Page 1

Australia

New Zealand

www.blackanddecker.com.au

BMT300KA-XE

BMT300-XE

Page 2

2

A

B

C

D E

Page 3

3

G

F

Page 4

4

ENGLISH

(Original instructions)

Intended use

Your Black & Decker oscillating tool has been designed for

DIY applications such as sanding operations. It is also suitable

for cutting wooden materials, plastic, gypsum, non-ferrous

metals and fastening elements (e.g., unhardened nails,

staples), working soft wall tiles and scraping of small surfaces.

This tool is intended for consumer use only.

Safety instructions

General power tool safety warnings

@

Warning! Read all safety warnings and all

instructions. Failure to follow the warnings and

instructions listed below may result in electric

Save all warnings and instructions for future reference.

The term "power tool" in the warnings refers to your mains

operated (corded) power tool or battery operated (cordless)

power tool.

1. Work area safety

a. Keep work area clean and well lit. Cluttered or dark

areas invite accidents.

b. Do not operate power tools in explosive atmospheres,

or dust. Power tools create sparks which may ignite the

dust or fumes.

c. Keep children and bystanders away while operating a

power tool. Distractions can cause you to lose control.

2. Electrical safety

a. Power tool plugs must match the outlet. Never modify

the plug in any way. Do not use any adapter plugs

with earthed (grounded) power tools.

and matching outlets will reduce risk of electric shock.

b. Avoid body contact with earthed or grounded

surfaces such as pipes, radiators, ranges and

refrigerators. There is an increased risk of electric shock

if your body is earthed or grounded.

c. Do not expose power tools to rain or wet conditions.

Water entering a power tool will increase the risk of

electric shock.

d. Do not abuse the cord. Never use the cord for

carrying, pulling or unplugging the power tool. Keep

cord away from heat, oil, sharp edges or moving

parts. Damaged or entangled cords increase the risk of

electric shock.

e. When operating a power tool outdoors, use an

extension cord suitable for outdoor use. Use of a cord

suitable for outdoor use reduces the risk of electric shock.

f. If operating a power tool in a damp location is

unavoidable, use a residual current device (RCD)

protected supply. Use of an RCD reduces the risk of

electric shock.

3. Personal safety

a. Stay alert, watch what you are doing and use common

sense when operating a power tool. Do not use a

of drugs, alcohol or medication. A moment of inattention

while operating power tools may result in serious personal

injury.

b. Use personal protective equipment. Always wear eye

protection. Protective equipment such as dust mask,

non-skid safety shoes, hard hat, or hearing protection

used for appropriate conditions will reduce personal

injuries.

c. Prevent unintentional starting. Ensure the switch is in

the off-position before connecting to power source

and/or battery pack, picking up or carrying the tool.

energising power tools that have the switch on invites

accidents.

d. Remove any adjusting key or wrench before turning

the power tool on. A wrench or a key left attached to a

rotating part of the power tool may result in personal injury.

e. Do not overreach. Keep proper footing and balance at

all times. This enables better control of the power tool in

unexpected situations.

f. Dress properly. Do not wear loose clothing or

jewellery. Keep your hair, clothing and gloves away

from moving parts. Loose clothes, jewellery or long hair

can be caught in moving parts.

g. If devices are provided for the connection of dust

extraction and collection facilities, ensure these are

connected and properly used. Use of dust collection can

reduce dust-related hazards.

4. Power tool use and care

a. Do not force the power tool. Use the correct power

tool for your application. The correct power tool will do

the job better and safer at the rate for which it was

designed.

b. Do not use the power tool if the switch does not turn it

on and off. Any power tool that cannot be controlled with

the switch is dangerous and must be repaired.

c. Disconnect the plug from the power source and/or the

battery pack from the power tool before making any

adjustments, changing accessories, or storing power

tools. Such preventive safety measures reduce the risk of

starting the power tool accidentally.

Page 5

5

ENGLISH

(Original instructions)

d. Store idle power tools out of the reach of children and

do not allow persons unfamiliar with the power tool or

these instructions to operate the power tool. Power

tools are dangerous in the hands of untrained users.

e. Maintain power tools. Check for misalignment or

binding of moving parts, breakage of parts and any

other condition that may affect the power tools

operation. If damaged, have the power tool repaired

before use. Many accidents are caused by poorly

maintained power tools.

f. Keep cutting tools sharp and clean. Properly

maintained cutting tools with sharp cutting edges are less

likely to bind and are easier to control.

g. Use the power tool, accessories and tool bits etc. in

accordance with these instructions, taking into

account the working conditions and the work to be

performed. Use of the power tool for operations different

from those intended could result in a hazardous situation.

5. Service

a.

person using only identical replacement parts. This

will ensure that the safety of the power tool is maintained.

@

Warning! Additional safety warnings for oscillating tools

Hold power tool by insulated gripping surfaces when

performing an operation where the cutting accessory

may contact hidden wiring or its own cord. Cutting ac-

cessory contacting a "live" wire may make exposed metal

parts of the power tool "live" and could give the operator

an electric shock

Use clamps or another practical way to secure and

support the workpiece to a stable platform. Holding the

work by hand or against your body leaves it unstable and

may lead to loss of control.

@

Warning! Contact with or inhalation of dusts

arising from sanding applications may endanger

the health of the operator and possible bystand-

protection against dust and fumes and ensure

that persons within or entering the work area are

also protected.

Thoroughly remove all dust after sanding.

Take special care when sanding paint which is possibly

lead based or when sanding some woods and metal which

may produce toxic dust:

Do not let children or pregnant women enter the work

area.

Do not eat, drink or smoke in the work area.

Dispose of dust particles and any other debris safely.

The intended use is described in this instruction manual.

The use of any accessory or attachment or performance

of any operation with this tool other than those recommended in this instruction manual may present a risk of

personal injury and/or damage to property.

The accessory will continue to move after releasing the

switch. Always switch the tool off and wait for the accessory to come to a complete standstill before putting the

tool down.

Keep hands away from cutting area. Never reach

underneath the work piece for any reason. Do not insert

and blade clamp. Do not stabilize the saw by gripping the

shoe.

Keep blades sharp. Dull or damaged blades may cause

the saw to swerve or stall under pressure. Always use the

appropriate type of saw blade for the workpiece material

and type of cut.

When cutting pipe or conduit, make sure that they are free

from water, electrical wiring, etc.

Do not touch the workpiece or the blade immediately after

operating the tool. They can become very hot.

Be aware of hidden hazards, before cutting into walls,

pipes.

Safety of others

This appliance is not intended for use by persons (includ-

ing children) with reduced physical, sensory or mental

capabilities, or lack of experience and knowledge, unless

they have been given supervision or instruction concerning use of the appliance by a person responsible for their

safety.

Children should be supervised to ensure that they do not

play with the appliance.

Residual risks.

Additional residual risks may arise when using the tool which

may not be included in the enclosed safety warnings. These

risks can arise from misuse, prolonged use etc.

Even with the application of the relevant safety regulations

and the implementation of safety devices, certain residual

risks can not be avoided. These include:

Injuries caused by touching any rotating/moving parts.

Injuries caused when changing any parts, blades or ac-

cessories.

Injuries caused by prolonged use of a tool. When using

any tool for prolonged periods ensure you take regular

b.

Power to the tool should always be supplied via

residual current device with a rated residual current

of 30mA or less.

Page 6

6

ENGLISH

(Original instructions)

Vibration

The declared vibration emission values stated in the technical

data and the declaration of conformity have been measured

in accordance with a standard test method provided by

EN 60745 and may be used for comparing one tool with

another. The declared vibration emission value may also be

used in a preliminary assessment of exposure.

Warning! The vibration emission value during actual use of

the power tool can differ from the declared value depending

on the ways in which the tool is used. The vibration level may

increase above the level stated.

When assessing vibration exposure to determine safety

measures required by 2002/44/EC to protect persons regularly

using power tools in employment, an estimation of vibration

exposure should consider, the actual conditions of use and the

way the tool is used, including taking account of all parts of the

operating cycle such as the times when the tool is switched off

and when it is running idle in addition to the trigger time.

Labels on tool

The following pictograms are shown on the tool:

:

Warning! To reduce the risk of injury, the user

must read the instruction manual.

6

Warning! Always wear a dust mask when using

this tool.

Electrical safety

#

This tool is double insulated; therefore no earth

wire is required. Always check that the power

supply corresponds to the voltage on the rating

plate.

If the supply cord is damaged, it must be replaced by the

manufacturer or an authorised Black & Decker Service

Centre in order to avoid a hazard.

Features

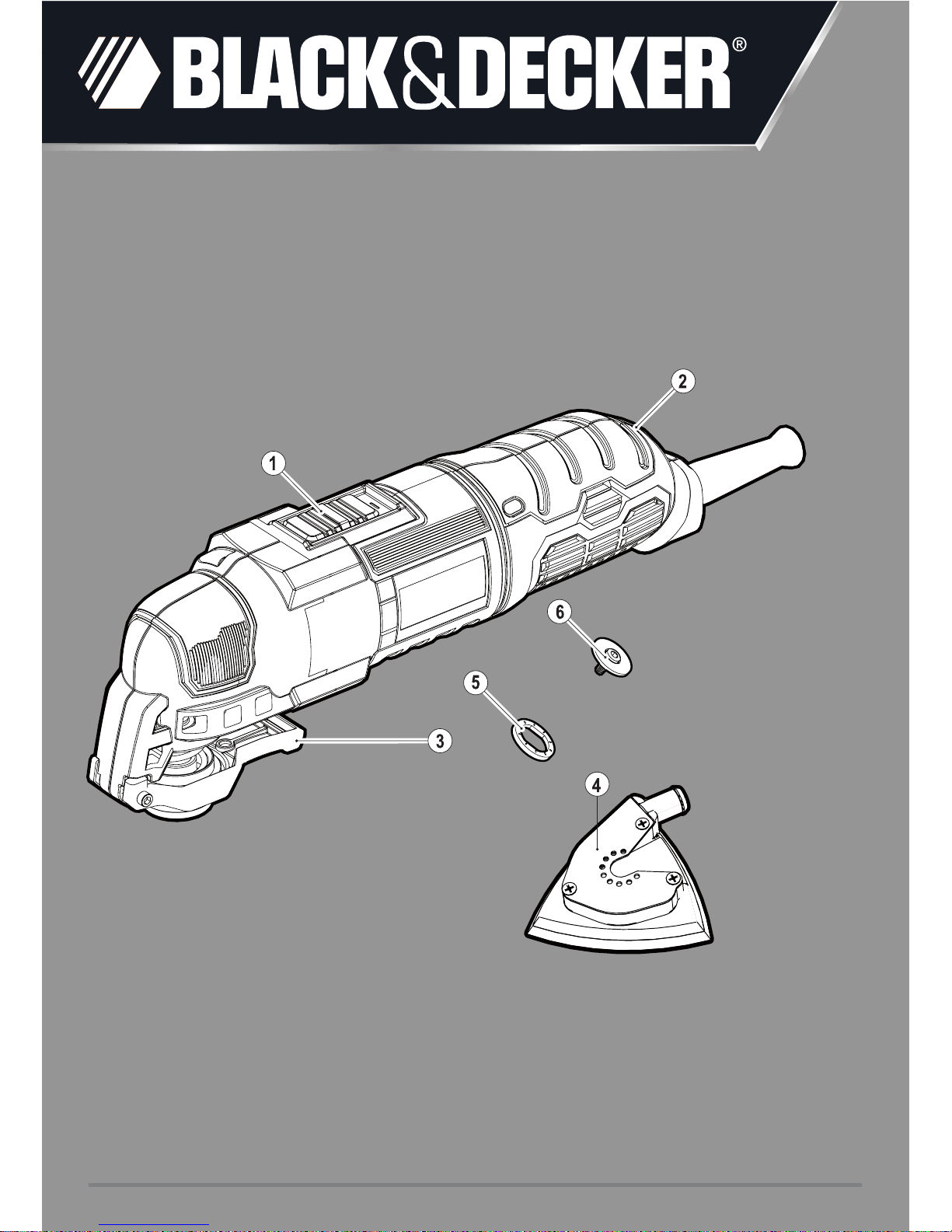

This tool includes some or all of the following features.

1. On/Off switch

2. Variable speed dial

3. Super-lokTM Tool free accessory clamping lever

4. Sanding base

Accessories

This tool includes some or all of the following accessories.

The performance of your tool depends on the accessory used.

Black & Decker and Piranha accessories are engineered to

