Page 1

Instruction Manual

4255 7" Angle Grinder

6112 779" Angle Sander

Page 2

Getting the most out of your tool.

Please take time to read this manual and pay particular attention to the safety

rules we’ve provided for your protection. Don’t forget to send in your owner’s

registration card. If you have any questions about your tool please call:

1-800-9-BD TOOL

(1-800-923-8665)

4255 7“ Angle Grinder

6112 7“/9" Angie Sander

Page 3

FOR YOUR SAFETY ■ ALL TOOLS

Important Safety Instructions

WARNING: When using electric tools, basic safety precautions should

always be followed to reduce risk of fire, electric shock, and personal

injury, including the following:

READ ALL INSTRUCTIONS

Double Insulation

Double insulated tools are constructed throughout with two separate layers

of electrical insulation or one double thickness of insulation between you

and the tool’s electrical system. Tools built with this insulation system are

not intended to be grounded. As a result, your tool is equipped with a two

prong plug which permits you to use extension cords without concern for

maintaining a ground connection.

NOTE: Double insulation does not take the place of normal safety precau

tions when operating this tool. The insulation system is for added protec

tion against injury resulting from a possible electrical insulation failure

within the tool.

CAUTION: WHEN SERVICING USE ONLY IDENTICAL REPLACEMENT

PARTS. Repair or replace damaged cords.

Polarized Plugs

Polarized plugs (one blade is wider than the other) are used on equipment

to reduce the risk of electric shock. When provided, this plug will fit into a

polarized outlet only one way. If the plug does not fit fully into the outlet,

reverse the plug. If it still does not fit, contact a qualified electrician to

install the proper outlet. Do not change the plug in any way.

Safety Instructions For All Tools

KEEP WORK AREA CLEAN. Cluttered areas and benches invite injuries.

CONSIDER WORK AREA ENVIRONMENT. Don’t expose power tools to rain.

Don’t use power tools in damp or wet locations. Keep work area well lit. Do

not use tool in presence of flammable liquids or gases.

GUARD AGAINST ELECTRIC SHOCK. Prevent body contact with grounded

surfaces. For example; pipes, radiators, ranges, and refrigerator enclosures.

KEEP CHILDREN AWAY. Do not let visitors contact tool or extension cord.

All visitors should be kept away from work area.

STORE IDLE TOOLS. When not in use, tools should be stored in dry, and

high or locked-up place — out of reach of children.

DON’T FORCE TOOL. It will do the job better and safer at the rate for which

it was intended.

USE RIGHT TOOL. Don’t force small tool or attachment to do the job of a

heavy-duty tool. Don’t use tool for purpose not intended.

DRESS PROPERLY. Do not wear loose clothing or jewelry. They can be

caught in moving parts. Rubber gloves and non-skid footwear are recom

mended when working outdoors. Wear protective hair covering to contain

long hair.

USE SAFETY GLASSES. Also use face or dust mask if operation is dusty.

DON’T ABUSE CORD. Never carry tool by cord or yank it to disconnect from

receptacle. Keep cord from heat, oil, and sharp edges.

SECURE WORK. Use clamps or a vise to hold work. It’s safer than using

your hand and it frees both hands to operate tool.

DON’T OVERREACH. Keep proper footing and balance at all times.

MAINTAIN TOOLS WITH CARE. Keep tools sharp and clean for better and

safer performance. Follow instructions for lubricating and changing acces

sories. Inspect tool cords periodically and if damaged, have repaired by

authorized service facility. Inspect extension cords periodically and replace if

damaged. Keep handles dry, clean, and free from oil and grease.

Page 4

• DISCONNECT OR LOCK OFF TOOLS when not in use, before servicing, and

when changing accessories, such as blades, bits, cutters.

• REMOVE ADJUSTING KEYS AND WRENCHES. Form habit of checking to see

that keys and adjusting wrenches are removed from tool before turning it on.

• AVOID UNINTENTIONAL STARTING. Don’t carry tool with finger on switch.

Be sure switch is off when plugging in.

• EXTENSION CORDS. Make sure your extension cord is in good condition.

