Page 1

General Safety Rules

WARNING! Read and understand all instructions. Failure to follow all

instructions listed below may result in electric shock, fire and/or serious injury.

The term “power tool” in all of the warnings listed below refers to your mainsoperated (corded) power tool or battery-operated (cordless) power tool.

WARNING: To reduce the risk of injury, user must read instruction manual.

SAVE THESE INSTRUCTIONS

1) WORK AREA SAFETY

a) Keep work area clean and well lit. Cluttered or dark areas invite accidents.

b) Do not operate power tools in explosive atmospheres, such as in the presence

of flammable liquids, gases or dust. Power tools create sparks which may ignite the

dust or fumes.

c) Keep children and bystanders away while operating a power tool. Distractions can

cause you to lose control

2) ELECTRICAL SAFETY

a) Power tool plugs must match the outlet. Never modify the plug in any way. Do

not use any adapter plugs with earthed (grounded) power tools. Unmodified plugs

and matching outlets will reduce risk of electric shock

b) Avoid body contact with earthed or grounded surfaces such as pipes, radiators,

ranges and refrigerators. There is an increased risk of electric shock if your body is

earthed or grounded.

c) Do not expose power tools to rain or wet conditions. Water entering a power tool

will increase the risk of electric shock

d) Do not abuse the cord. Never use the cord for carrying, pulling or unplugging

the power tool. Keep cord away from heat, oil, sharp edges or moving parts.

Damaged or entangled cords increase the risk of electric shock. Replace or repair

damaged cords. Make sure your extension cord is in good condition. Use only 3-wire

extension cords that have 3-prong grounding-type plugs and 3-pole receptacles that

accept the tool’s plug.

e) When operating a power tool outdoors, use an extension cord suitable for

outdoor use. Use of a cord suitable for outdoor use reduces the risk of electric shock.

When using an extension cord, be sure to use one heavy enough to carry the current

your product will draw. An undersized cord will cause a drop in line voltage resulting in

loss of power and overheating. The following table shows the correct size to use

depending on cord length and nameplate ampere rating. If in doubt, use the next heavier gage. The smaller the gage number, the heavier the cord.

Minimum Gage for Cord Sets

Volts Total Length of Cord in Feet

120V 0-25 26-50 51-100 101-150

240V 0-50 51-100 101-200 201-300

Ampere Rating

More Not more AWG

Than Than

0 - 6 18 16 16 14

6 - 10 18 16 14 12

10 - 12 16 16 14 12

12 - 16 14 12 Not Recommended

3) PERSONAL SAFETY

a) Stay alert, watch what you are doing and use common sense when operating a

power tool. Do not use a power tool while you are tired or under the influence of

drugs, alcohol or medication. A moment of inattention while operating power tool

may result in serious personal injury.

b) Use safety equipment. Always wear eye protection. Safety equipment such as dust

mask, non-skid safety shoes, hard hat, or hearing protection used for appropriate

conditions will reduce personal injuries.

c) Avoid accidental starting. Ensure the switch is in the off-position before plugging

in. Carrying power tools with your finger on the switch or plugging in power tools that

have the switch on invites accidents.

d) Remove any adjusting key or wrench before turning the power tool on. A wrench

or a key left attached to a rotating part of the power tool may result in personal injury.

e) Do not overreach. Keep proper footing and balance at all times. This enables better

control of the power tool in unexpected situations.

f) Dress properly. Do not wear loose clothing or jewelry. Keep your hair, clothing

and gloves away from moving parts. Loose clothes, jewelry or long hair can be

caught in moving parts. Air vents often cover moving parts and should also be avoided.

g) If devices are provided for the connection of dust extraction and collection

facilities, ensure these are connected and properly used. Use of these devices can

reduce dust-related hazards.

4) POWER TOOL USE AND CARE

a) Do not force the power tool. Use the correct power tool for your application. The

correct power tool will do the job better and safer at the rate for which it was designed.

b) Do not use the power tool if the switch does not turn it on and off. Any power tool

that cannot be controlled with the switch is dangerous and must be repaired.

c) Disconnect the plug from the power source and/or the battery pack from the

power tool before making any adjustments, changing accessories, or storing

power tools. Such preventive safety measures reduce the risk of starting the power

tool accidentally.

d) Store idle power tools out of the reach of children and do not allow persons

unfamiliar with the power tool or these instructions to operate the power tool.

Power tools are dangerous in the hands of untrained users.

e) Maintain power tools. Check for misalignment or binding of moving parts,

breakage of parts and any other condition that may affect the power tools

operation. If damaged, have the power tool repaired before use. Many accidents

are caused by poorly maintained power tools.

f) Keep cutting tools sharp and clean. Properly maintained cutting tools with sharp

cutting edges are less likely to bind and are easier to control.

g) Use the power tool, accessories and tool bits etc., in accordance with these

instructions and in the manner intended for the particular type of power tool,

taking into account the working conditions and the work to be performed. Use of

the power tool for operations different from those intended could result in a hazardous

situation.

5) SERVICE

a) Have your power tool serviced by a qualified repair person using only identical

replacement parts. This will ensure that the safety of the power tool is maintained.

b) If the replacement of the supply cord is necessary, this has to be done by the

manufacturer or his agent in order to avoid a safety hazard.

Specific Safety Rules

• Hold tool by insulated gripping surfaces when performing an operation where the

cutting tool may contact hidden wiring or its own cord. Contact with a "live" wire will

make exposed metal parts of the tool "live" and shock the operator.

• Keep hands away from cutting area. Never reach underneath the material for any reason.

Hold front of saw by grasping the contoured gripping area. Do not insert fingers or thumb into

the vicinity of the reciprocating blade and blade clamp. Do not stabilize the saw by gripping

the shoe.

• Keep blades sharp. Dull blades may cause the saw to swerve or stall under pressure.

• Use extra caution when cutting overhead and pay particular attention to overhead wires

which may be hidden from view. Anticipate the path of falling branches and debris ahead of

time.

• When cutting pipe or conduit ensure that they are free from water, electrical wiring, etc.

WARNING: Some dust created by power sanding, sawing, grinding, drilling, and

other construction activities contains chemicals known to cause cancer, birth

defects or other reproductive harm. Some examples of these chemicals are:

• lead from lead-based paints,

• crystalline silica from bricks and cement and other masonry products, and

• arsenic and chromium from chemically-treated lumber (CCA).

Your risk from these exposures varies, depending on how often you do this type of

work. To reduce your exposure to these chemicals: work in a well ventilated area, and

work with approved safety equipment, such as those dust masks that are specially

designed to filter out microscopic particles.

• Avoid prolonged contact with dust from power sanding, sawing, grinding, drilling,

and other construction activities. Wear protective clothing and wash exposed

areas with soap and water. Allowing dust to get into your mouth, eyes, or lay on the

skin may promote absorption of harmful chemicals.

WARNING: Use of this tool can generate and/or disperse dust, which may cause

serious and permanent respiratory or other injury. Always use NIOSH/OSHA

approved respiratory protection appropriate for the dust exposure. Direct particles

away from face and body.

CAUTION: Wear appropriate hearing protection during use. Under some conditions

and duration of use, noise from this product may contribute to hearing loss.

The label on your tool may include the following symbols.

V ..........................volts A..........................amperes

Hz ........................hertz W ........................watts

min........................minutes ......................alternating current

......................direct current

n

o ........................no load speed

..........................

Class II Construction

........................earthing terminal

........................safety alert symbol .../min ..................revolutions or

reciprocations

per minute

INSTRUCTION MANUAL

RECIPROCATING SAW - Cat. No. FS9500RS

VEA EL ESPAÑOL EN LA CONTRAPORTADA.

SAVE THIS MANUAL FOR FUTURE REFERENCE.

INSTRUCTIVO DE OPERACIÓN, CENTROS DE SERVICIO Y PÓLIZA

DE GARANTÍA. ADVERTENCIA: LÉASE ESTE INSTRUCTIVO ANTES

DE USAR EL PRODUCTO.

CAT. NO. FS9500RS FORM NO. 638034-00

Copyright © 2005 Black & Decker (DEC. ‘05) Printed in China

BEFORE RETURNING THIS PRODUCT

FOR ANY REASON PLEASE CALL

1-800-544-6986

IF YOU SHOULD EXPERIENCE A PROBLEM

WITH YOUR BLACK & DECKER PRODUCT,

CALL 1-800-544-6986

BEFORE YOU CALL, HAVE THE FOLLOWING INFORMATION AVAILABLE, CATALOG No., TYPE

No., AND DATE CODE. IN MOST CASES, A BLACK & DECKER REPRESENTATIVE CAN

RESOLVE YOUR PROBLEM OVER THE PHONE. IF YOU HAVE A SUGGESTION OR

COMMENT, GIVE US A CALL. YOUR FEEDBACK IS VITALTO BLACK & DECKER.

