Page 1

3/8 INCH (10MM) DRILL

INSTRUCTION MANUAL

Catalog Numbers 7252, 7152

Thank you for choosing Black & Decker! Go to

www.BlackandDecker.com/NewOwner

to register your new product.

PLEASE READ BEFORE RETURNING

THIS PRODUCT FOR ANY REASON:

If you have a question or experience a problem with your

WWW.BLACKANDDECKER.COM/INSTANTANSWERS

If you canʼt find the answer or do not have access to the internet,

call 1-800-544-6986 from 8 a.m. to 5 p.m. EST Mon. - Fri

Please have the catalog number available when you call.

KEY INFORMATION YOU SHOULD KNOW:

Black & Decker purchase, go to

for instant answers 24 hours a day.

to speak with an agent.

• Reversing drills must be switched into forward or reverse in order to operate.

They will not run in neutral.

SAVE THIS MANUAL FOR FUTURE REFERENCE.

VEA EL ESPAÑOL EN LA CONTRAPORTADA.

POUR LE FRANÇAIS, VOIR LA COUVERTURE ARRIÈRE.

INSTRUCTIVO DE OPERACIÓN, CENTROS DE SERVICIO Y PÓLIZA DE GARANTÍA.

ADVERTENCIA: LÉASE ESTE INSTRUCTIVO ANTES DE USAR EL PRODUCTO.

SSAAVVEE TTHHIISS IINNSSTTRRUUCCTTIIOONN MMAANNUUAALL FFOORR FFUUTTUURREE RREEFFEERREENNCCEE..

Page 2

SAFETY GUIDELINES - DEFINITIONS

It is important for you to read and understand this manual. The information it contains

relates to protecting YOUR SAFETY and PREVENTING PROBLEMS. The symbols

below are used to help you recognize this information.

DANGER: Indicates an imminently hazardous situation which, if not avoided, will

result in death or serious injury.

WARNING: Indicates a potentially hazardous situation which, if not avoided, could

result in death or serious injury.

CAUTION: Indicates a potentially haz ard ous situation which, if not avoided, may

result in minor or mod er ate injury.

NOTICE: Used without the safety alert symbol indicates a potentially hazardous situation

which, if not avoided, may result in property damage.

GENERAL POWER TOOL SAFETY WARNINGS

WARNING!

warnings and instructions may result in electric shock, fire and/or serious injury.

Save all warnings and instructions for future reference.

The term “power tool” in the warnings refers to your mains-operated (corded) power tool or

battery-operated (cordless) power tool.

1) Work area safety

a) Keep work area clean and well lit. Cluttered or dark areas invite accidents.

b) Do not operate power tools in explosive atmospheres, such as in the presence

of flammable liquids, gases or dust. Power tools create sparks which may ignite

the dust or fumes.

c) Keep children and bystanders away while operating a power tool. Distractions

can cause you to lose control.

2) Electrical safety

a) Power tool plugs must match the outlet. Never modify the plug in any way. Do

not use any adapter plugs with earthed (grounded) power tools. Unmodified

plugs and matching outlets will reduce risk of electric shock.

b) Avoid body contact with earthed or grounded surfaces such as pipes,

radiators, ranges and refrigerators. There is an increased risk of electric shock if

your body is earthed or grounded.

c) Do not expose power tools to rain or wet conditions. Water entering a power tool

will increase the risk of electric shock.

d) Do not abuse the cord. Never use the cord for carrying, pulling or unplugging

the power tool. Keep cord away from heat, oil, sharp edges or moving parts.

Damaged or entangled cords increase the risk of electric shock.

e) When operating a power tool outdoors, use an extension cord suitable for

outdoor use. Use of a cord suitable for outdoor use reduces the risk of electric shock.

f) If operating a power tool in a damp location is unavoidable, use a ground fault

circuit interrupter (GFCI) protected supply. Use of a GFCI reduces the risk of

electric shock.

3) Personal safety

a) Stay alert, watch what you are doing and use common sense when operating a

power tool. Do not use a power tool while you are tired or under the influence

of drugs, alcohol or medication. A moment of inattention while operating power

tools may result in serious personal injury.

b) Use personal protective equipment. Always wear eye protection. Protective

equipment such as dust mask, non-skid safety shoes, hard hat, or hearing protection

used for appropriate conditions will reduce personal injuries.

c) Prevent unintentional starting. Ensure the switch is in the off-position before

connecting to power source and/or battery pack, picking up or carrying the

tool. Carrying power tools with your finger on the switch or energizing power tools

that have the switch on invites accidents.

Read all safety warnings and instructions. Failure to follow the

2

Page 3

d) Remove any adjusting key or wrench before turning the power tool on. A wrench

r a key left attached to a rotating part of the power tool may result in personal injury.

o

e) Do not overreach. Keep proper footing and balance at all times. This enables

better control of the power tool in unexpected situations.

f) Dress properly. Do not wear loose clothing or jewelry. Keep your hair, clothing

and gloves away from moving parts. Loose clothes, jewelry or long hair can be

caught in moving parts.

g) If devices are provided for the connection of dust extraction and collection

facilities, ensure these are connected and properly used. Use of dust collection

can reduce dust-related hazards.

44))

Power tool use and care

a) Do not force the power tool. Use the correct power tool for your application.

The correct power tool will do the job better and safer at the rate for which it was designed.

b) Do not use the power tool if the switch does not turn it on and off. Any power

tool that cannot be controlled with the switch is dangerous and must be repaired.

c) Disconnect the plug from the power source and/or the battery pack from the

power tool before making any adjustments, changing accessories, or storing

power tools. Such preventive safety measures reduce the risk of starting the power

tool accidentally.

d) Store idle power tools out of the reach of children and do not allow persons

unfamiliar with the power tool or these instructions to operate the power tool.

Power tools are dangerous in the hands of untrained users.

e) Maintain power tools. Check for misalignment or binding of moving parts,

breakage of parts and any other condition that may affect the power toolʼs

operation. If damaged, have the power tool repaired before use. Many accidents

are caused by poorly maintained power tools.

f) Keep cutting tools sharp and clean. Properly maintained cutting tools with sharp

cutting edges are less likely to bind and are easier to control.

g) Use the power tool, accessories and tool bits etc., in accordance with these

instructions, taking into account the working conditions and the work to be

performed. Use of the power tool for operations different from those intended could

result in a hazardous situation.

5) Service

a) Have your power tool serviced by a qualified repair person using only identical

replacement parts. This will ensure that the safety of the power tool is maintained.

SPECIFIC SAFETY RULES

• Hold tool by insulated gripping surfaces when performing an operation where the

tool may contact hidden wiring or its own cord. Contact with a “live” wire will also

make exposed metal parts of the tool “live” and shock the operator.

• Use clamps or other practical way to secure and support the workpiece to a

stable platform. Holding the work by hand or against your body is unstable and may

lead to loss of control.

• When working on a ladder or on scaffolding be sure to lay the tool down on its

side when not in use. Some tools with large battery packs will stand upright but may

be easily knocked over.

WARNING: ALWAYS use safety glasses. Everyday eyeglasses are NOT safety glasses.

Also use face or dust mask if drilling operation is dusty. ALWAYS WEAR CERTIFIED

SAFETY EQUIPMENT:

• ANSI Z87.1 eye protection (CAN/CSA Z94.3),

• ANSI S12.6 (S3.19) hearing protection,

• NIOSH/OSHA respiratory protection.

WARNING: Some dust created by power sanding, sawing, grinding, drilling, and

other construction activities contains chemicals known to cause cancer, birth

defects or other reproductive harm. Some examples of these chemicals are:

• lead from lead-based paints,

• crystalline silica from bricks and cement and other masonry products, and

• arsenic and chromium from chemically-treated lumber.

Your risk from these exposures varies, depending on how often you do this type of work.

To reduce your exposure to these chemicals: work in a well ventilated area, and work with

approved safety equipment, such as those dust masks that are specially designed to filter

out microscopic particles.

3

Page 4

• Avoid prolonged contact with dust from power sanding, sawing, grinding, drilling,

and other construction activities. Wear protective clothing and wash exposed areas

with soap and water. Allowing dust to get into your mouth, eyes, or lay on the skin may

promote absorption of harmful chemicals.

WARNING: Use of this tool can generate and/or disburse dust, which may cause

serious and permanent respiratory or other injury. Always use NIOSH/OSHA approved

respiratory protection appropriate for the dust exposure. Direct particles away from face

and body.

• When using an extension cord, be sure to use one heavy enough to carry the current

your product will draw. An undersized cord will cause a drop in line voltage resulting in

loss of power and overheating. The following table shows the correct size to use

depending on cord length and nameplate ampere rating. If in doubt, use the next heavier

gauge. The smaller the gauge number, the heavier the cord.

Recommended Minimum Wire Size for Extension Cords

Total Length of Cord

25 ft. 50 ft. 75 ft. 100 ft. 125 ft. 150 ft. 175 ft.

