Page 1

www.blackanddecker.ae

BPDH7013

Page 2

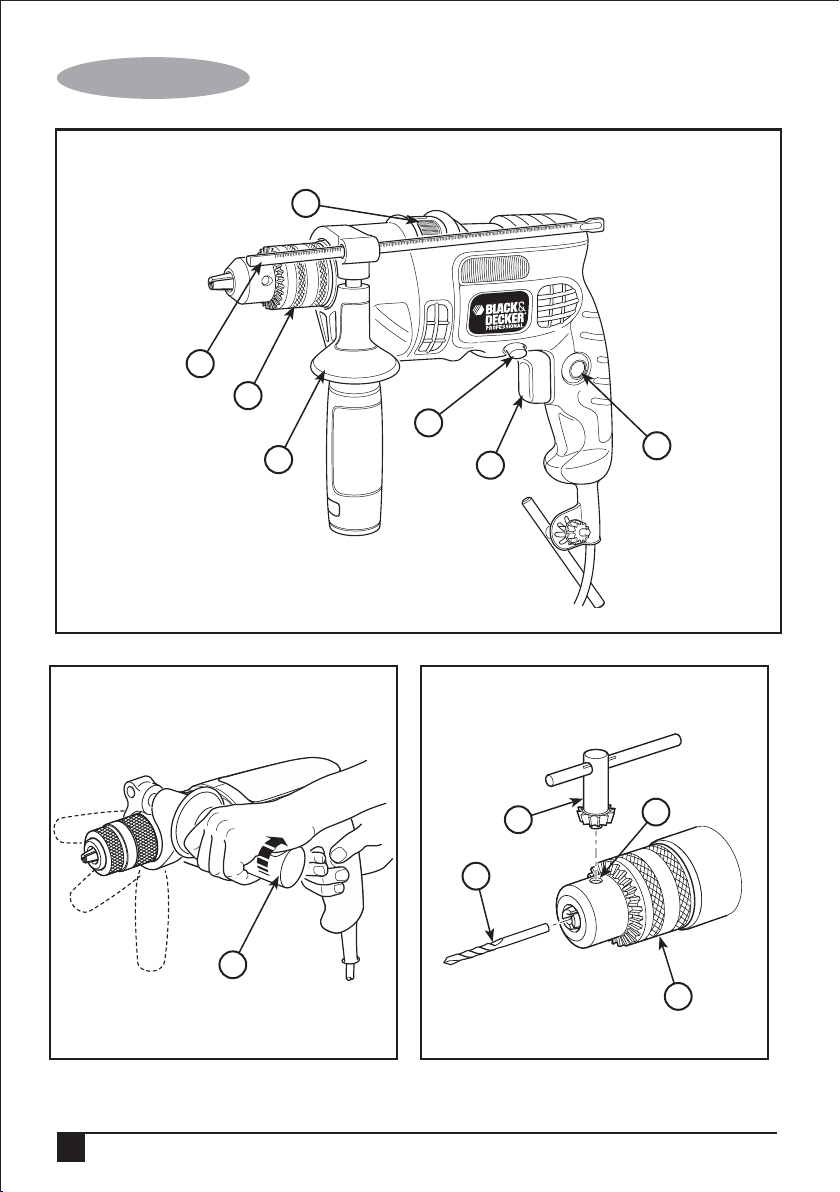

FIG. A

ENGLISH

4

6

5

3

7

1

2

FIG. B

2

FIG. C

10

11

9

7

8

Page 3

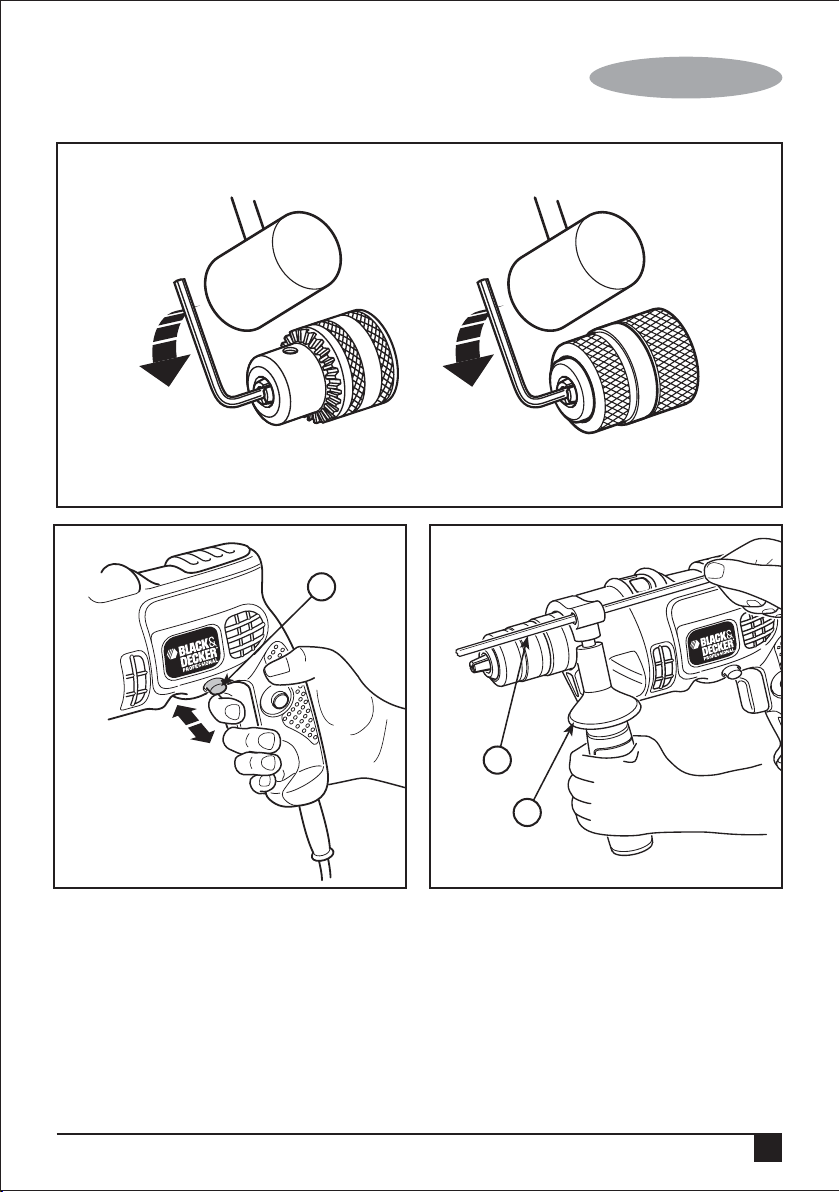

FIG. D

FIG. E FIG. F

3

ENGLISH

6

7

3

Page 4

ENGLISH

Do not return this product to the store,

first contact your local Black & Decker office or nearest

authorized service center.

General safety rules

Warning! Read and understand all

instructions. Failure to follow all instructions

listed below, may result in electric shock, fire

and/or serious personal injury.

Save these instructions

Safety instructions

General power tool safety warnings.

Warning! Read all safety warnings and all

instructions. Failure to follow the warnings

and instructions listed below may result in

electric shock, fire and/or serious injury.

Save all warnings and instructions for future reference.

The term “power tool” in all of the warnings listed below

refers to your mains operated (corded) power tool or battery

operated (cordless) power tool.

1. Work Area Safety

a. Keep work area clean and well lit. Cluttered and dark

areas invite accidents.

b. Do not operate power tools in explosive

atmospheres, such as in the presence of flammable

liquids, gases or dust. Power tools create sparks

which may ignite the dust or fumes.

c. Keep children and bystanders away while operating

a power tool. Distractions can cause you to lose

control.

2. Electrical Safety

a. Power tool plugs must match the outlet. Never

modify the plug in any way. Do not use any adapter

plugs with earthed (grounded) power tools.

Unmodified plugs and matching outlets will reduce risk

of electric shock.

b. Avoid body contact with earthed or grounded

surfaces such as p ipes, radiators, ranges and

refrigerators. There is an increased risk of electric

shock if your body is earthed or grounded.

c. Do not expose power tools to rain or wet conditions.

Water entering a power tool will increase the risk of

electric shock.

d. Do not abuse the cord. Never use the cord for

carrying, pulling or unplugging the power tool. Keep

cord away from heat, oil, sharp edges or moving

parts. Damaged or entangled cords increase the risk of

electric shock.

e. When operating a power tool outdoors, use an

extension cord suitable for outdoor use. Use of a cord

suitable for outdoor use reduces the risk of electric

shock.

f. If operating a power tool in a damp location is

unavoidable, use a residual current device (RCD)

protected supply. Use of an RCD reduces the risk of

electric shock.

Note: The term “Residual Curent Device (RCD)” can be

replaced by “Ground Fault Circuit Interrupter (GFCI)” or by

“Earth Leakage Circuit Breaker (ELCB)”.

3. Personal Safety

a. Stay alert, watch what you are doing and use

common sense when operating a power tool. Do not

use a power tool while you are tired or under the

influence of drugs, alcohol or medication. A moment

of inattention while operating power tools may result in

serious personal injury.

b. Use personal protective equipment. Always wear eye

protection. Protective equipment such as dust mask,

non-skid safety shoes, hard hat, or hearing protection

used for appropriate conditions will reduce personal

injuries.

c. Prevent unintentional starting. Ensure the switch is

in the off-position before connecting to power

source and/or battery pack, picking up or carrying

the tool. Carrying power tools with your finger on the

switch or energising power tools that have the switch on

invites accidents.

d. Remove any adjusting key or wrench before turning

the power tool on. A wrench or a key left attached to a

rotating part of the power tool may result in personal

injury.

4

Page 5

ENGLISH

e. Do not overreach. Keep proper footing and balance

at all times. This enables better control of the power

tool in unexpected situations.

f. Dress properly. Do not wear loose clothing or

jewellery. Keep your hair, clothing and gloves away

from moving parts. Loose clothes, jewellery or long

hair can be caught in moving parts.

g. If devices are provided for the connection of dust

extraction and collection facilities, ensure these are

connected and properly used. Use of these devices

can reduce dust related hazards.

4. Power Tool Use and Care

a. Do not force the power tool. Use the correct power

tool for your application. The correct power tool will do

the job better and safer at the rate for which it was

designed.

b. Do not use the power tool if the switch does not turn

it on and off. Any power tool that cannot be controlled

with the switch is dangerous and must be repaired.

c. Disconnect the plug from the power source and/or

the battery pack from the power tool before making

any adjustments, changing accessories, or storing

power tools. Such preventive safety measures reduce

the risk of starting the power tool accidentally.

d. Store idle power tools out of the reach of children

and do not allow persons unfamiliar with the power

tool or these instructions to operate the power tool.

Power tools are dangerous in the hands of untrained

users.

e. Maintain power tools. Check for misalignment or

binding of moving parts, breakage of parts and any

other condition that may affect the power tools

operation. If damaged, have the power tool repaired

before use. Many accidents are caused by poorly

maintained power tools.

f. Keep cutting tools sharp and clean. Properly

maintained cutting tools with sharp cutting edges are

less likely to bind and are easier to control.

5. Service

a. Have your power tool serviced by a qualified repair

person using only identical replacement parts. This

will ensure that the safety of the power tool is

maintained.

6. Electrical safety

Your tool is double insulated; therefore no earth

wire is required. Always check that the main

voltage corresponds to the voltage on the rating plate.

Warning! If the power cord is damaged, it must

be replaced by the manufacturer, authorized

Black & Decker Service Center or an equally

qualified person in order to avoid damage or

injury. If the power cord is replaced by an equally qualified

person, but not authorized by Black & Decker, the warranty

will not be valid.