TRIGGER SWITCH

INTERRUPTEUR À DÉTENTE

GATILLO INTERRUPTOR

3

1

2A

2B

Page 2

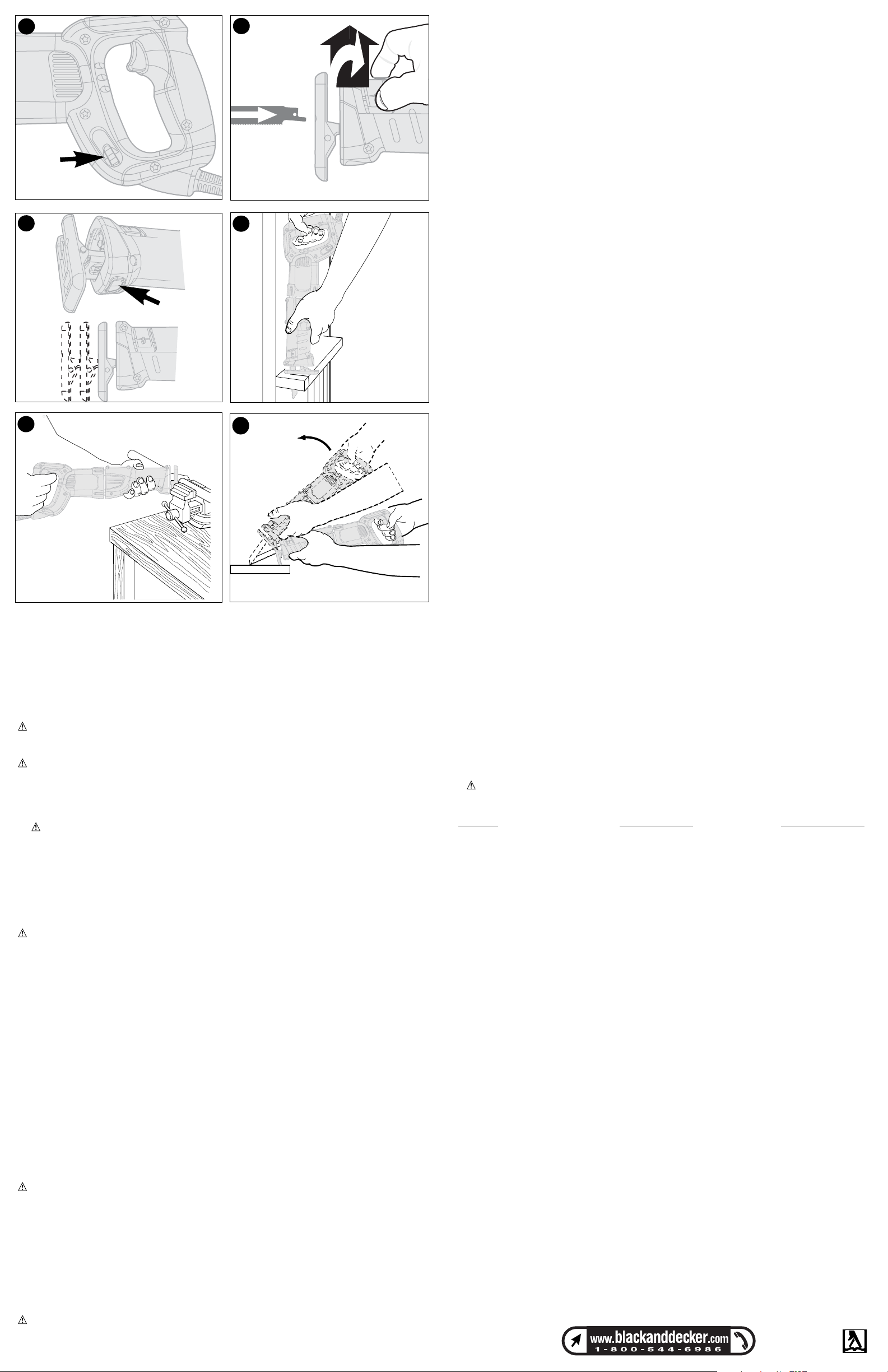

FLUSH CUTTING (FIGURE 7)

• The compact design of the reciprocating saw motor housing and pivoting shoe permit

close cutting to floors, corners and other difficult areas.

• To maximize flush cutting capabilities, insert the blade shaft into the blade clamp with the

teeth of the blade facing up.

• Turn the saw upside down so you are as close to the work surface as possible.

METAL CUTTING (FIGURE 8)

• Use a finer blade for ferrous metals and a coarse blade for non-ferrous materials.

• In thin gauge sheet metals it is best to clamp wood to both sides of sheet. This will

ensure a clean cut without excess vibration or tearing of metal.

• Avoid forcing cutting blade as this reduces blade life and causes costly blade breakage.

NOTE: Spread a thin film of oil or other coolant along the line ahead of the saw cut for

easier operation and longer blade life. For cutting aluminum, kerosene is preferred.

POCKET CUTTING - WOOD ONLY (FIGURE 9)

• Measure the surface area to be cut and mark clearly with a pencil, chalk or scriber.

• Insert blade in blade clamp and tighten blade clamp securely.

• Tip the saw backward until the back edge of the shoe is resting on the work surface and

the moving blade will clear the surface.

• Switch motor on, permitting blade to obtain maximum speed.

• Grip handle steadily and begin a slow, deliberate upward swing with the handle of the

saw.

• The blade will begin to feed into material. Always be sure blade is completely through

material before continuing with pocket cut.

NOTE: In areas where blade visibility is limited, use the edge of the shoe as a guide.

PROJECT TIPS

• Cut only with sharp blades; they cut cleaner, faster and put less strain on the motor while

cutting.

• When cutting, always ensure that the shoe is resting firmly against the workpiece. This

will improve operator control and minimize vibration.

• For longer blade life, use bi-metal blades. These utilize a carbon steel back welded to

high speed steel teeth making the blade more flexible and less prone to breaking.

MAINTENANCE

UNPLUG SAW AND REMOVE ACCESSORY WHEN PERFORMING ANY CLEANING OR

OTHER MAINTENANCE. WHEN SERVICING USE ONLY IDENTICAL REPLACEMENT

PARTS.

• Avoid using solvents when cleaning plastic parts. Most plastics are susceptible to various

types of commercial solvents and may be damaged by their use. Use clean cloths to

remove dirt, carbon dust etc.

• When electric tools are used on fiberglass boats, sports cars, drywall etc., they are

subject to accelerated wear and possible premature failure, as the fiberglass chips and

grindings and drywall dust are highly abrasive to bearings, brushes, commutator, etc.

During any use on fiberglass or drywall it is extremely important that the tool be cleaned

frequently by blowing with an air jet.

LUBRICATION

Your saw was properly lubricated before leaving the factory. Once every year take or send

your saw to a Black & Decker service center, or authorized service station, for a complete

cleaning, inspection and lubrication. Tools "out of service" for long periods should be

relubricated before being put back to work.

IMPORTANT: To assure product SAFETY and RELIABILITY, repairs, maintenance and

adjustment should be performed by authorized service centers or other qualified service

personnel, always using identical replacement parts

ACCESSORIES

BLADES

The saw will accept up to a 12 inch long blade. Always use the shortest blade suitable for

your project but long enough to keep the blade cutting through the material. Longer blades

are more likely to be bent or damaged during use. During operation some longer blades may

vibrate or shake if the saw is not kept in contact with the workpiece.

PRUNING ATTACHMENT

A pruning attachment is also available for use with your Reciprocating Saw. This accessory

attaches to the shoe of the saw and applies spring loaded pressure to the branch while

cutting.

Recommended accessories for use with your saw are available from your local dealer or

authorized service center. If you need assistance regarding accessories, please call:

1-800-544-6986.

WARNING: The use of any accessory not recommended for use with this tool could be

hazardous.

Troubleshooting

Problem Possible Cause Possible Solution

• Unit will not start. • Cord not plugged in. • Plug in cord.

• Circuit fuse is blown. • Replace circuit

fuse.

• Circuit breaker is tripped. • Reset circuit

breaker.

• Cord or switch is damaged. • Have cord or

switch replaced at

Black &Decker

Service Center or

Authorized Servicer

For assistance with your product, visit our website www.black&decker.com for the location

of the service center nearest you or call the BLACK & DECKER help line at

1-800-544-6986.

SERVICE INFORMATION

Black & Decker offers a full network of company-owned and authorized service locations

throughout North America. All Black & Decker Service Centers are staffed with trained

personnel to provide customers with efficient and reliable power tool service. Whether you

need technical advice, repair, or genuine factory replacement parts, contact the

Black & Decker location nearest you. To find your local service location, refer to the yellow

page directory under "Tools—Electric" or call: 1-800-544-6986.

FULL TWO YEAR WARRANTY

Black & Decker (U.S.) Inc. warrants this product for two years against any defects in

material or workmanship. The defective product will be replaced or repaired at no charge in

either of two ways.

The first, which will result in exchanges only, is to return the product to the retailer from whom

it was purchased (provided that the store is a participating retailer). Returns should be made

within the time period of the retailer’s policy for exchanges (usually 30 to 90 days after the

sale). Proof of purchase may be required. Please check with the retailer for their specific

return policy regarding returns that are beyond the time set for exchanges.

The second option is to take or send the product (prepaid) to a Black & Decker owned or

authorized Service Center for repair or replacement at our option. Proof of purchase may be

required. Black & Decker owned and authorized Service Centers are listed under

"Tools-Electric" in the yellow pages of the phone directory and available on our website

www.blackanddecker.com.

This warranty does not apply to accessories. This warranty gives you specific legal rights and

you may have other rights which vary from state to state. Should you have any

questions, contact the manager of your nearest Black & Decker Service Center.

Free warning label replacement: If your warning labels become illegible or are missing,

call 1-800-544-6986 for a free replacement.

SPECIAL WARRANTY NOTE TO CONTRACTORS:

FIRESTORM

TM

branded products are offered as high end consumer home use tools and

carry a HOME USE WARRANTY. These tools are designed, manufactured and tested to

meet or exceed the needs of the do-it-yourselfer in the execution of projects and repairs in

and around the home. With proper use they will provide the home owner with step up power

and performance well beyond their two year warranty. However, if you use tools for a living

and use FIRESTORM

TM

branded products or any of Black & Decker’s other Consumer Home

Use tools ON THE JOBSITE you should know that they CANNOT BE COVERED UNDER

OUR WARRANTY.

