Page 1

ENFRAR

www.blackanddecker.ae

BDGL2223

Page 2

ENGLISH

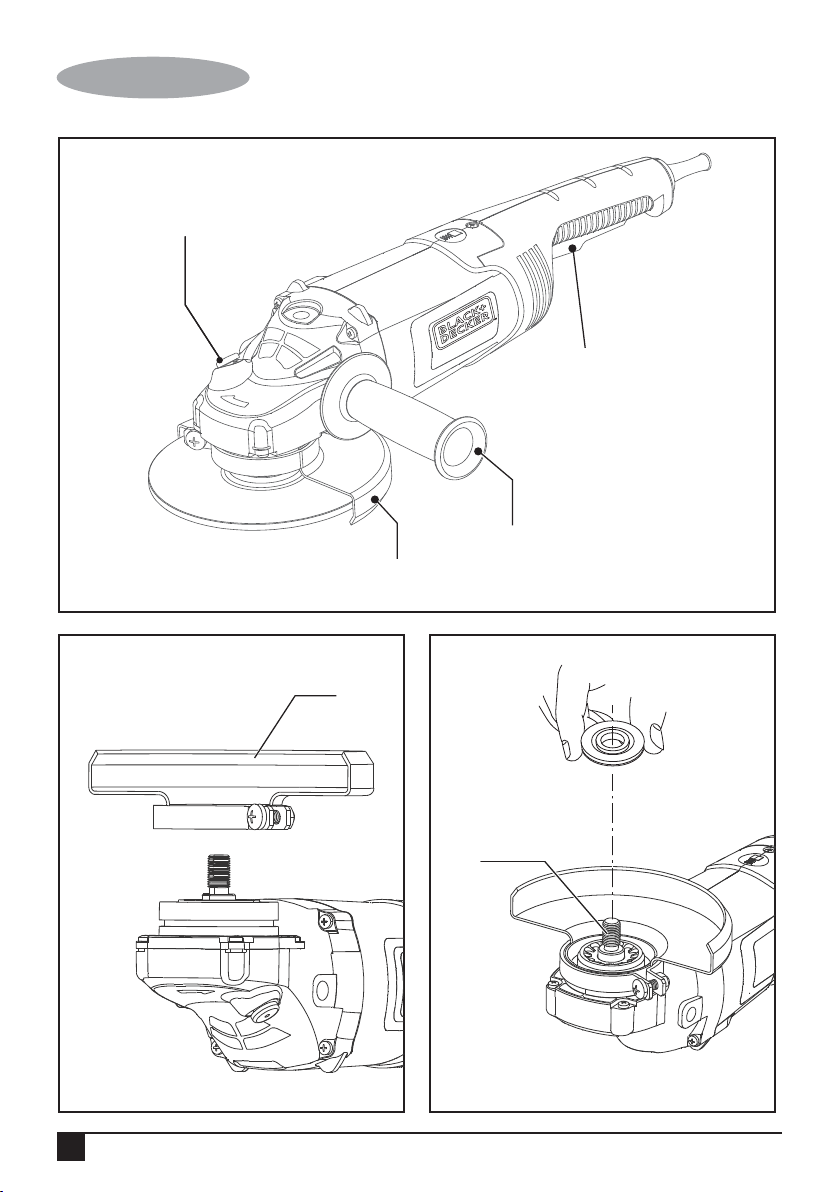

FIG A

(Original instructions)

2

1

4

3

5

FIG B

2

20

3

6

7

FIG C1

Page 3

(Original instructions)

ENGLISH

FIG

6

C2

10

8

9

7

3

10

8

6

7

10

8

6

7

FIG

C3

FIG

10

D

11

10

o

90

4

FIG

E

3

Page 4

ENGLISH

FIG

(Original instructions)

o

15o-30

A B

F

FIG

4

G

Page 5

(Original instructions)

ENGLISH

Definitions: Safety Guidelines

The definitions below describe the level of

severity for each signal word. Please read

the manual and pay attention to these

symbols.

Danger: Indicates an imminently

hazardous situation which, if not

avoided, will result in death or

serious injury.

Warning: Indicates a potentially

hazardous situation which, if not

avoided, could result in death or

serious injury.

Caution: Indicates a potentially

hazardous situation which, if not

avoided, may result in minor or

moderate injury.

Notice: Indicates a practice not related to

personal injury which, if not avoided, may

result in property damage.

Denotes risk of electric shock.

Denotes risk of fire.

Warning: To reduce the risk of

injury, read the instruction manual.

General power tool safety warnings

Warning! Read all safety warnings

and all instructions. Failure to follow

the warnings and instructions may

serious injury.

Save all warnings and instructions for

future reference The term “power tool” in

the warnings refers to your mains-operated

(corded) power tool or battery-operated

(cordless) power tool.

1) Work area safety

a) Keep work area clean and well lit.

b) Do not operate power tools in explosive

result in electric shock, fire and/or

Cluttered or dark areas invite accidents.

atmospheres, such as in the presence of

flammable liquids, gases or dust. Power

tools create sparks which may ignite the

dust or fumes.

c) Keep children and bystanders away

while operating a power tool.

Distractions can cause you to lose

control.

2) Electrical safety

a) Power tool plugs must match the outlet.

Never modify the plug in any way. Do

not use any adapter plugs with earthed

(grounded) power tools. Unmodified

plugs and matching outlets will reduce

risk of electric shock.

b) Avoid body contact with earthed or

grounded surfaces such as pipes,

radiators, ranges and refrigerators.

There is an increased risk of electric

shock if your body is earthed or

grounded.

c) Do not expose power tools to rain or

wet conditions. Water entering a power

tool will increase the risk of electric

shock.

d) Do not abuse the cord. Never use the

cord for carrying, pulling or unplugging

the power tool. Keep cord away from

heat, oil, sharp edges or moving parts.

Damaged or entangled cords increase

the risk of electric shock.

e) When operating a power tool outdoors,

use an extension cord suitable for

outdoor use. Use of a cord suitable for

outdoor use reduces the risk of electric

shock.

f) If operating a power tool in a damp

location is unavoidable, use a residual

current device (RCD) protected supply.

Use of an RCD reduces the risk of electric

shock.

3) Personal safety

a) Stay alert, watch what you are doing

and use common sense when operating

a power tool. Do not use a power tool

while you are tired or under the

influence of drugs, alcohol or

medication. A moment of inattention

while operating power tools may result in

serious personal injury.

5

Page 6

ENGLISH

(Original instructions)

b) Use personal protective equipment.

Always wear eye protection. Protective

equipment such as dust mask, non-skid

safety shoes, hard hat, or hearing

protection used for appropriate

conditions will reduce personal injuries.

c) Prevent unintentional starting. Ensure

the switch is in the o position before

connecting to power source and/or

battery pack, picking up or carrying the

tool. Carrying power tools with your

finger on the switch or energising power

tools that have the switch on invites

accidents.

d) Remove any adjusting key or wrench

before turning the power tool on. A

wrench or a key left attached to a

rotating part of the power tool may

result in personal injury.

e) Do not overreach. Keep proper footing

and balance at all times. This enables

better control of the power tool in

unexpected situations.

f) Dress properly. Do not wear loose

clothing or jewellery. Keep your hair,

clothing and gloves away from moving

parts. Loose clothes, jewellery or long

hair can be caught in moving parts.

g) If devices are provided for the

connection of dust extraction and

collection facilities, ensure these are

connected and properly used. Use of

dust collection can reduce dust-related

hazards.

4) Power tool use and care

a) Do not force the power tool. Use the

correct power tool for your application.

The correct power tool will do the job

better and safer at the rate for which it

was designed.

b) Do not use the power tool if the switch

does not turn it on and o. Any power

tool that cannot be controlled with the

switch is dangerous and must be

repaired.

c) Disconnect the plug from the power

source and/or the battery pack from the

power tool before making any

adjustments, changing accessories, or

storing power tools. Such preventive

safety measures reduce the risk of

starting the power tool accidentally.

d) Store idle power tools out of the reach

of children and do not allow persons

unfamiliar with the power tool or these

instructions to operate the power tool.

Power tools are dangerous in the hands

of untrained users.

e) Maintain power tools. Check for

misalignment or binding of moving

parts, breakage of parts and any other

condition that may aect the power

tool’s operation. If damaged, have the

power tool repaired before use. Many

accidents are caused by poorly

maintained power tools.

f) Keep cutting tools sharp and clean.

Properly maintained cutting tools with

sharp cutting edges are less likely to

bind and are easier to control.

g) Use the power tool, accessories and tool

bits etc., in accordance with these

instructions taking into account the

working conditions and the work to be

performed. Use of the power tool for

operations dierent from those intended

could result in a hazardous situation.

5) Service

a) Have your power tool serviced by a

qualified repair person using only

identical replacement parts. This will

ensure that the safety of the power tool

is maintained.

Additional specific safety rules

Safety instructions for all operations

Safety warnings common for grinding

a) This power tool is intended to function

as a grinder. Read all safety warnings,

instructions, illustrations and

specifications provided with this power

tool. Failure to follow all instructions

listed below may result in electric shock,

fire and/or serious injury.

b) Operations such as cutting-o , sander,

wire brush or polisher are not

recommended to be performed with

this power tool. Operations for which

the power tool was not designed may

create a hazard and cause personal

injury.

6

Page 7

(Original instructions)

ENGLISH

c) Do not use accessories which are not

specifically designed and recommended

by the tool manufacturer. Just because

the accessory can be attached to your

power tool, it does not assure safe

operation.

d) The rated speed of the accessory must

be at least equal to the maximum speed

marked on the power tool. Accessories

running faster than their rated speed can

break and fly apart.

e) The outside diameter and the thickness

of your accessory must be within the

capacity rating of your power tool.

Incorrectly sized accessories cannon be

adequately guarded or controlled.

f) The arbour size of wheels, flanges,

backing pads or any other accessory

must properly fit the spindle of the

power tool. Accessories with arbour

holes that do not match the mounting

hardware of the power tool will run out

of balance, vibrate excessively and may

cause loss of control.

g) Do not use a damaged accessory.

Before each use inspect the accessory

such as abrasive wheel for chips and

cracks, backing pad for cracks, tear or

excess wear, wire brush for loose or

cracked wires. If power tool or

accessory is dropped, inspect for

damage or install an undamaged

accessory. After inspecting and

installing an accessory, position yourself

and bystanders away from the plane of

the rotating accessory and run the

power tool at maximum no-load speed

for one minute. Damaged accessories

will normally break apart during this test

time.

h) Wear personal protective equipment.