When using an extension cord, be sure to use one heavy enough to carry the

current your product will draw. An undersized cord will cause a drop in line

voltage resulting in loss of power and overheating. The following table

shows the correct size to use depending on cord length and nameplate

ampere rating. If in doubt, use the next heavier gage. The smaller the gage

number, the heavier the cord.

Minimum Gage for Cord Sets

Volts

120V 0-25 26-50

240V

Ampere

More Not more AWG

Than Than

0 6 - 10

10 12 -

Rating

6 18 16 16 14

12

16

Total Length of Cord in Feet

51-100 101

0-50 51-100 101-200

18 16

16 16 14 12

14 12

14

Not Recommer

201

12

OUTDOOR USE EXTENSION CORDS. When tool is used outdoors, use only

extension cords intended for use outdoors and so marked.

STAY ALERT. Watch what you are doing. Use common sense. Do not oper

ate tool when you are tired.

CHECK DAMAGED PARTS. Before further use of the tool, a guard or other

part that is damaged should be carefully checked to determine that it will

operate properly and perform its intended function. Check for alignment of

moving parts, binding of moving parts, breakage of parts, mounting, and

any other conditions that may affect its operation. A guard or other part that

is damaged should be properly repaired or replaced by an authorized service

center unless otherwise indicated elsewhere in this instruction manual. Have

defective switches replaced by authorized service center. Do not use tool if

switch does not turn it on and off.

Page 5

ADDITIONAL SAFETY INSTRUCTIONS

TOOL OPERATION

Additional Safety Instructions for Grinders

• ALWAYS WEAR EYE PROTECTION.

• KEEP GUARDS IN PLACE.

• Use only grinding wheels having a maximum operating speed at least high

as “No Load RPM” marked on the tool’s nameplate.

• Before using, inspect recommended accessory for cracks or flaws. If such a

crack or flaw is evident, discard the accessory. The accessory should also

be inspected whenever you think the tool may have been dropped.

• When starting the tool (with a new or replacement wheel installed) hold the

tool in a well protected area and let it run for one minute. If the wheel has an

undetected crack or flaw, it should burst in less than one minute. Never start

the tool with a person in line with the wheel. This includes the operator.

• In operation, avoid bouncing the wheel or giving it rough treatment. If this

occurs, stop the tool and inspect the wheel.

• ALWAYS USE GUARDS with depressed center wheels or flaring cup grind

ing wheels.

• Clean your tool out periodically.

• CAUTION: Some wood contains preservatives such as copper chromium

arsenate (CCA) which can be toxic. When sanding these materials extra care

should be taken to avoid inhalation and minimize skin contact.

