Page 1

GENERAL SAFETY RULES

WARNING: Read and understand all instructions. Failure to follow all instructions listed

below may result in electric shock, fire and/or serious personal injury.

SAVE THESE INSTRUCTIONS

Work Area

• Keep your work area clean and well lit. Cluttered benches and dark areas invite

accidents.

• Do not operate power tools in explosive atmospheres, such as in the presence of

flammable liquids, gases, or dust. Power tools create sparks which may ignite the dust or

fumes.

• Keep bystanders, children, and visitors away while operating a power tool.

Distractions can cause you to lose control.

Electrical Safety

• Double insulated tools are equipped with a polarized plug (one blade is wider than

the other.) This plug will fit in a polarized outlet only one way. If the plug does not fit

fully in the outlet, reverse the plug. If it still does not fit, contact a qualified electrician

to install a polarized outlet. Do not change the plug in any way.Double insulation

eliminates the need for the three wire grounded power cord and grounded power supply

system.

• Avoid body contact with grounded surfaces such as pipes, radiators, ranges and

refrigerators. There is an increased risk of electric shock if your body is grounded.

• Don’t expose power tools to rain or wet conditions. Water entering a power tool will

increase the risk of electric shock.

• Do not abuse the cord. Never use the cord to carry the tools or pull the plug from an

outlet. Keep cord away from heat, oil, sharp edges or moving parts. Replace

damaged cords immediately.Damaged cords increase the risk of electric shock.

• When operating a power tool outside, use an outdoor extension cord marked "W-A"

or "W." These cords are rated for outdoor use and reduce the risk of electric shock.

Personal Safety

• Stay alert, watch what you are doing and use common sense when operating a power

tool. Do not use tool while tired or under the influence of drugs, alcohol, or

medication. Amoment of inattention while operating power tools may result in serious

personal injury.

• Dress properly. Do not wear loose clothing or jewelry. Contain long hair. Keep your

hair, clothing, and gloves away from moving parts. Loose clothing, jewelry, or long hair

can be caught in moving parts. Air vents cover moving parts and should be avoided.

• Avoid accidental starting. Be sure switch is off before plugging in. Carrying tools with

your finger on the switch or plugging in tools that have the switch on invites accidents.

• Remove adjusting keys or wrenches before turning the tool on.A wrench or key that is

left attached to a rotating part of the tool may result in personal injury.

• Do not overreach. Keep proper footing and balance at all times. Proper footing and

balance enables better control of the tool in unexpected situations.

• Use safety equipment. Always wear eye protection. Dust mask, non-skid safety shoes,

hard hat, or hearing protection must be used for appropriate conditions.

Tool Use and Care

• Use clamps or other practical way to secure and support the workpiece to a stable

platform. Holding the work by hand or against your body is unstable and may lead to loss

of control.

• Do not force tool. Use the correct tool for your application. The correct tool will do the

job better and safer at the rate for which it is designed.

• Do not use tool if switch does not turn it on or off. Any tool that cannot be controlled

with the switch is dangerous and must be repaired.

• Disconnect the plug from the power source before making any adjustments,

changing accessories, or storing the tool. Such preventative safety measures reduce

the risk of starting the tool accidentally.

• Store idle tools out of reach of children and other untrained persons. Tools are

dangerous in the hands of untrained users.

• Maintain tools with care. Keep cutting tools sharp and clean. Properly maintained

tools, with sharp cutting edges are less likely to bind and are easier to control.

• Check for misalignment or binding of moving parts, breakage of parts, and any

other condition that may affect the tools operation. If damaged, have the tool

serviced before using. Many accidents are caused by poorly maintained tools.

• Use only accessories that are recommended by the manufacturer for your model.

Accessories that may be suitable for one tool, may become hazardous when used on

another tool.

Service

• Tool service must be performed only by qualified repair personnel.Service or

maintenance performed by unqualified personnel could result in a risk of injury.

• When servicing a tool, use only identical replacement parts. Follow instructions in

the Maintenance section of this manual. Use of unauthorized parts or failure to follow

Maintenance Instructions may create a risk of electric shock or injury.

Specific Safety Rule

• Hold tool by insulated gripping surfaces when performing an operation where the

cutting tool may contact hidden wiring or its own cord. Contact with a "live" wire will

make exposed metal parts of the tool "live" and shock the operator.

Additional Safety Instructions for Planers

• Read instruction manual thoroughly before using this tool.

• Be sure the switch is in OFF position before connecting tool to power supply .

• Switch OFF immediately if tool is jammed in work.

• Disconnect from power source when cleaning or making adjustments to the tool.

• Always hold the tool with both hands and by the handles provided.

• Be sure tool is properly held or set for right use before turning switch to ON.

• Maintain tool with care. Follow instructions for changing accessories.

• Store tool in a clean dry place after disconnecting from power source.

• Keep air vents unobstructed for proper motor cooling.

• Keep side discharge chute unobstructed at all times.

• Never reach under the tool for any reason unless it is turned off and UNPLUGGED. •

BLADES ARE EXPOSED AND EXTREMELYSHARP.

• Use this tool for working with wood and wood products only.

• Remove all nails and metal objects from the workpiece before planing.

• Use sharp cutting blades only. Planer blades are extremely sharp - Handle with great care.

• Never put the tool down until the cutting blades have come to a complete stop. DO NOT lay

tool down on shoe when the blades are exposed. This can chip the blades.

The label on your tool may include the following symbols.

V ..........................volts A..........................amperes

Hz ........................hertz W ........................watts

min........................minutes ......................alternating current

......................direct current

n

o........................no load speed

..........................

Class II Construction

........................earthing terminal

........................safety alert symbol .../min ..................revolutions or

reciprocations

per minute

WARNING: Some dust created by power sanding, sawing, grinding, drilling, and other

construction activities contains chemicals known to cause cancer, birth defects or other

reproductive harm. Some examples of these chemicals are:

• lead from lead-based paints,

• crystalline silica from bricks and cement and other masonry products, and

• arsenic and chromium from chemically-treated lumber. (CCA)

Y our risk from these exposures varies, depending on how often you do this type of work. To

reduce your exposure to these chemicals: work in a well ventilated area, and work with

approved safety equipment, such as those dust masks that are specially designed to filter

out microscopic particles.

• Avoid prolonged contact with dust from power sanding, sawing, grinding, drilling,

and other construction activities. Wear protective clothing and wash exposed areas

with soap and water . Allowing dust to get into your mouth, eyes, or lay on the skin may

promote absorption of harmful chemicals.

WARNING: Use of this tool can generate and/or disburse dust, which may cause serious

and permanent respiratory or other injury. Always use NIOSH/OSHA approved respiratory

protection appropriate for the dust exposure. Direct particles away from face and body.

CAUTION: Wear appropriate hearing protection during use. Under some conditions

and duration of use, noise from this product may contribute to hearing loss.

SAVE THESE INSTRUCTIONS

Motor

Be sure your power supply agrees with nameplate marking. 120 Volts AC only means your

drill will operate on standard 60 Hz household power. Do not operate AC tools on DC. A

rating of 120 volts AC/DC means that your tool will operate on standard 60 Hz AC or DC

power. This information is printed on the nameplate. Lower voltage will cause loss of power

and can result in over-heating. All Black & Decker tools are factory-tested; if this tool does

not operate, check the power supply.

Use of Extension Cords

Make sure the extension cord is in good condition before using. Always use the proper size

extension cords with the tool – that is, proper wire size for various lengths of cord and heavy

enough to carry the current the tool will draw. Use of an undersized cord will cause a drop in

line voltage resulting in loss of power and overheating. For proper size cords see chart

below.

