Page 1

Advertencia: Léase este instructivo antes de usar el producto!

INSTRUCTION MANUAL

MANUAL DE INSTRUCCIONES

MANUAL DE INSTRUÇÕES

D25500 D25600

SDS Rotary Hammer

Rotomartillo SDS

Martelo Eletropneumático SDS

Page 2

6 7 4 5 10 12

A B

C1 C2

D1 D2

2

1

3

2

11 9

8

2 3

6

4 5

Page 3

16

15

14

13

9

8

7

6

E1 E2

F

8

10

E3 E4

1711

3

Page 4

Technical Information

D25500 D25600

Power input 120V~ 1050W 1150W

220V~ 1050W 1150W

Impact energy (J) 1 - 9 1 - 10

Maximum drilling range in concrete:

- solid bits mm 12 - 40 12 - 45

- core bits mm 40 - 90 40 - 100

Optimum drilling range in concrete:

- solid bits mm 18 - 30 20 - 38

Chisel positions 8 8

Tool holder SDS-max®SDS-max

®

Weight kg 6.5 6.6

The following symbols are used throughout this manual:

Denotes risk of personal injury, loss of life

or damage to the tool in case of non-observance of the instructions in this manual.

Denotes risk of electric shock.

EC-Declaration of conformity

D25500/D25600

DeWALT declares that these power tools have been

designed in compliance with: 98/37/EEC,

89/336/EEC, 73/23/EEC, EN 50144, EN 55014-2,

EN 55014-1, EN 61000-3-2 & EN 61000-3-3.

For more information, please contact DeWALT at the

address below, or refer to the back of the manual.

Level of sound pressure according to 86/188/EEC &

98/37/EEC, measured according to EN 50144:

D25500 D25600

LpA(sound pressure) dB(A)* 95 95

LWA(acoustic power) dB(A) 103.5 103.5

* at the operator’s ear

Take appropriate measures for the protection

of hearing.

Weighted root mean square acceleration value according to EN 50144:

D25500 D25600

9.7 m/s29.8 m/s

2

Director Engineering and Product Development

Horst Großmann

DeWALT, Richard-Klinger-Straße 40,

D-65510, Idstein, Germany

DEMOLITION HAMMER D25500/25600

ENGLISH

4

Page 5

Safety instructions

When using Power Tools, always observe the safety

regulations applicable in your country to reduce the

risk of fire, electric shock and personal injury. Read

the following safety instructions before attempting

to operate this product.

Keep these instructions in a safe place!

General

1 Keep work area clean

Cluttered areas and benches can cause accidents.

2 Consider work area environment

Do not expose Power Tools to humidity. Keep work

area well lit. Do not use Power Tools in the presence

of flammable liquids or gases.

3 Guard against electric shock

Prevent body contact with earthed surfaces (e.g.

pipes, radiators, cookers and refrigerators). For use

under extreme conditions (e.g. high humidity, when

metal swarf is being produced, etc.) electric safety

can be improved by inserting an isolating transformer or a (FI) earth-leakage circuit-breaker.

4 Keep children away

Do not let children or visitors come into contact with

the tool or extension cord. Supervision is required for

those under 16 years of age.

5 Extension cords for outdoor use

When the tool is used outdoors, always use extension cords intended for outdoor use and marked

accordingly.

6 Store idle tools

When not in use, Power Tools must be stored in a

dry place and locked up securely, out of reach of

children.

7Dress properly

Do not wear loose clothing or jewellery. They can be

caught in moving parts. Preferably wear rubber

gloves and non-slip footwear when working outdoors. Wear protective hair covering to keep long

hair out of the way.

8Wear safety goggles

Also use a face or dust mask in case the operations

produce dust or flying particles.

9 Beware of maximum sound pressure

Take appropriate measures for the protection of

hearing if the sound pressure of 85 dB(A) is exceeded.

10 Secure workpiece

Use clamps or a vice to hold the workpiece. It is

safer and it frees both hands to operate the tool.

11 Do not overreach

Keep proper footing and balance at all times.

12 Avoid unintentional starting

Do not carry the plugged-in tool with a finger on the

switch. Be sure that the switch is released when

plugging in.

13 Stay alert

Watch what you are doing. Use common sense.

Do not operate the tool when you are tired.

14 Disconnect tool

Shut off power and wait for the tool to come to a

complete standstill before leaving it unattended.

Unplug the tool when not in use, before servicing or

changing accessories.

15 Remove adjusting keys and wrenches

Always check that adjusting keys and wrenches

are removed from the tool before operating the

tool.

16 Use appropriate tool

The intended use is described in this instruction

manual. Do not force small tools or attachments to

do the job of a heavy-duty tool. The tool will do the

job better and safer at the rate for which it was

intended. Warning! The use of any accessory or

attachment or performance of any operation with

this tool, other than those recommended in this

instruction manual may present a risk of personal

injury.

17 Do not abuse cord

Never carry the tool by its cord or pull it to disconnect from the socket. Keep the cord away from

heat, oil and sharp edges.

18 Maintain tools with care

Keep the tools in good condition and clean for better and safer performance. Follow the instructions

for maintenance and changing accessories.

Inspect the tool cords at regular intervals and, if

damaged, have them repaired by an authorized

DeWALT repair agent. Inspect the extension cords

periodically and replace them if damaged. Keep all

controls dry, clean and free from oil and grease.

19 Check for damaged parts

Before using the tool, carefully check it for damage

to ensure that it will operate properly and perform

ENGLISH

5

Page 6

its intended function. Check for misalignment and

seizure of moving parts, breakage of parts and any

other conditions that may affect its operation. Have

damaged guards or other defective parts repaired

or replaced as instructed. Do not use the tool if the

switch is defective. Have the switch replaced by an

authorized DeWALT repair agent.

20 Have your tool repaired by an authorized

DeWALT repair agent

This Power Tool is in accordance with the relevant

safety regulations. To avoid danger, electric appliances

must only be repaired by qualified technicians.

Package contents

The package contains:

1 Rotary hammer

1 Side handle

1 Depth adjustment rod

1 Tube of bit lubricant

1 Kitbox (K-models only)

1 Instruction manual

1 Exploded drawing

• Check for damage to the tool, parts or accessories

which may have occurred during transport.

•Take the time to thoroughly read and understand this

manual prior to operation.

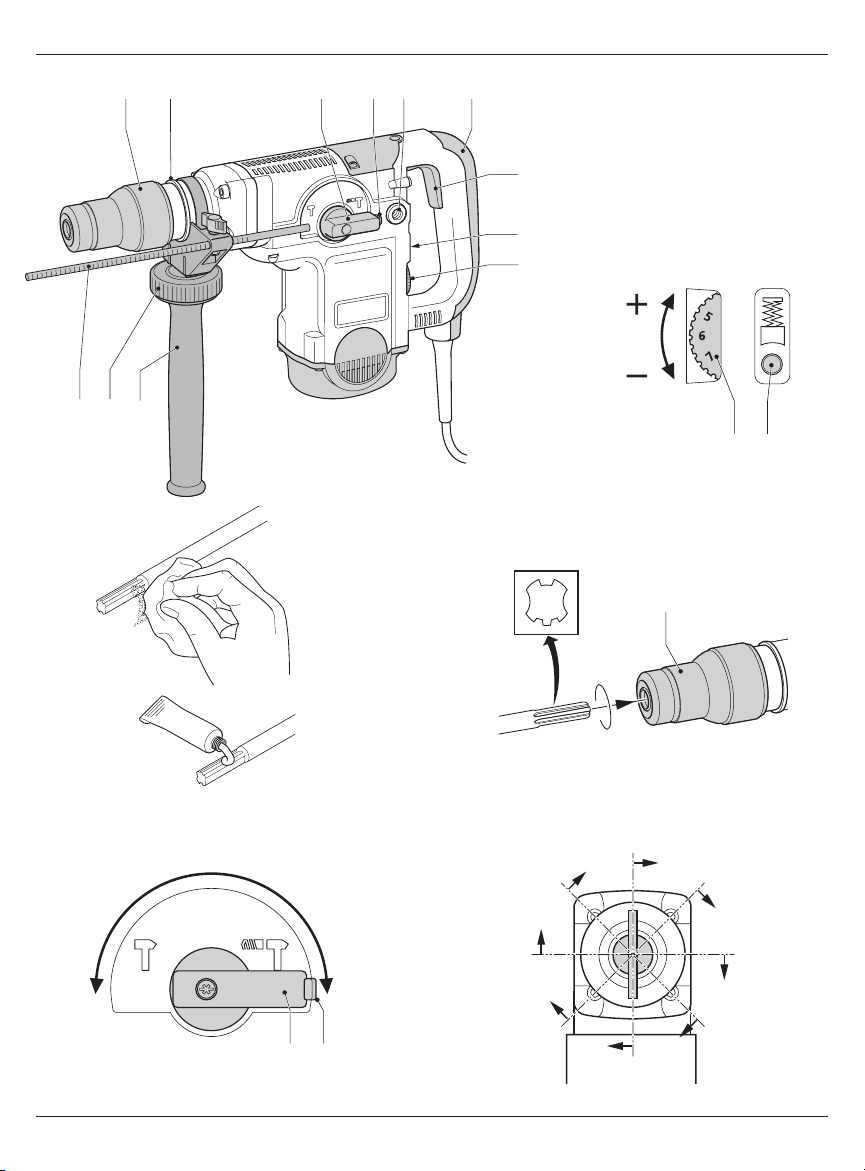

Description (fig. A)