high quality standards and designed to enhance the performance of your tool. By using these accessories you will get the

very best from your tool.

Plunge cut saw blade for wood and

metal. (Part number - X26110-XJ)

of wood, plastics, thin-walled

non-ferrous pipes and extrusions,

nails and screws.

Plunge cut saw blade for wood and

metal.

(Part number - X26115-XJ)

of wood, plastics, thin-walled

non-ferrous pipes and extrusions.

Segmented saw blade.

(Part number - X26120-XJ)

Long life blade which is ideal for

cutting wood, plastics, thin walled

ferrous and non-ferrous material.

Rigid scraper.

(Part number - X26135-XJ)

Ideal for removal of hard and soft

grout, paint and varnish.

breaks.

Impairment of hearing.

Health hazards caused by breathing dust developed when

using your tool (example:- working with wood, especially

oak, beech and MDF.)

5. Tooled accessory adapter (spacer)

6. Tooled accessory adapter (Fixing bolt)

Sanding Sheets.

Various grades for sanding of wood,

painted and varnished surfaces.

painted and varnished surfaces.

for BMT300-XE and BMT300KA-XE

for BMT300-XE only

Precision plunge cut saw blade for

wooden materials, soft plastics.

(Part number - X26105-XJ)

of wood and soft plastics. Ideal for

working on doors, skirting boards,

Page 7

7

ENGLISH

(Original instructions)

Carbide grout removal blade.

(Part number - X26125-XJ)

Carbide coated surface ideal for

clearing grout and tile adhesive from

removal of wood, chipboard and

Carbide rasp.

(Part number - X26130-XJ)

Carbide coated surface ideal for grout

removal and for fast stock removal of

Assembly

Warning!

the mains supply.