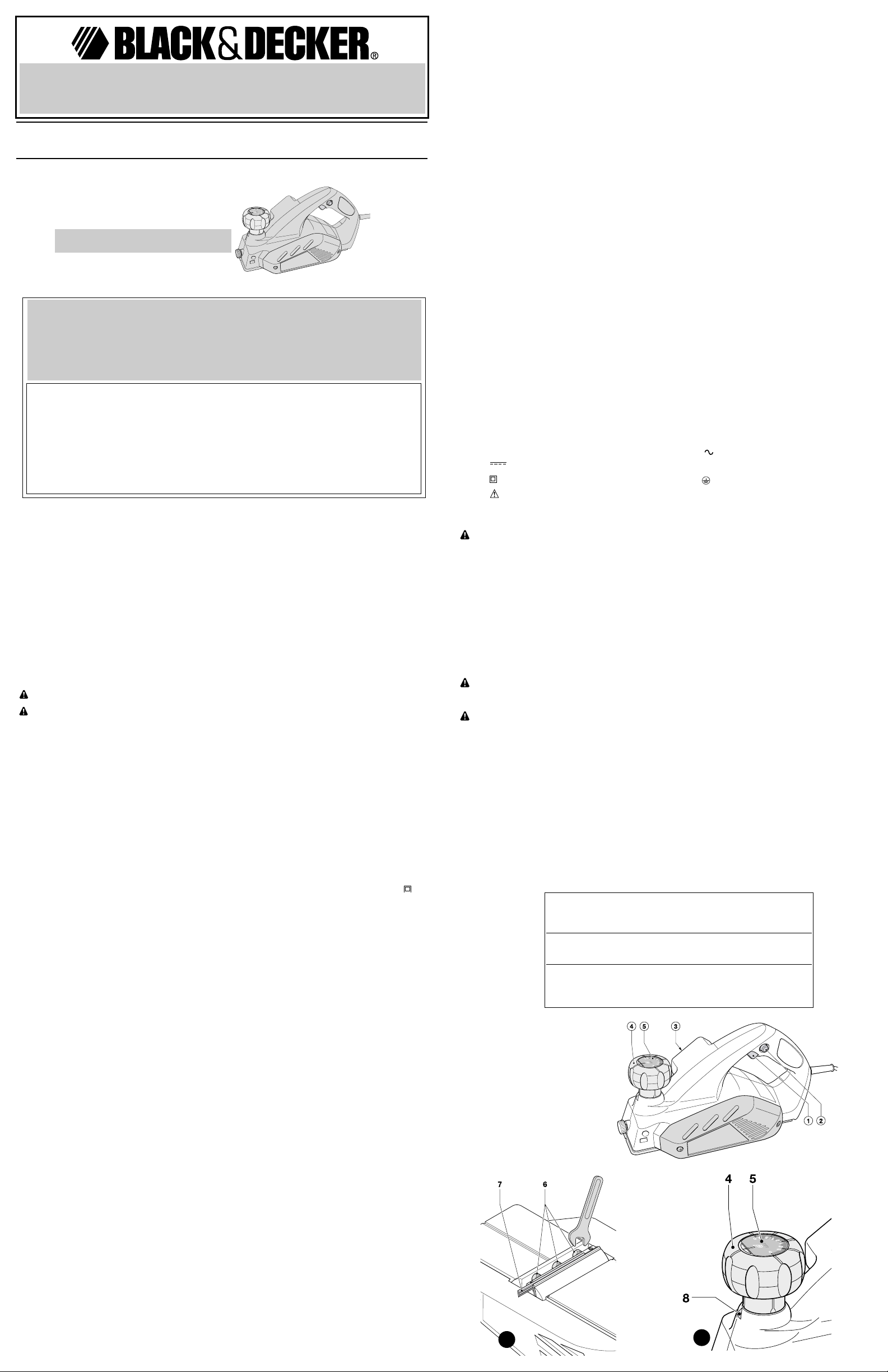

Features

1. On/off switch

2. Lock-on button

3. Shavings discharge outlet

4. Planing depth adjustment knob

5. Planing depth graduation

KEY INFORMATION YOU SHOULD KNOW :

• For aggressive material removal, use several controlled passes at a shallow depth

of cut.

• For optimum results use smooth uninterrupted passes.

VEA EL ESPAÑOL EN LA CONTRAPORTADA.

SAVE THIS MANUAL FOR FUTURE REFERENCE.

INSTRUCTIVO DE OPERACIÓN, CENTROS DE SERVICIO Y

PÓLIZADE GARANTÍA. ADVERTENCIA: LÉASE ESTE

INSTRUCTIVO ANTES DE USAR ELPRODUCTO.

Catalog No. 7698 Form No. 585453-00 (JUN-03-1) Copyright © 2003 Black & Decker Printed in China

Minimum Gage for Cord Sets

Volts Total Length of Cord in Feet

120V 0-25 26-50 51-100 101-150

240V 0-50 51-100 101-200 201-300

Ampere Rating

More Not more American Wire Gage

Than Than

0-6 18 16 16 14

6 - 10 18 16 14 12

10 - 12 16 16 14 12

12 - 16 14 12 Not Recommended

INSTRUCTION MANUAL

BEFORE RETURNING THIS PRODUCT

FOR ANY REASON PLEASE CALL

1-800-544-6986

IF YOU SHOULD HAVE AQUESTION OR EXPERIENCE A

PROBLEM WITH YOUR BLACK &DECKER PRODUCT ,

CALL 1-800-544-6986

BEFORE YOU CALL, HA VE THE FOLLOWING INFORMATION AVAILABLE, CATALOG No., TYPE No., AND

DATE CODE (e.g. 20000130M). IN MOSTCASES, ABLACK & DECKER REPRESENTATIVE CAN

RESOLVE YOUR PROBLEM OVER THE PHONE. IF YOU HAVE ASUGGESTION OR COMMENT, GIVE

US ACALL. YOUR FEEDBACK IS VITALTO BLACK & DECKER.

3333--

--

11

11

//

//

44

44

""""

((((88882222....5555mmmmmmmm))

))

PP

PPllllaaaannnneeeerrrr

CCCCaaaattttaaaalllloooogggg NNNNoooo.... 77776666999988

88

A

B

Page 2

RÈGLES GÉNÉRALES DE SÉCURITÉ

AVERTISSEMENT : lire et comprendre les présentes directives avant d’utiliser l’outil,

afin d’éviter les risques de choc électrique, d’incendie ou de blessure grave.

CONSERVER CES DIRECTIVES

Zone de travail

• Garder la zone de travail propre et bien éclairée; les établis encombrés et les endroits

sombres sont propices aux accidents.

• Ne pas utiliser l’outil dans une atmosphère explosive, comme en présence de liquide, de

gaz ou de poussière inflammables; les étincelles produites par l’outil risquent d’enflammer

des gaz ou des poussières.

• S’assurer que personne, ni enfant ni visiteur, ne s’approche de la zone de travail lorsque

l’outil est utilisé; les distractions peuvent provoquer la perte de la maîtrise de l’outil.

Mesures de sécurité – électricité

• Les outils à double isolation sont munis d’une fiche polarisée (c’est-à-dire que l’une des

lames est plus large que l’autre), laquelle ne peut être raccordée qu’à une prise polarisée et

ce, dans un seul sens; on doit l’inverser si on est incapable de l’enfoncer complètement. Si

la fiche ne s’adapte toujours pas, on doit faire appel à un électricien qualifié pour qu’il

installe une prise appropriée. On ne doit jamais modifier la fiche. La double isolation (Add

Symbol) élimine le besoin d’installer un cordon d’alimentation trifilaire et un système

d’alimentation électrique pourvus d’une mise à la terre.

• Éviter tout contact entre le corps et les éléments mis à la terre, comme les tuyaux, les

radiateurs, les cuisinières et des réfrigérateurs, afin de réduire les risques de choc

électrique.

• Ne pas exposer les outils électriques à la pluie ou à l'humidité. Tout pénétration d'un outil

électrique par un liquide augmente les risques de choc électrique.

• Ne pas utiliser le cordon de manière abusive; on ne doit pas transporter l’outil en le tenant

par le cordon, ni tirer dessus pour le débrancher. On doit tenir le cordon à l’écart des

sources de chaleur, de l’huile, des bords tranchants ou des pièces mobiles. Remplacer

immédiatement les cordons endommagés; ces derniers augmentent les risques de choc

électrique.

• Lorsqu’on utilise un outil électrique à l’extérieur, on ne doit utiliser que des rallonges

the cutting stroke.

• It is a good idea to try a piece of scrap wood before doing finish work.

Emptying the shavings collection bag

The shavings collection bag should be emptied regularly while using it.

• Unzip the bag and empty it before continuing.

Hints for optimum use

• Move the tool along the grain of the wood.

• If the grain is cross or curly, or if the workpiece material is a hard type of wood, adjust

the depth of cut to take only a very thin shaving at each pass and take several passes to

achieve the desired result.

• To keep the tool in a straight line, press down the front of the tool at the start, and press

down the back of the tool at the end of the cutting stroke.