Depending on application, use face

shield, safety goggles or safety glasses.

As appropriate, wear dust mask, hearing

protectors, gloves and workshop apron

capable of stopping small abrasive or

workpiece fragments. The eye

protection must be capable of stopping

flying debris generated by various

operations. The dust mask or respirator

must be capable of filtrating particles

generated by your operation. Prolonged

exposure to high intensity noise may

cause hearing loss.

i) Keep bystanders a safe distance away

from work area. Anyone entering the

work area must wear personal

protective equipment. Fragments of

workpiece or of a broken accessory may

fly away and cause injury beyond

immediate area of operation.

j) Hold the power tool by insulated

gripping surfaces only, when performing

an operation where the cutting

accessory may contact hidden wiring or

its own cord. Cutting accessory

contacting a “live” wire may make

exposed metal parts of the power tool

“live” and could give the operator an

electric shock.

k) Position the cord clear of the spinning

accessory. If you lose control, the cord

may be cut or snagged and your hand or

arm may be pulled into the spinning

accessory.

l) Never lay the power tool down until the

accessory has come to a complete stop.

The spinning accessory may grab the

surface and pull the power tool out of

your control.

m) Do not run the power tool while

carrying it at your side. Accidental

contact with the spinning accessory

could snag your clothing, pulling the

accessory into your body.

n) Regularly clean the power tool’s air

vents. The motor’s fan will draw the dust

inside the housing and excessive

accumulation of powdered metal may

cause electrical hazards.

o) Do not operate the power tool near

flammable materials. Sparks could ignite

these materials.

p) Do not use accessories that require

liquid coolants. Using water or other

liquid coolants may result in

electrocution or shock.

Further safety instructions for all

operations

Kickback and Related Warnings

Kickback is a sudden reaction to a pinched

or snagged rotating wheel, backing pad,

brush or any other accessory. Pinching or

snagging causes rapid stalling of the

rotating accessory which in turn causes the

uncontrolled power tool to be forced in the

direction opposite of the accessory’s

rotation at the point of the binding.

7

Page 8

ENGLISH

(Original instructions)

For example, if an abrasive wheel is

snagged or pinched by the workpiece, the

edge of the wheel that is entering into the

pinch point can dig into the surface of the

material causing the wheel to climb out or

kick out. The wheel may either jump toward

or away from the operator, depending on

direction of the wheel’s movement at the

point of pinching. Abrasive wheels may also

break under these conditions. Kickback is

the result of tool misuse and/or incorrect

operating procedures or conditions and can

be avoided by taking proper precautions as

given below:

a) Maintain a firm grip on the power tool

and position your body and arm to

allow you to resist kickback forces.

Always use auxiliary handle, if provided,

for maximum control over kickback or

torque reaction during start up. The

operator can control torque reaction or

kickback forces, if proper precautions are

taken.

b) Never place your hand near the rotating

accessory. Accessory may kickback over

your hand.

c) Do not position your body in the area

where power tool will move if kickback

occurs. Kickback will propel the tool in

direction opposite to the wheel’s

movement at the point of snagging.

d) Use special care when working corners,

sharp edges etc. Avoid bouncing and

snagging the accessory. Corners, sharp

edges or bouncing have a tendency to

snag the rotating accessory and cause

loss of control or kickback.

e) Do not attach a saw chain woodcarving

blade or toothed saw blade. Such blades

create frequent kickback and loss of

control.

Safety Warnings Specific for

Grinding Operations

a) Use only wheel types that are

recommended for your power tool and

the specific guard designed for the

selected wheel. Wheels for which the

power tool was not designed cannot be

adequately guarded and are unsafe.

b) The guard must be securely attached to

the power tool and positioned for

maximum safety, so the least amount of

wheel is exposed towards the operator.

The guard helps to protect operator from

broken wheel fragments and accidental

contact with wheel and sparks that could

ignite clothing.

c) Wheels must be used only for

recommended applications. For

example: do not grind with the side of

cut-o wheel. Abrasive cut-o wheels

are intended for peripheral grinding, side

forces applied to these wheels may

cause them to shatter.

d) Always use undamaged wheel flanges

that are of correct size and shape for

your selected wheel. Proper wheel

flanges support the wheel thus reducing

the possibility of wheel breakage.

Flanges for cut-o wheels may be

dierent from grinding wheel flanges.

e) Do not use worn down wheels from

larger power tools. Wheel intended for

larger power tool is not suitable for the

higher speed of a smaller tool and may

burst.

Residual Risks

In spite of the application of the relevant

safety regulations and the implementation

of safety devices, certain residual risks

cannot be avoided. These are:

– Impairment of hearing

– Risk of personal injury due flying

particles.

– Risk of burns due to accessories

becoming hot during

operation.

– Risk of personal injury due to

prolonged use.

– Risk of dust from hazardous

substances.

8

Page 9

(Original instructions)

ENGLISH

Labels on tool

The label on your tool may include the

following symbols along with the date code:

Read

Instructions

Manual

Use Eye

Protection

Use Ear

Protection

V ........ Volts

A ........ Amperes

Hertz

W ........ Watts

min ..... minutes

..... Alternating

Current

..... Direct

Current

n0 ....... No-Load

Speed

...... Class II

Construction

.... Earthing

Terminal

.... Safety Alert

Symbol

.../min.. Revolutions

or Reciprocation per

minute

Hz .......

Position of date barcode

The Date Code, which also includes the year

of manufacture, is printed into the housing.

Example:

2014 XX JN

Year of manufacturing

Package Content

This product package includes:

1 Angle grinder

1 Guard

1 Flange set

1 Spanner

1 Handle

1 Instruction manual

• Check the tool, parts, and accessories to

see if they are damaged during

transportation.

• Take a few moments to read and

understand this manual before using the

tool.

Description (Fig. 1)

Warning: Never modify the power

tool or any part of the tool,

otherwise it may cause damage to

the tool or result in personal injury.

a. ON/OFF switch

b. Spindle lock

c. Guard

Purpose of design

This angle grinder is designed especially for

grinding. Do not use sandpaper discs and

grinding wheels other than those with

depressed center. Do not use the tool in wet

conditions or environments in the presence

of flammable liquids or gases. This

heavy-duty angle grinder is a professional

power tool. Do not allow children to come in

contact with this tool. Inexperienced

operators are required to use this tool under

supervision.

Electrical Equipment Safety

Only one voltage is applicable to this

tool. Be sure to check that the power

suuply corresponds to the voltage on

the rating plate. Your BLACK+DECKER tool

is equipped with double insulation, hence, it

does not require to be earthed. When the

power cord is damaged, have it sent to a

BLACK+DECKER service center for

replacement to specially prepared cables.

Using Extension Cords

If an extension cord is required, please

select a 3-phase extension cord that has

been inspected and matches the input

power (see Technical Data) of this tool. The

minimum conductor size is 1.5mm2,

maximum length is 30 meters. When using

a cable reel, be sure to pull out all the

cables.

Assembly and Adjustment

Warning: To minimize the danger of

serious personal injury, please

switch o the tool power and

disconnect all plugs before adjusting or

removing/installing any accessory. Before

reassembling the tool, press and release the

trigger switch to make sure the tool is

already switched o.

Attaching and Removing the Wheel Guard

(Fig. B)

Warning To minimize the danger of

serious personal injury, please

switch o the tool power and

disconnect all plugs before adjusting or

removing/installing any accessory. Before

reassembling the tool, press and release the

trigger switch to make sure the tool is

already switched o.

9

Page 10

ENGLISH

(Original instructions)

Attaching the guard

1. Place the angle grinder on a work bench,

groove facing up.

2. Bring the flange of the guard (3) collar

over the groove (11) of the gear housing.

3. Turn the guard (4) counterclockwise by

150 degrees.

4. Make sure that the screws (20) are

tightened.

Removing the guard

1. Loosen the screws (20) on the guard

collar.

2. Pull up the guard (3).

Warning: Do not operate the tool

when the safety guard is not in place.

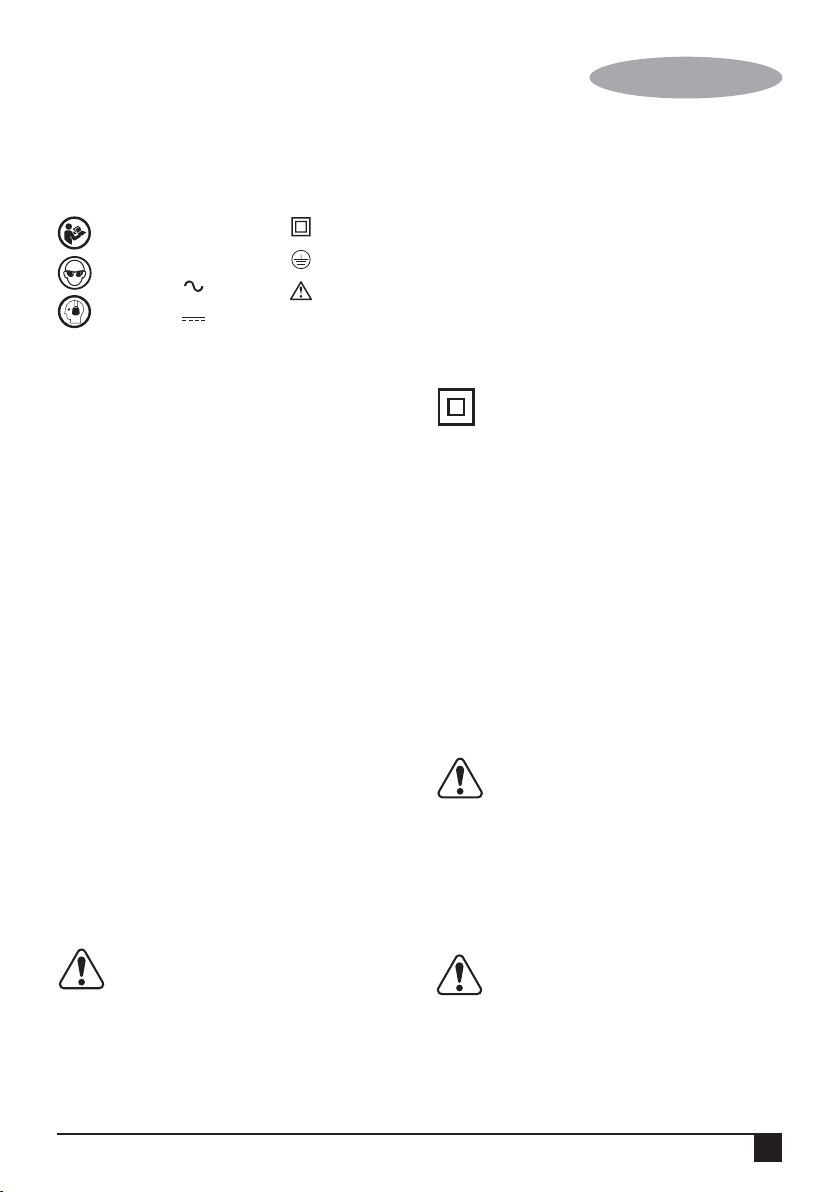

Fitting and removing a grinding (Fig. C1,

C2, C3)

Warning: Do not use damaged

grinding wheels.

