Page 1

B/ack&Deckep, jigsaw.

SAFETY RULES

+

1. KNOW mm POWEi tool ^ Read owner's manual care»

fully. Learn its applications and limitations as well as the

specific potential hazards peculiar to this tool.

2. KEEP GOAIDS IN PLACE and in working order.

3. KEEP WORK AREA CLEAN. Cluttered areas and benches

invite accidents.

4. A¥OID DANGEIO'US ENfllONMENT. Don't use power tool

in damp or wet locations. And keep work area well lit.

5. KEEP CHILDREN AWAY. All visitors should be kept safe

distance from work area.

6. STORE IDLE TOOLS. When not in use, tools should be

stored in dry, high or locked-up place — out of reach of

children.

7. DON'T FORCE TOOL. It will do the job better and safer at

the rate for which it was designed.

8. USE RIGHT TOOL. Don't force small tool or attachment to

do the Job of a heavy duty tool.

9. WEAR PROPER APPAREL. No loose clothing or Jewelry to

get caught in moving parts. Rubber gloves and footwear

are recommended when working outdoors.

10. USE SAFETY GLASSES with most tools. Also face or dust

mask if cutting operation is dusty.

11. DON'T ABUSE CORD. Never carry tool by cord or yank It

to disconnect from receptacle. Keep cord from heat, oil

and sharp edges.

12. SECURE WORK. Use clamps or a vise to hold work. It's

safer than using your hand and it frees both hands to

operate tool.

13. DON'T 0¥E11EACH. Keep proper footing and balance at

all times.

14. MAINTAIN TOOLS WITH CARE. Keep tools sharp at all

times, and clean for best and safest performance. Follow

instructions for lubricating and changing accessories.

15. DISCONNECT TOOLS. When not in use, before servicing;

when changing accessories such as blades, bits, cutters,

etc.

16.

REMO¥E ADJUSTING KEYS AND WRENCHES. Form habit

of checking to see that keys and adjusting wrenches are

removed from tool before turning it on.

17.

A¥OID ACCIDENTAL STARTING: Don't carry plugged-in

tool with finger on switch.

FOR POWER TOOLS

DOUBLE-INSULATION

Your tool is DOUBLE-INSULATED to give you added safety.

This means that it is constructed throughout with TWO separate

“layers" of electrical insulation or one DOUBLE thickness of

insulation between you and the tool's electrical system.

Tools built with this improved insulation system are not in

tended to be grounded. As a result, your tool is equipped with

a two-prong plug which permits you to use any conventional

120 volt electrical outlet without concern for maintaining a

ground connection.

NOTE: DOUBLE-INSULATION does not take the place of norma!

safety precautions when operating this tool. The improved

insulation system is for added protection against injury result

ing from a possible electrical insulation failure within the tool.

CAUTION: When servicing Double-Insulated Tools, it is extremely

important that ONLY IDENTICAL REPLACEMENT PARTS BE

USED.

EXTENSION CORD

When using the tool at a considerable distance from the power

source, an extension cord of adequate size must be used for

safety, and to prevent loss of power and over-heating. Use the

table below to determine m.inimum wire size required.

Before using cords, inspect them for loose or exposed wires

and damaged insulation. Make any needed repairs or replace

ment before using your power tool.

Extension Cord Length

Minimum | 120 Volt Tools

Wire Size-

* American Wire Gauge

1

220 Volt Tools

Up to

75 Ft.

18

18

100 Ft.

to 125 Ft. to 200 Ft.

16

18

150 Ft.

14

16

LUBRICATION

After every 15 hours of actual running time, place 2 drops of

machine oil in the oil hole located in the side of the tool near

the front. It is recommended that, at least once a year, you

take or send the tool to a B&D Service Center for a thorough

cleaning, inspection and lubrication of the gear case.

ATTACHING BLADES

WHEN SAWING, never reach under or behind the material being

cut for any reason.

MOTOR

Your Black and Decker tool is powered by a B&D-built motor.

Be sure your power supply agrees with nameplate marking.

120 ¥olts 50/60 Hz means Alternating Current (normal 120

volt, 60 cycle house current). Voltage variation of more than

10% will cause loss of power and over-heating. All B&D tools

are factory-tested; if this tool does not operate, check the

supply line for blown fuses; plug and receptacle for contact.

Disconnect tool from extension cord or wall receptacle. Loosen

screw at side of chuck with screwdriver. Insert blade in chuck

as far as it will go (about Tighten screw until it is firm

against blade.

Your B&D Dealer carries a wide selection of Jig Saw Blades

for cutting many kinds of materials. These include wood, metal,

plastics, fiberglass, formica, asbestos, slate, etc.

Page 2

Bbok a Decker, jig saw.

