucciones y advertenciasde seguridad:Cables prolongadores..29

Componentes...........................................................................30

Ensamblaje / Ajuste .................................................................30

Instrucciones de operación ......................................................32

Accesorios de repuesto ...........................................................33

Mantenimiento .........................................................................35

Detección de problemas ..........................................................36

Información de mantenimiento.................................................35

Garantía completa de dos años para uso en el hogar.............38

PAUTAS DE SEGURIDAD/DEFINICIONES

Es importante que lea y comprenda este manual. La información

que contiene se relaciona con la protección de SU SEGURIDAD y

la PREVENCIÓN DE PROBLEMAS. Los símbolos que siguen se

utilizan para ayudarlo a reconocer esta información.

PELIGRO: indica una situación de peligro inminente que, si no se

evita, provocará la muerte o lesiones graves.

ADVERTENCIA: indica una situación de peligro potencial que, si

no se evita, provocará la muerte o lesiones graves.

PRECAUCIÓN: indica una situación de peligro potencial que, si

no se evita, provocará lesiones leves o moderadas.

AVISO: utilizado sin el símbolo de alerta de seguridad indica una

situación de peligro potencial que, si no se evita, puede provocar daños

en la propiedad.

ADVERTENCIAS E INSTRUCCIONES

IMPORTANTES SOBRE SEGURIDAD

ADVERTENCIA: Al utilizar herramientas eléctricas para el

jardín, siempre se deben tomar ciertas precauciones básicas de

seguridad para minimizar el riesgo de incendio, descarga eléctrica y

lesiones personales, entre ellas:

Lea todas las instrucciones

• SIEMPRE UTILICE PROTECCIÓN PARA LOS OJOS: utilice

gafas o anteojos de seguridad en todo momento que esta

herramienta esté enchufada.

• PROTECTOR: nunca utilice esta herramienta sin el protector.

• UTILICE LA VESTIMENTA ADECUADA: no utilice ropa holgada

ni joyas. Pueden atascarse en las piezas móviles. Se recomienda

utilizar guantes de goma y calzado con una suela de goma

considerable al trabajar al aire libre. No opere la herramienta

descalzo ni con sandalias abiertas. Utilice pantalones largos para

protegerse las piernas. Recójase y cubra el cabello largo.

• CUERDA DE NYLON: mantenga la cara, las manos y los pies

lejos de la cuerda de nylon giratoria en todo momento.

• LA CUERDA GIRATORIA REALIZA UNA FUNCIÓN DE CORTE:

tenga precaución al podar alrededor de pantallas y plantas que

desea.

• MANTENGA ALEJADOS A TODOS LOS ESPECTADORES: a

una distancia segura, especialmente a los niños.

• ADVERTENCIA IMPORTANTE: al utilizar la herramienta como

Bordeadora, las piedras, las piezas de metal y otros objetos

pueden ser arrojados a alta velocidad por la acción de la cuerda.

La herramienta y el protector están diseñados para reducir el

peligro. No obstante, se deben tener en cuenta las siguientes

precauciones especiales:

• ASEGÚRESE de que las demás personas y mascotas estén a no

menos de 30 m (100 pies) de distancia.

• PARA REDUCIR EL RIESGO de lesiones por repercusión

(rebote), trabaje lejos de cualquier objeto sólido cercano, como

27

Page 28

pared, escalones, piedras grandes, árboles, etc. Tenga suma

precaución al trabajar cerca de objetos sólidos y, cuando sea

necesario, pode o recorte los bordes en forma manual.

• EVITE EL ARRANQUE ACCIDENTAL: nunca transporte la

herramienta enchufada con el dedo en el interruptor.

• NO FUERCE LA HERRAMIENTA: a una velocidad más rápida

de la velocidad para la que fue diseñada para cortar en forma eficaz.

• UTILICE LAHERRAMIENTA ADECUADA:noutilice estaherramienta

parauntrabajo diferente a aquéllosparalos quefue diseñada.

• NO SE ESTIRE: conserve el equilibrio adecuado y manténgase

parado correctamente en todo momento.

• NO TIRE DEL CABLE: no jale el cable de la fuente de energía.

Mantenga el cable alejado del calor, el aceite y los bordes afilados.

• DAÑO A LA UNIDAD: si golpea la herramienta o ésta se atasca

con un objeto extraño, deténgala de inmediato, desenchúfela,

verifique que no se haya dañado y repare cualquier daño antes

de seguir utilizándola. No opere la herramienta si la bobina o el

carrete están dañados.

• DAÑOS DEL CABLE: mantenga el cable de alimentación lejos

de la cuerda giratoria. Si daña el cable, desenchúfelo de la fuente

de alimentación antes de mover la herramienta o examinar el

cable. Un cable dañado debe reemplazarse antes de utilizarlo.