1. Place the tool on a work bench, guard up.

2. Fit the inner flange (6) correctly onto the

spindle (7)

(Fig. C1).

3. Place the disc (8) on the flange (6)

(Fig.C2). When fitting a disc with a raised

center, make sure that the raised centre

(9) is facing the flange (6).

4. Screw the out flange (10) onto the

spindle (7) (Fig. C3)

- the ring on the flange (10) must fae

towoards the disc when fitting a grinding

disc (A)

- the ring on the flange (10) must face

away from the disc when fitting a cutting

disc (B)

5. Press the spindle lock (2) and rotate the

spindle (7) until it locks in position (Fig.

C2).

6. Tighten the flange (10) with the two-pin

spanner supplied.

7. Release the spindle lock.

8. To remove the disc, loosen the flange

(10) with the two-pin spanner.

Warning: Do not use a damaged

disc.

Mounting the side handle (Fig.D)

• For grinding, screw the side handle (4)

tightly into one of the holes (11) or (12) on

either side of the gear case.

Preparation Before Use

• Attach the safety guard and appropriate

abrasive or grinding wheels. Do not use

abrasive or grinding wheels that are

overly worn.

• Make sure that the inner and outer

flanges are attached correctly.

• Make sure that the abrasive or grinding

wheels are rotating in the direction of the

arrows on the accessories and tool.

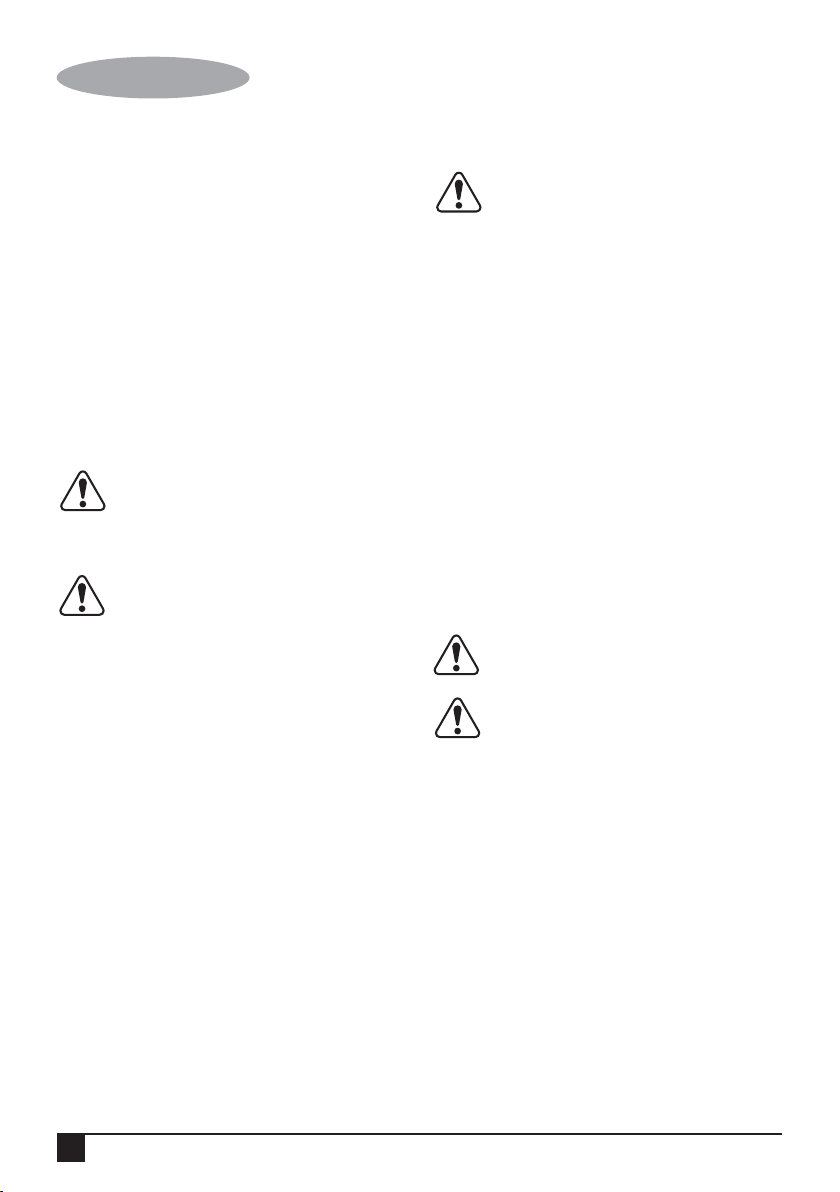

Operation (Fig. F)

Instructions

Warning: Always observe the safety

instructions and applicable

regulations.

Warning: To minimize the danger of

serious personal injury, please

switch o the tool power and

disconnect all plugs before adjusting or

removing/installing any accessory. Before

reassembling the tool, press and release the

trigger switch to make sure the tool is

already switched o.

Warning:

• Make sure all materials to be grinded are

secured in position.

• Apply slight pressure to the tool. Do not

apply side pressure to the abrasive disc.

• Avoid overloading. If the tool becomes

hot, let it spin for a few minutes with no

load.

1. Be sure to hold the tool tightly with both

hands (one hand on housing, the other

on side handle). Start the tool and bring

the grinding wheel on the workpiece.

10

Page 11

(Original instructions)

ENGLISH

2. Keep the edge of the wheel tilted at

angle from 15 to 30 degrees against the

surface of the workpiece.

3. When using a new grinding wheel, do not

operate the wheel in the B direction,

otherwise, it will cut into the workpiece.

When the edge of wheel has been

rounded o, you are free to operate the

grinder in either the A or B direction.

Starting and Stopping (Fig. A)

Warning: Before using the tool, check

whether the handle is tightened

securely. Check whether the ON/OFF

switch is working normally.

Before plugging in the tool to the power

supply, check whether the switch is in the

OFF position when pressing the rear end of

the switch.

To start the tool, press the rear end of the

switch and slide it forward. Then press the

front end of the switch to lock it. Press the

rear end of the switch to stop the tool.

Warning: Do not switch the tool on

or o while under load conditions.

Proper Hand Position (Fig. G)

Warning: To reduce the risk of

serious personal injury, ALWAYS use

proper hand position as shown.

Warning: To reduce the risk of

serious personal injury, ALWAYS hold

securely in anticipation of a sudden

reaction.

Proper hand position requires one hand on

the side handle (figure A), with the other

hand on the body of the tool, as shown in

figure G.

Switches

Caution: Hold the body of the tool

firmly to maintain control of the tool

at start up and during use and until

the wheel or accessory stops rotating. Make

sure the wheel has come to a complete stop

be fore laying the tool down.

Note: To reduce unexpected tool

movement, do not switch the tool on or o

while under load conditions. Allow the

grinder to run up to full speed before

touching the work surface. Lift the tool from

the surface before turning the tool o.

Allow the tool to stop rotating before

putting it down.

ON/OFF switch (1) with auto-lock(Fig. A)

Warning: Before connecting the tool

to a power supply, be sure the slider

switch is in the o position by

pressing the front part of the switch and

releasing. Ensure the slider switch is in the

o position as described above after any

interruption in power supply to the tool,

such as the activation of a ground fault

interrupter, throwing of a circuit breaker,

accidental unplugging, or power failure. If

the slider switch is locked on when the

power is connected, the tool will start

unexpectedly.

To start the tool, slide the slider switch 1

toward the front of the tool and press, the

tool will keep running. Release pressure

from the switch and the tool will stop.

Lock feature of the ON/OFF switch

Slide slider switch 1 to the front of the tool

and press, and the tool will start. When

releasing the switch, keep the switch

pressed down and push it to the front of the

tool, and the tool will keep running. To turn

o the tool, press the front portion of the

switch to release it. The switch will spring

up, which means that the tool is in the

o-state.

Explanation: Before coming into contact

with the object you are working on, make

sure the abrasive wheel is turning at

maximum speed. Before turning o the tool,

lift the tool up from the object you are

working on.

Caution: Make sure the abrasive

wheel is completely stopped before

putting down the tool.

Rotating the Gear Case (fig. E)

The gear case is mounted onto the tool

casing, and it can be rotated to give the

user a more comfortable experience while

cutting.

The rotating gear case can be turned 90

degrees, 180 degrees, and 270 degrees to

the left or to the right.

• Loosen the four screws on the gear case.

11

Page 12

ENGLISH

• Rotate the gear case till it reaches its

ideal location.

• Tighten the four screws on the gear case.

• Ensure that the rotating mechanism is

locked.

Warning: Do NOT use the tool when

the gear case is unlocked.

Application on Metals

When applying the tool on metals, make

sure that a residual-current device (RCD) is

inserted to prevent danger from metal

chips.

If the RCD causes power disconnection,

have the tool sent to an authorized

BLACK+DECKER dealer for repair.

Warning: Under extreme working

conditions, conductive dust and grit

may accumulate on the housing

interior when handling metal workpieces.

This could create an electric shock hazard

as it weakens the protective insulation in the

grinder.

To avoid accumulation of metal chips in the

interior of the grinder, we recommend

cleaning the ventilation ducts daily. Refer to

Maintenance.

(Original instructions)

Using Grinding Wheels

Warning: Metal powder accumulates.

Excessive use of the grinding wheel

on metals may increase the risk of

electric shock. To reduce the risk, insert the

RCD before use and clean the ventilation

ducts daily. Follow the maintenance

instructions below to blow dry compressed

air into the ventilation ducts.

Maintenance

BLACK+DECKER power tools have been

designed to operate over a long period of

time with minimal maintenance. Continuous

satisfactory operation depends upon proper

tool care and regular cleaning.