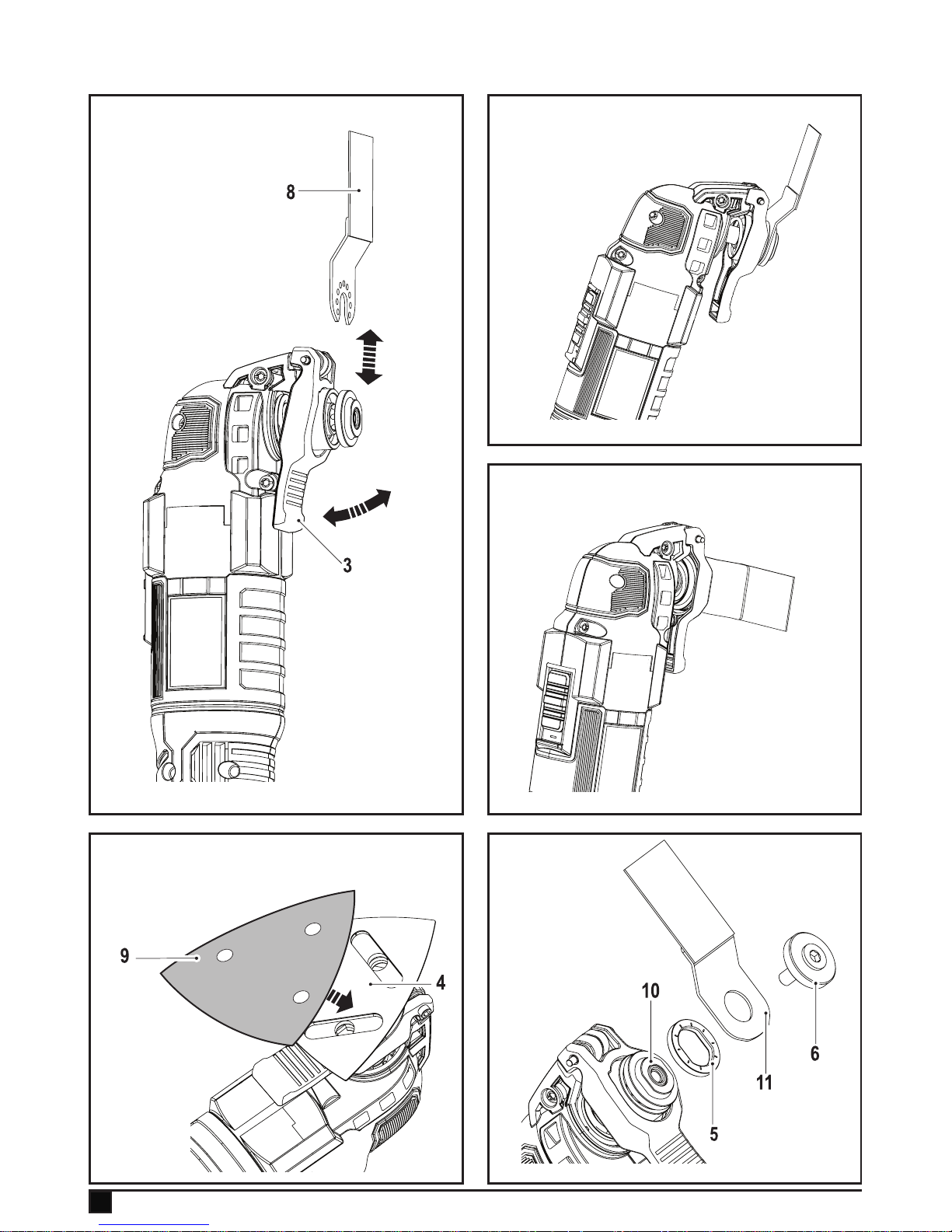

Hold the tool and squeeze the accessory clamping lever

(3).

Slide the accessory (8) between the shaft and the acces-

sory holder making sure the accessory engages all eight

Release the accessory clamping lever.

Note: Some accessories, such as scrapers and blades can be

Removing a Black & Decker / Piranha accessory

Hold the tool and squeeze the accessory clamping lever

(3).

Pull the accessory from the tool making sure the acces-

sory dis-engages from all eight pins on the holder.

Release the accessory clamping lever.

Warning: Gloves must be worn when removing accessories

as they may become hot during use.

Line up the sanding sheet (9) with the sanding base (4) as

shown.

making sure that the holes in the sheet coincide with the

holes in the base.

Removing a sanding sheet

Pull the sanding sheet off the sanding base (4).

Warning! Never use the sanding base without a sanding

sheet or accessory in place.

Place the spacer (5) onto the collar (10).

Place the alternative accessory (11) onto the collar (10).

Note:

& Decker accessories. Black and decker accessories are

attached using the Super-lokTM Tool free accessory clamping

lever.

Use

Warning! Let the tool work at its own pace. Do not overload.

Warning!

the location of wiring and pipes.