MOTOR

Be sure your power supply agrees with nameplate marking. 120 Volts AC only means your

tool will operate on standard 60 Hz household power. Do not operate AC tools on DC. A

rating of 120 volts AC/DC means that you tool will operate on standard 60 Hz AC or DC

power. This information is printed on the nameplate. Lower voltage will cause loss of power

and can result in over-heating. All Black & Decker tools are factory-tested; if this tool does

not operate, check the power supply.

SAVE THESE INSTRUCTIONS

OPERATION

CAUTION: For your own safety, do not connect the machine to the power source

until the machine is completely assembled and you read and understand the entire

instruction manual.

WARNING: Always wear eye protection while operating this power tool.

NOTE: Before cutting any type of material, be sure it is firmly anchored or clamped to pre-

vent slipping.

• Place blade lightly against work to be cut.

• Switch on saw motor before applying pressure.

• WARNING: LACERATION HAZARD. Never hold and use the product with your

fingers wrapped around shoe adjustment button. Always hold saw firmly with both

hands while cutting as shown in Figure 1 or , if you prefer, use the auxilary handle.

Whenever possible, the saw shoe must be held firmly against the material being cut.

This will prevent the saw from jumping or vibrating and minimize blade breakage.

AUXILIARY HANDLE (FIGURE 2)

The auxiliary handle offers a greater choice of gripping positions. 8 clamping locations are

available for auxiliary handle placement.

CAUTION: TURN OFF AND UNPLUG SAW.

ATTACHING THE AUXILIARY HANDLE TO THE SAW:

• Wrap the handle and strap around the forward gripping area of the saw (shown in

figure 2A).

• Be certain the handle and strap indexing features are fully engaged in the matching saw

positions.

• Hook the clamp and strap together and press the clamp lever to the handle to securely

latch the handle as shown in figure 2B.

• Check to ensure the handle is secure before cutting.

REMOVING THE AUXILIARY HANDLE.

• Lift lever and unhook clamp from strap.

• Separate and remove the handle and strap from the saw

SWITCH (ON-OFF) (FIGURE 3)

Depress the trigger switch to turn tool “ON”. Releasing the trigger turns the tool “OFF”

NOTE: This tool has no provision to lock the switch in the ON position, and should never be

locked in the ON position by any other means.

VARIABLE SPEED SELECTOR WHEEL (FIGURE 4)

The variable speed selector wheel offers a choice of speeds for greatly improved cutting

rates in various materials. To select a slower speed for operating the saw, rotate the wheel to

a low number on the dial. To select a higher speed, rotate the wheel to a higher number.

BLADE CLAMP RELEASE LEVER (FIGURE 5)

CAUTION: LACERATION HAZARD. TURN OFF AND UNPLUG FROM POWER

SUPPLY WHEN CHANGING BLADES.

To install blade into saw:

1. Lift the blade clamp release lever to its full open position as shown in Figure 5.

2. Insert blade shank from the front locating hole in blade over pin on reciprocating shaft.

3. Close blade clamp release lever.

4. Check to ensure blade is secure before cutting.

To remove blade from saw:

1. Open blade clamp release lever to its full open position.

2. Remove blade.

ADJUSTABLE SHOE (FIGURE 6)

CAUTION: TURN OFF AND UNPLUG SAW.

The shoe will adjust to limit the depth of cut. Hold the saw with the underside facing up.

Push the button (shown in Figure 6) on the hand grip and slide the shoe out to one of the

7

8

6

9

5

4

See ‘Tools-Electric’

– Yellow Pages –

for Service & Sales

Black & Decker (U.S.) Inc.,

701 E. Joppa Rd.

Towson, MD 21286 U.S.A.

Page 3

Règles de sécurité générales

AVERTISSEMENT : Lire et comprendre toutes les directives. Tout manquement aux

directives suivantes pose des risques de choc électrique, d’incendie et/ou de blessure

grave. Le terme « outil électrique » dans tous les avertissements ci-après se rapporte à

votre outil électrique à alimentation sur secteur (avec fil) ou par piles (sans fil).

AVERTISSEMENT : afin de réduire le risque de blessures, l’utilisateur doit lire le

mode d’emploi.

CONSERVER CES DIRECTIVES

1) SÉCURITÉ DU LIEU DE TRAVAIL

a) Tenir la zone de travail propre et bien éclairée. Les endroits sombres sont souvent

des causes d'accidents.

b) Ne pas faire fonctionner d’outils électriques dans un milieu déflagrant, soit en

présence de liquides inflammables, de gaz ou de poussière. Les outils électriques

produisent des étincelles qui peuvent enflammer la poussière ou les vapeurs.

c) Éloigner les enfants et les curieux au moment d’utiliser un outil électrique. Une

distraction pourrait vous en faire perdre la maîtrise.

2) SÉCURITÉ EN MATIÈRE D’ÉLECTRICITÉ

a) Les fiches des outils électriques doivent correspondre à la prise. Ne jamais

modifier la fiche en aucune façon. Ne jamais utiliser de fiche d’adaptation avec un

outil électrique mis à la terre. Le risque de choc électrique sera réduit par l’utilisation de

fiches non modifiées correspondant à la prise.

b) Éviter tout contact physique avec des surfaces mises à la terre comme des

tuyaux, des radiateurs, des cuisinières et des réfrigérateurs. Le risque de choc

électrique est plus élevé si votre corps est mis à la terre.

c) Ne pas exposer les outils électriques à la pluie ou à d'autres conditions où il

pourrait être mouillé. La pénétration de l’eau dans un outil électrique augmente le

risque de choc électrique.

d) Ne pas utiliser abusivement le cordon d’alimentation. Ne jamais utiliser le cordon

pour transporter, tirer ou débrancher un outil électrique. Tenir le cordon éloigné

de la chaleur, de l’huile, des bords tranchants ou des pièces mobiles. Les cor-

dons endommagés ou emmêlés augmentent les risques de choc électrique. Remplacer

ou réparer les cordons endommagés. S’assurer que la rallonge est en bon état. Utiliser

uniquement une rallonge à 3 fils pourvue d'une fiche de mise à la terre à 3 lames et

une prise à 3 fentes correspondant à la fiche.

e) Pour l’utilisation d’un outil électrique à l’extérieur, se servir d’une rallonge

convenant à une telle utilisation. L’utilisation d’une rallonge conçue pour l’extérieur

réduit les risques de choc électrique. Lorsque qu’une rallonge électrique est utilisée,

s’assurer d’en utiliser une de calibre suffisamment élevé pour assurer le transport du

courant nécessaire au fonctionnement de votre appareil. Un cordon de calibre inférieur

causera une chute de tension de ligne et donc une perte de puissance et une

surchauffe. Le tableau suivant indique le calibre approprié à utiliser selon la longueur

du cordon et l’intensité nominale de la plaque signalétique. En cas de doute, utiliser le

calibre suivant le plus gros. Plus le numéro de calibre est petit, plus le cordon est

lourd.

3) SÉCURITÉ PERSONNELLE

a) Être vigilant, surveiller le travail effectué et faire preuve de jugement lorsqu’un

outil électrique est utilisé. Ne pas utiliser d’outil électrique en cas de fatigue ou

sous l’influence de drogues, d’alcool ou de médicaments. Un moment d’inatten-

tion, durant l’utilisation d’un outil électrique, peut se solder par des blessures graves.

b) Utiliser un équipement de sécurité. Toujours porter une protection oculaire.

L’utilisation d’un équipement de sécurité comme un masque anti-poussières, des

chaussures antidérapantes, un casque de sécurité ou des protecteurs auditifs lorsque

la situation le requiert réduira les risques de blessures corporelles.

c) Attention de ne pas mettre en marche l’outil accidentellement. S’assurer que

l’interrupteur est en position d’arrêt avant tout branchement. Transporter un outil

électrique alors que le doigt est sur l’interrupteur ou brancher un outil électrique alors

que l’interrupteur est en position de marche risque de causer un accident.

d) Retirer toute clé de réglage ou clé standard avant de démarrer l’outil. Une clé

standard ou une clé de réglage attachée à une partie pivotante peut causer des

blessures.

e) Ne pas trop tendre les bras. Conserver son équilibre en tout temps. Cela permet

de mieux maîtriser l’outil électrique dans les situations imprévues.

f) S’habiller de manière appropriée. Ne pas porter de vêtements amples ni de

bijoux. Maintenir cheveux, vêtements et gants éloignés des pièces mobiles. Les

vêtements amples, bijoux ou cheveux longs pourraient s'enchevêtrer dans les pièces

mobiles. Se tenir éloigné des évents puisque ces derniers pourraient camoufler des

pièces mobiles.

g) Si des composants sont fournis pour le raccordement de dispositifs de

dépoussiérage et de ramassage, s’assurer que ceux-ci sont bien raccordés et

utilisés. L’utilisation de ces dispositifs peut réduire les risques engendrés par les

poussières.

4) UTILISATION ET ENTRETIEN D’UN OUTIL ÉLECTRIQUE

a) Ne pas forcer un outil électrique. Utiliser l’outil électrique approprié à

l’application. L’outil électrique approprié effectuera un meilleur travail, de façon plus

sûre et à la vitesse pour laquelle il a été conçu.

b) Ne pas utiliser un outil électrique dont l’interrupteur est défectueux. Tout outil

électrique dont l’interrupteur est défectueux est dangereux et doit être réparé.

c) Débrancher la fiche du secteur ou le bloc-piles de l’outil électrique avant de faire

tout réglage ou changement d’accessoire, ou avant de ranger l’outil électrique.