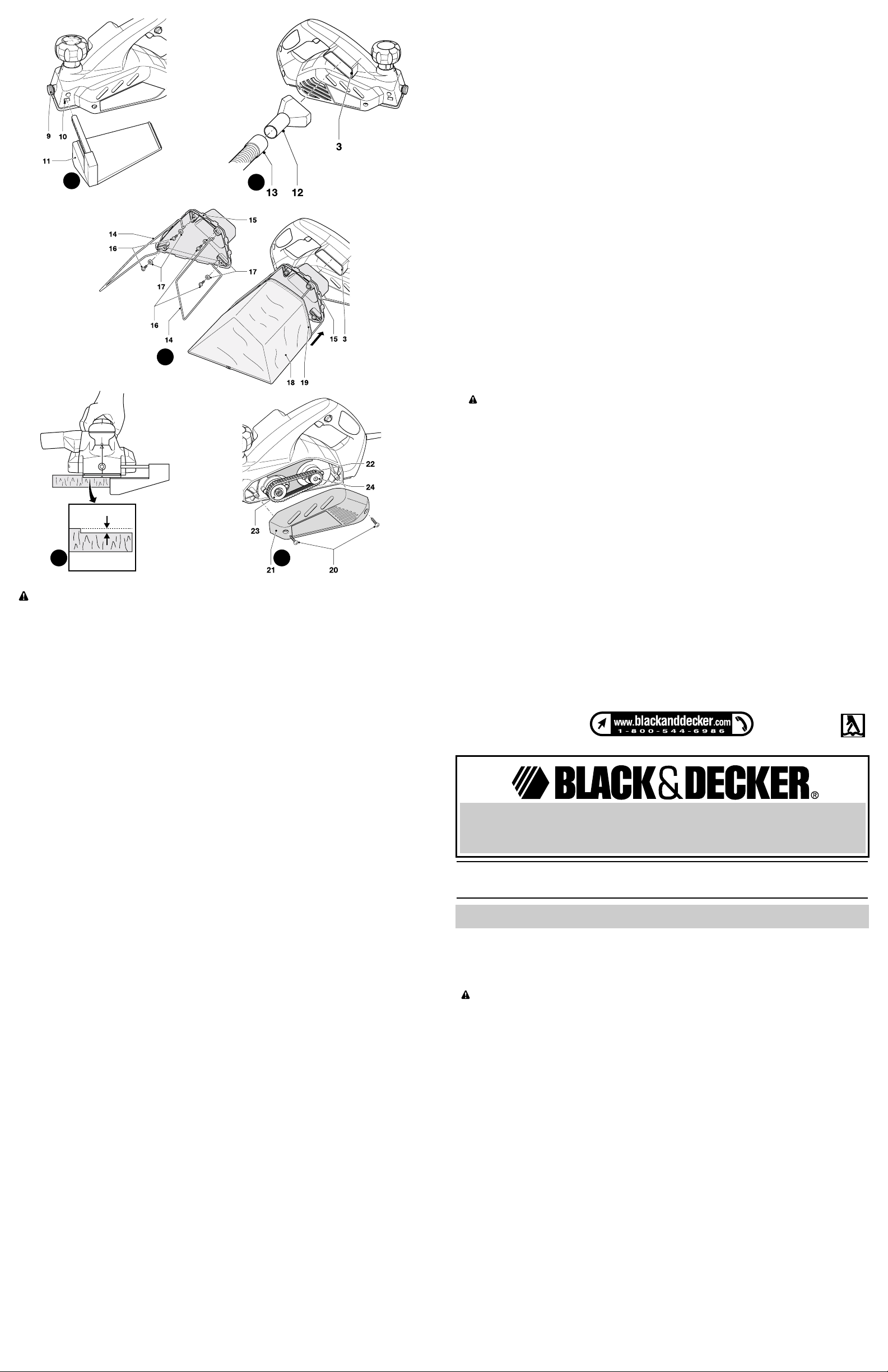

Replacing the drive belt (fig. G)

• Loosen the screws (20) and remove the cover (21).

• Remove the old drive belt.

• Place the new belt (22) over the pulleys. Place the belt over the large pulley (23) first,

then over the small pulley (24), while manually rotating the belt steadily.

• Put the cover back in place and tighten the screws.

Maintenance

Y our tool has been designed to operate over a long period of time with a minimum of

maintenance. Continuous satisfactory operation depends upon proper tool care, including

the following:

• Regularly clean the ventilation slots in your tool using a soft brush or dry cloth.

• Regularly clean the motor housing using a damp cloth.

• Do not use any abrasive or solvent-based cleaner. Never let any liquid get inside the

tool and never immerse any part of the tool into liquid.

IMPORTANT: To assure product SAFETYand RELIABILITY, repairs, maintenance and

adjustment (other than those listed in this manual) should be performed by authorized service

centers or other qualified service personnel, always using identical replacement parts.

Accessories

Recommended accessories for use with your tool are available from your local dealer or

authorized service center. If you need assistance regarding accessories, please call:

1-800-544-6986.

WARNING: The use of any accessory not recommended for use with this tool could be

hazardous.

Service Information

All Black & Decker Service Centers are staffed with trained personnel to provide customers

with efficient and reliable power tool service. Whether you need technical advice, repair, or

genuine factory replacement parts, contact the Black & Decker location nearest you. To find

your local service location, refer to the yellow page directory under "Tools—Electric" or call:

1-800-544-6986 or visit www.blackanddecker .com

Full Two-Year Home Use Warranty

Black & Decker (U.S.) Inc. warrants this product for two years against any defects in material

or workmanship. The defective product will be replaced or repaired at no charge in either of

two ways.

The first, which will result in exchanges only, is to return the product to the retailer from

whom it was purchased (provided that the store is a participating retailer). Returns should be

made within the time period of the retailer’s policy for exchanges (usually 30 to 90 days after

the sale). Proof of purchase may be required. Please check with the retailer for their specific

return policy regarding returns that are beyond the time set for exchanges.

The second option is to take or send the product (prepaid) to a Black & Decker owned or

authorized Service Center for repair or replacement at our option. Proof of purchase may be

required. Black & Decker owned and authorized Service Centers are listed under "ToolsElectric" in the yellow pages of the phone directory and on our website

www.blackanddecker.com.

This warranty does not apply to accessories. This warranty gives you specific legal rights

and you may have other rights which vary from state to state. Should you have any

questions, contact the manager of your nearest Black & Decker Service Center. This product

is not intended for commercial use.

FREE WARNING LABELREPLACEMENT: If your warning labels become illegible or are

missing, call 1-800-544-6986 for a free replacement.

See ‘Tools-Electric’

– Yellow Pages –

for Service & Sales

Black & Decker (U.S.) Inc.,

701 E. Joppa Rd.

Towson, MD 21286 U.S.A.

Assembly

Warning: Make sure that the tool is switched off and unplugged when performing the

following Assembly steps.

Replacing the cutting blades (fig. A)

The cutting blades provided with this tool are reversible. An extra set of blades is included.

Replacement cutting blades can be obtained from your local retailer.

Removing

• Loosen the bolts (6) using the wrench supplied.

• Slide the blade (7) out of the holder.

• Reverse the blade so that the unused side comes in position. If both sides are worn,

the blade must be replaced.

Fitting

• Slide the blade into the holder until it is against the end stop.

• Tighten the bolts using the wrench supplied.

• Always replace both cutters.

Adjusting the depth of cut (fig. B)

The depth of cut is indicated by the marking (8). The setting range can be read from the

graduation (5).

• Turn the planing depth adjustment knob (4) to the required depth of cut.

• To prevent damage to the blade, turn the knob to the ‘P’ (park) position whenever the

tool is not in use.

NOTE: 10 positive stops indicate 1/32" increase in cut for accurate measurement. The

maximum depth of cut is 5/64". It is recommended that test cuts be made in scrap wood

after each readjustment to make sure that the desired amount of wood is being removed by

the planer. Several shallow passes will produce a smoother finish than one deep one.

Fitting and removing the parallel fence (fig. C)

The parallel fence is used to for optimum control on narrow workpieces.

• Loosen the locking knob (9).

• Insert the parallel fence (11) through the opening (10).

• Slide the parallel fence into the desired position.

• Tighten the locking knob.

• To remove the parallel fence proceed in reverse order.

Connecting a vacuum cleaner to the tool (fig. D)

• Slide the adaptor (12) over the shavings discharge outlet (3).

• Connect a vacuum cleaner hose (13) (not included) to the adaptor.

Assembling and fitting the shavings collection bag (fig. E)

The shavings collection bag is particularly useful when working in confined spaces.

Before first use, you will have to assemble the shavings collection bag.

• Fit the wire frames (14) to the connecting plate (15) using the screws (16) and washers (17).

• Pull the cloth bag (18) over the frame structure as shown.

• Take care that the bag opening (19) is well fitted around the edge of the connecting

plate (15).

• Slide the connecting plate over the shavings discharge outlet (3).

Operation

• Adjust the depth of cut.

• If necessary, fit and adjust the parallel fence.

• Use sharp cutters only.

Switching on and off

Switching on (Always pick up your planer before depressing the switch.)

• The planer is started by depressing the on/off switch (1) in the handle.

• To LOCK the tool ON, for continuous use, hold the trigger depressed and push in the

locking button (2). Hold the button in while gently releasing the trigger.

Switching off

• Release the on/off switch. Wait for the blades to stop before setting down.

• To turn the tool OFF from a locked-on position, depress and release the trigger once.

Planing

• Hold the tool with the nose piece of the shoe resting on top of the workpiece surface.

• Switch the tool on.