SAVE THESE INSTRUCTIONS

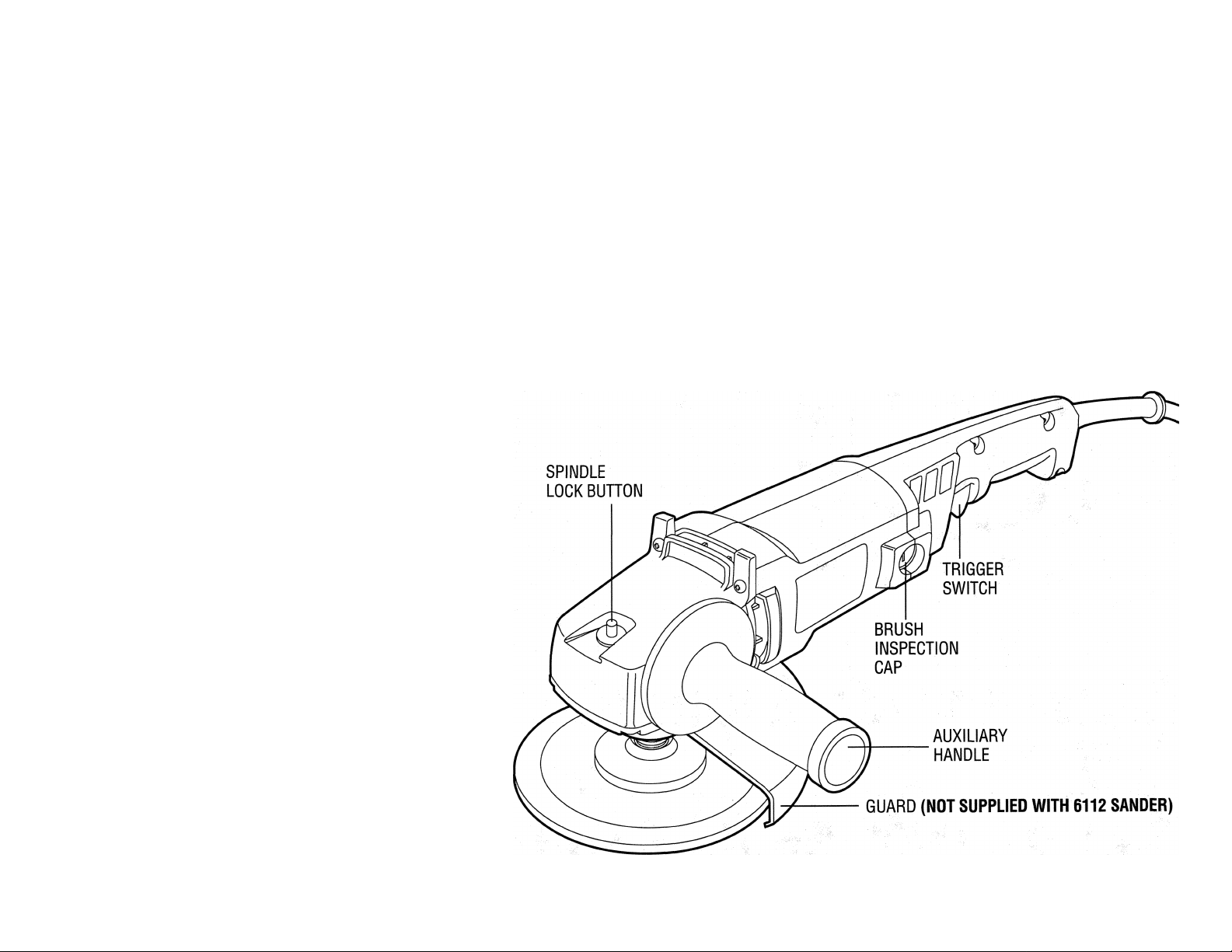

Switch

To start the tool, squeeze the trigger switch shown in Figure 1. To turn the tool

off, release the switch.The tool can be locked on for continuous use by holding

the trigger switch depressed while you depress the switch locking button next

to the trigger, shown in Figure 1. Hold the locking button in as you gently

release the trigger. Release the locking button and the tool will continue to run.

To turn the tool off from a locked on condition, squeeze and release the trigger

once.

Auxiliary Handle

An auxiliary handle is provided with your tool for convenience. The handle can

be screwed into either side of the gear case, shown in Figure 2, and should be

used at all times when sanding or grinding.

Figure 1

AUXILIARY HANDLE

Figure 2

Motor

Your B&D tool is powered by a B&D built motor. Be sure your power supply

agrees with the nameplate marking. Voltage decrease of more than 10% will

cause loss of power and overheating. All B&D tools are factory tested; if this

tool does not operate, check the power supply.

Page 6

Spindle Lock Button

Turn off and unplug tool. In order to prevent the spindle of the unit from rotat

ing while installing or removing accessories, a spindle lock button has been

provided in the gear head of the machine. Depress spindle lock button and

rotate the spindle until the lock pin engages to lock the spindle.

NEVER DEPRESS THE SPINDLE LOCK BUTTON WITH THE TOOL RUNNING OR COASTING.

Sanding With Abrasive Discs (Figure 3)

To install sanding discs;

1. TURN OFF TOOL AND DISCONNECT FROM POWER SUPPLY.

2. Push the hub of the disc nut through the center of the sanding disc, as far

as it will go, and also through the backing disc.

Figure 3

SPINDLE

3. Put the assembled discs on the tool spindle and engage the disc nut into

the disc nut hub.

4. Thread the assembly clockwise, completely down on the spindle.

5. Engage the lock button to lock the spindle in place.

When using a sanding disc, hold the tool at an angle of 10°-15° to the work. If

only the outer edge of the sanding disc is used, a rough cut surface will result.

If the sanding disc is pressed flat against the work, the surface will be irregular

and bumpy, and the tool will be difficult to control.