7. Labels on tool

The label on your tool may include the following symbols:

Read

Instructions

Manual

Use Eye

Protection

Use Ear

Protection

V ........ Volts

A ........ Amperes n

Speed

Hz ....... Hertz

W ....... Watts

min ..... minutes

..... Alternating

Current

..... Direct

Current

....... No-Load

0

...... Class II

Construction

...... Earthing

Terminal

...... Safety

Alert Symbol

.../min.. Revolutions

or Recipro cation per

minute

Features (Fig. A)

1. Variable speed switch

2. Lock-on button

3. Forward/reverse slider

4. Drilling mode selector

5. Chuck

6. Depth stop

7. Side handle

Additional safety instructionsfor hammer

drill

• Wear ear protectors with impact drills. Exposure to

noise can cause hearing loss.

5

Page 6

ENGLISH

• Use auxiliary handles supplied with the tool. Loss of

control can cause personal injury.

• Hold power tool by insulated gripping surfaces when

performing an operation where the cutting tool may

contact hidden wiring or its own cord. Contact with a

“live” wire will also make exposed metal parts of the

power tool “live” and shock the operator.

• Use clamps or another practical way to secure and

support the workpiece to a stable platform. Holding

the work by hand or against your body leaves it unstable

and may lead to loss of control.

• Before drilling into walls, floors or ceilings check for the

location of wiring and pipes.

• Avoid touching the tip of a drill bit just after drilling, as it

may be hot.

Assembly

Warning! Before assembly, make sure that the

tool is switched off and unplugged.

Fitting the side handle and depth stop (Fig. B)

• Turn the grip counterclockwise until you can slide the

side handle (7) onto the front of the tool as shown.

• Rotate the side handle into the desired position.

• Insert the depth stop (6) into the mounting hole as

shown.

• Set the drilling depth as described below.

• Tighten the side handle by turning the grip clockwise.

Fitting a drill bit or screwdriver bit Keyed chuck (Fig. C)

• Open the chuck by turning the sleeve (8)

counterclockwise.

• Remove the chuck retaining screw, located in the chuck,

by turning it clockwise using a screwdriver.

• Tighten an Allen key into the chuck and strike it with a

hammer as shown.

• Remove the Allen key

• Remove the chuck by turning it counterclockwise.

• To refit the chuck, screw it onto the spindle and secure it

with the chuck retaining screw.

Use

Warning! Let the tool work at its own pace. Do

not overload.

Warning! Before drilling into walls, floors or

ceilings, check for the location of wiring and

pipes.

Selecting the direction of rotation (Fig. E)

For drilling and for tightening screws, use forward

(clockwise) rotation. For loosening screws or removing a

jammed drill bit, use reverse (counterclockwise) rotation.

• To select forward rotation, push the forward/reverse

slider (3) to the centre position.

• To select reverse rotation, push the forward/reverse

slider to the left.

Warning! Never change the direction of rotation

while the motor is running.

Selecting the drilling mode

For drilling in masonry, set the drilling mode selector (4) to

the position.

For drilling in other materials and for screwdriving, set the

drilling mode selector to the position.

Setting the drilling depth (Fig. F)

• Insert the bit shaft (9) into the chuck.

• Insert the chuck key (10) into each hole (11) in the side

of the chuck and turn clockwise until tight.

Removing and refitting the chuck (Fig. D)

• Open the chuck as far as possible.

6

• Slacken the side handle (7) by turning the grip

counterclockwise.

• Set the depth stop (6) to the desired position. The

maximum drilling depth is equal to the distance between

the tip of the drill bit and the front end of the depth stop.

• Tighten the side handle by turning the grip clockwise.

Page 7

ENGLISH

Switching on and off

• To switch the tool on, press the variable speed switch

(1). The tool speed depends on how far you press the

switch. As a general rule, use low speeds for large

diameter drill bits and high speeds for smaller diameter

drill bits.

• For continuous operation, press the lock-on button (2)

and release the variable speed switch. This option is

available only at full speed. This option does not work in

reverse rotation.

• To switch the tool off, release the variable speed switch.

To switch the tool off when in continuous operation,

press the variable speed switch once more and release

it.

Maintenance

Your tool has been designed operate over a long period of

time with minimum of maintenance. Continuous satisfactory

operation depends proper tool care and regular cleaning.

Warning! Before performing any maintenance, switch off

and unplug the tool.

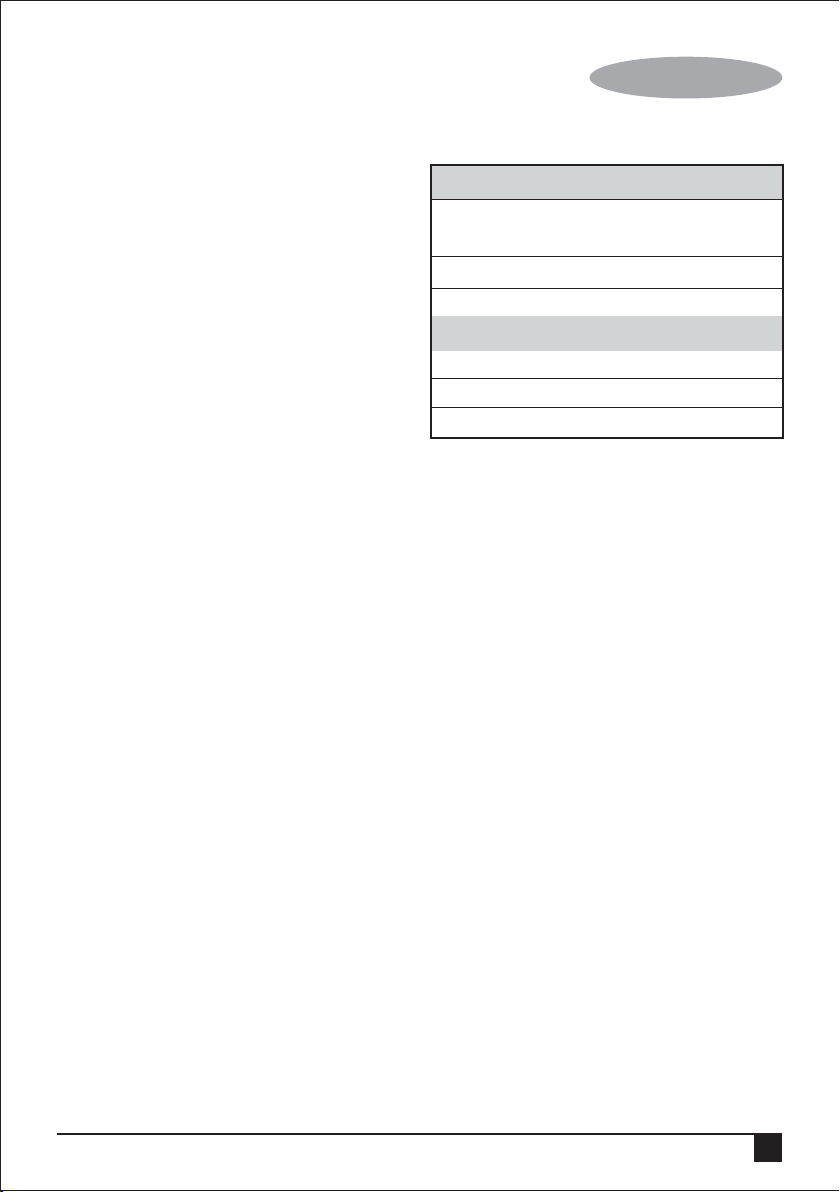

Specifications

BPDH7013

Voltage Vac

B5,B9 220-240 V ~ 50/60 Hz

Power input W 700

No-load speed

Max drilling capacity

Steel/concrete mm 13

Wood mm 20

Weight kg 1,9

/min

0-2800

• Regularly clean the ventilation slots in your tool using a

soft brush or dry cloth.

• Regularly clean the motor housing using a damp cloth.

Do not use any abrasive or solvent-based cleaner.

Accessories

The performance of your tool depends on the accessory

used. Black & Decker accessories are engineered to high

quality standards and designed to enhance the performance

of your tool. By using these accessories you will get the very

best from your tool.

7

Page 8

ENGLISH

Protecting the environment

Separate collection. This product must not be

disposed of with normal household waste.

Should you find one day that your Black & Decker

product needs replacement, or if it is of no further use to you,

do not dispose of it with household waste. Make this product

available for separate collection.

Separate collection of used products and

packaging allows materials to be recycled and used

again. Reuse of recycled materials helps prevent

environmental pollution and reduces the demand for raw

materials.

Local regulations may provide for separate collection of

electrical products from the household, at municipal waste

sites or by the retailer when you purchase a new product.

Black & Decker provides a facility for the collection and

recycling of Black & Decker products once they have

reached the end of their working life. To take advantage of

this service please return your product to any authorised

repair agent who will collect them on our behalf.

You can check the location of your nearest authorised repair

agent by contacting your local Black & Decker office at the

address indicated in this manual. Alternatively, a list of

authorised Black & Decker repair agents and full details of

our after-sales service and contacts are available on the

Internet at: www.2helpU.com.

Service information

Black & Decker offers a full network of company-owned and

authorized service locations. All Black & Decker Service

Centers are staffed with trained personnel to provide

customers with efficient and reliable power tool service. For

more information about our authorized service centers and if

you need technical advice, repair, or genuine factory

replacement parts, contact the Black & Decker location

nearest you, or visit us at www.BlackandDecker-la.com

Guarantee

Black & Decker is confident of the quality of its products and

offers an outstanding guarantee. This guarantee statement is

in addition to and in no way prejudices your statutory rights.

The guarantee is valid within the territories of the Member

States of the European Union and the European Free Trade

Area.

If a Black & Decker product becomes defective due to faulty

materials, workmanship or lack of conformity, within 12

months from the date of purchase, Black & Decker

guarantees to replace defective parts, repair products

subjected to fair wear and tear or replace such products to

make sure of the minimum inconvenience to the customer

unless:

The product has been used for trade, professional or hire

purposes.

The product has been subjected to misuse or neglect.

The product has sustained damage through foreign

objects, substances or accidents.

Repairs have been attempted by persons other than

authorised repair agents or Black & Decker service staff.

To claim on the guarantee, you will need to submit proof of

purchase to the seller or an authorised repair agent. You can

check the location of your nearest authorised repair agent by

contacting your local Black & Decker office at the address

indicated in this manual. Alternatively, a list of authorised

Black & Decker repair agents and full details of our aftersales

service and contacts are available on the Internet at:

www.2helpU.com

Please visit our website www.blackanddecker.co.uk to

register your new Black & Decker product and to be kept up

to date on new products and special offers. Further

information on the Black & Decker brand and our range of

products is available at www.blackanddecker.co.uk.

8

Page 9

FIG. A

FRANÇAIS

4

6

5

3

7

1

2

FIG. B

FIG. C

10

11

9

7

8

9

Page 10

FRANÇAIS

FIG. D

FIG. E FIG. F

3

10

6

7

Page 11

FRANÇAIS

Ne retournez pas cet appareil en magasin,

Contactez d’abord le bureau local Black & Decker ou le

centre de service le plus proche.

Règles générales de sécurité

Attention! Bien lire et comprendre toutes les

instructions. Le non-respect de cette consigne

peut entraîner un choc électrique, un incendie

et/ou des blessures corporelles graves.

Conservez ces instructions

Consignes de sécurité

Consignes de sécurité concernant les outils

électroportatifs.

Attention! Lire avec attention tous les avertissements et

Conservez tous les avertissements et instructions pour

référence ultérieure.

Le terme “outil électroportatif” mentionné dans les

avertissements se rapporte à des outils raccordés au

secteur (avec câble de raccordement) ou fonctionnant sur

piles ou batterie.