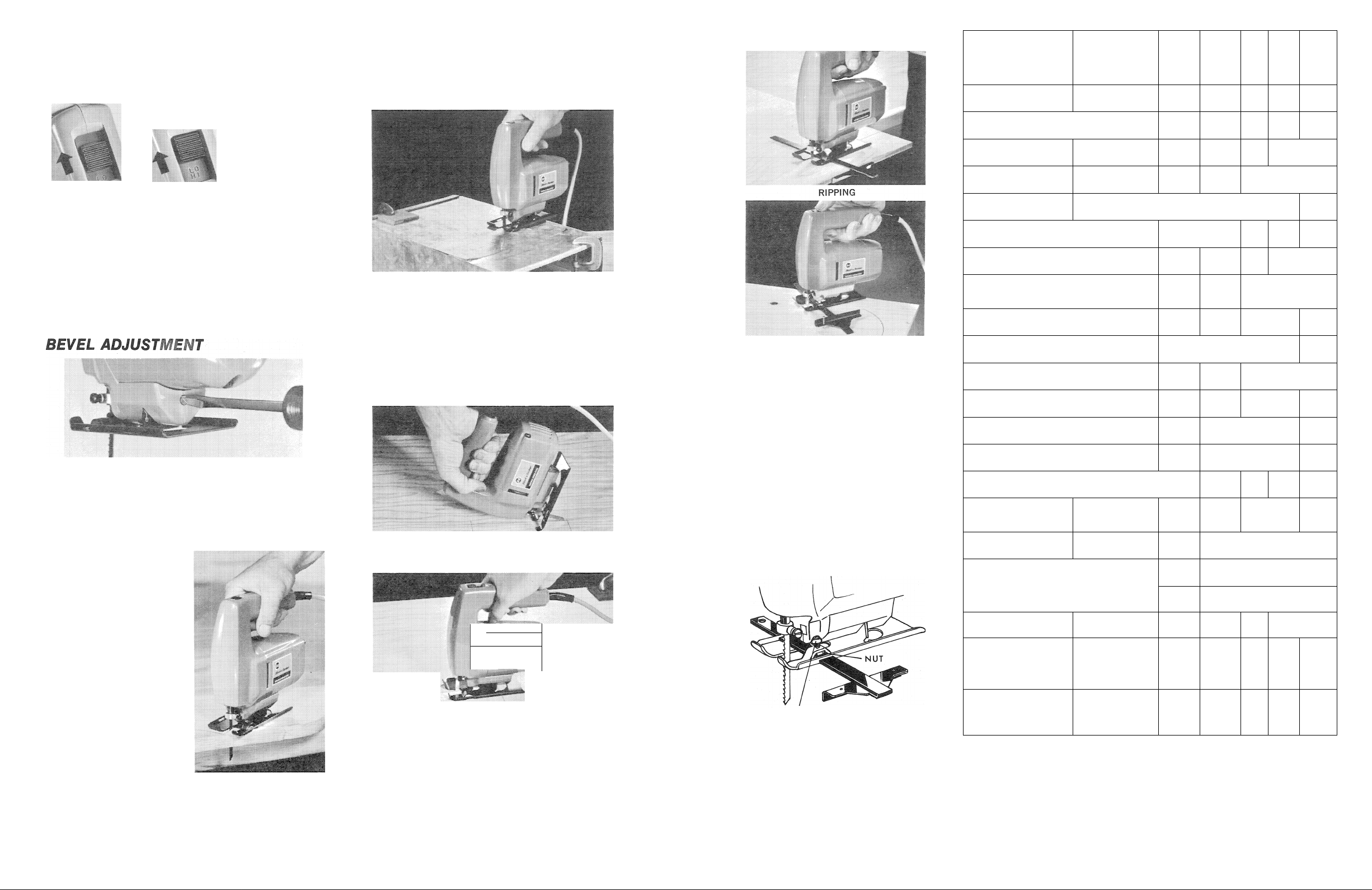

RIP & CIRCLE CUTTING

IIG SAW

SL A D E S

llllllllll

iiiliiiiiiii

JfT.i

.jjjjjiliiiiiiiii

Teeth

Per

Inch

lìlilìlìll

¡llllllli

B&D

Cat.

No.

SWITCH

FIGUiE 1

Push the Switch Button forward to turn the saw “ON”. As you

push the button forward it will first dick into a position expos

ing the letters “LO” (Figure 1). This is the low speed position

for cutting metals and plastics.

Pushing the button farther forward until it clicks again will

expose the letters “HI” (Figure 2). This is the high speed posi

tion for cutting woods and composition boards.

Pulling the switch button ail the way back turns the tool “OFF”

(Figure 3).

The Jig Saw Shoe may be tilted to permit bevel cutting at any

angle from 0° to 45^ To change the angle of the shoe, loosen

screw (see above) and tilt shoe to desired cutting angle with

blade. Retighten screw. Cutting angles of 0° and 45° are indi

cated on the left side, raised portion of shoe when viewed from

rear of saw.