To remove disc:

1. Engage spindle lock button to lock the spindle in place.

2. Using a cloth or glove to protect your hand, turn disc assembly counter

clockwise to remove it from the tool spindle. (Figure 4)

BACKING DISC

Figure 4

SANDING DISC

DISC NUT

Page 7

Figure 5

Figure6

Depressed-Center Wheels

Depressed center wheels may be used for moderate metal removal on flat or

contoured surfaces. CAUTION: Never use depressed center wheels without the

proper guard.

To install depressed center wheels: (See Figure 6)

as shown above.

M/ften sanding, leave 10°-15°

between the wheel and the work.

RAISED

PORTION OF

FLANGE

TOWARD

SPINDLE

RAISED

PORTION

WHEEL

TOWARD

FLANGE

DEPRESSED CENTER WHEEL

SPINDLE

BACKING FLANGE

1. TURN OFF TOOL AND DISCONNECT FROM POWER SUPPLY.

2. Be sure the guard assembly is securely attached to the spindle housing.

Position guard so that the open part of the guard is facing away from the

operator.

3. Put the backing flange onto the tool spindle.

4. Check rated speed on depressed center wheel. Never use wheel with rated

speed lower than the speed in the “WARNING” statement on the nameplate

of the tool.

5. Place the depressed center wheel on the tool spindle.

6. Thread the clamp washer on tool spindle, hold the tool spindle by engaging

the lock button, and tighten clamp washer with wrench.

When using a depressed center wheel, hold the tool so that an angle of approx

imately 30° exists between the wheel and the work. (See Figure 5)

Wire Brushing

Common applications for wire cup brushes include cleaning welds, angles,

corners and removal of paint.

1. Disconnect tool from power source. Rest grinder on its back with spindle

facing up.

2. Ensure that the rated speed of the wire brush is equal to or higher than the

rated speed of the grinder found on the nameplate.

Page 8

3. Thread wire cup brush onto spindle and tighten.

ENVIRONMENTAL SAFETY

4. Always wear eye protection and appropriate protective clothing.

Precautions To Take When Sanding Paint

1. Sanding of lead based paint is NOT RECOMMENDED due to the difficulty

of controlling the contaminated dust. The greatest danger of lead poison

ing is to children and pregnant women.

2. Since it is difficult to identify whether or not a paint contains lead without

a chemical analysis, we recommend the following precautions when sand

ing any paint:

PERSONAL SAFETY

a. No children or pregnant women should enter the work area where the

paint sanding is being done until all clean up is completed.

b. A dust mask or respirator should be worn by all persons entering the work

area. The filter should be replaced daily or whenever the wearer has diffi

culty breathing.

NOTE: Only those dust masks suitable for working with lead paint dust

and fumes should be used. Ordinary painting masks do not offer this pro

tection. See your local hardware dealer for the proper N.I.O.S.H. approved

mask.

a. Paint should be removed in such a manner as to minimize the amount of

dust generated.

b. Areas where paint removal is occurring should be sealed with plastic

sheeting of 4 mils thickness.

c. Sanding should be done in a manner to reduce tracking of paint dust out

side the work area.

CLEANING AND DISPOSAL

a. All surfaces in the work area should be vacuumed and thoroughly cleaned

daily for the duration of the sanding project. Vacuum filter bags should be

changed frequently.

b. Plastic drop cloths should be gathered up and disposed of along with any

dust chips or other removal debris. They should be placed in sealed refuse

receptacles and disposed of through regular trash pick-up procedures.

During clean up, children and pregnant women should be kept away from

the immediate work area.

c. All toys, washable furniture and utensils used by children should be

washed thoroughly before being used again.

c. NO EATING, DRINKING or SMOKING should be done in the work area to

prevent ingesting contaminated paint particles. Workers should wash and

clean up BEFORE eating, drinking or smoking. Articles of food, drink, or

smoking should not be left in the work area where dust would settle on

them.

Page 9

MAINTENANCE

ACCESSORIES

Cleaning

Blowing dust and grit out of the motor housing using compressed air is a nec

essary regular maintenance procedure. Dust and grit containing metal parti

cles often accumulate on interior surfaces and could create an electrical shock

hazard if not frequently cleaned out. ALWAYS WEAR SAFETY GLASSES.