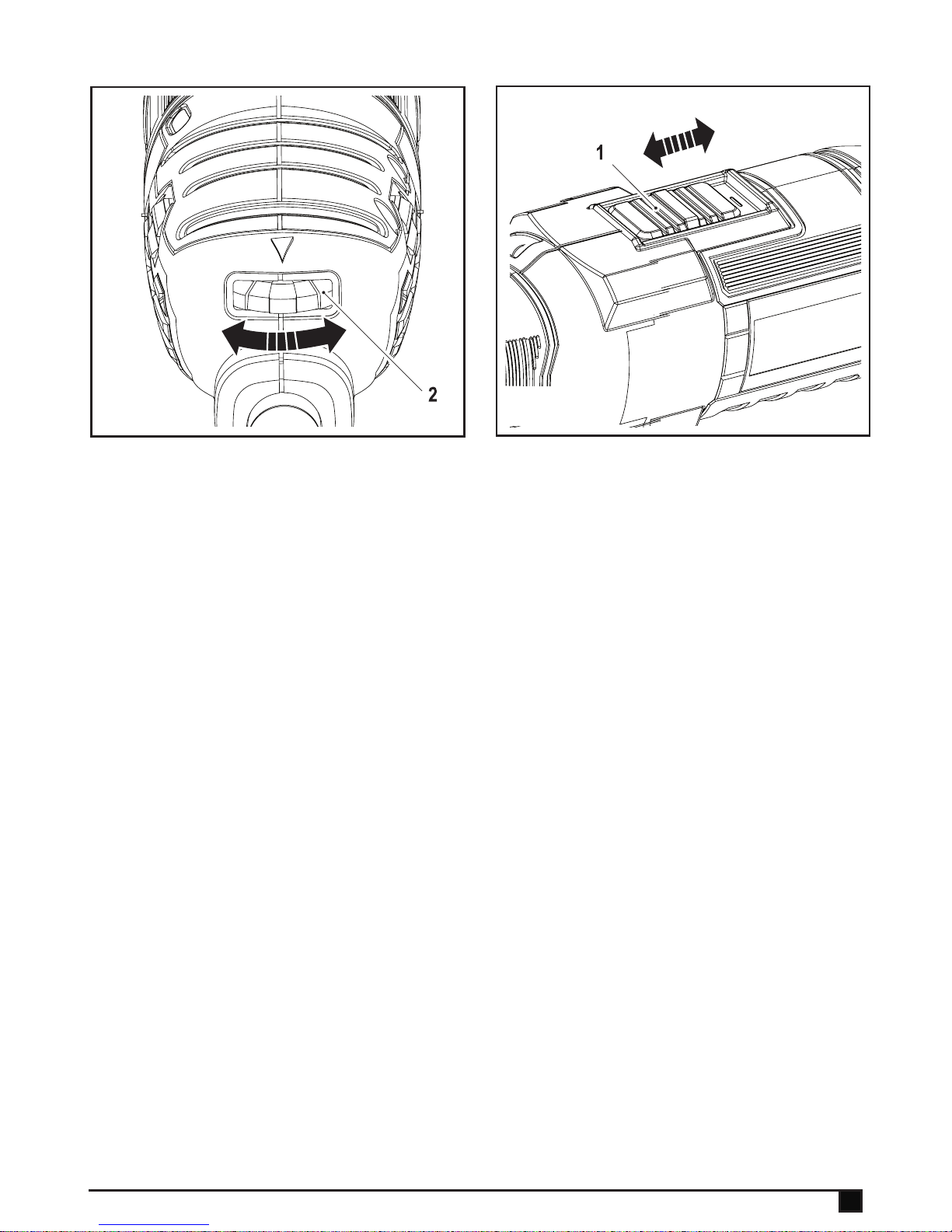

The variable speed control allows you to adapt the speed of

the tool to the application.

Set the variable speed dial (2) to the desired setting. At

setting 1 the tool will operate at low speed, 10,000 min-1.