7.6 m 15.2 m 22.9 m 30.5 m 38.1 m 45.7 m 53.3 m

Wire Size AWG

18 18 16 16 14 14 12

SYMBOLS

The label on your tool may include the following symbols.

V ..........................volts A..........................amperes

Hz ........................hertz W ........................watts

min........................minutes ......................alternating

current

......................direct current

..........................

Class II Construction

n

o ........................no load speed

........................earthing terminal

........................safety alert symbol spm ....................strokes per

minute

SAVE THESE INSTRUCTIONS

1

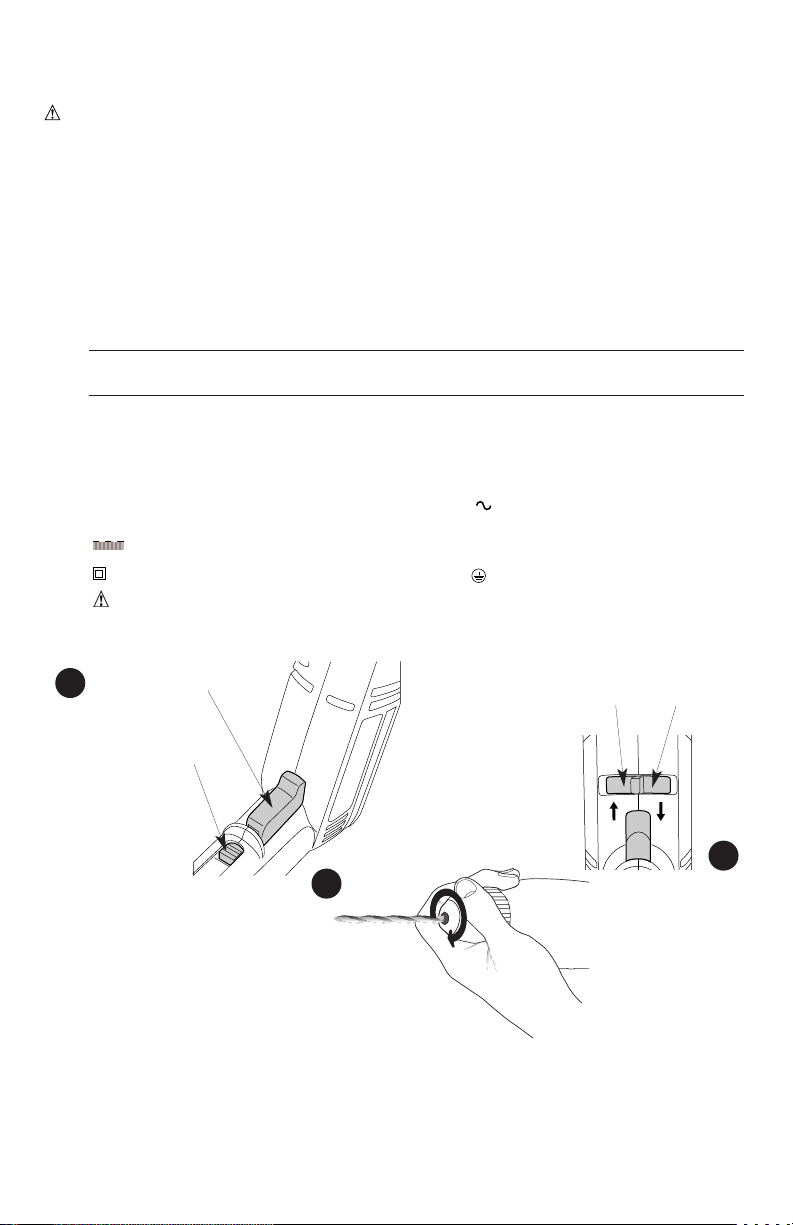

Trigger Switch

Interrupteur à

détente

Gatillo interruptor

Locking Button

Bouton de verrouillage

Botón de seguro

Forward

Marche avant

Adelante

Reverse

Marche arrière

Reversa

3

Motor

Your Black & Decker tool is powered by a Black & Decker-built motor. Be sure your power

supply agrees with nameplate marking. 120 Volts AC only means your drill will operate on

standard 60 Hz household power. Do not operate AC tools on DC. A rating of 120 volts

AC/DC means that your tool will operate on standard 60 Hz AC or DC power. This

information is printed on the nameplate. Lower voltage will cause loss of power and can

result in over-heating. All Black & Decker tools are factory-tested; if this tool does not

operate, check the power supply.

4

2

Page 5

OPERATING INSTRUCTIONS

WARNING: To reduce the risk of serious personal injury, read, understand and follow

all important safety warnings and instructions prior to using tool.

Switch

To turn the drill ON squeeze the trigger switch. The farther the trigger is depressed, the

higher the speed of the drill. To turn the tool OFF release the trigger switch.

The drill can be locked ON (maximum RPM only) for continuous use by squeezing the

trigger while pushing up on the locking button (Fig .1). Hold the locking button up while you

release the trigger switch and then release the locking button. The drill will continue to run.

To turn the drill OFF from a locked ON condition, squeeze and release the trigger

WARNING: The drill should only be locked ON when it is held stationary in a drill

press stand or other means; NOT BY HAND! Never unplug the tool with the locking feature

engaged. To do so will cause the tool to start immediately the next time it is plugged in.

REVERSING

With the trigger switch released, slide the reversing switch, (Fig. 2) to align with the arrow

pointing forward for drilling or toward the arrow pointing backward for running in reverse.

After all reversing operations, switch the tool to the forward running mode.

NOTE: WHEN THE REVERSING SWITCH IS IN NEUTRAL THE DRILL WILL NOT

OPERATE. DO NOT FORCE TRIGGER. SELECT FORWARD OR REVERSE BEFORE

TURNING DRILL ON.

KEYLESS CHUCK OPERATION

This tool is equipped with a feature that automatically locks the spindle when the tool is not

running. This feature is a normal condition which allows for tightening or loosening of the

chuck with one hand while holding the drill with the other. Loosen the chuck by rotating the

sleeve counterclockwise (Fig. 3). Insert the bit or other accessory fully into the chuck, and

tighten securely by rotating the sleeve in the clockwise direction as viewed from the chuck

end.

Drilling

• Always unplug the drill when attaching or removing accessories. When using a keyless

chuck, hand tighten firmly.

• Use sharp drill bits only.

• Support and secure work properly, as instructed in the Safety Instructions.

• Use appropriate and required safety equipment, as instructed in the safety instructions.

• Secure and maintain work area, as instructed in the safety instructions.

• Run the drill very slowly, using light pressure, until the hole is started enough to keep the

drill bit from slipping out of it.

• Apply pressure in a straight line with the bit. Use enough pressure to keep the bit biting

but not so much as to stall the motor or deflect the bit.

• Hold the drill firmly to control its twisting action.

• DO NOT CLICK THE TRIGGER OF A STALLED DRILL OFF AND ON IN AN ATTEMPT

TO START IT. DAMAGE TO THE DRILL CAN RESULT.

• Minimize stalling on breakthrough by reducing pressure and slowly drilling through the

last part of the hole.

• Keep the motor running while pulling the bit out of a drilled hole This will help reduce

jamming.

• Use a cutting lubricant when drilling metals. The exceptions are cast iron and brass which

should be drilled dry. The lubricants that work best are sulphurized cutting oil or lard oil.

Bacon grease will also serve.

• When using twist drill bits to drill holes in wood, it will be necessary to pull the bits out

frequently to clear chips from the flutes.

• Plug in drill. Make sure switch turns drill on and off.

WARNING: It is important to support the work properly and to hold the drill firmly to

prevent loss of control which could cause personal injury If you have any questions on how

to properly operate tool, call: 1-800-544-6986

MAINTENANCE

Use only mild soap and damp cloth to clean the tool. Never let any liquid get inside the

tool; never immerse any part of the tool into a liquid.

IMPORTANT: To assure product SAFETY and RELIABILITY, repairs, maintenance and

adjustment should be performed by authorized service centers or other qualified service

organizations, always using identical replacement parts.

5

Page 6

TROUBLESHOOTING

Problem Possible Cause Possible Solution

• Unit will not start. • Cord not plugged in. • Plug tool into a working outlet.

For assistance with your product, visit our website www.blackanddecker.com for the

location of the service center nearest you or call the BLACK & DECKER help line at

1-800-544-6986.

• Circuit fuse is blown. • Replace circuit fuse. (If the product

repeatedly causes the circuit fuse to blow,

discontinue use immediately and have it

serviced at a Black & Decker service center

or authorized servicer.)

• Circuit breaker is • Reset circuit breaker. (If the product

tripped. repeatedly causes the circuit breaker

to trip, discontinue use immediately and

have it serviced at a Black & Decker service

center or authorized servicer.)

• Cord or switch is • Have cord or switch replaced at a Black &

damaged. Decker Service Center or Authorized Servicer.

ACCESSORIES

Recommended accessories for use with your tool are available from your local dealer or

authorized service center. If you need assistance regarding accessories, please call:

1-800-544-6986.