Ces mesures préventives réduisent les risques de démarrage accidentel de l’outil

électrique.

d) Ranger les outils électriques hors de la portée des enfants, et ne permettre à

aucune personne n’étant pas familière avec un outil électrique (ou son manuel

d’instruction) d’utiliser ce dernier. Les outils électriques deviennent dangereux entre

les mains d’utilisateurs inexpérimentés.

e) Entretenir les outils électriques. Vérifier les pièces mobiles pour s’assurer

qu’elles sont bien alignées et tournent librement, qu’elles sont en bon état et ne

sont affectées par aucun trouble susceptible de nuire au bon fonctionnement de

l’outil électrique. En cas de dommage, faire réparer l’outil électrique avant toute

nouvelle utilisation. Beaucoup d’accidents sont causés par des outils électriques mal

entretenus.

f) S’assurer que les outils de coupe sont aiguisés et propres. Les outils de coupe

bien entretenus et affûtés sont moins susceptibles de se coincer et sont plus faciles à

contrôler.

g) Utiliser l’outil électrique, les accessoires, les mèches, etc., conformément aux

présentes directives et suivant la manière prévue pour ce type particulier d’outil

électrique, en tenant compte des conditions de travail et du travail à effectuer.

L’utilisation d’un outil électrique pour toute opération autre que celle pour laquelle il a

été conçu est dangereuse.

5) RÉPARATION

a) Faire réparer l’outil électrique par un réparateur professionnel en n’utilisant que

des pièces de rechange identiques. Cela permettra de maintenir une utilisation

sécuritaire de l’outil électrique.

b) S’il faut remplacer le cordon d’alimentation, ceci doit être fait par le fabricant ou son

agent pour éviter tout risque d’accident.

Règles de sécurité spécifiques

• Tenir l’outil par sa surface de prise isolée dans une situation où l’outil de coupe peut

entrer en contact avec un câblage caché ou avec son propre cordon d’alimentation.

Tout contact avec un fil « sous tension » mettra « sous tension » les pièces métalliques de

l’outil et provoquera un choc électrique chez l’opérateur de l’outil.

• Tenir les mains éloignées de la zone de découpe. Ne jamais mettre la main sous le

matériau pour quelque raison que ce soit. Tenir la partie avant de la scie par sa zone de

prise profilée. Ne pas mettre les doigts ou le pouce à proximité de la scie alternative et du

mécanisme de serrage de la lame. Ne pas stabiliser la scie en saisissant la semelle.

• Maintenir les lames affûtées. Les lames émoussées peuvent faire zigzaguer la lame ou

la bloquer sous la pression.

• Être très prudent pour effectuer une coupe au-dessus de votre tête et porter une

attention accrue aux fils en hauteur pouvant être cachés. Prévoir la direction de la chute

des branches et de débris.

• Au moment de couper un tuyau ou un conduit, s’assurer qu’ils sont exempts d’eau, de

câblage électrique, etc.

AVERTISSEMENT : Certaines poussières produites par les activités de ponçage, de

sciage, de meulage, de perçage et autres activités de construction peuvent contenir

des produits chimiques pouvant causer le cancer, des anomalies

congénitales ou d'autres dangers pour la reproduction. Voici quelques exemples de

ces produits chimiques :

• le plomb contenu dans les peintures à base de plomb;

• la silice cristalline de la brique, du ciment et d'autres produits de maçonnerie ;

• l'arsenic et le chrome provenant du bois traité chimiquement (arséniate de cuivre

et de chrome).

Les risques reliés à l'exposition à ces poussières varient selon la fréquence à laquelle

l’utilisateur effectue ce type de travail. Afin de réduire votre exposition à ces produits

chimiques : travailler dans un endroit bien ventilé ; porter un équipement de sécurité

homologué comme le masque antipoussières conçu spécialement pour filtrer les particules

microscopiques.

• Éviter le contact prolongé avec les poussières produites par les activités de

ponçage, sciage, meulage, perçage et autres activités de construction. Porter des

vêtements de protection et laver les parties exposées au savon et à l’eau. Laisser la

poussière pénétrer dans la bouche, les yeux ou reposer sur la peau favorise l’absorption

de produits chimiques nocifs.

AVERTISSEMENT : L’utilisation de cet outil peut produire de la poussière et la

disperser, ce qui peut causer des troubles respiratoires graves et permanents et

d’autres blessures. Toujours utiliser un dispositif de protection respiratoire homologué par

le NIOSH/OSHA qui permet de protéger contre la poussière. Diriger les particules loin du

visage et du corps.

MISE EN GARDE : Porter un dispositif de protection anti-bruit pendant l’utilisation

de l’outil. Dans certaines conditions et selon la durée d’utilisation, le bruit causé par ce

produit peut contribuer à une perte auditive.

L’étiquette apposée sur votre outil peut comprendre les symboles suivants.

V ................. volts A....................ampères

Hz ................ hertz W...................watts

min .. .............minutes .................courant alternatif

.............. courant continu

n

o

................vitesse à vide

...............assemblage de classe II .................borne de terre

...................symbole d’alerte à .../min ............min ou alternances par minute

la sécurité

Moteur

S’assurer que le bloc d’alimentation est compatible avec l’inscription de la plaque

signalétique. 120 volts c.a. signifie seulement que l’outil fonctionnera sur une alimentation

domestique standard de 60 Hz. Ne pas faire fonctionner des outils à courant alternatif (c.a.)

sur un courant continu (c.c.). Un régime nominal de 120 volts c.a./c.c. signifie que l’outil

fonctionnera avec une alimentation standard 60 Hz c.a. ou c.c. Ce renseignement figure

sur la plaque signalétique. Une plus faible tension entraînera une baisse de régime, ce qui

peut entraîner une surchauffe. Tous les outils Black & Decker sont testés en usine; si cet

outil ne fonctionne pas, vérifier le bloc d’alimentation.

CONSERVER CES DIRECTIVES

FONCTIONNEMENT

MISE EN GARDE : pour votre propre sécurité, ne pas brancher la machine à une

source d’alimentation avant que la machine ne soit entièrement assemblée, ni avant

d’avoir lu et compris l’intégralité de ce mode d’emploi.

AVERTISSEMENT : toujours porter une protection oculaire durant l’utilisation de

l’outil électrique.

REMARQUE : avant de couper tout matériau, s’assurer que ce dernier est bien ancré ou

serré dans un étau pour éviter tout glissement.

• Placer la lame légèrement contre la pièce à couper.

• Mettre en marche le moteur de la scie avant d’appliquer toute pression.

AVERTISSEMENT : RISQUE DE LACÉRATION. Ne jamais tenir et utiliser le produit

avec les doigts enroulés autour du bouton qui affiche les réglages. Toujours tenir

fermement la scie avec les deux mains en cours de coupe comme indiqué à la figure 1 ou

utiliser la poignée auxiliaire. Autant que possible, la semelle de la scie doit être solidement

appuyée contre le matériau à couper. Cela évite tout écart ou vibration de la scie et réduira

le bris de lame.

POIGNÉE AUXILIAIRE (FIGURE 2)

La poignée auxiliaire comporte un plus grand nombre de positions pour la prise de l’outil.

Huit emplacements de fixation, pour la poignée auxiliaire, sont disponibles.

MISE EN GARDE : ÉTEINDRE ET DÉBRANCHER LA SCIE.

FIXATION DE LAPOIGNÉE AUXILIAIRE À LA SCIE :

• Placer la poignée et enrouler la sangle autour de la section de prise avant de la scie

(comme indiqué à la figure 2A).

• S’assurer que les dispositifs d’indexation de la poignée et de la sangle soient entièrement

engagés dans les positions correspondantes sur la scie.

• Joindre la fixation et la sangle et appuyer sur le levier de la fixation sur la poignée pour la

bloquer solidement comme indiqué à la figure 2B.

• S’assurer que la poignée soit fixe avant d’effectuer une coupe.

DÉSASSEMBLAGE DE LA POIGNÉE AUXILIAIRE.

• Soulever le levier et décrocher la fixation de la sangle.

• Désaccoupler et dégager la poignée et la sangle de la scie

INTERRUPTEUR (MARCHE-ARRÊT) (FIGURE 3)

Enfoncer la gâchette pour mettre l’outil à la position de MARCHE. Le fait de relâcher la

gâchette règle l’outil à la position d’ARRÊT. REMARQUE : Cet outil n’est doté d’aucun

dispositif permettant de verrouiller l’interrupteur à la position de MARCHE ; il ne doit donc

jamais être verrouillé à cette position par quelque moyen que ce soit.

ROUE SÉLECTRICE DE VITESSE VARIABLE (FIGURE 4)

Cette roue sélectrice offre un choix de vitesses permettant d’améliorer grandement les

vitesses de coupe de divers matériaux. Pour choisir une vitesse inférieure pour le

fonctionnement de la scie, tourner la roue à un chiffre inférieur figurant sur le cadran. Pour

choisir une vitesse plus élevée, tourner la roue à un chiffre supérieur.

AVANT DE RETOURNER CE PRODUIT POUR QUELQUE

RAISON QUI SOIT, VEUILLEZ APPELER AU

1-800-54-HOW-TO (544-6986)

Calibre minimum pour les rallonges

Volts Longueur totale du cordon en pieds

120 V 0-25 26-50 51-100 101-150

240 V 0-50 51-100 101-200 201-300

Intensité nominale

Plus Pas plus Calibrage américain normalisé des fils

(AWG)

de de

0 - 6 18 16 16 14

6 - 10 18 16 14 12

10 - 12 16 16 14 12

12 - 16 14 12 Non recommandé

Page 4

LEVIER DE DÉGAGEMENT DU MÉCANISME DE SERRAGE DE LA LAME (FIGURE 5)

MISE EN GARDE : ÉTEINDRE L’OUTIL, PUIS LE DÉBRANCHER POUR LE

CHANGEMENT DE LAME.

Pour insérer une lame dans la scie :

1. Soulever le levier de dégagement de la bride de lame de manière à l’ouvrir

complètement comme le montre la figure 5.