At setting 6 the tool will operate at the maximum speed,

22,000 min-1.

To switch the tool on, slide the on/off switch (1) forward

(position I).

To switch the tool off, slide the on/off switch (1) to the rear

(position O).

Flexible scraper.

(Part number - X26140-XJ)

Ideal for removal of elastomer

sealant and other caulking materials.

6

Hints for optimum use

Always hold the tool securely. For precision work, hold the

tool near the front.

Clamp the workpiece whenever possible, especially when

using cutting blades.

Do not exert too much pressure on the tool.

Always use the appropriate type of attachment for the

workpiece material and type of cut.

Regularly check the condition of accessories. Replace

when necessary.

Mark the desired starting point.

Switch the tool on and slowly feed attachments into the

workpiece at the desired starting point.

Page 8

8

ENGLISH

(Original instructions)

Clamp a piece of plywood or soft wood to the back of the

workpiece and saw through the combination in order to

obtain a clear cut.

Do not force the cutting blade into the workpiece. Note

that cutting sheet metal will normally take more time than

sawing thicker wooden workpieces.

ting line before cutting.

When sanding new layers of paint before applying another

On very uneven surfaces, or when removing layers of

paint, start with a coarse grit. On other surfaces, start with

Consult your retailer for more information on available

accessories.

Maintenance

Your Black & Decker corded/cordless appliance/tool has been

designed to operate over a long period of time with a minimum

of maintenance. Continuous satisfactory operation depends

upon proper tool care and regular cleaning.

Warning! Before performing any maintenance on corded/

cordless power tools:

Switch off and unplug the appliance/tool.

Or switch off and remove the battery from the appliance/

tool if the appliance/tool has a separate battery pack.

Or run the battery down completely if it is integral and then

switch off.

Regularly clean the ventilation slots in your appliance/tool/

charger using a soft brush or dry cloth.

Regularly clean the motor housing using a damp cloth. Do

not use any abrasive or solvent-based cleaner.

Protecting the environment

Z

Separate collection. This product must not be

disposed of with normal household waste.

needs replacement, or if it is of no further use to you, do not

dispose of it with household waste. Make this product available for separate collection.

z

Separate collection of used products and packaging allows materials to be recycled and used again.

Re-use of recycled materials helps prevent

environmental pollution and reduces the demand

for raw materials.

Local regulations may provide for separate collection of electrical products from the household, at municipal waste sites or

by the retailer when you purchase a new product.

Black & Decker provides a facility for the collection and

recycling of Black & Decker products once they have reached

the end of their working life. To take advantage of this service

please return your product to any authorised repair agent who

will collect them on our behalf.

You can check the location of your nearest authorised repair

the address indicated in this manual. Alternatively, a list of

authorised Black & Decker repair agents and full details of our

after-sales service and contacts are available on the Internet

at: www.2helpU.com

Technical data

Voltage V

AC

230

No-load speed min

-1

10,000-22,000

Oscillating angle Degrees

1.4 or 2.8

Power

W

300

Weight

kg 1.53

Level of sound pressure according to EN 60745:

Sound pressure (LpA) 90 dB(A), uncertainty (K) 3 dB(A)

Sound power (LWA) 101 dB(A), uncertainty (K) 3 dB(A)

Vibration total values (triax vector sum) according to EN 60745:

Cutting wood (a

h, CW

) 4.5 m/s2, uncertainty (K) 1.5 m/s

2

Cutting metal (a

h, CM

) 10.3 m/s2, uncertainty (K) 1.5 m/s

2

Sanding (ah) 11.4 m/s2, uncertainty (K) 1.5 m/s

2

Australia & New Zealand

Stanley Black & Decker

82 Taryn Drive, Epping, VIC 3076 Australia

Tel.1800 338 002 (Aust) or Tel. 0800 339 258 (NZ)

90591195 09/12

BMT300-XE/BMT300KA-XE

Loading...

Loading...