• Move the tool steadily forward to perform the cutting stroke.

• Switch the tool off after the stroke has been completed.

Rabbeting (fig. F)

• Fit and adjust the parallel fence.

• Proceed as for planing.

Chamfering edges

The V-groove in the nose piece of the shoe enables you to chamfer edges at 45 angles.

• Hold the tool at an angle with the groove around the edge of the workpiece and perform

C

E

G

D

F

GUIDE D’UTILISATION

RRRRaaaabbbbooootttteeeeuuuusssseeee ddddeeee 88882222,,,,5555 mmmmmmmm ((((3333----1111////4444 ppppoooo))

))

NNNNoooo ddddeeee ccccaaaattttaaaalllloooogggguuuueeee 77776666999988

88

AVANT DE RETOURNER CE PRODUIT

POUR QUELQUE RAISON QUE CE SOIT , COMPOSEZ LE 1 800 544-6986

Page 3

conçues pour cet usage, comme celles de type W-Aou W, afin de réduire les risques de

choc électrique.

Sécurité personnelle

• Rester vigilant en tout temps et faire preuve de jugement lorsqu’on utilise un outil électrique.

Ne pas utiliser l’outil lorsqu’on est fatigué ou sous l’influence de drogues, d’alcool ou de

médicaments. Un moment d’inattention pourrait entraîner des blessures graves.

• Porter des vêtements appropriés. Ne pas porter de vêtements amples ni de bijoux. Couvrir

ou attacher les cheveux longs. Garder les cheveux, les vêtements, les bijoux et les gants

éloignés des pièces mobiles; ceux-ci peuvent s’y coincer. Se tenir éloigné des évents

puisque ces derniers couvrent souvent des pièces mobiles.

• Éviter tout démarrage accidentel. S'assurer que l'interrupteur est verrouillé ou en position

d'arrêt avant tout branchement. Le fait de porter un outil le doigt sur l'interrupteur ou de le

brancher alors que l'interrupteur est en position de marche favorise les accidents.

• Retirer les clés de réglage avant de démarrer l’outil; une clé laissée sur une pièce rotative

peut entraîner des blessures.

• Ne pas trop étendre les bras. Les pieds doivent rester bien ancrés au sol afin de maintenir

son équilibre en tout temps, et de mieux maîtriser l’outil dans des situations imprévues.

• Utiliser le matériel de sécurité approprié. Toujours porter des lunettes de protection. Porter

un masque anti-poussière, des chaussures antidérapantes, un casque de sécurité ou des

protecteurs auditifs lorsque la situation le requiert.

Utilisation et entretien de l’outil

• Utiliser des serre-joints ou tout autre moyen pour fixer et immobiliser le matériau sur une

surface stable. Tenir la pièce à la main ou contre son corps offre une stabilité insuffisante

qui pourrait vous en faire perdre le contrôle.

• Ne pas forcer l'outil. Utiliser l'outil approprié au travail en cours. L'outil approprié effectuera

un meilleur travail, de façon plus sûre et à la vitesse désirée.

• Ne pas utiliser un outil dont l'interrupteur est défectueux. Tout appareil dont l'interrupteur est

défectueux est dangereux et doit être réparé.

• Débrancher tout outil avant de faire tout réglage et changement d'accessoire ou avant de le

ranger. Ces mesures de sécurité préventives réduisent les risques de démarrage

accidentel.

• Lorsqu’on n’utilise pas l’outil, le ranger hors de la portée des enfants ou des personnes non

qualifiées. Les outils sont dangereux entre les mains de personnes inexpérimentées.

• Prendre soin de ses outils. Maintenir toute lame aiguisée et propre. Les outils bien

entretenus, aux lames bien affûtées sont moins susceptibles de se coincer et sont plus

faciles à contrôler.

• Vérifier les pièces mobiles afin de s'assurer qu’elles sont bien alignées et qu’elles ne restent

pas coincées; vérifier également les pièces pour s'assurer qu’il n’y a ni bris ni aucune autre

condition susceptible de nuire au bon fonctionnement de l’outil; faire réparer l’outil si ce

dernier est endommagé avant de s'en servir à nouveau, car les accidents sont souvent

causés par des outils mal entretenus.

• N’utiliser que les accessoires recommandés par le fabricant pour le modèle utilisé. Un

accessoire destiné à un outil particulier peut devenir dangereux lorsqu’il est utilisé avec un

autre.

Réparation

• L’outil doit être entretenu ou réparé par du personnel qualifié seulement; toute maintenance

effectuée par une personne non qualifiée pourrait entraîner des risques de blessure.

• Lors de l’entretien, n’utiliser que des pièces de rechange identiques et suivre les directives

de la section « Entretien » du présent guide afin de prévenir les risques de choc électrique

ou de blessure.

Règles de sécurité particulières

• Tenir l’outil par les surfaces isolées prévues à cette fin lorsqu’il risque d’entrer en contact

avec des fils cachés, ou son propre cordon. De tels contacts peuvent mettre les pièces

métalliques de l’outil sous tension, engendrant des risques de choc électrique.

Règles de sécurité supplémentaires concernant la raboteuse

• Lire le manuel d’utilisation au complet avant d’utiliser cet outil.

• S’assurer que l’interrupteur de l’outil soit en position d’ARRÊT avant de brancher le cordon

dans une prise d’alimentation.

• COUPER immédiatement le contact si l’outil se coince dans la pièce travaillée.

• Toujours débrancher l’outil avant de le nettoyer ou d’en effectuer les réglages.

• Toujours tenir l’outil des deux mains, au moyen des poignées prévues à cet effet.

• S’assurer que l’outil soit bien maintenu et prêt à être utilisé correctement avant de mettre l’in-

terrupteur en position de MARCHE.

• Bien entretenir l’outil; suivre les consignes lorsqu’on le lubrifie ou qu’on remplace des acces-

soires.

• Ranger l’outil dans un endroit propre et sec, et le débrancher de toute source d’alimentation.

• Garder les évents libres de toute obstruction afin de permettre le refroidissement du moteur.

• Garder l’orifice d’éjection latéral libre de toute obstruction en tout temps.

• Ne jamais mettre les mains sous l’outil, pour quelque raison que ce soit, à moins que l’outil

soit arrêté et DÉBRANCHÉ.

LES LAMES DE L’OUTIL SONT EXPOSÉES ET EXTRÊMEMENT COUPANTES.

• N’utiliser cet outil que pour travailler le bois ou les articles en bois.

• Retirer les clous et les ferrures métalliques de la pièce à travailler avant de commencer le

rabotage.

• N’utiliser que des lames bien aiguisées. Les lames de la raboteuse sont extrêmement

coupantes – les manipuler avec précaution.

• Attendre que les lames se soient complètement immobilisées avant de déposer l’outil. NE

JAMAIS déposer l’outil sur son patin lorsque les lames sont exposées afin de ne pas les

endommager.

L’étiquette de l’outil peut comporter les symboles suivants.

V ....................................volts A..........................ampères

Hz ..................................hertz W ........................watts

min..................................minutes ......................courant alternatif

................................courant continu

n

o........................sous vide

....................................

Construction de classe II

........................borne de mise à la

minute

..................................symbole d´avertissement .../min ..................tours ou courses

à la minute

AVERTISSEMENT : certains outils électriques, tels que les sableuses, les scies, les

meules, les perceuses et certains autres outils de construction, peuvent produire de la

poussière contenant des produits chimiques susceptibles d’entraîner le cancer, des

malformations congénitales ou pouvant être nocifs pour le système reproductif. Parmi ces

produits chimiques, on retrouve :

• le plomb dans les peintures à base de plomb,

• la silice cristalline dans les briques et le ciment et autres produits de maçonnerie, et

• l'arsenic et le chrome dans le bois ayant subi un traitement chimique (ACC).

Le risque associé à de telles expositions varie selon la fréquence avec laquelle on effectue

ces travaux. Pour réduire l’exposition à de tels produits : il faut travailler dans un endroit bien

aéré et utiliser le matériel de sécurité approprié, tel un masque anti-poussière spécialement

conçu pour filtrer les particules microscopiques.

• Limiter tout contact prolongé avec les poussières provenant du ponçage, sciage,

meulage, perçage ou toute autre activité relative à la construction. Porter des vêtements de protection et nettoyer les parties exposées du corps avec de l’eau savonneuse. S’assurer de bien se protéger afin d’éviter d’absorber par la bouche, les yeux

ou la peau des produits chimiques nocifs.

AVERTISSEMENT : cet outil peut produire et répandre de la poussière susceptible de

causer des dommages sérieux et permanents au système respiratoire. Toujours utiliser un

appareil respiratoire anti-poussière approuvé par le NIOSH ou l’OSHA. Diriger les particules

dans le sens opposé au visage et au corps.

