Page 1

Single Speed Jigsaw

INSTRUCTION MANUAL

Catalog Number

7662

d) Remove any adjusting key or wrench before turning the power tool on. A wrench

or a key left attached to a rotating part of the power tool may result in personal injury.

e) Do not overreach. Keep proper footing and balance at all times. This enables bet-

ter control of the power tool in unexpected situations.

f) Dress properly. Do not wear loose clothing or jewelry. Keep your hair, clothing

and gloves away from moving parts. Loose clothes, jewelry or long hair can be

caught in moving parts.

g) If devices are provided for the connection of dust extraction and collection

facilities, ensure these are connected and properly used. Use of dust collection

can reduce dust-related hazards.

4) POWER TOOL USE AND CARE

a) Do not force the power tool. Use the correct power tool for your application. The cor-

rect power tool will do the job better and safer at the rate for which it was designed.

b) Do not use the power tool if the switch does not turn it on and off. Any power tool

that cannot be controlled with the switch is dangerous and must be repaired.

c) Disconnect the plug from the power source and/or the battery pack from the

power tool before making any adjustments, changing accessories, or storing

power tools. Such preventive safety measures reduce the risk of starting the power

tool accidentally.

d) Store idle power tools out of the reach of children and do not allow persons

unfamiliar with the power tool or these instructions to operate the power tool.

Power tools are dangerous in the hands of untrained users.

e) Maintain power tools. Check for misalignment or binding of moving parts,

breakage of parts and any other condition that may affect the power tool’s operation. If damaged, have the power tool repaired before use. Many accidents are

caused by poorly maintained power tools.

f) Keep cutting tools sharp and clean. Properly maintained cutting tools with sharp

cutting edges are less likely to bind and are easier to control.

g) Use the power tool, accessories and tool bits, etc. in accordance with these

instructions, taking into account the working conditions and the work to be

performed. Use of the power tool for operations different from those intended could

result in a hazardous situation.

Thank you for choosing Black & Decker!

Go to www.BlackandDecker.com/NewOwner

to register your new product.

PLEASE READ BEFORE RETURNING THIS

PRODUCT FOR ANY REASON:

If you have a question or experience a problem with your Black & Decker purchase, go to

HTTP://WWW.BLACKANDDECKER.COM/INSTANTANSWERS

for instant answers 24 hours a day.

If you can’t find the answer or do not have access to the internet,

call 1-800-544-6986 from 8 a.m. to 5 p.m. EST Mon. -- Fri. to speak with an agent.

Please have the catalog number available when you call.

SAVE THIS INSTRUCTION MANUAL FOR FUTURE REFERENCE.

VEA EL ESPA—OL EN LA CONTRAPORTADA.

INSTRUCTIVO DE OPERACIÓN, CENTROS DE SERVICIO Y PÓLIZA DE GARANTÍA.

ADVERTENCIA: LÉASE ESTE INSTRUCTIVO ANTES DE USAR EL PRODUCTO.

CAT. NO. 7662 FORM NO. 90590169 AUG. 2012

Copyright © 2012 Black & Decker Printed in China

SAFETY GUIDELINES - DEFINITIONS

It is important for you to read and understand this manual. The information it contains

relates to protecting YOUR SAFETY and PREVENTING PROBLEMS. The symbols below

are used to help you recognize this information.

DANGER: Indicates an imminently hazardous situation which, if not avoided, will result

in death or serious injury.

WARNING: Indicates a potentially hazardous situation which, if not avoided, could

result in death or serious injury.

CAUTION: Indicates a potentially haz ard ous situation which, if not avoided, may

result in minor or mod er ate injury.

NOTICE: Used without the safety alert symbol indicates potentially hazardous situation

which, if not avoided, may result in property damage.

General Safety Rules

WARNING: Read all safety warnings and all instructions. Failure

to follow the warnings and instructions may result in electric shock,

fire and/or serious injury.

SAVE ALL WARNINGS AND INSTRUCTIONS FOR FUTURE REFERENCE

The term “power tool” in the warnings refers to your mains-operated (corded) power tool or battery-operated (cordless) power tool.

5) SERVICE

a) Have your power tool serviced by a qualied repair person using only identical

replacement parts. This will ensure that the safety of the power tool is maintained.

Specic Safety Rules

• Hold power tool by insulated gripping surfaces, when performing an operation

where the cutting accessory may contact hidden wiring or its own cord. Cutting

accessory contacting a “live” wire may make exposed metal parts of the power tool “live”

and could give the operator an electric shock.

• Use clamps or another practical way to secure and support the work piece to a

stable platform. Holding the work by hand or against your body leaves it unstable and

may lead to loss of control.

• Keep hands away from cutting area. Never reach underneath the material for any rea-

son. Hold front of saw by grasping the contoured gripping area. Do not insert fingers or

thumb into the vicinity of the reciprocating blade and blade clamp. Do not stabilize the

saw by gripping the shoe.

• Keep blades sharp. Dull blades may cause the saw to swerve or stall under pressure.

• When cutting pipe or conduit ensure that they are free from water, electrical wiring, etc.

• Allow the motor to come to a complete stop before withdrawing the blade from the

kerf (the slot created by cutting). A moving blade may impact the workpiece causing a

broken blade, workpiece damage or loss of control and possible personal injury.

• Never hold work in your hand, lap or against parts of your body when sawing. The

saw my slip and the blade could contact the body causing injury.

• Keep handles dry, clean, free from oil and grease. This will enable better control of the tool.

• Use extra caution when cutting overhead and pay particular attention to overhead

wires which may be hidden from view. Anticipate the path of falling branches and

debris ahead of time.

•

Clean out your tool often, especially after heavy use. Dust and grit containing metal

particles often accumulate on interior surfaces and could create an electric shock hazard.

• Do not operate this tool for long periods of time. Vibration caused by the operating

action of this tool may cause permanent injury to fingers, hands, and arms. Use gloves to

provide extra cushion, take frequent rest periods, and limit daily time of use.

WARNING: Some dust created by power sanding, sawing, grinding, drilling, and

other construction activities contains chemicals known to cause cancer, birth

defects or other reproductive harm. Some examples of these chemicals are:

•lead from lead-based paints,

•crystalline silica from bricks and cement and other masonry products, and

•arsenic and chromium from chemically-treated lumber (CCA).

Your risk from these exposures varies, depending on how often you do this type of work.

To reduce your exposure to these chemicals: work in a well ventilated area, and work with

approved safety equipment, such as those dust masks that are specially designed to filter

out microscopic particles.

• Avoid prolonged contact with dust from power sanding, sawing, grinding, drilling,

and other construction activities. Wear protective clothing and wash exposed areas

with soap and water. Allowing dust to get into your mouth, eyes, or lay on the skin may

promote absorption of harmful chemicals.

WARNING: Use of this tool can generate and/or disperse dust, which may cause serious

and permanent respiratory or other injury. Always use NIOSH/OSHA approved respiratory

protection appropriate for the dust exposure. Direct particles away from face and body.

CAUTION: Wear appropriate hearing protection during use. Under some conditions

and duration of use, noise from this product may contribute to hearing loss.

1) WORK AREA SAFETY

a) Keep work area clean and well lit. Cluttered or dark areas invite accidents.

b) Do not operate power tools in explosive atmospheres, such as in the presence

of ammable liquids, gases or dust. Power tools create sparks which may ignite

the dust or fumes.

c) Keep children and bystanders away while operating a power tool. Distractions

can cause you to lose control.

2) ELECTRICAL SAFETY

a) Power tool plugs must match the outlet. Never modify the plug in any way. Do

not use any adapter plugs with earthed (grounded) power tools. Unmodified

plugs and matching outlets will reduce risk of electric shock.

b) Avoid body contact with earthed or grounded surfaces such as pipes, radiators,

ranges and refrigerators. There is an increased risk of electric shock if your body is

earthed or grounded.

c) Do not expose power tools to rain or wet conditions. Water entering a power tool

will increase the risk of electric shock.

d) Do not abuse the cord. Never use the cord for carrying, pulling or unplugging

the power tool. Keep cord away from heat, oil, sharp edges or moving parts.

Damaged or entangled cords increase the risk of electric shock.

e) When operating a power tool outdoors, use an extension cord suitable for outdoor

use. Use of a cord suitable for outdoor use reduces the risk of electric shock.

f) If operating a power tool in a damp location is unavoidable, use a ground fault

circuit interrupter (GFCI) protected supply. Use of a GFCI reduces the risk of elec-

tric shock.

3) PERSONAL SAFETY

a) Stay alert, watch what you are doing and use common sense when operating a

power tool. Do not use a power tool while you are tired or under the inuence

of drugs, alcohol or medication. A moment of inattention while operating power

tools may result in serious personal injury.

b) Use personal protective equipment. Always wear eye protection. Protective

equipment such as dust mask, nonskid safety shoes, hard hat, or hearing protection

used for appropriate conditions will reduce personal injuries.

c) Prevent unintentional starting. Ensure the switch is in the off position before

connecting to power source and/ or battery pack, picking up or carrying the

tool. Carrying power tools with your finger on the switch or energizing power tools

that have the switch on invites accidents.

The label on your tool may include the following symbols.

V ..................volts A ...................amperes

Hz ................hertz W ..................watts

min ..............minutes or AC ......alternating current

or DC.....direct current

................Class I Construction ..................earthing terminal

(grounded)

................Class II Construction .../min or rpm ....revolutions or reciprocation

(double insulated) per minute

SPM ............Strokes per minute

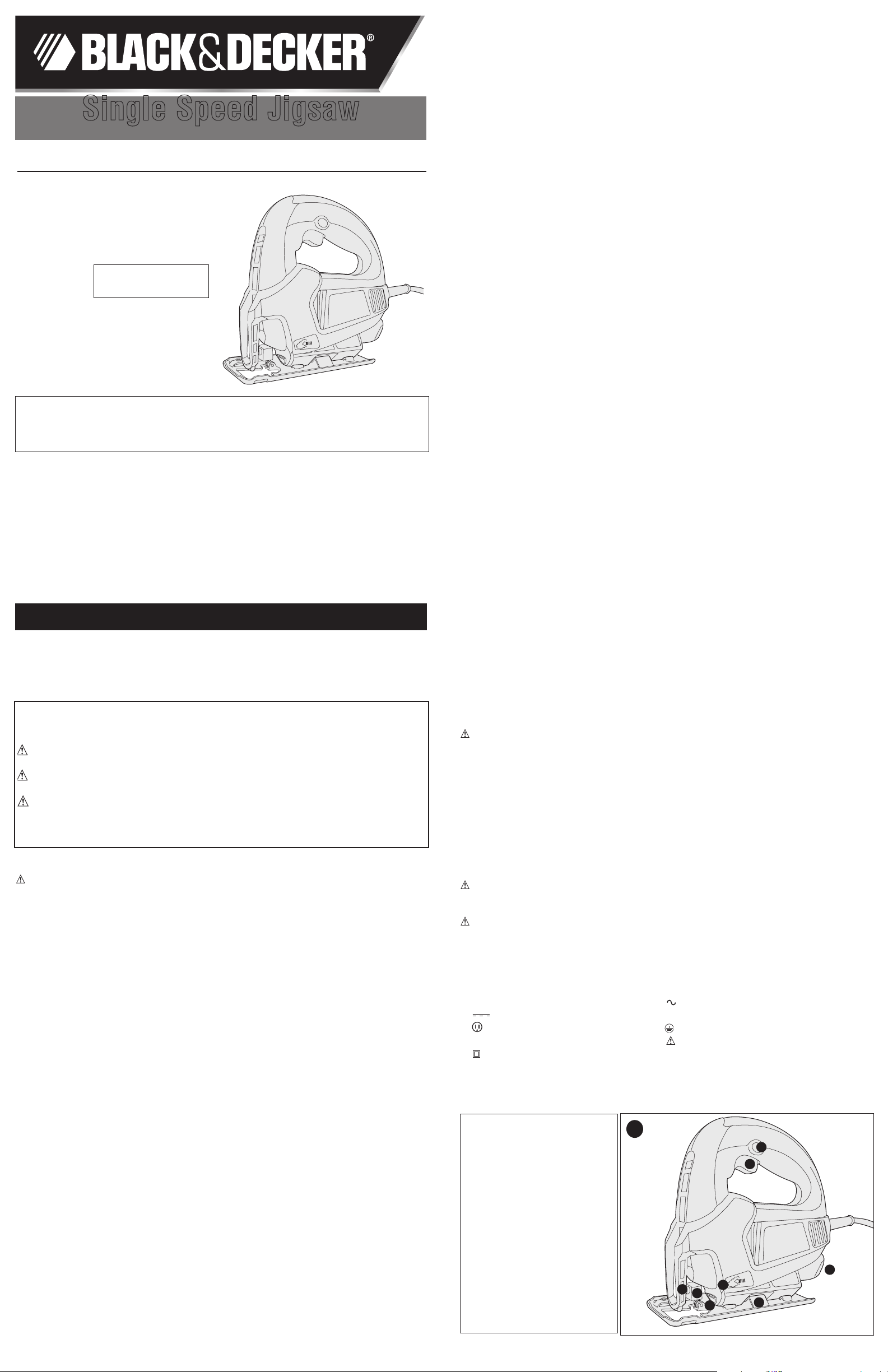

Features - Figure A

1. Single speed switch

2. Lock-on button

3. Saw blade clamp

4. Saw blade clamp screws

5. Saw blade support roller

6. Dust blower

7. Shoe plate

8. Saw blade storage compartment

n

o .................no load speed

................safety alert symbol

A

2

1

4

6

3

5

7

8

Page 2

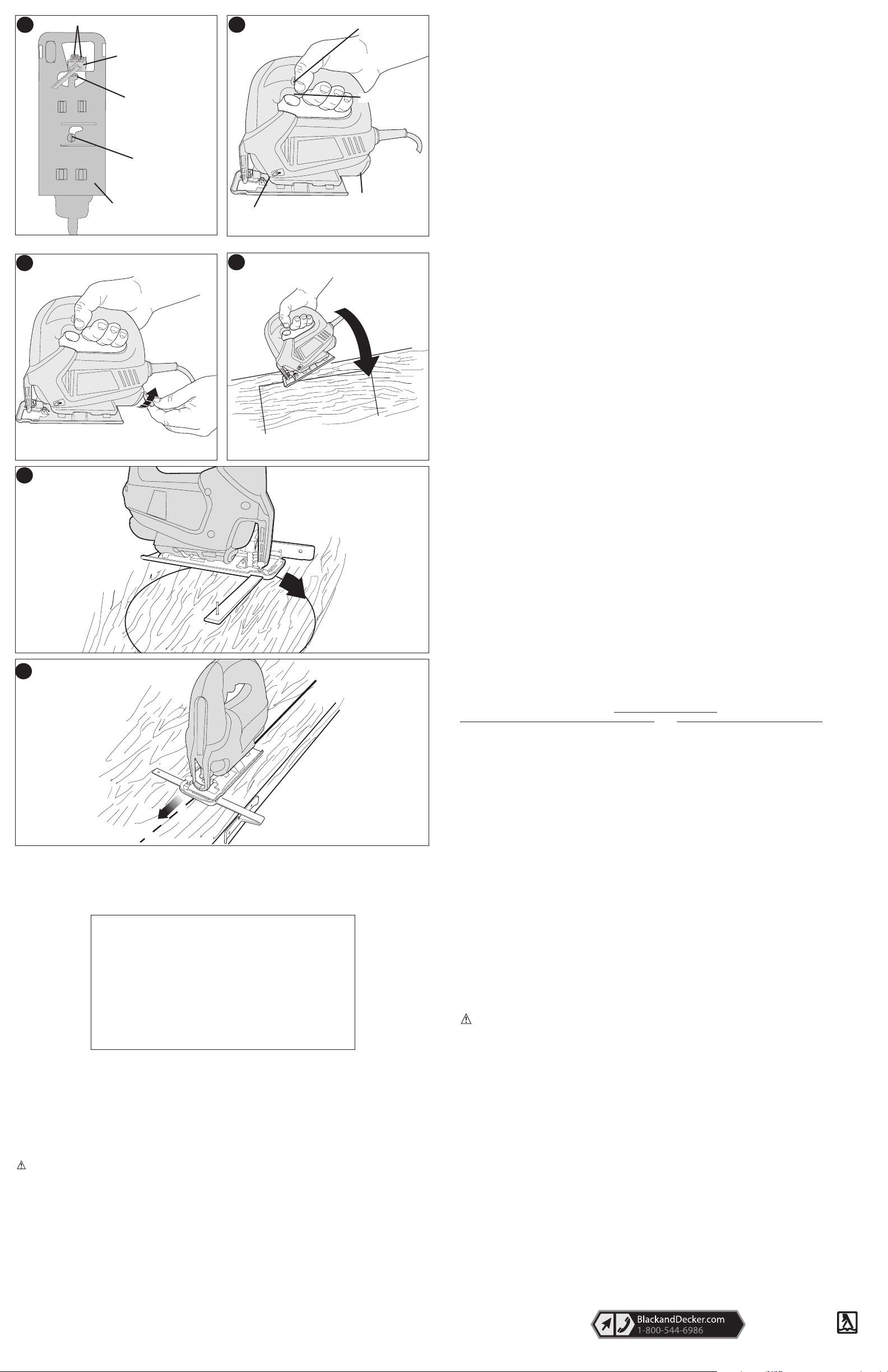

B

D

A

BLADE CLAMP

ROLLER SUPPORT

GUIDE

SCREW

SHOE

C

DUST BLOWER

E

LOCK ON BUTTON

TRIGGER SWITCH

BLADE STORAGE

F

G

USE OF EXTENSION CORDS

Make sure the extension cord is in good condition before using. Always use the proper size

extension cords with the tool – that is, proper wire size for various lengths of cord and heavy

enough to carry the current the tool will draw. Use of an undersized cord will cause a drop

in line voltage resulting in loss of power and overheating. For proper size cords see chart

below.

Minimum Gauge for Cord Sets

MOTOR

Volts Total Length of Cord in Feet

120V 0-25 26-50 51-100 101-150

(0-7,6m) (7,6-15,2m) (15,2-30,4m) (30,4-45,7m)

240V 0-50 51-100 101-200 201-300

(0-15,2m) (15,2-30,4m) (30,4-60,9m) (60,9-91,4m)

Ampere Rating

More Not more American Wire Gauge

Than Than

0 - 6 18 16 16 14

6 - 10 18 16 14 12

10 - 12 16 16 14 12

12 - 16 14 12 Not Recommended

Be sure your power supply agrees with nameplate marking. 120 Volts AC only means your

tool will operate on standard 60 Hz household power. Do not operate AC tools on DC. A

rating of 120 volts AC/DC means that you tool will operate on standard 60 Hz AC or DC

power. This information is printed on the nameplate. Lower voltage will cause loss of power

and can result in over-heating. All Black & Decker tools are factory-tested; if this tool does

not operate, check the power supply.

SAVE THESE INSTRUCTIONS

Assembly/Adjustment Set-up

INSTALLING BLADES

WARNING: Before attempting any of the following operations, make sure that the tool is

switched off and unplugged and that the saw blade has stopped. Used saw blades can be

hot.

Using a flat blade screwdriver, loosen (do not remove) the two screws “A” in Figure B.

Ensure the blade teeth are facing forward and insert the saw blade shank fully into the blade

clamp. Slightly tighten screws alternately to position the blade, then fully tighten screws. To

release, turn both screws one turn counterclockwise.

Note: To improve cutting performance, ensure back of blade is touching blade support

roller. See “Roller Support Guide”for instructions on how to change position of blade support

roller.

BLADE SUPPORT ROLLER

TURN OFF AND UNPLUG TOOL.

The blade support roller on your jigsaw improves its performance when cutting tough

materials by adding support to the blade. This support should be adjusted so that the roller

touches the back of the blade when cutting. Ensure the blade is aligned with the groove in

the roller. Adjust the support roller by loosening the screw on the bottom of the shoe (Fig.B)

and moving the shoe so that the roller touches the back edge of the blade. Retighten screw.

Lubricating the guide roller from time to time with a drop of oil will extend the life of the roller.

NOTE: Roller support guide not applicable when shoe is beveled to 45 degrees.

ON/OFF SWITCH

BEFORE PLUGGING YOUR JIGSAW IN, ENSURE THAT THE TRIGGER SWITCH IS IN

THE OFF POSITION.

To turn the saw on, squeeze the trigger switch, as shown in Figure C. To turn the tool

off, release the trigger switch. The tool can be locked on for continuous operation by fully

squeezing and holding the trigger switch while you depress the lock-on button shown in

Fig. C. With the lock-on button depressed, release the trigger switch and the tool will

continue to run. To release from lock position, squeeze and release the trigger. Always

disengage the lock before disconnecting from the power supply.

BEVEL ADJUSTMENT

TURN OFF AND UNPLUG TOOL.

To adjust the bevel angle, loosen the screw (approximately 3 full turns) on the bottom of

the shoe, as shown in Figure B. Lift the shoe slightly and pull backward, then set the shoe

at 45° (accuracy +/-5°) and retighten screw. To reset the shoe for a square cut, loosen the

screw and move the shoe until it is approximately 90° to the blade. Adjust the blade support

roller to the blade and retighten the screw.

GENERAL CUTTING

Be sure board is firmly secured. Hold jigsaw by the handle and operate switch to turn the

unit on. Don’t attempt to turn on the unit when blade is against material to be cut. This

could stall the motor. Place front of shoe on material to be cut and hold jigsaw shoe down

firmly against the work surface while cutting. Don’t force the tool; let the blade cut at its own

speed. Whenever possible, clamp or support work close to the line of cut; when the cut is

completed, shut off power and lay the saw aside before loosening the work.

AUTOMATIC DUST BLOWER

To aid visibility when cutting, your jigsaw is equipped with an automatic dust blower (Fig. C)

which will keep the work area clear of dust as you saw.

BLADE STORAGE

A convenient blade storage compartment (Fig. D) is provided at the rear of the saw.

METAL & PLASTIC CUTTING

In cutting thin gauge sheet metals, it is best to clamp wood or plywood to the bottom of the

metal sheet; this will insure a clean cut without the danger of vibration or tearing of metal.

Use a fine-tooth blade for ferrous metals (for those that have an iron content); and use a

coarser blade for nonferrous metals (those that do not have an iron content).

Cutting thin metal will take longer than cutting relatively thick wood so do not be tempted

to speed up the process by forcing the saw. Spread a thin film of cutting lubricant along the

cutting line (any light weight oil).

When cutting laminated plastic, place the finished side down and use a fine tooth hollow

ground blade.

POCKET CUTTING

• Measurethesurfacetobecutandmarkclearlywithapencil.Nexttipthesawforward

until the front edge of the shoe sits firmly on the work surface, but with the blade well

clear of it Figure E.

• Turnthetoolonandallowittoattainmaximumspeedbyfullydepressingthetriggerswitch.

• Gripthehandlefirmlyandslowlylowerthebackedgeoftooluntilthebladecuts

smoothly into material. Do not move the jigsaw forward along the cut line until the saw

blade has completely entered the material and shoe comes to rest flat on its surface.

RIP & CIRCLE CUTTING

Ripping and circle cutting without a pencil line are easily done with the rip fence and circle

guide (available at extra cost).

Using the screw supplied with the accessory guide, position as shown in Figure F and thread

the screw into the shoe to clamp the fence securely.

When circle cutting, adjust rip fence so that distance from blade to hole in cross bar is at

the desired radius and tighten screw (use hole which lines up best with saw blade). Place

saw so that hole in cross bar is over center of circle to be cut (make pocket cut, drill hole for

blade or cut inward from edge of material to get blade into position). When saw is properly

positioned, drive a small nail through hole in cross bar. Using rip fence as a pivot arm, begin

cutting circle. For circle cutting, the cross bar should be up, as shown in Figure F.

When ripping, slide the rip fence under the screw from either side of the saw. Set the cross

bar at desired distance from blade and tighten screw. For ripping, the cross bar should be

down and against the straight edge of the workpiece.

MAINTENANCE

Use only mild soap and damp cloth to clean the tool. Never let any liquid get inside the tool;

never immerse any part of the tool into a liquid.

IMPORTANT: To assure product SAFETY and RELIABILITY, repairs, maintenance and

adjustment should be performed by authorized service centers or other qualified service

organizations, always using identical replacement parts.

TROUBLESHOOTING

Problem Possible Cause Possible Solution

• Unitwillnotstart. •Cordnotpluggedin. •Plugtoolintoaworking

outlet.

•Circuitfuseisblown. •Replacecircuitfuse.

(If the product repeatedly

causes the circuit fuse to

blow, discontinue use

immediately and have it

serviced at a Black &

Decker service center or

authorized servicer.)

•Circuitbreakeristripped. •Resetcircuitbreaker.

(If the product repeatedly

causes the circuit breaker

to trip, discontinue use

immediately and have it

serviced at a Black &

Decker service center or

authorized servicer.)

•Cordorswitchisdamaged. •Havecordorswitch

replaced at Black &

Decker Service Center or

Authorized Servicer.

For assistance with your product, visit our website www.blackanddecker.com for the location of the service center nearest you or call the BLACK & DECKER help line at

1-800-544-6986.

ACCESSORIES

Recommended accessories for use with your tool are available from your local dealer or

authorized service center. If you need assistance regarding accessories, please call:

1-800-544-6986

WARNING: The use of any accessory not recommended for use with this tool could be

hazardous.

SERVICE INFORMATION

Black & Decker offers a full network of company-owned and authorized service locations

throughout North America. All Black & Decker Service Centers are staffed with trained

personnel to provide customers with efficient and reliable power tool service. Whether you

need technical advice, repair, or genuine factory replacement parts, contact the

Black & Decker location nearest you. To find your local service location, refer to the yellow

page directory under “Tools—Electric” or call: 1-800-544-6986.

FULL TWO-YEAR HOME USE WARRANTY

Black & Decker (U.S.) Inc. warrants this product for two years against any defects in

material or workmanship. The defective product will be replaced or repaired at no charge in

either of two ways.

The first, which will result in exchanges only, is to return the product to the retailer from

whom it was purchased (provided that the store is a participating retailer). Returns should

be made within the time period of the retailer’s policy for exchanges (usually 30 to 90 days

after the sale). Proof of purchase may be required. Please check with the retailer for their

specific return policy regarding returns that are beyond the time set for exchanges.

The second option is to take or send the product (prepaid) to a Black & Decker owned

or authorized Service Center for repair or replacement at our option. Proof of purchase

may be required. Black & Decker owned and authorized Service Centers are listed under

“Tools–Electric” in the yellow pages of the phone directory.

This warranty does not apply to accessories. This warranty gives you specific legal rights

and you may have other rights which vary from state to state. Should you have any

questions, contact the manager of your nearest Black & Decker Service Center. This

product is not intended for commercial use.

Free warning label replacement: If your warning labels become illegible or are missing,

call 1-800-544-6986 for a free replacement.

Black & Decker (U.S.) Inc.,

Imported by

701 E. Joppa Rd.

Towson, MD 21286 U.S.A.

See ‘Tools-

Electric’

– Yellow Pages –

for Service &

Sales

Page 3

Scie SauteuSe à une viteSSe

MODE D’EMPLOI

N° de catalogue 7662

Merci d’avoir choisi Black & Decker!

Consulter le site Web www.BlackandDecker.com/

NewOwner

pour enregistrer votre nouveau produit.

ÀLIRE AVANT DE RETOURNER CE PRODUIT

POUR QUELQUE RAISON QUE CE SOIT :

Si des questions ou des problèmes surgissent après l’achat d’un produit Black & Decker,

HTTP://WWW.BLACKANDDECKER.COM/INSTANTANSWERS

pour obtenir des réponses instantanément 24 heures par jour.

Si la réponse est introuvable ou en l’absence d’accès à Internet, composer le

1-800-544-6986 de 8 h à 17 h HNE, du lundi au vendredi, pour parler avec un agent.

Prière d’avoir le numéro de catalogue sous la main lors de l’appel.

CONSERVER CE MANUEL POUR UN USAGE ULTÉRIEUR.

LIGNES DIRECTRICES EN MATIÈRE DE SÉCURITÉ - DÉFINITIONS

Il est important que vous lisiez et compreniez ce mode d’emploi. Les informations qu’il

contient concernent VOTRE SÉCURITÉ et visent à ÉVITER TOUT PROBLÈME. Les

symboles ci-dessous servent à vous aider à reconnaître cette information.

DANGER : Indique une situation dangereuse imminente qui, si elle n’est pas évitée,

causera la mort ou des graves blessures.

AVERTISSEMENT : Indique une situation potentiellement dangereuse qui, si elle

n’est pas évitée, pourrait causer la mort ou de graves blessures.

MISE EN GARDE: Indique une situation potentiellement dangereuse qui, si elle n’est

pas évitée, pourrait causer des blessures mineures ou modérées.

AVIS: Utilisé sans le symbole d’alerte à la sécurité, indique une situation potentiellement

dangereuse qui, si elle n’est pas évitée, peut résulter en des dommages à la propriété.

Avertissements de sécurité généraux pour les outils électriques

AVERTISSEMENT Lire tous les avertissements de sécurité et toutes les

directives. Le non-respect des avertissements et des directives pourrait se solder

par un choc électrique, un incendie et/ou une blessure grave.

Conserver tous les avertissements et toutes les directives pour

un usage ultérieur.

Le terme «outil électrique» cité dans les avertissements se rapporte à votre outil

électrique à alimentation sur secteur (avec fil) ou par piles (sans fil).

1) Sécurité du lieu de travail

a) Tenir la zone de travail propre et bien éclairée. Les endroits sombres sont souvent

des causes d’accidents.

b) Ne pas faire fonctionner d’outils électriques dans un milieu déagrant, soit en

présence de liquides inammables, de gaz ou de poussière. Les outils électriques

produisent des étincelles qui peuvent enammer la poussière ou les vapeurs.

c) Éloigner les enfants et les curieux au moment d’utiliser un outil électrique. Une

distraction pourrait vous en faire perdre la maîtrise.

2) Sécurité en matière d’électricité

a) Les ches des outils électriques doivent correspondre à la prise. Ne jamais

modier la che en aucune façon. Ne jamais utiliser de che d’adaptation avec un

outil électrique mis à la terre. Le risque de choc électrique sera réduit par l’utilisation

de ches non modiées correspondant à la prise.

b) Éviter tout contact physique avec des surfaces mises à la terre comme des tuy-

aux, des radiateurs, des cuisinières et des réfrigérateurs. Le risque de choc élec-

trique est plus élevé si votre corps est mis à la terre.

c) Ne pas exposer les outils électriques à la pluie ou à d’autres conditions où il

pourrait être mouillé. La pénétration de l’eau dans un outil électrique augmente le

risque de choc électrique.

d) Ne pas utiliser abusivement le cordon d’alimentation. Ne jamais utiliser le

cordon pour transporter, tirer ou débrancher un outil électrique. Tenir le cordon

éloigné de la chaleur, de l’huile, des bords tranchants ou des pièces mobiles. Les

cordons endommagés ou emmêlés augmentent les risques de choc électrique.

e) Pour l’utilisation d’un outil électrique à l’extérieur, se servir d’une rallonge

convenant à une telle utilisation. L’utilisation d’une rallonge conçue pour l’extérieur

réduit les risques de choc électrique.

f) S’il est impossible d’éviter l’utilisation d’un outil électrique dans un endroit

humide, brancher l’outil dans une prise ou sur un circuit d’alimentation dotés

d’un disjoncteur de fuite à la terre (GFCI). L’utilisation de ce type de disjoncteur

réduit les risques de choc électrique.

3) Sécurité personnelle

a) Être vigilant, surveiller le travail effectué et faire preuve de jugement lorsqu’un

outil électrique est utilisé. Ne pas utiliser d’outil électrique en cas de fatigue

ou sous l’inuence de drogues, d’alcool ou de médicaments. Un simple moment

d’inattention en utilisant un outil électrique peut entraîner des blessures corporelles

graves.

b) Utiliser des équipements de protection individuelle. Toujours porter une protection

oculaire. L’utilisation d’équipements de protection comme un masque antipoussière, des

chaussures antidérapantes, un casque de sécurité ou des protecteurs auditifs lorsque la

situation le requiert réduira les risques de blessures corporelles.

c) Empêcher les démarrages intempestifs. S’assurer que l’interrupteur se trouve à la

position d’arrêt avant de relier l’outil à une source d’alimentation et/ou d’insérer un

bloc-piles, de ramasser ou de transporter l’outil. Transporter un outil électrique alors

que le doigt repose sur l’interrupteur ou brancher un outil électrique dont l’interrupteur est

à la position de marche risque de provoquer un accident.

d) Retirer toute clé de réglage ou clé standard avant de démarrer l’outil. Une clé

standard ou une clé de réglage attachée à une partie pivotante peut causer des

blessures.

e) Ne pas trop tendre les bras. Conserver son équilibre en tout temps. Cela permet

de mieux maîtriser l’outil électrique dans les situations imprévues.

f) S’habiller de manière appropriée. Ne pas porter de vêtements amples ni de

bijoux. Garder les cheveux, les vêtements et les gants à l’écart des pièces

mobiles. Les vêtements amples, les bijoux ou les cheveux longs risquent de rester

coincés dans les pièces mobiles.

g) Si des composants sont fournis pour le raccordement de dispositifs de dépous-

siérage et de ramassage, s’assurer que ceux-ci sont bien raccordés et utilisés.

L’utilisation d’un dispositif de dépoussiérage peut réduire les dangers

engendrés par les poussières.

consulter le site Web

4) Utilisation et entretien d’un outil électrique

a) Ne pas forcer un outil électrique. Utiliser l’outil électrique approprié à

l’application. L’outil électrique approprié effectuera un meilleur travail, de façon plus

sûre et à la vitesse pour laquelle il a été conçu.

b) Ne pas utiliser un outil électrique dont l’interrupteur est défectueux. Tout outil

électrique dont l’interrupteur est défectueux est dangereux et doit être réparé.

c) Débrancher la che du secteur ou le bloc-piles de l’outil électrique avant de faire

tout réglage ou changement d’accessoire, ou avant de ranger l’outil électrique. Ces

mesures préventives réduisent les risques de démarrage accidentel de l’outil électrique.

d) Ranger les outils électriques hors de la portée des enfants, et ne permettre à

aucune personne n’étant pas familière avec un outil électrique (ou son manuel

d’instruction) d’utiliser ce dernier. Les outils électriques deviennent dangereux

entre les mains d’utilisateurs inexpérimentés.

e) Entretenir les outils électriques. Vérier les pièces mobiles pour s’assurer qu’elles

sont bien alignées et tournent librement, qu’elles sont en bon état et ne sont

affectées par aucun trouble susceptible de nuire au bon fonctionnement de l’outil

électrique. En cas de dommage, faire réparer l’outil électrique avant toute nouvelle

utilisation. Beaucoup d’accidents sont causés par des outils électriques mal entretenus.

f) S’assurer que les outils de coupe sont aiguisés et propres. Les outils de coupe bien

entretenus et affûtés sont moins susceptibles de se coincer et sont plus faciles à contrôler.

g) Utiliser l’outil électrique, les accessoires, les forets, etc. conformément aux

présentes directives en tenant compte des conditions de travail et du travail à

effectuer. L’utilisation d’un outil électrique pour toute opération autre que celle pour

laquelle il a été conçu est dangereuse.

5) Réparation

a) Faire réparer l’outil électrique par un réparateur professionnel en n’utilisant que

des pièces de rechange identiques. Cela permettra de maintenir une utilisation

sécuritaire de l’outil électrique.

Consignes de sécurité particulières

• Saisir l’outil électrique par ses surfaces de prises isolées lorsque l’outil peut entrer en

contact avec des ls cachés ou son cordon. En cas de contact avec un fil sous tension, les

pièces métalliques de l’outil seront sous tension et l’utilisateur subira des secousses électriques.

• Utiliser des brides de xation ou un autre dispositif de xation permettant de xer

solidement et de soutenir la pièce sur une plateforme stable. Tenir la pièce avec la main ou

contre son corps la rend instable et risque de provoquer une perte de maîtrise de l’outil.

• Garderlesmainséloignéesdes zones de coupe. Ne pas mettre les mains sous la pièce

pour quelque raison que ce soit. Saisir la section profilée à l’avant de l’outil. Ne pas mettre

les doigts ou le pouce près de la lame à va-et-vient ni de sa bride de serrage. Ne pas

stabiliser la scie en saisissant le patin.

• Maintenirleslamesbienaiguiséesentouttemps; les lames usées peuvent faire dévier

la scie ou faire caler le moteur lorsqu’on exerce une pression sur l’outil.

• Lorsqu’oncoupedestuyauxoudesconduits, on doit s’assurer qu’ils ne renferment pas

d’eau ni de fil électrique, etc.

• Attendrequelemoteurs’arrêtecomplètementavantderetirerlalamedel’entaille(lafente

créée par la coupe). Une lame qui bouge peut rebondir contre la pièce et se briser ou endommager

la pièce ou encore, faire perdre la maîtrise de l’outil et causer des risques de blessure.

• Ne tenez jamais le travail dans votre main, recouvrement ou contre des parties de

votre corps en sciant. La scie ma glissade et la lame a pu entrer en contact avec le corps

causant des dommages.

• Garderlespoignéespropres,sèchesetexemptesdetoutetraced’huileetdegraisse

afin d’éviter de perdre la maîtrise de l’outil.

• Utiliser la prudence supplémentaire en coupant des fraiss généraux et paie l’attention

particulière à au-dessus les ls qui peuvent être cachés de la vue. Prévoir le chemin de

branches et le débris en baisse en avance.

• Biennettoyerl’outilpériodiquement,surtoutaprèsl’avoirutilisélonguement,car la

poussière et les particules métalliques tendent à s’accumuler sur les surfaces internes et

peuvent entraîner des risques de choc électrique.

• Nepasutilisercetoutilpendantdespériodesprolongées. Les vibrations causées par

l’action de fonctionnement de l’outil peuvent blesser en permanence les doigts, les mains et

les bras. Porter des gants pour amortir les vibrations, faire des pauses fréquentes et limiter le

temps d’utilisation quotidien de l’outil.

AVERTISSEMENT : Certains outils électriques, tels que les sableuses, les scies, les

meules, les perceuses ou certains autres outils de construction, peuvent produire de

la poussière contenant des produits chimiques susceptibles d’entraîner le cancer,

des malformations congénitales ou pouvant être nocifs pour le système reproductif.

Parmi ces produits chimiques, on retrouve :

•le plomb dans les peintures à base de plomb,

•la silice cristalline dans les briques et le ciment et autres produits de maçonnerie,

•l’arsenic et le chrome dans le bois de sciage ayant subi un traitement chimique (comme

l’arséniate de cuivre et de chrome).

Le risque associé à de telles expositions varie selon la fréquence avec laquelle on effectue

ces travaux. Pour réduire l’exposition à de tels produits, il faut travailler dans un endroit

bien aéré et utiliser le matériel de sécurité approprié, tel un masque anti-poussières

spécialement conçu pour filtrer les particules microscopiques.

• Évitertoutcontactprolongéaveclapoussièresoulevéeparcetoutilouautresoutils

électriques. Porter des vêtements de protection et nettoyer les parties exposées du

corps avec de l’eau savonneuse. S’assurer de bien se protéger afin d’éviter d’absorber

par la bouche, les yeux ou la peau des produits chimiques nocifs.

AVERTISSEMENT : Cet outil peut produire et répandre de la poussière susceptible de

causer des dommages sérieux et permanents au système respiratoire. Toujours utiliser un

appareil respiratoire anti-poussières approuvé par le NIOSH ou l’OSHA. Diriger les

particules dans le sens opposé du visage et du corps.

AVERTISSEMENT : Porter un dispositif de protection personnel anti-bruit approprié

durant l’utilisation. Sous certaines conditions et pendant toute la durée de

l’utilisation, le bruit émanant de ce produit pourrait contribuer à la perte d’audition.

L’étiquette de l’outil peut comporter les symboles suivants.

V ..................................... volts A ......................... ampères

Hz ................................... hertz W ........................ watts

min .................................minutes

ou DC ....................courant continu

....................................

....................................symbole d´avertissement .../min ...............tours ou courses

COUP/MIN ..................... coups par minute à la minute

construction de classe II

Caractéristiques – Figure A

1. Interrupteur à une vitesse

2. Bouton de verrouillage

3. Bride de serrage de la lame de scie

4. Vis de la bride de serrage de la lame de scie

5. Roulette d’appui de la lame de scie

6. Dépoussiéreur

7. Plaque de la semelle

8. Compartiment de rangement pour lames

RALLONGES

S’assurer que la rallonge est en bon état avant de l’utiliser. Toujours utiliser une rallonge

qui convient à l’outil, c’est-à-dire dont le calibre des fils, la longueur du cordon et les valeurs

nominales correspondent à l‘outil alimenté. L’usage d’une rallonge de calibre insuffisant

pourrait causer une chute de tension entraînant une perte de puissance et une surchauffe.

Pour s’assurer qu’on utilise le calibre approprié, consulter le tableau indiqué ci-dessous.

Tension Longueur totale du cordon en pieds

120V 0-25 26-50 51-100 101-150

(0-7,6m) (7,6-15,2m) (15,2-30,4m) (30,4-45,7m)

240V 0-50 51-100 101-200 201-300

(0-15,2m) (15,2-30,4m) (30,4-60,9m) (60,9-91,4m)

Intensité (A)

Au Au Calibre moyen des fils (AWG)

moins plus

0 - 6 18 16 16 14

6 - 10 18 16 14 12

10 - 12 16 16 14 12

12 - 16 14 12 Non recommandé

Calibre minimal des cordons de rallonge

ou AC ............courant alternatif

n

o ....................... sous vide

........................ borne de terre

Page 4

MOTEUR

S’assurer que l’intensité nominale du cordon d’alimentation corresponde à celle indiquée sur

la plaque signalétique; sur cette dernière, la mention «120 V c.a.» signifie que l’outil ne doit

être branché que dans une prise résidentielle standard de courant alternatif de 60 Hz et non

pas dans une prise de courant continu, alors que «120 V c.a. / c.c.» signifie que l’outil peut

fonctionner sur une prise standard de 60 Hz de courant alternatif ou continu. Une tension

inférieure à celle indiquée pourrait entraîner une perte de puissance et une surchauffe. Tous

les outils Black & Decker sont soumis à des essais en usine; si cet outil ne fonctionne pas,

on doit d’abord vérifier l’intensité nominale du cordon d’alimentation.

CONSERVER CES DIRECTIVES

Préparation pour l’assemblage et le réglage

INSTALLATION DES LAMES

AVERTISSEMENT : avant de réaliser une des opérations suivantes, s’assurer de la mise

hors tension et du débranchement de l’outil et de l’immobilisation de la lame de scie. Les

lames de scie utilisées peuvent être chaudes.

À l’aide d’un tournevis à lame plate, desserrer (ne pas enlever) les deux vis « A » de la

figure B. S’assurer que les dents de la lame sont vers l’avant, puis insérer le pied de la

lame complètement dans la bride de serrage de la lame de scie. Serrer légèrement les vis

en alternance pour positionner la lame, puis serrer complètement les vis. Pour dégager,

tourner les deux vis d’un tour, dans le sens antihoraire.

Remarque : pour améliorer la performance de coupe, s’assurer que le dos de la lame entre

en contact avec la roulette d’appui de la lame. Consulter le « guide de la roulette d’appui »

pour connaître les directives sur la façon de changer la position de la roulette d’appui de la

lame.

ROULETTE D’APPUI DE LA LAME

ÉTEINDRE L’OUTIL ET LE DÉBRANCHER.

La roulette d’appui de la lame de la scie sauteuse permet d’améliorer la performance de

cette dernière lors de la coupe de matériaux résistants en ajoutant un soutien à la lame. Ce

support doit être réglé de manière à ce que la roulette d’appui entre en contact avec le dos

de la lame au moment de la coupe. S’assurer que la lame est alignée avec la rainure de la

roulette d’appui. Régler la roulette d’appui en desserrant la vis située au fond de la semelle

(fig. B), puis déplacer la semelle de manière à ce que la roulette d’appui entre en contact

avec le bord du dos de la lame. Serrer de nouveau la vis. Lubrifier d’une goutte d’huile la

roulette de guidage de temps à autre pour prolonger sa durée de vie.

REMARQUE : il est impossible d’utiliser le guide de la roulette d’appui lorsque la semelle

est inclinée à 45 degrés.

Fig. B

Bride de serrage de la lame, Guide de la roulette d’appui, Vis, Semelle

INTERRUPTEUR MARCHE/ARRÊT

AVANT DE BRANCHER LA SCIE SAUTEUSE, S’ASSURER QUE LA DÉTENTE EST À

LA POSITION D’ARRÊT.

Pour mettre en marche la scie sauteuse, presser la détente, comme le montre la fig. C. Pour

l’éteindre, simplement relâcher la détente. L’outil peut être verrouillé pour une opération

continue. Il suffit de presser et de tenir la détente tout en enfonçant le bouton de verrouillage

indiqué à la fig. C. Une fois le bouton de verrouillage enfoncé, relâcher la détente et l’outil

continuera de fonctionner. Pour sortir de la position de verrouillage, presser la détente et la

relâcher. Toujours dégager le dispositif de verrouillage avant de débrancher l’appareil de la

source d’alimentation.

Fig. C

Bouton de verrouillage, Détente, Dépoussiéreur, Rangement de la lame

RÉGLAGE DU BISEAU

METTRE L’OUTIL HORS TENSION ET LE DÉBRANCHER.

Pour régler l’angle de biseau, desserrer la vis (environ 3 tours complets) logée au fond de

la semelle, comme le montre la fig. B. Soulever légèrement la semelle, puis la tirer vers

l’arrière, la régler ensuite à un angle de 45° (précision de + / -5 ° et resserrer la vis. Pour

régler de nouveau la semelle afin d’avoir une coupe à l’équerre, desserrer la vis, puis

déplacer la semelle de manière à ce qu’elle forme un angle d’environ 90° avec la lame.

Régler la roulette d’appui par rapport à la lame, puis serrer de nouveau la vis.

COUPE GÉNÉRALE

S’assurer que la planche est bien assujettie. Tenir la scie sauteuse par la poignée, puis

activer la détente pour allumer l’outil. Ne pas allumer l’outil si la lame repose contre le

matériau à couper. Cela pourrait faire caler le moteur. Mettre l’avant de la semelle sur le

matériau à couper et maintenir fermement la semelle de la scie sauteuse contre la surface

de travail durant la coupe. Ne pas faire forcer l’outil; laisser la lame couper à sa vitesse.

Dans la mesure du possible, assujettir ou soutenir la pièce près de la ligne de coupe; lorsque

la coupe est terminée, éteindre la scie et la mettre de côté avant de desserrer la pièce.

DÉPOUSSIÉREUR AUTOMATIQUE

Pour accroître la visibilité durant la coupe, la scie sauteuse est pourvue d’un dépoussiéreur

automatique (fig. C), ce qui permet de dégager la zone de travail de la poussière produite

durant le sciage.

RANGEMENT DE LA LAME

Un compartiment de rangement de lame pratique (fig. D) est logé à l’arrière de la scie.

COUPE DE MÉTAUX ET DE PLASTIQUE

Pour la coupe de tôle mince, il est préférable de fixer une pièce de bois ou une feuille de

contreplaqué sous la tôle; cela assurera une coupe nette sans risque de vibration ou de

déchirure du métal. Utiliser une lame à dents fines pour les métaux ferreux (les métaux

ayant une teneur en fer) et utiliser une lame plus grossière pour les métaux non ferreux (les

métaux sans teneur en fer).

La coupe de métal mince est plus longue que la coupe d’une pièce de bois relativement

épaisse, ne pas tenter d’accélérer l’opération en forçant la scie. Étendre un mince film de

lubrifiant de coupe le long de la ligne de coupe (toute huile légère fera l’affaire).

Pour la coupe de plastique stratifié, mettre le côté fini vers le bas et utiliser une lame de scie

biconcave à dents fines.

DÉCOUPE EN POCHE

• Mesurerlazoneàcouperetlamarquerclairementavecuncrayon.Ensuite,inclinerla

scie vers l’avant de manière à ce que le bord avant de la semelle repose fermement

contre la surface de travail, mais loin de la lame, fig. E.

• Allumerl’outil,puislelaisseratteindresavitessemaximaleenenfonçantpleinementla

détente.

• Saisirfermementlapoignéeetdescendredoucementlebordarrièredel’outiljusqu’à

ce que la lame coupe le matériau d’un mouvement régulier. Ne pas déplacer la scie

sauteuse vers l’avant le long de la ligne de coupe avant que la lame ne soit entrée

complètement dans le matériau et que la semelle repose à plat sur sa surface.

SCIAGE EN LONG ET COUPE CURVILIGNE

Le sciage en long et la coupe curviligne sans trait de crayon se font facilement à l’aide du

guide longitudinal et du guide circulaire (offerts moyennant des frais supplémentaires).

À l’aide de la vis fournie avec le guide accessoire, positionner comme dans la figure F et

enfiler la vis dans la semelle pour bien fixer le guide longitudinal.

Pour la coupe curviligne, régler le guide longitudinal de manière à ce que la distance

séparant la lame de l’orifice de la traverse soit au rayon voulu, puis serrer la vis (utiliser le

trou qui s’aligne le mieux avec la lame de scie). Placer la scie de manière à ce que l’orifice

de la traverse se trouve au-dessus du centre du cercle à couper (effectuer une coupe de

poche, percer un trou pour la lame ou couper vers l’intérieur à partir du bord du matériau

pour mettre en place la lame). Une fois la scie bien placée, enfoncer un petit clou dans

l’orifice de la traverse. Couper le cercle au moyen du guide longitudinal utilisé comme bras

pivotant. Pour la coupe curviligne, la traverse doit être à la verticale, comme le montre la

figure F.

Au moment du sciage en long, glisser le guide longitudinal sous la vis d’un côté ou de l’autre

de la scie. Placer la traverse à la distance voulue de la lame, puis serrer la vis. Pour le

sciage en long, la traverse doit être en bas, contre le bord droit de la pièce.

DÉPANNAGE

Problème Cause possible Solution possible

•L’appareilrefusede •Cordond’alimentation •Brancherl’outildans

démarrer. non branché. une prise qui fonctionne.

•Lefusibleducircuitestgrillé. •Remplacerlefusibledu

circuit. (Si le produit fait

griller de façon répétée

le fusible du circuit, arrêter

immédiatement d’utiliser le

produit et le faire réparer

dans un centre de

réparation Black & Decker

ou un centre de réparation

autorisé.)

•Ledisjoncteurestdéclenché. •Remettreledisjoncteurà

zéro. (Si le produit fait

déclencher de façon

répétée le disjoncteur,

arrêter immédiatement

d’utiliser le produit et le

faire réparer dans un

centre de réparation

Black & Decker ou un centre

de réparation autorisé.)

•Lecordond’alimentation •Faireremplacerle

ou la prise de courant est cordon ou l’interrupteur

endommagé(e). au centre de réparation

Black & Decker ou à un

centre de réparation

autorisé.

Pour obtenir de l’aide avec l’outil, consulter notre site Web www.blackanddecker.

com pour l’emplacement du centre de réparation le plus près ou communiquer avec

l’assistance BLACK & DECKER au 1-800-544-6986.

ENTRETIEN

Nettoyer l’outil au moyen d’un savon doux et d’un linge humide seulement. Ne jamais laisser

de liquide s’infiltrer à l’intérieur de l’outil ni tremper ce dernier dans un liquide quelconque.

IMPORTANT : pour assurer la SÉCURITÉ et la FIABILITÉ de ce produit, toutes les

opérations de réparation, d’entretien et de réglage doivent être effectuées dans un centre de

service autorisé ou par du personnel qualifié; on ne doit utiliser que des pièces de rechange

identiques.

ACCESSOIRES

Les accessoires recommandés pour l’outil sont vendus chez les dépositaires locaux ou dans

les centres de service autorisés. Pour obtenir de l’aide concernant un accessoire, composer

le 1 800 544-6986.

AVERTISSEMENT : l’usage d’un accessoire non recommandé peut présenter un danger.

INFORMATION SUR LES SERVICES

Black & Decker dispose d’un réseau complet composé de centres de service et de centres

autorisés situés partout en Amérique du Nord. Tous les centres de service Black & Decker

sont dotés de personnel qualifié en matière d’outillage électrique; ils sont donc en mesure

d’offrir à leur clientèle un service efficace et fiable. Pour obtenir un conseil technique ou une

pièce d’origine ou pour faire réparer un outil, on peut communiquer avec le centre

Black & Decker le plus près. Pour obtenir le numéro de téléphone, consulter les pages

jaunes sous la rubrique «Outils - électriques» ou composer le 1 800 544-6986.

GARANTIE COMPLÈTE DE DEUX ANS POUR USAGE RÉSIDENTIEL

Black & Decker (U.S.) Inc. garantit ce produit pour une période de deux ans contre tout

défaut de matériel ou de fabrication. Le produit défectueux sera remplacé ou réparé sans

frais, suivant l’une des deux méthodes suivantes.

La première méthode consiste en un échange seulement. On doit retourner le produit au

détaillant qui l’a vendu (pourvu qu’il s’agisse d’un détaillant participant), en respectant les

délais stipulés dans sa politique relative aux échanges (normalement de 30 à 90 jours après

la vente). Une preuve d’achat peut être requise. On doit vérifier la politique de retour du

détaillant pour tout produit retourné après le délai prescrit pour les échanges.

La deuxième méthode consiste à apporter ou à envoyer le produit (prépayé) à un centre

Black & Decker ou à un centre de service autorisé aux fins de réparation ou de remplacement, selon notre choix. Une preuve d’achat peut être requise. Les centres Black & Decker

et les centres de service autorisés sont répertoriés dans les pages jaunes sous la rubrique

«Outils - électriques».

Cette garantie ne s’applique pas aux accessoires. Elle confère des droits légaux particuliers à l’acheteur, mais celui-ci pourrait aussi bénéficier d’autres droits variant d’un territoire à

l’autre. Toute question doit être adressée au gérant du centre Black & Decker le plus près.

Ce produit n’est pas destiné à un usage commercial.

Remplacement gratuit des étiquettes d’avertissement : Si vos étiquettes

d’avertissement deviennent illisibles ou sont manquantes, composez le 1 (800) 544-6986

pour faire remplacer gratuitement vos étiquettes.

Imported by / Importé par

Black & Decker Canada Inc.

100 Central Ave.

Brockville (Ontario) K6V 5W6

Voir la rubrique “Outils électriques”

des Pages Jaunes

pour le service et les ventes.

Sierra caladora de velocidad única

MANUAL DE INSTRUCCIONES

Catálogo N° 7662

Merci d’avoir choisi Black & Decker!

Consulter le site Web www.BlackandDecker.com/

NewOwner

pour enregistrer votre nouveau produit.

ÀLIRE AVANT DE RETOURNER CE PRODUIT

POUR QUELQUE RAISON QUE CE SOIT :

Si des questions ou des problèmes surgissent après l’achat d’un produit Black & Decker,

consulter le site Web

HTTP://WWW.BLACKANDDECKER.COM/INSTANTANSWERS

pour obtenir des réponses instantanément 24 heures par jour.

Si la réponse est introuvable ou en l’absence d’accès à Internet, composer le

1-800-544-6986 de 8 h à 17 h HNE, du lundi au vendredi, pour parler avec un agent.

Prière d’avoir le numéro de catalogue sous la main lors de l’appel.

CONSERVER CE MANUEL POUR UN USAGE ULTÉRIEUR.

PAUTAS DE SEGURIDAD/DEFINICIONES

Es importante que lea y comprenda este manual. La información que contiene se relaciona

con la protección de SU SEGURIDAD y la PREVENCIÓN DE PROBLEMAS. Los símbolos

que siguen se utilizan para ayudarlo a reconocer esta información.

PELIGRO: indica una situación de peligro inminente que, si no se evita, provocará la

muerte o lesiones graves.

ADVERTENCIA: indica una situación de peligro potencial que, si no se evita,

provocará la muerte o lesiones graves.

PRECAUCIÓN: indica una situación de peligro potencial que, si no se evita, provocará

lesiones leves o moderadas.

PRECAUCIÓN: utilizado sin el símbolo de alerta de seguridad indica una situación de

peligro potencial que, si no se evita, puede provocar daños en la propiedad.

Page 5

Advertencias generales de seguridad para herramientas eléctricas

ADVERTENCIA: Lea todas las advertencias de seguridad e instrucciones El

incumplimiento de las advertencias e instrucciones puede provocar descargas eléctricas,

incendios o lesiones graves.

Conserve todas las advertencias e instrucciones para futuras consultas.

El término “herramienta eléctrica” incluido en las advertencias hace referencia a

las herramientas eléctricas operadas con corriente (con cable eléctrico) o a las

herramientas eléctricas operadas con baterías (inalámbricas).

1) Seguridad en el área de trabajo

a) Mantenga el área de trabajo limpia y bien iluminada. Las áreas abarrotadas y

oscuras propician accidentes.

b) No opere herramientas eléctricas en atmósferas explosivas, como ambientes

donde se encuentran líquidos, gases o polvo inamables. Las herramientas eléctri-

cas originan chispas que pueden encender el polvo o los vapores.

c) Mantenga a los niños y espectadores alejados de la herramienta eléctrica en

funcionamiento. Las distracciones pueden provocar la pérdida de control.

2) Seguridad eléctrica

a) Los enchufes de la herramienta eléctrica deben adaptarse al tomacorriente. Nunca

modique el enchufe de ninguna manera. No utilice ningún enchufe adaptador con

herramientas eléctricas con conexión a tierra. Los enchufes no modicados y que se

adaptan a los tomacorrientes reducirán el riesgo de descarga eléctrica.

b) Evite el contacto corporal con supercies puestas a tierra, como por ejemplo

tuberías, radiadores, rangos y refrigeradores. Existe mayor riesgo de descarga

eléctrica si su cuerpo está puesto a tierra.

c) No exponga las herramientas eléctricas a la lluvia o a condiciones de humedad. Si

ingresa agua a una herramienta eléctrica, aumentará el riesgo de descarga eléctrica.

d) No maltrate al cable. Nunca utilice el cable para transportar, tirar o desenchufar

la herramienta eléctrica. Mantenga el cable lejos del calor, aceite, bordes alados o piezas móviles. Los cables dañados o enredados aumentan el riesgo de

descarga eléctrica.

e) Al operar una herramienta eléctrica en el exterior, utilice un cable prolongador

adecuado para tal uso. Utilice un cable adecuado para uso en exteriores a n de

reducir el riesgo de descarga eléctrica.

f) Si el uso de una herramienta eléctrica en un lugar húmedo es imposible de evitar,

utilice un suministro protegido con un interruptor de circuito por falla a tierra

(GFCI). El uso de un GFCI reduce el riesgo de descargas eléctricas.

3) Seguridad personal

a) Permanezca alerta, controle lo que está haciendo y utilice el sentido común

cuando emplee una herramienta eléctrica. No utilice una herramienta eléctrica si

está cansado o bajo el efecto de drogas, alcohol o medicamentos. Un momento de

descuido mientras se opera una herramienta eléctrica puede provocar lesiones personales graves.

b) Utilice equipos de protección personal. Siempre utilice protección para los

ojos. En las condiciones adecuadas, el uso de equipos de protección, como más-

caras para polvo, calzado de seguridad antideslizante, cascos o protección auditiva,

reducirá las lesiones personales.

c) Evite el encendido por accidente. Asegúrese de que el interruptor esté en la

posición de apagado antes de conectarlo a la fuente de energía o paquete de

baterías, o antes de levantar o transportar la herramienta. Transportar herramien-

tas eléctricas con el dedo apoyado en el interruptor o enchufar herramientas eléctricas con el interruptor en la posición de encendido puede propiciar accidentes.

d) Retire las clavijas de ajuste o llaves de tuercas antes de encender la herramienta

eléctrica. Una llave de tuercas o una clavija de ajuste que se deje conectada a una

pieza giratoria de la herramienta eléctrica pueden provocar lesiones personales.

e) No se estire. Conserve el equilibrio adecuado y manténgase parado correcta-

mente en todo momento. Esto permite un mejor control de la herramienta eléctrica

en situaciones inesperadas.

f) Use la vestimenta adecuada. No use ropas holgadas ni joyas. Mantenga el cabello,

la ropa y los guantes alejados de las piezas en movimiento. Las ropas holgadas,

las joyas o el cabello largo pueden quedar atrapados en las piezas en movimiento.

g) Si se suministran dispositivos para la conexión de accesorios con nes de

recolección y extracción de polvo, asegúrese de que estén conectados y que

se utilicen correctamente. El uso de dispositivos de recolección de polvo puede

reducir los peligros relacionados con el polvo.

4) Uso y mantenimiento de la herramienta eléctrica

a) No fuerce la herramienta eléctrica. Utilice la herramienta eléctrica correcta para

el trabajo que realizará. La herramienta eléctrica correcta hará el trabajo mejor y

más seguro a la velocidad para la que fue diseñada.

b) No utilice la herramienta eléctrica si no puede encenderla o apagarla con el

interruptor. Toda herramienta eléctrica que no puede ser controlada mediante el

interruptor es peligrosa y debe ser reparada.

c) Desconecte el enchufe de la fuente de energía y/o el paquete de baterías de la

herramienta eléctrica antes de realizar ajustes, cambiar accesorios o almacenar

herramientas eléctricas. Estas medidas de seguridad preventivas reducen el ries-

go de encender la herramienta eléctrica en forma accidental.

d) Guarde las herramientas eléctricas que no están en uso fuera del alcance de

los niños y no permite que otras personas no familiarizadas con ella o con

estas instrucciones operen la herramienta. Las herramientas eléctricas son pelig-

rosas en las manos de usuarios no entrenados.

e) Mantenimiento de las herramientas eléctricas. Controle que no haya piezas

móviles mal alineadas o trabadas, piezas rotas y toda otra situación que pueda

afectar el funcionamiento de las herramientas eléctricas. Si encuentra daños,

haga reparar la herramienta eléctrica antes de utilizarla. Se producen muchos

accidentes a causa de las herramientas eléctricas que carecen de un mantenimiento adecuado.

f) Mantenga las herramientas de corte aladas y limpias. Las herramientas de corte

con mantenimiento adecuado, con los bordes de corte alados son menos propensas a trabarse y son más fáciles de controlar.

g) Utilice la herramienta eléctrica, los accesorios y las brocas de la herramienta, etc.

de acuerdo con estas instrucciones y teniendo en cuenta las condiciones de trabajo

y el trabajo que debe realizarse. El uso de la herramienta eléctrica para operaciones

diferentes de aquéllas para las que fue diseñada podría originar una situación peligrosa.

5) Mantenimiento

a) Haga que una persona de reparaciones calicada realice el mantenimiento de

su herramienta eléctrica y utilice piezas de repuesto idénticas solamente. Esto

garantizará la seguridad de la herramienta eléctrica.

Reglas de Seguridad Especícas

• Sujete la herramienta eléctrica por las supercies aislantes cuando realice una

operación en que la herramienta pueda hacer contacto con cableados ocultos. Al

hacer contacto con un cable “vivo”, las partes metálicas de la herramienta se vuelven

“vivas” y pueden originar un choque al operador.

• Utilice abrazaderas u otra forma práctica para asegurar y sostener la pieza de trabajo

sobre una plataforma estable. Sostener el trabajo con la mano o contra el cuerpo no

brinda la estabilidad requerida y puede llevar a la pérdida del control.

• Mantengasusmanosfueradeláreadecorte. Nunca se incline por debajo del material

por ningún motivo. Sujete la parte frontal de la sierra asiéndola por el área contorneada de

agarre. No inserte los dedos o el pulgar cerca de la hoja de vaivén o el sujetador de la hoja.

No estabilice la sierra asiéndola por la platina.

• Mantengalashojasaladas. Las hojas sin filo pueden hacer que la sierra se desvíe o se

atasque al estar bajo presión.

• Alcortaruntubooconductoportacables, asegúrese de que estos no contienen agua o

cables, etc.

• Permita que el motor se detenga por completo antes de retirar la hoja de la línea de

corte. Las hojas en movimiento pueden impactar la pieza de trabajo y romperse, dañar

la pieza de trabajo o causar la pérdida de control de la herramienta y posibles lesiones

corporales.

• Nunca celebre el trabajo en su mano, regazo o contra partes de su cuerpo al aserrar.

La sierra mi resbalón y la lámina podía entrar en contacto con el cuerpo que causaba lesión.

• Mantenga las empuñaduras secas, limpias, libres de aceite y grasa. Esto permitirá un

mejor control de la herramienta.

• Utilice el cuidado extra al cortar de arriba y pagar la atención particular alambres

de arriba que se pueden esconder de la vista. Anticipe el sendero de caer ramas y

escombros temprano.

• Limpie su herramienta con frecuencia, especialmente después de usos prolongados.

El polvo y la arenilla que contienen partículas metálicas se acumulan con frecuencia en las

superficies interiores y podrían ocasionar peligro de descarga eléctrica.

• No opere esta herramienta durante períodos largos de tiempo. La vibración causada

por la acción de operación de esta herramienta puede causar lesiones permanentes a

los dedos, las manos y los brazos. Utilice guantes para una mayor amortiguación, tome

descansos frecuentes y limite el tiempo de uso diario.

AVERTISSEMENT : El polvo creado al lijar, aserrar, pulir, taladrar o realizar otras

actividades de la construcción, contiene substancias químicas que se sabe

producen cáncer, defectos de nacimiento u otros defectos del sistema reproductor.

Algunos ejemplos de esos productos químicos son:

•El plomo de las pinturas a base de plomo,

•La sílice cristalina de los ladrillos, del cemento y de otros productos de albañilería, y

•El arsénico y el cromo de la madera tratada químicamente (CCA).

El riesgo que se corre a causa del contacto con esos productos varía según la frecuencia

con que usted realice este tipo de trabajos. Con el fin de reducir su exposición a esas

substancias químicas, trabaje en un área bien ventilada y utilice un equipo de seguridad

reglamentario, tal como una máscara contra el polvo especialmente diseñada para filtrar

partículas microscópicas.

• Eviteelcontactoprolongadoconelpolvoprovenientedellijado,aserrado,amolado

y taladrado eléctrico y otras actividades de construcción. Use vestimenta protectora

y lave todas las áreas expuestas con agua y jabón. De entrar polvo en sus ojos, boca, o

que este permanezca sobre su piel puede promover la absorción de químicos dañinos.

AVERTISSEMENT : El uso de esta herramienta puede generar y/o dispersar el polvo, el

cual puede ocasionar lesión respiratoria u otro tipo de lesión grave y permanente. Utilice

siempre protección respiratoria NIOSH/OSHA apropiada para la exposición al polvo. Dirija

las partículas lejos de su cara o su cuerpo.

ATENCIÓN: Use protección auditiva apropiada cuando usa la herramienta. Bajo

ciertas condiciones y el tiempo que se usa la herramienta, el ruido proveniente de

este producto podría contribuir a pérdida auditiva.

La etiqueta de su herramienta puede incluir los siguientes símbolos.

V ........................... volts A ......................... amperes

Hz ......................... hertz W ........................ watts

min ........................minutos

o DC ............corriente directa

..........................construcción clase II

conexión a tierre

..........................símbolo de alerta seguridad .../min ..................revoluciones o

GPM ..................... golpes por minuto reciprocaciones por minuto

o AC ..............corriente alterna

n

o ....................... velocidad sin carga

........................ terminales de

Características - Figura A

1. Interruptor de velocidad única

2. Botón de bloqueo

3. Abrazadera de la hoja de la sierra

4. Tornillos de la abrazadera de la hoja de la sierra

5. Soporte giratorio de la hoja de la sierra

6. Soplador de polvo

7. Placa de la zapata

8. Compartimiento para almacenamiento de la hoja de la sierra

USO DE CABLES DE EXTENSIÓN

Asegúrese que el cable de extensión esté en buenas condiciones antes de usar. Al utilizar

un cable de extensión, asegúrese de que sea del tamaño correspondiente a la herramienta,

o sea, lo suficientemente “pesado” como para transportar la corriente que la herramienta

va a extraer. Un cable de tamaño insuficiente causará una caída en la línea de voltaje

resultando en pérdida de energía y recalentamiento. Vea la tabla siguiente para el tamaño

apropiado de cable.

Volts Longitud total del cable en pies

120V 0-25 26-50 51-100 101-150

(0-7,6m) (7,6-15,2m) (15,2-30,4m) (30,4-45,7m)

240V 0-50 51-100 101-200 201-300

(0-15,2m) (15,2-30,4m) (30,4-60,9m) (60,9-91,4m)

Amperaje

0 - 6 18 16 16 14

6 - 10 18 16 14 12

10 - 12 16 16 14 12

12 - 16 14 12 No se recomienda

MOTOR

Verifique que su suministro de corriente concuerde con el marcaje de la placa de datos.

120 Voltios de corriente alterna (AC) solo indica que su herramienta operará con corriente

casera estándar de 60 Hz. No opere herramientas de corriente alterna (AC) con corriente

directa (DC). Una potencia de régimen de 120 voltios AC/DC significa que su herramienta

operará con corriente estándar de 60 Hz AC o DC. Esta información está impresa en la

placa de datos. Un voltaje menor ocasionará pérdida de corriente y puede resultar en

recalentamiento. Todas las herramientas Black & Decker se prueban en fábrica; si esta

herramienta no funciona, verifique el suministro de corriente.

Calibre mínimo para cables de extensión

Más de No más de American Wire Gage

GUARDE ESTAS INSTRUCCIONES

Ensamblado/Regulaciones

INSTALACIÓN DE LAS HOJAS

ADVERTENCIA: Antes de intentar cualquiera de las siguientes operaciones, asegúrese

de que la herramienta esté apagada y desconectada y que la hoja de la sierra se haya

detenido. Las hojas de la sierra que se utilizaron pueden estar calientes.

Con un destornillador de hoja plana afloje (y no retire) los dos tornillos “A” de la figura B.

Asegúrese de que los dientes de la hoja miren hacia adelante e inserte el vástago de la

hoja de la sierra completamente dentro de la abrazadera de la hoja. Ajuste levemente los

tornillos en forma alternativa para colocar la hoja en posición, luego ajuste los tornillos

completamente. Para liberar la hoja, gire ambos tornillos una vuelta en sentido contrario a

las agujas del reloj.

Nota: Para mejorar la calidad del corte, asegúrese de que la parte posterior de la hoja

toque el rodillo de apoyo de la hoja. Consulte la sección “Guía de apoyo del rodillo” para ver

las instrucciones sobre cómo cambiar la posición del rodillo de apoyo de la hoja.

RODILLO DE APOYO DE LA HOJA

APAGUE Y DESENCHUFE LA HERRAMIENTA..

El rodillo de apoyo de la hoja de la sierra caladora mejora su rendimiento al cortar

materiales difíciles ya que brinda mayor apoyo a la hoja. Este soporte debe ajustarse de

manera que el rodillo toque la parte posterior de la hoja al realizar el corte. Asegúrese de

que la hoja esté alineada con la ranura del rodillo. Ajuste el rodillo de apoyo aflojando el

tornillo de la parte inferior de la zapata (Fig.B) y moviendo la zapata de manera que el rodillo

toque el borde posterior de la hoja. Vuelva a ajustar el tornillo. Lubrique el rodillo guía cada

tanto con una gota de aceite para prolongar la vida útil del rodillo.

NOTA: La guía de apoyo del rodillo no es aplicable cuando la zapata está biselada a 45

grados.

Fig. B.

Abrazadera de hoja

Guía de apoyo del rodillo

Tornillo

Mostrar

Page 6

INTERRUPTOR DE ENCENDIDO/APAGADO

ANTES DE ENCHUFAR LA SIERRA CALADORA, ASEGÚRESE DE QUE EL

INTERRUPTOR DISPARADOR ESTÉ EN LA POSICIÓN DE APAGADO.

Para encender la sierra, oprima el interruptor disparador, como se muestra en la figura

C. Para apagar la herramienta, suelte el interruptor disparador. La herramienta puede

bloquearse para operar en forma continua oprimiendo a fondo y sosteniendo el interruptor

disparador mientras presiona el botón de bloqueo que se muestra en la figura C. Con el

botón de bloqueo presionado, suelte el interruptor disparador y la herramienta continuará

funcionando. Para salir de la posición de bloqueo, oprima y suelte el disparador. Siempre

libere el bloqueo antes de desconectar la herramienta de la fuente de energía.

Fig. C.

Botón de bloqueo

Interruptor disparador

Almacenamiento de hojas

Soplador de polvo

AJUSTE DEL BISEL

APAGUE Y DESENCHUFE LA HERRAMIENTA.

Para ajustar el ángulo de bisel, afloje el tornillo (tres vueltas completas aproximadamente)

de la parte inferior de la zapata, como se muestra en la figura B. Levante levemente la

zapata y tire hacia atrás, luego coloque la zapata a 45° (precisión de + / -5 °) y vuelva a

ajustar el tornillo. Para volver a fijar la zapata para un corte en escuadra, afloje el tornillo y

mueva la zapata hasta que esté a 90° aproximadamente con respecto a la hoja. Ajuste el

rodillo de apoyo de la hoja a la hoja y vuelva a ajustar el tornillo.

CORTES GENERALES

Asegúrese de que la tabla esté bien sujeta. Sostenga la sierra caladora por el mango y

accione el interruptor para encender la unidad. No intente encender la unidad cuando

la hoja esté contra el material a cortar. Esto podría atascar el motor. Coloque la parte

delantera de la zapata sobre el material a cortar y sostenga la sierra caladora firmemente

contra la superficie de trabajo mientras realiza el corte. No fuerce la herramienta, deje que

la hoja realice el corte a su propia velocidad. Cuando sea posible, ajuste o apoye la pieza de

trabajo cerca de la línea de corte; cuando complete el corte, apague la herramienta y deje la

sierra a un costado antes de soltar la pieza de trabajo.

SOPLADOR DE POLVO AUTOMÁTICO

Para mejorar la visibilidad durante el corte, la sierra caladora está equipada con un soplador

de polvo automático (Fig. C) que mantendrá la superficie de trabajo libre de polvo mientras

realiza el corte.

ALMACENAMIENTO DE HOJAS

La parte posterior de la sierra cuenta con un práctico compartimiento para almacenamiento

de hojas (Fig. D).

CORTES EN METALES Y PLÁSTICOS

Al realizar cortes en metales de bajo calibre es mejor sujetar con madera o madera

contrachapada la parte inferior de la hoja de metal; esto garantizará un corte limpio sin

riesgo de que se produzcan vibraciones o que el metal se rompa. Utilice una hoja de dientes

finos para los metales ferrosos (aquéllos que contienen hierro) y use una hoja más gruesa

para metales no ferrosos (aquéllos que no contienen hierro).

Los cortes en metales delgados llevarán más tiempo que los cortes en madera

relativamente gruesa por lo que no debe intentar acelerar el proceso forzando la sierra.

Coloque una película fina de lubricante de corte a lo largo de la línea de corte (cualquier

aceite liviano).

Al realizar cortes en plásticos laminados, coloque el lado con la terminación hacia abajo y

utilice una hoja ahuecada de dientes finos.

CORTE INTERNO

• Midalasuperficiequedeseacortarymárquelaclaramenteconunlápiz.A

continuación, incline la sierra hacia adelante hasta que el borde delantero de la zapata

se apoye con firmeza sobre la superficie de trabajo, pero con la hoja bien alejada de

ella, figura E.

• Enciendalaherramientaydejequealcancesuvelocidadmáximaoprimiendo

completamente el interruptor disparador.

• Agarreelmangoconfirmezaybajelentamenteelbordeposteriordelaherramienta

hasta que la hoja corte en forma uniforme el material. No mueva la sierra caladora

hacia adelante a lo largo de la línea de corte hasta que la hoja de la sierra haya

ingresado completamente en el material y la zapata esté plana sobre la superficie.

CORTES LONGITUDINALES Y CORTES DE CÍRCULOS

Sin utilizar una línea de lápiz, el corte longitudinal y el corte de círculos se realizan

fácilmente con una guía para corte longitudinal y una guía de círculo (disponibles por un

costo adicional).

Utilizando el tornillo provisto con la guía accesoria, colóquelo como se muestra en la figura

F y enrosque el tornillo en la zapata para ajustar bien la guía.

Cuando realice cortes de círculos, ajuste la guía para corte longitudinal de manera que la

distancia entre la hoja y el orificio de la barra transversal esté en el radio deseado y ajuste

el tornillo (utilice el orificio que se alinee mejor con la hoja de la sierra). Coloque la sierra de

modo que el centro del orificio de la barra transversal quede sobre el centro del círculo que

se cortará (haga un corte interno, perfore un orificio para la hoja o corte hacia adentro desde

el borde del material para colocar la hoja en posición). Cuando la sierra esté colocada

adecuadamente, deslice un clavo pequeño a través del orificio de la barra transversal. Con

la guía para corte como brazo giratorio, comience a cortar el círculo. Para realizar cortes de

círculos, la barra transversal debe estar levantada, como se muestra en la figura F.

Al realizar cortes longitudinales, deslice la guía para corte longitudinal debajo del tornillo de

cualquier lado de la sierra. Coloque la barra transversal a la distancia deseada con respecto

a la hoja y ajuste el tornillo. Para realizar cortes longitudinales, la barra transversal debe

estar hacia abajo y contra el borde recto de la pieza de trabajo.

DETECCIÓN DE PROBLEMAS

Problema Causa posible Solución posible

•Launidadnoenciende. •Cabledesenchufado. •Enchufeelcargadorenun

tomacorriente que funcione.

•Fusiblequemado. •Reemplaceelfusible

quemado. (Si repetidamente el

producto hace que el fusible del

circuito se queme, deje de

utilizarlo inmediatamente y

haga que le realicen

mantenimiento en un centro de

mantenimiento Black & Decker

o en un centro de servicio

autorizado.)

•Elinterruptorautomático •Reinicieelinterruptor

está activado. automático. (Si repetidamente

el producto hace que el fusible

del circuito se queme, deje de

utilizarlo inmediatamente y

haga que le realicen

mantenimiento en un centro de

mantenimiento Black & Decker

o en un centro de servicio

autorizado.)

•Interruptorocabledañado. •Hagarepararelcableoel

interruptor en un centro de

mantenimiento Black & Decker

o en un centro de

mantenimiento autorizado.

Para conocer la ubicación del centro de mantenimiento más cercano a fin de recibir ayuda

con su producto, visite nuestro sitio Web www.blackanddecker.com o llame a la línea de

ayuda BLACK & DECKER al 55-5326-7100

ACCESORIOS

Los accesorios que se recomiendan usar con su herramienta están disponibles donde su

distribuidor o centro de servicio local. De necesitar asistencia para obtener un accesorio,

favor llamar a: (55) 5326-7100.

ADVERTENCIA: Puede ser peligroso usar cualquier accesorio no recomendado.

INFORMATION ACERCA DE NUESTROS CENTROS DE SERVICIO

Black & Decker ofrece una red completa de centros de servicio y centros autorizados en

toda Norteamérica. Todos los centros de servicio Black & Decker disponen de personal

entrenado para dar un servicio eficiente y confiable a las herramientas eléctricas de sus clientes. De necesitar orientación técnica, reparación o repuestos originales de fábrica,

diríjase al centro Black & Decker local. Para hallar la ubicación del centro de servicio