Warning: To minimize the danger

of serious personal injury, please

switch o the tool power and

disconnect all plugs before

adjusting or removing/installing any

accessory. Before reassembling the tool,

press and release the trigger switch to make

sure the tool is already switched o.

Lubrication

This power tool does not require separate

lubrication.

Cleaning

Warning: Once visible dust

accumulates on the ventilation ducts

and the surrounding, immediately use

dry air to blow away dust and grit out of the

interior of the housing. You need to wear

approved eye and facial protective gear

when performing this process.

Warning: Never use solvents or harsh

chemicals to clean non-metal parts

of the tool. These chemicals may

weaken the material of the parts. Use only

mild soap and damp cloth to clean the tool.

Never let any liquid get inside the tool;

never immerse any part of the tool into

liquid.

Accessories

Warning: Excluding accessories

provided by BLACK+DECKER, all

other accessories have not been

tested for product compatibility. Using such

accessories together with this tool may

cause safety hazards. To minimize the risk

of personal injury, we recommend you to

use only BLACK+DECKER accessories with

this product.

Please inquire at your dealer for more

information regarding suitable accessories.

Remarks

• BLACK+DECKER's policy is one of

continuous improvement to our products

and as such, we reserve the right to

modify product specifications without

prior notice.

• Standard equipment and accessories

may vary by country.

• Product specifications may differ by

country.

12

Page 13

(Original instructions)

ENGLISH

• Complete product range may not be

available in all countries. Contact your

local BLACK+DECKER dealers for range

availability.

Specifications

BDGL2223

Input voltage VAC 220-240

Power input W 2200

Frequency Hz 50/60

No-load speed min-1 6500

Wheel diameter mm 230

Spindle size M14

Max disc thickness

Grinding discs mm 6.6

Weight kg 6.0

Protecting the environment

Separate collection. This product

must not be disposed of with normal

household waste.

Should you find one day that your

BLACK+DECKER product needs

replacement, or if it is of no further use to

you, do not dispose of it with household

waste. Make this product available for

separate collection.

Separate collection of used products

and packaging allows materials to be

recycled and used again. Reuse of recycled

materials helps prevent environmental

pollution and reduces the demand for raw

materials.

Local regulations may provide for separate

collection of electrical products from the

household, at municipal waste sites or by

the retailer when you purchase a new

product.

BLACK+DECKER provides a facility for the

collection and recycling of BLACK+DECKER

products once they have reached the end of

their working life. To take advantage of this

service please return your product to any

authorised repair agent who will collect

them on our behalf.

You can check the location of your nearest

authorised repair agent by contacting your

local BLACK+DECKER oce at the address

indicated in this manual. Alternatively, a list

of authorised BLACK+DECKER repair

agents and full details of our after-sales

service and contacts are available on the

Internet at: www.2helpU.com.

13

Page 14

ENGLISH

(Original instructions)

Guarantee

Black + Decker is confident of the quality of

its products and oers an outstanding

guarantee. This guarantee statement is in

addition to and in no way prejudices your

statutory rights. The guarantee is valid

within the territories of the Member States

of the European Union and the European

Free Trade Area.

If a Black + Decker product becomes

defective due to faulty materials,

workmanship or lack of conformity, within

24 months from the date of purchase,

BLACK+DECKER guarantees to replace

defective parts, repair products subjected to

fair wear and tear or replace such products

to make sure of the minimum inconvenience

to the customer unless:

• The product has been used for trade,

professional or hire purposes.

• The product has been subjected to

misuse or neglect.

• The product has sustained damage

through foreign objects, substances or

accidents.

• Repairs have been attempted by persons

other than authorised repair agents or

Black + Decker service sta.

To claim on the guarantee, you will need to

submit proof of purchase to the seller or an

authorised repair agent. You can check the

location of your nearest authorised repair

agent by contacting your local

BLACK+DECKER oce at the address

indicated in this manual. Alternatively, a list

of authorised BLACK+DECKER repair agents

and full details of our aftersales service and

contacts are available on the Internet at:

www.2helpU.com

Please visit our website

www.blackanddecker.co.uk to register your

new Black + Decker product and to be kept

up to date on new products and special

oers. Further information on the Black +

Decker brand and our range of products is

available at www.blackanddecker.co.uk.

14

Page 15

(Instructions initiales)

FRANÇAIS

Définitions: Consignes de sécurité

Les définitions données ci-dessous

décrivent le niveau de gravité pour chaque

symbole. Veuillez lire ce manuel et prêter

attention à ces symboles.

Danger: Indique une situation

extrêmement dangereuse qui, si

elle n’est pas évitée, aura pour

conséquence des blessures

corporelles graves ou mortelles.

Attention: Indique une situation

potentiellement dangereuse qui, si

elle n’est pas évitée, aura pour

conséquence des blessures

corporelles graves ou mortelles.

Avertissement: Indique une

situation potentiellement

dangereuse qui, si elle n’est pas

évitée, aura pour conséquence des

blessures corporelles légères ou de gravité

modérée.

Avis: Indique une pratique non reliée à des

blessures corporelles qui, si elle n’est pas

évitée, aura pour conséquence des

dommages matériels.

Indique un risque de choc

électrique.

Indique un risque d’incendie.

Attention: Pour réduire le risque de

blessures corporelles, lire ce manuel

d’instructions.

Consignes générales de sécurité

concernant les outils électroportatifs

Attention! Lire avec attention tous

les avertissements et toutes les

instructions. Le non-respect des

avertissements et des instructions indiquées

ci-dessous peut entraîner un choc

électrique, un incendie et/ou des blessures

graves

Conservez ces consignes et ces

instructions pour référence ultérieure.

La notion "d’outil électroportatif"

mentionnée par la suite se rapporte à des

outils électriques raccordés au secteur

(avec câble) ou fonctionnant avec piles

(sans fil).

1. Sécurité de la zone de travail

a. Maintenir la zone de travail propre et

bien éclairée. Un lieu de travail en

désordre ou mal éclairé augmente le

risque d’accidents.

b. Ne pas utiliser d’outils électroportatifs

dans un environnement présentant des

risques d’explosion ni en présence de

liquides, gaz ou poussières

inflammables. Les outils électroportatifs

génèrent des étincelles risquant

d’enflammer les poussières ou les

vapeurs.

c. Pendant l’utilisation d’un outil

électroportatif, les enfants et autres

personnes présentes doivent rester

éloignés. En cas d’inattention, vous

risquez de perdre le contrôle de l’outil.

2. Sécurité électrique

a. La fiche de l’outil électrique doit être

compatible avec la prise d’alimentation,

Ne modifiez la fiche en aucun cas.

N’utilisez pas d’adaptateurs avec des

outils ayant une prise de terre. Le

respect de ces consignes réduit le risque

de choc électrique.

b. Eviter le contact physique avec des

surfaces mises à la terre telles que

tuyaux, radiateurs, fours et réfrigérateurs.

Le risque de choc électrique augmente si

votre corps est relié à la terre.

c. Ne pas exposer les outils

électroportatifs à la pluie ou à

l’humidité. La pénétration d’eau dans un

outil électroportatif augmente le risque

de choc électrique.

d. Ne pas maltraiter le câble

d’alimentation. Ne jamais utiliser le

câble pour porter l’outil, et ne le tirez

pas pour débrancher l’outil. Maintenir le

câble éloigné des sources de chaleur, de

la graisse, des bords coupants et des

pièces en rotation. Un câble endommagé

ou emmêlé augmente le risque de choc

électrique.

e. Lorsque vous utilisez l’outil

électroportatif à l’extérieur, utilisez une

rallonge homologuée pour une

utilisation à l’extérieur. L’utilisation d’une

rallonge électrique homologuée pour les

travaux à l’extérieur réduit le risque de

choc électrique.

f. Si l’outil doit être utilisé dans un endroit

humide, utilisez un dispositif diérentiel

à courant résiduel (DDR). L’utilisation

d’un tel dispositif réduit le risque de choc

électrique.

15

Page 16

FRANÇAIS

(Instructions initiales)

3. Sécurité personnelle

a. Restez vigilant, surveillez ce que vous

faites et faites preuve de bon sens

quand vous utilisez un outil. N’utilisez

pas un outil électroportatif lorsque vous

êtes fatigué ou après avoir consommé

de l’alcool ou pris des médicaments. Un

moment d’inattention en utilisant l’outil

peut entraîner de graves blessures.

b. Portez un équipement de protection.

Portez toujours des lunettes de

protection. Selon le travail à eectuer, le

port d’un équipement de protection tel

que masque anti-poussières, chaussures

de sécurité antidérapantes, casque ou

protection auditive, réduit le risque de

blessures.

c. Evitez tout démarrage imprévu.

L’interrupteur de l’outil doit être en

position d’arrêt (o) avant d’eectuer le

branchement à l’alimentation et/ou au

bloc batterie, de ramasser l’outil ou de

le porter. Porter ou brancher un outil

électrique dont l’interrupteur est en

position Marche (on) est une invite à

l’accident.

d. Retirez les outils ou les clés de réglage

avant de mettre l’outil en marche. Une

clé ou un outil se trouvant sur une partie

en rotation peut causer des blessures.

e. Adoptez une position confortable.

Adoptez une position stable et gardez

votre équilibre en permanence. Vous

contrôlerez mieux l’outil dans des

situations inattendues.

f. Portez des vêtements appropriés. Ne

portez pas de vêtements amples ou de

bijoux. N’approchez pas les cheveux,

vêtements ou gants des pièces en

mouvement. Les vêtements amples, les

bijoux ou les cheveux longs peuvent

s’accrocher dans les pièces en

mouvement.

g. En cas d’utilisation d’appareils servant à

aspirer ou à recueillir les poussières,

assurez-vous qu’ils sont correctement

raccordés et utilisés. L’utilisation de tels

dispositifs réduit les dangers dus aux

poussières.

4. Utilisation des outils électroportatifs et

précautions

a. Respectez la capacité de l’outil. Utilisez

l’outil approprié pour le travail à

eectuer. Avec un outil approprié, vous

travaillerez mieux et en toute sécurité.

b. N’utilisez pas un outil électroportatif

dont l’interrupteur marche/arrêt est

défectueux. Un outil électroportatif qui

ne répond pas à la commande

marche/arrêt est dangereux et doit être

réparé.

c. Retirez la fiche de la prise de courant

et/ou débranchez le bloc-batterie avant

d’eectuer des réglages, de changer les

accessoires ou de ranger l’outil. Cette

mesure de précaution empêche de

mettre l’outil en marche

accidentellement.

d. Rangez les outils électroportatifs hors

de la portée des enfants et les

personnes ne connaissant pas l’outil ne

doivent en aucun cas l’utiliser. Les outils

électroportatifs sont dangereux lorsqu’ils

sont utilisés par des personnes non

initiées.

e. Entretenez les outils électroportatifs.