WARNING: The use of any accessory not recommended for use with this tool could

be hazardous.

IMPORTANT

To assure product SAFETY and RELIABILITY, repairs, maintenance and adjustments

should be performed by Black & Decker service centers or other qualified service

organizations, always using Black & Decker replacement parts.

SERVICE INFORMATION

All Black & Decker Service Centers are staffed with trained personnel to provide customers

with efficient and reliable power tool service. Whether you need technical advice, repair, or

genuine factory replacement parts, contact the Black & Decker location nearest you. To

find your local service location, refer to the yellow page directory under "Tools—Electric" or

call: 1-800-544-6986 or visit www.blackanddecker.com

FULL TWO-YEAR HOME USE WARRANTY

Black & Decker (U.S.) Inc. warrants this product for two years against any defects in

material or workmanship. The defective product will be replaced or repaired at no charge in

either of two ways.

The first, which will result in exchanges only, is to return the product to the retailer from

whom it was purchased (provided that the store is a participating retailer). Returns should

be made within the time period of the retailerʼs policy for exchanges (usually 30 to 90 days

after the sale). Proof of purchase may be required. Please check with the retailer for their

specific return policy regarding returns that are beyond the time set for exchanges.

The second option is to take or send the product (prepaid) to a Black & Decker owned or

authorized Service Center for repair or replacement at our option. Proof of purchase may

be required. Black & Decker owned and authorized Service Centers are listed under

"Tools-Electric" in the yellow pages of the phone directory and on our website

www.blackanddecker.com.

This warranty does not apply to accessories. This warranty gives you specific legal rights

and you may have other rights which vary from state to state. Should you have any

questions, contact the manager of your nearest Black & Decker Service Center. This

product is not intended for commercial use.

LATIN AMERICA: This warranty does not apply to products sold in Latin America. For

products sold in Latin America, check country specific warranty information contained in the

packaging, call the local company or see the website for warranty information.

FREE WARNING LABEL REPLACEMENT: If your warning labels become illegible or are

missing, call 1-800-544-6986 for a free replacement.

Black & Decker (U.S.) Inc.,

701 E. Joppa Rd.

Towson, MD 21286 U.S.A.

6

See ʻTools-

Electricʼ

– Yellow Pages –

for Service &

Sales

Page 7

PERCEUSE DE 10MM (3/8 PO)

MODE D’EMPLOI

N° de catalogues 7252, 7152

Merci dʼavoir choisi Black & Decker!

Consulter le site Web

www.BlackandDecker.com/NewOwner

pour enregistrer votre nouveau produit.

À LIRE AVANT DE RETOURNER CE PRODUIT POUR

QUELQUE RAISON QUE CE SOIT :

Si des questions ou des problèmes surgissent après lʼachat dʼun produit

WWW.BLACKANDDECKER.COM/INSTANTANSWERS

pour obtenir des réponses instantanément 24 heures par jour.

Si la réponse est introuvable ou en lʼabsence dʼaccès à l'Internet, composer le

1 800 544-6986 de 8 h à 17 h HNE, du lundi au vendredi, pour parler avec un agent.

Prière dʼavoir le numéro de catalogue sous la main lors de lʼappel.

Black & Decker, consulter le site Web

IMPORTANTS RENSEIGNEMENTS :

• Il faut actionner les perceuses dotées dʼun inverseur de marche lorsquʼelles

sont en position de marche avant ou arrière. Elles ne fonctionnent pas en

position neutre.

CONSERVER CE MANUEL POUR UN USAGE ULTÉRIEUR.

7

Page 8

LIGNES DIRECTRICES EN MATIÈRE DE SÉCURITÉ - DÉFINITIONS

Il est important que vous lisiez et compreniez ce mode dʼemploi. Les informations quʼil

contient concernent VOTRE SÉCURITÉ et visent à ÉVITER TOUT PROBLÈME. Les

symboles ci-dessous servent à vous aider à reconnaître cette information.

DANGER : Indique une situation dangereuse imminente qui, si elle nʼest pas évitée,

causera la mort ou des graves blessures.

AVERTISSEMENT : Indique une situation potentiellement

dangereuse qui, si elle nʼest pas évitée, pourrait causer la mort ou de graves blessures.

MISE EN GARDE : Indique une situation potentiellement dangereuse qui, si elle

nʼest pas évitée, pourrait causer des blessures mineures ou modérées.

AVIS : Utilisé sans le symbole dʼalerte à la sécurité, indique une situation potentiellement

dangereuse qui, si elle nʼest pas évitée, peut résulter en des dommages à la propriété.

AVERTISSEMENTS DE SÉCURITÉ GÉNÉRAUX

AVERTISSEMENT! Lire tous les avertissements de sécurité et toutes les

directives. Le non-respect des avertissements et des directives pourrait se

solder par un choc électrique, un incendie et/ou une blessure grave.

Conserver tous les avertissements et toutes les directives pour un usage

ultérieur.

Le terme «outil électrique» cité dans les avertissements se rapporte à votre

outil électrique à alimentation sur secteur (avec fil) ou par piles (sans fil).

1) Sécurité du lieu de travail

a) Tenir la zone de travail propre et bien éclairée. Les endroits sombres sont

souvent des causes d'accidents.

b) Ne pas faire fonctionner d’outils électriques dans un milieu déflagrant, soit en

présence de liquides inflammables, de gaz ou de poussière. Les outils électriques

produisent des étincelles qui peuvent enflammer la poussière ou les vapeurs.

c) Éloigner les enfants et les curieux au moment d’utiliser un outil électrique.

Une distraction pourrait vous en faire perdre la maîtrise.

2) Sécurité en matière d’électricité

a) Les fiches des outils électriques doivent correspondre à la prise. Ne jamais

modifier la fiche en aucune façon. Ne jamais utiliser de fiche dʼadaptation avec

un outil électrique mis à la terre. Le risque de choc électrique sera réduit par

lʼutilisation de fiches non modifiées correspondant à la prise.

b) Éviter tout contact physique avec des surfaces mises à la terre comme des

tuyaux, des radiateurs, des cuisinières et des réfrigérateurs. Le risque de choc

électrique est plus élevé si votre corps est mis à la terre.

c) Ne pas exposer les outils électriques à la pluie ou à d'autres conditions où il

pourrait être mouillé. La pénétration de lʼeau dans un outil électrique augmente le

risque de choc électrique.

d) Ne pas utiliser abusivement le cordon d’alimentation. Ne jamais utiliser le

cordon pour transporter, tirer ou débrancher un outil électrique. Tenir le cordon

éloigné de la chaleur, de l’huile, des bords tranchants ou des pièces mobiles.

Les cordons endommagés ou emmêlés augmentent les risques de choc électrique.

e) Pour l’utilisation d’un outil électrique à l’extérieur, se servir d’une rallonge

convenant à une telle utilisation. Lʼutilisation dʼune rallonge conçue pour

lʼextérieur réduit les risques de choc électrique.

f) S’il est impossible d’éviter l’utilisation d’un outil électrique dans un endroit

humide, brancher l’outil dans une prise ou sur un circuit d’alimentation dotés

d’un disjoncteur de fuite à la terre (GFCI). Lʼutilisation de ce type de disjoncteur

réduit les risques de choc électrique.

3) Sécurité personnelle

a) Être vigilant, surveiller le travail effectué et faire preuve de jugement lorsqu’un

outil électrique est utilisé. Ne pas utiliser d’outil électrique en cas de fatigue

ou sous l’influence de drogues, d’alcool ou de médicaments. Un simple

moment dʼinattention en utilisant un outil électrique peut entraîner des blessures

corporelles graves.

8

Page 9

b) Utiliser des équipements de protection individuelle. Toujours porter une

protection oculaire. Lʼutilisation dʼéquipements de protection comme un masque

antipoussière, des chaussures antidérapantes, un casque de sécurité ou des protecteurs

auditifs lorsque la situation le requiert réduira les risques de blessures corporelles.

c) Empêcher les démarrages intempestifs. S’assurer que l’interrupteur se trouve à

la position d’arrêt avant de relier l’outil à une source d’alimentation et/ou

d’insérer un bloc-piles, de ramasser ou de transporter l’outil. Transporter un outil

électrique alors que le doigt repose sur lʼinterrupteur ou brancher un outil électrique

dont lʼinterrupteur est à la position de marche risque de provoquer un accident.

d) Retirer toute clé de réglage ou clé standard avant de démarrer l’outil. Une clé

standard ou une clé de réglage attachée à une partie pivotante peut causer des

blessures.

e) Ne pas trop tendre les bras. Conserver son équilibre en tout temps. Cela

permet de mieux maîtriser lʼoutil électrique dans les situations imprévues.

f) S’habiller de manière appropriée. Ne pas porter de vêtements amples ni de

bijoux. Garder les cheveux, les vêtements et les gants à l’écart des pièces

mobiles. Les vêtements amples, les bijoux ou les cheveux longs risquent de rester

coincés dans les pièces mobiles.

g) Si des composants sont fournis pour le raccordement de dispositifs de

dépoussiérage et de ramassage, s’assurer que ceux-ci sont bien raccordés

et utilisés. Lʼutilisation dʼun dispositif de dépoussiérage peut réduire les dangers

engendrés par les poussières.