Your D25500/D25600 rotary hammer has been

designed for professional hammer drilling and light

chipping, chiselling and demolition applications.

1 On/off switch

2 Electronic speed and impact control dial

3 Service indicator LED (D25600)

4 Mode selector switch

5 Safety lock

6 Tool holder

7 Collar

8 Side handle

9 Side handle clamp wheel

10 Rear side handle position

11 Depth adjustment rod

12 Rear handle

Soft start feature

The soft start feature allows to build up speed slowly,

thus preventing the drill bit from walking off the intended hole position when starting. The soft start feature

also reduces the immediate torque reaction transmitted

to the gearing and the operator if the hammer is started with the drill bit in an existing hole.

Torque limiting clutch

The torque limiting clutch reduces the maximum torque

reaction transmitted to the operator in case of jamming

of a drill bit. This feature also prevents the gearing and

electric motor from stalling.

The torque limiting clutch has been factory-set and

cannot be adjusted.

Electronic speed and impact control (fig. B)

The electronic speed and impact control (2) offers the

following advantages:

- use of smaller accessories without risk of breakage

-minimised break-out when chiselling or drilling in soft

or brittle materials

- optimal tool control for precise chiselling

Service indicator LED (fig. B)

The red service indicator LED (3) lights up when the

carbon brushes are nearly worn out to indicate that the

tool needs servicing. After a further 8 hours of use the

motor will automatically be shut off.

The carbon brushes are not user-serviceable.

Take the tool to an authorized DeWALT repair agent.

Electrical safety

The electric motor has been designed for one voltage

only. Always check that the power supply corresponds

to the voltage on the rating plate.

Your DeWALT tool is double insulated in

accordance with EN 50144; therefore no

earth wire is required.

Using an extension cable

If an extension cable is required, use an approved

extension cable suitable for the power input of this tool

(see technical data). The minimum conductor size is

1.5 mm2. When using a cable reel, always unwind the

cable completely. Also refer to the table below.

ENGLISH

6

Page 7

Conductor size (mm2) Cable rating (Amperes)

0.75 6

1.00 10

1.50 15

2.50 20

4.00 25

Cable length (m) 7.5 15 25 30 45 60

Voltage Amperes Cable rating (Amperes)

120V~ 0 - 2.0 6 6 6 6 6 10

2.1 - 3.4 6 6 6 6 15 15

3.5 - 5.0 6 6 10 15 20 20

5.1 - 7.0 10 10 15 20 20 25

7.1 -12.0 15 15 20 25 25 -

12.1 -20.0 20 20 25 - - -

220V~ 0 - 2.0 6 6 6 6 6 6

2.1 - 3.4 6 6 6 6 6 6

3.5 - 5.0 6 6 6 6 10 15

5.1 - 7.0 10 10 10 10 15 15

7.1 -12.0 15 15 15 15 20 20

12.1 -20.0 20 20 20 20 25 -

Assembly and adjustment

Prior to assembly and adjustment always

unplug the tool.

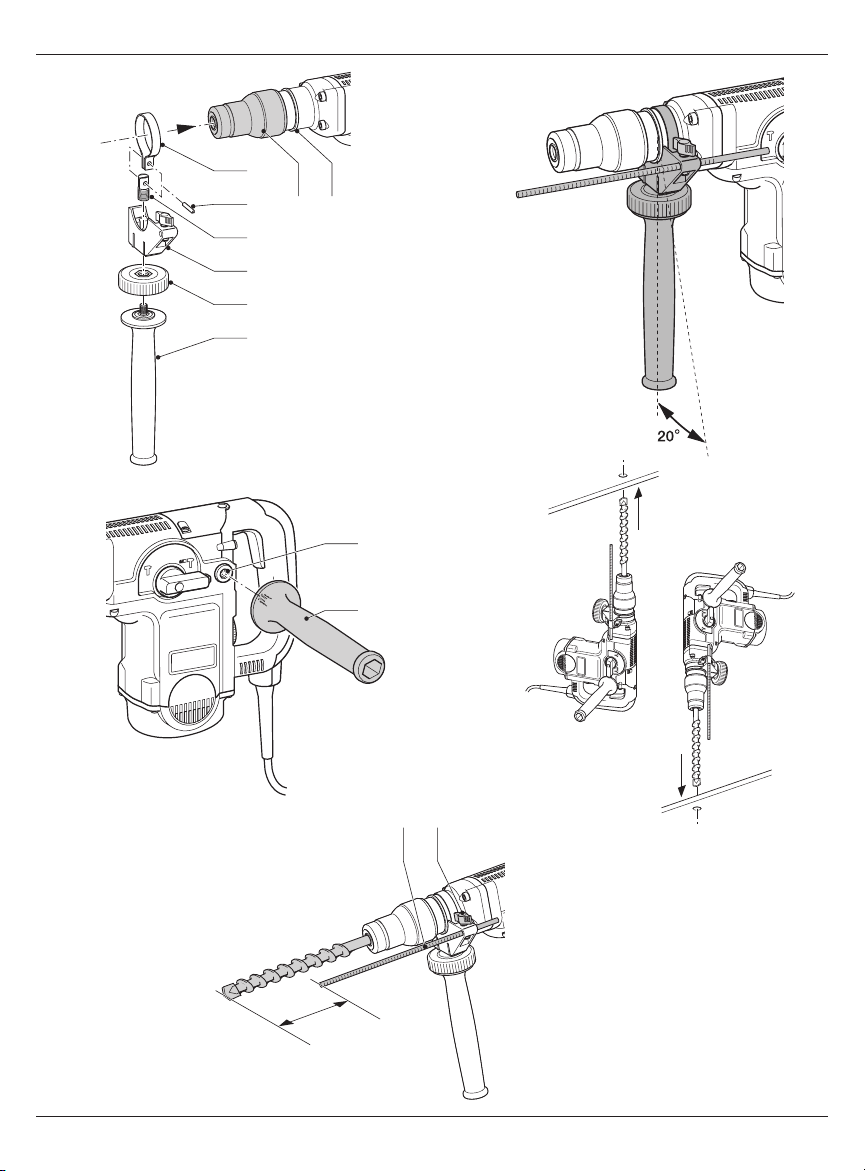

Inserting and removing SDS-max® accessories

(fig. C1 & C2)

This machine uses SDS-max® drill bits and chisels

(refer to the inset in fig. C2 for a cross-section of an

SDS-max® bit shank).

• Clean and grease the bit shank.

Only apply a slight amount of lubricant to the

bit shank. Do not apply lubricant to the

machine.

• Insert the bit shank into the tool holder (6), and press

and turn the bit slightly until the sleeve snaps into

position.

• Pull on the bit to check if it is properly locked. The

hammering function requires the bit to be able to

move axially several centimetres when locked in the

tool holder.

•To remove a bit pull back the tool holder locking

sleeve (6) and pull the bit out of the tool holder.

Selecting the operating mode (fig. D1 & D2)

The tool can be used in two operating modes (fig. D1):

Hammer drilling: for concrete and masonry

drilling operations.

Hammering only: for light chipping, chiselling and demolition applications. In this

mode the tool can also be used as a lever

to free a jammed drill bit.

•To select the operating mode, press the safety lock

(5) and rotate the mode selector switch (4) until it is

points to the symbol of the required mode.