CAUTION: Never use solvents or other harsh chemicals for cleaning the non-

metallic parts of the tool. Use clean, dry rag only.

Lubrication

B&D tools are properly lubricated at the factory and are ready for use. Tools

should be relubricated regularly every sixty days to six months, depending on

usage. (Tools used constantly on production or heavy-duty jobs and tools

exposed to heat may require more frequent lubrication.) This lubrication

should only be attempted by trained power tool repairpersons, such as those

at B&D service centers or in other qualified service organizations.

Motor Brushes

Be sure tool is turned off and disconnected before inspecting brushes. Carbon

brushes should be regularly inspected for wear. To inspect brushes, unscrew

the plastic brush inspection caps (located in the sides of the motor housing)

and the spring and brush assemblies may be withdrawn from the tool.

Keep brushes clean and sliding freely in their guides. Carbon brushes have

varying symbols stamped into them, and if the brush is worn down to the line

closest to the spring, they must be replaced. New brush assemblies are avail

able at B&D service centers.

NOTE: Use accessories recommended per chart below:

Accessory Type

DEPRESSED CENTER

WHEEL

SANDING DISCS

WIRE CUP

BRUSHES

Depressed center grinding wheels must fit within the confines of the guard and

must be rated higher than the recommended speed as marked on the name

plate.

CAUTION: Strands of wire cup brushes may break and fly off while in use.

Users and others in the area should wear adequate eye, face and body protec

tion. Use only wire cup brushes that are rated at or greater than the RPM

shown on the tool’s nameplate.

WARNING: To reduce the risk of injury, always use proper guards when grind

ing and wear eye protection.

CAUTION: The use of any non-recommended accessory may be hazardous.

Recommended accessories for use with your tool are available at extra cost

from your distributor or local service center. A complete listing of service cen

ters is included with your tool.

Max - 4" Knotted Wheel

Max-2-3/4" Cup Wheel

Notes Usage

Use guard supplied

with tool

Use for moderate metal

Use for smoothing welds,

Use for rust removal and

and masonry removal

on flat or contoured

surfaces

and sharp edges, and

automotive body work

surface preparation

before painting

Page 10

IMPORTANT!

To assure product safety and reliability, particularly for double insulated tools,

repairs, maintenance and adjustment (excluding maintenance described in this

manual) should be performed by B&D service centers or authorized service

centers, using identical B&D replacement parts.

One Year Free Maintenance

All B&D tools for Industry and Construction are covered under a service/safety check program where B&D will inspect your tool for safety and provide nec

essary maintenance or repairs, including normal wear and tear parts, for one

year, FREE OF CHARGE.

Full Warranty

All B&D tools for Industry and Construction are warranted to be free of any

defects in materials or workmanship. Upon thorough examination of tool,

B&D will repair or replace, at our option, any product that is determined to be

defective.

Conditions

The service/safety check and the warranty do not apply to: repairs made or

attempted by anyone other than an authorized B&D service location; misuse,

abuse, neglect, improper application of the tool; missing parts; or normal wear

and tear (after first year of ownership). Please return the complete unit, trans

portation prepaid, to any B&D factory owned or B&D authorized service center

location (list provided with tool or see Yellow Pages under “Tools Electric”).

Page 11

YOUR POWER TOOLS MAY BE SERVICED AT THE FOLLOWING B&D SERVICE CENTERS.

AUBAMA:

Birmingham 35209, 2412 Green Springs Hwy

Mobile 36608, 3831 Airport Blvd..........................................205-343-6624

ALASKA:

Anchorage 99518, 910 West International Airport Rd

ARIZONA:

Mesa 85202, 535 S. Dobson, Suite 7

Phoenix 85013, 4501 N. 7th Avenue

Tucson 85712, 4845 E. Speedway Blvd

ARKANSAS:

Little Rock 72201,519 W. Seventh St

CALIFORNIA;

Anaheim 92806, 540 South State College Blvd

Chula Vista 91910, 309 Broadway ......................................