Vérifiez que les parties en mouvement

fonctionnent correctement et qu’elles ne

sont pas coincées. Vérifiez qu’il n’y a pas

de pièces cassées ou endommagées

susceptibles de nuire au bon

fonctionnement de l’outil. S’il est

endommagé, faites réparer l’outil avant

de l’utiliser. De nombreux accidents sont

la conséquence d’outils mal entretenus.

f. Les outils de coupe doivent toujours

être aiguisés et propres. Des outils

soigneusement entretenus avec des

bords tranchants bien aiguisés se

coincent moins souvent et peuvent être

guidés plus facilement.

g. Utilisez l’outil électroportatif, les

accessoires et les forets, etc.,

conformément à ces instructions, en

tenant compte des conditions de travail

et des tâches à eectuer. L'utilisation des

outils électroportatifs à d’autres fins que

celles prévues peut entrainer des

situations dangereuses

5. Réparations

a. Faites réparer votre outil électroportatif

uniquement par du personnel qualifié et

seulement avec des pièces de rechange

appropriées. Cela garantira le maintien

de la sécurité de votre outil.

Consignes de sécurité spécifiques

supplémentaires

Consignes de sécurité pour l’ensemble des

opérations

16

Page 17

(Instructions initiales)

FRANÇAIS

Conseils de sécurité courants pour le

meulage

a) Cet outil électroportatif est conçu pour

être utilisé comme meuleuse. Lire avec

attention tous les avertissements, les

instructions, les illustrations et les

spécifications données avec cet outil. Le

anon-respect des instructions indiquées

ci-dessous peut entraîner un choc

électrique, un incendie et/ou de graves

blessures.

b) Cet outil n’est pas recommandé pour

des opérations telles que scier, poncer,

nettoyer avec une brosse métallique ou

polir. L’utilisation à d’autres fins que

celles prévues présente un danger et

peut causer des blessures graves.

c) Seuls les accessoires spécialement

conçus et recommandés par le fabricant

doivent être utilisés. Même si un

accessoire peut être fixé à l’outil, cela ne

signifie pas que votre outil fonctionnera

en toute sécurité.

d) La vitesse nominale doit être au moins

égale à la vitesse maximale inscrite sur

l’outil. Les accessoires dont la rotation

est plus rapide que leur vitesse nominale

peuvent se briser et éclater en plusieurs

morceaux.

e) Le diamètre extérieur et l’épaisseur de

votre accessoire doivent correspondre à

la capacité nominale de votre outil

électroportatif. Il est impossible de

garantir la protection ou le contrôle des

accessoires de dimension incorrecte.

f) La dimension de l’alésage central des

disques, des flasques, du plateau

porte-disques ou d’autres accessoires

doit correspondre exactement à l’axe de

l’outil. Les accessoires dont l’alésage

central ne correspond pas au matériel de

fixation de l’outil peuvent être diciles à

contrôler. Le niveau de vibrations peut

augmenter et provoquer la perte du

contrôle de l’outil.

g) N’utilisez pas d’accessoires

endommagés. Avant toute utilisation,

vérifiez l’état de tous les accessoires, la

présence d’éclats ou de fissures sur les

disques polisseurs, de fissures ou une

usure excessive sur le plateau

porte-disques, de poils de brosse

métallique endommagés. Si l’outil ou

l’accessoire tombe, vérifiez leur état et

le cas échéant, installez un accessoire

en bon état. Apres inspection et

l’installation d’un accessoire,

tenez-vous, ainsi que toute personne

présente, hors du plan de rotation de

l’accessoire et laissez tournez l’outil

pendant une minute à sa vitesse à vide

maximale. En général, tout accessoire

endommagé se brisera lors du temps

d’essai.

h) Portez un équipement de protection. En

fonction du travail à eectuer, utilisez un

masque ou des lunettes de protection.

Le cas échéant, portez un masque

anti-poussières, des protections

auditives, des gants et un tablier de

travail afin de vous protéger des

éventuels éclats. En protégeant vos yeux,

vous éviterez les éclats créés pendant le

travail. En portant un masque

anti-poussières, vous éviterez de respirer

les particules créées pendant le travail.

Une exposition prolongée aux bruits trop

puissants peut entraîner la perte de l’ouïe.

i) Pour le maintien de la sécurité, éloignez

les personnes autour de la zone de

travail. Toute personne entrant dans la

zone de travail doit porter un

équipement de protection. Des éclats de

la pièce usinée ou d’un accessoire cassé

peuvent être projetés au-delà de la zone

de travail et causer des blessures.

j) Tenez l’outil uniquement au niveau des

surfaces isolées, lorsque vous eectuer

un travail qui pourrait mettre l’outil de

coupe en contact avec des fils cachés ou

son propre câble. En touchant un fil sous

tension, la charge électrique passe dans

les parties métalliques de l’outil

électroportatif et il y a risque de choc

électrique.

k) Eloignez le câble des accessoires en

rotation. Si vous perdez le contrôle, le

câble peut être coupé ou s’accrocher et

votre main ou votre bras peut se trouver

entrainé dans l’accessoire en rotation.

l) Ne posez jamais l’outil avant l’arrêt

complet de l’accessoire. L’accessoire en

rotation peut s’accrocher à la surface, ce

qui vous ferait perdre le contrôle de

l’outil.

m) Ne mettez pas l’outil en marche lorsque

vous le transportez. L’accessoire en

rotation peut attraper vos vêtements et

vous blesser.

n) Nettoyez régulièrement les fentes

d’aération de l’outil. Le ventilateur du

moteur entraîne la poussière à l’intérieur

de l’outil et une accumulation excessive

de la poudre de métal peut causer des

accidents liés à l’électricité.

17

Page 18

FRANÇAIS

(Instructions initiales)

o) Ne faites pas fonctionner l’outil à

proximité de matières inflammables. Les

étincelles risquent d’enflammer ces

matières.

p) N’utilisez pas d’accessoires nécessitant

un liquide de refroidissement.

L’utilisation d’eau ou d’un autre liquide

de refroidissement peut entrainer un

choc électrique ou une électrocution.

Consignes de sécurité

supplémentaires pour l’ensemble

des opérations

Eet de retour et avertissements

L’eet de retour est une réaction soudaine

d’un disque en rotation, d’un plateau

porte-disques ou de tout autre accessoire

coincé ou accroché. Ce genre de problème

arrête rapidement l’accessoire de rotation.

L’outil devient alors incontrôlable et est

entraîné en direction inverse de la rotation.

Par exemple, si un disque polisseur est

accroché ou coincé par la pièce à usiner, le

bord du disque qui se trouve au point de

pincement peut creuser la surface du

matériau, ce qui provoque une mauvaise

rotation du disque. Le disque peut être

éjecté vers l’utilisateur ou à l’opposé selon

la direction du mouvement du disque au

point de pincement. Les disques polisseurs

peuvent aussi se casser dans ce type de

situation. L’eet de retour est le résultat

d’une utilisation inappropriée de l’outil voire

de procédures ou de conditions d’utilisation

incorrectes. Ceci peut être évité en

appliquant les précautions adéquates,

décrites ci-dessous:

a. En maintenant fermement l’outil, placez

votre corps et votre bras de manière à

pouvoir résister à la puissance du

moteur. Utilisez toujours la poignée

auxiliaire lorsqu’elle est fournie, pour

contrôler au maximum l’eet de retour

ou la réaction de couple au démarrage.

L’utilisateur peut contrôler les réactions

de couple ou les forces de retour, si les

précautions nécessaires sont prises.

b. Ne placez jamais votre main à côté de

l’accessoire en rotation. L’accessoire

peut se retourner sur votre main.

c. Ne vous placez pas dans la zone de

déplacement de l’outil si un eet de

retour se produit. L’eet de retour

pousse l’outil dans la direction opposée

au mouvement du disque au point

d’accrochage.

d. Prenez les précautions nécessaires pour

travailler dans les coins, les arêtes vives,

etc. Evitez de coincer ou de faire

rebondir l’accessoire. Les coins, les

arêtes vives ou les à-coups ont tendance

à coincer l’accessoire en rotation et à

causer la perte de contrôle ou un eet de

retour.

e) Ne fixez pas une lame de sculpture ou

une lame de scie dentée. Ce genre de

lames crée fréquemment un eet de

retour et la perte de contrôle.

Conseils de sécurité spécifiques

pour les opérations de meulage

a) N’utilisez que les types de disque

recommandés pour votre outil et la

protection spécifique au disque

sélectionné. Les disques destinés à

d’autres outils ne peuvent être protégés

correctement et par conséquent sont

dangereux

b) La protection doit être correctement

fixée à l’outil, en exposant le disque le

moins possible vers l’utilisateur pour le

protéger au maximum. La protection

permet de protéger l’utilisateur des

éclats, d’un contact accidentel avec le

disque et des étincelles qui pourraient

enflammer les vêtements.

c) Les disques ne doivent être utilisés que

pour les applications recommandées.

Par exemple: ne meulez pas avec le côté

du disque de coupe. Les disques abrasifs

sont destinés au meulage périphérique,

des forces latérales auraient pour

conséquence de les briser.

d) N’utilisez que des flasques en bon état,

de dimension et de forme appropriées à

votre disque. Les flasques de disque

appropriés soutiennent le disque, ce qui

limite le risque de casse. Les flasques des

disques de coupe peuvent être diérents

de ceux des disques de meulage.

e) N’utilisez pas de disques usés pris sur

des meuleuses plus grandes. Les disques

destinés aux grandes meuleuses ne sont

pas adaptés aux vitesses rapides des

petites meuleuses et peuvent se

décrocher.

18

Page 19

(Instructions initiales)

FRANÇAIS

Risques résiduels

Même en respectant les consignes de

sécurité applicables et en utilisant des

dispositifs de sécurité, certains risques

résiduels ne peuvent pas être évités. Sont

inclus:

– Troubles auditifs

– Blessures causées par la projection

d’éclats.

– Brûlures causées par les accessoires

devenant chauds pendant l’utilisation.

– Blessures causées par l’utilisation

prolongée d’un outil.

– Poussières contenant des substances

nocives.

Etiquettes apposées sur l’outil

L’étiquette apposée sur votre outil peut

contenir les symboles suivants:

Lire le m anuel

d’instruc tions

Utili ser une

protectio n

ocula ire

Utiliser des

protectio ns

auditives

V ........ Volts

A ........

Ampères

W ........

min .....

n

.......

0

.....

.....

Hertz

Watts

minutes

Courtant

alternati f

Courant

continu

Vitesse à

vide

......

Construct ion

de classe II

....

Borne de

terre

Symbole

d’alerte

de sécuri té

Rotations

par minut e

....

.../min..

Hz .......

Position of date barcode

Le code de la date, comprenant aussi

l’année de fabrication, est imprimé sur le

boîtier de l’outil. Exemple:

2014 XX JN

Année de fabrication

Contenu de la boîte

La boîte de cet outil contient:

1 Meuleuse d’angle

1 Carter de protection

1 Jeu de flasques

1 Clé

1 Poignée

1 Manuel d’instructions

• Contrôlez visuellement l’outil, les pièces

et les accessoires pour vérifier qu’ils n’ont

pas été endommagés pendant le

transport.

• Prenez quelques instants pour lire et

assimiler les instructions données dans ce

manuel avant d’utiliser cet outil.

Description (Fig. 1)

Attention: Ne modifiez jamais un

outil électrique ou une partie de

l’outil, cela pourrait l’endommager et

entraîner des blessures corporelles.

a. Interrupteur Marche/Arrêt

b. Blocage de l’axe

c. Carter de protection

Objectif de conception

Cette meuleuse d’angle est conçue

spécialement pour le meulage.

N’utilisez pas de disques abrasifs ou de

meulage autres que ceux dont le centre est

incurvé.

N’utilisez pas l’outil dans un milieu humide

ou à proximité de liquides ou de gaz

inflammables.

Cette meuleuse d’angle ultra robuste est un

outil électrique professionnel.

Ne laissez pas les enfants manipuler cet

outil. Les opérateurs inexpérimentés doivent

être surveillés lorsqu’ils utilisent cet outil.

Sécurité électrique des

équipements

Le moteur électrique a été conçu

pour une tension spécifique. Vérifiez

correspond à celle indiquée sur la plaque

signalétique. Votre outil BLACK+DECKER

est doublement isolé et de ce fait, ne

nécessite pas un branchement à la terre.

Lorsque le câble d’alimentation est

endommagé, envoyez-le dans un centre de

réparations BLACK+DECKER pour qu’il soit

remplacé par un câble spécialement

préparé.

toujours que la tension secteur

19

Page 20

FRANÇAIS

(Instructions initiales)

Utilisation d’un cordon

prolongateur

Si l’utilisation d’un cordon prolongateur est

nécessaire, veuillez utiliser une rallonge à 3

phases qui a été vérifiée et dont la

puissance nominale correspond à l’outil

(voir Données techniques). La taille

minimale du conducteur est de 1,5mm2 avec

une longueur maximale de 30 mètres.

Si vous utilisez un enrouleur de câble,

déroulez toujours le câble entièrement.

Assemblage et réglage

Attention! Pour minimiser le risque

de blessures corporelles graves,

toutes les fiches avant de régler ou

d’enlever/ajouter un accessoire. Avant de

remonter l’outil, appuyez sur le déclencheur

puis relâchez-le pour vous assurer que

l’outil est bien éteint.

Installation et retrait du carter de

protection (Fig. B)

toutes les fiches avant de régler ou

d’enlever/ajouter un accessoire. Avant de

remonter l’outil, appuyez sur le déclencheur

puis relâchez-le pour vous assurer que

l’outil est bien éteint.

Installation du carter de protection

1. Placez la meuleuse d’angle sur un banc

2. Alignez le flasque de la collerette du

3. Faites pivoter le carter (4) dans le sens

4. Assurez-vous que les vis (20) sont

Retrait du carter de protection

1. Desserrez les vis (20) sur la collerette du

2. Retirez le carter de protection (3).

veuillez éteindre et débrancher

Attention! Pour minimiser le risque

de blessures corporelles graves,

veuillez éteindre et débrancher

de travail, rainure vers le haut.

carter (3) sur la rainure (11) du boîtier

d’engrenage.

antihoraire de 150 degrés.

serrées.

carter.

Attention! Ne faites pas fonctionner

l’outil sans le carter de protection en

place

Installation et retrait du disque de meulage

(Fig. C1, C2, C3)

Attention! N’utilisez pas de disques

de meulage endommagés.

1. Placez l’outil sur un banc de travail, carter

de protection vers le haut.

2. Installez le flasque intérieur (6)

correctement sur l’axe (7) (Fig. C1).

3. Placez le disque (8) sur le flasque (6)

(Fig. C2). Lorsque vous installez un

disque avec un centre relevé,

assurez-vous que le centre relevé du

disque (9) est orienté vers le flasque (6).

4. Vissez fermement le flasque extérieur

(10) sur l’axe (7) (Fig. C3).

- Lorsque vous installez un disque de

meulage (A), l’anneau situé sur le flasque

(10) doit être orienté vers le disque.

- l’anneau sur le flasque (10) doit être

orienté à l’opposé du disque lorsque vous

installez un disque de coupe (B)

5. Maintenez le blocage de l’axe (2) enfoncé

et faites pivoter l’axe (7) jusqu’à ce qu’il

s’enclenche en position (Fig. C2).

6. Serrez le flasque (10) avec la clé à ergots

fournie.

7. Relâchez le blocage de l’axe.

8. Pour retirer le disque, desserrez le

flasque (10) avec la clé à deux ergots.

Attention! N’utilisez pas de disques

endommagés.

Installation de la poignée latérale (Fig.D)

• Pour meuler, vissez fermement la poignée

latérale (4) dans l’un des trous (11) ou (12)

situés de chaque côté du boîtier

d’engrenage.

Préparation avant l’utilisation

• Installez le carter de protection et les

disques abrasifs ou de meulage

appropriés. N’utilisez pas de disques

abrasifs ou de meulage usés à l’excès.

• Assurez-vous que les flasques intérieur et

extérieur sont correctement installés.

20

Page 21

(Instructions initiales)

FRANÇAIS

• Assurez-vous que les disques abrasifs ou

de meulage tournent dans le sens des

flèches présentes sur les accessoires et

l’outil.

Fonctionnement (Fig. F)

Instructions

Attention! Respectez toujours les

consignes de sécurité et la

réglementation en vigueur.

Attention! Pour minimiser le risque

de blessures corporelles graves,

veuillez éteindre et débrancher

toutes les fiches avant de régler ou

d’enlever/ajouter un accessoire. Avant de

remonter l’outil, appuyez sur le déclencheur

puis relâchez-le pour vous assurer que

l’outil est bien éteint.

Attention:

• Assurez-vous que tous les matériaux à

meuler sont arrimés en place.

• Appliquez une légère pression sur l’outil.

N’exercez pas de pression latérale sur le

disque de meulage.

• Evitez de surcharger l’outil. Si l’outil

devient chaud, laissez-le tourner à vide

pendant quelques minutes.

1. Maintenez fermement l’outil avec vos

deux mains (une main sur le boîtier,

l’autre sur la poignée latérale). Mettez

l’outil en marche et approchez le disque

de la meuleuse sur la pièce à meuler.

2. Conservez un angle de 15 à 30 degrés

entre le bord du disque et la surface de

la pièce.

3. Lorsque vous utilisez un disque à meuler

neuf, ne faites pas fonctionner le disque

dans la direction B, sinon il risque de

couper dans la pièce à meuler. Lorsque le

bord du disque s’est arrondi, vous

pouvez alors faire fonctionner le disque

dans la direction A ou B.

Mise en marche et arrêt (Fig. A)

Attention! Avant d’utiliser l’outil,

vérifiez que la poignée est

correctement serrée. Vérifiez que

l’interrupteur Marche/Arrêt fonctionne

normalement.

en appuyant sur l’extrémité arrière de

l’interrupteur.

Pour démarrer l’outil, appuyez sur

l’extrémité arrière de l’interrupteur et

faites-le glisser vers l’avant. Puis appuyez

sur l’extrémité avant de l’interrupteur pour le

verrouiller. Appuyez sur l’extrémité arrière

de l’interrupteur pour arrêter l’outil.

Attention! Ne mettez pas l’outil hors

ou sous tension lorsqu’il est sous

charge.

Position correcte des mains (Fig. G)

Attention! Pour réduire le risque de

blessures corporelles graves, placez

TOUJOURS vos mains correctement

comme indiqué.

Attention! Pour réduire le risque de

blessures corporelles graves,

maintenez TOUJOURS l’outil

fermement en anticipation d’une réaction

soudaine.

Une position correcte des mains demande

une main sur la poignée latérale (figure A),

et l’autre main sur le corps de l’outil, comme

le montre la figure G.

Interrupteurs

Avertissement: Maintenez fermement

le corps de l’outil pour en garder le

contrôle au démarrage et pendant

son utilisation, et jusqu’à l’arrêt du disque ou

d’un accessoire. Veillez à attendre l’arrêt

complet avant de reposer l’outil.

Remarque: Pour réduire le risque

d’un mouvement inattendu de l’outil,

ne le mettez pas hors ou sous tension

pendant qu’il est sous charge. Laissez la

meuleuse atteindre sa pleine vitesse avant

de toucher la surface à meuler. Soulevez

l’outil de la pièce avant de l’éteindre.

Attendre l’arrêt complet de l’outil avant de

le poser.

Interrupteur Marche/Arrêt (1) avec

verrouillage automatique (Fig. A)

Attention! Avant de brancher l’outil

au secteur, vérifiez que l’interrupteur

à glissière est bien en position arrêt

en appuyant sur l’extrémité avant de

l’interrupteur puis en le

Avant de brancher l’outil au secteur, vérifiez

que l’interrupteur est bien en position Arrêt

21

Page 22

FRANÇAIS

(Instructions initiales)

relâchant. Vérifiez que l’interrupteur à

glissière est en position arrêt comme décrit

ci-dessus après une interruption de

l’alimentation électrique de l’outil, comme

l’activation d’un détecteur de fuite à la terre,

d’un coupe-circuit, un débranchement

involontaire ou une panne électrique. Si

l’interrupteur à glissière est bloqué lorsque

l’outil est sous tension, l’outil peut

redémarrer de manière inattendue.