4) Utilisation et entretien d’un outil électrique

a) Ne pas forcer un outil électrique. Utiliser l’outil électrique approprié à

l’application. Lʼoutil électrique approprié effectuera un meilleur travail, de façon

plus sûre et à la vitesse pour laquelle il a été conçu.

b) Ne pas utiliser un outil électrique dont l’interrupteur est défectueux. Tout outil

électrique dont lʼinterrupteur est défectueux est dangereux et doit être réparé.

c) Débrancher la fiche du secteur ou le bloc-piles de l’outil électrique avant de

faire tout réglage ou changement d’accessoire, ou avant de ranger l’outil

électrique. Ces mesures préventives réduisent les risques de démarrage

accidentel de lʼoutil électrique.

d) Ranger les outils électriques hors de la portée des enfants, et ne permettre à

aucune personne n’étant pas familière avec un outil électrique (ou son

manuel d’instruction) d’utiliser ce dernier. Les outils électriques deviennent

dangereux entre les mains dʼutilisateurs inexpérimentés.

e) Entretenir les outils électriques. Vérifier les pièces mobiles pour s’assurer

qu’elles sont bien alignées et tournent librement, qu’elles sont en bon état et

ne sont affectées par aucun trouble susceptible de nuire au bon

fonctionnement de l’outil électrique. En cas de dommage, faire réparer l’outil

électrique avant toute nouvelle utilisation. Beaucoup dʼaccidents sont causés

par des outils électriques mal entretenus.

f) S’assurer que les outils de coupe sont aiguisés et propres. Les outils de coupe

bien entretenus et affûtés sont moins susceptibles de se coincer et sont plus faciles

à contrôler.

g) Utiliser l’outil électrique, les accessoires, les forets, etc. conformément aux

présentes directives en tenant compte des conditions de travail et du travail

à effectuer. Lʼutilisation dʼun outil électrique pour toute opération autre que celle

pour laquelle il a été conçu est dangereuse.

5) Réparation

a) Faire réparer l’outil électrique par un réparateur professionnel en n’utilisant

que des pièces de rechange identiques. Cela permettra de maintenir une

utilisation sécuritaire de lʼoutil électrique.

RÈGLES DE SÉCURITÉ SPÉCIFIQUES

• Tenir lʼoutil par les surfaces isolées prévues à cette fin lorsquʼil risque dʼentrer en

contact avec des fils cachés ou le cordon, car de tels contacts peuvent mettre les pièces

métalliques de lʼoutil sous tension, engendrant des risques de choc électrique.

• Utiliser des brides de fixation ou un autre dispositif de fixation permettant de fixer

solidement et de soutenir la pièce sur une plateforme stable. Tenir la pièce avec la main

ou contre son corps la rend instable et risque de provoquer une perte de maîtrise de lʼoutil.

• Lorsquʼon est installé sur une échelle ou un échafaudage pour travailler, on doit

déposer lʼoutil sur le côté lorsquʼon ne sʼen sert plus. Bien que certains outils munis

dʼun gros bloc-piles puissent être placés à la verticale, dans cette position, ils peuvent

facilement être renversés.

9

Page 10

AVERTISSEMENT : TOUJOURS porter des lunettes de sécurité. Les lunettes de vue

ne constituent PAS des lunettes de sécurité. Utiliser également un masque facial ou

anti-poussière si lʼopération de découpe génère de la poussière. TOUJOURS PORTER

UN ÉQUIPEMENT DE PROTECTION HOMOLOGUÉ :

• protection oculaire conforme à la norme ANSI Z87.1 (CAN/CSA Z94.3);

• protection auditive ANSI S12.6 (S3.19);

• protection des voies respiratoires conformes aux normes NIOSH/OSHA/MSHA.

AVERTISSEMENT : Certains outils électriques, tels que les sableuses, les scies,

les meules, les perceuses ou certains autres outils de construction, peuvent

produire de la poussière contenant des produits chimiques susceptibles dʼentraîner

le cancer, des malformations congénitales ou pouvant être nocifs pour le système

reproductif. Parmi ces produits chimiques, on retrouve :

Le risque associé à de telles expositions varie selon la fréquence avec laquelle on

effectue ces travaux. Pour réduire lʼexposition à de tels produits, il faut travailler dans un

endroit bien aéré et utiliser le matériel de sécurité approprié, tel un masque anti-pous

sières spécialement conçu pour filtrer les particules microscopiques.

• Éviter tout contact prolongé avec la poussière soulevée par cet outil ou autres

susceptible de causer des dommages sérieux et permanents au système

respiratoire. Toujours utiliser un appareil respiratoire anti-poussières approprié approuvé

par le NIOSH ou lʼOSHA. Diriger les particules dans le sens opposé du visage et du corps.

• En cas dʼutilisation dʼune rallonge, sʼassurer que les valeurs nominales de la rallonge

Moteur

Un moteur Black & Decker entraîne lʼoutil Black & Decker. Veiller à ce que la tension

dʼalimentation soit conforme aux exigences de la plaque signalétique de lʼoutil. La mention

«120 volts c.a. seulement» signifie que la scie fonctionne sur une alimentation domestique

standard de 60 Hz. Ne pas tenter dʼutiliser une alimentation en courant continu (c.c.) pour

des outils à courant alternatif (c.a.). La mention «120 volts c.a./c.c.» signifie que lʼoutil

fonctionne sur du courant alternatif ou continu standard de 60 Hz. Ces renseignements se

trouvent sur la plaque signalétique de lʼoutil. Une baisse de tension entraîne une perte de

puissance et la surchauffe. Tous les outils Black & Decker sont essayés avant de quitter

lʼusine. Lorsque celui-ci refuse de fonctionner, vérifier la source de courant électrique.

• le plomb dans les peintures à base de plomb,

• la silice cristalline dans les briques et le ciment et autres produits de maçonnerie,

• lʼarsenic et le chrome dans le bois de sciage ayant subi un traitement chimique

(comme lʼarséniate de cuivre et de chrome).

outils électriques. Porter des vêtements de protection et nettoyer les parties

exposées du corps à lʼeau savonneuse. Sʼassurer de bien se protéger afin dʼéviter

dʼabsorber par la bouche, les yeux ou la peau des produits chimiques nocifs.

AVERTISSEMENT : Cet outil peut produire et répandre de la poussière

utilisée correspondent bien à celles de lʼoutil alimenté. Lʼusage dʼune rallonge de calibre

insuffisant causera une chute de tension entraînant perte de puissance et surchauffe. Le

tableau ci-dessous illustre les calibres à utiliser selon la longueur de rallonge et lʼintensité

nominale indiquée sur la plaque signalétique. En cas de doutes, utiliser le calibre suivant.

Plus le calibre est petit, plus la rallonge peut supporter de courant.

Calibre de fil minimum recommandé pour les rallonges

Longueur totale de la rallonge

25 pi 50 pi 75 pi 100 pi 125 pi 150 pi 175 pi

7,6 m 15,2 m 22,9 m 30,5 m 38,1 m 45,7 m 53,3 m

Calibre AWG

18 18 16 16 14 14 12

CONSERVER CES DIRECTIVES

FONCTIONNEMENT

AVERTISSEMENT : Afin de minimiser les risques de graves blessures, il faut lire,

comprendre et respecter les mesures de sécurité ainsi que les consignes relatives au

fonctionnement de lʼoutil avant de sʼen servir.

Interrupteur

Pour mettre lʼoutil en marche, il suffit dʼenfoncer la détente de lʼinterrupteur. Plus on enfonce

la détente, plus le régime de lʼoutil augmente. Pour arrêter lʼoutil, il suffit de relâcher la

détente de lʼinterrupteur.

Pour verrouiller lʼinterrupteur en position de marche (au régime maximal seulement), il suffit

dʼenfoncer la détente de lʼinterrupteur et de pousser vers le haut le bouton de verrouillage

(fig. 1). On relâche ensuite la détente, puis le bouton de verrouillage. La perceuse est alors

en mode de fonctionnement continu. Pour dégager le mécanisme de verrouillage, enfoncer

à fond la détente et la relâcher aussitôt.

10

Page 11

AVERTISSEMENT : Il faut verrouiller la perceuse en mode de fonctionnement continu

seulement lorsque lʼoutil est fixé dans un support dʼétabli ou de toute autre façon, JAMAIS

LORSQUʼON SʼEN SERT MANUELLEMENT! Ne jamais débrancher lorsque le

mécanisme de verrouillage est enclenché. Sinon, la perceuse se mettra immédiatement en

marche la prochaine fois quʼon la branchera.

INVERSEUR DE MARCHE

Sans enfoncer la détente de lʼinterrupteur, faire glisser lʼinverseur de marche (fig. 2) de

sorte quʼil sʼaligne sur la flèche pointant vers lʼavant pour percer ou vers lʼarrière pour

lʼactionner en marche arrière.