2. Insérer la queue de la lame, à partir du trou de localisation avant situé dans la lame, sur

la tige de l’arbre alternatif.

3. Fermer le levier de dégagement de la bride de lame.

4. S’assurer que la lame est fixe avant d’effectuer une coupe.

Pour retirer la lame de la scie :

1. Ouvrir complètement le levier de dégagement de la bride de lame.

2. Retirer la lame.

SEMELLE RÉGLABLE (FIGURE 6)

MISE EN GARDE : METTRE LA SCIE HORS TENSION ET LA DÉBRANCHER.

La semelle se réglera de manière à limiter la profondeur de la coupe. Tenir la scie de

manière à ce que sa face inférieure soit vers le haut. Enfoncer le bouton (illustré à la

figure 6) logé sur la poignée, puis glisser la semelle à une des trois positions et relâcher le

bouton.

COUPE À RAS (FIGURE 7)

• Le modèle compact du boîtier du moteur et de la semelle pivotante de la scie alternative

permet une coupe à ras aux planchers, dans les coins et dans tous les autres endroits

difficiles d’accès.

• Pour accroître la possibilité de coupe à ras, insérer l’arbre de la lame dans la bride de

lame de manière à ce que les dents de la lame soient vers le haut.

• Inverser la scie de manière à être aussi près que possible de la surface de la pièce.

COUPE DU MÉTAL (FIGURE 8)

• Utiliser une lame plus fine pour les métaux ferreux et une lame pour grossière pour les

matériaux non ferreux.

• Pour la tôle de fin calibre, il est préférable de serrer un morceau de bois de chaque côté

de la tôle. Cela permet d’assurer une coupe nette sans vibration excessive ou déchirure

de la tôle.

• Éviter de forcer la lame de coupe, car cela réduit sa durée de vie et provoque des bris

de lame coûteux.

REMARQUE : Étendre un mince film d’huile ou de tout autre fluide de refroidissement le

long de la ligne devant le trait de scie pour faciliter le fonctionnement de l’outil et accroître

la durée de vie de la lame. Il est préférable d’utiliser du kérosène pour couper l’aluminium.

DÉCOUPE EN POCHE – BOIS SEULEMENT (FIGURE 9)

• Mesurer la zone à couper et la marquer clairement avec un crayon, une craie ou une

pointe à tracer.

• Insérer la lame dans sa bride, puis bien serrer cette dernière.

• Incliner la scie vers l’arrière de manière à ce que le bord arrière de la semelle repose

contre la surface de la pièce, la surface sera dégagée de la lame mobile.

• Mettre le moteur en marche et laisser la lame atteindre sa vitesse maximale.

• Saisir la poignée de la scie de manière constante et imprimer un mouvement ascendant

lent.

• La lame pénétrera dans le matériau. Toujours s’assurer que la lame traverse

complètement le matériau avant de continuer la découpe en poche.

REMARQUE : Dans les endroits où la visibilité de la lame est limitée, utiliser le bord de la

semelle comme guide.

CONSEILS POUR LES PROJETS

• Effectuer une coupe uniquement au moyen de lames affûtées, la coupe est plus nette,

plus rapide et l’effort subi par le moteur est moindre durant la coupe.

• Pour effectuer une coupe, toujours s’assurer que la semelle repose fermement contre la

pièce. Cela permet à l’opérateur d’avoir une plus grande maîtrise et de réduire les

vibrations.

• Pour assurer une durée de vie accrue à la lame, utiliser des lames bimétalliques. Cette

lame est constituée d’acier au carbone soudé à l’envers sur les dents en acier à coupe

rapide, ce qui rend la lame plus flexible et donc moins sujette à se briser.

ENTRETIEN

DÉBRANCHER LA SCIE ET ENLEVER L’ACCESSOIRE POUR EFFECTUER TOUT

NETTOYAGE OU AUTRE ENTRETIEN. EN CAS DE RÉPARATION, UTILISER

UNIQUEMENT DES PIÈCES DE RECHANGE IDENTIQUES.

• Éviter l’utilisation de solvants pour nettoyer les pièces de plastique. La plupart des

plastiques sont sensibles aux différents types de solvants commerciaux et risquent

d’être endommagés par l’utilisation de solvants. Utiliser des chiffons propres pour

enlever la saleté, la poussière de carbone, etc.

• Les outils électriques utilisés sur des bateaux en fibre de verre, des voitures sport, des

cloisons sèches, etc. subissent une usure accélérée et peuvent présenter une défaillance prématurée, car les copeaux de fibre de verre, les particules de meulage et la

poussière de cloison sèche sont hautement abrasifs pour les roulements, les balais, le

collecteur, etc. Durant l’utilisation de l’outil sur de la fibre de verre ou une cloison sèche,

il est très important que l’outil soit fréquemment nettoyé par jet d’air.

GRAISSAGE

Votre scie à été bien lubrifiée avant de quitter l’usine. À chaque année, apporter ou envoyer

sa scie à un centre de réparation Black & Decker ou à un centre de réparation autorisé

pour subir un nettoyage complet, une inspection et une lubrification. Les outils « inutilisés »

pendant une longue période doivent être lubrifiés de nouveau avant d’être réutilisés.

IMPORTANT : Pour garantie la SÉCURITÉ et la FIABILITÉ du produit, les réparations,

l’entretien et le réglage doivent être réalisés par un centre de réparation autorisé ou tout

autre centre de réparation professionnel et les des pièces de rechange identiques doivent

être utilisées.

ACCESSOIRES

LAMES

La scie est compatible avec toute lame de longueur maximale de 30,5 cm (12 po). Toujours

utiliser la plus petite lame convenant à votre projet, mais sa longueur doit être suffisante

pour pouvoir traverser le matériau. Les lames longues risquent davantage d’être pliées ou

endommagées durant leur utilisation. Durant leur utilisation, certaines lames longues

peuvent vibrer ou émettre des secousses si la scie n’est pas maintenue en contact avec la

pièce.

ACCESSOIRE D’ÉLAGAGE

Il est aussi possible de se procurer un accessoire d’élagage à utiliser avec la scie

alternative. Cet accessoire se fixe à la semelle de la scie et applique une pression à ressort

sur la branche à couper.

Les accessoires recommandés pouvant être utilisés avec la scie sont disponibles auprès

du distributeur ou centre de réparation autorisé de votre région. Pour tout renseignement

concernant les accessoires, veuillez appeler au : 1-800-544-6986.

AVERTISSEMENT : L'utilisation de tout accessoire non recommandé avec cet outil

pourrait s'avérer dangereuse.

Dépannage

Problème Cause possible Solution possible

•L’appareil refuse • Cordon d’alimentation • Brancher le cordon

de démarrer. non branché. d’alimentation.

• Le fusible du circuit • Remplacer le fusible

est grillé. du circuit.

• Le disjoncteur s’est • Remettre le disjoncteur

déclenché. à la position initiale.

• Cordon d’alimentation • Faire remplacer le cordon ou

ou interrupteur l’interrupteur au centre de

endommagé. réparation Black & Decker ou à un

centre de réparation autorisé.

Pour de l’aide avec l’outil, consulter notre site Web www.black&decker.com pour

l’emplacement du centre de réparation le plus près ou communiquer avec l’assistance

BLACK & DECKER au 1-800-544-6986.

ANTES DE DEVOLVER ESTE PRODUCTO POR

CUALQUIER RAZÓN, POR FAVOR LLAME AL

(55)5326-7100

Normas generales de seguridad

ADVERTENCIA: Lea y comprenda todas las instrucciones. El incumplimiento de

todas y cada una de las instrucciones enumeradas a continuación puede provocar descarga

eléctrica, incendio y/o lesiones graves. El término “herramienta eléctrica” incluido en todas

las advertencias enumeradas a continuación hace referencia a su herramienta eléctrica

operada con corriente (cable eléctrico) o a su herramienta eléctrica operada con baterías

(inalámbrica).

ADVERTENCIA: Para reducir el riesgo de lesiones, el usuario debe leer el manual

de instrucciones.

CONSERVE ESTAS INSTRUCCIONES

1) SEGURIDAD EN EL ÁREA DE TRABAJO

a) Mantenga el área de trabajo limpia y bien iluminada. Las áreas abarrotadas y

oscuras propician accidentes.

b) No opere herramientas eléctricas en atmósferas explosivas, como ambientes

donde se encuentran líquidos, gases o polvo inflamables. Las herramientas

eléctricas originan chispas que pueden encender el polvo o los vapores.

c) Mantenga a los niños y espectadores alejados de la herramienta eléctrica en

funcionamiento. Las distracciones pueden provocar la pérdida de control.

2) SEGURIDAD ELÉCTRICA

a) Los enchufes de la herramienta eléctrica deben adaptarse al tomacorriente.

Nunca modifique el enchufe de ninguna manera. No utilice ningún enchufe

adaptador con herramientas eléctricas con conexión a tierra. Los enchufes no

modificados y que se adaptan a los tomacorrientes reducirán el riesgo de descarga

eléctrica.

b) Evite el contacto corporal con superficies puestas a tierra, como por ejemplo

tuberías, radiadores, rangos y refrigeradores. Existe mayor riesgo de descarga

eléctrica si su cuerpo está puesto a tierra.

c) No exponga las herramientas eléctricas a la lluvia o a condiciones de humedad.

