Page 1

before using. Many accidents are caused by poorly maintained tools.

• Use only accessories that are recommended by the manufacturer for your model.

Accessories that may be suitable for one tool may create a risk of injury when used on

another tool.

Service

• Tool service must be performed only by qualified repair personnel. Service or

maintenance performed by unqualified personnel may result in a risk of injury.

• When servicing a tool, use only identical replacement parts. Follow instructions in

the Maintenance section of this manual. Use of unauthorized parts or failure to follow

Maintenance Instructions may create a risk of shock or injury.

SPECIFIC SAFETY RULES

DANGER: Keep hands away from cutting area and blade. Keep your second hand

on auxiliary handle, or motor housing. If both hands are holding the saw, they cannot be

cut by the blade.

• Keep your body positioned to either side of the saw blade, but not in line with the

saw blade. KICKBACK could cause the saw to jump backwards. (See "Causes and

Operator Prevention of Kickback").

• Do not reach underneath the work. The guard cannot protect you from the blade below

the work.

• Check lower guard for proper closing before each use. Do not operate saw if lower

guard does not move freely and close instantly. Never clamp or tie the lower guard

into the open position. If saw is accidentally dropped, lower guard may be bent. Raise the

lower guard with the Retracting Lever and make sure it moves freely and does not touch the

blade or any other part, in all angles and depths of cut.

• Check the operation and condition of the lower guard spring. If the guard and the

spring are not operating properly, they must be serviced before use. Lower guard

may operate sluggishly due to damaged parts, gummy deposits, or a buildup of debris.

• Lower guard should be retracted manually only for special cuts such as "Pocket

Cuts" and "Compound Cuts". Raise the lower guard by Retracting Lever. As soon as

blade enters the material, lower guard must be released. For all other sawing, the lower

guard should operate automatically.

• Always observe that the lower guard is covering the blade before placing saw down

on bench or floor. An unprotected, coasting blade will cause the saw to walk backwards,

cutting whatever is in its path. Be aware of the time it takes for the blade to stop after switch

is released.

• NEVER hold piece being cut in your hands or across your leg. It is important to support

the work properly to minimize body exposure, blade binding, or loss of control.

• Hold tool by insulated gripping surfaces when performing an operation where the

cutting tool may contact hidden wiring. Contact with a “live” wire will also make exposed

metal parts of the tool "live" and shock the operator.

• When ripping, always use a rip fence or straight edge guide. This improves the

accuracy of the cut and reduces the chance for blade binding.

• Always use blades with correct size and shape (diamond vs. round) arbor holes.

Blades that do not match the mounting hardware of the saw will run eccentrically, causing

loss of control.

• Never use damaged or incorrect blade washers or bolts. The blade washers and bolt

were specially designed for your saw, for optimum performance and safety of operation.

CAUSES AND OPERATOR PREVENTION OF KICKBACK

• Kickback is a sudden reaction to a pinched, bound or misaligned saw blade, causing an

uncontrolled saw to lift up and out of the workpiece toward the operator.

• When the blade is pinched or bound tightly by the kerf closing down, the blade stalls and

the motor reaction drives the unit rapidly back toward the operator.

• If the blade becomes twisted or misaligned in the cut, the teeth at the back edge of the

blade can dig into the top surface of the wood causing the blade to climb out of the kerf and

jump back toward the operator.

• Kickback is the result of tool misuse and/or incorrect operating procedures or conditions

and can be avoided by taking proper precautions as given below:

• Maintain a firm grip on the saw and position your body and arm in a way that allows

you to resist KICKBACK forces. KICKBACK forces can be controlled by the operator, if

proper precautions are taken.

• When blade is binding or when interrupting a cut for any reason, release the trigger

and hold the saw motionless in the material until the blade comes to a complete stop.

Never attempt to remove the saw from the work or pull the saw backward while the

blade is in motion or KICKBACK may occur. Investigate and take corrective actions to

eliminate the cause of blade binding.

• When restarting a saw in the workpiece, center the saw blade in the kerf and check

that teeth are not engaged into the material. If saw blade is binding it may walk up or

KICKBACK from the workpiece as the saw is restarted.

• Support large panels to minimize the risk of blade pinching and KICKBACK. Large

panels tend to sag under their own weight. Supports must be placed under the panel on

both sides, near the line of cut and near the edge of the panel.

• Do not use dull or damaged blade. Unsharpened or improperly set blades produce

narrow kerf causing excessive friction, blade binding and KICKBACK.

• Blade depth and bevel adjusting locking levers must be tight and secure before

making cut. If blade adjustment shifts while cutting, it may cause binding and KICKBACK.

• Use extra caution when making a "Pocket Cut" into existing walls or other blind

areas. The protruding blade may cut objects that can cause KICKBACK.

The label on your tool may include the following symbols.

V ..........................volts A..........................amperes

Hz ........................hertz W ........................watts

min........................minutes ......................alternating current

......................direct current

n

o ........................no load speed

..........................

Class II Construction

........................earthing terminal

........................safety alert symbol .../min ..................revolutions or

reciprocations per minute

ADDITIONAL SAFETY RULES: Circular Saws

WARNING: Some dust created by power sanding, sawing, grinding, drilling, and

other construction activities contains chemicals known to cause cancer, birth

defects or other reproductive harm. Some examples of these chemicals are:

• lead from lead-based paints,

• crystalline silica from bricks and cement and other masonry products, and

• arsenic and chromium from chemically-treated lumber (CCA).

Your risk from these exposures varies, depending on how often you do this type of work. To

reduce your exposure to these chemicals: work in a well ventilated area, and work with

approved safety equipment, such as those dust masks that are specially designed to filter

out microscopic particles.

• Avoid prolonged contact with dust from power sanding, sawing, grinding, drilling,

and other construction activities. Wear protective clothing and wash exposed areas

with soap and water. Allowing dust to get into your mouth, eyes, or lay on the skin may

promote absorption of harmful chemicals.

WARNING: Use of this tool can generate and/or disperse dust, which may cause

serious and permanent respiratory or other injury.Always use NIOSH/OSHA approved

respiratory protection appropriate for the dust exposure. Direct particles away from face and

body.

CAUTION: Wear appropriate hearing protection during use. Under some conditions

and duration of use, noise from this product may contribute to hearing loss.

• Snagging the lower guard on a surface below the material being cut can momentarily

reduce operator control. The saw can lift partially out of the cut increasing the chance of

blade twist. Ensure there is sufficient clearance under the workpiece.

• When necessary to raise lower guard manually, use the retracting lever.

• KEEP THE BLADES CLEAN AND SHARP. Sharp blades minimize stalling and kickback.

The use of dull and/or dirty blades can increase the saw loading causing the operator to

push harder which promotes twisting.

DANGER: KEEP HANDS AWAY FROM CUTTING AREA. Keep hands away from blades.

Never place hands in front of or behind the path of the blade while cutting. Do not reach

underneath work while blade is rotating. Do not attempt to remove cut material when blade

is moving.

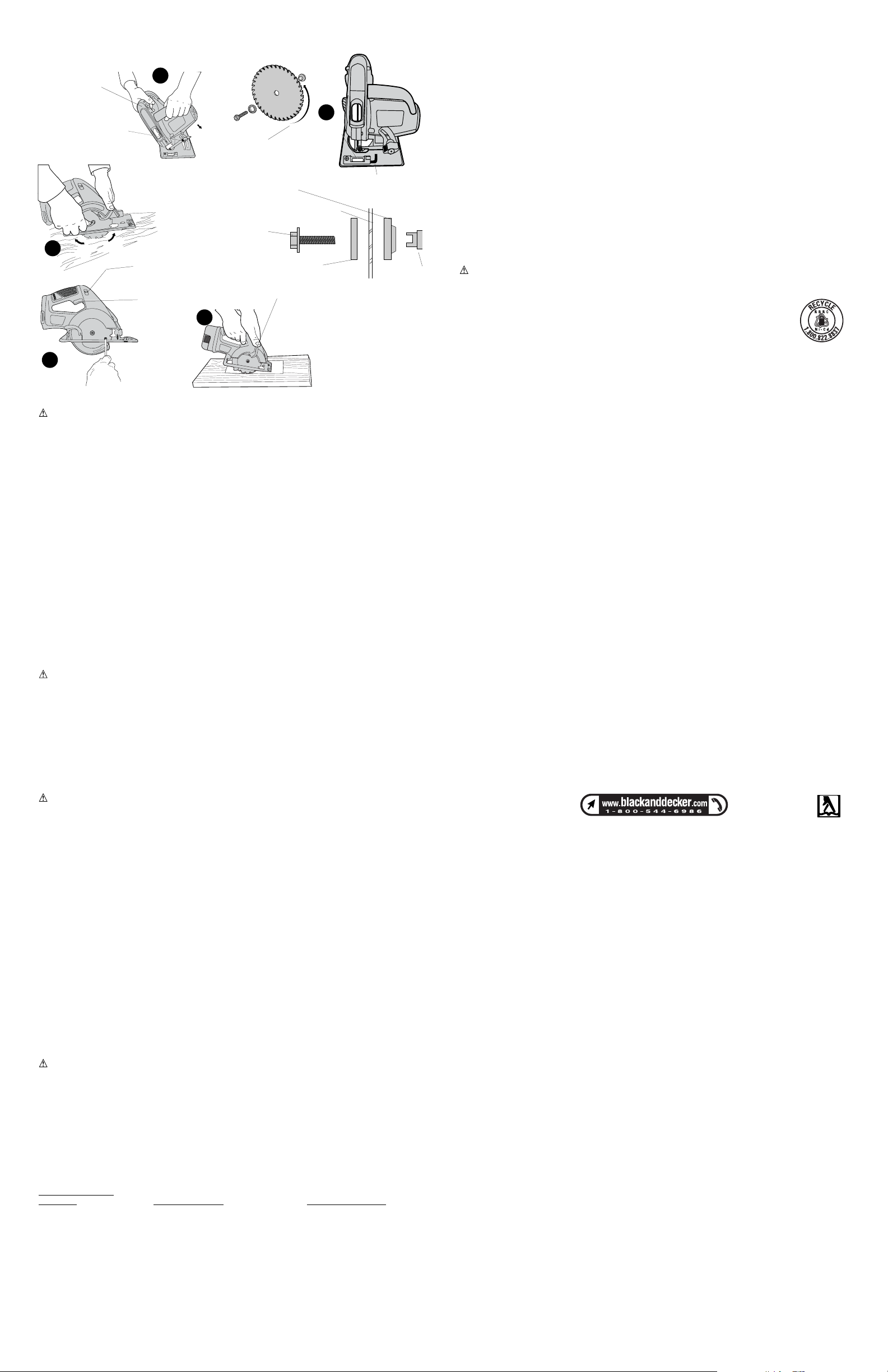

• SUPPORT LARGE PANELS. Large panels must be supported as shown (Fig. 1) in this

manual to minimize the risk of blade pinching and kickback. When cutting operation

requires the resting of the saw on the workpiece, the saw shall be rested on the larger

portion and the smaller piece cut off.

• USE ONLY CORRECT BLADES AND BLADE ASSEMBLY COMPONENTS WHEN

MOUNTING BLADES. Do not use blades with incorrect size holes. Never use defective or

incorrect blade washers or bolts. Follow blade assembly procedures.

• ADJUSTMENTS. Before cutting be sure depth and bevel adjustments are tight.

CAT. NOS. FS1800CS / FS2400CS FORM NO.609747-26 REV. 1

C

OPYRIGHT©2006 BLACK &DECKER PRINTED IN CHINA MAR. - 06)

KEY INFORMATION YOU SHOULD KNOW:

•Carbide blades stay sharp much longer than steel blades. Use a carbide blade

whenever possible.

•A dull blade will cause slow, inefficient cutting.

•Always support work properly. (See illustrations on work support in this manual.)

VEA EL ESPAÑOL EN LA CONTRAPORTADA.

SAVE THIS MANUAL FOR FUTURE REFERENCE.

INSTRUCTIVO DE OPERACIÓN, CENTROS DE SERVICIO Y

PÓLIZA DE GARANTÍA. ADVERTENCIA: LÉASE ESTE

INSTRUCTIVO ANTES DE USAR EL PRODUCTO.

CATALOG NUMBERS

FS1800CS / FS2400CS

INSTRUCTION

MANUAL

GENERAL SAFETY RULES - FOR ALL BATTERY OPERATED TOOLS

WARNING: READ AND UNDERSTAND ALL INSTRUCTIONS.

Failure to follow all instructions listed below, may result in electric shock, fire and/or serious

personal injury.

SAVE THESE INSTRUCTIONS

Work Area

• Keep your work area clean and well lit. Cluttered benches and dark areas invite

accidents.

• Do not operate power tools in explosive atmospheres, such as in the presence of

flammable liquids, gases, or dust. Power tools create sparks which may ignite the dust or

fumes.

• Keep bystanders, children, and visitors away while operating a power tool.

Distractions can cause you to lose control.

Electrical Safety

• Do not abuse the cord. Never use the cord to carry the tool. Keep cord away from

heat, oil, sharp edges or moving parts. Replace damaged cords immediately.

Damaged cords may create a fire.

• A battery operated tool with integral batteries or a separate battery pack must be

recharged only with the specified charger for the battery. Acharger that may be

suitable for one type of battery may create a risk of fire when used with another battery.

• Use battery operated tool only with specifically designated battery pack. Use of any

other batteries may create a risk of fire.

Personal Safety

• Stay alert, watch what you are doing and use common sense when operating a power

tool. Do not use tool while tired or under the influence of drugs, alcohol, or

medication. A moment of inattention while operating power tools may result in serious

personal injury,

• Dress properly. Do not wear loose clothing or jewelry. Contain long hair. Keep your

hair, clothing, and gloves away from moving parts. Loose clothes, jewelry, or long hair

can be caught in moving parts.

• Avoid accidental starting. Be sure switch is in the locked or off position before

inserting battery pack. Carrying tools with your finger on the switch or inserting the battery

pack into a tool with the switch on invites accidents.

• Remove adjusting keys or wrenches before turning the tool on. Awrench or a key that

is left attached to a rotating part of the tool may result in personal injury.

• Do not overreach. Keep proper footing and balance at all times. Proper footing and

balance enable better control of the tool in unexpected situations.

• Use safety equipment. Always wear eye protection. Dust mask, non-skid safety shoes,

hard hat, or hearing protection must be used for appropriate conditions.

Tool Use and Care

• Use clamps or other practical way to secure and support the workpiece to a stable

platform. Holding the work by hand or against your body is unstable and may lead to loss of

control.

• Do not force tool. Use the correct tool for your application. The correct tool will do the

job better and safer at the rate for which it is designed.

• Do not use tool if switch does not turn it on or off. Atool that cannot be controlled with

the switch is dangerous and must be repaired.

• Disconnect battery pack from tool or place the switch in the locked or off position

before making any adjustments, changing accessories, or storing the tool. Such

preventive safety measures reduce the risk of starting the tool accidentally.

• Store idle tools out of reach of children and other untrained persons. Tools are

dangerous in the hands of untrained users.

• When battery pack is not in use, keep it away from other metal objects like: paper

clips, coins, keys, nails, screws or other small metal objects that can make a

connection from one terminal to another. Shorting the battery terminals together may

cause sparks, burns, or a fire.

• Maintain tools with care. Keep cutting tools sharp and clean. Properly maintained tools,

with sharp cutting edge are less likely to bind and are easier to control.

• Check for misalignment or binding of moving parts, breakage of parts, and any other

condition that may affect the tool’s operation. If damaged, have the tool serviced

11118888 &&&&22224444 VVVVOOOOLLLLTTTT CCCCOOOORRRRDDDDLLLLEEEESSSSSSSS CCCCIIIIRRRRCCCCUUUULLLLAAAARRRR SSSSAAAAWWWWSS

SS

BEFORE RETURNING THIS PRODUCT

FOR ANY REASON PLEASE CALL

1-800-544-6986

BEFORE YOU CALL, HAVE THE CATALOG No. AND DATE CODE AVAILABLE. IN MOST CASES, A

BLACK & DECKER REPRESENTATIVE CAN RESOLVE THE PROBLEM OVER THE PHONE. IF

YOU HAVE A SUGGESTION OR COMMENT, GIVE US A CALL. YOUR FEEDBACK IS VITAL TO

BLACK & DECKER.

T

T

HANK

HANK

YOU

YOU

FOR

FOR

CHOOSING

CHOOSING

F

F

IREST

IREST

ORM

ORM

! G

! G

OOTTO

O

WWW

WWW

.F

.F

IREST

IREST

ORMT

ORMT

OOLS

OOLS

.

.

COM

COM

/P

/P

RODUCT

RODUCT

R

R

EGISTRA

EGISTRA

TION

TION

TTOOREGISTER

REGISTER

YOUR

YOUR

NEW

NEW

PRODUCT

PRODUCT

.

.

Page 2

• SUPPORT AND SECURE THE WORK PROPERLY. Insure that the material to be cut is

clamped (Fig. 3) and solidly supported and balanced on a strong, stable and level wor

surface. Support the work so that the wide portion of the saw shoe is on the portion of the

material that doesn’t fall after the cut is made. Never hold cut off piece by hand (Fig. 4 ).

KICKBACK from blade pinch can result. Keep both hands on saw at all times.

• STAY ALERT AND EXERCISE CONTROL. Keep body positioned to one side of blade.

Always maintain a firm grip and control of saw with both hands. Do not change hand grip or

body position while saw is running. Take precaution to avoid injury from cut off pieces and

other falling material during operation.

• VIEWING WINDOW MUST BE IN PLACE AT ALL TIMES and it must stay closed against

the upper guard of the saw at all times when operating the saw.

DANGER: RELEASE SWITCH IMMEDIATELY IF BLADE BINDS OR SAW STALLS.

• TURN OFF AND REMOVE BATTERY before attempting to clean the viewing window.

WARNING: Do not operate your saw if window becomes damaged or fails to stay in place

as noted above. Take your saw to your closest Black & Decker Service Center or authorized

service facility.

GUARD AGAINST KICKBACK

• KICKBACK CAN BE CAUSED BY the saw blade becoming pinched, twisted or bound while

cutting, or when the saw stalls. When the blade becomes twisted or misaligned in the cut, the

teeth at the back edge of the blade can dig into the top surface of the wood causing the

blade to climb out of the cut and move suddenly back toward the operator.

TO REDUCE THE RISK OF KICKBACK

• Keep a firm grip on saw with both hands at all times.

• Stay alert – exercise control.

• Support long overhanging materials. As the material is cut and weakens, it will sag, causing

a pinched blade.

• Support large panels as shown (Fig. 1). Material supported only at the ends (Fig. 2) will lead

to blade pinching.

• Avoid sawing overhead. Material can sag and will pinch blade.

• Keep blades sharp and clean.

• Use fence or straight edge guide when ripping. Be careful as the cut off strip can sag or

twist, closing the cut and pinching the blade, leading to KICKBACK.

• Don’t force tool. Wood variables such as knots, hardness, toughness, wetness, pressure

treated and freshly cut green lumber can heavily load the saw which can lead to stalling.

Push the saw slower when this occurs.

• Don’t remove saw from work during a cut while the blade is moving.

• Allow saw to reach full speed before blade contacts material to be cut. Starting the saw with

the blade against the work or pushed forward into cut can lead to stalling or sudden

backward movement of saw.

• Never attempt to lift saw when making a bevel cut. This leads to blade binding and stalling.

• Always secure work to prevent workpiece movement during cut.

• Do not try to force saw back on line if your cut begins to go off line. This can cause

KICKBACK. Stop saw and allow blade to coast down to a stop. Withdraw from cut and start

a new cut on the line.

• Set depth adjustment of saw such that one tooth of the blade projects below the workpiece

as shown in (Fig. 6).

• Do not back up a rotating blade in the cut. Twisting the saw can cause the back edge of the

blade to dig into the material, climb out of the work and run back toward the operator.

• Avoid cutting nails. Inspect for and remove all nails from lumber before cutting.

• Some wood contains preservatives such as copper chromium arsenate (CCA) which can be

toxic. When cutting these materials, extra care should be taken to avoid inhalation and

minimize skin contact.

BATTERY CAP INFORMATION

Battery storage and carrying caps are provided for use whenever the battery is out of the

tool or charger. Remove cap before placing battery in charger or tool.

WARNING: Do not store or carry battery so that metal objects can contact exposed

battery terminals. For example, do not place battery in aprons, pockets, tool boxes,

product kit boxes, drawers, etc. with loose nails, screws, keys, etc. without battery cap.

Transporting batteries can possibly cause fires if the battery terminals inadvertently come

in contact with conductive materials such as keys, coins, hand tools and the like. The US

Department of Transportation Hazardous Material Regulations (HMR) actually prohibit

transporting batteries in commerce or on airplanes (i.e. packed in suitcases and carryon

luggage) UNLESS they are properly protected from short circuits. So when transporting

individual batteries, make sure that the battery terminals are protected and well insulated

from materials that could contact them and cause a short circuit.

IMPORTANT SAFETY INSTRUCTIONS

• SAVE THESE INSTRUCTIONS.

• Before using charger, read and understand all instructions and cautionary markings on

(1) charger, (2) battery pack, and (3) product using battery pack.

DANGER: 120 volts present at charging terminals. Do not probe with conductive objects.

Danger of electric shock or electrocution.

DANGER: If battery pack case is cracked or damaged, do not insert into charger. Danger

of electric shock or electrocution.

DANGER: Never attempt to open the battery pack for any reason. If the plastic housing of

the battery pack breaks or cracks, return to a service center for recycling.

WARNING: Don’t allow any liquid to get inside charger. Electric shock may result.

CAUTION: To reduce risk of injury, charge only Black & Decker rechargeable batteries.

Other types of batteries may burst, causing personal injury and damage.

• To facilitate the cooling of the battery pack after use, avoid placing the charger or

battery pack in a warm environment such as in a metal shed, or an uninsulated trailer.

• Do not expose charger to rain or snow.

• Use of an attachment not recommended or sold by Black & Decker may result in risk of

fire, electric shock, or injury to persons.

• This charger is not intended for any uses other than charging Black & Decker

rechargeable batteries. Any other uses may result in risk of fire, electric shock or

electrocution.

• To reduce risk of damage to electric plug and cord, pull by plug rather than cord when

disconnecting charger.

• Make sure cord is located so that it will not be stepped on, tripped over, or otherwise

subjected to damage or stress.

• An extension cord should not be used unless absolutely necessary. Use of improper

extension cord could result in risk of fire, electric shock, or electrocution. If an extension

cord must be used, make sure:

• That the pins on plug of extension cord are the same number, size and shape of those

of plug on charger.

• That extension cord is properly wired and in good electrical condition and the wire size

is large enough for AC ampere rating of charger as specified below.

An extension cord must have adequate wire size (AWG or American Wire Gauge) for

safety. The smaller the gauge number of the wire, the greater the capacity of the cable, that

is, 16 gauge has more capacity than 18 gauge. When using more than one extension to

make up the total length, be sure each individual extension contains at least the minimum

wire size.

RECOMMENDED MINIMUM AWG SIZE FOR EXTENSION CORDS

TOTAL EXTENSION CORD LENGTH (FEET)

25 50 75 100 125 150 175

WIRE GAUGE

18 18 16 16 14 14 12

• The charger is ventilated through slots in the housing. Do not place any object on top of

charger or place the charger on a soft surface that might block the ventilation slots and

result in excessive internal heat. Place the charger in a position away from any heat source.

• Do not operate charger with damaged cord or plug — have them replaced immediately.

• Do not operate charger if it has received a sharp blow, been dropped, or otherwise

damaged in any way; take it to an authorized service center.

• Do not disassemble charger; take it to an authorized service center when service or repair

is required. Incorrect reassembly may result in risk of electric shock, electrocution or fire.

• The charger is designed to operate on standard120 VAC, 60Hz household electrical

power. Do not attempt to use it on any other voltage.

• To reduce risk of electric shock, unplug charger from outlet before attempting any cleaning.

Removing the battery pack will not reduce this risk.

• NEVER attempt to connect 2 chargers together.

• DO NOT store or use the tool and battery pack in locations where the temperature may

reach or exceed 105°F (such as outside sheds or metal buildings in summer).

• A small leakage of liquid from the battery cells may occur under extreme usage, charging

or temperature conditions. This does not indicate a failure. However, if the outer seal is

broken and this leakage gets on your skin:

a. Wash quickly with soap and water.

b. Neutralize with a mild acid such as lemon juice or vinegar.

c. If the battery liquid gets in your eyes, flush them with clean water for a minimum of 10

minutes and seek immediate medical attention.

MEDICAL NOTE: The liquid is a

25-35% solution of potassium hydroxide.

SAVE THESE INSTRUCTIONS

INTRODUCTION

READ AND UNDERSTAND ALL OF THE INSTRUCTIONS IN THIS MANUAL BEFORE

ATTEMPTING TO CHARGE THE BATTERY PACK FOR YOUR TOOL.

Your charger is designed to use standard 120 volt AC, 60 Hz power. Do not use DC or any

other voltage. Charge time is 3 to 6 hours depending on battery pack type and condition.

CHARGING PROCEDURE

1. Plug the charger into an appropriate outlet.

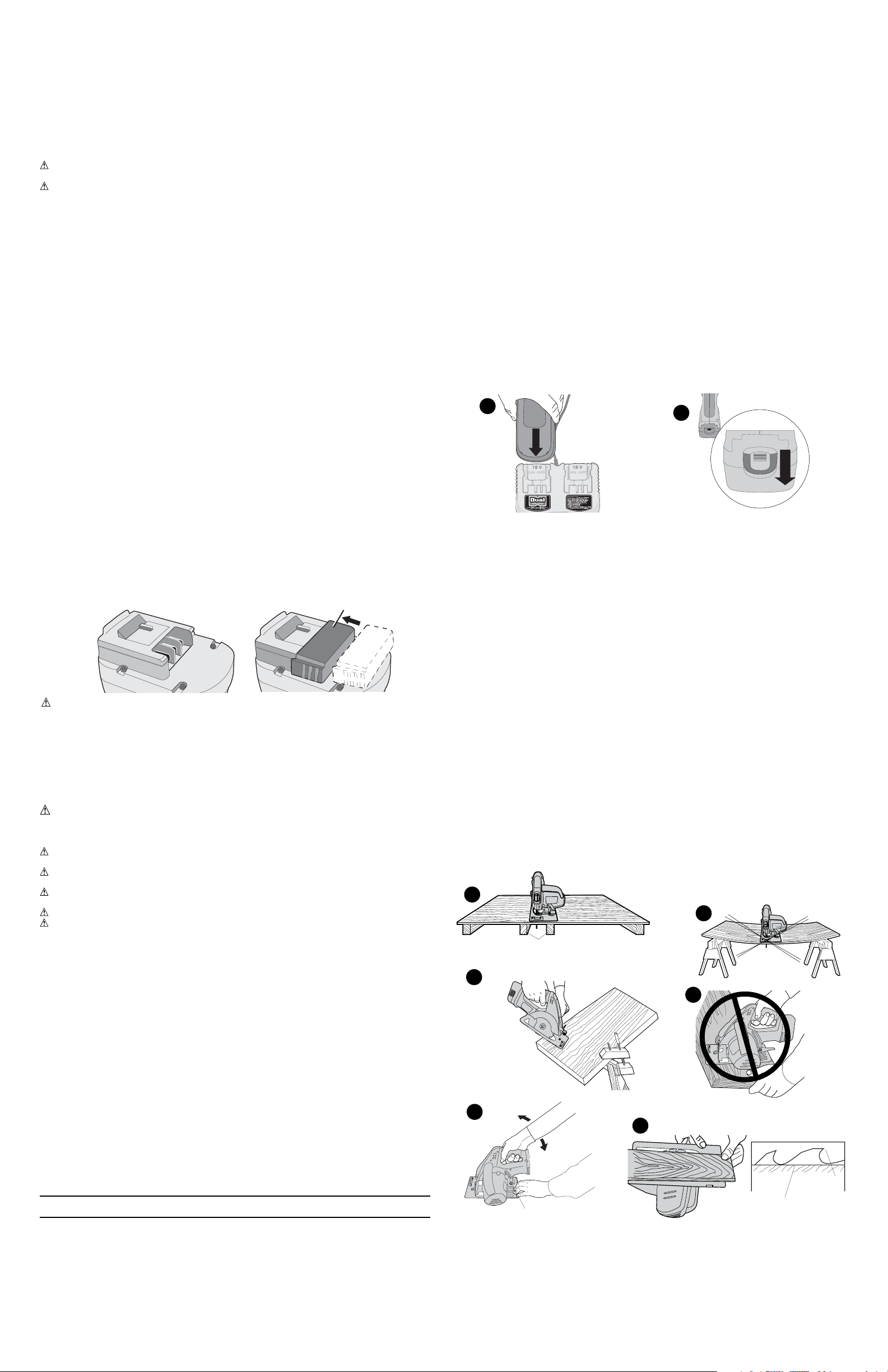

2. Insert 1 or 2 batteries into the charger (Figure A).

NOTE: Charge time is the same for multiple batteries. Be sure the battery is fully

seated in the charger. The red “Charging Indicator” light will come on indicating that

there is contact between the battery and charger. The light will stay on as long as the

battery is in the charger and the charger is plugged into a working outlet. It WILL NOT

flash, go out or change to a different color when the charging cycle is complete.

Remove pack from the charger and place in tool. NOTE: To remove the battery from

the tool, press down on the release button on the back of the battery (Figure B) and pull

out.

LEAVING THE BATTERY PACK IN THE CHARGER

The charger and battery pack can be left connected with the red light glowing indefinitely. The

charger will keep the battery pack fresh and fully charged.

NOTE: A battery pack will slowly lose its charge when kept out of the charger. If the battery

pack has not been kept on maintenance charge, it may need to be recharged before use. A

battery pack may also slowly lose its charge if left in a charger that is not plugged into an

appropriate AC source.

IMPORTANT CHARGING NOTES

1. Longest life and best performance can be obtained if the battery pack is charged when

the air temperature is between 65°F and 75°F (18°- 24°C). DO NOT charge the battery

pack in an air temperature below +40°F(+4.5°C), or above +105°F (+40.5°C). This is

important and will prevent serious damage to the battery pack.

2. The charger and battery pack may become warm to touch while charging. This is a

normal condition, and does not indicate a problem.

3. If the battery pack does not charge properly — (1) Check power at receptacle by

plugging in a lamp or other appliance. (2) Check to see if receptacle is connected to a

light switch which turns power off when you turn out the lights. (3) Move charger and battery pack to a location where the surrounding air temperature is approximately

65°F - 75°F (18°- 24°C). (4) If charging problems persist, take or send the tool, battery

pack and charger to your local service center.

4. The battery pack should be recharged when it does not produce sufficient power on jobs

which were easily done previously. DO NOT CONTINUE use under these

conditions. Follow the charging procedures. You may also charge a partially used pack

whenever you desire with no adverse affect on the battery pack.

5. Black & Decker battery packs that are labeled “NiMH” should only be used with

chargers labeled “NiMH“ or “NiCd/NiMH.”

6. Under certain conditions, with the charger plugged into the power supply, the exposed

charging contacts inside the charger can be shorted by foreign material. Foreign

materials of a conductive nature such as, but not limited to, steel wool, aluminum foil, or

any buildup of metallic particles should be kept away from charger cavities. Always

unplug the charger from the power supply when there is no battery pack in the cavity.

Unplug charger before attempting to clean.

7. Do not immerse charger in water or any other liquid.

1

2

Correct

Correct

Correcto

Wrong

Incorrect

Incorrecto

Material bends on blade causing heavy loads or kickback

Le matériau plie au contact de la lame causant de lourdes surcharges ou

des rebonds.

El material oprime el disco ocasionando sobrecarga o contragolpe

Support work near cut

Soutenir la pièce près de la ligne de

coupe.

Apoye la pieza cerca del corte

3

4

Correct

Correct

Correcto

Wrong

Incorrect

Incorrecto

5

6

Depth adjustment lever

Bouton de réglage de la

profondeur

Perilla de ajuste de profundidad

Tip of tooth

Bout de la

dent

Punta del

diente

Surface of wood

Surface du bois

Superficie de

madera

Proper depth: one tooth below surface of wood

Profondeur appropriée : une dent sous la surface du bois.

Profundidad correcta: un diente debajo de la superficie de

madera

Battery Cap

A

B

Page 3

• Surrounding air temperature • Move charger and tool to

too hot or too cold. a surrounding air

temperature of above 40

degree F(4,5°C) or below

105 degree F (+40,5°C).

For assistance with your product, visit our website www.blackanddecker.com for the

location of the service center nearest you or call the BLACK & DECKER help line at

1-800-544-6986.

MAINTENANCE

REMOVE BATTERY FROM SAW WHEN PERFORMING ANY CLEANING OR OTHER

MAINTENANCE.

Use only mild soap and damp cloth to clean the tool. Never let any liquid get inside the tool;

never immerse any part of the tool into a liquid. IMPORTANT: To assure product SAFETY

and RELIABILITY, repairs, maintenance and adjustment should be performed by authorized

service centers or other qualified service organizations, always using identical replacement

parts.

ACCESSORIES

Recommended accessories for use with your tool are available from your local dealer or

authorized service center. If you need assistance regarding accessories, please call:

1-800-54-HOW-TO. (800-544-6986)

WARNING: The use of any accessory not recommended for use with this tool could be

hazardous. Always use 5-3/8” (136 mm) diameter blades. Carbide blades are strongly

recommended for optimum saw performance. NEVER USE ABRASIVE TYPE OR METAL

CUTTING BLADES ON SAW.

THE RBRC™ SEAL

The RBRC™ (Rechargeable Battery Recycling Corporation)

Seal on the nickel-cadmium battery (or battery pack) indicates that the costs to

recycle the battery (or battery pack) at the end of its useful life have already

been paid by Black & Decker. In some areas, it is illegal to place spent nickel-cadmium

batteries in the trash or municipal solid waste stream and the RBRC program provides an

environmentally conscious alternative.

RBRC in cooperation with Black & Decker and other battery users, has established

programs in the United States and Canada to facilitate the collection of spent nickelcadmium batteries. Help protect our environment and conserve natural resources by

returning the spent nickel-cadmium battery to an authorized Black & Decker service center

or to your local retailer for recycling. You may also contact your local recycling center for

information on where to drop off the spent battery, or call 1-800-8-BATTERY.

SERVICE INFORMATION

Black & Decker offers a full network of company-owned and authorized service locations

throughout North America. All Black & Decker Service Centers are staffed with trained

personnel to provide customers with efficient and reliable power tool service.

Whether you need technical advice, repair, or genuine factory replacement parts, contact the

Black & Decker location nearest you.

To find your local service location, refer to the yellow page directory under “Tools—Electric”

or call: 1-800-54-HOW-TO. (800-544-6986)

SPECIAL WARRANTY NOTE TO CONTRACTORS:

FIRESTORM

TM

branded products are offered as high end consumer home use tools and

carry a HOME USE WARRANTY. These tools are designed, manufactured and tested to

meet or exceed the needs of the do-it-yourselfer in the execution of projects and repairs in

and around the home. With proper use they will provide the home owner with step up power

and performance well beyond their two year warranty. However, if you use tools for a living

and use FIRESTORM

TM

branded products or any of Black & Decker’s other Consumer

Home Use tools ON THE JOBSITE you should know that they CANNOT BE COVERED

UNDER OUR WARRANTY.

FULL TWO-YEAR HOME USE WARRANTY

Black & Decker (U.S.) Inc. warrants this product for two years against any defects in material

or workmanship. The defective product will be replaced or repaired at no charge in either of

two ways.

The first, which will result in exchanges only, is to return the product to the retailer from

whom it was purchased (provided that the store is a participating retailer). Returns should be

made within the time period of the retailer’s policy for exchanges (usually 30 to 90 days after

the sale). Proof of purchase may be required. Please check with the retailer for their specific

return policy regarding returns that are beyond the time set for exchanges.

The second option is to take or send the product (prepaid) to a Black & Decker owned or

authorized Service Center for repair or replacement at our option. Proof of purchase may be

required. Black & Decker owned and authorized Service Centers are listed under “ToolsElectric” in the yellow pages of the phone directory.

This warranty does not apply to accessories. This warranty gives you specific legal rights

and you may have other rights which vary from state to state and province to province.

Should you have any questions, contact the manager of your nearest Black & Decker

Service Center. This product is not intended for commercial use.

See ‘Tools-Electric’

– Yellow Pages –

for Service & Sales

Imported by

Black & Decker (U.S.) Inc.,

701 E. Joppa Rd.

Towson, MD 21286 U.S.A.

ASSEMBLY/ADJUSTMENT SET-UP

WARNING: Always remove battery from tool before any of the following operations.

ATTACHING AND REMOVING THE BLADE

NOTE: The first time the blade bolt is removed from saw without a blade installed, it

may be necessary to place the blade wrench on the bolt head and tap it sharply in the

counter clockwise direction.

Retract lower guard and assemble blade and clamp washers, as shown in Fig. 8. To prevent

blade rotation while tightening the blade clamping screw, raise the lower guard and place

the saw down on a piece of scrap wood as shown in Fig. 9A. The blade teeth will dig into the

scrap wood and prevent rotation while you tighten the blade clamping screw. Tighten the

blade clamping screw securely, using the wrench provided. Figure 9B illustrates an

alternative method of loosening and tightening the blade by inserting a screwdriver through

the hole in the blade to prevent it from moving. NOTE: The blade wrench is stored in the kerf

plate as shown in Fig. 8.

CUTTING DEPTH ADJUSTMENT

Adjust depth of cut using depth adjustment lever. See (Figs. 5 & 6) for proper setting.

Tighten lever securely.

BEVEL ANGLE ADJUSTMENT

Adjust bevel angle (Fig. 7) using bevel adjustment knob and bevel scale. Tighten knob

securely.

KERF PLATE ADJUSTMENT

Adjust kerf plate (Fig. 8) to read zero when the bevel scale reads zero by loosening the kerf

plate screw and sliding the plate as necessary. Align mark on kerf plate with drawn pencil

line and advance blade into cut. The kerf plate has lines for zero bevel and 45 degree bevel

cutting.

OPERATING INSTRUCTIONS

WARNING: To reduce the risk of serious personal injury, read, understand and follow all

important safety warnings and instructions prior to using tool.

GENERAL CUTS (IMPORTANT: Read safety warnings and instructions.

)

GUARD AGAINST KICKBACK

With battery removed, follow all assembly, adjustment and set up instructions.

Make sure lower guard operates. Select the proper blade for the material to be cut.

• Measure and mark work for cutting.

• Support and secure work properly (See Safety Rules and Instructions).

• Use appropriate and required safety equipment (See Safety Rules).

• Secure and maintain work area (See Safety Rules).

• With battery inserted, make sure switch turns saw on and off.

WARNING: It is important to support the work properly and to hold the saw firmly to prevent

loss of control which could cause personal injury. Fig. 3 illustrates typical hand support.

SWITCH

Saw is equipped with a switch lock-off feature to prevent unintentional running. To operate

the tool, push down on the lock-off lever shown in Fig.9B from either side of the saw and

hold it down as you depress the trigger switch. After you have depressed the trigger and

the tool is running, release the lock-off lever. The tool will continue to run as long as the

trigger is depressed.

To turn the tool off, release the trigger switch. There is no provision for locking the tool on,

and the switch should never be locked on by any other means.

AUTOMATIC ELECTRIC BRAKE

Your saw is equipped with an electric blade brake which stops the saw blade within 1-1/2

seconds of trigger release. This is automatic and requires no adjustment.

Occasionally, under certain conditions, the brake will not function properly and won’t stop the

saw in the 1-1/2 seconds as discussed above. If this condition occurs, turn the saw on and

off four or five times. If the problem still persists, have the tool serviced at a Black & Decker

service center or company authorized service facility.

POCKET CUTTING (SEE FIG. 10)

Pocket cutting is used to cut a hole in a piece of material without cutting from the side.

• Measure and mark work.

• Tilt saw forward and rest front of the shoe on material to be cut. Align so that cut will begin

at the back of the drawn rectangle.

• Using the retracting lever, retract blade guard to an upward position, with the blade just

clearing the material, start motor and gradually lower the saw into the material.

WARNING: As blade starts cutting the material, release the retracting lever immediately.

• Never tie the blade guard in a raised position.

• When the shoe rests flat on the material being cut, complete the cut in forward direction.

• Allow the blade to come to a complete stop before lifting saw from material.

• When starting each new cut, repeat the above steps.

BLADE VIEWING WINDOW

Your saw features a blade viewing window through which you can look at the blade as it

cuts, therefore enhancing cutting accuracy. Follow layout lines easily without leaning over at

awkward angles just to see the blade. To clean the window, first remove the battery from the

saw and then, lift up the window so that you can reach beneath it to clean with a soft cloth. If

necessary a little mild soap and water may be used. When you release the window, its

internal spring will hold it tightly against the upper guard.

T

roubleshooting

Problem

Possible Cause Possible Solution

• Unit will not start. • Battery not installed properly. • Check battery installation.

• Battery not charged. • Check battery charging

requirements.

• Battery will not charge. • Battery not inserted into charger. • Insert battery into charger

until red LED appears.

• Charger not plugged in. • Plug charger into a

working outlet. Refer to

“Important Charging Notes”

for more details.

8

Blade

Lame

Disco

Inner clamp washer

Rondelle de fixation

externe

Roldana de sujeción

exterior

Saw spindle

Arbre de la scie

Flecha de la

sierra

Blade clamping screw

Vis de fixation de la lame

Tornillo de sujeción del

disco

Outer clamp washer

Rondelle de fixation externe

Roldana de sujeción interior

Direction of teeth

Sens des dents

Dirección de los

dientes

Kerf Plate and

Screw

Plaque de trait de

scie et vis

Placa indicadora

de corte y tornillo

For pocket cuts only

Pour coupes en retrait seulement

Solamente para cortes de bolsillo

10

7

Bevel adjustment knob

Bouton de réglage pour coupes en

biseau

Perilla de ajuste de bisel

Switch Handle

Poignée de

l’interrupteur

Mango del

interruptor

Warning: When blade starts cutting, release

retraction lever immediately

Avertissement : Lorsque la lame commence à

découper, relâcher immédiatement le ressort de

rappel.

Advertencia: Cuando el disco inicie el corte,

suelte inmediatamente la palanca del

mecanismo retráctil

9A

9B

Blade Wrench

Clé de réglage de la

lame

Llave del disco

Switch lock-off lever

Levier de verrouillage en position

«arrêt»

Palanca de seguro de apagado

Switch trigger

Interrupteur à

gâchette

Interruptor de gatillo

Tighten

Serrer

Apriete

Loosen

Desserrer

Afloje

Page 4

VOICI DES RENSEIGNEMENTS IMPORTANTS À CONNAÎTRE

• Des lames au carbure restent affûtées plus longtemps que des lames en acier.

Utiliser des lames au carbure dans la mesure du possible.

• Une lame émoussée produira une coupe lente et inefficace.

• Toujours bien soutenir le matériau. (Voir les illustrations relatives au soutien du

matériau du présent guide.)

NUMÉROS DE CATALOGUE

FS1800CS / FS2400CS

GUIDE

D’UTILISATION

SSSSCCCCIIIIEEEESSSS CCCCIIIIRRRRCCCCUUUULLLLAAAAIIIIRRRREEEESSSS SSSSAAAANNNNSSSS FFFFIIIILLLL DDDDEEEE

11118888 EEEETTTT 22224444 VVVVOOOOLLLLTTTTSS

SS

RÈGLES GÉNÉRALES DE SÉCURITÉ CONCERNANT TOUS LES

OUTILS À PILES

AVERTISSEMENT : LIRE ET COMPRENDRE TOUTES LES DIRECTIVES. Le

non-respect de toutes les directives suivantes présente des risques d'électrocution,

d’incendie ou de blessures graves.

CONSERVER CES DIRECTIVES.

ZONE DE TRAVAIL

• S’assurer que la zone de travail est propre et bien éclairée. Des établis encombrés et

des endroits sombres présentent des risques d’accidents.

• Ne pas utiliser des outils électriques en présence de vapeurs explosives, comme

celles dégagées par des liquides, des gaz ou des poussières inflammables. Les

étincelles générées par le moteur des outils électriques peuvent enflammer les poussières

ou les vapeurs.

• Éloigner les curieux, les enfants et les visiteurs de la zone de travail lorsqu’on

utilise un outil électrique. Une distraction peut entraîner la perte de maîtrise de l’outil.

Mesures de sécurité – Électricité

• Ne pas utiliser le cordon de manière abusive; on ne doit pas transporter l’outil en le

tenant par le cordon. On doit tenir le cordon à l’écart des sources de chaleur, de

l’huile, des bords tranchants ou des pièces mobiles. Remplacer immédiatement les

cordons endommagés, car ces derniers peuvent causer un incendie.

• Un outil à piles intégrées ou à bloc-piles externe doit être rechargé seulement au

moyen du chargeur approprié, car un chargeur destiné à une pile particulière peut

entraîner un risque d’incendie lorsqu’il est utilisé avec une autre.

• N’utiliser l’outil à piles qu’avec le bloc-piles indiqué, car l’utilisation d’un autre type de

piles peut entraîner un risque d’incendie.

SÉCURITÉ PERSONNELLE

• Demeurer vigilant, prendre soin et faire preuve de jugement lorsqu’on utilise un

outil électrique. Ne pas s’en servir lorsqu’on est fatigué ou affaibli par des drogues, de

l’alcool ou des médicaments. De graves blessures peuvent résulter d’un moment

d’inattention lors de l’utilisation d’un outil électrique.

• Porter des vêtements appropriés. Éviter de porter des vêtements amples ou des

bijoux. Recouvrir la chevelure si elle est longue. Éloigner les cheveux, les vêtements et

les gants des pièces en mouvement qui peuvent les happer.

• Éviter les démarrages accidentels. S’assurer que l’interrupteur est en position hors

tension avant de brancher l’outil. Afin d’éviter les risques de blessures, ne pas

transporter l’outil avec le doigt sur l’interrupteur ni brancher un outil dont l’interrupteur est

en position sous tension.

• Enlever les clés de réglage avant de mettre l’outil sous tension. Une clé qui est

laissée sur une pièce rotative de l’outil présente des risques de blessures.

• Ne pas dépasser sa portée. Garder son équilibre en tout temps. On s’assure d’une

meilleure maîtrise de l’outil dans des situations imprévues grâce à une position stable et

un bon équilibre.

• Porter de l’équipement de sécurité. Toujours porter des lunettes de sécurité. Dans

certaines conditions, il faut porter des masques respiratoires, des chaussures

antidérapantes, un casque de sécurité ou des protège-tympans.

UTILISATION ET ENTRETIEN DE L’OUTIL

• Utiliser des pinces de serrage ou de tout autre moyen pratique afin de fixer et de

soutenir la pièce à ouvrer sur une plate-forme stable. La pièce est instable lorsqu’elle

est retenue par la main ou le corps de l’utilisateur. Cela présente des risques de perte de

maîtrise de l’outil.

• Ne pas forcer l’outil. Utiliser l’outil approprié à la tâche. L’outil approprié fonctionne

mieux et sûrement lorsqu’on s’en sert à son rendement nominal.

• Ne pas se servir de l’outil lorsque l’interrupteur est défectueux. Le cas échéant, l’outil

est dangereux et il faut le réparer.

• Débrancher l’outil de la source d’alimentation avant de le régler, d’en remplacer les

accessoires ou de le ranger. On minimise de la sorte le risque de démarrage accidentel

de l’outil.

• Ranger l’outil hors de portée des enfants et de toute autre personne qui n’en connaît

pas le fonctionnement. L’outil est dangereux entre les mains de ces personnes.

• Lorsqu’on n’utilise pas le bloc-pile, le ranger à l’écart des objets métalliques tels

que les trombones, les pièces de monnaie, les clés, les clous, les vis ou autres petits

objets susceptibles de conduire l’électricité entre les bornes et d’occasionner ainsi un

court-circuit pouvant provoquer des étincelles, des brûlures ou un incendie.

• Prendre soin des outils. S’assurer que les outils de coupe sont tranchants et

propres. Des outils bien entretenus à arêtes tranchantes ont moins tendance à se coincer

et ils se maîtrisent mieux.

• Vérifier l’alignement et les attaches des pièces mobiles, le degré d’usure des pièces

ainsi que tout autre facteur susceptible de nuire au bon fonctionnement de l’outil.

Faire réparer un outil endommagé avant de s’en servir. Des outils mal entretenus sont la

cause de nombreux accidents.

• Utiliser seulement les accessoires recommandés par le fabricant. Des accessoires qui

conviennent à un outil peuvent présenter des risques avec un autre outil.

ENTRETIEN

• Confier l’entretien de l’outil seulement à du personnel qualifié. Le non-respect de la

présente directive présente des risques de blessures.

• Lors de l’entretien de l’outil, utiliser seulement des pièces de rechange identiques.

Respecter les consignes relatives à l’entretien du présent guide d’utilisation. Il y a risque de

secousses électriques ou de blessures lorsqu’on utilise des pièces non autorisées ou

lorsqu’on ne respecte pas les consignes relatives à l’entretien.

MESURES DE SÉCURITÉ SPÉCIFIQUES

DANGER :

Éloigner les mains de la zone de coupe et de la lame. Laisser l’autre

main sur la poignée auxiliaire ou sur le boîtier du moteur. Lorsque les deux mains

tiennent la scie, la lame ne peut pas les couper.

• Se placer d’un côté ou de l’autre de la lame de la scie, jamais en ligne avec celle-ci.

Un REBOND provoquerait le saut de la scie vers l’arrière. (Voir la rubrique relatives aux

cause de rebonds et à leur prévention.)

• Ne pas placer les doigts sous la pièce. Le protecteur ne protège pas les doigts de la

lame sous la pièce.

• Vérifier le bon fonctionnement du protecteur inférieur avant chaque utilisation. Ne

jamais se servir de la scie lorsque le protecteur inférieur est coincé et qu’il se

referme instantanément. Ne jamais fixer ni attacher le protecteur inférieur en

position ouverte. En cas de chute accidentelle de la scie, le protecteur inférieur peut être

tordu. Le soulever à l’aide du ressort de rappel et s’assurer de son bon fonctionnement,

vérifier s’il ne touche pas à la lame ou à tout autre composant à tous les angles et toutes

les profondeurs de coupe.

• Vérifier le fonctionnement et l’état du ressort du protecteur inférieur. Lorsque le

ressort et le protecteur ne fonctionnent pas bien, il faut les réparer avant d’utiliser

l’outil. Des pièces endommagées, des dépôts gluants ou une accumulation de débris

peuvent causer le mauvais fonctionnement du protecteur inférieur.

• Le protecteur inférieur se soulève manuellement seulement pour effectuer des

coupes particulières (comme des coupes en retrait ou des coupes mixtes). Se servir

du ressort de rappel afin de soulever le protecteur inférieur. Dès que la lame entre en

contact avec le matériau, il faut le relâcher le protecteur inférieur. Pour toutes les autres

coupes, le protecteur inférieur doit fonctionner automatiquement.

• Toujours s’assurer que le protecteur inférieur couvre la lame avant de déposer la

scie sur l’établi ou le plancher. Si la lame tourne et qu’elle n’est pas recouverte, la scie

se déplacera vers l’arrière en découpant tout sur son chemin. Vérifier le temps

d’immobilisation complète de la lame après avoir relâché l’interrupteur.

• NE JAMAIS tenir la pièce à couper dans les mains ni sur les jambes. Il est essentiel de

bien soutenir la pièce afin de minimiser les risques de blessures, de coincement de la lame

ou de perte de maîtrise de l’outil.

• Saisir l’outil par ses surfaces de grippe isolées lorsqu’on découpe et que l’outil

pourrait entrer en contact avec un fil sous tension caché ou son propre cordon. Le

contact avec des fils sous tension rend les pièces métalliques à découvert de l’outil sous

tension et présente des risques d'électrocution.

• Toujours utiliser un guide de refente ou un guide à rebord droit pour effectuer des

coupes de refente. On améliore de la sorte la précision de la coupe et on minimise les

risques de coincement de la lame.

• Toujours utiliser des lames de dimensions appropriées et à trou d’arbre de formes

appropriées (en forme de diamant ou de cercle). Des lames ne correspondant pas aux

accessoires de montage de l’outil auront un mouvement excentrique et entraîneront la

perte de maîtrise de l’outil.

• Ne jamais utiliser des rondelles ou des boulons endommagés ou inappropriés pour

la lame. Les rondelles et boulons de lame ont été conçus spécifiquement pour la scie afin

d’en optimiser le rendement et la sûreté.

CAUSE DE REBONDS ET MESURES DE PRÉVENTION

• Le rebond est une réaction soudaine au coincement, à la torsion ou au mauvais alignement

de la lame qui cause le soulèvement incontrôlable de la scie hors de la pièce et vers

l’arrière.

• Lorsque la lame est coincée dans la voie qui se referme, elle bloque et le moteur réagit en

faisant reculer rapidement la scie vers l’utilisateur.

• Lorsque la lame est tordue ou mal alignée dans la coupe, les dents à l’arrière de la lame

peuvent s’enfoncer sur le dessus du matériau et faire sortir la lame de sa trajectoire vers

l’arrière.

• Une mauvaise utilisation de l’outil ou le non-respect des consignes causent les rebonds et

on peut y remédier en prenant les mesures appropriées suivantes.

• Bien saisir l’outil des deux mains et placer le corps et les bras de manière à résister

aux forces de rebond. L’utilisateur peut maîtriser ces forces en prenant les mesures

appropriées.

• Lorsque la lame se coince ou ne coupe plus, peu importe la raison, relâcher la

détente et laisser la scie dans le matériau sans la bouger jusqu’à l’immobilisation

complète de la lame. Ne jamais tenter de retirer la scie du matériau ni de la faire

reculer lorsque la lame tourne car cela présente des risques de rebond. Vérifier le

problème et y remédier.

• Lorsqu’on démarre de nouveau la scie dans le matériau, centrer la lame dans la voie

et s’assurer que les dents de la lame ne sont pas en contact avec le matériau. Si la

lame est coincée, il y a risque de rebond au moment du redémarrage.

• Soutenir les grands panneaux afin de minimiser les risques de coincement de la

lame et de rebonds. Les grands panneaux ont tendance à s’affaisser sous leur propre

poids. Les éléments de soutien doivent être placés sous le panneau de chaque côté, près

de la ligne de coupe et du rebord du panneau.

• Ne pas utiliser une lame émoussée ou endommagée. Une lame mal affûtée ou réglée

donne une voie étroite et cause de la friction, le coincement de la lame et des risques de

rebond.

• Les leviers de verrouillage du réglage de la profondeur et de l’angle de coupe

doivent être serrés et fixés avant d’effectuer la coupe. Lorsque les réglages sont

modifiés en cours de coupe, il y a risque de coincement de la lame et de rebonds.

• Faire preuve d’une extrême prudence lors de coupes en retrait dans des murs

existants ou à tout autre endroit qui cache la face arrière. La lame pourrait alors couper

des objets qui présentent des risques de rebonds.

L’étiquette de l’outil peut comporter les symboles suivants.

V ....................................volts A..........................ampères

Hz ..................................hertz W ........................watts

min..................................minutes ......................courant alternatif

................................courant continu

n

o ........................sous vide

....................................

Construction de classe II

........................borne de mise à la

minute

..................................symbole d´avertissement .../min ..................tours ou courses

à la minute

MESURES DE SÉCURITÉ ADDITIONNELLES : Scies circulaires

AVERTISSEMENT

::

Certains outils, tels que les sableuses électriques, les scies, les

meules, les perceuses ou certains autres outils de construction, peuvent soulever de

la poussière contenant des produits chimiques susceptibles d’entraîner le cancer,

des malformations congénitales ou pouvant être nocifs pour le système reproductif.

Parmi ces produits chimiques, on retrouve :

• le plomb dans les peintures à base de plomb;

• la silice cristalline dans les briques et le ciment et autres produits de maçonnerie;

• l’arsenic et le chrome dans le bois de sciage ayant subi un traitement chimique (CCA).

Le risque associé à de telles expositions peut varier selon la fréquence avec laquelle on

effectue ces travaux. Pour réduire l’exposition à de tels produits, il faut travailler dans un

endroit bien ventilé et utiliser l’équipement de sécurité approprié tel un masque anti-poussières spécialement conçu pour filtrer les particules microscopiques.

• Éviter tout contact prolongé avec la poussière soulevée par cet outil ou autres outils

électriques. Porter des vêtements de protection et nettoyer les parties exposées du

AVANT DE RETOURNER CE PRODUIT POUR QUELQUE

RAISON QUE CE SOIT, COMPOSER LE

1-800-544-6986

AVANT D’APPELER, AYEZ EN MAIN LE N° DE CATALOGUE ET LE CODE DE DATE. DANS LA PLUPART

DES CAS, UN REPRÉSENTANT DE BLACK & DECKER PEUT RÉSOUDRE LE PROBLÈME PAR

TÉLÉPHONE. SI VOUS AVEZ UNE SUGGESTION OU UN COMMENTAIRE, APPELEZ-NOUS. VOS

IMPRESSIONS SONT CRUCIALES POUR BLACK & DECKER.

M

M

ERCI

ERCIDD

’

’

AAVOIR

VOIR

CHOISI

CHOISI

F

F

IREST

IREST

ORM

ORM

! V

! V

ISITEZ

ISITEZ

WWW

WWW

.F

.F

IREST

IREST

ORMT

ORMT

OOLS

OOLS

.

.

COM

COM

/P

/P

RODUCT

RODUCT

R

R

EGISTRA

EGISTRA

TION

TION

POUR

POUR

ENREGISTRER

ENREGISTRER

VOTRE

VOTRE

NOUVEAU

NOUVEAU

PRODUIT

PRODUIT

.

.

CONSERVER CE MANUEL POUR UN USAGE ULTÉRIEUR.

Clé de la lame

Page 5

corps avec de l’eau savonneuse. S’assurer de bien se protéger afin d’éviter d’absorber

par la bouche, les yeux ou la peau des produits chimiques nocifs.

AVERTISSEMENT : cet outil peut produire et répandre de la poussière susceptible de

causer des dommages sérieux et permanents au système respiratoire. Toujours utiliser

un appareil respiratoire anti-poussières approuvé par le NIOSH ou l’OSHA. Diriger les

particules dans le sens opposé du visage et du corps.

MISE EN GARDE : porter un dispositif de protection personnel anti-bruit approprié

durant l’utilisation. Sous certaines conditions et pendant toute la durée de l’utilisation, le

bruit émanant de ce produit pourrait contribuer à la perte d’audition.

• Lorsque le protecteur inférieur se bloque sur une surface sous le niveau du

matériau découpé, l’utilisateur peut perdre momentanément la maîtrise de l’outil. La

scie peut alors se soulever partiellement hors de la coupe ce qui augmente les risques de

torsion de la lame. S’assurer qu’il y a suffisamment de jeu sous le matériau.

• Lorsqu’il faut soulever manuellement le protecteur inférieur, se servir du ressort de

rappel.

• S’ASSURER QUE LES LAMES SONT PROPRES ET AFFÛTÉES. On minimise les

risques de blocage et de rebond en se servant de lames affûtées. L’utilisation d’une lame

émoussée ou sale augmente la charge de la scie. L’utilisateur pousse alors davantage sur

la scie ce qui favorise la torsion de la lame.

DANGER : ÉLOIGNER LES MAINS DE LA ZONE DE COUPE. Éloigner les mains de

la lame. Ne jamais placer les mains devant ou derrière le trajet de la lame pendant la coupe.

Ne pas placer les mains sous le matériau lorsque la lame tourne. Ne pas tenter d’enlever

des matériaux coupés lorsque la lame tourne.

• SOUTENIR LES GRANDS PANNEAUX. Il faut soutenir les grands panneaux de la façon

illustrée à la figure 1 du présent guide afin de minimiser les risques de blocage de la lame

et de rebond. Lorsque la scie doit reposer contre le panneau pendant la coupe, il faut la

placer sur la partie la plus large du panneau alors qu’on en coupe la partie la plus étroite.

• UTILISER LES LAMES ET LES FERRURES APPROPRIÉES LORSQU’ON INSTALLE

UNE LAME. Ne pas utiliser une lame dont le diamètre du trou n’est pas correct. Ne jamais

utiliser de rondelles ni de boulons de lames défectueux ou inappropriés. Respecter les

consignes d’installation de la lame.

• RÉGLAGES. Avant de couper, s’assurer que les réglages de la profondeur et de l’angle de

coupe sont bien serrés.

• BIEN SOUTENIR ET FIXER LE MATÉRIAU. S’assurer que le matériau à découper est

fixé (fig. 3), bien soutenu et en équilibre sur une surface de travail solide, stable et de

niveau. Soutenir le matériau de sorte que la portion large du patin de la scie repose contre

la portion du matériau qui ne tombe pas après la coupe. Ne jamais retenir le matériau

découpé à la main (fig. 4). Cela présente des risques de rebond en raison du coincement

de la lame. Laisser les deux mains sur la scie en tout temps.

• DEMEURER VIGILANT ET GARDER LE CONTRÔLE DE LA SITUATION. Se placer d’un

côté de la scie. Toujours la saisir fermement et la maîtriser des deux mains. Ne pas

modifier sa prise ni sa position lorsque la scie fonctionne. Éviter d’être blessé par les bouts

de matériau découpés.

• LA FENÊTRE D’OBSERVATION DOIT ÊTRE EN PLACE EN TOUT TEMPS et elle doit

reposer contre le protecteur supérieur de la scie en tout temps lorsqu’on utilise la scie.

AVERTISSEMENT : Ne pas se servir de la scie lorsque la fenêtre est endommagée ou

lorsqu’elle ne repose plus en place. En confier la réparation au personnel du centre de

service autorisé Black & Decker de la ¸région.

• METTRE LA SCIE HORS TENSION et la débrancher avant de nettoyer la fenêtre

d’observation de la lame.

MESURES DE PRÉCAUTION CONTRE LES REBONDS

• QU’EST-CE QU’UN REBOND? Il s’agit d’un mouvement soudain de la scie, pendant une

coupe, vers l’utilisateur qui peut causer de graves blessures.

DANGER : RELÂCHER IMMÉDIATEMENT L’INTERRUPTEUR EN CAS DE COINCEMENT

DE LA LAME OU DE BLOCAGE DE LA SCIE.

• CAUSES DE REBONDS la lame de la scie est coincée, tordue ou bloquée pendant la

coupe, ou la scie cale. Lorsque la lame est tordue ou mal alignée dans la coupe, les dents à

l’arrière de la lame peuvent s’enfoncer sur le dessus du matériau et faire sortir la lame de sa

trajectoire vers l’arrière en direction de l'opérateur.MESURES POUR MINIMISER LES

RISQUES DE REBONDS

• Saisir fermement la scie à l’aide des deux mains en tout temps.

• Demeurer vigilant – contrôler la situation.

• Soutenir les matériaux longs qui dépassent. En effet, pendant la coupe, le matériau

s’affaisse et risque de coincer la lame.

• Soutenir les grands panneaux de la façon illustrée à la figure 1. Les matériaux soutenus de

la manière montrée à la figure 2 présentent des risques de coincement de la lame.

• Éviter de découper au-dessus de la tête. Le matériau peut s’affaisser et coincer la lame.

• S’assurer que les lames sont propres et affûtées.

• Utiliser un guide de refente ou à rebord droit pour effectuer des coupes de refente.

S’assurer que le matériau découpé ne s’affaisse pas ou ne se tord pas car cela pourrait

coincer la lame et causer un rebond.

• Ne pas forcer l’outil. Différents facteurs inhérents au bois (comme les nœuds, la dureté, la

résistance, la teneur en humidité, le traitement sous pression et le degré de séchage)

peuvent charger lourdement la scie et la faire caler. Il faut pousser lentement le cas

échéant.

• Ne pas retirer la scie de la coupe lorsque la lame tourne.

• Attendre le plein régime de la scie avant de mettre la lame en contact avec le matériau à

découper. Le démarrage de la scie avec la lame en contact avec le matériau ou avec la

lame poussée dans la coupe présente des risques de blocage ou de mouvement soudain

vers l’arrière de la scie.

• Ne jamais soulever la scie lors d’une coupe en biseau. Cela coince et bloque la lame.

• Toujours fixer le matériau afin d’en empêcher le mouvement pendant la coupe.

• Ne pas forcer la scie vers la ligne de coupe lorsqu’on s’en éloigne. Cela présente des

risques de rebonds. Il faut plutôt arrêter la scie et attendre l’immobilisation complète de la

lame. Retirer alors la scie de la ligne de coupe et recommencer sur la ligne de coupe.

• Régler la profondeur de coupe de sorte qu’une dent de la lame dépasse sous le matériau

(fig. 6).

• Ne pas faire reculer une lame en mouvement dans la coupe. Cela présente des risques de

torsion de la lame. Le rebord arrière de la lame s’enfoncerait alors dans le matériau et

ferait ressortir la scie du matériau vers l’utilisateur.

• Éviter de couper des clous. Vérifier s’il y en a dans le matériau et les retirer au préalable.

• Certaines essences de bois renferment des agents de conservation (comme de l’arséniate

de cuivre et de chrome) qui peuvent être toxiques. Lorsqu’on doit couper de tels

matériaux, prendre des mesures supplémentaires afin d’éviter d’inhaler les vapeurs

toxiques et de minimiser les contacts avec la peau.

INFORMATION CONCERNANT LE CAPUCHON DU BLOC-PILE

Un capuchon est fourni avec le bloc-pile en vue d’être utilisé chaque fois qu’on retire ce

dernier de l’outil ou du chargeur en vue de le ranger ou de le transporter; enlever le

capuchon avant de remettre le bloc-pile dans le chargeur ou

dans l’outil.

AVERTISSEMENT : S’assurer, au moment de ranger ou de transporter un bloc-piles ou

une pile, qu’aucun objet métallique n’entre en contact avec leurs bornes à découvert de

celui-ci. Par exemple, il faut éviter de placer un bloc-piles ou une pile sans capuchon dans

un tablier, une poche, une boîte à outils ou un tiroir (etc.) contenant des objets tels que

des clous, des vis ou des clés, car tout contact entre les bornes à découvert et un objet

métallique comme une clé, une pièce de monnaie, un outil à main etc. pourrait causer un

incendie. En effet, les règlements américains Hazardous Material Regulations (HMR) du

US Department of Transportation interdisent le transport d’un bloc-piles ou d’une pile dans

tout moyen de transport commercial ou aéronef (que ce soit dans une valise ou le bagage

de cabine) SAUF s’ils sont bien protégés contre les courts-circuits. On doit donc s’assurer,

lorsqu’on transporte un bloc-piles ou une pile séparément, de bien protéger et isoler les

bornes contre tout matériau qui risque d’entrer en contact avec eux et de causer un

court-circuit.

MESURES DE SÉCURITÉ IMPORTANTES

• CONSERVER CES DIRECTIVES.

• Bien lire toutes les directives et tous les avertissements qui se trouvent sur (1) le

chargeur, (2) l’ensemble de piles et (3) l’outil avant d’utiliser le chargeur.

DANGER : Les bornes du chargeur sont sous une tension de 120 volts. Ne pas les

examiner avec un objet conducteur; cela présente des risques de secousses électriques.

DANGER : Ne pas placer dans le chargeur un ensemble de piles craqué ou endommagé;

cela présente des risques de secousses électriques.

MISE EN GARDE : Ne jamais tenter d’ouvrir un ensemble de piles. Lorsque le boîtier en

plastique craque ou se casse, en confier le recyclage à un centre de service.

AVERTISSEMENT : Ne laisser aucun liquide s’infiltrer dans le chargeur car cela

représente des risques de secousses électriques.

MISE EN GARDE : Afin de réduire les risques de blessures, charger seulement des piles

rechargeables Black & Decker. Tout autre type de piles peut exploser; ce qui présente des

risques de blessures et de dommages.

• Pour faciliter le refroidissement de l’ensemble de piles après s’en être servi, éviter de

placer le chargeur ou l’ensemble de piles dans un endroit chaud comme une remise en

métal ou une remorque non isolée.

• Protéger le chargeur de la pluie ou de la neige.

• L’utilisation d’un accessoire non recommandé ni vendu par Black & Decker comporte des

risques d’incendie, de secousses électriques ou de blessures.

• L’utilisation du chargeur pour tout ensemble de piles autres que les ensembles

rechargeables Black & Decker comporte des risques d’incendie et de secousses électriques.

• Pour minimiser les risques de dommages au cordon et à sa fiche, débrancher l’appareil

en tirant sur la fiche plutôt que sur le cordon.

• Placer le cordon de sorte qu’on ne puisse pas marcher ni s’accrocher dessus et qu’il ne

soit pas autrement sujet aux dommages et aux contraintes.

• Ne pas utiliser de rallonge à moins que cela ne soit absolument nécessaire, car l’usage

d’une rallonge ayant une puissance inadéquate pourrait causer des risques d’incendie, de

choc électrique ou d’électrocution. Si une rallonge est nécessaire, s’assurer que :

• les broches de la prise de la rallonge sont de mêmes nombre, taille et forme que

celles de la prise du chargeur.

• la rallonge est correctement câblée et en bonne condition, et que le calibre du fil est

suffisant pour l’intensité nominale de courant alternatif du chargeur comme spécifié

ci-dessous.

Pour la sécurité de l’utilisateur, utiliser une rallonge du calibre AWG approprié. Plus le

calibre est petit, plus la capacité est grande; autrement dit, une rallonge de calibre 16 est

plus puissante qu’une rallonge de calibre 18. Lorsqu’on utilise plusieurs rallonges pour

obtenir la longueur voulue, s’assurer que chacune d’elles présente les valeurs

minimales requises.

CALIBRE MINIMAL (AWG) RECOMMANDE DES RALLONGES

LONGUEUR TOTALE DE LA RALLONGE (EN METRES)

7,6 15,2 22,8 30,4 38,1 45,7 53,3

CALIBRE AWG

18 18 16 16 14 14 12

• La ventilation du chargeur se fait par les fentes sur le dessus et le dessous de l’appareil.

Ne rien déposer sur le chargeur et ne pas déposer ce dernier sur une surface qui

pourrait en bloquer les orifices car cela risque de provoquer la surchauffe de l’appareil.

Éloigner le chargeur des sources de chaleur.

• Ne jamais se servir d’un chargeur dont le cordon ou la fiche sont endommagés. Les

remplacer immédiatement.

• Ne jamais se servir d’un chargeur qui a encaissé un coup brusque, qui est tombé ou qui

est endommagé. Le faire vérifier à un centre de service autorisé.

• Ne jamais démonter le chargeur. N’en confier la réparation ou l’entretien qu’à un centre

de service autorisé. Le remontage non conforme du produit comporte des risques

d’incendie ou de secousses électriques.

• Le chargeur est conçu pour fonctionner sur une alimentation domestique standard. Ne

pas essayer de s’en servir sous toute autre tension.

• Pour minimiser les risques de secousses électriques, débrancher le chargeur avant de le

nettoyer. Le risque n’est pas éliminé en enlevant l’ensemble de piles du chargeur.

• NE JAMAIS raccorder deux chargeurs l’un à l’autre.

• NE PAS ranger le produit dans un endroit où la température peut atteindre ou dépasser

40 °C (105 °F) (comme dans une remise métallique en été).

• Ne pas incinérer les piles, car elles peuvent exploser en présence de flammes. Les

cellules peuvent subir une fuite légère par suite d’un usage extrême, du chargement ou

d’une exposition à certaines températures; cela n’indique pas un problème. Cependant, si

le scellant externe est percé et le liquide entre en contact avec la peau, on doit :

a. se laver rapidement la partie du corps touchée avec de l’eau savonneuse;

b. neutraliser l’effet au moyen d’un acide doux tel que du jus de citron ou du vinaigre;

c. si les yeux sont touchés, les rincer à fond avec de l’eau propre pendant au moins

10 minutes et consulter immédiatement un médecin.

REMARQUE AUX FINS MÉDICALES : ce liquide contient une solution composée de 25

à 35 % d’hydroxyde de potassium.

CONSERVER CES MESURES

INTRODUCTION

LIRE ET COMPRENDRE TOUTES LES INSTRUCTIONS DE CE MANUEL AVANT DE

TENTER DE RECHARGER LE BLOC-PILES DE VOTRE APPAREIL.

Ce Chargeur a été conçu pour fonctionner sur 120 volts de courant alternatif, à une puissance

de 60 Hz. Ne pas utiliser sur courant continu (CC) ou tout autre voltage. La durée de charge

peut prendre de 3 à 6 heures selon le type de bloc-piles et sa condition.

MÉTHODE DE CHARGEMENT

1. Brancher le chargeur dans la prise appropriée.

2. Insérer 1 ou 2 piles dans le chargeur (Fig. A).

REMARQUE : La durée de charge est la même pour une ou plusieurs piles.

S’assurer que la pile est insérée à fond dans le chargeur. Le voyant rouge de charge

s’allumera indiquant qu’il y a contact entre la pile et le chargeur. Le voyant restera allumé

tant que la pile sera dans le chargeur et que le chargeur sera branché dans une prise

alimentée en courant. Il NE clignotera pas, NE s’éteindra pas ou NE changera pas de

couleur en fin du cycle de charge.

Sortir le bloc-piles du chargeur et le mettre dans l’outil. REMARQUE : Pour sortir le blocpiles de l’outil, enfoncer le bouton de dégagement situé à l’arrière du bloc-piles

(figure B) et le retirer.

BLOC-PILES LAISSE DANS LE CHARGEUR

Le chargeur et son bloc-piles peuvent rester connectés avec le voyant rouge allumé

indéfiniment. Le chargeur maintiendra la pile pleinement chargée.

REMARQUE : Un bloc-pile perdra graduellement sa charge s’il est laissé hors du chargeur.

Si le bloc-pile n’a pas été maintenu en mode de maintenance de charge, il peut être

nécessaire de le recharger avant chaque utilisation. Un bloc-pile peut aussi perdre sa

charge graduellement s’il est laissé dans un chargeur qui n’est pas branché à une source

de courant alternatif appropriée.

NOTES IMPORTANTES RELATIVES AU CHARGEMENT

1. Pour optimiser la durée et le rendement de l’ensemble de piles, il est préférable de le

charger à des températures variant entre 18 °C et 24 °C (65 °F et 75 °F). NE PAS charger l’ensemble de piles lorsque la température ambiante est inférieure à 4,5 °C (40 °F) ou

supérieure à 40,5 °C (105 °F). Cette mesure est importante et aide à prévenir les risques

de graves dommages à l’ensemble de piles.

2. Pendant le chargement, l’ensemble de piles et le chargeur peuvent devenir chauds au

toucher. