Page 1

MAINTENANCE

LUBRICATION j

Self lubricating bearings are used in th^ tool land periodic relubricatiqn

is not required. However, it is recommeilided once a yepr, you ta^e

or send the tool to a B&D Service Center for a thorough cteaning, Inspec

tion and lubrication of the gear case. Service Center addresses are sho#i

on the guarantee card packed with your tool.

IMPORTANT

To assure product SAFETY and RELIABILITY, repairs, maintenance aCd

adjustment should be performed by Biabk &. Decker Service Centers ér

other qualified service organizations, always using Black & Decker

replacement parts.

RAPID EXCHANGE CONSUMER sj\TISEACTION GUARANTEE

Most Black & Decker consumer portable power tools pnd lawn-and«garden portable

power tools are guaranteed for one year froiC date iof purchase. If you are

completely satisfied with one of these products, you | will receive free of charge | a

replacement tool upon return of the original tool tolth® seller (If a partlcipatlf|g

retailer) or to a Black & Decker Service Centjer. i ^ "

in returning a tool for replacement proof-of-piirchas# is required and ail original

standard equipment must also be returned (for| example, chuck, chuck key, auxiliary

handies, circular saw blades). Expendable original : equipment such as sandiqg

sheets, belts and discs and jig saw blades need not be returned. For kits arid

assortments only the basic power tool will be ¡replaced. i

This Rapid Exchange Satisfaction Guarantee does not cover commerciai duty toolb,

home workshop and lawn-and-garden tools used In corrtmercial service, lawn mower|s,

stationary tools, tools used in rental service or accessories. On these products |a

one-year guarantee on defects will apply, excluding ajccessorles. j

ONE-YEAR GU/^RANtEE

Applicable to products not covered by the Rapid Exchange Consumer Satisfaction

Guarantee: Commercial Duty Tools, Home Workshop and Lawn*and*Garten Toops

used In Commercial Service, Stationary Tools LawO Mowers, and Tools used |n ^

Rental Service. 1 ^ !

Black & Decker guarantees for one year frolm date of purchase to correct by

repair or parts replacement without charge i any product defect due to faulty

material or workmanship on Commercial Duty toolb, home workshop and lawhand-garden tools used in commercial servlceJ stationary tools, lawn mowers, ^ pr

tools used In ■ rental service. Simply return] the complete unit, transportation

prepaid, to any Black & Decker Service Cepter or| Authorized Service Station.

Black & Decker assumes no responsibility for damage! or faulty perforipance caused

by misuse, careless handling, or where repairs hake been made or attempted

by others. 5 I

No other guarantees, written or verbal, are aiithorized, ' |

I !

1 ; ; I

' ' ' |

,

I

Eisv, ,4;P

iWiEil liilliL

EYE SHIELD

TOOL REST

.WHEEL GUARD

SWITCH

/•v.'civl

Me

&

RUBBER l-EET-

END COVER

W A.

3*5« C

i«3ig

C® *-+■ 3

ao Q.§

g rnm^

•.■■Oi-n-i :';o.

Zogo§

I OW$i

2 I’ ^ § 2

o ° ^ o 2.

^ » a »

O k-j

I 1 ^

Md. 21204, D M A .

jWirSwiHct % tilt

f

m

(j3

8 - S

5. 5 <

a ® »

Nf]

m m

If

$ 2

m 0

rt. ^

— to

0 -t

n ^

2-.S p

g rn

cn

O <

f“ CD

$ 3* »

3 E.

® cr »

'A z

O

0

T3

ri*

-1

S)

»

0

0

0

3*

3

0

y

0

cm

E

p

Q.

ce

n

m

a

’O

to

3

>

5

Q. X

m m

s «

m

“ ?

* m cr

O ^ c

*T| IS

: «5, 3

•

o

3 o

- i

< m

o ^

4 =

n<< J

•H C.

3- «

CT m

m ^

3* .

® 0

Ei’, 5

«> T3

w ^

? I

r? m

2 ®

®

3 o*

3 c

a

O o

O

3

3“

3-

3 H

m S'

3 m

® m

rt‘ fd

® lì

[S'

c o.

3

tx fA

3* Cb

...i^ Q

o

rv IT

"J* ®

•

« o

a 2.

il m

l§^

m S

j«+

3* ^

CP m

^ E

o

Co

3 o ®

il 8 3

S

i

f-i) 2; 3:

'W ® r-

•3 ®

3 “ i;

■0*0

• ® ®

«8

- m

m

I

ti'

O

if“

is's

o

m

W I Q.3>i

g?

o f>

3 o

•§ a

s-'

w O’

"O ®

11

J «I

№ fi

r =• ® :

o 5. < !

! □ g § <

;•№ I 5. :

‘ 3 3 O I

: I s

•S's.E

i

« - iH ^ Q. <

ro-g § ® o f

o S. S.T3 S 1

llotii

0% 3 OQ

= f ^ ®

< =5. ^ 3 i

i. - y « a

i 3 fi: 2. 3 ^

® ® a a z

'Iv.i

50

a

m '

-

2^ „‘'Is

o 2

o 5. •

sg

tt S g

-£ S* »

1“ ^ ®

® J*

_ 3 I J a

3 T*

o dd f

o ^ c p <

^ »agafi

o' <4 a

>

3

K

» a ®

m

C

O . ,

o

3*

»

.a 3 o

if'5

a a o

= o

3 c

OQ m

^1®

O j®

f 3 X

P--0 -g

? s

o S-^o O

-g_o-. >

i.|g?g

3 Q. -s W

5-!.xvO

I 3 =;

JO

Ila

rf. ^

I o —,

J =: 3- H

' 3 15

5 g O- o

W XI 0^ 01

Ig-g

m

§ Mm

à =• Q.

m

3* ^ o

® rr

3 ® ^

s a®

3* in

i O.E

®, ® o.

-, 2.®

3« »

i. c

I S’

Q.

S

O

«

3.'B‘

o «

ai

Sc

V» 3

■D ffl

5S

o?

3*3 a 2:

-s CB i> ®

c 3 a

^ »

•p t.3 a

i a I"

_ » ® »

psi-

SS'3--.|

H '-'r <

V.:

S. Ì

r. 3* m

# # 3

a» ; - d

3 CJ

fi. >./ 5*

iV

S’ É 21

o •’

3" C

S

a -•

i?|№

'•t 5 «"*•

S’wif

O »

<

*o

s » a

® 2 o

w “t

O 3 if fll

O o 3: ®

3 p

O V) ^ 3

m ° S S,’-

iS -i.®

5; fi

®. 3* r.

3 ® ® 3*

n I»

3

o

'3

o

E.' ®

CL fd 0X3 “!' •po g; x'mj >

.

.............

o 3- = ^-?

a> ^ - »

3-1^ as

cS ® < ft)

® E 3* < o № ® Q m

g 3

|cl‘® li

|t E ^ ii 3 w ® C

E o

i“i“ 3 ^

3*»

: to

to ^

'to fi

® C/5 ;

o '

— ft)

, ®

a y ^

31

m

c

i

\ii to

Stg-I

„/0 o to

® “D *D ^

3 to T1 CD

Q. Q.

, to X

?S' g

to ® o =

® c ®

to

s 3 03*

® 0Q H ®

® 1. E

<. 3 c <«

a to m o

(D ^ to Qj

3 ® 2

r** a » f

# S i

g ® O'

ft)

5^»

3 3*3”

3’ 3*

® ® s**

3 3*

sg?i

» rt* X*

D-a

3 ®

3 ®

I o 3

x’

» Z f £

i .

(I Tr ®

®, ® o c

m

m* -

3 m ®

E-Er’"'

fl d

® 2

^ »

$ -T

T3 ..

m

'X O

® C'» ’

”T”0

to

1 ,t S

1 3 >!?

tS № »

■o =; «

§2-g

o 3 a'

3 D.'<

' S'

$

I

S

I

«

§

'X

S

m

o

E

□“

•o

o

m

□

Q.

®

3

a

®

Q.

3

»

3

3

®

3 ®

I-

3 ro

® m

3 5

,-f. o

* J ,

VO

oogo-a.*£.^o

3 =’ W TP

O'"'®

m •

*o

» o

a. o

i«i. 3

O

r*f* Q,

2.

5'

» - ii

O OQ ~ ®

a

„3 o

m m-u 3

S-Sa.

o

3

m

ft) 3

^ g S

O'

#

Q.'< £ -

« ^ *2 m o

3*

o 2 S ®

o

S. o ® ^ w ■*

-,

W "O

•o

® o

£

"O ®

ÒS a|gc

a

•o 3

E

® o o

3 3 c

o

K • □ S. Ò.

‘•T! 5*5 « ® ^

•o

g > □ « 2 » Z

•Q _ ® -t ®

S

» ® - ? 3, ® ......

§

^ ^ 3.2 c o

3

Q. Q. Q. F 3 K 3-

» ■

^ ^ m

X* o o f\ E

S il

3-Sl 3«?

m

□ <. « ® ■

1 W

58

® •

o

2 ^

Q. ®

3 >

§ °

s I

" □

w » <©

CP 2

^ Q.

ag

|go

3

3

m

o a. 3

a

®

§' ;a

a 3! ®

CS g

SS. 5!

— CD

3 «

=^S-E

J 31

m

l?H

Ì8i

o

So-

Q.

3*

£.

3

3

-, ^ 'O

«

c 3 2.

3

3*

c

m

3

£

5*

«

Q. o

• o

c »

. S-* 3

¿*>>0 < $oq HCJQ ® =•

g«5w.^ = =>°|3g-S^^

« 2^ ® Q.01'* <-»-50Q32m

® 9 — » 0 = 0 a.3 Q.'S ®

col.^ls d S'- ^

'^3

CD 3 ’

§:craS ®

a> o f& "a

w V#

s 2.,--o agT3 s -

fa.-g_.Si=‘-®R®§3

^ 3 ® ® ® 0*43 5 X* ■

3 -t 3 0Q ® 3”0Q E 3 o c o

3"’3mO'-^sgo5aoo

o“°S-D

m

® =® i o

= j'-'O o 3

r+Z!o2^0f4'=

h» c ^^^3

ZT A:

3Ì.s88o.>o^=>wS.^

S sr° §-5 s _= 2 =i-a-s o

“ £ Ó5 S-Iro 3^ 3 ^

ro2;=5«d,r:s = ™

n> ^0.2.3 “ o

„oc 2 = -n»cf 0.5 S

0-1 oqs,*'(ra'-Ka^< “-S 0)

.WO) “ S oSo.®« mS-

I

=>^cl3!= ° ols'^-ó 3

a>

o z

3

r-t*

m o

® 9.

S- w

2. 3-

o o

w E

3* Q.

o O'

X- ®

«

^ 3

c

3

a.

m

3-

O

*0

-t

S

a

rf.

3-

®

o

S

o

g

s

!

a.

Page 2

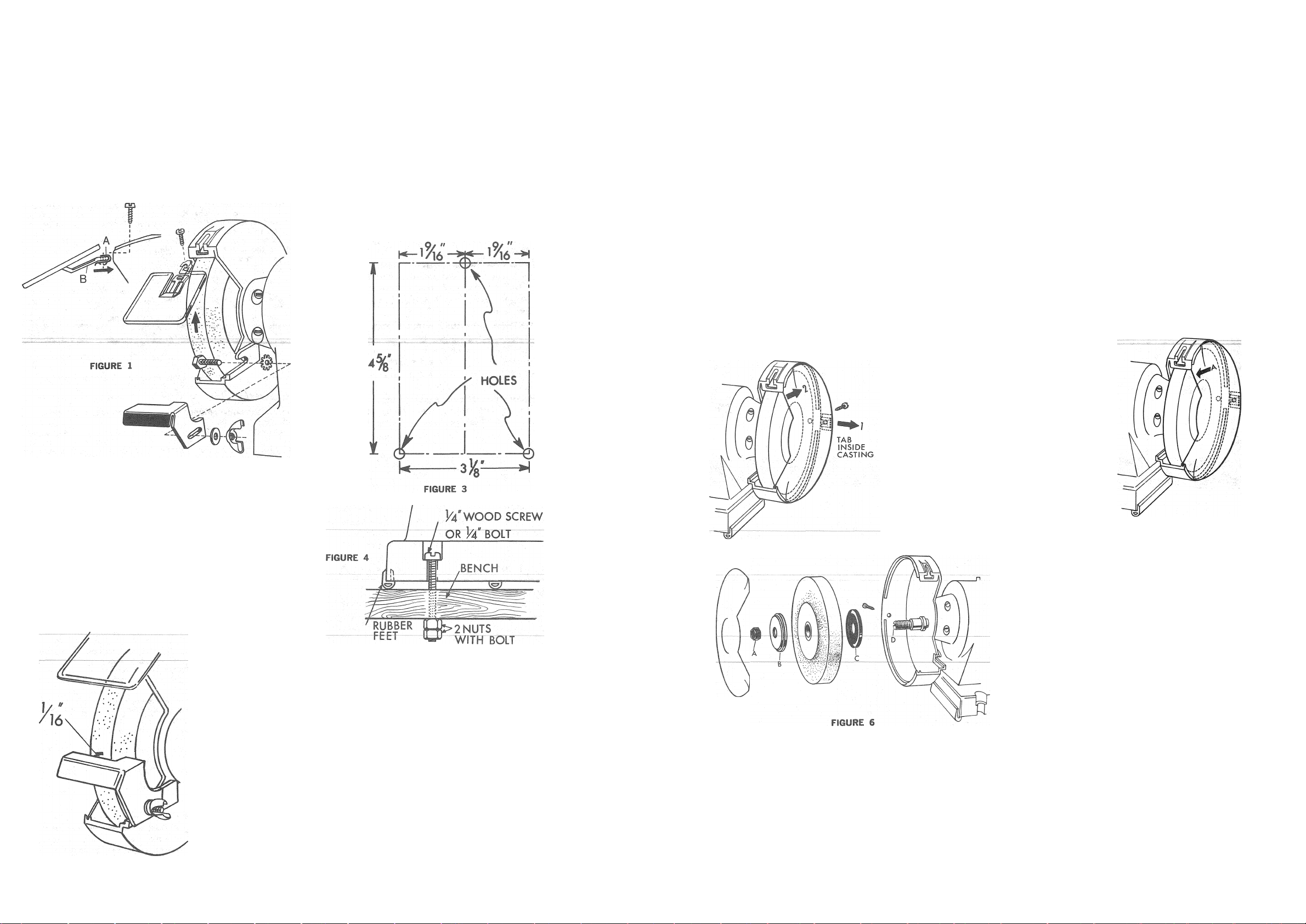

TTACHING EYE SHIELDS

The two Eye Shields are made of clear, shatterproof plastic, and

are attached to the top of each wheel guard as shown in Figure

1. First, slide the sheet metal nut “A” over the tang “B” in

the eye shield. Slide tang under top of wheel guard and fasten

shield in place with screw.

5” BENCH GRINDER

BENCH MOUNTING

Mounting the grinder on a bench is strongly recommended in

order to prevent movement of the grinder when pressure is

applied against a wheel. First, slide Rubber Feet on both sides

and In the middle of the grinder base as indicated in Figure 4.

Then drill three holes for wood screws or bolts In the

bench as shown in Figure 3. Use wood screws or bolts as

shown In Figure 4, and tighten down only enough to partially

compress rubber feet (about 1/16"). The rubber feet will not

be effective in absorbing virbratlon if fully compressed. When

using bolts, a second nut is required to lock against the

first nut and keep grinder from loosening during operation.

Never operate the grinder without the rubber feet attached to

its base.

WIRE BRUSHING INSTRUCTIONS

Wire Brushing quickly removes rust, scale or old paint. ALWAYS

wear safety glasses or other eye protection when using wire

wheels as pieces of wire may break off and be thrown from the

rotating brush. Handle Wire Wheel Brushes carefully with gloves

or rags to avoid punctyring the skin.

BUFFING INSTRUCTIONS

Use Cotton Buffing Wheels, normally with stick'buffing com

pound applied to the face of the wheel (usually about %" wide).

Wear safety goggles for protection against particles of compound

thrown off by the wheel. Remove the tool rest if* it interferes

with the buffing operation. Do not jam work into wheel. Hold

work firmly.

CmMGiMG WHEELS

UNPLUG POWER CORD AND BE SURE THAT SWITCH STAYS

IN THE “OFF” POSITION.

1. Remove End Cover—see Figure 5. Remove the screw in the

back of the wheel guard. Using a screwdriver if necessary,

pry the end cover outward from the wheel in the direction

of arrow #1. Slide the cover backward (arrow #2) out of

the grooves in the front of the wheel guard.

CHANGING WHEELS (Continued)

4.

Each Grinding Wheel purchased should be equipped with a

blotter fastened to each side of the wheel. Blotters must

always be used between the wheel and the inner and outer

clamp washers. Contact surfaces of wheels, blotters and

washers must be clean and flat.

5.

Always use the exact type of clamp washers that are supplied

with your tool. Never substitute flat or odd sized washers.

Replace them in the exact order and position shown in

Figure 6. Always place hollow sides of washers against

wheel.

6.

Only tighten arbor nut sufficiently to drive the wheel without

slippage. Hold spindle with screwdriver in end slot “D”.

Do not overtighten. •

7.

Be sure to replace end covers (see Figure 7). Slide cover in

direction of arrow “A” into upper and lower grooves in wheel

guard. Push cover toward wheel (arrow “B”) with threaded

tab inside wheel guard. Replace screw.

After installing replacement wheel, put on safety goggles and

8.

stand to the side of the grinder, turn switch “ON” and allow

wheel to revolve freely for one minute before beginning to

grind.

If a new wheel has excess vibration, loosen nut and rotate

wheel about Vz turn on shaft. Retighten nut.

ATTACHING TOOL RESTS

The two Tool Rests are not interchangeable •—■ one fits the left

side of the grinder and one the right side. Be careful to assemble

parts exactly as shown in Figure 1, and note that the star iock-

.__washer-gaes-between.the wheel guard and the. inside^-of the-Tool

Rest. Tighten the wing nut firmly with a clearance of 1/16"

between the grinding v^heel and the Tool Rest-—see Figure 2.

Tool Rests are adjustable for wheel wear. Keep them adjusted so

that a clearance of 1/16" is continually maintained between the

wheel and the Tool Rest as the wheel wears. This clearance is

very important as it will prevent any loose piece of significant

size from^ jamming between the v/heel and the Tool Rest. Such

jamming could fracture the wheel, break the Tool Rest, or both.

FIGURE 2

OPERATION INSTRUCTIONS

'When you face the Bench Grinder, the wheel on your left is a

5" Grinding ¥/hee!. This v/heel is used for metal grinding and

sharpening operations.

The wheel to your right is a 4" Sanding/Polishing Wheel,* This

wheel IS used for sanding wood and plastic, removing paint and

rust, polishing metal, honing cutting tools, smoothing rough

edges on glass, and de-burring pipe, sheet metal, etc.

To operate the Bench Grinder, put on safety glasses or other

eye protection and hold the work firmly. Rest the work on the

tool rest and feed it slowly into the wheel at the desired grinding

angle. Treat the wheel with respect ... do not jam the work

into the wheel or use unnecessary pressure.

Grind only on the face of the grinding wheel, unless you have a

special wheel specifically made to permit grinding on the side of

the wheel.

= Some 5"

Wheels.

Bench Grinders are equipped with two 5" Grinding

.........

2. See Figure 6. Remove clamp nut “A” by turning it in the

direction the wheel normally rotates. (The nut “A” shown

is black and has a left-hand thread. The silver-colored nut

at the other end of the grinder has a right-hand thread).

Use a screwdriver in the end slot “D” to hold spindle when

removing nuts.

3. Remove Outer Clamp Washer “B” (silver colored with small

hole), Wheel, and Inner Clamp Washer “C” (black with large

hole). Inspect washers. If they are burred or not perfectly

flat, repair or replace them.

FIGURE 7

TAB

INSIDE

CASTING

LUBRICATION

Bench grinder spindles are mounted on lubricant impregnated

bearings. Nc periodic lubrication is required.

ACCESSORIES

GRINDING WHEELS (5" Diam. x V2" Face x Vz" Arbor Hole).

Manufactured by the nation's leading abrasive manufacturers to

stringent quality specifications.

Cat. No. 79-555 Coarse — 36 Grit

Cat. No. 79-556 Medium — 60 Grit

SANDING/POLISHING WHEEL (4" Diam. x face x 1/2" hole)

Cat. No. 79-255 For sanding, polishing, honing, etc.

WIRE WHEEL BRUSHES (V2" Arbor Hole).

Each wire tuft is locked independently, giving a dense, even

brushing surface, and less danger of loose wires.

Cat. No. 70-142 4", Coarse Wire

Cat. No. 70-143 4", Fine Wire

COTTON BUFF:

For general purpose buffing and polishing.

Cat. No. U-1322 4" Diam. x %" FacP v 1/2"

NOTE; The above accessories are recommended for use with

your Bench Grinder. CAUTION: The use of any other accessory

or attachment might be hazardous.

Arbor Hole.

Loading...

Loading...