MISE EN GARDE : porter un dispositif de protection personnel anti-bruit approprié

durant l’utilisation. Sous certaines conditions et suivant la longueur d’utilisation, le

bruit émanant de ce produit pourrait contribuer à une perte de l'ouïe.

CONSERVER CES DIRECTIVES

Moteur

S’assurer que l’intensité nominale du circuit corresponde à celle indiquée sur la plaque

signalétique; la mention « 120 Volts AC » signifie que l’outil peut être branché dans une prise

résidentielle de 60 Hz. Ne jamais brancher un outil requérant du courant alternatif (c.a.) dans

une prise de courant continu (c.c.). Si la plaque indique « 120 volts AC/DC », l’outil peut alors

être branché à une prise de 60 Hz de courant alternatif ou continu. Ces données sont

toujours indiquées sur la plaque signalétique de l’outil. Si celui-ci est branché à une prise

d’intensité insuffisante, cela pourrait causer une perte de puissance et une surchauffe. Tous

les outils Black & Decker sont mis à l’essai en usine. Si cet outil ne fonctionne pas, vérifier

l’alimentation électrique.

Rallonges

S’assurer que la rallonge soit en bon état avant de l’utiliser. Toujours utiliser une rallonge qui

convient à l’outil, c’est-à-dire dont le calibre des fils, la longueur du cordon et les valeurs

nominales correspondent à l‘outil alimenté. L’usage d’une rallonge de calibre insuffisant

pourrait causer une chute de tension entraînant une perte de puissance et une surchauffe.

Pour s’assurer qu’on utilise le calibre approprié, consulter le tableau ci-dessous.

Assemblage

AVERTISSEMENT :s’assurer que le contact de l’outil soit coupé et que ce dernier soit

débranché avant de procéder aux étapes d’assemblage.

Remplacement des lames (figure A)

Les lames de l’outil sont réversibles; des lames de rechanges sont offertes chez les détaillants participants.

Retrait

• Desserrer les boulons (6) au moyen de la clé fournie.

• Glisser la lame (7) hors de son support.

• Inverser la lame de manière à ce que le côté inutilisé soit exposé. Si les deux côtés sont

usés, la lame doit être remplacée.

Installation

• Glisser la lame dans son support jusqu’à ce qu’elle repose sur la butée.

• Serrer les boulons au moyen de la clé fournie.

• Remplacer les deux lames simultanément.

Réglage de la profondeur de coupe (figure B)

L’indicateur (8) donne la profondeur de coupe; on peut connaître la plage de réglage au

moyen de l’échelle graduée (5).

• Tourner le bouton de réglage de profondeur (4) afin d’obtenir la profondeur de rabotage

voulue.

• Mettre le bouton à la position « P » lorsque l’outil n’est pas utilisé.

REMARQUE : chacun des 10 crans indique une augmentation de profondeur de 0,8 mm

(1/32 po), caractéristique qui permet d’obtenir des mesures plus exactes. La profondeur

maximale de rabotage est de 1,9 mm (5/64 po). On recommande d’effectuer des coupes

d’essai sur des retailles de bois après chaque nouveau réglage afin de vérifier la quantité de

bois retirée après un passage. Plusieurs passages peu profonds procureront une surface

plus lisse qu’un seul passage plus profond.

Installation et retrait du guide parallèle (figure C)

Le guide parallèle sert à procurer une meilleure maîtrise lors du rabotage de pièces plus

étroites.

• Desserrer le bouton de verrouillage (9).

• Insérer le guide parallèle (11) dans l’ouverture (10).

• Faire glisser le guide parallèle afin de le mettre à la position voulue.

• Serrer le bouton de verrouillage.

• Pour retirer le guide parallèle, reprendre les étapes ci-dessus en sens inverse.

Raccordement d’un aspirateur à l’outil (figure D)

• Glisser l’adaptateur (12) sur l’orifice d’éjection des copeaux (3).

• Fixer le boyau de l’aspirateur (13) sur l’adaptateur.

Assemblage et installation du sac collecteur de copeaux (figure E)

Le sac collecteur de copeaux est particulièrement utile lorsqu’on doit travailler dans des

espaces restreints.

Avant de l’utiliser pour la première fois, le sac doit être assemblé.

• Fixer les renforts métalliques (14) à la plaque de raccordement (15) au moyen des vis (16)

et des rondelles (17) fournies.

• Tirer le sac en tissu (18) au-dessus des renforts, tel qu’illustré.

• S’assurer que l’ouverture du sac (19) soit bien ajustée autour du rebord de la plaque de

raccordement (15).

• Glisser la plaque de raccordement au-dessus de l’orifice d’éjection des copeaux (3).

Fonctionnement

• Régler la profondeur de coupe.

• Placer et régler le guide parallèle au besoin.

• Utiliser des lames bien aiguisée seulement.

Démarrage et arrêt de la raboteuse

Démarrage (soulever la raboteuse avant d’appuyer sur l’interrupteur)

• Enfoncer le bouton de verrouillage en position d’arrêt (2) puis appuyer sur l’interrupteur de

marche-arrêt (1).

• Relâcher le bouton de verrouillage en position d’arrêt.

Arrêt

• Relâcher l’interrupteur de marche-arrêt.

Rabotage

• Tenir l’outil de manière à ce que le nez du patin repose sur le dessus de la pièce à raboter.

• Faire démarrer l’outil.

• Déplacer l’outil vers l’avant de manière à effectuer un passage uniforme.

• Couper le contact une fois le passage effectué.

Feuillement (figure F)

• Placer et régler le guide parallèle.

• Suivre les mêmes étapes que pour le rabotage.

Chanfreinage

La rainure en V située sur le nez du patin permet de chanfreiner une arête à un angle de 45°.

• Tenir l’outil en angle en plaçant la rainure autour de l’arête de la pièce à travailler, puis

effectuer un passage.

• On recommande de faire des essais sur des retailles avant de procéder au chanfreinage de

la pièce voulue.

Vidange du sac collecteur de copeaux

Le sac collecteur de copeaux doit être vidé régulièrement lorsqu’on l’utilise.

• Ouvrir l’ouverture à glissière et vider le sac, puis poursuivre le travail.

Conseils pour assurer les meilleurs résultats

• Faire avancer l’outil dans le sens du grain du bois.

• Si le grain est croisé ou courbé, ou si la pièce à travailler est faite de bois dur, régler la

Calibre minimal des cordons de rallonge

Tension Longueur totale du cordon en pieds

120 V De 0 à 25 De 26 à 50 De 51 à 100 De 101 à 150

240 V De 0 à 50 De 51à 100 De 101 à 200 De 201 à 300

Intensité (A)

Au Au Calibre moyen de fil (AWG)

moins plus

0-6 18 16 16 14

6 - 10 18 16 14 12

10 - 12 16 16 14 12

12 - 16 14 12 Non recommandé

Caractéristiques

1. Interrupteur de marche-arrêt

2. Bouton de verrouillage en position d’arrêt

3. Orifice d’éjection des copeaux

4. Bouton de réglage de la profondeur de rabotage

5. Échelle graduée de la profondeur de rabotage

Page 4

profondeur de coupe de manière à ne retirer qu’une mince couche à chaque passage, puis

effectuer des passages répétitifs jusqu’à ce que le résultat voulu soit obtenu.

• Pour faire avancer l’outil en ligne droite, exercer une pression sur l’avant de l’outil au début

du passage, puis sur l’arrière à la fin du passage.

Remplacement de la courroie d’entraînement (figure G)

• Desserrer les vis (20) et retirer le couvercle (21).

• Retirer l’ancienne courroie.

• Insérer la nouvelle courroie (22) sur les poulies, en la faisant d’abord passer sur la grande

poulie (23), puis sur la petite (24), tout en faisant tourner la courroie d’un mouvement

uniforme.

• Replacer le couvercle et serrer les vis.

Entretien

Cet outil a été conçu pour fonctionner longtemps en ne requérant qu’un entretien minimal.

Son bon fonctionnement repose sur un entretien adéquat, dont :

• le nettoyage périodique des fentes de ventilation au moyen d’une brosse souple ou d’un

chiffon sec, et

• le nettoyage périodique du boîtier du moteur au moyen d’un chiffon humide.

• Ne jamais utiliser de nettoyants abrasifs ou à base de solvant; ne jamais laisser de

liquide s’infiltrer dans l’outil; ne jamais immerger quelque pièce de l’outil que ce soit dans un

liquide.

IMPORTANT : pour assurer la SÉCURITÉ et la FIABILITÉ de ce produit, toutes les

opérations de réparation, d’entretien et de réglage (autres que celles expliquées dans ce

manuel) doivent être effectuées dans un centre de service autorisé ou par du personnel

qualifié; on ne doit utiliser que des pièces de rechange identiques.