Concord 94520, 1500 Monument Blvd., #C2

Fresno 93710, 5412 North Blackstone Ave

Long Beach 90805, 2011 South St

Los Angeles 90040, 4820 South Eastern Ave., Suite “L”

Riverside 92506, 6215 Magnolia Ave., Suite “B”................. 909-787-9700

Sacramento 95825, 2033 Fulton Ave

San Diego 92123, 9270 Clairemont Mesa Blvd

San Jose 95128, 1185 So. Bascom Ave

San Leandro 94578, 15206 E. 14th St................................. 510-276-1610

Van Nuys 91411, 14920 Victory Blvd

COLORADO:

Denver 80219, 1171 S. Federal Blvd................................... 303-922-8325

CONNECTICUT:

Orange 06477, 481 Boston Post Rd

Wethersfield (Hartford) 06109, 662 Silas Dean Hwy

DISTRICT OF COLUMBIA: Washington

Colmar Manor 20722, 4153 Bladensburg Rd<

Falls Church, VA 22046, 344 W. Broad St

FLORIDA:

Ft. Lauderdale 33334, 799 E. Oakland Pk. Blvd

Ft. Myers 33907, 5224 Bank Street

Jacksonville 32205, 920 Cassat Ave...........................

Miami (North) 33168, 13345 N.W. Seventh Ave.

Miami (South) 33156, 12233 So. Dixie Hwy...

Orlando 32803, 3807 E. Colonial Dr

St. Petersburg 33709, 5635 49th St„ N

Tampa 33609, 3432 W. Kennedy Blvd

West Palm Beach 33415, 310 South Military Trail

GEORGIA:

Atlanta (South) 30349, 5330 Old National Hwy

Smyrna 30080, 2550 Cobb Pkwy

Stone Mountain (Atlanta) 30086, 5723 Memorial Dr

HAWAII:

Honolulu 96819, 330 Sand Island Access Road

ILLINOIS:

Des Plaines (Chicago) 60018,1277 South Elmhurst Rd..

Lincolnwood (Chicago) 60646, 6710 N. Crawford Ave

Lisle (West Chicago) 60532, 2950 Ogden Ave., Unit H.... 708-717-1075

Moline 61265, 4433 23rd Ave

Oak Lawn (Chicago) 60453, 6343 W. 95th St

Waukegan 60085, 39 S. Greenbay Rd.

INDIANA;

Evansville 47710, 307 First Ave., Crescent Ctr

Hammond 46323, 7103 Kennedy Ave..

Indianapolis 46224, 5999 Crawfordsville Rd

......................................

....................................

.....................................

....................................

.......................................404-956-0869

..............................................

.....

.............

.........

..................................

.................................

....

..........................

..................................

..................

......................

.........................

..................................

................. 619-279-2011

.............................

..................................

...........

....................

..........................

.................

.......

................

.................

............................

..........................

813-872-8317

..............

...................

...........

.................

.......

.....................

...........

................... 708-249-4390

...................

..............................

.......................

. 205-942-0538

907-563-4664

602-461-1074

602-279-6414

602-323-3388

501-372-3040

714-772-4050

619-420-6350

510-682-4880

209-435-0810

310-422-5825

....

213-720-1834

916-972-9090

408-293-7350

818-787-5531

203-795-3583

203-563-5800

301-779-3808

703-533-7313

305-566-5102

813-278-1188

904-781-2253

305-681-6658

305-232-9497

407-894-7011

813-525-0273

407-689-3247

404-762-8844

404-292-4714

808-847-7447

....708-364-5220

708-673-0923

309-762-3000

708-423-7212

812-425-4269

219-845-5100

317-243-8308

IOWA:

Des Moines 50310, 3427 Merle Hay Rd

KANSAS:

Wichita 67213, 155 S. West St.............................................316-943-1271

KENTUCKY:

Louisville 40213, 5211 Preston Hwy.................................... 502-968-7100

LOUISIANA:

Baton Rouge 70815, 11859 Florida Blvd

Harvey 70058, 2500 Lapalco Blvd

Metairie (New Orleans) 70002, 3504 N. Causeway Blvd

Shreveport 71108, 7710-7714 Jewella Rd...........................318-688-1553

MARYLAND:

Baltimore (East) 21205, 4712 Erdman Ave

Baltimore (North) 21030, 29-31 Cranbrook Rd., Cockeysville ... 410-666-5966

Baltimore (South) 21122, 8220 Ritchie Hwy., Pasadena

Colmar Manor 20722, 4153 Bladensburg Rd. .