FIGURE 2

FIGURES

IVOOD CUTTING

Be sure board is firmly posi

tioned. Hold Jig Saw by the

convenient overhead handle

and operate switch to turn the

unit on. Don’t attempt to turn

on when blade is against mate

rial to be cut. This could stall

the motor. Place front of shoe

on material to be cut and hold

Jig Saw shoe down firmly

against the wood while cutting.

Don't force the tool; let the

blade cut at its own speed.

Whenever possible, clamp or

support work close to the line

of cut; when the cut is com

pleted, shut off power and lay

the saw aside before loosening

the work.

CAUTION: When sawing into walls, floors or wherever “live”

eieccrical wires may be encountered, DO NOT TOUCH ANY

METAL PARTS OF THE TOOL! Hold the Jig Saw only by its plastic

handle to prevent electric shock if you saw into a “live” wire.

METAL CUTTING

In cutting thin gage sheet metals it is best to clamp wood or

plywood to bottom of metal sheet, this will Insure a clean cut

without the danger of vibration or tearing of metal. Always

remember to use a finer blade for ferrous metals (those that

have an iron content). Use a coarser blade for non-ferrous

metals (those that do not have an iron content).

III

ifc # .... ■!

1

A pocket cut is an easy method of making an Inside cut. The

saw can be inserted directly into a panel or board without first

drilling a lead or pilot hole. In pocket cutting measure the

surface to be cut and mark clearly with a pencil. Next tip the

saw forward until the front edge of the shoe sits firmly on the

work surface. Switch the too! on and allow it to attain maximum

speed. Grip the handle firmly and lower the back edge of tool

until the blade cuts smoothly into material. Always be sure

blade reaches its complete depth before starting to cut.

CIRCLE CUTTING

Ripping and circle cutting without a pen

cil line are easily done with the No. U-

2151

Accessory Rip Fence and Circle

Guide. (The attachment of this Accessory

is explained In the drawing below.) When

ripping; insert rip fence in either side of

saw; adjust to width of cut and tighten

thumb screw. When circle cutting, insert

rip fence from either side with cross bar

facing up; adjust rip fence so that dis

tance from blade to hole in cross bar is

the desired radius and tighten thumb

screw; place saw so that center of hole

in cross bar is over center of circle to be

cut (make pocket cut, drill hole for blade

or cut inward from edge of material to

get blade into position). When saw Is

properly positioned, drive a small nail

through hole of cross-bar into exact cen

ter of circle to be cut. Using rip fence as

a pivot arm, begin cutting circle.

THUMB SCREW

The Nut and Thumb Screw shown above

are included with this Accessory. Hold

the nut in the position shown and thread

the thumb screw into it just enough to

hold the nut loosely in position.

Pull up on the thumb screw and slide

the Rip Fence under the nut from either

side of the Saw. Set the cross bar at

desired distance from blade and tighten

thumb screw. For ripping the cross bar

should be down as shown. For circle cut

ting the cross bar should be up.

..

/A//-/-, ^ ^

• '-V ...

^B Ê Ê Ê m H tÊÊÊ Ê U K Ê k . !■ ■•■ ■ ■ ■■■■

iiiiiiiliiiiàiÉiiiiii®

..........

.....................

lllilllillll II

■■

----------------

Ferrol.'S fin e 1 iiiilllll 32

Plywoo d , plÿnd ie i.

:|||i||||||||i|i|||i

Illllllllillllllllll

Illllllllillllllllll

-----------------

Rough

;|||||||||| 7

Medium

Smooth Jlllll lililí 7

Smooth

Smooth

Medium

; Medium

:....

Smootli

C<«u rr.e

Smooth

Medi un-:

Rough

Medium

Rough

Medium

lliiillilll 10

llllllllllill

F'ï

1 illllllllilll

Fioe llllllllll

Sllllllllllillllllllll

Rough 9

...

..........

llliilllilll

Fine

Medium 10

.................... ...........................

Fine

Meelum 10 3“ 58147

Rough

Medium

Slew 14

Fast 7 3'^ 58146

Fast

Fast 3

illllllllilll

lllllllllllllllllll

1Ú 39754

;

iiiililiiiiiiili

0

i 10

................

7 . S'- : «493

Ì

.................

rnm em m m

1 s llllllillilllllllll

i iiliiiiiiiiiiíiiiííiiii

'

i ;................................^

3 0 R-' 39757

6

llllllllllill

Kr.-:; ■

Eci: ■

Fast ^5 3" 58145

! ^

7 3"' 58149

llllllllll

llllllllllill

1

¡llllllllllill

54368

54369

r 54370

^ 39755

39756

:r 49492

1

.

49494

31004

i

39758

58148

4949Ü

49491

31005

31002

31003

CAUTION: Recommended saw blades and accessories for your Saw are listed above

and at left. The use of any other type of blade or accessory might be hazardous.

Loading...

Loading...