Accessoires

Les accessoires recommandés pour chaque outil sont vendus séparément chez les

dépositaires locaux ou dans les centres de service autorisés. Pour obtenir plus d’information

sur les accessoires, composer le 1 800 544-6986.

MISE EN GARDE : l’usage d’un accessoire non recommandé peut présenter un danger .

Information sur les services

Tous les centres de service Black & Decker sont dotés de personnel qualifié en matière

d’outillage électrique; ils sont donc en mesure d’offrir à leur clientèle un service efficace et

fiable. Pour obtenir un conseil technique ou une pièce d’origine ou pour faire réparer un outil,

on peut communiquer avec le centre Black & Decker le plus près. Pour obtenir un numéro de

téléphone, consulter les pages jaunes sous la rubrique « Outils – électriques », composer le

1 800 544-6986 ou encore, visiter notre site Web www.blackanddecker.com.

Garantie complète de deux ans pour usage résidentiel

Black & Decker (U.S.) Inc. garantit ce produit pour une période de deux ans contre tout

défaut de matériel ou de fabrication. Le produit défectueux sera réparé sans frais, suivant

l’une des deux méthodes suivantes.

La première méthode consiste en un échange seulement. On doit retourner le produit au

détaillant qui l’a vendu (pourvu qu’il s’agisse d’un détaillant participant), en respectant les

délais stipulés dans sa politique relative aux échanges (normalement de 30 à 90 jours après

la vente). Une preuve d’achat peut être requise. On doit vérifier la politique de retour du

détaillant pour tout produit retourné après le délai prescrit pour les échanges.

La deuxième méthode consiste à apporter ou à envoyer le produit (prépayé) à un centre

Black & Decker ou à un centre de service autorisé aux fins de réparation ou de

remplacement, selon notre choix. Une preuve d’achat peut être requise. Les centres Black &

Decker et les centres de service autorisés sont répertoriés dans les pages jaunes sous la

rubrique « Outils – électriques », et dans le site Web www.blackanddecker.com.

Cette garantie ne s’applique pas aux accessoires. Cette garantie confère des droits légaux

particuliers à l’acheteur, mais celui-ci pourrait aussi bénéficier d’autres droits variant d’un

territoire à l’autre.

T oute question doit être adressée au gérant du centre Black & Decker le plus près. Ce produit

n’est pas destiné à un usage commercial.

REMPLACEMENT GRATUIT D’ÉTIQUETTES D’AVERTISSEMENT : en cas de perte ou

d’endommagement des étiquettes d’avertissement, composer le 1 800 544-6986 afin d’en

obtenir de nouvelles sans frais.

Imported by / Importé par

Black & Decker Canada Inc.

100 Central Ave.

Brockville (Ontario) K6V 5W6

Voir la rubrique “Outils électriques”

des Pages Jaunes

pour le service et les ventes.

NORMAS DE SEGURIDAD GENERAL

ADVERTENCIA: Lea y asegúrese de comprender bien todas las instrucciones. El

incumplimiento de todas las instrucciones enumeradas más abajo puede resultar en

descarga eléctrica, incendio y/o lesiones corporales serias.

GUARDE ESTAS INSTRUCCIONES

Área de trabajo

• Mantenga su área de trabajo limpia y bien iluminada. Los accidentes abundan en las

mesas de trabajo desordenadas y áreas oscuras.

• No opere máquinas herramienta en ambientes explosivos, tales como en presencia de

líquidos, gases o polvos inflamables. Las máquinas herramienta generan chispas que

pueden inflamar el polvo o los gases.

• No use máquinas herramienta en presencia de niños u otras personas. Las distracciones

pueden hacerle perder el control.

Seguridad eléctrica

• Las herramientas con doble aislamiento vienen equipadas con un enchufe polarizado (con

una pata más ancha que la otra.) Este enchufe sólo tiene una manera de ser insertado en

una toma de corriente polarizada. Si el enchufe no entra completamente en la toma de

corriente, inviértalo. Si aún así no entra, comuníquese con un electricista calificado para

instalar una toma de corriente polarizada. No altere el enchufe. El doble aislamiento elimina

la necesidad de tener un cable eléctrico trifilar conectado a tierra y un sistema de

alimentación eléctrica conectado a tierra.

• Evite el contacto corporal con superficies conectadas a tierra, tales como tuberías,

radiadores, cocinas eléctricas y refrigeradores. El riesgo de descarga eléctrica aumenta si

su cuerpo está conectado a tierra.

• No exponga máquinas herramienta a condiciones lluviosas o húmedas. Si entra agua a la

máquina herramienta, aumentará el riesgo de descarga eléctrica.

MANUAL DE INSTRUCCIONES

CCCCeeeeppppiiiilllllllloooo ddddeeee 8888,,,,22225555 ccccmmmm.... ((((3333----1111////4444 ppppuuuullllgggg....))

))

NNNNoooo.... ddddeeee ccccaaaattttáááállllooooggggoooo 77776666999988

88

POR FAVOR LLAME AL 1-800-544-6986 ANTES DE DEVOLVER ESTE

PRODUCTO, CUALQUIERA SEA LA RAZÓN.

• No abuse del cable. Nunca levante las herramientas por el cable, ni tire de él para

desenchufarlas. Mantenga el cable alejado de fuentes de calor, aceite, bordes afilados o

piezas en movimiento. Reemplace de inmediato cualquier cable dañado. Los cables

dañados aumentan el riesgo de descarga eléctrica.

• Cuando use una máquina herramienta en la intemperie, use un alargador de exterior

marcado "W-A" o "W." Estos cables están calificados para uso exterior y reducen el riesgo

de descarga eléctrica.

Seguridad personal

• Manténgase alerta, ponga atención a su trabajo y use su sentido común cuando opere una

máquina herramienta. No use la herramienta cuando esté cansado o bajo la influencia de

drogas, alcohol o medicamentos. Sólo hace falta un momento de distracción durante la

operación de máquinas herramienta para causar lesiones corporales serias.

• Vístase debidamente. No se ponga ropa suelta o joyas. Amárrese el pelo. Mantenga alejados

de las piezas en movimiento su pelo, ropa y guantes. Ropa suelta, joyas o pelo largo pueden

quedar atrapados en piezas en movimiento. Las rejillas de ventilación cubren piezas en

movimiento y deberían ser evitadas.

• Evite encender la herramienta en forma accidental. Asegure que el conmutador esté

apagado antes de enchufarla. El sujetar la herramienta con el dedo en el conmutador o

enchufar herramientas ya encendidas, se presta para que ocurran accidentes.

• Quite toda llave de ajuste antes de encender la herramienta. El dejar una llave puesta en una

pieza rotante de la herramienta puede resultar en lesión corporal.

• No se sobreextienda. Mantenga siempre el equilibrio. Si mantiene el equilibrio podrá tener

mejor control de la herramienta en situaciones inesperadas.

• Use equipo de seguridad. Siempre use gafas de protección. Se debe usar máscara

antipolvo, calzado de seguridad antideslizante, casco de seguridad o protección auditiva,

dependiendo de las condiciones que apliquen.

Uso y cuidado de la herramienta

• Use abrazaderas u otra manera práctica de fijar y sujetar la pieza de trabajo a una plataforma

estable. No sujete su trabajo en forma manual o contra su cuerpo pues no quedará estable y

podrá perder el control.

• No fuerce la herramienta. Use la herramienta correcta para su aplicación. La herramienta

apropiada hará un trabajo mejor y más seguro para el propósito para el cual fue diseñada.

• No use la herramienta si el conmutador no funciona bien. Cualquier herramienta que no

puede ser controlada con el conmutador es peligrosa y debe ser reparada.

• Desenchufe la herramienta antes de ajustarla, cambiar de accesorio o guardarla. Tales

medidas preventivas reducen el riesgo de encender la herramienta en forma accidental.

• Cuando no esté en uso, almacene su herramienta fuera del alcance de niños y otras

personas no capacitadas en su funcionamiento. Las herramientas son peligrosas en manos

de personas no capacitadas.

• Cuide sus herramientas. Mantenga herramientas usadas para cortar afiladas y limpias. Las

herramientas afiladas tienen menos probabilidades de trabarse y son más fáciles de

controlar si son debidamente mantenidas.

• Revise la herramienta para verificar que no esté mal alineada, que sus piezas móviles no

estén trabadas o rotas y que no exista otra condición que pudiera afectar su operación. Si

está dañada, llévela a ser reparada antes de usarla. Muchos accidentes son causados por

usar herramientas que no han sido bien mantenidas.

• Utilice sólo aquellos accesorios que hayan sido recomendados por el fabricante para su

modelo. Algunos accesorios pueden ser apropiados para una herramienta pero pueden

crear un riesgo de lesión cuando se utilizan con otra.