MASSACHUSEHS:

Brighton (Boston) 02135, 12 Market St...

Seekonk 02771, 120 Highland Ave......................................508-336-6510

MICHIGAN;

Grand Rapids 49512, 3040 28th St., S.E.............................616-949-8331

Lansing 48917, 3203 W. Saginaw Hwy

Warren 48093, 27035 Van Dyke Blvd.................................. 313-756-6711

Westland (Detroit) 48185, 8067 North Wayne Rd............ . 313-427-1520

MINNESOTA:

Bloomington (Minneapolis-St. Paul) 55420, 9517 Lyndale Ave., S. . 612-884-9191

MISSOURI:

Kansas City 64111, 4324 Main St........................................ 816-531 -0629

St. Ann (North St. Louis) 63074, 3637 North Lindbergh Blvd. . . . 314-739-4661

St. Louis 63131, 12852 Manchester Rd...............................314-821-8740

NEBRASKA;

Omaha 68127, 4225 S. 84th St............................................402-592-5666

NEVADA;

Las Vegas 89104, 3411 East Charleston Blvd

NEW JERSEY;

Cherry Hill 08034, 1444 E. Marlton Pike/Rte. 70

Little Falls 07424, 1189 U.S. Highway 46

Union (Scotch Plains) 07076, 2520 Route #22 East

NEW MEXICO:

Albuquerque 87110, 5617 Menaul Blvd., N.E

NEW YORK:

Buffalo 14209, 881 W. Delavan Ave

Centereach L.I. 11720, 2061-63 Middle Country Rd.

Elmhurst (New York) 11373, 77-20 Queens Blvd

Latham (Albany) 12110, 836 Troy-Schenectady Rd............ 518-785-1867

Rochester 14623, 2969 W. Henrietta Rd

Syracuse 13214, 3485 Erie Blvd., East................................315-446-3086

Westbury L.I. (New York) 11590, 1061 Old Country Rd

NORTH CAROLINA:

Charlotte 28205, 3007 E. Independence Blvd

Greensboro 27407, 3716 High Point Rd

Raleigh 27604, 2930 Capital Blvd

OHIO:

Cincinnati 45241,2310 E. Sharon Rd

Columbus 43227, 3975 E, Livingston Ave

Dayton 45409, 2898 S. Dixie Dr....................................

Mayfield Heights (East Cleveland) 44124, 5881 Mayfield Rd... . 216-449-2770

..............................

.............................

.............................. 504-366-8676

.........................

................... 301-779-3808

...........................

..............................

....................

.................

............................

....

....

...........

515-270-1340

504-272-8111

504-837-2550

410-485-5550

410-647-8456

617-782-6264

517-323-4181

702-641-6555

609-429-2822

201-256-9373

908-233-5665

................. 505-884-1002

....................................

...............

.............................

.................... 704-374-1779

............................

......................................

...................................

...........................

716-884-6220

.... 516-737-4706

718-335-1042

716-424-1310

......

516-997-6140

910-852-1300

919-878-0357

513-772-3111

614-237-0461

.......

513-298-1951

OHIO (CONT’D)

Parma Heights (Cleveland) 44130, 6483 Pearl Road..

Toledo 43607, 3231 Dorr St............................................. 419-531-8921

OKLAHOMA;

Oklahoma City 73106, 1318 Linwood Blvd

Tulsa 74145, 3120 S. Sheridan Rd

OREGON;

Portland 97209, 1640 N.W. Johnson St

PENNSYLVANIA:

Evans City 16033, 20808 Rt. 19 North

Harrisburg 17112, 6080 Allentown Blvd...............................717-545-0651

Lancaster 17601,118 Keller Ave................................ 717-393-5251 ,

Philadelphia 19103, 333 N. 20th St

Philadelphia (North) 19115, 9977-81 Bustleton Ave. .......... 215-464-7771

Pittsburgh 15232, 5437 Baum Blvd

Whitehall (Allentown) 18052, 2242 MacArthur Rd

Wilkes-Barre 18702, 759 Kidder Street

PUERTO RICO:

Puerto Nuevo............................................................... 809-783-3535

RHODE ISLAND:

See Seekonk, MA

SOUTH CAROLINA;

Greenville 29607, 1557 Laurens Rd

TENNESSEE:

Chattanooga 37421,6231 Perimeter Drive, Space E. ......... 615-894-5957

Knoxville 37917, 4118 N. Broadway.