Si ingresa agua a una herramienta eléctrica, aumentará el riesgo de descarga

eléctrica.

d) No maltrate al cable. Nunca utilice el cable para transportar, tirar o desenchufar

la herramienta eléctrica. Mantenga el cable lejos del calor, aceite, bordes afilados o

piezas móviles. Los cables dañados o enredados aumentan el riesgo de descarga

eléctrica. Repare o reemplace los cables dañados. Asegúrese de que el cable

prolongador esté en buenas condiciones. Utilice solamente cables prolongadores de

3 conductores que tengan enchufes a tierra de 3 patas y receptáculos de tripolares

que se adapten al enchufe de la herramienta.

e) Al operar una herramienta eléctrica en el exterior, utilice un cable prolongador

adecuado para tal uso. Utilice un cable adecuado para uso en exteriores a fin de

reducir el riesgo de descarga eléctrica. Cuando utilice un cable prolongador,

asegúrese de que tenga la capacidad para conducir la corriente que su producto

exige. Un cable de menor capacidad provocará una disminución en el voltaje de la

línea que producirá pérdida de potencia y sobrecalentamiento. La siguiente tabla

muestra la medida correcta que debe utilizar según la longitud del cable y la

capacidad nominal en amperios indicada en la placa. En caso de duda, utilice el

calibre inmediatamente superior. Cuanto menor es el número de calibre, más grueso

es el cable.

3) SEGURIDAD PERSONAL

a) Permanezca alerta, controle lo que está haciendo y utilice el sentido común

cuando emplee una herramienta eléctrica. No utilice una herramienta eléctrica

si está cansado o bajo el efecto de drogas, alcohol o medicamentos. Un

momento de descuido mientras se opera una herramienta eléctrica podría provocar

daños personales graves.

b) Use equipo de seguridad. Siempre utilice protección para los ojos. El equipo de

seguridad, como las máscaras para polvo, el calzado de seguridad antideslizante, los

cascos o la protección auditiva utilizados para condiciones adecuadas reducirán las

lesiones personales.

Calibre mínimo para cables prolongadores

Voltios Largo total del cable en pies

120 V 0-25 26-50 51-100 101-150

240 V 0-50 51-100 101-200 201-300

Capacidad nominal en amperios

Más de No más de Medida de conductor estadounidense

que que

0-6 18 16 16 14

6 - 10 18 16 14 12

10 - 12 16 16 14 12

12 - 16 14 12 No Recomendado

INFORMATION SUR LES RÉPARATIONS

Black & Decker dispose d’un réseau complet de centres de réparation et de centres

autorisés situés partout en Amérique du Nord. Tous les centres de réparation Black &

Decker sont dotés de personnel qualifié en matière d’outillage électrique; ils sont donc en

mesure d'offrir à leur clientèle un service efficace et fiable. Que vous ayez besoin d’un avis

technique, d’une réparation ou de pièces de rechange authentiques installées en usine,

communiquez avec l’établissement Black & Decker le plus près de chez vous. Pour trouver

l’établissement de réparation de votre région, consulter le répertoire des pages jaunes à la

rubrique « Outils électriques » ou composez le numéro suivant : 1-800-544-6986.

GARANTIE COMPLÈTE DE DEUX ANS

Black & Decker (É.-U.) Inc. garantit ce produit pour une durée de deux ans contre tout

défaut de matériau ou de fabrication. Le produit défectueux sera remplacé ou réparé sans

frais de l’une des deux façons suivantes :

La première façon consiste en un échange chez le détaillant où le produit a été acheté (à la

condition que le magasin soit un détaillant participant). Tout retour doit se faire durant la

période correspondant à la politique d'échange du détaillant (habituellement, de 30 à 90

jours après l’achat). Une preuve d’achat peut être requise. Vérifier auprès du détaillant

pour connaître sa politique concernant les retours hors de la période définie pour les

échanges.

La deuxième option est d’apporter ou d’envoyer le produit (transport payé d'avance) à un

centre de réparation autorisé ou à un centre de réparation de Black & Decker pour faire

réparer ou échanger le produit, à notre discrétion. Une preuve d’achat peut être requise.

Les centres de service de Black & Decker et les centres de réparation autorisés sont

répertoriés dans les pages jaunes sous la rubrique « Outils électriques » du bottin

téléphonique et sur notre site Web www.blackanddecker.com.

Cette garantie ne s’applique pas aux accessoires. Cette garantie vous accorde des droits

légaux spécifiques et vous pourriez avoir d’autres droits qui varient d’un État ou d'une

province à l'autre. Si vous avez des questions, communiquez avec le directeur du centre

de réparation Black & Decker le plus près de chez vous.

REMPLACEMENT GRATUIT DES ÉTIQUETTES D’AVERTISSEMENT : Si vos étiquettes

d’avertissement deviennent illisibles ou sont manquantes, composer le 1-800-544-6986

pour faire remplacer gratuitement vos étiquettes.

REMARQUE À L’INTENTION DES ENTREPRENEURS CONCERNANT LA GARANTIE

SPÉCIALE

Les produits de marque FIRESTORM

MC

sont des outils hauts de gamme destinés aux

consommateurs et comportent une GARANTIE POUR USAGE RÉSIDENTIEL. Ces

outils sont conçus, fabriqués et mis à l’essai en vue de répondre aux besoins du

bricoleur, ou de les dépasser, lorsque ce dernier réalise des projets ou effectue des

réparations à l’intérieur ou à l’extérieur de sa résidence. Utilisés correctement, ces outils

procurent à l’utilisateur un rendement et une puissance supérieurs qui excèdent de loin la

période de garantie de deux ans. Par contre, tout outil utilisé à des fins commerciales ou

tout produit de marque FIRESTORM

MC

ou tout autre produit Black & Decker destiné aux

consommateurs et réservé à un usage résidentiel, utilisé dans le cadre d’une ACTIVITÉ

RELIÉE AU TRAVAIL, N’EST PAS COUVERT PAR LA PRÉSENTE GARANTIE.

Imported by / Importé par

Black & Decker Canada Inc.

100 Central Ave.

Brockville (Ontario) K6V 5W6

Voir la rubrique “Outils électriques”

des Pages Jaunes

pour le service et les ventes.

Page 5

c) Evite el encendido por accidente. Asegúrese de que el interruptor esté en la

posición de apagado antes de enchufar la herramienta. Transportar herramientas

eléctricas con su dedo apoyado sobre el interruptor o enchufar herramientas

eléctricas con el interruptor en posición de encendido puede propiciar accidentes.

d) Retire las clavijas de ajuste o llaves de tuercas antes de encender la

herramienta eléctrica. Una llave de tuercas o una clavija de ajuste que se deje

conectada a una pieza giratoria de la herramienta eléctrica pueden provocar lesiones

personales.

e) No se estire. Conserve el equilibrio adecuado y manténgase parado

correctamente en todo momento. Esto permite un mejor control de la herramienta

eléctrica en situaciones inesperadas.

f) Vístase apropiadamente. No use ropas holgadas ni joyas. Mantenga el cabello,

las ropas y los guantes alejados de las piezas móviles. Las ropas holgadas, las

joyas o el cabello largo pueden quedar atrapados en las piezas móviles. Los

orificios de ventilación suelen cubrir piezas móviles, por lo que también se deben evitar.

g) Si se suministran dispositivos para la conexión de accesorios para la

recolección y extracción de polvo, asegúrese de que estén conectados y se

utilicen correctamente. El uso de estos dispositivos puede reducir los peligros

relacionados con el polvo.

4) USO Y MANTENIMIENTO DE LA HERRAMIENTA ELÉCTRICA

a) No fuerce la herramienta eléctrica. Utilice la herramienta eléctrica correcta para

el trabajo que realizará. La herramienta eléctrica correcta hará el trabajo mejor y

más seguro a la velocidad para la que fue diseñada.

b) No utilice la herramienta eléctrica si no puede encenderla o apagarla con el

interruptor. Toda herramienta eléctrica que no puede ser controlada mediante el

interruptor es peligrosa y debe ser reparada.

c) Desconecte el enchufe de la fuente de energía y/o el paquete de baterías de la

herramienta eléctrica antes de realizar ajustes, cambiar accesorios o almacenar

herramientas eléctricas. Estas medidas de seguridad preventivas reducen el riesgo

de encender la herramienta eléctrica en forma accidental.

d) Guarde las herramientas eléctricas que no están en uso fuera del alcance de

los niños y no permite que otras personas no familiarizadas con ella o con

estas instrucciones operen la herramienta. Las herramientas eléctricas son peli-

grosas en las manos de usuarios no entrenados.

e) Mantenimiento de las herramientas eléctricas. Controle que no haya piezas

móviles mal alineadas o trabadas, piezas rotas y toda otra situación que pueda

afectar el funcionamiento de las herramientas eléctricas. Si encuentra daños,

haga reparar la herramienta eléctrica antes de utilizarla. Se producen muchos

accidentes a causa de las herramientas eléctricas que carecen de un mantenimiento

adecuado.

f) Mantenga las herramientas de corte afiladas y limpias. Las herramientas de corte

con mantenimiento adecuado, con los bordes de corte afilados son menos propensas

a trabarse y son más fáciles de controlar.

g) Utilice la herramienta eléctrica, los accesorios y las brocas de la herramienta,

etc. de acuerdo con estas instrucciones y de la forma prevista para el tipo de

herramienta eléctrica en particular, teniendo en cuanta las condiciones de

trabajo y el trabajo que debe realizarse. El uso de la herramienta eléctrica para

operaciones diferentes de aquéllas para las que fue diseñada puede provocar una

situación peligrosa.

5) MANTENIMIENTO

a) Haga que una persona de reparaciones calificada realice el mantenimiento de

su herramienta eléctrica y utilice piezas de repuesto idénticas solamente. Esto

garantizará la seguridad de la herramienta eléctrica.

b) Si necesita un cable de alimentación de repuesto, debe adquirirlo a través del fabri-

cante o su agente para evitar un riesgo de seguridad.

Seguridad personal

• Permanezca alerta, controle lo que está haciendo y utilice el sentido común cuando

emplee una herramienta eléctrica. No utilice herramientas si está cansado o bajo el

efecto de drogas, alcohol o medicamentos. Un momento de descuido mientras se opera

una herramienta eléctrica podría provocar daños personales graves.