•Release the safety lock and check that the mode

selector switch is locked in place.

Indexing the chisel position

The chisel can be indexed and locked into 8 different

positions (fig. D2).

• Rotate the mode selector switch (4) until it points

upward.

• Rotate the chisel in the desired position.

• Set the mode selector switch (4) to the “hammering

only” position.

•Twist the chisel until it locks in position.

Setting the electronic speed and impact control

dial (fig. B)

•Turn the dial (2) to the desired level. The higher the

number, the greater the speed and impact energy.

With dial settings from “1” (low) to “5” (full power) the

tool is extremely versatile and adaptable for many

different applications. The required setting is a matter

of experience. E.g.:

- when chiselling or drilling in soft, brittle materials or

when minimum break-out is required, set the dial to

“1” or “2” (low);

- when breaking or drilling in harder materials, set the

dial to “5” (full power).

D25600

With dial settings from “1” to “7” the tool allows a further fine-adjustment to the choice of application.

ENGLISH

7

Page 8

Assembling and fitting the side handle (fig. E1 - E4)

The side handle (8) can be mounted in front or in rear

position on either side of the machine to suit both RHand LH-users.

Always operate the tool with the side handle

properly assembled.

Mounting in front position (fig. E1 & E2)

• Snap the steel ring (16) over the collar (7) behind the

tool holder (6). Squeeze both ends together, mount

the bush (14) and insert the pin (15).

• Place the side handle clamp (13) and screw on the

clamp wheel (9). Do not tighten.

• Screw the side handle (8) into the clamp wheel and

tighten it.

• Rotate the side handle mounting assembly to the

desired position. For drilling horizontally with a heavy

drill bit, we recommend to place the side handle at

an angle of approx. 20° for optimum control (fig. E2).

• Lock the side handle mounting assembly in place by

tightening the clamp wheel (9).

Mounting in rear position (fig. E3 & E4)

The rear position is particularly useful when drilling

overhead or down into a floor. Refer to fig. D4.

• Unscrew the side handle (8) and remove it from the

front position. Leave the side handle mounting

assembly in front position so that the depth adjust

ment rod can still be used.

• Screw the side handle directly into one of the rear

side handle positions (10) on either side of the tool.

Setting the drilling depth (fig. F)

• Insert the required drill bit.

• Loosen the clamp nut (17) and fit the depth adjustment

rod (11) through the hole in the side handle clamp.

• Push the drill bit into a surface at a right angle and

adjust the depth adjustment rod (11) as shown.

•Tighten the clamp nut (17).

Instructions for use

• Always observe the safety instructions and

applicable regulations.

• For your own safety, always use the tool

with both hands.

• Be aware of the location of pipework and

wiring.

• Apply only a gentle pressure to the tool

(approx. 20 kg). Excessive force does not

speed up drilling or chiselling but

decreases tool performance and may

shorten tool life.

Switching on and off (fig. A)

•To switch on the tool, press the on/off switch (1).

•To stop the tool, release the switch.

Drilling with a solid bit (fig. A)

• Insert the appropriate drill bit.

• Set the mode selector switch (4) to the “hammer

drilling” position.

• Set the electronic speed and impact control dial (2).

• Fit and adjust the side handle (8).

• If necessary, set the drilling depth.

• Mark the spot where the hole is to be drilled.

• Place the drill bit on the spot and switch on the tool.

• Always switch off the tool when work is finished and

before unplugging.

Drilling with a core bit (fig. A)

• Insert the appropriate core bit.

• Assemble the centerdrill into the core bit.

• Set the mode selector switch (4) to the “hammer

drilling” position.

•Turn the electronic speed and impact control dial (2)

to a medium or high speed setting.

• Fit and adjust the side handle (8).

• Place the centerdrill on the spot and switch on the

tool. Drill until the core penetrates into the concrete

approx. 1 cm.

• Stop the tool and remove the centerdrill. Place the

core bit back into the hole and continue drilling.

When drilling through a structure thicker than the

depth of the core bit, break away the round cylinder

of concrete or core inside the bit at regular intervals.

•To avoid unwanted breaking away of concrete

around the hole, first drill a hole the diameter of the

centerdrill completely through the structure. Then

drill the cored hole halfway from each side.

• Always switch off the tool when work is finished and

before unplugging.

ENGLISH

8

Page 9

Chipping and chiselling (fig. A)

• Insert the appropriate chisel and rotate it by hand to

lock it into one of 8 positions.

• Set the mode selector switch (4) to the “hammering

only” position.

• Set the electronic speed and impact control dial (2).

• Fit and adjust the side handle (8).

• Switch on the tool and start working.

• Always switch off the tool when work is finished and

before unplugging.

Various types of SDS-max® drill bits and chisels are

available as an option. Consult your dealer for further

information on the appropriate accessories.

Maintenance

Your DeWALT Power Tool has been designed to operate

over a long period of time with a minimum of maintenance. Continuous satisfactory operation depends upon

proper tool care and regular cleaning.

Tool maintenance has to be carried out as soon as the

indicator LED lights up.

• This machine is not user-serviceable. Take the tool to

an authorised DeWALT repair agent after approximately

80 hours of use. If problems occur before this time

contact an authorised DeWALT repair agent.

Lubrication

Your power tool requires no additional lubrication.

Cleaning

Keep the ventilation slots clear and regularly clean the

housing with a soft cloth.

Unwanted tools and the environment

Take your tool to an authorized DeWALT repair agent

where it will be disposed of in an environmentally safe

way.

GUARANTEE

• 1 YEAR WARRANTY •

DEWALT warrants this product for one year from

date of purchase against any defects that are due to

faulty material or workmanship. This warranty does

not include damage to the product resulting from

accidents, misuse or repairs performed by nonauthorized repair shops. We will repair or elect to

replace the product free of charge. Note: Only in

Mexico and Argentina, this warranty includes transportation charges originated within our service network. To honor this warranty, the product with this

policy and/or proof of purchase is required.

• 30 DAY NO RISK SATISFACTION GUARANTEE •

If you are dissatisfied with the performance of this

DEWALT tool within 30 days of purchase simply

return it to the point of purchase with your sales

receipt to replace it with a new identical or similar

tool. To honor this warranty, the product and accessories must be returned in its original packaging.

• 1 YEAR OF FREE MAINTENANCE •

DEWALT will maintain the tool and replace worn

parts, for free, any time during the first year after purchase. This contract covers general cleaning,

grease, brushes and workmanship. To honor this

warranty, bring the tool with your sales receipt to any

authorized service center. Enclosed you will find the

Service Centers where you will be able to make

effective the guarantee policy and to acquire parts,

refractions and original accessories.

ENGLISH

9

Page 10

¡Enhorabuena!

Usted ha optado por una herramienta DeWALT.

Muchos años de experiencia y una gran asiduidad en

el desarrollo y la innovación de sus productos han convertido DeWALT en un socio muy fiable para el usuario

profesional.

Información técnica

D25500 D25600

Voltaje 120V~ 1050W 1150W

220V~ 1050W 1150W

Energía del impacto (J) 1 - 9 1 - 10

Capacidad de perforación en hormigón:

- broca sólida mm 12 - 40 12 - 45

- barrena cilíndrica hueca mm 40 - 90 40 - 100

Capacidad de perforación optima en hormigón:

- broca sólida mm 18 - 30 20 - 38

Posiciones del cincel 8 8

Portaherramienta SDS-max®SDS-max

®

Peso kg 6.5 6.6

En el presente manual figuran los pictogramas siguientes:

Indica peligro de lesiones, de accidentes mortales o de averías en la herramienta en caso

de no respeto de las instrucciones en este

manual.

Indica tensión eléctrica.

Declaración CE de conformidad

D25500/D25600

DeWALT certifica que estas herramientas eléctricas

han sido construidas de acuerdo a las normas

siguientes: 98/37/CEE, 89/336/CEE, 73/23/CEE,

EN 50144, EN 55014-2, EN 55014-1, EN 61000-3-2 &

EN 61000-3-3.

Para información más detallada, contacte a DeWALT,

véase abajo o consulte el dorso de este manual.

El nivel de la presión acústica de acuerdo con las normas 86/188/CEE & 98/37/CEE, medida de acuerdo

con EN 50144:

D25500 D25600

LpA (presión acústica) dB(A)* 95 95

LWA (potencia acústica) dB(A) 103,5 103,5

* al oído del usuario

To me medidas adecuadas para la protección

de los oídos.

Valor cuadrático medio ponderado en frecuencia de la

aceleración según EN 50144:

D25500 D25600

9,7 m/s29,8 m/s

2

Director Engineering and Product Development

Horst Großmann

DeWALT, Richard-Klinger-Straße 40,

D-65510, Idstein, Alemania

ROTOMARTILLO SDS D25500/D25600

ESPAÑOL

10

Page 11

ESPAÑOL

11

Instrucciones de seguridad

Al utilizar Herramientas Eléctricas, observe las

reglas de seguridad en vigor en su país, a fin de

reducir el riesgo de descarga eléctrica, de lesiones

y de incendio. Lea las instrucciones de seguridad

siguientes antes de utilizar este producto.

¡Conserve bien estas instrucciones de seguridad!

Generalidades

1 Mantenga limpia el área de trabajo

Un área o un banco de trabajo en desorden

aumentan el riesgo de accidentes.

2Tenga en cuenta el entorno del área de trabajo

No exponga las Herramientas Eléctricas a la

humedad. Procure que el área de trabajo esté bien

iluminada. No utilice Herramientas Eléctricas en la

proximidad de líquidos o gases inflamables.

3Protéjase contra las descargas eléctricas

Evite el contacto del cuerpo con las superficies

conectadas a tierra (p. ej. tuberías, radiadores,

cocinas eléctricas y refrigeradores). Para aplicaciones de uso extremas (por ej. humedad elevada

formación de polvo metálico, etc.), se puede

aumentar la seguridad eléctrica a través de

intercalar un transformador de separación o un

interruptor de protección de corriente de defecto (FI).

4 ¡Mantenga alejados a los niños!

No permita que los niños u otras personas toquen

la herramienta o el cable de prolongación. En caso

de uso por menores de 16 años, se requiere supervisión.

5 Cables de prolongación para el exterior

Al trabajar fuera, utilice siempre cables de prolongación destinados al uso exterior y marcados en

consecuencia para ello.

6 Guarde las herramientas que no utiliza

Las Herramientas Eléctricas que no se utilizan,

deben estar guardadas en un lugar seco, cerrado

y fuera del alcance de los niños.

7Vista ropa de trabajo apropiada

No lleve vestidos anchos ni joyas. Estos podrían

ser atrapados por piezas en movimiento. Para trabajos al exterior, se recomienda llevar guantes de

goma y calzado de suela antideslizante. Si tiene el

pelo largo, téngalo recogido y cubierto.

8 Lleve gafas de protección

Utilice también una mascarilla si el trabajo ejecutado produce polvo u otras partículas volantes.

9 Respete el nivel máximo de la presión acústica

To me medidas adecuadas para la protección de

los oídos cuando la presión acústica exceda el

valor de 85 dB(A).

10 Sujete bien la pieza de trabajo

Utilice abrazaderas o un torno para sujetar la pieza

de trabajo. Es más seguro que sujetarla con la

mano y le permite utilizar ambas manos para

manejar la herramienta.

11 No alargue demasiado su radio de acción

Mantenga un apoyo firme sobre el suelo y conserve el equilibrio en todo momento.

12 Evite un arranque involuntario

No mantenga el dedo en el interruptor al transportar la herramienta enchufada. Asegúrese de

que el interruptor esté en posición de parada al

enchufar la herramienta.

13 Esté siempre alerta

Mire lo que está haciendo. Use el sentido común.

No maneje la herramienta cuando está cansado.

14 Desenchufe la herramienta

Desconecte la herramienta y espere que esté completamente parada antes de dejarla sin vigilar. Desenchufe

la herramienta cuando no se utilice y antes de proceder

al mantenimiento o sustituir accesorios.

15 Retire las llaves de maniobra

Antes de poner la herramienta en marcha,

asegúrese de que las llaves y utensilios de reglaje

hayan sido retirados.

16 Utilice la herramienta adecuada

En este manual, se indica para qué uso está destinada la herramienta. No utilice herramientas o dispositivos acoplables de potencia demasiado débil

para ejecutar trabajos pesados. La herramienta

funcionará mejor y con mayor seguridad al ser utilizada de acuerdo con sus características técnicas.

¡ATENCION! El uso de accesorios o acoplamientos, o el uso de la herramienta misma distintos de

los recomendados en este manual de instrucciones, puede dar lugar a lesiones de personas.

17 Cuide el cable de alimentación

No lleve la herramienta por el cable, ni tire del cable

para desenchufar la herramienta. Proteja el cable del

calor, del aceite y de las aristas vivas.

Page 12

18 Mantenga las herramientas asiduamente

Mantenga sus herramientas afiladas y limpias para

trabajar mejor y más seguro. Siga las instrucciones

para el mantenimiento y la sustitución de accesorios. Verifique los cables de las herramientas con

regularidad y, en caso de avería, llévelos a un

Centro de Servicio DeWALT para que sean reparados. Inspeccione los cables de prolongación

periódicamente y sustitúyalos cuando presenten

defectos. Mantenga todos los mandos secos,

limpios y libres de aceite y grasa.

19 Comprobar que no haya partes averiadas

Antes de utilizar la herramienta, compruebea que

no haya averías, a fin de asegurar que funcionará

correctamente y sin problemas. Compruebe que

no haya desalineamiento o enganchamiento de

piezas en movimiento, ni roturas de piezas, ni

accesorios mal montados, ni cualquier otro defecto que pudiera perjudicar al buen funcionamiento

de la herramienta. Haga reparar o sustituir los dispositivos de seguridad u otros componentes

defectuosos según las instrucciones. No utilice la

herramienta cuando el interruptor esté defectuoso.

Haga sustituir el interruptor en un Centro de

Servicio DeWALT.

20 Haga reparar su herramienta en un Centro de

Servicio DeWALT

Esta Herramienta Eléctrica cumple con las reglas

de seguridad en vigor. Para evitar situaciones peligrosas, la reparación de Herramientas Eléctricas

debe ser efectuada únicamente por un técnico

competente.

Verificación del contenido del embalaje

El paquete contiene:

1 Rotomartillo SDS con percusión

1 Empuñadura lateral

1 Tope de profundidad

1 Tubo de lubricante para brocas

1 Caja de transporte (solo modelos K)

1 Manual de instrucciones

1 Dibujo despiezado

• Compruebe si la herramienta, piezas o accesorios

han sufrido algún daño durante el transporte.

• Tómese el tiempo necesario para leer y comprender

este manual antes de utilizar la herramienta.

Descripción (fig. A)

Este rotomartillo D25500/D25600 ha sido diseñado

para aplicaciones profesionales, tales como las de perforar, escodar (ligero), cincelar y demoler.

1 Interruptor de marcha/parada

2 Control electrónico de velocidad e impacto

3 LED indicador de servicio (D25600)

4 Interruptor selector de modo

5 Bloqueo de seguridad

6 Portaherramienta

7 Collar

8 Empuñadura lateral

9 Pomo de fijación de empuñadura lateral

10 Posición trasera para empuñadura

11 Tope de profundidad

12 Empuñadura trasera

Arranque suave

El arranque suave permite una aceleración suave, evitando así que la broca se desvíe de la posición prevista

a la puesta en marcha. Esta característica reduce también el par de torsión transmitido al engranaje y al

usuario cuando el martillo es activado con la broca en

un agujero ya existente.

Embrague limitador de torsión

El embrague limitador de torsión reduce el par de torsión máximo transmitido al usuario al quedarse atascada una broca. Esta característica impide también el

calado del engranaje y del motor eléctrico. El

embrague limitador de torsión es ajustado en la fábrica

y no puede ser ajustado luego por el usuario.

Control electrónico de velocidad y de impacto (fig. B)

El control electrónico de velocidad y de impacto (2)

ofrece las ventajas siguientes:

- utilización de accesorios más pequeños sin riesgo

de rotura

- reducción de la rotura en el cincelado o taladrado de

materiales blandos o frágiles

- control óptimo de la herramienta para cincelado de

precisión

LED indicador de servicio (fig. B)

El indicador rojo de servicio (3) se enciende cuando las

escobillas de carbono están casi desgastadas, para

indicar que la herramienta necesita ser revisada.

ESPAÑOL

12

Page 13

Después de 8 horas de operación, el motor se apagará

automáticamente. Las escobillas de carbono no

pueden ser sustituidas por el usuario. Confíe la

herramienta al servicio técnico autorizado DeWALT.

Seguridad eléctrica

El motor eléctrico ha sido diseñado para un solo voltaje.

Compruebe siempre que el voltaje de la red corresponde

al valor indicado en la placa de características.

Su herramienta DeWALT tiene doble aislamiento, conforme a la norma EN 50144; por

consiguiente, no se requiere conexión a tierra.

Sustitución de cable o enchufe

Al sustituir el cable o el enchufe hágalo con sumo cuidado:

un enchufe con conectores de cobre desprotegidos es

peligroso si se conecta a una toma de corriente activa.

Utilización de un cable de prolongación

En caso de que sea necesario utilizar un cable de

prolongación, deberá ser un cable de prolongación

aprobado, adecuado para la potencia de esta

herramienta (véanse las características técnicas). La

sección mínima de conductor es de 1,5 mm2. Si utiliza

un carrete de cable, desenrolle siempre el cable

completamente.

Montaje y ajustes

Desenchufe la herramienta antes de proceder

con el montaje y los ajustes.

Inserción y desmontaje de los accesorios

SDS-max® (fig. C1 & C2)

Esta máquina utiliza las brocas y los cinceles de SDSmax® (véase la inserción en la fig. C2 para un corte

transversal de una cola de broca SDS-max®).

• Limpie y engrase el vástago de la broca.

Aplique sólo una ligera cantidad de lubricante

al vástago de la broca.

No aplique lubricante a la máquina.

• Introduzca el vástago de la broca en el

portaherramientas (6) y presione y gire la broca

ligeramente hasta que el casquillo quede acoplado

en su posición.

•Tire de la broca para verificar si está bien sujetada.

Para la función de percusión es preciso que la broca

pueda moverse axialmente varios centímetros una

vez sujeta en el portaherramientas.

• Para desmontar una broca, retire el manguito

sujetador del portaherramientas (6) y saque la broca

del portaherramientas.

Seleccionar el modo de operación (fig. D1 & D2)

La herramienta puede usarse en dos modos operativos (fig. D1):

Perforación de percusión: para operaciones de taladro de hormigón y ladrillos.

Sólo percusión: para aplicaciones de

escodado ligero, cincelado y demolición.

En este modo, la herramienta se puede

utilizar también como palanca para sacar

una broca atascada.

• Para seleccionar el modo de operación, presione el

bloqueo de seguridad (5) y gire el interruptor selector

de modo (4) hasta que apunte al símbolo del modo

requerido.

• Suelte el bloqueo de seguridad y compruebe que el

interruptor selector de modo esté bloqueado en su

posición.

Ajuste de la posición del cincel

El cincel se puede ajustar y fijar en 8 posiciones diferentes

(fig. D2).

• Gire el interruptor selector de modo (4) hasta que

apunte hacia arriba.

• Gire el cincel en la posición deseada.

• Ajuste el interruptor selector de modo (4) a la posición

“sólo percusión”.

• Gire el cincel para que quede bloqueado en su

posición.

ESPAÑOL

13

Page 14

Ajuste del control electrónico de velocidad y de

impacto (fig. B)

• Gire el control (2) al nivel adecuado. Cuanto más alto

el número, tanto mayores serán la velocidad y la

energía del impacto. Con ajustes desde “1” (mínimo)

hasta “5” (máximo), la herramienta es

extremadamente versátil y adaptable para muchas

aplicaciones diferentes. El conocimiento de los valores

adecuados se adquiere con la experiencia.

Ej.:

- cuando cincele o taladre materiales blandos y frágiles

o cuando se requiera una rotura mínima, sitúe el

control en “1” ó “2” (mínimo);

- cuando rompa o taladre materiales duros, utilice la

posición “5” (máximo).

D25600

Mediante los ajustes de “1” a “7”, la herramienta permite un ajuste fino según la aplicación elegida.

Montar la empuñadura lateral (fig. E1 - E4)

La empuñadura lateral (8) puede montarse tanto en la

parte frontal como en la trasera y en ambos lados de la

máquina, para acomodar tanto los usuarios diestros

como los zurdos.

Utilice siempre la herramienta con la

empuñadura lateral debidamente montada.

Montaje en posición frontal (fig. E1 & E2)

• Pase la mordaza de acero (16) por encima del collar

(7) detrás del portaherramientas (6). Junte ambos

extremos, apretándolos; monte el pasador (14) e

inserte la clavija (15).

• Coloque la empuñadura lateral (13) y atornille el

pomo de fijación (9). No apriete demasiado.

• Atornille la empuñadura lateral (8) en el manguito

sujetador, y apriétela.

• Gire el soporte de la empuñadura lateral hasta

alcanzar la posición deseada. Para un control óptimo

en perforaciones horizontales con una broca pesada,

coloque la empuñadura lateral en un ángulo de

aprox. 20° (fig. E).

• Para bloquear el conjunto de montaje de la

empuñadura lateral, apriete el pomo de fijación (9).

Montaje en posición trasera (fig. E3 & E4)

Esta posición resulta de gran utilidad para perforaciones ejecutadas por encima de la cabeza, o para

perforaciones en el suelo. Véase la fig. D4.

• Desenrosque la empuñadura lateral (8) y quítela de

la posición frontal. Deje el soporte de la empuñadura

lateral en la posición frontal, de modo que aún se

pueda utilizar la varilla de ajuste de la profundidad.

• Enrosque la empuñadura lateral directamente en

una de las posiciones traseras para la empuñadura

lateral (10) en cualquier lado de la herramienta.

Ajuste de la profundidad de perforación (fig. F)

• Inserte la broca apropiada en el portaherramientas.

• Afloje la tuerca de la mordaza (17) y pase la varilla

para el ajuste de la profundidad (11) por el agujero

en la mordaza de la empuñadura lateral.

• Introduzca la broca perpendicularmente en alguna

superficie y ajuste la varilla de ajuste (11) como

indicado.

• Apriete la tuerca de la mordaza (17).

Instrucciones para el uso

• Respete siempre las instrucciones de

seguridad y las normas de aplicación.

• Por su propia seguridad, utilice siempre la

herramienta con las dos manos.

• Infórmese sobre la ubicación de tuberías

y de cables eléctricos.

•Sólo se debe ejercer una ligera presión

sobre la herramienta (aprox. 20 kg). Una

presión excesiva no acelera el taladrado o

cincelado, sino que reduce la efectividad

de la herramienta e incluso puede reducir

su vida útil.

Encendido y apagado (fig. A)

• Para encender la herramienta, presione el interruptor

on/off (1).

• Para parar la herramienta, suelte el conmutador.

Perforación con una broca sólida (fig. A)

• Inserte la broca apropiada.

• Ajuste el interruptor selector de modo (4) a la posición

“perforación de percusión”.

• Ajuste el control electrónico de velocidad e impacto (2).

ESPAÑOL

14

Page 15

• Monte y ajuste la empuñadura lateral (8).

• Si es necesario, ajuste la profundidad de perforación.

• Marque el punto a ser perforado.

• Coloque la broca en el punto y encienda la

herramienta.

• Siempre se debe desconectar la herramienta nada

más terminado el trabajo y antes de desenchufarla.

Perforación con una barrena cilíndrica hueca (fig. A)

• Inserte la broca apropiada.

• Monte la broca de centrar en la barrena cilíndrica

hueca.

• Ajuste el interruptor selector de modo (4) a la posición

“perforación de percusión”.

• Coloque el control electrónico de velocidad e

impacto (2) en posición de velocidad mediana o alta.

• Monte y ajuste la empuñadura lateral (8).

• Coloque la broca de centrar en el punto y encienda

la herramienta. Perfore hasta que la barrena haya

penetrado en el hormigón hasta aprox. 1 cm.

• Pare la herramienta y quite la broca de centrar.

Vuelva a colocar la barrena cilíndrica hueca en el

agujero y siga perforando.

• Cuando se perfora una estructura que sea más

espesa que la profundidad de la barrena hueca, se

debe sacar con frecuencia el cilindro de hormigón

que se acumula en la barrena hueca. Para evitar que

el hormigón se rompa alrededor del orificio, perfore

primero un agujero con el diámetro de la broca de

centrar que atraviese completamente la estructura.

Luego se puede perforar con barrena hueca en

ambos lados de la estructura.

• Siempre se debe desconectar la herramienta nada

más terminado el trabajo y antes de desenchufarla.

Escodar y cincelar (fig. A)

• Inserte el cincel apropiado y gírelo manualmente

hasta bloquearlo en una de las 8 posiciones.

• Ajuste el interruptor selector de modo (4) a la posición

“sólo percusión”.

• Ajuste el control electrónico de velocidad e impacto (2).

• Monte y ajuste la empuñadura lateral (8).

• Encienda la herramienta y empiece a trabajar.

• Siempre se debe desconectar la herramienta nada

más terminado el trabajo y antes de desenchufarla.

Varios tipos de brocas y cinceles de SDS-max® están

disponibles como accesorios opcionales. Consulte a

su proveedor si desea información más detallada sobre

los accesorios apropiados.

Mantenimiento

Su herramienta eléctrica DeWALT ha sido diseñada

para funcionar mucho tiempo con un mínimo de mantenimiento. El funcionamiento satisfactorio depende

del buen cuidado de la herramienta y de una limpieza

frecuente.

El mantenimiento de la herramienta debe efectuarse en

cuanto se enciendan los LED indicadores.

• Esta máquina no está diseñada para que la repare el

usuario. Lleve la herramienta a un agente DeWALT

autorizado después de unas 80 horas de operación.

En caso de problemas antes del término de dicho

plazo, póngase en contacto con un agente DeWALT

autorizado.

Lubricación

Su herramienta eléctrica no requiere lubricación

adicional.

Limpieza

Evite que se obturen las ranuras de ventilación y limpie

el exterior con regularidad utilizando un paño suave.

Herramientas desechadas y el medio ambiente

Lleve la herramienta vieja a un Centro de Servicio

DeWALT, donde será eliminada sin efectos perjudiciales para el medio ambiente.

ESPAÑOL

15

Page 16

GARANTÍA

• 1 AÑO DE GARANTIA •

Este producto está garantizado por 1 año a partir de

la fecha de compra contra cualquier defecto en su

funcionamiento, así como en materiales y mano de

obra empleada en su fabricación. Esta garantía no

incluye daños al producto ocasionados por accidentes, mal uso, o reparaciones por talleres no

autorizados por Black & Decker. Nuestra garantía

incluye la reparación o reposición del producto y/o

componentes sin cargo alguno para el cliente

incluyendo mano de obra. Nota: Solamente en

México y Argentina, esta garantía incluye los gastos

de transportación razonablemente erogados que se

originen dentro de su red de servicio nacional. Para

hacer efectiva esta garantía deberá presentar su herramienta y esta póliza sellada por el establecimiento

comercial donde se adquirió el producto y/o la factura de compra.

• 30 DIAS DE SATISFACCION GARANTIZADA •

Si durante los primeros 30 días posteriores a la fecha

de compra Ud. No se encuentra satisfecho con la

herramienta DEWALT debido a falla de funcionamiento, o si ésta no satisface sus necesidades

de trabajo; Ud. podrá canjear esta herramienta por

una igual o similar a la adquirida. Para hacer válida

esta garantía deberá presentar su factura de compra

y devolver el producto y accesorios en su empaque

original.

• 1 AÑO DE MANTENIMIENTO •

DEWALT garantiza el mantenimiento gratuito del producto que acaba de adquirir por 1 año a partir de la

fecha de compra. Dicho mantenimiento cubre:

limpieza general, cambio de grasa, cambio de carbones y mano de obra gratuita. La garantía de mantenimiento gratuito podrá efectuarse solamente en

los centros de servicio autorizados con la presentación de la factura original de compra.

Anexo encontrará una relación de centros de servicio

donde podrá hacer efectiva su garantía y adquirir

partes, refracciones y accesorios originales.

ESPAÑOL

16

Page 17

Parabéns!

Escolheu uma ferramenta DeWALT. Muitos anos de

experiência, um desenvolvimento contínuo de produtos e o espírito de inovação fizeram da DeWALT um

dos parceiros mais fiáveis para os utilizadores profissionais.

Dados técnicos

D25500 D25600

Voltagem 120V~ 1050W 1150W

220V~ 1050W 1150W

Energia de impacto (J) 1 - 9 1 - 10

Gama de perfuração total em betão:

- brocas sólidas mm 12 - 40 12 - 45

- brocas de caixa mm 40 - 90 40 - 100

Gama de perfuração máxima em betão:

- brocas sólidas mm 18 - 30 20 - 38

Posições do cinzel 8 8

Suporte de ferramenta SDS-max®SDS-max

®

Peso kg 6,5 6,6

Os seguintes símbolos são usados neste manual:

Indica risco de ferimentos, perda de vida ou

danos à ferramenta no caso do não-cumprimento das instruções deste manual.

Indica tensão eléctrica.

Declaração CE de conformidade

D25500/D25600

A DeWALT declara que estas ferramentas eléctricas

foram concebidas em conformidade com 98/37/CEE,

89/336/CEE, 73/23/CEE, EN 50144, EN 55014-2,

EN 55014-1, EN 61000-3-2 & EN 61000-3-3.

Para mais informações, quieira consultar a DeWALT no

endereço abaixo ou a parte de trás do presente manual.

De acordo com as Directivas 86/188/CEE & 98/37/CEE

da Comunidade Europeia, o nível de potência sonora,

medido de acordo com a EN 50144, é:

D25500 D25600

LpA (pressão sonora) dB(A)* 95 95

LWA (potência sonora) dB(A) 103,5 103,5

* junto ao ouvido do operador

Use protectores auditivos.

Valor médio quadrático ponderado em frequência de

aceleração conforme à EN 50144:

D25500 D25600

9,7 m/s29,8 m/s

2

Director Engineering and Product Development

Horst Großmann

DeWALT, Richard-Klinger-Straße 40,

D-65510, Idstein, Alemanha

MARTELO ELECTROPNEUMÁTICO SDS

D25500/D25600

PORTUGUÊS

17

Page 18

Instruções de segurança

Quando usar Ferramentas Eléctricas, cumpra sempre os regulamentos de segurança aplicáveis no

seu país para reduzir o risco de incêndio, de

choque eléctrico e de ferimentos. Leia as seguintes

instruções de segurança antes de tentar utilizar

este produto.

Guarde estas instruções!

Instruções gerais

1 Mantenha a área de trabalho arrumada

As mesas e áreas de trabalho desarrumadas

podem provocar ferimentos.

2 Cuide do ambiente da área de trabalho

Não exponha Ferramentas Elétricas à humidade.

Ilumine bem as áreas de trabalho. Não utilize

Ferramentas Elétricas em presença de líquidos ou

gases inflamáveis.

3Tenha cuidado com os choques elétricos

Evite o contacto direto com superfícies ligadas à

terra (p.ex. tubos, radiadores, fogões, frigoríficos).

Nos casos de serviço sob condições extremas (tais

como humidade elevada, execução de soldadura,

etc.) a segurança elétrica pode ser aumentada

intercalando-se um transformador de separação

ou um disjuntor de corrente de defeito (FI).

4 Mantenha as crianças afastadas

Não deixe as crianças ou visitantes tocarem na

nem no cabo de extensão. As crianças com

menos de 16 anos de idade devem ser vigiadas.

5 Cabos para uso exterior

Quando utilizar ferramentas, empregue sempre

cabos previstos para uso ao livre exterior.

6 Guarde as ferramentas que não estiverem em uso

Quando não forem utilizadas as Ferramentas

Elétricas, estas devem ser guardadas num lugar

seco, fechado à chave e fora do alcance das

crianças.

7 Vista-se de maneira apropriada

Não use vestuário largo nem jóias porque podem

prender-se numa peça móvel. Quando se trabalha

no exterior, é aconselhável o uso de luvas de

borracha e de calçado antiderrapante. Cubra o

cabelo se tiver cabelo comprido.

8 Utilize óculos de proteção

Utilize também uma máscara no caso de os trabalhos produzirem pó.

9 Tenha cuidado com o ruído

Tome medidas de protecção apropriadas se o nível

do ruído exceder 85 dB(A).

10 Segure firmemente as peças de trabalho

Utilize grampos ou um torno para segurar as peças

a trabalhar. É mais seguro e permite manter as

duas mãos livres para trabalhar.

11 Verifique a sua posição

Mantenha sempre o equilíbrio.

12 Evite arranques acidentais

Não transporte uma ferramenta ligada à rede com o

dedo colocado no interruptor. Verifique se o interruptor

está desligado ao ligar a ferramenta à rede.

13 Esteja atento

Dê atenção ao que vai fazendo. Trabalhe com

precaução. Não utilize ferramentas quando estiver

cansado.

14 Desligue a ferramenta

Desligue e espere até a ferramenta parar

completamente antes de a deixar sem vigilância.

Tire o plugue da tomada quando a ferramenta não

estiver a ser utilizada, antes de proceder à

manutenção ou à substituição de acessórios.

15 Tire as chaves de aperto

Verifique sempre se as chaves de aperto foram

retiradas da ferramenta antes de a utilizar.

16 Empregue as ferramentas apropriadas

Este manual indicam as aplicações da ferramenta.

Não force pequenas ferramentas ou acessórios

para fazer o trabalho de uma ferramenta forte. A

ferramenta trabalhará melhor e de uma maneira

mais segura se for utilizada para o efeito indicado.

AVISO O uso de qualquer acessório ou o uso da

própria ferramenta, além do que é recomendado

neste manual de instruções pode dar origem a

risco de ferimento.

17 Não force o cabo elétrico

Nunca transporte a ferramenta pelo cabo e não

puxe pelo cabo para tirar o plugue da tomada.

Proteja o cabo contra o calor e evite o contato com

óleo e objectos cortantes.

18 Cuide das suas ferramentas com atenção

Para uma maior rentabilidade, mantenha as

ferramentas sempre afinadas e limpas.

PORTUGUÊS

18

Page 19

Cumpra as instruções relativas à manutenção e

substituição dos acessórios. Verifique regularmente os cabos da ferramenta e, no caso de estes

estarem danificados, mande-os consertar em um

Centro de Assistência Técnica DeWALT. Verifique

periodicamen

te os cabos de extensão e substituaos

se estiverem danificados. Mantenha os comandos

secos, limpos e sem óleo ou gordura

.

19 Verifique as peças danificadas

Antes de utilizar a ferramenta, verifique cuidadosamente se esta apresenta sinais de danos de modo

a assegurar um bom funcionamento e a obtenção

do resultado desejado. Verifique o bom alinhamento e fixação das peças móveis e confirme a ausência de ruptura das peças. Verifique ainda se a montagem foi bem feita ou se existe qualquer outra

condição que possa impedir que a ferramenta funcione bem. Mande consertar ou substituir os dispositivos de proteção ou outras peças danificadas

conforme as instruções. Não utilize a ferramenta se

o interruptor não estiver a funcionar. Mande substituir o interruptor num Centro de Assistência

Técnica DeWALT.

20 Mande consertar a sua ferramenta por um

Centro de Assistência Técnica DeWALT

Esta Ferramenta Elétrica está conforme às regulamentações de segurança que lhe dizem respeito.

Para evitar qualquer perigo, a reparação de ferramentas elétricas deverá estar exclusivamente a

cargo de técnicos qualificados.

Verificação do conteúdo da embalagem

A embalagem contém:

1 Martelo electropneumático SDS

1 Punho lateral

1 Batente de profundidade

1 Embalagem com lubrificante

1 Caixa de transporte (apenas modelos K)

1 Manual de instruções

1 Vista dos componentes destacados

•Verifique se a ferramenta, as peças ou os acessórios

apresentam sinais de danos que possam ter ocorrido

durante o transporte.

• Antes de utilizar a ferramenta, dedique o tempo

necessário à leitura e compreensão deste manual.

Descrição (fig. A)

O seu martelo electropneumatico D25500/D25600 foi

concebido para aplicações profissionais de perfuração

com impacto e de trabalhos de rompimento e de

demolição mais leves.

1 Interruptor on/off

2 Mostrador de controle eletrônico de impacto e de

velocidade

3 LED indicador de assistência (D25600)

4 Selector de modo

5 Trava de segurança

6 Mandril

7 Pescoço

8 Punho lateral

9 Fixação do punho lateral

10 Posição do punho lateral traseiro

11 Batente de profundidade

12 Punho traseiro

Função de arranque suave

A função de arranque suave permite que a velocidade

aumente lentamente evitando que a broca se desloque

da posição de furo pretendida, quando a máquina

começa a funcionar. A função de arranque lento também reduz o contragolpe transmitido às engrenagens

e ao operador no caso do martelo começar a funcionar

com a broca colocada num furo.

Embreagem limitadora de torque

A embreagem limitadora de torque evita o contragolpe

no caso de bloqueio da broca. Esta característica também impede que as engrenagens e o motor elétrico

parem repentinamente. A embreagem limitadora de

torque possui uma regulagem de fábrica e não pode

ser ajustada.

Controle eletrônico de velocidade e de impacto

(fig. B)

O controle electrônico de velocidade e de impacto (2)

proporciona as seguintes vantagens:

- utilização de acessórios de pequenas dimensões,

sem o risco de se partirem;

- minimização das quebras durante o rompimento ou

perfuração de materiais moles ou quebradiços;

- um controlo óptimo da ferramenta para uma operação

de rompimento precisa.

PORTUGUÊS

19

Page 20

LED indicador de assistência (fig. B)

O LED (3) vermelho indicador de assistência acende

quando as escovas de carvão estão ficando gastas,

informando desta forma que a ferramenta precisa fazer

uma revisão. Aproximadamente 8 horas de utilização

após o LED acender, o motor pára automaticamente.

As escovas de carvão não podem ser reparadas pelo

utilizador. Leve a ferramenta a um agente de reparação

autorizado DeWALT.

Segurança elétrica

O motor eléctrico foi concebido para uma única tensão. Verifique sempre se a tensão da rede corresponde

à voltagem indicada na placa de identificação.

A sua ferramenta DeWALT tem duplo isolamento em conformidade com o estipulado

na norma EN 50144, não sendo, por isso,

necessária uma ligação à terra.

Substituição do cabo ou plugue

Ao substituir o cabo ou plugue, elimine-os de forma

segura; um plugue com condutores de cobre a

descoberto é perigosa quando entra em contato com

uma tomada com corrente.

Extensões

Se fôr necessário um fio de extensão, use um cabo

especial, conveniente para a corrente desta ferramenta (Veja os dados técnicos). A dimensão mínima do

condutor é 1,5 mm2. No caso de se usar uma bobina,

desenrole o cabo todo.

Montagem e afinação

Antes da montagem de acessórios e da afinação retire sempre o plugue da tomada.

Como inserir e retirar os acessórios SDS-max®

(fig. C1 & C2)

Esta máquina utiliza brocas e acessórios SDS-max®

(consulte a gravura na fig. C2 para corte transversal de

uma haste de broca SDS-max®).

• Limpe e lubrifique a haste da broca.

Aplique apenas uma pequena quantidade de

lubrificante na haste da broca.

Não aplique lubrificante na máquina.

• Insira a haste da broca no mandril (6) e gire-o

levemente até que encaixe no mandril.

• Puxe a broca para verificar se está corretamente

fixada. Na função de impacto, a broca deverá deslocar-

se axialmente alguns centímetros, quando estiver

fixada no suporte de ferramentas.

• Para retirar a broca puxe para trás o mandril (6) e tire

a broca de dentro do suporte.

Selecção do modo de operação (fig. D1 & D2)

Os berbequins de percussão podem ser utilizados em

dois modos de operação (fig. D1):

Perfuração com impacto: para perfuração

em concreto e alvenaria.

Impacto: para aplicações ligeiras de

rompimento e de demolição.

A ferramenta pode também ser utilizada

neste modo como uma alavanca para

soltar uma broca encravada.

•Para selecionar o modo de funcionamento, pressione

o fecho de segurança (5) e rode o seletor de modo (4)

até ao símbolo do modo desejado.

•Solte o fecho de segurança e verifique se o seletor

de modo está fixe na respectiva posição.

Determinação da posição da talhadeira

Pode ser seleccionado, ajustada e travada em 8

posições diferentes (fig. D2).

• Rode o seletor de modo (4) até ficar virado para

cima.

• Rode a talhadeira para a posição requerida.

• Regule o seletor de modo (4) para a posição

“impacto”.

• Rode a talhadeira até à respectiva posição.

Regulagem do mostrador de controle eletrônico de

velocidade e de impacto (fig. B)

• Rode o mostrador (2) para o nível desejado. Quanto

mais alto for o número, maior será a energia de

impacto e velocidade. As regulagens do mostrador

PORTUGUÊS

20

Page 21

que vão desde “1” (baixo) até “5” (potência máxima),

tornam esta ferramenta extremamente flexível e de

fácil adaptação a muitas e variadas aplicações. A

regulagem requerida é apenas uma questão de

experiência.

Por exemplo:

- para romper ou partir azulejos ou materiais moles e

quebradiços ou quando se exige a taxa de quebra

mínima, regule o mostrador na posição “1” ou “2”

(baixo);

- para quebrar ou demolir materiais mais duros, regule

o mostrador no “5” (potência máxima).

Montagem e encaixe do punho lateral (fig. E1 - E4)

O punho lateral (8) pode ser montado à frente ou atrás

nos dois lados da máquina para se adaptar a utilizadores canhotos ou destros.

Utilize a máquina sempre com o punho lateral montado corretamente.

Montagem à frente (fig. E1 & E2)

• Encaixe o anel de aço (16) no pescoço (7) atrás do

encabadouro (6). Aperte as duas extremidades,

monte o eixo dupla rosca (14) e insira o pino (15).

• Coloque o grampo do punho lateral (13) e aparafuse

fixação (9). Não aperte.

• Aparafuse o punho lateral (8) à roda de grampo e

aperte-o.

• Rode o conjunto de montagem do punho lateral

para a posição desejada. Para uma perfuração

horizontal com uma broca reforçada, coloque o

punho lateral num ângulo de aproximadamente 20°

para máximo controle (fig. E).

•Prenda o conjunto de fixação do punho lateral no

devido lugar apertando o parafuso (9).

Montagem atrás (fig. E3 & E4)

A montagem atrás torna-se especialmente útil quando se

está a fazer furos ao alto ou no chão. Consulte a fig. D4.

• Desaparafuse o punho lateral (8) e remova-o da

parte da frente. Deixe o conjunto de montagem do

punho lateral à frente para se poder continuar a utilizar

a haste de afinação de profundidade.

• Aparafuse o punho lateral directamente num dos

orifícios traseiros do punho lateral (10) nos dois

lados da ferramenta.

Regulagem da profundidade do furo (fig. F)

• Insira a broca necessária.

• Desaperte a porca de fixação (17) e encaixe a haste

de afinação de profundidade (11) no furo do grampo

do punho lateral.

• Enfie a broca numa superfície, em ângulo reto, e

ajuste a profundidade da haste de afinação (11)

conforme indicado.

• Aperte a porca de fixação (17).

Modo de emprego

• Cumpra sempre as instruções de

segurança e os regulamentos aplicáveis.

• Para a sua própria segurança, utilize sempre

a ferramenta com ambas as mãos.

• Esteja informado sobre a localização de

tubos e de fios elétricos dentro da parede.

•Aplique apenas uma ligeira pressão na

ferramenta. Uma força excessiva não vai

acelerar a operação de perfuração ou de

rompimento, mas sim diminuir o rendimento

da ferramenta podendo diminuir o seu

período de vida útil.

Ligar e desligar (fig. A)

• Para ligar a máquina, aperte o interruptor de

ligar/desligar (1).

• Para desligar a máquina, liberte o interruptor.

Perfuração com uma broca (fig. A)

• Insira a broca apropriada.

• Regule o seletor de modo (4) para a posição

“perfuração com impacto”.

• Regule o mostrador de controle eletrônico de

velocidade e impacto (2).

• Encaixe e regule o punho lateral (8).

• Se necessário, ajuste a profundidade de perfuração.

• Marque o ponto onde pretende executar um orifício.

• Coloque a broca no ponto e ligue a ferramenta.

• Sempre desligue a ferramenta quando o trabalho

está acabado e antes de tirar ao plugue da tomada.

Perfuração com uma broca de caixa (fig. A)

• Insira a broca de caixa apropriada.

• Coloque a broca de centrar na broca de caixa.

• Regule o selector de modo (4) para a posição

PORTUGUÊS

21

Page 22

“perfuração com impacto”.

• Ponha o mostrador de controlo electrónico de

impacto e velocidade (2) na posição de velocidade

moderada ou alta.

• Encaixe e regule o punho lateral (8).

• Coloque a broca de centrar no ponto e ligue a

ferramenta. Perfure até a caixa penetrar cerca de 1 cm

no concreto.

• Pare a ferramenta e retire a broca de centrar.

Coloque a broca de caixa no furo e continue a

perfuração.

• Quando estiver a perfurar uma estrutura mais espessa

que a profundidade da broca de caixa, retire o cilindro

de betão ou de caixa dentro da broca a intervalos

regulares. Para evitar partir betão a mais à volta do

orifício, faça primeiro um furo com o diâmetro da broca

de centrar através de toda a estrutura. Depois perfure

o espaço oco até meio de cada lado.

• Sempre desligue a ferramenta quando o trabalho

está acabado e antes de tirar a ficha da tomada.

Rompimento (fig. A)

• Insira o acessório apropriado e rode à mão para o

prender numa das 8 posições.

• Regule o selector de modo (4) para a posição

“impacto”.

• Regule o mostrador de controle eletrônico de

velocidade e impacto (2).

• Encaixe e regule o punho lateral (8).

• Ligue a ferramenta e inicie os trabalhos.

• Sempre desligue a ferramenta quando o trabalho

está acabado e antes de tirar a ficha da tomada.

A DEWALT possui diversos tipos de acessórios e brocas de SDS-max®. Para mais informações sobre os

acessórios apropriados, consulte o seu Revendedor

autorizado.

Manutenção

A sua Ferramenta Elétrica DeWALT foi concebida para

funcionar durante muito tempo com um mínimo de

manutenção. O funcionamento satisfatório contínuo

depende de bons cuidados e limpeza regular da ferramenta.

A manutenção da ferramenta deve ser efectuada logo

que o LED se acenda.

•Esta ferramenta não deve ser reparada pelo operador.

Leve-a a um Centro de Assisténcia Técnica

Autorizada da DeWALT após cerca de 80 horas de

utilização. Caso haja problemas antes de cumprir

esse prazo, contate um Centro de Assisténcia

Técnica Autorizada da DeWALT.

Lubrificação

A sua Ferramenta Elétrica não precisa de lubrificação

suplementar.

Limpeza

Conserve livres as aberturas de ventilação e limpe

regularmente o corpo da máquina utilizando um pano

macio.

Ferramentas indesejadas e o ambiente

Leve a sua ferramenta velha a um Centro de

Assistência Técnica DeWALT onde ela será eliminada

de um modo seguro para o ambiente.

PORTUGUÊS

22

Page 23

PORTUGUÊS

GARANTIA

• 30 DIAS DE SATISFAÇÃO TOTAL DE QUALIDADE •

Ao comprar sua ferramenta DeWALT, durante os

primeiros 30 dias (comprovado pela nota fiscal), se

ocorrer qualquer problema de funcionamento, o

revendedor estará autorizado a trocar seu produto

por outro idêntico e novo.

• 1 ANO DE MANUTENÇÃO GRATUITA •

A DeWALT oferece como uma forma de prevenção,

duas manutenções gratuitas no prazo de um ano,

para reparos, limpeza, ajustes, lubrificação, sem

ônus ao consumidor. É necessário apresentar uma

prova de compra da ferramenta

• 1 ANO DE GARANTIA •

Se o seu produto DeWALT se avariar durante os

primeiros 12 meses, garantimos a substituição das

peças defeituosas, exceto as que tiverem desgaste

normal, sem encargos desde que:

• O produto não tenha sido mal usado

• Não tenha sido reparado em postos não autorizados

• Tenha comprovante de compra

Anexo o Sr./Sra. Encontrará a relação de nossos

Centros de Serviço autorizados onde poderá registrar sua garantia e onde poderá adquirir partes e

acessórios originais.

Page 24

Black&Decker

Cat No. D25500/D25600 - Form No. 581371-02

Copyright © 2003

Printed in China

IMPORTADO: BLACK & DECKER S.A. DE C.V.

BOSQUES DE CIDROS ACCESO RADIATAS NO. 42

COL. BOSQUES DE LAS LOMAS.

3A SECCIÓN, CP 05120

DELEGACIÓN CUAJIMALPA

MÉXICO, D.F.

TEL. (52) 555-326-7100

R.F.C.: BDE810626-1W7

Loading...

Loading...