• DESCONECTE LA HERRAMIENTA: cuando no la utilice, al

reemplazar la cuerda o antes de limpiarla.

• EVITE LAS CONDICIONES AMBIENTALES PELIGROSAS: no

utilice herramientas eléctricas en lugares húmedos o mojados.

Siga todas las instrucciones incluidas en este Manual de

instrucciones para una operación adecuada de la herramienta.

No utilice la herramienta bajo la lluvia.

• NO OPERE herramientas eléctricas portátiles en atmósferas

gaseosas o explosivas. Los motores de estas herramientas

normalmente chispean, y las chispas pueden encender los vapores.

• GUARDE LAS HERRAMIENTASQUE NO SE UTILICENENEL

INTERIOR: cuandonolas utilice, las herramientas debenguardarseen un

lugar seco,altoo bajo llave, fueradel alcance delos niños.

• La protección del INTERRUPTOR DE CORTE POR FALLA A

TIERRA (GFCI) debe aplicarse a los circuitos o los

tomacorrientes que se utilizarán en electrodomésticos para

jardín. Hay tomacorrientes con protección GFCI incorporada y

pueden utilizarse para tomar esta medida de protección.

• FIJE EL CABLE DE PROLONGACIÓN utilizando el dispositivo

de retención del cable que se muestra en la Figura H.

• MANTÉNGASE ALERTA:No haga funcionar estaunidad si está

cansado,enfermoobajolainfluencia del alcohol,drogas o medicamentos.

• CONSERVE LAS HERRAMIENTAS ADECUADAMENTE: siga

las instrucciones enlasección demantenimiento.Inspeccione los cables

prolongadores periódicamente y reemplácelossiestán dañados.

Mantengalos mangos secos, limpios y libres deaceite y grasas.

• VERIFIQUE LAS PIEZAS AVERIADAS: antes de volver a utilizar

la herramienta, se debe controlar cualquier protección u otra

pieza que esté averiada para determinar si funcionará

correctamente y realizará la función para la que fue diseñada.

Verifique la alineación y la sujeción de las piezas móviles, la

rotura de piezas, el montaje y cualquier otra condición que pueda

afectar el funcionamiento. Cualquier protección u otra pieza que

esté dañada debe ser reparada correctamente o reemplazada

por un centro de mantenimiento autorizado, a menos que este

manual indique otra cosa.

ADVERTENCIA: No utilice la herramienta si el gatillo interruptor

no enciende o apaga la herramienta. Toda herramienta que no

pueda controlarse mediante el gatillo interruptor es peligrosa y

debe repararse.

ADVERTENCIA: Al realizar el mantenimiento de las

herramientas con doble aislamiento, UTILICE SÓLO PIEZAS DE

REPUESTOIDÉNTICAS. Repare o reemplace los cablesdañados.

ADVERTENCIA: Para evitar el riesgo de descargas eléctricas,

sólo utilice con un cable de prolongación adecuado para uso en

exteriores. Siempre conecte los cables prolongadores a una línea

con fusible o a una protegida por un interruptor de circuitos.

• NO sumerja la herramienta en agua ni la salpique con una

manguera. NO permita que ningún líquido entre en ella.

• NO guarde la herramienta sobre o cerca de fertilizantes o

productos químicos.

• NO limpie con una lavadora a presión.

28

Page 29

La etiqueta de su herramienta puede incluir los siguientes símbolos.

Los símbolos y sus definiciones son los siguientes:

V ..............voltios A ............amperios

Hz ............hertz W ............vatios

min..minutos ..........corriente alterna

corriente continua

..............

ADVERTENCIA: Parte del polvo generado por este producto

contiene sustancias químicas reconocidas por el Estado de

California como causantes de cáncer, defectos congénitos u

otros problemas reproductivos. Algunos ejemplos de estas

sustancias químicas:

• compuestos en los fertilizantes

• compuestos en los insecticidas, herbicidas y pesticidas

• arsénico y cromo de la madera con tratamiento químico

Para reducir su exposición a estas sustancias químicas, utilice el

equipo de seguridad aprobado, como máscaras para polvo

especialmente diseñadas para filtrar partículas microscópicas.