• Vístase apropiadamente. No use ropas holgadas ni joyas. Sujete el cabello largo.

Mantenga el cabello, las ropas y los guantes alejados de las piezas móviles. Las

ropas holgadas, las joyas o el cabello largo pueden ser atrapados en las piezas móviles. Se

deben evitar los orificios de ventilación, que cubren las piezas móviles.

• Evite el encendido por accidente. Asegúrese de que el interruptor esté apagado

antes de enchufar la herramienta. Si transporta herramientas con su dedo apoyado sobre

el interruptor o conecta una herramienta con el interruptor en posición de encendido, puede

propiciar accidentes.

• Retire las llaves de ajuste o de tuercas antes de encender la herramienta. Una llave de

tuercas o clavija que se deja conectada a una pieza giratoria de la herramienta podría

provocar daños personales.

• No se estire. Conserve el equilibrio adecuado y manténgase parado correctamente

en todo momento. El equilibrio adecuado mientras se está de pie permite un mejor control

de la herramienta en situaciones inesperadas.

• Use equipo de seguridad. Siempre utilice protección para los ojos. Se debe usar

máscara para polvo, calzado de seguridad antideslizante, casco o protección auditiva

según corresponda en cada caso.

Uso y cuidados de la herramienta

• Utilice abrazaderas u otra forma práctica para asegurar y sostener la pieza de trabajo

en una plataforma estable. Sostener el trabajo con la mano o contra el cuerpo no brinda la

estabilidad requerida y puede llevar a la pérdida del control.

• No fuerce la herramienta. Utilice la herramienta correcta para el trabajo que realizará.

La herramienta correcta hará el trabajo mejor y más seguro a la velocidad para la que fue

diseñada.

• No utilice la herramienta si no puede encenderla o apagarla con el interruptor. Toda

herramienta que no puede ser controlada mediante el interruptor es peligrosa y debe ser

reparada.

• Desconecte el enchufe de la fuente de energía antes de realizar algún ajuste, cambiar

accesorios o guardar la herramienta. Estas medidas de seguridad preventivas reducen

el riesgo de encender la herramienta en forma accidental.

• Guarde las herramientas que no están en uso fuera del alcance de los niños y de

personas no entrenadas. Las herramientas son peligrosas en las manos de usuarios no

entrenados.

• Realice un mantenimiento cuidadoso de las herramientas. Mantenga las

herramientas de corte afiladas y limpias. Las herramientas con mantenimiento

adecuado, con los bordes de corte afilados son menos propensas a trabarse y son más

fáciles de controlar.

• Controle que no haya piezas móviles mal alineadas o trabadas, piezas rotas y toda

otra situación que pueda afectar el funcionamiento de la herramienta. Si encuentra

daños, haga reparar la herramienta antes de utilizarla. Se producen muchos accidentes

a causa de las herramientas que carecen de un mantenimiento adecuado.

• Utilice sólo accesorios recomendados por el fabricante para el modelo que posee.

Los accesorios que pueden ser aptos para una herramienta, pueden convertirse en un

factor de riesgo cuando se los utiliza en otra herramienta.

Mantenimiento

• El mantenimiento de la herramienta debe ser realizado únicamente por personal de

reparaciones calificado. El mantenimiento realizado por personal no calificado puede

provocar riesgo de lesiones personales.

• Al reparar una herramienta, sólo utilice piezas de repuesto idénticas. Siga las

instrucciones de la sección de Mantenimiento de este manual. El uso de piezas no

autorizadas o el incumplimiento de las instrucciones de mantenimiento pueden crear un

riesgo de descarga eléctrica o lesiones.

Normas de seguridad específicas

• Sostenga la herramienta por las superficies de agarre aisladas cuando realice una

operación donde la herramienta de corte puede tocar cables eléctricos escondidos o

su propio cable. El contacto con un cable con "corriente eléctrica" hará que las partes

metálicas expuestas de la herramienta tengan "corriente eléctrica" y el operador sufra una

descarga eléctrica.

• Mantenga las manos lejos de las zonas de corte. Nunca se estire por debajo del material

por ningún motivo. Sostenga la parte frontal de la sierra desde el área de sujeción

contorneada. No inserte los dedos en la zona cercana a la hoja alternativa y a la

abrazadera de la hoja. No estabilice la sierra sujetando la zapata.

• Mantenga las hojas afiladas. Las hojas sin filo pueden hacer que la sierra se desvíe o

atasque al recibir presión.

• Tenga especial cuidado al cortar en lugares altos y preste mucha atención a los

cables altos que pueden estar ocultos. Prevea el trayecto de la caída de las ramas y los

desechos con anticipación.

• Al cortar tuberías o conductos, asegúrese de que no contengan agua, cableado

eléctrico, etc.

ADVERTENCIA: Algunas partículas originadas al lijar, aserrar, amolar, taladrar y

realizar otras actividades de construcción contienen productos químicos que

producen cáncer, defectos de nacimiento y otros problemas reproductivos. Algunos

ejemplos de estos productos químicos son:

• el plomo de las pinturas con base de plomo,

• la sílice cristalina de los ladrillos, el cemento y otros productos de mampostería,

• el arsénico y el cromo de la madera con tratamiento químico (CCA).

El riesgo derivado de estas exposiciones varía según la frecuencia con la que se realice este

tipo de trabajo. Para reducir la exposición a estos productos químicos, se recomienda

trabajar en áreas bien ventiladas y usar equipos de seguridad aprobados, como las

máscaras para polvo especialmente diseñadas para filtrar las partículas microscópicas.

• Evite el contacto durante tiempo prolongado con las partículas de polvo originadas

al lijar, aserrar, esmerilar, taladrar y otras actividades de la construcción. Utilice ropa

protectora y limpie las áreas expuestas con jabón y agua. Permitir que el polvo ingrese

en su boca, ojos o entre en contacto con la piel puede estimular la absorción de sustancias

químicas perjudiciales.

ADVERTENCIA: El uso de esta herramienta puede generar o dispersar polvo. Esto

puede provocar problemas respiratorios graves y permanentes u otras lesiones.

Siempre utilice protección respiratoria aprobada por NIOSH/OSHA (Instituto Nacional de

Salud y Seguridad Ocupacional de EE.UU./Administración de la Salud y Seguridad

Ocupacional de EE.UU.) apropiada para la exposición al polvo. Aleje las partículas de la

cara y el cuerpo.

PRECAUCIÓN: Utilice la protección auditiva apropiada durante el uso. Bajo ciertas

condiciones y según el período de uso, el ruido provocado por este producto puede llevar

a la pérdida de audición.

La etiqueta de su herramienta puede incluir los siguientes símbolos.

V....................voltios A .................amperios

Hz..................hertz W.................vatios

min.................minutos ................corriente alternante

............corriente directa no ................velocidad sin carga

.................Construcción Clase II ................terminal a tierra

................símbolo de alerta .../min ........ .revoluciones u

de seguridad oscilaciones por minuto

Motor

Asegúrese de que el suministro de energía concuerde con lo marcado en la placa. CA de

120 voltios solamente significa que su herramienta funcionará con la energía doméstica

estándar de 60 Hz. No haga funcionar herramientas para corriente alternante (CA) con

corriente directa (CD). Una capacidad nominal de CA/CD de 120 voltios significa que su

herramienta funcionará con energía estándar de CA o CD de 60 Hz. Esta información está

impresa en la placa. Un voltaje menor producirá pérdida de potencia y puede provocar

sobrecalentamiento. Todas las herramientas Black & Decker son probadas en fábrica. Si

esta herramienta no funciona, controle el suministro eléctrico.

CONSERVE ESTAS INSTRUCCIONES

OPERACIÓN

PRECAUCIÓN: Por su propia seguridad, no conecte la máquina a la fuente de

alimentación hasta que esté armada completamente, y usted haya leído y comprenda

todo el manual de instrucciones.

ADVERTENCIA: Mientras utilice esta herramienta, utilice siempre protección para

los ojos.

NOTA: Antes de cortar cualquier tipo de material, asegúrese de que esté sujetado o fijado

firmemente para evitar el deslizamiento.

• Coloque la hoja levemente contra la pieza de trabajo que desea cortar.

• Encienda el motor de la sierra antes de aplicar presión.

• ADVERTENCIA: PELIGRO DE LACERACIÓN. Nunca sostenga ni use el producto

con los dedos alrededor del botón de ajuste de la zapata. Al cortar, siempre sujete la

sierra firmemente con ambas manos como se muestra en la Figura 1 o, si lo prefiere, use

el mango auxiliar. Siempre que sea posible, la zapata de la sierra debe sujetarse con

firmeza contra el material que desee cortar. Esto evitará que la sierra salte o vibre y

minimizará el daño a la hoja.

MANGO AUXILIAR (FIGURA 2)

El mango auxiliar le ofrece más posiciones de agarre entre las que puede optar. El mango

auxiliar posee 8 lugares de sujeción disponibles.

PRECAUCIÓN: APAGUE Y DESENCHUFE LA SIERRA.

CÓMO CONECTAR EL MANGO AUXILIAR A LA SIERRA:

• Agarre el mango y sujételo con la correa en el área de agarre delantera de la sierra

(Figura 2A).

• Asegúrese de que el mango y el índice de la correa encajen perfectamente en las

posiciones correspondientes de la sierra.

• Enganche la abrazadera y la correa en forma conjunta y presione la palanca de la

abrazadera hacia el mango para asegurar el mango como se muestra en la figura 2b.

• Antes de proceder a cortar, controle que el mango esté firme.

EXTRACCIÓN DEL MANGO AUXILIAR:

• Levante la palanca y desenganche la abrazadera de la correa.