1. Sécurité de la zone de travail

a. Maintenez la zone de travail propre et bien éclairée.

b. N'utilisez pas les outils électroportatifs dans un

c. Pendant l’utilisation d’un outil électroportatif, les

2. Sécurité électrique

a. La prise de l'outil électroportatif doit convenir à la

toutes les instructions. Le non-respect de

cette consigne peut entraîner un choc

électrique, un incendie et/ou des blessures

graves.

Un lieu de travail en désordre ou mal éclairé augmente

le risque d'accidents.

environnement présentant des risques d'explosion

ni en présence de liquides, gaz ou poussières

inflammables. Les outils électroportatifs génèrent des

étincelles risquant d'enflammer les poussières ou les

vapeurs.

enfants et autres personnes doivent rester éloignés.

En cas d'inattention, vous risquez de perdre le contrôle

de l'outil.

prise de courant. Ne modifiez en aucun cas la prise.

N'utilisez pas de prises d'adaptateur avec des

appareils ayant une prise de terre. Le respect de ces

consignes réduit le risque de choc électrique.

b. Évitez le contact physique avec des surfaces mises

à la terre telles que tuyaux, radiateurs, fours et

réfrigérateurs. Le risque de choc électrique augmente si

votre corps est relié à la terre.

c. N'exposez pas l'outil électroportatif à la pluie ni à

l'humidité. La pénétration d'eau dans un outil

électroportatif augmente le risque de choc électrique.

d. Préservez le câble d'alimentation. N'utilisez pas le

câble pour porter l'outil, pour l'accrocher ou encore

pour le débrancher. Maintenez le câble éloigné des

sources de chaleurs, des parties huilées, des bords

tranchants ou des parties de l'appareil en rotation.

Le risque de choc électrique augmente si les câbles sont

endommagés ou emmêlés.

e. Si vous utilisez l'outil électroportatif à l'extérieur,

utilisez une rallonge homologuée pour utilisation à

l'air libre. L'utilisation d'une rallonge électrique

homologuée pour les travaux à l’extérieur réduit le risque

de choc électrique.

f. Si l’outil doit être utilisé dans un endroit humide,

prenez des précautions en utilisant un dispositif à

courant résiduel (RCD). L’utilisation d’un tel dispositif

réduit les risques de chocs électriques.

Remarque: Le terme “dispositif à courant résiduel (RCD)”

peut être remplacé par “disjoncteur de fuite à la terre (GFCI)”

ou par “interrupteur différentiel de sécurité (ELCB)”.

3. Sécurité personnelle

a. Restez vigilant, surveillez ce que vous faites. Faites

preuve de bon sens quand vous utilisez un outil

électroportatif. N’utilisez pas l’outil lorsque vous

êtes fatigué ou après avoir consommé de l’alcool

ainsi que des médicaments. Un moment d'inattention

lors de l'utilisation de l'outil peut entraîner de graves

blessures.

b. Portez un équipement de protection. Portez toujours

des lunettes de protection. Selon le travail à effectuer,

le port d'équipement de protection tels que masque

anti-poussières, chaussures de sécurité antidérapantes,

casque ou protection auditive, réduit le risque de

blessures.

c. Evitez un démarrage imprévu. L’appareil doit être en

position OFF (arrêt) avant d’effectuer le branchement

à l’alimentation électrique et/ou au bloc-batterie, et

avant de le ramasser ou de le porter. Ne laissez pas

votre doigt sur l’interrupteur de commande en le

transportant et n’alimentez pas l’outil avec l’interrupteur

en position de marche, cela pourrait être à l’origine

d’accidents.

d. Retirez tout outil ou clé de réglage avant de mettre

l’outil en marche. Une clé ou un outil se trouvant sur

une partie en rotation peut causer des blessures.

11

Page 12

FRANÇAIS

e. Adoptez une position confortable. Adoptez une

position stable et gardez votre équilibre en

permanence. Vous contrôlerez ainsi mieux l'outil dans

des situations inattendues.

f. Portez des vêtements appropriés. Ne pas porter de

vêtements flottants ou de bijoux. N’approchez pas

les cheveux, vêtements ou gants des parties des

pièces mobiles. Les vêtements amples, les bijoux ou

les cheveux longs peuvent être attrapés dans les pièces

en mouvement.

g. En cas d’utilisation d’appareils servant à aspirer ou

à recueillir les poussières, assurez-vous qu’ils sont

correctement raccordés et utilisés. L'utilisation de tels

appareils permet de réduire les dangers liés aux

poussières.

4. Utilisation des outils électroportatifs et

précautions

a. Respectez la capacité de l'outil. Utilisez l'outil

électroportatif approprié pour le travail à effectuer.

Avec un outil approprié, vous travaillerez mieux et en

toute sécurité.

b. N’utilisez pas un outil électroportatif dont

l’interrupteur marche/arrêt est défectueux. Un outil

électroportatif qui ne peut plus être mis en marche ou

arrêter est dangereux et doit être réparé.

c. Retirez la prise de courant et/ou débranchez le

blocbatterie avant d'effectuer des réglages, de

changer les accessoires ou de ranger l'outil. Cette

mesure de précaution empêche de mettre l’outil en

marche accidentellement.

d. Rangez les outils électroportatifs hors de portée des

enfants. Les personnes ne connaissant pas l’outil

ou n’ayant pas lu ces instructions ne doivent en

aucun cas l’utiliser. Les outils électroportatifs sont

dangereux lorsqu'ils sont utilisés par des personnes non

initiées.

e. Prenez soin des outils électroportatifs. Vérifiez que

les parties en mouvement fonctionnent

correctement et qu'elles ne sont pas coincées.

Vérifiez qu'il n’y a pas de pièces cassées ou

endommagées susceptibles de nuire au bon

fonctionnement de l'outil. S’il est endommagé, faites

réparer l’outil avant de l’utiliser. De nombreux

accidents sont la conséquence d’outils mal entretenus.

f. Maintenez les outils de coupe aiguisés et propres.

Des outils soigneusement entretenus avec des bords

tranchants bien aiguisés se coincent moins souvent et

peuvent être guidés plus facilement. L’utilisation des

outils électroportatifs à d’autres fins que celles prévues

peut entraîner des situations dangereuses.

5. Réparations

a. Faites réparer votre outil électroportatif uniquement

par du personnel qualifié et seulement avec des

pièces de rechange appropriées. La fiabilité de l’outil

sera ainsi maintenue.

12

6. Etiquettes apposées sur l’outil

Cet outil est doublement isolé; par conséquent,

aucun câble de mise à la terre n’est nécessaire.

Vérifiez bien que la tension secteur correspond à celle

indiquée sur la plaque signalétique.

Attention! Si le câble d’alimentation est

endommagé, il doit être remplacé par le

fabricant, un centre de réparation Black &

Decker agréé ou par un technicien qualifié, de façon à éviter

tout dommage matériel ou corporel. En cas de

remplacement du câble d’alimentation par un technicien

qualifié mais non agréé par Black & Decker, la garantie ne

sera pas valable.

7. Etiquettes apposées sur l’outil

L’étiquette apposée sur votre outil peut contenir les

symboles suivants:

Lire le

manuel

d’instructions

Utiliser une

protection

oculaire

Utiliser des

protections

auditives

V ........ Volts

A ........ Ampères n

à vide

Hz ....... Hertz

W ....... Watts

min ..... minutes

..... Courant

alternatif

..... Courant

continu

....... Vitesse

0

...... Construction

de classe II

...... Borne

de terre

...... Symbole

d’alerte de

sécurité

.../min.. Rotations

par minute

Description (Fig. A)

1. Sélecteur de vitesse

2. Bouton de verrouillage

3. Bouton de commande avant/arrière

4. Sélecteur de mode de perçage

5. Mandrin

6. Butée de profondeur

7. Poignée latérale

Consignes de sécurité supplémentaires pour

les perceuses à percussion

• Portez des protège-oreilles lorsque vous utilisez une

perceuse à percussion. Une exposition au bruit peut

entrainer des lésions auditives.

Page 13

FRANÇAIS

• Utilisez les poignées auxiliaires fournies avec l’outil.

La perte de contrôle peut entrainer des blessures

corporelles.

• Lorsque l’outil est utilisé pour un travail risquant de

le mettre en contact avec des fils électriques cachés

ou son propre câble d’alimentation, tenez-le par les

surfaces de prise isolées. En touchant un fil sous

tension, la charge électrique passe dans les parties

métalliques de l’outil électroportatif et l’utilisateur risque

de recevoir un choc électrique.

• Utilisez des pinces de serrage ou tout autre

dispositif de fixation pour sécuriser la pièce à usiner

sur un support stable. Tenir la pièce à usiner à la main

ou contre son corps la rend instable et peut conduire à

une perte de contrôle.

• Avant de percer un mur, un plancher ou un plafond,

vérifiez l’emplacement des câblages et des tuyaux.

• Evitez de toucher la pointe d’un foret juste après le

perçage car il peut être chaud.

Assemblage

Attention! Avant l’assemblage, assurez-vous

que l’outil est éteint et débranché.

Installation de la poignée latérale et de la butée de

profondeur (Fig. B)

• Tournez le manche dans le sens antihoraire jusqu’à ce

que la poignée latérale (7) puisse glisser sur l’avant de

l’outil comme illustré.

• Tournez la poignée latérale dans la position souhaitée.

• Insérez la butée de profondeur (6) dans le trou de

montage comme illustré.

• Réglez la profondeur de perçage comme indiqué

ci-dessous.

• Serrez la poignée latérale en tournant le manche dans le

sens horaire.

Montage d’un foret ou d’un embout de tournevis

Mandrin à clé (Fig. C)

• Ouvrez le mandrin en tournant la douille (8) dans le sens

antihoraire.

• Insérez l’axe du foret (9) dans le mandrin.

• Insérez la clé du mandrin (10) dans chaque trou (11) sur

le côté du mandrin et serrez en tournant dans le sens

horaire.

Retrait et remontage du mandrin (Fig. D)

• Ouvrez le mandrin le plus possible.

• Retirez la vis de fixation du mandrin, située dans le

mandrin, en la tournant dans le sens horaire à l’aide d’un

tournevis.

• Insérez une clé Allen dans le mandrin et frappez-la avec

un marteau comme illustré.

• Retirez la clé Allen

• Retirez le mandrin en le tournant dans le sens

antihoraire.

• Pour remonter le mandrin, vissez-le sur la broche et

fixez-le à l’aide de la vis de fixation du mandrin.

Utilisation

Attention! Laissez l’outil fonctionner à sa propre

vitesse. Ne le surchargez pas.

Attention! Avant de percer un mur, un plancher

ou un plafond, vérifiez l’emplacement des

câblages et des tuyaux.

Sélection du sens de rotation (Fig. E)

Pour percer ou serrer des vis, utilisez la rotation avant (sens

horaire). Pour desserrer les vis ou retirer un foret bloqué,

utilisez la rotation arrière (sens antihoraire).

• Pour sélectionner la rotation avant, poussez le bouton

de commande avant/arrière (3) vers la position centrale.

• Pour sélectionner la rotation arrière, poussez le bouton

de commande avant/arrière vers la gauche.

Attention! Ne changez jamais le sens de rotation

quand le moteur tourne.

Sélection du mode de perçage

Pour percer dans la pierre, réglez le sélecteur de mode de

perçage (4) en position.

Pour percer dans d’autres matériaux ou pour visser, réglez

le sélecteur de mode de perçage en position.

Réglage de la profondeur de perçage (Fig. F)

• Desserrez la poignée latérale (7) en tournant le manche

dans le sens antihoraire.

• Réglez la butée de profondeur (6) sur la position

souhaitée. La profondeur de perçage maximale est

égale à la distance entre la pointe du foret et l’extrémité

avant de la butée de profondeur.

• Serrez la poignée latérale en tournant le manche dans le

sens horaire.

13

Page 14

FRANÇAIS

Démarrage et arrêt

Pour mettre l’outil en marche, appuyez sur l’interrupteur (1).

Pour les interrupteurs de vitesse variable, la vitesse de

l’outil dépend de la force que vous exercez sur l’interrupteur.

En règle générale, utilisez une vitesse lente pour les forets

de gros diamètres et une vitesse rapide pour les forets de

petits diamètres.

• Pour un fonctionnement en continu, appuyez sur le

bouton de verrouillage (2) et relâchez l’interrupteur.

Cette option n’est disponible qu’en vitesse maximale.

Cette option n’existe pas en mode de rotation vers

l’arrière.

• Pour éteindre l’outil, relâchez l’interrupteur. Pour

éteindre l’outil lorsqu’il est en fonctionnement continu,

appuyez sur l’interrupteur une fois de plus et relâchez-le.

ntretien

Votre outil a été conçu pour fonctionner sur une longue

période de temps avec un minimum d’entretien. Un

fonctionnement continu satisfaisant dépend d’un nettoyage

et d’un entretien soigneux et régulier.

Attention ! Avant toute activité d'entretien sur les outils

électriques avec/sans fil:

Caractéristiques techniques

BPDH7013

Tension Vac

B5,B9 220-240 V ~ 50/60 Hz

Puissance nominale W 700

Vitesse à vide /min 0-2800

Capacité max. de perçage

Acier/béton mm 13

Bois mm 20

Poids kg 1,9

• Nettoyez régulièrement les fentes de ventilation de votre

outil/appareil/chargeur à l'aide d'une brosse douce ou

d'un chiffon sec.

• Nettoyez régulièrement le carter moteur à l'aide d'un

chiffon humide. N'utilisez pas de produit abrasif ou à

base de solvant.

Accessoires

La performance de votre outil dépend de l’accessoire utilisé.

Les accessoires Black & Decker sont conçus selon des

normes de qualité supérieure pour améliorer les

performances de votre outil. En utilisant ces accessoires

vous obtiendrez le meilleur de votre outil.

14

Page 15

FRANÇAIS

Protection de l'environnement

Recyclage. Cet appareil ne doit pas être jeté avec

les déchets ménagers.

Si votre appareil Black & Decker doit être remplacé ou si

vous n'en avez plus l'usage, ne le jetez pas avec les ordures

ménagères. Songez à la protection de l'environnement et

recyclez-les.

La collecte séparée des produits et des

emballages usagés permet de recycler et de

réutiliser des matériaux. La réutilisation de

matériaux recyclés évite la pollution de l'environnement et

réduit la demande de matières premières.

Des réglementations locales peuvent stipuler la collecte

séparée des produits électriques et des produits ménagers,

dans des déchetteries municipales ou par le revendeur

lorsque vous achetez un nouveau produit.

Black & Decker offre une solution permettant de recycler les

produits Black & Decker lorsqu'ils ont atteint la fin de leur

cycle de vie. Pour pouvoir profiter de ce service, veuillez

retourner votre produit à un réparateur agréé qui se

chargera de le collecter pour nous.

Pour connaître l'adresse du réparateur agréé le plus proche

de chez vous, contactez le bureau Black & Decker à

l'adresse indiquée dans ce manuel. Vous pourrez aussi

trouver une liste de réparateurs agréés de Black & Decker et

de plus amples détails sur notre service après-vente sur le

site Internet à l'adresse suivante : www.2helpU.com.

Informations sur le service après-vente

Black & Decker offre un large réseau de centres de service

Black & Decker ou agréés partout en Asie. Tous les centres

de services Black & Decker sont dotés d’un personnel

qualifié afin de garantir aux clients une qualité et une fiabilité

de service dans la réparation de leurs outils. Que vous ayez

besoin de conseils techniques, de réparation ou de pièces

de rechange d’origine, il suffit de contacter le centre Black &

Decker le plus proche.

Garantie

Black & Decker vous assure la qualité de ses produits et vous offre

une garantie très étendue.

Ce certificat de garantie est un document supplémentaire et ne peut

en aucun cas se substituer à vos droits légaux.

La garantie est valable sur tout le territoire des États Membres de

l'Union Européenne et de la Zone de Libre Échange Européenne.

Si un produit Black & Decker s'avère défectueux en raison de

matériaux en mauvais état, d'une erreur humaine, ou d'un manque

de conformité dans les 12 mois suivant la date d'achat, Black &

Decker garantit le remplacement des pièces défectueuses, la

réparation des produits usés ou cassés ou remplace ces produits à

la convenance du client, sauf dans les circonstances suivantes :

Le produit a été utilisé dans un but commercial, professionnel,

ou a été loué.

Le produit a été mal utilisé ou avec négligence.

Le produit a subi des dommages à cause de corps étrangers,

de substances ou d'accidents.

Des réparations ont été tentées par des techniciens ne faisant

pas partie du service technique de Black & Decker.

Pour avoir recours à la garantie, il est nécessaire de fournir une

preuve d'achat au vendeur ou à un réparateur agréé.

Pour connaître l'adresse du réparateur agréé le plus proche de

chez vous, contactez le bureau Black & Decker à l'adresse indiquée

dans ce manuel. Vous pourrez aussi trouver une liste de

réparateurs agréés de Black & Decker et de plus amples détails sur

notre service après-vente sur le site Internet à l'adresse suivante :

www.2helpU.com

Visitez notre site Web www.blackanddecker.eu pour enregistrer

votre nouveau produit Black & Decker et être informé des nouveaux

produits et des offres spéciales. Pour plus d'informations

concernant la marque Black & Decker et notre gamme de produits,

consultez notre site www.blackanddecker.eu.

15

Page 16

Arabic

¿Éª°†dG

¿É«H ¿ƒµjh .kGõ«‡ kÉfɪ°V Ωó≤Jh É¡JÉéàæe IOƒéH ôµjO ófBG ∑ÓH ≥ãJ

¥ƒ≤◊ÉH ∫GƒMC’G øe ∫ÉM …CÉH πîj ’h áaÉ°VE’ÉH Gòg ¿Éª°†dG

OÉ–E’G ‘ AÉ°†YC’G ∫hódG º«∏bEG πNGO ¿Éª°†dG Gòg …öùjh .á«fƒfÉ≤dG

.á«HhQhC’G Iô◊G IQÉéàdG á≤£æeh »HQhC’G

áYÉæ°üdGh OGƒŸG ܃«Y ÖÑ°ùH kÉÑ«©e ôµjO ófBG ∑ÓH èàæe íÑ°UCG GPEG

ïjQÉJ øe kGô¡°T 12 ¿ƒ°†Z ‘ ôµjO ófBG ∑ÓH øª°†J ,á≤HÉ£ŸG ΩóYh

»∏СdG IЙYGфe ™e дЙйажŸG мУ°UEGh бС«©ŸG AGхLC’G ∫GуСа°SG AGцыdG

AУª©dG Й°VQ шe уcCЙа∏d дЙйажŸG √тg ∫GуСа°SG hCG …OЙ©dG ΩGуоа°S’ЙH

:⁄ Ée

.ÒLCÉà∏d hCG á«æ¡e hCG ájQÉŒ ¢VGôZC’ èàæŸG ΩGóîà°SG ”