Après avoir utilisé lʼoutil en marche arrière, toujours le remettre en marche avant.

NOTE : LORSQUE LʼINVERSEUR DE MARCHE EST EN POSITION NEUTRE, LʼOUTIL

NE FONCTIONNE PAS. NE PAS FORCER LA DÉTENTE. CHOISIR LA MARCHE AVANT

OU ARRIÈRE AVANT DE METTRE LʼOUTIL EN MARCHE.

FONCTIONNEMENT - MANDRIN SANS CLÉ

Lʼoutil est muni dʼun dispositif qui verrouille automatiquement la broche lorsque lʼoutil est

hors tension. Ce dispositif permet de serrer ou de desserrer le mandrin dʼune main et

dʼutiliser lʼautre pour tenir lʼoutil. Pour desserrer le mandrin, tourner le manchon vers la

gauche (fig. 3), puis insérer la mèche ou lʼaccessoire jusquʼau fond du mandrin et serrer

fermement en faisant tourner le manchon vers la droite (lorsquʼon le regarde de

lʼextrémité du mandrin).

Perçage

• Toujours débrancher la perceuse avant dʼen remplacer un accessoire. Lorsquʼon installe

un accessoire dans le mandrin de la perceuse, il faut bien le serrer le mandrin dans

chacun des trois trous afin dʼempêcher le glissement de lʼaccessoire. Dans le cas dʼun

mandrin sans clé, il faut bien le serrer à la main.

• Nʼutiliser que des forets bien affûtés.

• Veiller à ce que la pièce à percer soit solidement retenue ou fixée en place, selon les

mesures de sécurité.

• Porter lʼéquipement de sécurité approprié et requis, selon les mesures de sécurité.

• Rendre la zone de travail sûre et en assurer lʼentretien, selon les mesures de sécurité.

• Actionner la perceuse à basses vitesses en exerçant une pression minimale jusquʼà ce

que le trou soit suffisamment percé afin dʼempêcher le glissement du foret hors du trou.

• Toujours exercer la pression en ligne directe avec le foret. Nʼuser que de la force

nécessaire pour que le foret continue de percer; éviter de trop forcer, ce qui pourrait faire

étouffer le moteur ou dévier le foret.

• Bien saisir la perceuse afin de maîtrise son effet de torsion.

• NE PAS ACTIONNER À PLUSIEURS REPRISES LA DÉTENTE DʼUNE PERCEUSE

BLOQUÉE DANS LE BUT DE LA DÉCOINCER AU RISQUE DE LʼENDOMMAGER.

• Réduire la pression exercée sur lʼoutil et le foret vers la fin de la course afin dʼéviter que le

moteur ne cale en traversant le matériau.

• Laisser le moteur en marche lorsquʼon retire le foret du trou afin dʼen prévenir le coincement.

• Utiliser de lʼhuile de coupe pour percer dans les métaux, sauf la fonte et le laiton qui se

percent à sec. Les huiles de coupe les plus efficaces sont lʼhuile sulfurisée ou lʼhuile de

lard; la graisse de bacon est parfois suffisante.

• Les forets hélicoïdaux à métal peuvent servir à percer le bois, mais il faut les retirer

souvent du trou pour chasser les copeaux et rognures des goujures.

• Brancher la perceuse. Sʼassurer que lʼinterrupteur met lʼoutil en marche et quʼil lʼarrête.

AVERTISSEMENT : Il est essentiel de bien soutenir la pièce à ouvrer et de saisir

fermement la perceuse afin de prévenir la perte de maîtrise de lʼoutil qui pourrait

occasionner de graves blessures. Pour obtenir de plus amples renseignements relatifs au

bon fonctionnement de lʼoutil, composer le : 1 800 544-6986.

ENTRETIEN

Nettoyer lʼoutil seulement à lʼaide dʼun savon doux et dʼun linge humide. Ne laisser aucun

liquide sʼinfiltrer dans lʼoutil et ne jamais immerger lʼoutil.

IMPORTANT : Pour assurer la SÉCURITÉ DʼEMPLOI et la FIABILITÉ de lʼoutil, nʼen confier

la réparation, lʼentretien et les rajustements quʼà un centre de service ou à un atelier

dʼentretien autorisé nʼutilisant que des pièces de rechange identiques.

ACCESSOIRES

Les détaillants et le centre de service de la région vendent les accessoires recommandés

pour lʼoutil. Pour trouver un accessoire, composer le 1 800 544-6986.

AVERTISSEMENT : Lʼutilisation de tout accessoire non recommandé pour lʼoutil peut

être dangereuse.

11

Page 12

DÉPANNAGE

Problème Cause possible Solution possible

• Lʼappareil refuse de • Cordon dʼalimentation • Brancher lʼoutil dans

démarrer. non branché. une prise qui fonctionne.

Pour de lʼaide avec lʼoutil, consulter notre site Web www.blackanddecker.com pour

lʼemplacement du centre de réparation le plus près ou communiquer avec lʼassistance

BLACK & DECKER au 1-800-544-6986.

INFORMATION SUR LES RÉPARATIONS

Tous les centres de réparation Black & Decker sont dotés de personnel qualifié en matière

dʼoutillage électrique; ils sont donc en mesure dʼoffrir à leur clientèle un service efficace et

fiable. Que ce soit pour un avis technique, une réparation ou des pièces de rechange

authentiques installées en usine, communiquer avec lʼétablissement Black & Decker le

plus près de chez vous. Pour trouver lʼétablissement de réparation de votre région,

consulter le répertoire des Pages jaunes à la rubrique « Outils électriques » ou composer le

numéro suivant : 1-800-544-6986 ou consulter le site www.blackanddecker.com

• Le fusible du circuit est • Remplacer le fusible du circuit.

grillé. (Si le produit fait griller de façon

répétée le fusible du circuit, arrêter

immédiatement dʼutiliser le produit et

le faire réparer dans un centre de

réparation Black & Decker ou un

centre de réparation autorisé.)

• Le disjoncteur est • Remettre le disjoncteur à

déclenché. zéro . (Si le produit fait déclencher de

façon répétée le disjoncteur, arrêter

immédiatement dʼutiliser le produit et

le faire réparer dans un centre de

réparation Black & Decker ou un

centre de réparation autorisé.)

• Le cordon dʼalimentation • Faire remplacer le cordon ou

ou la prise de courant est lʼinterrupteur au centre de réparation

Black & Decker ou à un centre de

réparation autorisé.

GARANTIE COMPLÈTE DE DEUX ANS POUR UNE UTILISATION DOMESTIQUE

Black & Decker (É.-U.) Inc. garantit ce produit pour une durée de deux ans contre tout défaut

de matériau ou de fabrication. Le produit défectueux sera remplacé ou réparé sans frais de

lʼune des deux façons suivantes :

La première façon consiste en un simple échange chez le détaillant qui lʼa vendu (pourvu quʼil

sʼagisse dʼun détaillant participant). Tout retour doit se faire durant la période correspondant à

la politique dʼéchange du détaillant (habituellement, de 30 à 90 jours après lʼachat). Une

preuve dʼachat peut être requise. Vérifier auprès du détaillant pour connaître sa politique

concernant les retours hors de la période définie pour les échanges.

La deuxième option est dʼapporter ou dʼenvoyer le produit (transport payé dʼavance) à un

centre de réparation autorisé ou à un centre de réparation de Black & Decker pour faire

réparer ou échanger le produit, à notre discrétion. Une preuve dʼachat peut être requise. Les

centres Black & Decker et les centres de service autorisés sont répertoriés dans les pages

jaunes, sous la rubrique « Outils électriques ».

Cette garantie ne sʼapplique pas aux accessoires. Cette garantie vous accorde des droits

légaux spécifiques et vous pourriez avoir dʼautres droits qui varient dʼun État ou dʼune provinceà

lʼautre. Pour toute question, communiquer avec le directeur du centre de réparation Black &

Decker le plus près de chez vous. Ce produit nʼest pas destiné à un usage commercial.

REMPLACEMENT GRATUIT DES ÉTIQUETTES D’AVERTISSEMENT : si les étiquettes

dʼavertissement deviennent illisibles ou sont manquantes, composer le 1-800-544-6986 pour

en obtenir le remplacement gratuit.

Imported by / Importé par

Black & Decker Canada Inc.

100 Central Ave.

Brockville (Ontario) K6V 5W6

Voir la rubrique “Outils

électriques”

des Pages Jaunes

pour le service et les ventes.

12

Page 13

TALADRO DE 10MM (3/8 PULG.)

MANUAL DE INSTRUCCIONES

Números de catálogo 7252, 7152

Gracias por elegir Black & Decker!

Visite www.BlackandDecker.com/NewOwner

para registrar su nuevo producto.

LEA EL MANUAL ANTES DE DEVOLVER

ESTE PRODUCTO POR CUALQUIER MOTIVO:

Si tiene una consulta o algún inconveniente con su producto Black & Decker, visite

HTTP://WWW.BLACKANDDECKER.COM/INSTANTANSWERS

para obtener respuestas instantáneas las 24 horas del día.

Si no encuentra la respuesta o no tiene acceso a Internet, llame al 1-800-544-6986 de

lunes a viernes de 8 a. m. a 5 p. m. hora del Este para hablar con un agente.

Cuando llame, tenga a mano el número de catálogo.

INFORMACIÓN CLAVE QUE DEBE CONOCER:

• En los taladros reversibles el interruptor debe colocarse en posición de marcha

hacia adelante o reversa para que funcionen. No operaran cuando estén en

neutral.

CONSERVE ESTE MANUAL PARA FUTURAS CONSULTAS.

13

Page 14

PAUTAS DE SEGURIDAD/DEFINICIONES

Es importante que lea y comprenda este manual. La información que contiene se

relaciona con la protección de SU SEGURIDAD y la PREVENCIÓN DE PROBLEMAS.

Los símbolos que siguen se utilizan para ayudarlo a reconocer esta información.

PELIGRO: indica una situación de peligro inminente que, si no se evita, provocará la

muerte o lesiones graves.

ADVERTENCIA: indica una situación de peligro potencial que, si no se evita, provocará

la muerte o lesiones graves.

PRECAUCIÓN: indica una situación de peligro potencial que, si no se evita, provocará

lesiones leves o moderadas.

AVISO: utilizado sin el símbolo de alerta de seguridad indica una situación de peligro potencial

que, si no se evita, puede provocar daños en la propiedad.

Advertencias generales de seguridad para herramientas

eléctricas

ADVERTENCIA: Lea todas las advertencias de seguridad e instrucciones El

incumplimiento de las advertencias e instrucciones puede provocar descargas eléctricas,

incendios o lesiones graves.

Conserve todas las advertencias e instrucciones para futuras consultas.

El término “herramienta eléctrica” incluido en las advertencias hace referencia a

las herramientas eléctricas operadas con corriente (con cable eléctrico) o a las

herramientas eléctricas operadas con baterías (inalámbricas).

1) Seguridad en el área de trabajo

a) Mantenga el área de trabajo limpia y bien iluminada. Las áreas abarrotadas y

oscuras propician accidentes.

b) No opere herramientas eléctricas en atmósferas explosivas, como ambientes

donde se encuentran líquidos, gases o polvo inflamables. Las herramientas

eléctricas originan chispas que pueden encender el polvo o los vapores.

c) Mantenga a los niños y espectadores alejados de la herramienta eléctrica en

funcionamiento. Las distracciones pueden provocar la pérdida de control.

2) Seguridad eléctrica

a) Los enchufes de la herramienta eléctrica deben adaptarse al tomacorriente.

Nunca modifique el enchufe de ninguna manera. No utilice ningún enchufe

adaptador con herramientas eléctricas con conexión a tierra. Los enchufes no

modificados y que se adaptan a los tomacorrientes reducirán el riesgo de

descarga eléctrica.

b) Evite el contacto corporal con superficies puestas a tierra, como por

ejemplo tuberías, radiadores, rangos y refrigeradores. Existe mayor riesgo de

descarga eléctrica si su cuerpo está puesto a tierra.

c) No exponga las herramientas eléctricas a la lluvia o a condiciones de humedad.

Si ingresa agua a una herramienta eléctrica, aumentará el riesgo de descarga eléctrica.

d) No maltrate al cable. Nunca utilice el cable para transportar, tirar o

desenchufar la herramienta eléctrica. Mantenga el cable lejos del calor, aceite,

bordes afilados o piezas móviles. Los cables dañados o enredados aumentan el

riesgo de descarga eléctrica.

e) Al operar una herramienta eléctrica en el exterior, utilice un cable

prolongador adecuado para tal uso. Utilice un cable adecuado para uso en

exteriores a fin de reducir el riesgo de descarga eléctrica.

f) Si el uso de una herramienta eléctrica en un lugar húmedo es imposible de

evitar, utilice un suministro protegido con un interruptor de circuito por falla a

tierra (GFCI). El uso de un GFCI reduce el riesgo de descargas eléctricas.

3) Seguridad personal

a) Permanezca alerta, controle lo que está haciendo y utilice el sentido común

cuando emplee una herramienta eléctrica. No utilice una herramienta eléctrica si

14

Page 15

está cansado o bajo el efecto de drogas, alcohol o medicamentos. Un momento de

descuido mientras se opera una herramienta eléctrica puede provocar lesiones

personales graves.

b) Utilice equipos de protección personal. Siempre utilice protección para los

ojos. En las condiciones adecuadas, el uso de equipos de protección, como

máscaras para polvo, calzado de seguridad antideslizante, cascos o protección

auditiva, reducirá las lesiones personales.

c) Evite el encendido por accidente. Asegúrese de que el interruptor esté en la

posición de apagado antes de conectarlo a la fuente de energía o paquete de

baterías, o antes de levantar o transportar la herramienta. Transportar herramientas

eléctricas con el dedo apoyado en el interruptor o enchufar herramientas eléctricas

con el interruptor en la posición de encendido puede propiciar accidentes.

d) Retire las clavijas de ajuste o llaves de tuercas antes de encender la herramienta

eléctrica. Una llave de tuercas o una clavija de ajuste que se deje conectada a una

pieza giratoria de la herramienta eléctrica pueden provocar lesiones personales.

e) No se estire. Conserve el equilibrio adecuado y manténgase parado

correctamente en todo momento. Esto permite un mejor control de la

herramienta eléctrica en situaciones inesperadas.

f) Use la vestimenta adecuada. No use ropas holgadas ni joyas. Mantenga el

cabello, la ropa y los guantes alejados de las piezas en movimiento. Las ropas

holgadas, las joyas o el cabello largo pueden quedar atrapados en las piezas en

movimiento.

g) Si se suministran dispositivos para la conexión de accesorios con fines de

recolección y extracción de polvo, asegúrese de que estén conectados y que

se utilicen correctamente. El uso de dispositivos de recolección de polvo puede

reducir los peligros relacionados con el polvo.

4) Uso y mantenimiento de la herramienta eléctrica

a) No fuerce la herramienta eléctrica. Utilice la herramienta eléctrica correcta

para el trabajo que realizará. La herramienta eléctrica correcta hará el trabajo

mejor y más seguro a la velocidad para la que fue diseñada.

b) No utilice la herramienta eléctrica si no puede encenderla o apagarla con el

interruptor. Toda herramienta eléctrica que no puede ser controlada mediante el

interruptor es peligrosa y debe ser reparada.

c) Desconecte el enchufe de la fuente de energía y/o el paquete de baterías de

la herramienta eléctrica antes de realizar ajustes, cambiar accesorios o

almacenar herramientas eléctricas. Estas medidas de seguridad preventivas

reducen el riesgo de encender la herramienta eléctrica en forma accidental.

d) Guarde las herramientas eléctricas que no están en uso fuera del alcance de

los niños y no permite que otras personas no familiarizadas con ella o con

estas instrucciones operen la herramienta. Las herramientas eléctricas son

peligrosas en las manos de usuarios no entrenados.

e) Mantenimiento de las herramientas eléctricas. Controle que no haya piezas

móviles mal alineadas o trabadas, piezas rotas y toda otra situación que

pueda afectar el funcionamiento de las herramientas eléctricas. Si encuentra

daños, haga reparar la herramienta eléctrica antes de utilizarla. Se producen

muchos accidentes a causa de las herramientas eléctricas que carecen de un

mantenimiento adecuado.

f) Mantenga las herramientas de corte afiladas y limpias. Las herramientas de

corte con mantenimiento adecuado, con los bordes de corte afilados son menos

propensas a trabarse y son más fáciles de controlar.

g) Utilice la herramienta eléctrica, los accesorios y las brocas de la herramienta,

etc. de acuerdo con estas instrucciones y teniendo en cuenta las condiciones

de trabajo y el trabajo que debe realizarse. El uso de la herramienta eléctrica

para operaciones diferentes de aquéllas para las que fue diseñada podría originar

una situación peligrosa.

5) Mantenimiento

a) Haga que una persona de reparaciones calificada realice el mantenimiento de

su herramienta eléctrica y utilice piezas de repuesto idénticas solamente. Esto

garantizará la seguridad de la herramienta eléctrica.

15

Page 16

NORMAS DE SEGURIDAD ESPECÍFICAS

• Sostenga la herramienta por sus superficies de empuñadura aisladas cuando

realice una operación en la cual la herramienta para cortar pudiera entrar en

contacto con instalaciones eléctricas ocultas o con su propio cable. El contacto con

un cable cargado, cargará a su vez las partes metálicas expuestas de la herramienta y

dará un golpe de corriente al operador.

• Utilice abrazaderas u otra forma práctica para asegurar y sostener la pieza de

trabajo sobre una plataforma estable. Sostener el trabajo con la mano o contra el

cuerpo no brinda la estabilidad requerida y puede llevar a la pérdida del control.