Construcción de clase II

............símbolo de alerta de .../min ......revoluciones o

seguridad reciprocidad por minuto

n

o............no velocidad sin

carga

terminal a tierra

........

seguridad

INSTRUCCIONES Y ADVERTENCIAS DE

SEGURIDAD: ENCHUFES POLARIZADOS

Para disminuir el riesgo de descargas eléctricas, este equipo posee

un enchufe polarizado (una pata es más ancha que la otra) y

requerirá el uso de un cable prolongador polarizado. El enchufe de

la herramienta se ajustará en un cable prolongador polarizado de

una sola manera. Si el cable prolongador no se ajusta totalmente

en el tomacorriente, invierta el enchufe. Si aún así no se ajusta,

obtenga un cable prolongador polarizado adecuado. Un cable

CONSERVE ESTAS INSTRUCCIONES

prolongador polarizado requerirá el uso de un tomacorriente de

pared polarizado. Este enchufe se ajustará en un tomacorriente de

pared polarizado de una sola manera. Si el enchufe no se ajusta

totalmente en el tomacorriente de pared, invierta el enchufe. Si aún

así no se ajusta bien, recurra a un electricista calificado para que

instale un tomacorriente de pared adecuado. No cambie el enchufe

del equipo, el tomacorriente del cable prolongador ni el enchufe del

cable prolongador de ninguna manera.

INSTRUCCIONES Y ADVERTENCIAS DE

SEGURIDAD: CABLES PROLONGADORES

Asegúrese de que el cable prolongador esté en buenas

condiciones. Cuando utilice un cable prolongador, asegúrese de

que tenga la capacidad para conducir la corriente que su producto

exige. Un cable de menor capacidad provocará una disminución en

el voltaje de la línea que producirá pérdida de potencia y

sobrecalentamiento. La tabla muestra la medida correcta que debe

utilizar según la longitud del cable y la capacidad nominal en

amperios indicada en la placa. En caso de duda, utilice el calibre

inmediatamente superior. Cuanto menor sea el número de calibre,

más grueso será el cable. Si se utilizará el cable

prolongador en el exterior, éste debe ser el adecuado para trabajos

al aire libre. Las letras "WA" en la cubierta del cable indican que el

cable es apropiado para uso en el exterior.

Calibre mínimo para cables de extensión

Volts Longitud total del cable en pies

120V 0-25 26-50 51-100 101-150

(0-7,6m) (7,6-15,2m) (15,2-30,4m) (30,4-45,7m)

240V 0-50 51-100 101-200 201-300

(0-15,2m) (15,2-30,4m) (30,4-60,9m) (60,9-91,4m)

Amperaje

Más de No más de American Wire Gage

0-6 18 16 16 14

6-10 18 16 14 12

10 - 12 16 16 14 12

12 - 16 14 12 No se recomienda

29

Page 30

COMPONENTES

ENSAMBLADO/REGULACIONES

Figura A

1. Interruptor

2. Dispositivo de

retención del cable

3. Tomacorriente

del cable

4. Mango auxiliar

5. Anillo (para

ajustar la altura y

el borde)

6. Cubierta del

motor

7. Guía de borde

8. Protector

9. Carrete

A

1

4

HERRAMIENTAS QUE SE REQUIEREN PARA EL ENSAMBLAJE

QUE NO ESTÁN PROVISTAS:

- Destornillador Phillips

INSTALACIÓN DEL PROTECTOR

ADVERTENCIA: DESENCHUFE LA HERRAMIENTA

3

5

6

8

7

9

ANTES DE INSTALAR EL PROTECTOR, LA GUIA DE BORDE O

EL MANGO. NUNCA OPERE

LA HERRAMIENTA SIN EL

PROTECTOR

ADECUADAMENTE

INSTALADO. EL

PROTECTOR SIEMPRE

DEBE ESTAR INSTALADO

EN LA HERRAMIENTA PARA

PROTEGER AL USUARIO.

• Coloque la podadora boca

abajo de manera que vea la

tapa del carrete (1).

• Coloque el protector (2)

boca abajo y deslícelo en la

cubierta del motor (3).

Asegúrese de que las

lengüetas (4) del protector

estén sujetas a las varillas

(5) de la cubierta del motor

como se muestra.

• Continúe deslizando el

protector hasta que lo oiga

encajar en su lugar.

• Con un destornillador

Phillips, retire el tornillo de la

guardia.

30

B

2

3

4

5

1

C

Page 31

• Inserte el destornillador del protector, como se muestra en la

figura 2 para completar el ensamblaje del protector.

• Una vez instalado el protector, retire la cubierta de la hoja de

corte de la cuerda ubicada en el extremo del protector.

COLOCACION DEL MANGO AUXILIAR

• Para colocar el mango,

presione los botones (7) de

ambos lados de la cubierta

superior como se muestra

en la figura D.

D

7

• Presione completamente el

mango sobre la cubierta y

muévalo ligeramente hasta

que lo oiga encajar en su

lugar (figura F).

• Para ajustar el mango

hacia arriba o hacia abajo,

presione el botón (8) y eleve

o baje el mango.

• El mango se debe ajustar

de manera que el brazo

delantero esté recto cuando

la podadora esté en posición

de trabajo.