.èàæŸG ΩGóîà°SG IAÉ°SEG hCG ∫ɪgEG

.çOGƒ◊G hCG á«HôZ ¢VGôZCG hCG OGƒe ÖÑ°ùH ∞∏àd èàæŸG ¢Vô©J

øjôNB’G ¢UÉî°TC’G πÑb øe ìÓ°UE’G äÉ«∏ªY AGôLEG ádhÉfi

∑ÓÑd ™HÉàdG áeóÿG ≥jôa hCG º¡H ìöüŸG ìÓ°UE’G AÓch ±ÓîH

.ôµjO ófBG

™«ÑdG π«ch hCG ™FÉÑ∏d AGöûdG äÉÑKEG Ëó≤J Öéj ,¿Éª°†dÉH áÑdÉ£ª∏d

Öàµe á©LGôà óªà©e ìÓ°UEG π«ch ÜôbCG ¿Éµe áaô©e ∂æµÁh .óªà©ŸG

ôaƒàJ ɪc .π«dódG ‘ ¬«dEG QÉ°ûŸG ¿Gƒæ©dG ‘ »∏ëŸG ôµjO ófBG ∑ÓH

äÉeóN äÉfÉ«Hh ôµjO ófBG ∑ÓH iód øjóªà©ŸG ìÓ°UE’G AÓcƒH áªFÉb

:ÊhεdE’G ™bƒŸG ≈∏Y ∫É°üJ’Gh ™«ÑdG ó©H Ée

.www.2helpU.com

16

ÊhεdE’G Éæ©bƒe á©LGôe ≈Lôj

∑ÓH øe ójó÷G ∂éàæe π«é°ùàd www.blackanddecker.co.uk

≈∏Y ∫ƒ°ьл∏dh .б°UЙяG ¢Vhф©dGh дЙйажŸG зуMCG бaф©Ÿh фµjO уfBG

≈Lôj ,ÉæJÉéàæeh ôµjO ófBG ∑ÓH áeÓY ∫ƒM äÉeƒ∏©ŸG øe ójõŸG

.www.blackanddecker.co.uk IQÉjR

Page 17

Arabic

áÄ«ÑdG ájɪM

.á«dõæŸG äÉØ∏îŸG ™e èàæŸG Gòg AÉ≤dEG ΩóY Öéj .π°üØæe ™«ªŒ

∂H ¢UÉÿG ôµjO ófBG ∑ÓH RÉ¡L πjóÑJ Öéj ¬fCÉH ΩÉjC’G óMCG ‘ ∂d ÚÑJ GPEG

ºbh .á«dõæŸG äÉØ∏îŸG ™e ¬æe ¢ü∏îàJ ’ .¬eGóîà°S’ áLÉëH ó©J ⁄ hCG

.π°üØæŸG ™«ªéà∏d èàæŸG Gòg ÒaƒàH

шe бeуоа°щŸG дGƒС©dGh дЙйажª∏d π°ьШжŸG ™«ªйаdG шµБ

IOÉYEG óYÉ°ùj PEG ,iôNCG Iôe É¡eGóîà°SGh OGƒŸG ôjhóJ IOÉYEG

≈∏Y Ö∏£dG ¢†ØNh »Ä«ÑdG çƒ∏àdG ™æe ≈∏Y ÉgôjhóJ OÉ©ŸG OGƒŸG ΩGóîà°SG

ΩÉÿG OGƒŸG

шY б«FЙHф¡µdG дЙйажª∏d π°ьШжe ™«ªŒ ≈∏Y б«∏лŸG дЙ©jцыаdG ¢ьжJ уb

AGöT óæY áFõéàdG ôLÉJ hCG ájó∏ÑdG äÉØ∏fl ™bGƒe ‘ á«dõæŸG äÉØ∏îŸG

.ójóL èàæe

фµjO уfBG ∑УH дЙйажe фjhуJ IOЙYEGh ™«ªйаd ICЙ°ыжe фµjO уfBG ∑УH фaƒJ

√тg шe IOЙШа°SУdh .™aЙжdG ЙgфªY бjЙ¡жd дЙйажŸG ∂∏J ∫ƒ°Uh ужY

Ωƒ≤«°S …òdG óªà©e ìÓ°UEG π«ch …CG ¤EG èàæŸG IOÉYEG ≈Lôj ,áeóÿG

.ЙжY бHЙ«f дЙйажŸG ™«ªйаH

ôµjO ófBG ∑ÓH Öàµe á©LGôà óªà©e ìÓ°UEG π«ch ÜôbCG ¿Éµe áaô©e ∂æµÁ

ìÓ°UE’G AÓcƒH áªFÉb ôaƒàJ ɪc .π«dódG ‘ ¬«dEG QÉ°ûŸG ¿Gƒæ©dG ‘ »∏ëŸG

≈∏Y ∫É°üJ’Gh ™«ÑdG ó©H Ée äÉeóN äÉfÉ«Hh ôµjO ófBG ∑ÓH iód øjóªà©ŸG

.www.2helpU.com :ÊhεdE’G ™bƒŸG

áeóÿG äÉeƒ∏©e

ácƒ∏ªŸGh Ióªà©ŸG áeóÿG õcGôe øe á∏eÉc áµÑ°T ôµjO ófBG ∑ÓH ôaƒJ

∑ÓÑd á©HÉàdG áeóÿG õcGôe ™«ªL ‘ πª©jh .É«°SBG AÉLQCG ™«ªL ‘ ácöû∏d

™«ª÷ á≤ãdÉH IôjóLh ádÉ©a áeóN Ëó≤J ≈∏Y ¿ƒ∏gDƒe OGôaCG ôµjO ófBG

IQƒ°ûe ≈∏Y ∫ƒ°ü◊G ‘ ÖZôJ âæc GPEÉa .AÓª©dG É°VQ ≥≤ëj Éà Iõ¡LC’G

iƒ°S ∂«∏Y Ée ,á«∏°UCG QÉ«Z ™£b ≈∏Y ∫ƒ°ü◊G hCG Iõ¡LC’G ìÓ°UEG hCG á«æa

.ôµjO ófBG ∑ÓÑd áeóN õcôe ÜôbCÉH ∫É°üJ’G

17

Page 18

Arabic

äÉØ°UGƒŸG

BPDH7013

OOÎe QÉ«J §dƒa »FÉHô¡µdG ó¡÷G

60/50 – §dƒa ~240-220 9Ü,5Ü

700 •Gh πNGódG »FÉHô¡µdG QÉ«àdG Ió°T

2800-0 á≤«bódG ‘ IQhO πªM ¿hóH áYöùdG

Ö≤ã∏d ≥ªY ≈°übCG

13 º∏e áfÉ°SôÿG / P’ƒØdG

20 º∏e Ö°ûÿG

1^9 ºéc ¿RƒdG

𫨰ûàdG ±É≤jEGh 𫨰ûàdG

áYöS óªà©J .(1) áYöùdG πjóÑJ ìÉàØe ≈∏Y §¨°VG ,RÉ¡÷G 𫨰ûàd •

мЙаШГ kGOhхe RЙ¡чG ¿Йc GPEG мЙаШŸG ≈∏Y ∂£¨°V iуe ≈∏Y RЙ¡чG

óæY á°†Øîæe äÉYöS Ωóîà°SG ,áeÉY IóYÉ≤ch .Ò¨àe áYöS πjóÑJ

óæY á«dÉY äÉYöS Ωóîà°SGh ÒÑc ô£b äGP Ö≤K º≤d ΩGóîà°SG

.ô¨°UCG ô£b äGP Ö≤K º≤d ΩGóîà°SG

ìÉàØe QôMh (2) áYöùdG â«ÑãJ QR ≈∏Y §¨°VG ,π°UGƒàŸG 𫨰ûà∏d •

’h .á∏eÉc áYöùH 𫨰ûàdG óæY §≤a QÉ«ÿG Gòg ôaƒàj .áYöùdG πjóÑJ

.∞∏î∏d ¿GQhódG §‰ ‘ QÉ«ÿG Gòg πª©j

𫨰ûJ ±É≤jE’h .áYöùdG πjóÑJ ìÉàØe QôM ,RÉ¡÷G 𫨰ûJ ±É≤jE’ •

πjóÑJ ìÉàØe ≈∏Y §¨°VG ,ôªà°ùŸG 𫨰ûàdG ™°Vh ‘ ¿Éc GPEG RÉ¡÷G

.√QôMh iôNCG Iôe áYöùdG

áfÉ«°üdG

øe ÒãµdG AGôLEG ¿hO âbƒdG øe á∏jƒW IÎa πª©∏d RÉ¡÷G º«ª°üJ ”