Memphis 38116, 1085 East Brooks Rd,

Nashville 37211,4811 Noiensville Rd

TEXAS:

Amarillo 79106, 3008 West 6th Ave

Austin 78757, 6549 Burnet Rd

Dallas 75229, 2257 Royal Ln

El Paso 79915, 6822 Gateway East

Fort Worth 76111, 721 North Beach St

Garland 75043, 718 W. Centerville Rd.

Houston 77022, 536 E. Tidwell Rd............................. 713-692-7111

Houston (S.W.) 77025, 9319 Stella Link Blvd............ 713-664-3666

San Antonio 78201, 500 Culebra Ave........................ 210-732-1221

Webster 77598, 100 East Nasa Rd. One..................... 713-338-4556

UTAH:

Salt Lake City 84115, 1541 S. Third West St

VIRGINIA;

Falls Church 22046, 344 W. Broad St..................... 703-533-7313

Hampton 23666, 3416 W. Mercury Blvd

Norfolk 23513, 7631 Sewells Point Rd.

Richmond 23222, 1424 Chamberlayne Ave

WASHINGTON:

Seattle 98108, 421 S. Michigan St

Spokane 99208, N. 7011 Division St...................................

Tacoma 98409, 2602 S, 38th St................................... 206-473-6040

WEST VIRGINIA:

Charleston 25312, 1638 Sixth Ave

WISCONSIN;

Milwaukee (Wauwatosa) 53226, 10424 West Bluemound Rd,. ., 414-453-4240

............................................

................................... 214-620-6655

.............. 405-232-7515

.......................... 918-622-5666

.................. 503-228-8631

...............................

............................... 215-564-5520

........................... 412-362-2700

.........

..................

...................... 615-688-0921

...................... 901-332-3444

.......................... 615-833-8277

.....................................

........................ 915-778-9769

......................... 817-831-3828

.................. 214-686-9302

.............. 804-826-9382

.............................

............ 804-649-9245

.....................................

......................................

216-842-9100

412-779-9600

..... 610-435-9544

.......... 717-824-5704

.......

...... 803-232-3038

806-373-1531

512-459-1133

............ 801-486-5828

804-480-3333

206-763-2010

509-467-8190

304-343-0289

Page 12

ALBERTA

Edmonton T6E 6H6, 3845 99th St.......... . 403-462-5005

BRITISH COLUMBIA

Vancouver V5M 3Y7, 1735 Boundary Rd. .... 604-291-9942

MANITOBA

Winnipeg R3H OK3, 934 St. James St. ......204-783-7294

NOVA SCOTIA

Halifax B3K 2A4, 6100 Young Street. ........902-453-5090

ONTARIO

Brockville K6V 5W6, 100 Central Ave

Kanata K2L 1V3. 462 Hazeldean Rd #11 ..... 613-831-2332

Glencairn Plaza

London N6E 3A9, 981 Wellington Rd #6

Markham L3P 3J3, 9275 Hwy 48 Unit 12/13 .. . 905-472-6168

Mississauga L4X 1L3, 1480 Dundas St. E #7. . 905-277- 0011

North York M3J 3G5, 48 Kodiak Cres

QUEBEC

Brossard J4W 1M6, 5840 Boul Taschereau ... 514-462-4881

Montreal H1Y 1B4, 3061 Belanger

....... . 613-342-6641

.....

519-649-2407

.........

416-635-6740

......... 514-722-1021

FOR ADDITIONAL SERVICE LOCATIONS

CALL: 1-800-9-BO TOOL

10

Page 13

Black & Decker (U.S.) Inc. • 701 East Joppa Road, Towson, Maryland 21286

Printed in U.S.A. (APR95-CD-2) Form No. 159244-01 Copyright© 1994,1995

Loading...

Loading...