Servicio

• El servicio a la herramienta sólo deber ser realizado por personal de reparación calificado. Si

el servicio o mantenimiento es realizado por personal no calificado, podría resultar en riesgo

de lesión.

• Cuando se repare una herramienta, sólo se deben usar repuestos originales. Siga las

instrucciones en la sección de mantenimiento de este manual. El uso de repuestos no

autorizados o el incumplimiento de las instrucciones de mantenimiento pueden crear un

riesgo de descarga eléctrica o lesión.

Norma específica de seguridad

• Sostenga la herramienta por sus superficies de empuñadura aisladas cuando realice una

operación en la cual la herramienta para cortar pudiera entrar en contacto con instalaciones

eléctricas ocultas o con su propio cable. El contacto con un cable cargado, cargará a su vez

las partes metálicas expuestas de la herramienta y dará un golpe de corriente al operador.

Instrucciones adicionales de seguridad para cepillos

• Lea el manual de instrucciones detenidamente antes de utilizar esta herramienta.

• Asegúrese que el conmutador esté en la posición OFF(apagado) antes de enchufar la her-

ramienta.

• Apague la herramienta inmediatamente si se atasca en la pieza de trabajo.

• Desenchufe la herramienta cuando la limpie o ajuste.

• Siempre sostenga la herramienta con ambas manos y desde sus empuñaduras.

• Asegúrese de tener la herramienta bien sostenida o montada para su uso debido antes de

poner el conmutador en la posición ON (encendido).

• Cuide su herramienta. Siga las instrucciones de lubricación y de cambio de accesorios.

• Guarde la herramienta en un lugar limpio y seco luego de desenchufarla.

• Mantenga las rejillas de ventilación sin obstrucción para un enfriamiento adecuado del

motor.

• Mantenga el canal lateral de desecho libre de obstrucciones en todo momento.

• Por ningún motivo ponga los brazos o manos debajo de la herramienta, a no ser que esta

esté apagada y DESENCHUFADA. LAS HOJAS ESTÁN EXPUESTAS Y SON

EXTREMADAMENTE FILUDAS.

• Use esta herramienta sólo para trabajos con madera y productos de madera.

• Quítele todos los clavos y otros objetos metálicos a la pieza de trabajo antes de cepillarla.

• Use sólo hojas de corte afiladas. Las hojas del cepillo son extremadamente filudas: mané-

jelas con mucho cuidado.

• Nunca ponga a un lado la herramienta sin antes esperar a que las hojas de corte se hayan

detenido completamente. NO ponga la herramienta sobre su base metálica con las hojas

expuestas. Esto puede hacer que la hoja se rompa o desportille.

La etiqueta de su herramienta puede incluir los siguientes símbolos.

V ..........................volts A..........................amperes

Hz ........................hertz W ........................watts

min........................minutos ......................corriente alterna

......................corriente directa

n

o........................velocidadsin carga

..........................construcción clase II

........................erminales de

conexión a tierre

........................símbolo de alerta seguridad .../min ..................revoluciones o

reciprocaciones

porminuto

ADVERTENCIA: Algunos tipos de polvo, como aquellos generados por el lijado,

serruchado, pulido y taladrado mecánico y otras actividades de construcción, contienen

químicos que se sabe causan cáncer, defectos de nacimiento y otros daños reproductivos.

Algunos ejemplos de estos químicos son:

• plomo de algunas pinturas,

• polvo de sílice proveniente de ladrillos y cemento y otros productos de albañilería, y

• arsénico y cromo provenientes de maderas tratadas con químicos (arseniato de

cobre cromado).

Su riesgo de exposición a estos químicos varía, dependiendo de la frecuencia con la cual

realiza usted este tipo de trabajo. Para reducir su exposición a estos químicos, trabaje en un

lugar con buena ventilación y trabaje con equipo de seguridad aprobado, como máscaras

antipolvo especialmente diseñadas para filtrar partículas microscópicas.

• Evite el contacto prolongado con polvo generado por el lijado, serruchado, pulido y

taladrado mecánico y otras actividades de construcción. Vístase con ropa de protección y lave con agua y jabón las áreas de su cuerpo que hayan sido expuestas.

La penetración de polvo a la boca o los ojos o el contacto de este con la piel, puede

promover la absorción de químicos dañinos.

ADVERTENCIA: El uso de esta herramienta puede generar y/o dispersar polvo, lo cual

puede causar lesiones respiratorias o de otro tipo, serias y permanentes. Siempre use

protección respiratoria aprobada por NIOSH (Instituto Nacional de Seguridad y Salud en el

Trabajo) u OSHA (Administración de Seguridad y Salud en el Trabajo) apropiada para la

exposición al polvo. Dirija las partículas en dirección contraria a la cara y el cuerpo.

Page 5

ATENCIÓN: Use protección auditiva apropiada durante el uso de esta herramienta.

El ruido generado por este producto puede contribuir a la pérdida auditiva, en algunas

condiciones y duraciones de uso.

GUARDE ESTAS INSTRUCCIONES

MOTOR

Asegúrese que su tipo de alimentación eléctrica coincida con la señalada en la placa. 120

voltios de corriente alterna significa simplemente que su herramienta funcionará con la

corriente doméstica estándar de 60 Hz. No opere herramientas de corriente alterna con

corriente continua. Una clasificación de 120 voltios CA/CC (AC/DC) significa que su

herramienta operará con corriente estándar de 60 Hz, ya sea CA o CC. Esta información

está impresa en la placa. Un voltaje menor resultará en la pérdida de potencia y puede

resultar en sobrecalentamiento. Todas las herramientas Black & Decker han sido probadas

en la fábrica; si esta herramienta no funciona, revise la alimentación eléctrica.

USO DE ALARGADORES

Asegúrese que el alargador está en buenas condiciones antes de usarlo. Siempre use el

tamaño de alargador apropiado para la herramienta – es decir, el diámetro adecuado de

alambre para los diversos largos de cable y suficiente como para conducir la corriente que

tira la herramienta. El uso de un cable de menor tamaño producirá una caída en la tensión de

línea lo cual causará una pérdida de potencia y sobrecalentamiento. Para ver los tamaños

de cable adecuados, consulte el cuadro de más abajo.

Ensamblado

ADVERTENCIA: Asegúrese que la herramienta esté apagada y desenchufada cuando

siga los siguientes pasos de ensamblado.

Cambio de las hojas de corte (fig. A)

Las hojas de corte incluidas con esta herramienta son reversibles. Puede conseguir hojas de

corte de repuesto en su distribuidor local.

Cómo sacarlas

• Suelte los pernos (6) con la llave incluida.

• Deslice la hoja (7) para sacarla de su soporte.

• Invierta la hoja para poner el canto sin uso en posición. Si ambos cantos están romos, debe

cambiar la hoja.

Cómo ponerlas

• Deslice la hoja en el soporte hasta que tope con el otro extremo.

• Ajuste los pernos con la llave incluida.

• Siempre cambie ambas cuchillas.

Ajuste de profundidad del corte (fig. B)

La profundidad del corte se indica con la marca (8). El rango de configuración puede leerse en

el graduador (5).

• Gire el botón de ajuste de profundidad del cepillado (4) y colóquelo en la profundidad de

corte deseada.

• Gire el botón a la posición ‘P’ cuando la herramienta no esté en uso.

NOTA: 10 topes fijos indican un aumento de 0,7937 mm. (1/32 pulg.) en el corte para una

medición precisa. La profundidad máxima de corte es de 1,984 mm. (5/64 pulg.). Se

recomienda realizar cortes de prueba en pedazos de madera sobrante luego de cada

reajuste para asegurarse que el cepillo esté recortando la cantidad de madera deseada. Si

realiza varias pasadas de profundidad reducida, producirá un acabado más suave que si

realiza una pasada profunda.

Cómo poner y sacar el soporte guía paralelo (fig. C)

El soporte guía paralelo se usa para tener un control óptimo del corte cuando se trabaja con

piezas angostas.

• Suelte el botón de bloqueo (9).

• Inserte el soporte guía paralelo (11) por la apertura (10).

• Deslice el soporte guía paralelo y colóquelo en la posición deseada.

• Ajuste el botón de bloqueo.

• Para quitar el soporte guía paralelo, siga las mismas instrucciones en orden inverso.

Cómo conectarle una aspiradora a la herramienta (fig. D)

• Deslice el adaptador (12) sobre la salida de virutas de desecho (3).

• Conecte la manguera de la aspiradora (13) al adaptador.

Ensamblado y colocado de la bolsa de colección de virutas (fig. E)

La bolsa de colección de virutas es especialmente útil cuando se trabaja en espacios

limitados. Antes de usarla por primera vez tendrá que ensamblarla.

• Conecte los marcos de metal (14) a la placa conectora (15) con los tornillos (16) y las

arandelas (17).

• Jale la bolsa de tela (18) sobre la estructura metálica, como lo muestra la figura.

• Fíjese que la abertura de la bolsa (19) quede bien puesta sobre el borde de la placa

conectora (15).

• Deslice la placa conectora sobre la salida de virutas de desecho (3).

Operación

• Ajuste la profundidad del corte.

• Si es necesario, inserte y ajuste el soporte guía paralelo.

• Use sólo cuchillas filudas.

Encendido y apagado

Encendido (Siempre levante el cepillo antes de presionar el conmutador.)

• Mantenga presionado el botón de bloqueo en off (2) y presione el conmutador de

encendido y apagado (1).

• Suelte el botón de bloqueo en off.

Apagado

• Suelte el conmutador de encendido y apagado.

Cepillado

• Sostenga la herramienta con la pieza extrema de la base metálica puesta sobre la

superficie de la pieza de trabajo.

• Encienda la herramienta.

• Mueva la herramienta hacia adelante en forma pareja para realizar la pasada de corte.

• Apague la herramienta luego de completar la pasada.

Rebajado (fig. F)

• Inserte y ajuste el soporte guía paralelo.

• Siga las mismas instrucciones que para el cepillado.

Biselado de bordes

La ranura con forma de ‘V’ en la pieza extrema de la base metálica le permite biselar bordes

en ángulos de 45 grados.

• Sostenga la herramienta en un ángulo con la ranura sobre el borde de la pieza de trabajo y

realice la pasada de corte.

• Es buena idea probar con un pedazo de madera sobrante antes de hacer trabajos de

acabado.

Vaciado de la bolsa de colección de virutas

La bolsa de colección de virutas debería ser vaciada en forma regular durante su uso.

• Abra el cierre de la bolsa y vacíela antes de seguir.

Consejos para su uso óptimo

• Mueva la herramienta en dirección a la veta de la madera.

• Si la veta es transversal o rizada, o si el material de la pieza de trabajo es una madera dura,

ajuste la profundidad del corte para que sólo recorte una capa delgada con cada pasada y

que sean necesarias varias pasadas para lograr el resultado deseado.

• Para que la herramienta se mantenga en línea recta, presione hacia abajo la parte de

adelante de la herramienta al comienzo y la parte de atrás de la herramienta al final de la

pasada de corte.

Cambiado de la correa de transmisión (fig. G)

• Suelte los tornillos (20) y quite la cubierta (21).

• Quite la correa de transmisión vieja.

• Coloque la correa nueva (22) sobre las poleas. Coloque la correa sobre la polea más grande

(23) primero, y luego sobre la polea más pequeña (24), mientras gira manualmente la correa

en forma constante.

• Coloque la cubierta en su sitio nuevamente y ajuste los tornillos.

Mantenimiento

Su herramienta ha sido diseñada para funcionar durante un período largo de tiempo

necesitando un nivel mínimo de mantenimiento. Su funcionamiento continuo y satisfactorio

depende del cuidado debido de la herramienta lo que incluye lo siguiente:

• Limpie en forma regular las rejillas de ventilación de su herramienta con una escobilla suave

o paño seco.

• Limpie en forma regula la caja protectora del motor con un paño húmedo.

• No use un limpiador abrasivo o que tenga una base solvente. Nunca deje que le entre

líquido a la herramienta ni sumerja ninguna parte de la herramienta en líquido.

IMPORTANTE: Las reparaciones, el mantenimiento y los ajustes del dispositivo (fuera de

los mencionados en este documento) deberán ser realizados por centros de servicio

autorizados u otro personal de servicio calificado, utilizando siempre repuestos idénticos,

para asegurar la SEGURIDAD y FIABILIDAD de la unidad.

Accesorios

Los accesorios recomendados para ser utilizados con su herramienta se encuentran

disponibles donde su distribuidor o centro de servicio autorizado locales. Si tiene alguna

consulta acerca de estos accesorios, por favor llame al (55)5326-7100.

ADVERTENCIA: El uso de cualquier accesorio que no sea recomendado para ser

utilizado con esta herramienta podría ser peligroso.

Información de servicio

Todos los Centros de Servicio Black & Decker están dotados de personal capacitado para

proporcionar un servicio técnico eficiente y fiable a las máquinas herramientas de nuestros

clientes. Contacte al local Black & Decker más cercano para obtener consejos técnicos,

reparaciones o repuestos de fábrica originales. Para encontrar el local de servicio más

cercano, busque en las páginas amarillas bajo “Herramientas eléctricas”, llame al

(55)5326-7100 o visite nuestra página web www.blackanddecker.com

Garantía completa de dos años para uso doméstico

Black & Decker (U.S.) Inc. garantiza este producto por dos años contra cualquier defecto en

su material o fabricación. Existen dos opciones para reemplazar o reparar el producto

defectuoso, sin costo.

La primera, la cual resultará sólo en un cambio, es devolver el producto al vendedor del cual

fue comprado (siempre que sea un local participante). Las devoluciones deberán realizarse

durante el plazo especificado en la política de devoluciones del vendedor (generalmente

entre 30 y 90 días después de la fecha de compra). Puede que sea necesario presentar

prueba de compra. Por favor averigüe cuál es la política del vendedor para devoluciones

efectuadas más allá del plazo para cambios.

La segunda opción es llevar o enviar el producto (con franqueo pagado) a un centro de

servicio autorizado o al Centro de Servicio Black & Decker para su reparación o reemplazo,

a decisión nuestra. Puede que sea necesario presentar prueba de compra. Los centros de

servicio autorizados y Centros de Servicio Black & Decker se encuentran en las páginas

amarillas bajo “Herramientas eléctricas” y en nuestra página web

www.blackanddecker.com.

Esta garantía no aplica a los accesorios. Esta garantía le da derechos legales específicos

además de los cuales puede tener otros, los cuales varían entre estados. Si tuviese alguna

pregunta, contacte al gerente de su Centro de Servicio Black & Decker más cercano. Este

producto no es para uso comercial.

REEMPLAZO GRATUITO DE LA ETIQUETA DE ADVERTENCIAS: Si sus etiquetas de

advertencias se vuelven ilegibles o si se pierden, llame al 1-800-544-6986 para

reemplazarlas gratuitamente.

ARA REPARACION YSERVICIO DE SUS HERRAMIENT AS ELECTRICAS FA VOR DE

DIRIGIRSE ALCENTRO DE SERVICIO MAS CERCANO

CULIACAN Av. Nicolas Bravo #1063 Sur (56 77) 12 42 10

GAUDALAJARA Av . La Paz #1770 (33 38) 26 69 78

LEON Polara #32 (47 77) 13 14 56

MEXICO Sonora #134 Hiprodromo Condesa (55 55) 53 99 79

MERIDA Calle 63 #459 (99 99) 23 54 90

MONTERREY Av. Francisco I. Madero Pte. 1820-A (81 83) 72 11 25

PUEBLA 17 Norte #2057 (22 22) 46 90 20

QUERETARO Av . Madero 139 Pte. (44 22) 14 60 60

SAN LOUIS POTOSI Pedro Moreno #408 Fracc. la Victoria (44 48) 14 25 67

TORREON Blvd. Independencia, 96 pte. (87 17) 16 52 65

VERACRUZ Prolongación Diaz Miron #4280 (29 99) 21 70 18

VILLAHERMOSA Zaragoza #105 (99 33) 12 53 17

PARAOTRAS LOCALIDADES LLAME AL: (55) 5326-7100 INFORMACIÓN DE SERVICIO

Calibre mínimo para cordones de extensión

Volts Longitud total del cordón en metros

120V 0 - 7.62 7.63 - 15.24 15.25 - 30.48 30.49 - 45.72

240V 0 - 15.24 15.25 - 30.48 30.49 - 60.96 60.97 - 91.44

AMPERAJE

Más No más Calbre del cordón

de de

0-6 18 16 16 14

6 - 10 18 16 14 12

10 - 12 16 16 14 12

12 - 16 14 12 No Recomendado

Características

1. Conmutador on/off (de encendido y apagado)

2. Botón de bloqueo en off (apagado)

3. Salida de virutas de desecho

4. Botón de ajuste de profundidad del cepillado

5. Graduador de profundidad del cepillado

IMPORTADOR: BLACK & DECKER S.A. DE C.V.

BOSQUES DE RADIATAS NO. 42

BOSQUES DE LAS LOMAS, 05120 MEXICO,

D.F.

TEL 326-7100

Para servicio y ventas consulte

“HERRAMIENTAS ELECTRICAS”

en la sección amarilla.

ESPECIFICACIONES - 7698

Tension de alimentación: 120 Potencia nominal: 580 W

Frecuencia de operación: 60 Hz Consumo de corriente: 5,2 A

Loading...

Loading...