áÑ°SÉæŸG ájÉæ©dG ≈∏Y ôªà°ùŸG »°VôŸG 𫨰ûàdG óªà©jh .¬«∏Y áfÉ«°üdG

.…QhódG ∞«¶æàdGh RÉ¡÷ÉH

.RÉ¡÷G π°üah 𫨰ûJ ±É≤jEÉH ºb ,áfÉ«°U …CG AGôLEG πÑb !ôjò–

18

IÉ°Tôa ΩGóîà°SÉH QGôªà°SÉH RÉ¡÷G ‘ ájƒ¡àdG äÉëàa ∞«¶æàH ºb •

.áaÉL ¢Tɪb á©£b hCG áªYÉf

.áÑWQ ¢Tɪb á©£b ΩGóîà°SÉH QGôªà°SÉH ∑ôëŸG áà««ÑJ ∞«¶æàH ºb •

.áÑjòe IOÉe øe ´ƒæ°üe ∞¶æe hCG ᣰTÉc IOÉe …CG Ωóîà°ùJ ’h

äÉ≤ë∏ŸG

∑ÓH äÉ≤ë∏e º«ª°üJ ”h .áeóîà°ùŸG äÉ≤ë∏ŸG ≈∏Y ∑RÉ¡L AGOCG óªà©j

∂∏J ΩGóîà°SÉHh .∑RÉ¡L AGOCG Ú°ù– ¢Vô¨H á«dÉY IOƒéH ÉfGÒHh ôµjO ófCG

.RÉ¡é∏d πãeC’G AGOC’G ≈∏Y ∫ƒ°ü◊G øe øµªàà°S ,äÉ≤ë∏ŸG

Page 19

Arabic

‘ ¬Ød ∫ÓN øe ,±ô¶dG ‘ OƒLƒŸG ,±ô¶dG â«ÑãJ »ZôH ádGREÉH ºb •

.»ZGôH ∂Øe ΩGóîà°SÉH áYÉ°ùdG ÜQÉ≤Y √ÉŒG

.í°Vƒe ƒg ɪc ábô£Ã ¬«∏Y ¥ôWGh ±ô¶dG ‘ ÚdCG ìÉàØe §HQG •

.ÚdCG ìÉàØe ádGREÉH ºb •

.áYÉ°ùdG ÜQÉ≤Y √ÉŒG ¢ùµY ¬Ød ∫ÓN øe ±ô¶dG ádGREÉH ºb •

¬à«ÑãàH ºbh ¿GQhódG OƒªY ‘ »ZÈH ¬£HQG ,±ô¶dG Ö«côJ IOÉYE’ •

.±ô¶dG â«ÑãJ »ZÈH

ΩGóîà°S’G

‘ •ôØJ ’h ,¬d IOóëŸG áYöùdÉH πª©j RÉ¡÷G ´O !ôjò–

.¬«∏Y π«ªëàdG

¿GQó÷G Ö≤K πÑb Ö«HÉfC’Gh ∑Ó°SC’G øcÉeCG øe ≥≤– !ôjò–

.∞≤°ùdG hCG äÉ«°VQC’G hCG

(`g πµ°ûdG) ¿GQhódG √ÉŒG ójó–

.(áYÉ°ùdG ÜQÉ≤Y √ÉŒG) ΩÉeCÓd ¿GQhódG Ωóîà°SG ,»ZGÈdG â«ÑãJh Ö≤ã∏d

¿GQhódG Ωóîà°SG ,É¡àcôM ¥É©ŸG Ö≤ãdG ÒeÉ°ùe ádGREG hCG »ZGÈdG ∂Ødh

.(áYÉ°ùdG ÜQÉ≤Y √ÉŒG ¢ùµY) ∞∏î∏d

á«MÉf (3) ∞∏î∏d / ΩÉeCÓd ¿GQhódG QR ™aOG ,ΩÉeCÓd ¿GQhódG QÉ«àN’ •

.∞°üàæŸG

á«MÉf ∞∏î∏d / ΩÉeCÓd ¿GQhódG QR ™aOG ,∞∏î∏d ¿GQhódG QÉ«àN’ •

.QÉ°ù«dG

ΩóY ÖÑ°ùàj ¿CG øµÁ .RÉ¡÷G ™e IôaƒàŸG á«aÉ°VE’G ¢†HÉ≤ŸG Ωóîà°SG •

.á«°üî°T áHÉ°UEG çhóM ‘ ºµëàdG ≈∏Y IQó≤dG

óæY RÉ¡÷ÉH πª©dG óæY §≤a ádhõ©e í£°SCG ᣰSGƒH RÉ¡÷G ∂°ùeG •

RÉ¡÷G ∂∏°S hCG á«ØîŸG ∑Ó°SC’G ™e ™WÉ≤dG ¢ùeÓJ á«dɪàMG OƒLh

π°UƒJ ób "QÉ«àdG É¡H …öùj »àdG" ∑Ó°SC’G á°ùeÓe ¿CG º∏YGh .¬°ùØf

¤EG π¨°ûŸG ¢Vô©j ób ɇ ,áaƒ°ûµŸG á«fó©ŸG AGõLC’G ¤EG QÉ«àdG

.á«FÉHô¡µdG äÉeó°üdÉH áHÉ°UE’G ôWÉfl

πª©dG á©£b ™°Vƒd iôNCG á«∏ªY á≤jôW …CG hCG áeõ∏e Ωóîà°SG •

πHÉ≤e ‘ hCG ó«dÉH πª©dG á©£b ∑É°ùeEG .âHÉK í£°S ≈∏Y É¡à«ÑãJh

.ºµëàdG ¿Gó≤a ¤EG …ODƒj óbh Iô≤à°ùe ÒZ É¡∏©éj º°ù÷G

™°Vƒe øe ≥≤– ,∞≤°SC’G hCG äÉ«°VQC’G hCG ¿GQó÷G ‘ ôØ◊G πÑb •

.Ö«HÉfC’Gh ∑Ó°SC’G

áæNÉ°S ¿ƒµJ ó≤a .IöTÉÑe ôØ◊G ó©H ábô£ŸG áª≤d ±ôW ¢ùª∏J ’ •

.ájɨ∏d

™«ªéàdG

Ö«côJ .ábÉ£dG øe ¬∏°üah RÉ¡÷G 𫨰ûJ ±É≤jEÉH ºb ,™«ªéàdG πÑb !ôjò–

(Ü πµ°ûdG) ≥ª©dG Oófih »ÑfÉ÷G ¢†Ñ≤ŸG

â«ÑãJ ∂æµÁ ¿CG ¤EG áYÉ°ùdG ÜQÉ≤Y √ÉŒG ¢ùµY á°†Ñ≤dG ∞∏H ºb •

.í°Vƒe ƒg ɪc RÉ¡÷G áeó≤e ‘ (7) »ÑfÉ÷G ¢†Ñ≤ŸG

.܃∏£ŸG ™°VƒdG ¤EG »ÑfÉ÷G ¢†Ñ≤ŸG ∞∏H ºb •

.∑ôëŸG 𫨰ûJ AÉæKCG ¿GQhódG √ÉŒG ∫óÑJ ’ !ôjò–

Ö≤ãdG §‰ ójó–

™°VƒdG ≈∏Y (4) Ö≤ãdG §‰ Oófi §Ñ°VG ,IQÉé◊Gh áfÉ°SôÿG ‘ Ö≤ã∏d

. ∂dòd ¢ü°üîŸG

≈∏Y Ö≤ãdG §‰ Oófi §Ñ°VG ,»ZGÈdG Ö«côJh iôNC’G OGƒŸG ‘ Ö≤ã∏d

. ∂dòd ¢ü°üîŸG ™°VƒdG

("h" πµ°ûdG) Ö≤ãdG ≥ªY §Ñ°V

ÜQÉ≤Y √ÉŒG ¢ùµY á°†Ñ≤dG ôjhóàH (7) »ÑfÉ÷G ¢†Ñ≤ŸG AÉNQEÉH ºb •

.áYÉ°ùdG

≈°übCG ¿CÉH º∏©dG ™e ,܃∏£ŸG ™°VƒdG ≈∏Y (6) ≥ª©dG Oófi §Ñ°VG •

»eÉeC’G ±ô£dGh Ö≤ãdG áª≤d ±ôW ÚH áaÉ°ùŸG ∫OÉ©j Ö≤ã∏d ≥ªY

.≥ª©dG OóëŸ

.áYÉ°ùdG ÜQÉ≤Y √ÉŒG ‘ á°†Ñ≤dG ôjhóàH »ÑfÉ÷G ¢†Ñ≤ŸG §HQG •

.í°Vƒe ƒg ɪc â«ÑãàdG áëàa ‘ (6) ≥ª©dG Oófi πNOCG •

.»∏j ɪ«a í°VƒŸG ƒëædG ≈∏Y Ö≤ãdG ≥ªY §Ñ°VG •

ÜQÉ≤Y √ÉŒG ‘ á°†Ñ≤dG ∞d ∫ÓN øe »ÑfÉ÷G ¢†Ñ≤ŸG §HQG •

.áYÉ°ùdG

(ê πµ°ûdG) »ZGÈdG ∂Øe áª≤d ºFÓJ í«JÉØà ±ôX hCG Ö≤K áª≤d Ö«côJ

.áYÉ°ùdG ÜQÉ≤Y √ÉŒG ¢ùµY (8) áÑ∏÷G ∞d ∫ÓN øe ±ô¶dG íàaG •

.±ô¶dG ‘ (9) áª≤∏dG ¿GQhO OƒªY πNOG •

ºbh ±ô¶dG ÖfÉL ‘ (11) áëàa πc ‘ (10) ±ô¶dG ìÉàØe πNOCG •

.§HôdG ΩɵMEG ºàj ¿CG ¤EG áYÉ°ùdG ÜQÉ≤Y √ÉŒG ‘ ∞∏dÉH

(O πµ°ûdG) ¬Ñ«côJ IOÉYEGh ±ô¶dG ádGREG

.á浇 áLQO ÈcCÉH ±ô¶dG íàaG •

19

Page 20

Arabic

RÉ¡÷G ≈∏Y äÉeÓ©dG 6

∂∏°S ¤EG áLÉM ∑Éæg â°ù«d Gòd ;∫õ©dG êhOõe RÉ¡÷G Gòg

ó¡÷G á≤HÉ£e øe ≥≤ëàdG kÉehO ∂«∏Y Öéj øµdh .»°VQCG

.∞«æ°üàdG áMƒd ≈∏Y OƒLƒŸG »Hô¡µdG ó¡é∏d á«°ù«FôdG ∑Ó°SCÓd »Hô¡µdG

hCG á©æ°üŸG ácöûdG øe ¬dGóÑà°SG Öéj ,ábÉ£dG πÑc ∞∏J ádÉM ‘ !ôjò–

Öæéàd ∂dòH ΩÉ«≤∏d πgDƒe ¢üî°T hCG ôµjO ófBG ∑ÓH øe óªà©e áeóN õcôe

,πgDƒe ¢üî°T ᣰSGƒH ábÉ£dG πÑc ∫GóÑà°SG ádÉM ‘h .áHÉ°UE’G hCG Qö†dG

.¿Éª°†dG π£Ñj ±ƒ°ùa ,ôµjO ófBG ∑ÓH øe óªà©e ÒZ ¬æµdh

RÉ¡÷G ≈∏Y äÉeÓ©dG 7

:á«dÉàdG RƒeôdG RÉ¡÷G ≈∏Y IOƒLƒŸG äÉeÓ©dG øª°†àJ ób

êhOõe ∫õY

......

2 áÄØdG øe

......

»°VQCG ±ôW

......

¬«ÑæJ õeQ

¿ÉeC’G

.../min..