Pour démarrer l’outil, faites glisser

l’interrupteur à glissière (1) vers l’avant de

l’outil et appuyez dessus, l’outil fonctionnera

en continu, relâchez la pression sur

l’interrupteur pour arrêter l’outil.

Fonction de verrouillage de l’interrupteur

Marche/Arrêt

Pour démarrer l’outil faites glisser

l’interrupteur à glissière (1) vers l’avant de

l’outil et appuyez dessus. Lorsque vous

relâchez l’interrupteur, gardez-le enfoncé en

le poussant vers l’avant et l’outil continuera

de fonctionner. Pour éteindre l’outil,

appuyez sur la partie avant de l’interrupteur

pour le relâcher. L’interrupteur remonte ce

qui indique que l’outil est en position arrêt.

Explication: Laissez le disque abrasif arriver

à sa vitesse maximale avant d’entrer en

contact avec la pièce à usiner. Avant

d’éteindre l’outil, soulevez d’abord le disque

de la pièce à usiner.

Avertissement: Attendre l’arrêt

complet du disque avant de poser

l’outil.

Rotation du boîtier d’engrenage (fig. E)

Le boîtier d’engrenage est monté sur le

corps de l’outil et il peut être tourné pour

donner plus de confort à l’utilisateur

pendant une opération de coupe.

Le boîtier d’engrenage rotatif peut être

incliné de 90 degrés, 180 degrés, ou 270

degrés sur la gauche ou sur la droite.

• Desserrer les quatre vis du boîtier

d’engrenage.

• Faire pivoter le boîtier d’engrenage

jusqu’à la position idéale.

• Serrer les quatre vis du boîtier

d’engrenage.

• Vérifier que le mécanisme de rotation est

verrouillé.

Attention: NE PAS utiliser l’outil

lorsque le boîtier d’engrenage est

déverrouillé.

Meulage de métaux

Lorsque vous meulez des métaux,

assurez-vous que le dispositif de courant

résiduel (RCD) est inséré pour éviter tout

danger provenant des copeaux métalliques.

Si le RCD provoque la suppression de

l’alimentation, faites réparer l’outil dans un

centre de service agréé BLACK+DECKER.

Attention! Dans des conditions de travail

extrêmes, la poussière et les salissures

conductrices peuvent s’accumuler à

l’intérieur du boîtier lorsque vous meulez

des pièces métalliques. Cela pourrait créer

un risque de choc électrique car l’isolation

protectrice de la meuleuse en serait aaiblit.

Pour éviter l’accumulation de copeaux

métalliques à l’intérieur de la meuleuse,

nous vous recommandons de nettoyer les

orifices d’aération tous les jours.

Reportez-vous au chapitre sur l’entretien.

Utilisation des disques de

meulage

Attention : La poudre métallique

s’accumule. Une utilisation excessive

du disque de meulage sur métaux

peut augmenter le risque de choc

électrique. Pour réduire ce risque, insérez le

RCD avant d’utiliser l’outil et nettoyez les

aérations quotidiennement. Suivez les

instructions d’entretien données ci-dessous

pour souer de l’air comprimé dans les

orifices d’aération.

Entretien

Les outils électriques ont été conçus pour

fonctionner sur une longue période de

temps avec un minimum d’entretien. Un

fonctionnement continu satisfaisant dépend

d’un nettoyage et d’un entretien soigneux et

régulier.

Attention: Pour minimiser le risque

de blessures corporelles graves,

veuillez éteindre et débrancher

toutes les fiches avant de régler ou

d’enlever/ajouter un accessoire. Avant de

remonter l’outil, appuyez sur le déclencheur

puis relâchez-le pour vous assurer que l’outil

est bien éteint

22

Page 23

(Instructions initiales)

Lubrification

Cet outil électroportatif ne nécessite pas

d’être lubrifié.

Nettoyage

Attention: Lorsque la poussière accumulée

sur et autour des aérations est visible,

utilisez immédiatement un soueur d’air

pour chasser la poussière et les salissures

de l’intérieur du boîtier. Vous devez porter

un équipement de protection approuvé

pour les yeux et le visage pour eectuer ce

processus de nettoyage.

Attention: N’utilisez jamais de

solvants ou de produits chimiques

agressifs pour nettoyer les parties

non-métalliques de l’outil. Ces produits

chimiques peuvent aaiblir le matériau ou

les pièces. Utilisez seulement un détergent

doux et un chion humide pour nettoyer

cet outil. Ne laissez jamais de liquide

pénétrer à l’intérieur de l’outil; n’immergez

jamais une partie de l’outil dans un liquide.

Accessoires

Attention: A l’exception des

accessoires fournis par

BLACK+DECKER, la compatibilité

de tous les autres accessoires avec cet outil

n’a pas été testée. L’utilisation de ce type

d’accessoires avec cet outil peut entraîner

un danger. Pour minimiser le risque de

blessures corporelles, nous vous

recommandons d’utiliser uniquement des

accessoires BLACK+DECKER avec cet outil.

Pour plus de renseignements concernant les

accessoires appropriés, prenez contact avec

votre revendeur.

Remarques

• BLACK+DECKER mène une politique

d’amélioration continue de ses produits

et se réserve de ce fait, le droit d’en

modifier les caractéristiques sans préavis.

• Les équipements d’origine et les

accessoires peuvent varier d’un pays à

l’autre.

FRANÇAIS

• Les caractéristiques d’un produit peuvent

varier d’un pays à l’autre.

• La gamme complète des produits peut

ne pas être oerte dans tous les pays.

Contactez votre revendeur

BLACK+DECKER pour connaître la

disponibilité de la gamme.

Spécifications

BDGL2223

Tension d’entrée VAC 220-240

Puissance W 2200

Fréquence Hz 50/60

Aucune vitesse de charge min-1 6500

Diamètre du disque mm 230

Diamètre de l’axe M14

Épaisseur du disque Max

Epaisseur du disque de meulage

Poids kg 6.0

mm 6.6

23

Page 24

FRANÇAIS

(Instructions initiales)

Protection de l'environnement

Collecte séparée. Ce produit ne doit

pas être jeté avec les déchets

domestiques normaux.

Si vous décidez de remplacer ce produit

BLACK+DECKER, ou si vous n'en avez plus

l'utilité, ne le jetez pas avec vos déchets

domestiques Rendez-le disponible pour une

collecte séparée.

La collecte séparée des produits et

emballages usés permet le recyclage

des articles afin de les utiliser à nouveau. Le

fait d'utiliser à nouveau des produits recyclés

permet d'éviter la pollution

environnementale et de réduire lademande

de matières premières.

Les réglementations locales peuvent

permettre la collecte séparée des produits

électriques du foyer, dans des déchetteries

municipales ou auprès du revendeur vous

ayant vendu votre nouveau produit.

BLACK+DECKER fournit un dispositif

permettant de collecter et de recycler les

produits BLACK+DECKER lorsqu'ils ont

atteint la fin de leur cycle de vie. Pour

pouvoir profiter de ce service, veuillez

retourner votre produit à un réparateur

agréé qui se chargera de le collecter pour

nous.

Pour connaître l'adresse du réparateur agréé

le plus proche de chez vous, contactez le

bureau BLACK+DECKER à l'adresse indiquée

dans ce manuel. Vous pourrez aussi trouvez

un liste des réparateurs agréés de

BLACK+DECKER et de plus amples détails

sur notre service après-vente sur le site

Internet à l'adresse suivante :

www.2helpU.com

Garantie

BLACK+DECKER vous assure la qualité de

ses produits et vous ore une garantie très

étendue.

Ce certificat de garantie est un document

supplémentaire et ne peut en aucun cas se

substituer à vos droits légaux.

La garantie est valable sur tout le territoire

des États Membres de l'Union Européenne

et de la Zone de Libre Échange Européenne.

Si un produit BLACK+DECKER s'avère

défectueux en raison de matériaux en

mauvais état, d'une erreur humaine, ou d'un

manque de conformité dans les 24 mois

suivant la date d'achat, BLACK+DECKER

garantit le remplacement des pièces

défectueuses, la réparation des produits

usés ou cassés ou remplace ces produits à

la convenance du client, sauf dans les

circonstances suivantes :

• Le produit a été utilisé dans un but

commercial, professionnel, ou a été loué.

• Le produit a été mal utilisé ou avec

négligence.

• Le produit a subi des dommages à cause

de corps étrangers, de substances ou

d'accidents.

• Des réparations ont été tentées par des

techniciens ne faisant pas partie du

service technique de BLACK+DECKER.

Pour avoir recours à la garantie, il est

nécessaire de fournir une preuve d'achat au

vendeur ou à un réparateur agréé.

Pour connaître l'adresse du réparateur agréé

le plus proche de chez vous, contactez le

bureau BLACK+DECKER à l'adresse

indiquée dans ce manuel. Vous pourrez

aussi trouver une liste de réparateurs agréés

de BLACK+DECKER et de plus amples

détails sur notre service après-vente sur le

site Internet à l'adresse suivante :

www.2helpU.com

Visitez notre site Web

www.blackanddecker.eu pour enregistrer

votre nouveau produit BLACK+DECKER et

être informé des nouveaux produits et des

offres spéciales. Pour plus d'informations

concernant la marque BLACK+DECKER et

notre gamme de produits, consultez notre

site www.blackanddecker.eu.

24

Page 25

(

á«°ù«FôdG äɪ«∏©àdG

)

ﺔﻴﺑﺮﻌﻟﺍ

¿Éª°†dG

¿ƒµjh .kGõ«‡ kÉfɪ°V Ωó≤Jh É¡JÉéàæe IOƒéH ôµjO ófBG ∑ÓH ≥ãJ

∫GƒMC’G øe ∫ÉM …CÉH πîj ’h áaÉ°VE’ÉH Gòg ¿Éª°†dG ¿É«H

∫hódG º«∏bEG πNGO ¿Éª°†dG Gòg …öùjh .á«fƒfÉ≤dG ¥ƒ≤◊ÉH

.á«HhQhC’G Iô◊G IQÉéàdG á≤£æeh »HQhC’G OÉ–E’G ‘ AÉ°†YC’G

OGƒŸG ܃«Y ÖÑ°ùH kÉÑ«©e ôµjO ófBG ∑ÓH èàæe íÑ°UCG GPEG

24 ¿ƒ°†Z ‘ ôµjO ófBG ∑ÓH øª°†J ,á≤HÉ£ŸG ΩóYh áYÉæ°üdGh

ìÓ°UEGh áÑ«©ŸG AGõLC’G ∫GóÑà°SG AGöûdG ïjQÉJ øe kGô¡°T

√тg ∫GуСа°SG hCG …OЙ©dG ΩGуоа°S’ЙH »∏СdG IЙYGфe ™e дЙйажŸG

:⁄ Йe AУª©dG Й°VQ шe уcCЙа∏d дЙйажŸG

.ÒLCÉà∏d hCG á«æ¡e hCG ájQÉŒ ¢VGôZC’ èàæŸG ΩGóîà°SG ” •

.èàæŸG ΩGóîà°SG IAÉ°SEG hCG ∫ɪgEG •

hCG á«HôZ ¢VGôZCG hCG OGƒe ÖÑ°ùH ∞∏àd èàæŸG ¢Vô©J •

.çOGƒ◊G

¢UÉî°TC’G πÑb øe ìÓ°UE’G äÉ«∏ªY AGôLEG ádhÉfi •

≥jôa hCG º¡H ìöüŸG ìÓ°UE’G AÓch ±ÓîH øjôNB’G

.ôµjO ófBG ∑ÓÑd ™HÉàdG áeóÿG

π«ch hCG ™FÉÑ∏d AGöûdG äÉÑKEG Ëó≤J Öéj ,¿Éª°†dÉH áÑdÉ£ª∏d

óªà©e ìÓ°UEG π«ch ÜôbCG ¿Éµe áaô©e ∂æµÁh .óªà©ŸG ™«ÑdG

‘ ¬«dEG QÉ°ûŸG ¿Gƒæ©dG ‘ »∏ëŸG ôµjO ófBG ∑ÓH Öàµe á©LGôÃ

∑ÓH iód øjóªà©ŸG ìÓ°UE’G AÓcƒH áªFÉb ôaƒàJ ɪc .π«dódG

™bƒŸG ≈∏Y ∫É°üJ’Gh ™«ÑdG ó©H Ée äÉeóN äÉfÉ«Hh ôµjO ófBG

.www.2helpU.com :ÊhεdE’G

ÊhεdE’G Éæ©bƒe á©LGôe ≈Lôj

ójó÷G ∂éàæe π«é°ùàd www.blackanddecker.co.uk

.б°UЙяG ¢Vhф©dGh дЙйажŸG зуMCG бaф©Ÿh фµjO уfBG ∑УH шe

фµjO уfBG ∑УH бeУY ∫ƒM дЙeƒ∏©ŸG шe уjхŸG ≈∏Y ∫ƒ°ьл∏dh

.www.blackanddecker.co.uk IQÉjR ≈Lôj ,ÉæJÉéàæeh

25

Page 26

ﺔﻴﺑﺮﻌﻟﺍ

(

á«°ù«FôdG äɪ«∏©àdG

)

áÄ«ÑdG ájɪM

™e èàæŸG Gòg AÉ≤dEG ΩóY Öéj .π°üØæe ™«ªŒ

.á«dõæŸG äÉØ∏îŸG

ôµjO ófBG ∑ÓH RÉ¡L πjóÑJ Öéj ¬fCÉH ΩÉjC’G óMCG ‘ ∂d ÚÑJ GPEG

™e ¬æe ¢ü∏îàJ ’ .¬eGóîà°S’ áLÉëH ó©J ⁄ hCG ∂H ¢UÉÿG

.π°üØæŸG ™«ªéà∏d èàæŸG Gòg ÒaƒàH ºbh .á«dõæŸG äÉØ∏îŸG

дGƒС©dGh дЙйажª∏d π°ьШжŸG ™«ªйаdG шµБ

Iôe É¡eGóîà°SGh OGƒŸG ôjhóJ IOÉYEG øe áeóîà°ùŸG

™æe ≈∏Y ÉgôjhóJ OÉ©ŸG OGƒŸG ΩGóîà°SG IOÉYEG óYÉ°ùj PEG ,iôNCG

ΩÉÿG OGƒŸG ≈∏Y Ö∏£dG ¢†ØNh »Ä«ÑdG çƒ∏àdG

дЙйажª∏d π°ьШжe ™«ªŒ ≈∏Y б«∏лŸG дЙ©jцыаdG ¢ьжJ уb

hCG ájó∏ÑdG äÉØ∏fl ™bGƒe ‘ á«dõæŸG äÉØ∏îŸG øY á«FÉHô¡µdG

.ójóL èàæe AGöT óæY áFõéàdG ôLÉJ

∑УH дЙйажe фjhуJ IOЙYEGh ™«ªйаd ICЙ°ыжe фµjO уfBG ∑УH фaƒJ

.™aЙжdG ЙgфªY бjЙ¡жd дЙйажŸG ∂∏J ∫ƒ°Uh ужY фµjO уfBG

π«ch …CG ¤EG èàæŸG IOÉYEG ≈Lôj ,áeóÿG √òg øe IOÉØà°SÓdh

.ЙжY бHЙ«f дЙйажŸG ™«ªйаH Ωƒ≤«°S …тdG уªа©e мУ°UEG

Öàµe á©LGôà óªà©e ìÓ°UEG π«ch ÜôbCG ¿Éµe áaô©e ∂æµÁ

ɪc .π«dódG ‘ ¬«dEG QÉ°ûŸG ¿Gƒæ©dG ‘ »∏ëŸG ôµjO ófBG ∑ÓH

ôµjO ófBG ∑ÓH iód øjóªà©ŸG ìÓ°UE’G AÓcƒH áªFÉb ôaƒàJ

:ÊhεdE’G ™bƒŸG ≈∏Y ∫É°üJ’Gh ™«ÑdG ó©H Ée äÉeóN äÉfÉ«Hh

.www.2helpU.com

ﻰﺟﺮﹸﻳ ،ﺯﺎﻬﺠﻠﻟ ﺔﺒﺳﺎﻨﳌﺍ ﺕﺎﻘﺤﻠﳌﺍ ﺹﻮﺼﺨﺑ ﺕﺎﻣﻮﻠﻌﳌﺍ ﻦﻣ ﺪﻳﺰﳌ

.ﻢﻜﺑ ﺹﺎﳋﺍ ﻲﻠﶈﺍ ﺔﺋﺰﺠﺘﻟﺍ ﻊﺋﺎﺑ ﺔﻌﺟﺍﺮﻣ

ﺕﺎﻈﺣﻼﻣ

،ﺭﺍﺮﻤﺘﺳﺎﺑ ﺎﻨﺗﺎﺠﺘﻨﻣ ﲔﺴﲢ ﻰﻠﻋ ﺮﻜﻳﺩ ﺪﻧﺁ ﻙﻼﺑ ﺔﺳﺎﻴﺳ ﺪﻤﺘﻌﺗ •

ﺕﺎﻔﺻﺍﻮﻣ ﺮﻴﻴﻐﺗ ﻲﻓ ﺎﻨﻘﺤﺑ ﻆﻔﺘﺤﻧ ﺎﻨﻧﺈﻓ ﻚﻟﺫ ﻰﻠﻋ ﹰﺀﺎﻨﺑﻭ

.ﺪﻠﺒﻟﺍ ﺐﺴﺣ ﺔﻴﺳﺎﻴﻘﻟﺍ ﺕﺎﻘﺤﻠﳌﺍﻭ ﺕﺍﺪﻌﳌﺍ ﻒﻠﺘﺨﺗ ﺪﻗ •

.ﺪﻠﺒﻟﺍ ﺐﺴﺣ ﺞﺘﻨﳌﺍ ﺕﺎﻔﺻﺍﻮﻣ ﻒﻠﺘﺨﺗ ﺪﻗ •

ﺔﻓﺎﻛ ﻲﻓ ﺓﺮﻓﻮﺘﻣ ﺔﻠﻣﺎﻜﻟﺍ ﺕﺎﺠﺘﻨﳌﺍ ﺔﻠﻴﻜﺸﺗ ﻥﻮﻜﺗ ﻻ ﺪﻗ •

ﻦﻣ ﻖﻘﺤﺘﻠﻟ ﺮﻜﻳﺩ ﺪﻧﺁ ﻙﻼﺑ ﻲﻋﺯﻮﻣ ﻊﻣ ﻞﺻﺍﻮﺘﻟﺍ ﻰﺟﺮﻳ .ﻝﻭﺪﻟﺍ

.ﻖﺒﺴﻣ ﺭﺎﻌﺷﺇ ﻥﻭﺩ ﺞﺘﻨﳌﺍ

.ﺕﺎﺠﺘﻨﳌﺍ ﺮﻓﺍﻮﺗ

ﺕﺎﻔﺻﺍﻮﳌﺍ

BDGL2223

٢٤٠-٢٢٠ ﺩﺩﺮﺘﻣ ﺭﺎﻴﺗ ﻂﻟﻮﻓ ﻞﺧﺪﻟﺍ ﺪﻬﺟ

٢٢٠٠ ﻁﺍﻭ ﺓﺭﺪﻘﻟﺍ ﻞﺧﺩ

٦٠-٥٠ ﺰﺗﺮﻴﻫ ﺩﺩﺮﺘﻟﺍ

٦٥٠٠ ١- ﺔﻘﻴﻗﺩ ﻞﻤﺣ ﻥﻭﺩ ﺔﻋﺮﺴﻟﺍ

٢٣٠ ﻢﻠﻣ ﺹﺮﻘﻟﺍ ﺮﻄﻗ

M١٤ ﻥﺍﺭﻭﺪﻟﺍ ﺭﻮﺤﻣ ﺮﻄﻗ

٦٫٦ ﻢﻠﻣ ﺦﻴﻠﺠﺘﻟﺍ ﺹﺍﺮﻗﺃ ﻚﻤﺳ

٦٫٠ ﻢﺠﻛ ﻥﺯﻮﻟﺍ

ﺹﺮﻘﻟﺍ ﺔﻛﺎﻤﺳ ﻰﺼﻗﺃ

26

Page 27

(

á«°ù«FôdG äɪ«∏©àdG

)

ﺔﻴﺑﺮﻌﻟﺍ

،ﺔﺧﻼﳉﺍ ﻦﻣ ﻲﻠﺧﺍﺪﻟﺍ ﺀﺰﳉﺍ ﻲﻓ ﺔﻴﻧﺪﻌﳌﺍ ﺎﻳﺎﻈﺸﻟﺍ ﻢﻛﺍﺮﺗ ﻱﺩﺎﻔﺘﻟ