• Cuando trabaje en una escalera o una plataforma asegúrese de dejar la herramienta

de lado cuando no la use. Algunas herramientas con baterías grandes se paran sobre su

base, pero se pueden volcar fácilmente.

AVERTISSEMENT : USE SIEMPRE LENTES DE SEGURIDAD. Los anteojos de uso

diario NO son lentes de seguridad. Utilice también máscaras faciales o para polvo si el

corte produce polvillo. UTILICE SIEMPRE EQUIPOS DE SEGURIDAD CERTIFICADOS:

• Protección para los ojos según la norma ANSI Z87.1 (CAN/CSA Z94.3)

• Protección auditiva según la norma ANSI S12.6 (S3.19)

• Protección respiratoria según las normas NIOSH/OSHA/MSHA

ADVERTENCIA: Parte del polvo generado al lijar, serrar, esmerilar y taladrar, así

como al realizar otras actividades del sector de la construcción, contienen

productos químicos que pueden producir cáncer, defectos congénitos u otras

afecciones reproductivas. Ejemplos de esas substancias químicas son:

• plomo procedente de pinturas a base de plomo,

• óxido de silicio cristalino procedente de ladrillos, cemento y otros productos de

mampostería, y

• arsénico y cromo procedentes de madera tratada químicamente (CCA).

El peligro derivado de estas exposiciones que usted enfrente varía en función de la frecuencia

con que se realice este tipo de trabajo. Para reducir la exposición a esas sustancias

químicas: trabaje en una zona bien ventilada y llevando equipos de seguridad aprobados,

como mascarillas antipolvo especialmente diseñadas para filtrar partículas microscópicas.

• Evite el contacto prolongado con el polvo procedente del lijado, serrado,

esmerilado y taladrado eléctricos, así como de otras actividades del sector de la

construcción. Lleve ropa protectora y lave con agua y jabón las zonas expuestas.

Si permite que el polvo se introduzca en la boca u ojos o quede sobre la piel, puede

favorecer la absorción de productos químicos peligrosos.

ADVERTENCIA: El uso de esta herramienta puede generar o dispersar polvo lo

cual puede causar lesiones respiratorias serias y permanentes y otros tipos de

lesión. Siempre use protección respiratoria aprobada por NIOSH/OSHA para la

exposición al polvo. Dirija las partículas en dirección opuesta a su cara y cuerpo.

• Cuando use un alargador, asegúrese de usar uno de un calibre suficiente como para

cargar con la corriente que requerirá su producto. Un alargador de menor calibre

causará una caída en el voltaje de la línea lo que resultará en pérdida de potencia y

sobrecalentamiento. El siguiente cuadro muestra el tamaño correcto a utilizar,

dependiendo del largo del cable y el amperaje nominal. En caso de duda, utilice el de

mayor calibre. Mientras menor el número del calibre, mayor la capacidad del cable.

Tamaño mínimo recomendado del conductor para los cables de extensión

Longitud total del cable

25 pies 50 pies 75 pies 100 pies 125 pies 150 pies 175 pies

7.6 m 15.2 m 22.9 m 30.5 m 38.1 m 45.7 m 53.3 m

Tamaño AWG del conductor

18 18 16 16 14 14 12

CONSERVE ESTAS INSTRUCCIONES

16

Page 17

Motor

Su herramienta Black & Decker funciona con un motor Black & Decker integrado.

Asegúrese que su alimentación de corriente concuerde con la señalada en la placa de

identificación. 120 V~ significa que su sierra funciona con corriente doméstica estándar a

60 Hz. No utilice herramientas para corriente alterna con corriente continua. Una

especificación de 120 V AC/DC significa que su herramienta funcionará con corriente

alterna estándar a 60 Hz o con corriente continua. esta información está impresa en la

placa de identificación. Voltajes menores causarán pérdida de potencia y pueden producir

sobrecalentamiento. todas las herramientas Black & Decker se prueban en la fábrica; si

esta herramienta no funciona, revise la alimentación de corriente.

INSTRUCCIONES DE OPERACION

ADVERTENCIA: Para reducir el riesgo de lesiones personales graves, lea,

comprenda y siga todas las advertencias e instrucciones importantes de seguridad antes

de usar la herramienta.

Interruptor

Oprima el gatillo interruptor para ENCENDER el taladro. Mientras más oprima el gatillo,

mayor será la velocidad del taladro. Para APAGAR el taladro, libere el gatillo interruptor.

El taladro se puede asegurar en posición de ENCENDIDO (solamente al máximo de las

RPM) para operación continua al apretar el gatillo mientras se oprime el botón de seguro

(fig. 1). Sujete el botón del seguro mientras libera el gatillo interruptor, a continuación

libere el botón del seguro. El taladro continuará en funcionamiento. Para apagar el taladro

desde el modo de operación continua, oprima y libere el gatillo.

ADVERTENCIA: Solamente debe emplearse el modo de operación continua del

taladro cuando se emplee un adaptador de columna u otro medio de sujeción; ¡NO A

MANO! Nunca desconecte el taladro con el mecanismo de encendido permanente

activado, ya que la siguiente vez que conecte el taladro, se accionará instantáneamente.

REVERSA

Con el gatillo interruptor liberado, deslice el interruptor de reversa (fig. 2) para alinearlo

con la flecha que apunta hacia adelante o hacia la flecha que apunta hacia atrás para la

reversa.

Después de operaciones en reversa, cambie el interruptor hacia la posición de marcha

hacia adelante.

NOTA: CUANDO EL INTERRUPTOR DE REVERSA ESTE EN NEUTRAL, EL TALADRO

NO FUNCIONARA. NO FUERCE EL GATILLO. SELECCIONE LA POSICION DE

MARCHA HACIA ADELANTE O REVERSA ANTES DE ENCENDER EL TALADRO.

OPERACIÓN DE PORTABROCA SIN LLAVE

Esta herramienta viene equipada con un dispositivo que inmoviliza el eje

automáticamente cuando la herramienta no está funcionando. Este dispositivo es una

condición normal que permite apretar o aflojar el portabroca con una sola mano mientras

sujeta el taladro con la otra. Afloje el portabroca girando el manguito en sentido

antihorario (Fig. 3). Inserte la broca u otro accesorio de lleno en el portabroca, y apriete

muy bien girando el manguito en sentido horario, visto desde el portabroca.

Taladrado

• Desconecte siempre el taladro cuando coloque o retire accesorios. Cuando coloque

accesorios en el portabrocas, es importante asegurarlo con firmeza empleando los tres

orificios para evitar patinaduras. Cuando tenga un portabrocas sin llave, apriete

firmemente a mano.

• Solamente utilice brocas afiladas.

• Apoye y asegure apropiadamente la pieza de trabajo, como se recomienda en las

instrucciones de seguridad.

• Utilice el equipo de seguridad apropiado y requerido, como se señala en las

instrucciones de seguridad.

• Cuide el área de trabajo, como se menciona en las instrucciones de seguridad.

• Haga funcionar el taladro muy lentamente, utilizando poca presión, hasta haber perforado

lo suficiente para evitar que la broca se deslice hacia afuera del barreno.

• Aplique presión en línea recto con la broca. Haga presión suficiente para conservar a la

broca cortando, pero no tanta como para que el motor se atasque o la broca se desvíe.

• Sujete firmemente el taladro para controlar su acción de torsión.

• NO OPRIMA EL GATILLO DE UN TALADRO ATASCADO PARA INTENTAR

ENCENDERLO Y APAGARLO. PUEDE DAÑARLO.

17

Page 18

Minimice el atascamiento al iniciar el barreno reduciendo la presión y perforando

•

lentamente a través de la última parte del barreno.

• Conserve el motor en funcionamiento mientras saca la broca de un barreno. Esto ayudará

a evitar atascaduras.

• Emplee un lubricante para corte cuando perfore metales. Las excepciones son el hierro

colado y el latón, que deben taladrarse en seco. Los lubricantes que tienen mejor

funcionamiento son el aceite sulfúrico para corte y la manteca de cerdo. La grasa de

tocino funciona también.

• Cuando emplee brocas helicoidales para perforar en madera, será necesario sacarlas del

barreno con frecuencia para limpiar las virutas de los canales.

• Conecte el taladro. Asegúrese que el interruptor enciende y apaga el taladro.

ADVERTENCIA: Es importante apoyar la pieza de trabajo adecuadamente y sujetar al

taladro con firmeza para evitar la pérdida de control que pudiese ocasionar lesiones

personales. Si tiene preguntas sobre la operación correcta de la herramienta.

DETECCIÓN DE PROBLEMAS

Problema Causa posible Solución posible

• La unidad no enciende. • Cable • Enchufe el cargador en un

Para recibir asistencia con su producto, visite nuestro sitio web

www.blackanddecker.com para conocer la ubicación del centro de mantenimiento

más cercano o llame a la línea de ayuda de BLACK & DECKER al 1-800-544-6986

desenchufado. tomacorriente que funcione.

• Fusible quemado. • Reemplace el fusible quemado. (Si

repetidamente el producto hace que el

fusible del circuito se queme, deje de

utilizarlo inmediatamente y haga que le

realicen mantenimiento en un centro de

mantenimiento Black & Decker o en un

centro de servicio autorizado.)

• El interruptor • Reinicie el interruptor automático.

automático está Si repetidamente el producto hace que

activado. el fusible del circuito se queme, deje de

utilizarlo inmediatamente y haga que le

realicen mantenimiento en un centro de

mantenimiento Black & Decker o en un

centro de servicio autorizado.)

• Interruptor o cable • Haga reparar el cable o el interruptor

dañado. en un centro de mantenimiento

Black & Decker o en un centro de

mantenimiento autorizado.

MANTENIMIENTO

Solamente utilice jabón suave y un trapo húmedo para limpiar la herramienta. Nunca permita

que ningún líquido se introduzca en la herramienta; nunca sumerja ninguna parte de la

herramienta en ningún líquido.

IMPORTANTE: Para garantizar la SEGURIDAD y la CONFIABILIDAD del producto, las

reparaciones, el mantenimiento y los ajustes deben ser realizados por centros de servicio

autorizados u otras organizaciones de servicio calificadas, que siempre utilicen partes de

repuesto idénticas.

ACCESORIOS

Los accesorios recomendados para emplearse con su herramienta se encuentran a su

disposición con su distribuidor local o en los centros de servicio autorizado. Si necesita ayuda en

relación con los accesorios.

ADVERTENCIA: El uso de cualquier accesorio no recomendado para emplearse con

esta herramienta puede ser peligroso..

INFORMACIÓN DE MANTENIMIENTO

Todos los Centros de servicio de Black & Decker cuentan con personal altamente

capacitado dispuesto a brindar a todos los clientes un servicio eficiente y confiable en la

reparación de herramientas eléctricas. Si necesita consejo técnico, reparaciones o piezas

de repuesto originales de fábrica, póngase en contacto con el centro de servicio de Black

& Decker más cercano a su domicilio. Para ubicar su centro de servicio local, consulte la

18

Page 19

sección “Herramientas eléctricas” (Tools-Electric) de las páginas amarillas, llame al

1-800-544-6986 o visite nuestro sitio www.blackanddecker.com.

GARANTÍA COMPLETA DE DOS AÑOS PARA USO EN EL HOGAR

Black & Decker (Estados Unidos) Inc. ofrece una garantía de dos años por cualquier

defecto del material o de fabricación de este producto. El producto defectuoso se reparará

o reemplazará sin costo alguno de dos maneras.

La primera opción, el reemplazo, es devolver el producto al comercio donde se adquirió

(siempre y cuando se trate de un comercio participante). Las devoluciones deben

realizarse conforme a la política de devolución del comercio (generalmente, entre 30 y 90

días posteriores a la venta). Le pueden solicitar comprobante de compra. Consulte en el

comercio acerca de la política especial sobre devoluciones una vez excedido el plazo

establecido.

La segunda opción es llevar o enviar el producto (con flete pago) a un Centro de servicio

propio o autorizado de Black & Decker para su reparación o reemplazo según nuestro

criterio. Le pueden solicitar el comprobante de compra. Los Centros de servicio

autorizados y de propiedad de Black & Decker se detallan en la sección

“Herramientas eléctricas” (Tools-Electric) de las páginas amarillas de la guía telefónica.

Esta garantía no se extiende a los accesorios. Esta garantía le concede derechos legales

específicos; usted puede tener otros derechos que pueden variar según el estado o la

provincia. Si tiene alguna pregunta, comuníquese con el gerente del Centro de servicio de

Black & Decker de su zona. Este producto no está diseñado para uso comercial.

AMÉRICA LATINA: esta garantía no se aplica a los productos que se venden en América

Latina. Para los productos que se venden en América Latina, debe consultar la

información de la garantía específica del país que viene en el empaque, llamar a la

compañía local o visitar el sitio Web a fin de obtener esa información.

SOLAMENTE PARA PROPOSITOS DE MEXICO

Grupo Realsa en

herramientas,

S.A. de C.V.

Súper Manzana 69 MZ.01

Lote 30

(Av. Torcasita)

Col. Puerto Juárez

Cancún, Quintana Roo

Tel. 01 998 884 72 27

Ferre Pat de Puebla, S.A.

de C.V.

16 de Septiembre No. 6149

Col. El Cerrito

Puebla, Puebla

Tel. 01 222 264 12 12

Ferre Pat de Puebla, S.A.

de C.V.

Ejército Mexicano No. 15

Col. Ejido 1ro. de Mayo

Boca del Rio, Veracruz

Tel. 01 229 167 89 89

Servicio de Fabrica Black

& Decker,

S.A. de C.V.

Lázaro Cardenas No. 18

Col. Obrera

Distrito Federal

Tel. 55 88 95 02

PARA OTRAS LOCALIDADES LLAME AL 01 800 847 2309 o 01 800 847 2312.

ESPECIFICACIONES

7252 120V~ 288 W 60Hz 3A

Representaciones

Industriales Robles, S.A.

de C.V.

Tezozomoc No. 89

Col. La Preciosa

Distrito Federal

Tel. 55 61 86 82

Gpo. Comercial de Htas.

y Refacciones de

Occidente, S.A. de C.V.

Av. La Paz No. 1779

Col. Americana, S. Juaréz

Guadalajara, Jalisco

Tel. 01 33 38 25 69 78

Herramientas y Equipos

Profesionales

Av. Colón 2915 Ote.

Col. Francisco I. Madero

Monterrey, Nvo. León

Tel. 01 81 83 54 60 06

Htas. Portátiles de

Chihuahua,

S.A. de C.V.

Av. Universidad No. 2903

Col. Fracc. Universidad

Chihuahua, Chihuahua

Tel. 01 614 413 64 04

19

Fernando González

Armenta

Bolivia No. 605

Col. Felipe Carrillo Puerto

Cd. Madero, Tampico

Tel. 01 833 221 34 50

Perfiles y Herramientas de

Morelia

Gertrudis Bocanegra No. 898

Col. Ventura Puente

Morelia, Michoacán

Tel. 01 443 313 85 50

Enrique Robles

Av. de la Solidaridad No.

12713

Col. La Pradera

Irapuato, Guanajuato

Tel. 01 462 626 67 39

Hernández Martinez

Jeanette

Prolongación Corregidora

Nte. No. 1104

Col. Arboledas

Queretaro, Qro.

Tel. 01 442 245 25 80

Page 20

· GARANTÍA BLACK & DECKER · BLACK & DECKER WARRANTY

. SOLAMENTE PARA PROPOSITOS DE MEXICO

Distributor Name · Sello firma del distribuidor

Date of purchase · Fecha de compra Invoice No. · No. de factura

PRODUCT INFOMATION · IDENTIFICACIÓN DEL PRODUCTO

Cat. No. · Catalogo ó Modelo Serial Number · No. de serie

Name · Nombre Last Name · Apellido

Address · Dirección

City · Ciudad State · Estado

Postal Code · Código Postal Country · País

Telephone · No. Teléfono

2 AÑOS DE GARANTIA

Este producto cuenta con dos años de garantía a partir de la fecha de compra contra

cualquier defecto de su funcionamiento, así como cualquier falla debido a materiales

empleados para su fabricación ó mano de obra defectuosa.

Nuestra garantía incluye la reparación o reposición del producto y/o componentes sin

cargo alguno para el cliente incluyendo la mano de obra, esta incluye los gastos de

trasportación erogados para lograr cumplimiento de esta garantía en los domicilios

diversos señalados.

Para hacer efectiva esta garantía deberá presentar su herramienta y esta póliza sellada

por el establecimiento comercial donde se adquirió el producto.

Nos comprometemos a entregar el producto en un lapso no mayor a 30 días hábiles contados

a partir de la fecha de recepción del mismo en nuestros talleres de servicio autorizados.

ESTA GARANTIA NO APLICA CUANDO:

El producto se hubiese utilizado en condiciones distintas a las normales.

El producto no hubiese sido operado de acuerdo con el instructivo de uso que se acompaña.

El producto hubiese sido alterado o reparado por personas no autorizadas por nosotros.

Importador: Black & Decker S.A. de .C.V

Bosque de Cidros Acceso Radiatas No.42

3ra.Seccion de Bosques de las lomas

C.P.05120, Mexico, D.F. Tel: (01 55) 5326 7100

Vea “Herramientas

eléctricas (Tools-Electric)”

– Páginas amarillas –

para Servicio y ventas

Cat No. 7252, 7152 Form No. 90575867 August 2011

Copyright © 2011 Black & Decker Printed in China

BOSQUES DE CIDROS ACCESO RADIATAS NO. 42

BLACK & DECKER S.A. DE C.V.

COL. BOSQUES DE LAS LOMAS.

05120 MÉXICO, D.F

TEL. (01 55) 5326 7100

01 800 847 2309/01 800 847 2312

20

Loading...

Loading...