äGQhódG OóY

õJôg

•Gh

á≤«bO

OOÎe QÉ«J

ôªà°ùe QÉ«J

....... Hz

.......W

..... min

π«dO CGôbG

äɪ«∏©àdG

Ωóîà°SG

Ú©dG »bGh

ΩGóîà°SG

¿PC’G »bGh

äGOOÎdG hCG

á≤«bódG ‘

§dƒa

ÒÑe

áYöùdG

V

A

N

πªM ¿hóH

(CG πµ°ûdG) ¢üFÉ°üÿG

Ò¨àe áYöS ìÉàØe 1

πØb QR 2

∞∏î∏d hCG ΩÉeCÓd ¿GQhO ìÉàØe 3

𫨰ûàdG ´É°VhCG Oófi 4

±ôX 5

≥ª©dG Oófi 6

»ÑfÉL ¢†Ñ≤e 7

Ö≤ãdG ábô£e ¢Uƒ°üîH áeÓ°ù∏d á«aÉ°VEG äGôjò–

∂fRGƒJ ≈∏Y ßaÉMh ¿ÉeCÉH ∞b .á«©«Ñ£dG ÒZ ó°ù÷G ´É°VhCG ÖæŒ √

π°†aCG πµ°ûH RÉ¡÷G ≈∏Y Iô£«°ùdG øe ∂æµÁ ɇ äÉbhC’G ™«ªL ‘

.á©bƒàŸG ÒZ ∞bGƒŸG ‘

≈∏Y ßaÉM .»∏◊G hCG á°VÉØ°†ØdG ÜÉ«ãdG óJôJ ’h ,áÑ°SÉæe kÉHÉ«K óJQG h

PEG ,ácôëàŸG AGõLC’G øY äGRÉØ≤dGh á°VÉØ°†ØdG ÜÉ«ãdGh ô©°ûdG OÉ©HEG

AGõLC’ÉH πjƒ£dG ô©°ûdG hCG »∏◊G hCG á°VÉØ°†ØdG ÜÉ«ãdG ∂HÉ°ûàJ ób

É¡fCG øe ócCÉJ ,QÉѨdG ™«ªŒh §Ø°ûd äÉ≤ë∏à RÉ¡÷G õ«¡Œ ” GPEG R

ΩGóîà°SG ¿CG PEG ,º«∏°ùdG πµ°ûdÉH É¡eGóîà°SG ºàj ¬fCÉHh RÉ¡÷ÉH á∏°üàe

.QÉѨdG øY áŒÉædG ôWÉîŸG øe ¢†Øîj ób äÉ≤ë∏ŸG √òg

¬H ájÉæ©dGh »FÉHô¡µdG RÉ¡÷G ΩGóîà°SG 4

¢ü°üîŸG RÉ¡÷G ∂dɨ°TCG ò«Øæàd Ωóîà°SG .RÉ¡÷G 𫪖 ‘ •ôØJ ’ CG

OóëŸG AGOC’G ∫ó©Ÿ kÉ≤ah kÉfÉeCG ÌcCGh π°†aCG πµ°ûH πª©dG ò«Øæàd

.ΩGóîà°SÓd

πãÁ PEG ,kÉØdÉJ ¬∏«¨°ûJ ìÉàØe ¿Éc GPEG »FÉHô¡µdG RÉ¡÷G Ωóîà°ùJ ’ Ü

𫨰ûàdG ìÉàØe ᣰSGƒH ¬H ºµëàdG øµÁ ’ …òdG »FÉHô¡µdG RÉ¡÷G

.¬ë«∏°üJ Öéjh IÒÑc IQƒ£N

hCG RÉ¡÷G §Ñ°V πÑb ájQÉ£ÑdG ´õfG hCG/h ¢ùÑ≤ŸG øe ¢ùHÉ≤dG Öë°SG ê

äÉWÉ«àMG ™æ“h .á«FÉHô¡µdG Iõ¡LC’G øjõîJ hCG äÉ≤ë∏ŸG ∫GóÑà°SG

ÒZ πµ°ûH á«FÉHô¡µdG Ió©dG 𫨰ûJ øe IQƒcòŸG á«FÉbƒdG áeÓ°ùdG

0

∫hÉæàe øY kGó«©H áeóîà°ùŸG ÒZ á«FÉHô¡µdG Iõ¡LC’ÉH ßØàMG O

¿hó«éj ’ øjòdG ¢UÉî°TC’G πÑb øe É¡∏«¨°ûàH íª°ùJ ’h .∫ÉØWC’G

Iõ¡LC’G ¿CG PEG ,äɪ«∏©àdG ∂∏J ≈∏Y Gƒ©∏£j ⁄ øjòdG hCG É¡eGóîà°SG

¢UÉî°TCG πÑb øe É¡∏«¨°ûJ ” GPEG IÒÑc IQƒ£N πµ°ûJ ób á«FÉHô¡µdG

.É¡«∏Y ÚHQóàe ÒZ

¿CG øe ócCÉà∏d É¡°üëaGh á«FÉHô¡µdG Iõ¡LC’G áfÉ«°U ≈∏Y ßaÉM √

É¡àcôM á∏bôY ºàj ’ ¬fCÉHh ó«L πµ°ûH πª©J IQGhódG AGõLC’G

≈∏Y ôKDƒJ ób iôNCG ádÉM …CG hCG É¡«a Qƒ°ùc ájCG OƒLh ≈∏Y ±ô©à∏dh

PEG ,ΩGóîà°S’G πÑb É¡MÓ°UEG Öéj ,É¡Ø∏J ÚÑJ GPEÉa .Iõ¡LC’G 𫨰ûJ

.á«FÉHô¡µdG Iõ¡LCÓd áÄjOôdG áfÉ«°üdG ÖÑ°ùH çOGƒ◊G øe ójó©dG ™≤J

ÖÑ°ùàJ ¿CG QOÉædG øe .áaɶfh IOÉM ™£≤dG äGhOCG π¶J ¿CG ≈∏Y ¢UôMG h

ácô◊G ábÉYEG ‘ Ö°SÉæe πµ°ûH áXƒØëŸG ±GôWC’G IOÉM ™£≤dG äGhOCG

äÉ«∏ªY ‘ RÉ¡÷G ΩGóîà°SG …ODƒj óbh .É¡«a ºµëàdG ádƒ¡°S øY kÓ°†a

.ôWÉfl ´ƒbh ¤EG É¡d ¢ü°üîŸG ÒZ

»FÉHô¡µdG RÉ¡÷G ìÓ°UEG 5

.ácôëàŸG

.Oƒ°ü≤e

¢Vô©àdG …ODƒj ó≤a .Ö≤ãdG ¥QÉ£e ΩGóîà°SG AÉæKCG ¿PCÓd äÉ«bGh póJQG •

.™ª°ùdG ¿Gó≤a ¤EG AÉ°Vƒ°†dG ¤EG

20

ΩGóîà°SÉH πgDƒŸG áfÉ«°üdG π«ch iód ’EG »FÉHô¡µdG ∑RÉ¡L í∏°üJ ’ CG

RÉ¡÷G áeÓ°S ≈∏Y ®ÉØ◊G øª°†j Éà á≤HÉ£ŸG ∫GóÑà°S’G ™£b

.»FÉHô¡µdG

Page 21

Arabic

áÄaóàdG äGÎjOGQh Ö«HÉfC’Éc á°VQDƒŸG 샣°ùdG á°ùeÓe ÖæŒ Ü

á«FÉHô¡µdG äÉeó°ü∏d ¢Vô©àdG Iƒ£N OGOõJ PEG ,äÉLÓãdGh ÅaGóŸGh

.¢VQCÓd kÉ°ùeÓe ∂ª°ùL ¿ƒµj ÉeóæY

ÜöùJ ¿CÉH kɪ∏Y ,áHƒWôdG hCG ô£ª∏d á«FÉHô¡µdG Iõ¡LC’G ¢Vô©J ’ ê

äÉeó°ü∏d ¢Vô©àdG IQƒ£N ójõj »FÉHô¡µdG RÉ¡÷G πNGO ¤EG √É«ŸG

.á«FÉHô¡µdG

RÉ¡÷G πª◊ kGóHCG ¬eóîà°ùJ Óa ,∂∏°ùdG ΩGóîà°SG IAÉ°SEÉH º≤J ’ O

∂∏°ùdÉH ßØàMGh .¢ùÑ≤ŸG øY ¢ùHÉ≤dG π°üØd hCG ¬Hò÷ hCG »FÉHô¡µdG

AGõLC’G hCG IOÉ◊G ±GôWC’G hCG âjõdG hCG IQGô◊G QOÉ°üe øY kGó«©H

¢Vô©àdG IQƒ£N øe É¡Ø∏J hCG ∑Ó°SC’G ∂HÉ°ûJ ójõjh .ácôëàŸG

.á«FÉHô¡µdG äÉeó°ü∏d

»LQÉÿG ΩGóîà°S’G óæY áÑ°SÉæŸG ójóªàdG äÓHÉc iƒ°S Ωóîà°ùJ ’ √

ôWÉfl øe ¢†Øîj áÑ°SÉæŸG ójóªàdG äÓHÉc ΩGóîà°SG ¿CG PEG ,RÉ¡é∏d

.á«FÉHô¡µdG äÉeó°ü∏d ¢Vô©àdG

Ωóîà°SG »¨Ñæj ,ÖWQ ¿Éµe ‘ »Hô¡µdG RÉ¡÷G 𫨰ûJ Öéj ¿Éc GPEG h

π∏≤j IQhódG ™WÉb ΩGóîà°SG ¿EG .(RCD) IQhódG ™WÉ≤d »ªfi π°Uƒe

.á«Hô¡c áeó°U çhóM ô£N øe

"QÉ«àdG ™WÉb" áª∏µH (RCD) "IQhódG ™WÉb" áª∏c ∫GóÑà°SG øµÁ :á¶MÓe

."(ELCB) "»°VQC’G ÜöùàdG øe ájɪ◊G ™WÉb" áª∏µH hCG (GFCI)

á«°üî°ûdG áeÓ°ùdG 3

.»FÉHô¡µdG RÉ¡÷G 𫨰ûJ óæY kGQòM øch ,¬∏©ØJ ÉŸ ¬ÑàfGh kɶ≤j øc CG

¿ƒµJ ÉeóæY hCG Ö©àdÉH ∑Qƒ©°T óæY »FÉHô¡µdG RÉ¡÷G Ωóîà°ùJ ’h

√ÉÑàf’G ΩóY …ODƒj ób PEG .ájhOC’G hCG ∫ƒëµdG hCG äGQóîŸG ÒKCÉJ â–

áHÉ°UE’ ¢Vô©àdG ¤EG »FÉHô¡µdG RÉ¡÷G ΩGóîà°SG óæY IóMGh á¶ë∏d

.IÒ£N

´Éæb πãe á«°üî°ûdG ájɪ◊G äGó©eh ájÉbƒdG äGQɶf kɪFGO óJQG Ü

á«bGh hCG PƒÿGh ¥’õf’G øe á«bGƒdG ¿ÉeC’G ájòMCGh QÉѨdG øe ájÉbƒdG

¢Vô©àdG ô£N øe π∏≤j áÑ°SÉæŸG äGó©ŸG AGóJQG ¿CG PEG ,ÚfPC’G

.äÉHÉ°UEÓd

𫨰ûàdG ìÉàØe ¿ƒµj ¿CG ≈∏Y ¢UôMG .Oƒ°ü≤ŸG ÒZ 𫨰ûàdG ÖæŒ ê

äGhOC’G πªM áé«àf çOGƒM ™≤J ób .¬∏«°UƒJ πÑb ±É≤jE’G ™°Vh ‘

äGhOC’G π«°UƒJ hCG 𫨰ûàdG ìÉàØe ≈∏Y ™Ñ°UC’G ™°Vh ™e á«Hô¡µdG

.𫨰ûàdG ™°Vh ≈∏Y 𫨰ûàdG ìÉàØe ¿ƒµj ɪæ«M ¢ùÑ≤ŸÉH á«Hô¡µdG

ób PEG ,»FÉHô¡µdG RÉ¡÷G 𫨰ûJ πÑb §HôdG ìÉàØe hCG §Ñ°†dG IóY ´õfG O

áHÉ°UE’G ¤EG RÉ¡÷G øe QGhO AõL ‘ óLGƒàŸG ìÉàØŸG hCG Ió©dG …ODƒJ

.ìhôéH

,¿õîŸG ¤EG èàæŸG Gòg ó«©J ’

áfÉ«°U õcôe ÜôbCG hCG »∏ëŸG ôµjO ófBG ∑ÓH ÖàµÃ k’hCG ∫É°üJ’G ∂«∏Y

.óªà©e

áeÉ©dG áeÓ°ùdG óYGƒb

äɪ«∏©àdG ´ÉÑJG ΩóY …ODƒj ób PEG .kGó«L É¡ª¡aGh äɪ«∏©àdG áaÉc CGôbG !ôjò–

IÒ£N á«°üî°T áHÉ°UEG hCG ≥jôM hCG á«Hô¡c áeó°U çhóM ¤EG √ÉfOCG IOQGƒdG

.ɪ¡«∏c hCG

äɪ«∏©àdG √ò¡H ßØàMG

áeÓ°ùdG äɪ«∏©J

á«FÉHô¡µdG Iõ¡LC’G áeÓ°S ¢Uƒ°üîH áeÉ©dG äÉ¡«ÑæàdG

ób PEG .áeÓ°ùdG äGôjò– áaÉch äɪ«∏©àdG áaÉc CGôbG !ôjò–

¤EG √ÉfOCG IOQGƒdG äGôjòëàdGh äɪ«∏©àdG ´ÉÑJG ΩóY …ODƒj

IÒ£N á«°üî°T áHÉ°UEG hCG ≥jôM hCG á«Hô¡c áeó°U çhóM

.ɪ¡«∏c hCG

πÑ≤à°ùŸG ‘ É¡«dEG ´ƒLô∏d äɪ«∏©àdGh äGôjòëàdG áaɵH ßØàMG

RÉ¡÷G ¤EG √ÉfOCG IOQGƒdG äGôjòëàdG áaÉc ‘ "»Hô¡µdG RÉ¡÷G " áª∏c Ò°ûJ

RÉ¡÷G hCG á«°ù«FôdG äÓ°UƒŸG ᣰSGƒH πª©j …òdG (»µ∏°ùdG) »Hô¡µdG

.ájQÉ£H ᣰSGƒH πª©j …òdG »Hô¡µdG

πª©dG á≤£æe áe’¢S 1

ôWÉfl ójõJ PEG ,kGó«L IAÉ°†eh áØ«¶f πª©dG á≤£æe ¿ƒµJ ¿CG Öéj CG

.᪶æŸG ÒZ hCG áª∏¶ŸG ≥WÉæŸG ‘ çOGƒë∏d ¢Vô©àdG

‘ ɪc QÉéØfÓd á∏HÉ≤dG AGƒLC’G ‘ á«FÉHô¡µdG Iõ¡LC’G π¨°ûJ ’ Ü

øY ºéæj PEG ,∫É©à°TÓd á∏HÉ≤dG äGRɨdG hCG πFGƒ°ùdG hCG QÉѨdG §«fi

hCG QÉѨdG π©°ûJ ºK ôjÉ£àJ ób Éjɶ°T »FÉHô¡µdG RÉ¡÷G ΩGóîà°SG

.áæNOC’G

RÉ¡÷G 𫨰ûJ AÉæKCG πª©dG á≤£æe øY IQÉŸGh ∫ÉØWC’G OÉ©HEG Öéj ê

ºµëàdG ¿Gó≤a ¤EG √ÉÑàf’G ±öU πeGƒY …ODƒJ ó≤a ¬ÑàfGh ,»FÉHô¡µdG

.Iõ¡LC’G ∂∏àH

á«FÉHô¡µdG áeÓ°ùdG 2

Ò«¨J ô¶ëjh .¢ùÑ≤ŸG ™e »FÉHô¡µdG RÉ¡÷G ¢ùHÉb ≥aGƒàj ¿CG Öéj

™e ÅjÉ¡e ¢ùHÉb ájCG ΩGóîà°SG hCG ∫GƒMC’G øe ∫ÉM …CÉH ¢ùHÉ≤dG

ΩóY ¢†Øîjh .(»°VQCG) ¢VQDƒe ±ôW É¡d »àdG á«FÉHô¡µdG Iõ¡LC’G

äÉeó°ü∏d ¢Vô©àdG IQƒ£N øe á°ùfÉéàŸG ¢ùHÉ≤ŸGh ¢ùHÉ≤dG Ò«¨J

.á«FÉHô¡µdG

CG

21

Page 22

Arabic

FIG. D

FIG. E FIG. F

3

22

6

7

Page 23

FIG. A

Arabic

4

6

5

3

7

1

2

FIG. B

FIG. C

10

11

9

7

8

23

Page 24

Page 25

WARRANTY REGISTRATION CARD

YOUR NAME/

YOUR ADDRESS

POSTCODE

«ùßr

«∞FMu«Ê

«∞d±e «∞∂d¥bÍ

DATE OF PURCHASE

DEALER'S NAME & ADDRESS/

¢U¸¥a «∞Ad«¡

≈ßr Ë ´Mu«Ê «∞∂Uzl

PRODUCT MODEL NO.

BPDH7013

90613121 06/2014

Page 26

N a m e s & A dd re ss es fo r B la ck & D e c k e r S e r v i c e Co n c e s s i o n a r i e s

ALGERIA: Sarl Outillage Corporation, 08 Rue Med Boudiaf - Cheraga - Algiers, Algeria. Tel: (213-21) 375130, Fax: (213-21) 369667. ANGOLA: Angoferraria,

Lda., Rua Robert Shields, No. 61, Luanda, Angola, Tel: 00244-222-395837 / 222-395034, Fax: 00244-222-394790. AZERBAIJAN: Royalton Holdings Ltd. 41

Khagani St. Apt. 47 AZ 1001, Baku. Tel: (994-12) 4935544, Fax: (994-12) 5980378. BAHRAIN: Kavalani & Sons W.L.L., P.O. Box 71, Sitra, Manama, Tel: (973)

17732888, Fax: (973) 17737379. Alfouz Services Co. WLL., P.O. Box 26562, Tubli, Manama. Tel: (973) 17783562, Fax: (973) 17783479. EGYPT: El Farab

S.A.E., 15-Nabil El Wakkad Street, Dokki, Giza, Egypt, Tel: 00202-37603946 / 002-010-2582544, Fax: 00202-33352796. ETHIOPIA: Seif Tewfik Sherif, Arada

Sub-City, Kebele 01/02, Global Insurance Building, 2nd Floor, Room 43, P.O. Box 2525, Addis Ababa, Ethiopia. Tel: (251-11) 1563968/ 1563969, Fax: (251-11)

1558009. IRAQ: Financial Links, Kazzaz Building Arasat Al-Hindia Block No: 629 Street: 31Building No: 1 Baghdad – Iraq. Tel: 00964 (0)780 195 2223/ 00964

(0)781 3763044. Al Sard Co. for General Trading Ltd. Jbara Bldg. 3Flr, Al Rasheed St. Bagdad. Tel: (964) 18184102. Sakhar Group, Arrassat al-hindya Al

Masbah, Bagdad. (964) 7400144446. JORDAN: Palestine Bldg. Matl. (Bashiti Hardware), 93 King Abdullah 2nd Street, Opp. ELBA House, P.O. Box 3005,

Amman 11953, Tel: (962-6) 5349098, Fax: (962-6) 5330731. KENYA: Dextron Tools Ltd., P.O. Box 20121-00200, Shariff House, Kimathi Street, Nairobi. Tel:

(254-20) 6905000/ 2358021, Fax: (254-20) 6905111/ 6905112. KUWAIT: Al Omar Technical Co., P.O. Box 4062, 13041 Safat, Kuwait. Tel: (965) 24848595/

24840039, Fax: (965) 24845652. Fawaz Al Zayani Establishment, P.O. Box 42426, Shop No. 18, Al Humaizi Commercial Complex, Khalifa Al Jassim,

Shuwaikh, Kuwait. Tel: (965) 24828710, Fax: (965) 24828716. Fawaz Al Zayani Establishment, P.O. Box 42426, Shop No.18, Al Humaizi Commercial

Complex, Khalifa Al Jassim, Shuwaikh, Kuwait, Tel: (965) 24828710, Fax: (965) 24828716. Fawaz Al Zayani Establishment, Fahaheel Industrial Area, Main St.,

Sanaya, Kuwait, Tel: (965) 23925830, Fax: (965) 24828716. LEBANON: Est. Shaya & Azar S.A.R.L., Boulvard Jdeideh - Mar Takla - Bouchrieh .P.O. Box

90545 Jdeideh.Beirut - Lebanon, Tel: 00961 1 872305 / 306 , Fax: 00961 1 872303. LIBYA: North Africa Trading ( El Ghoul Brothers), AlHilal Service Center

Tawergha St. Misurata, Tel: 00218-091-3221408. (Benghazi) Sniydel st., Amr Ibn EL-Aas Rd. Tel: (+218) 92 5771120. (Tripoli) Al Barniq Service Center,

Mokhazin elsukar st., ElFallah. Tel: (+218) 21 4808019. (Misrata) Al Hilal Service Center, Tawergha st. Tel: (+218) 51 2626743. MAURITIUS: Robert Le Marie

Limited, Old Moka Road, Bell Village, P.O. Box 161, Port Louis, Tel: 00230-212 1865/ 212 2847, Fax: 00230-2080843. MOROCCO: Ets Louis Guillaud & Cie,

149, Quartier Industriel, Moulay Rachid, Casablanca, Postal Code 20450, Morocco, Tel: 00212-522729233, Fax: 00212-522729096. NIGERIA: Meridian

Power Tools Ltd., Gr.Floor, #1 Alhaji Masha Rd, Next toTeslim Balogun Stadium, Near National Stadium Surulere, Lagos, Nigeria, Tel: 00234-1-7740431 /

7740410, Fax: 00234-1-7913798. OMAN: Al Jizzi Company LLC, P.O. Box 1704,PC 112 Ruwi, Oman, Tel: (968) 24832618/ 24835153, Fax: (968)

24831334/24836460. Al Hassan Technical & Construction Supplies Co. LLC, P.O. Box 1948, P.C. 112, Ruwi, Tel: (968) 24810575 / 24837054, Fax: (968)

24810287/ 24833080. Oman Hardware Co. LLC, P.O. Box 635, Ruwi Postal Code 112, Te: (968) 24815131, Fax: (968) 24816491. Khimji Ramdas, P.O. Box

19, Post Code 100, Ghala, Muscat, Oman. Tel: (968) 24595906/ 907, Fax: (968) 24852752. Oman Marketing & Service Co. (Omasco), P.O. Box 2734, Behind

Honda Showroom, Wattayah, Oman. Tel: (968) 24560232/ 24560255, Fax: (968) 24560993. Oman Marketing & Service Co. (Omasco), Al Ohi, Sohar, Oman.

Tel: (968) 26846379, Fax: (968) 26846379. Oman Marketing & Service Co. (Omasco), Sanaya, Salalah, Oman. Tel: (968) 23212290, Fax: (968) 23210936.

PAKISTAN: ZIT Co - Nasir & Bros., 2nd Floor, Qadri Center, Chowk Dalgran Railway Road, Lahore, Pakistan, Tel: 0092 42 37670839, Fax: 0092 42

37652989. Ammar Service & Spares, 60-Bank Arcade, Serai Road, Karachi, Pakistan. Tel: (92-21) 32426905, Fax: (92-21) 32427214. QATAR: Teyseer

Industrial Supplies & Services Co. WLL, 55, Al Wakalat St. (Between St. 18 & 19) Salwa Industrial Area, P.O. Box 40523 Doha,Qatar, Te: (974) 44581536, Fax:

(974) 44682024. Shaheen Electrical Works & Trading Co. WLL, Gate 34, St. 44 Industrial Area P.O. Box 9756, Doha, Tel: (974) 44600230 /44600525, Fax:

(974) 44601338. Al Muftah Service Centre, Al Wakrah Road, P.O. Box 875, Doha,Qatar, Tel: (974) 44650880/ 44650110/ 44446868, Fax: (974) 44441415 /

44662599. SAUDI ARABIA: (Al Bahr) Mohamed Ahmed Bin Afif Est., P.O. Box 530, Yanbu, Al Bahr. Tel: (966-4) 3222626/ 3228867, Fax: (966-4) 3222210.

(Al Khobar) Fawaz Ebrahim Al Zayani Trading Est., P.O. Box 76026, Al Khobar # 31952, Tel: (966-3) 8140914, Fax: (966-3) 8140824. MSS (Al-Mojil Supply &

Services) P.O. Box 450, Jubail 31951, Opp. Gulf Bridge Library & Riyadh House. Tel: (966-3) 3612850/ 3624487/ 3621729, Fax: (966-3) 3623589/ 3620783.

(Dammam) MSS (Al-Mojil Supply & Services), P.O. Box 450, Jubail 31951.Opp-Gulf Bridge Library & Riyadh House, Tel: (966-3) 3612850 / 3624487 /

3621729, Fax: (966-3) 3623589 / 3620783. Al Bawardi Tools & Hardware, P.O. Box 112, Dammam, Tel: (966-3) 8330780 Ext.24 / 8348585 Ext. 24 /

+966-3-8335555, Fax: (966-3) 8336303. (Al Hassa) Mutawa Trading & Gen. Services, Maliki road Hafuf city, Al Hassa, KSA. Tel: (966) 502846275 (Jeddah) Al

Bawardi Tools & Hardware, P.O. Box 16905, Jeddah 21474, Tel: (966-2) 6444547 / 6439035 / 6456095, Fax: (966-2) 6439024. EAC (Al Yousef Contg. & Trdg.

Est.), P.O. Box 30377, Jeddah -21477, Tel: (966-2) 6519912, Fax: (966-2) 6511153. (Madina) Garziz Trading for Bldg Mat & Decoration, P.O. Box 3364,

Madina, Tel: (966-4) 826 14 90 / 8227636, Fax: (966-4) 8265741. (Riyadh) Industrial Material Organization (IMO), P.O. Box 623, Rail Street ,Riyadh, Tel:

(966-1) 4028010 Ext 26 / 8001245757, Fax: (966-1) 4037970. Sultan Garment Factory (RSC), P.O. Box 29912, Riyadh 11467, KSA, Tel: (966-1) 4055148 /

4042889, Fax: (966-1) 4055148. Al Bawardi Tools & Hardware, P.O. Box 68, Riyadh 11411, Tel: (966-1) 4484999, Fax: (966-1) 4487877. (Yanbu) Fawaz

Ebrahim Al Zayani, Opposite to Al Fouzan, Jeddah highway or King Abdul Aziz road, Yanbu. Tel: (966-4) 3960980, Fax: (966-4) 3961980. Mohamed Ahmed

Bin Afif Est., P.O. Box 530, Yanbu, Al Bahr, Tel: (966-4) 3222626/ 3228867, Fax: (966-4) 3222210. SOUTH AFRICA: Stanley Black & Decker - RSA, 199

Winze Drive Stormill Ext 9 Roodepoort, Tel: (2711) 472 0454, Fax: (2711) 472 0482. Trevco Power Tool Service 14 Steenbok Street, Koedoespoort, 0186,

Pretoria, South Africa. Tel: (27-86) 1873826, Fax: (27-86) 5001771. TANZANIA: General Motors investment Ltd., P.O. Box 16541, 14 Nyerere Road,

Vingunguti, Dar-es-Salaam. Tel: (255 22) 2862661/ 2865022, Fax: (255 22) 2862667. TUNISIA: Societe Tunisienne De Maintenance (STM), Rue de la

Physique. Nouvelle Zone Industrielle Ben Arous., 2013 Ben Arous, Tunisia. Tel: (+216) 79 389687, Fax: (+216) 71 385154. UAE: (Abu Dhabi) Light House

Electrical, P.O. Box 120, Abu Dhabi, Tel: (971-2) 6726131, Fax: (971-2) 6720667. Galaxy Equipment Trading, Madinath Zayed (Baada Zaid), Abu Dhabi P.C.

58910, Tel: (971-2) 8844279, Fax: (971-2) 8844297 (Ajman) Al Sukoon Gen. Trdg. Co. LLC, P.O. Box 2975, Ajman. Tel: (971-6) 7435725/ 7438317, Fax:

(971-6) 7437350. Al Sukoon Gen. Trdg. Co. LLC, P.O. Box 2975, Ajman, Tel: (971-6) 7435725 / 7438317, Fax: (971-6) 7437350 (Al Ain) Zillion Equipment and

Spare Parts Trading LLC, P.O. Box 19740, Opp. Bin Sadal/ Trimix Redymix Sanaiya, Al Ain. Tel: (971-3) 7216690, Fax: (971-3) 7216103. (Dubai) Black &

Decker (Overseas) GmbH, P.O. Box 5420, Dubai, Tel: (971-4) 8127400/ 8127406, Fax: (971-4)2822765. Ideal Star Workshop Eqpt.Trading LLC, P.O. Box

37116, Al Quoz, Dubai, Tel: (971-4) 3474160, Fax: (971-4) 3474157, Fine Tools, P.O.Box 30139 , Al Quoz, Dubai, Tel: (971-4) 3385240, Fax: (971-4) 3385239,

Alebrah Engineering Service, P.O. Box 78954, Al Qusais , Dubai, Tel: (971-4) 2850044, Fax: (971-4) 2844802. (Musaffah) Light House Electrical, P.O. Box

120, Abu Dhabi, Tel: (971-2) 5548315, Fax: (971-2) 5540461. (Sharjah) Mc Coy Middle East LLC, P.O. Box 25793, Sharjah, Tel: (971-6) 5395931, Fax:

(971-6) 5395932. Burj Al Madeena, Industrial Area No.1, Opp. Pakistani Masjid, P.O. Box 37635, Sharjah. Tel: (971-6) 5337747, Fax: (971-6) 5337719. Burj Al

Madeena, , Industrial Area No 1,opp Pakistani Masjid P.O. Box 37635, Sharjah, Tel: (971-6) 5337747, Fax: (971-6) 5337719 (Ras Al Khaimah) Mc Coy Middle

East LLC, P.O. Box 10584, Ras Al Khaimah, Tel: (971-7) 2277095, Fax: (971-7) 2277096. UGANDA: The Building Center (U) Ltd., 52 Station Road, Kitgum

House, P.O. Box 7436, Kampala, Uganda. Tel: (256-41) 4234567/ 4259754, Fax: (256-41) 4236413. YEMEN: (Aden) Middle East Trad. Co. Ltd. (METCO),

Mualla Dakka, Aden, Yemen. Tel: (967-2) 222670, Fax: (967-2) 222670. (Sana'a) Middle East Trad. Co. Ltd. (METCO), Hayel St., Sana'a, Yemen. Tel: (967-1)

204201, Fax: (967-1) 204204. (Taiz) Middle East Trading Co. (METCO), P.O. Box 12363, 5th Flr, Hayel Saeed Anam Bldg, Al-Mugamma St. Taiz, Yemen. Tel:

(967-4) 213455, Fax: (967-4) 219869.

Loading...

Loading...