• Separe el mango y la correa y retírelos de la sierra.

INTERRUPTOR (ENCENDIDO-APAGADO) (FIGURA 3)

Oprima el interruptor disparador para ENCENDER la herramienta. Al liberar el disparador,

la herramienta se APAGA. NOTA: Esta herramienta no permite bloquear el interruptor en la

posición de ENCENDIDO y nunca debe bloquearse en esta posición de ninguna otra

forma.

RUEDA SELECTORA DE VELOCIDAD VARIABLE (FIGURA 4)

La rueda selectora de velocidad variable le permite optar por velocidades para mejorar

enormemente las velocidades de corte en varios metales. Para seleccionar una velocidad

menor de operación de la sierra, gire la rueda a un número bajo en el dial. Para

seleccionar una velocidad más alta, gire la rueda a un número más alto.

PALANCA DE LIBERACIÓN DE LA ABRAZADERA DE HOJA (FIGURA 5)

PRECAUCIÓN: PELIGRO DE LACERACIÓN. APAGUE Y DESENCHUFE DE LA

FUENTE DE ENERGÍA AL CAMBIAR LAS HOJAS.

Para instalar la hoja en la sierra:

1. Levante la palanca de liberación de la abrazadera de la hoja a la posición

completamente abierta como se muestra en la Figura 5.

2. Inserte el vástago de la hoja desde el orificio ubicado en el frente de la hoja sobre la

clavija en la sierra.

3. Cierre la palanca de liberación de la abrazadera de la hoja.

4. Verifique para asegurarse de que la hoja esté firme antes de cortar.

Para retirar la hoja de la sierra:

1. Abra la palanca de liberación de la abrazadera de la hoja a su posición

completamente abierta.

2. Retire la hoja.

ZAPATA AJUSTABLE (FIGURA 6)

PRECAUCIÓN: APAGUE Y DESENCHUFE LA SIERRA.

La zapata se ajustará para limitar la profundidad del corte. Sujete la sierra con parte

inferior hacia arriba. Presione el botón (como se muestra en la Figura 6) en el mango y

deslice la zapata hacia afuera para establecerla en uno de los tres ajustes, y libere el

botón.

CORTE AL RAS (FIGURA 7)

• El diseño compacto de la caja del motor de la sierra alternativa y de la zapata giratoria

permite cortes cerrados en pisos, esquinas y otras áreas difíciles.

• Para maximizar las capacidades de cortes al ras, inserte el eje de la hoja en la

abrazadera de hoja con los dientes de la hoja hacia arriba.

• Gire la sierra hacia abajo de modo que usted esté lo más cerca posible de la superficie

de trabajo.

Page 6

CORTES EN METAL (FIGURA 8)

• Utilice una hoja más fina para metales ferrosos y una hoja gruesa para materiales no

ferrosos.

• En piezas de metal de bajo calibre es mejor sujetar con madera ambos lados de la

pieza. De esta forma, garantizará un corte limpio sin exceso de vibración o rotura del

metal.

• Evite forzar la hoja de corte, esto reducirá la duración de la hoja y ocasionará roturas

costosas de la hoja.

NOTA: Distribuya una capa delgada de aceite u otro refrigerante a lo largo de la línea en la

parte frontal del corte de la sierra para una mejor operación y mayor duración de la hoja.

Para cortes en aluminio, coloque kerosén preferentemente.

CORTES INTERNOS - MADERA SOLAMENTE (FIGURA 9)

• Mida la superficie que desea cortar y márquela claramente con un lápiz, tiza o punzón.

• Inserte la hoja en la abrazadera de hoja y ajústela bien.

• Incline la sierra hacia atrás hasta que el borde inferior de la zapata esté sobre la

superficie de trabajo y la hoja en movimiento limpiará la superficie.

• Encienda el motor de modo de permitir que la hoja logre la máxima velocidad.

• Sujete el mango con firmeza y comience con un balanceo lento, intencional y hacia

arriba con el mango de la sierra.

• La hoja comenzará a introducirse en el material. Siempre asegúrese de que la hoja esté

completamente adentro del material antes de continuar con el corte interno.

NOTA: En áreas en donde la visibilidad de la hoja sea limitada, utilice el borde de la

zapata como guía.

SUGERENCIAS PARA EL PROYECTO

• Corte solamente con las hojas afiladas, éstas pueden realizar cortes más limpios, más

rápidos y requieren menos esfuerzo del motor durante el corte.

• Al cortar, siempre asegúrese de que la zapata esté firme contra la pieza de

trabajo. Esto mejorará el control del operador y minimizará la vibración.

• Para una mayor duración de la hoja, utilice hojas bimetálicas. Éstas

utilizan un respaldo de acero duro soldado para lograr mayor velocidad de los dientes

de acero, de manera que la hoja es más flexible y menos propensa a las roturas.

MANTENIMIENTO

DESENCHUFE LA SIERRA Y RETIRE EL ACCESORIO AL REALIZAR LA LIMPIEZA U

OTRO TIPO DE MANTENIMIENTO. AL REPARAR, SÓLO UTILICE PIEZAS DE

REPUESTO IDÉNTICAS A LAS ORIGINALES.

• Evite utilizar solventes al limpiar las piezas de plástico. La mayoría de los

plásticos son susceptibles a varios tipos de solventes comerciales y posiblemente se

dañen con su uso. Utilice paños limpios para eliminar la suciedad, el polvo del carbón,

etc.

• Al utilizar herramientas eléctricas en botes de fibra de vidrio, automóviles deportivos,

madera contrachapada, etc., éstas pueden acelerar el desgaste y ocasionar posibles

daños prematuros, ya que las astillas de la fibra de vidrio y el polvo de esmerilados y

madera contrachapada son altamente abrasivos a los rodamientos, cepillos,

conmutador, etc. Durante cualquier uso en fibra de vidrio o madera contrachapada, es

de extrema importancia que se limpie la herramienta con frecuencia mediante soplado

con una tobera de aire.

LUBRICACIÓN

Su sierra fue lubricada adecuadamente antes de salir de fábrica. Todos los años, lleve o

envíe su sierra a un centro de mantenimiento de Black & Decker o a un centro de

mantenimiento autorizado para limpieza, inspección y lubricación completas. Las

herramientas "sin mantenimiento" durante períodos prolongados deben volver a lubricarse

antes de utilizarlas nuevamente.

IMPORTANTE: Para garantizar la SEGURIDAD y la CONFIABILIDAD del producto, las

reparaciones, el mantenimiento y los ajustes se deben realizar en los centros de

mantenimiento autorizados o con otro personal de mantenimiento calificado, y siempre

deben utilizarse piezas de repuesto idénticas.

ACCESORIOS

HOJAS

La sierra es compatible con hojas de hasta 30,5 cm (12 pulgadas) de largo. Siempre utilice

la hoja más corta que corresponda con su proyecto, pero lo suficientemente larga para

permitir que la hoja corte a través del material. Las hojas más largas son más propensas a

doblarse o dañarse durante el uso. Durante la operación, algunas hojas más largas pueden

vibrar o temblar si la sierra no se mantiene en contacto con la pieza de trabajo.

ACCESORIO PARA PODAR

Además, hay un accesorio de poda disponible para utilizar con su Sierra alternativa. Este

accesorio se anexa a la zapata de la sierra y aplica presión a resorte a la rama durante el

corte.

Los accesorios que se recomiendan para la sierra están disponibles a través de su

distribuidor local o en el centro de mantenimiento autorizado. Si necesita ayuda con

respecto a los accesorios, llame al: (55)5326-7100

ADVERTENCIA: El uso de accesorios no recomendados para utilizar con esta

herramienta puede resultar peligroso.

Detección de problemas

Problema Causa posible Solución posible

•La unidad no enciende. • Cable desenchufado. • Enchufe el cable.

• Fusible quemado. • Reemplace el fusible quemado.

• Disparo del interruptor • Reinicie el interruptor automático.

automático.

• Interruptor o cable • Haga reparar el cable o el

dañado. interruptor en un centro de

mantenimiento Black & Decker o en

un centro de mantenimiento

autorizado.

Para conocer la ubicación del centro de mantenimiento más cercano a fin de recibir ayuda

con su producto, visite nuestro sitio Web www.black&decker.com o llame a la línea de

ayuda BLACK & DECKER al (55)5326-7100.

INFORMACIÓN DE SERVICIO

Black & Decker ofrece una amplia red de puntos de servicio propios y autorizados en toda

Norteamérica. Todos los Centros de mantenimiento de Black & Decker cuentan con

personal altamente capacitado dispuesto a brindar a todos los clientes un servicio eficiente

y confiable en la reparación de herramientas eléctricas. Si necesita consejo técnico,

reparaciones o piezas de repuesto originales de fábrica, póngase en contacto con el centro

de mantenimiento de Black & Decker más cercano a su domicilio. Para ubicar a su servicio

local, consulte “Herramientas eléctricas (Tools-Electric)” en la sección amarilla, o llame al:

(55)5326-7100

GARANTÍA COMPLETA DE DOS AÑOS

Black & Decker (EE.UU.) Inc. ofrece una garantía de dos años por cualquier defecto del

material o de fabricación de este producto. El producto defectuoso se reparará o

reemplazará sin costo alguno de dos maneras.

La primera opción, el reemplazo, es devolver el producto al comercio donde se lo adquirió

(siempre y cuando se trate de un comercio participante). Las devoluciones deben

realizarse conforme a la política de devolución del comercio (generalmente, entre 30 y 90

días posteriores a la venta). Le pueden solicitar comprobante de compra. Consulte en el

comercio acerca de la política especial sobre devoluciones una vez excedido el plazo

establecido.

La segunda opción es llevar o enviar el producto (con flete pago) a un Centro de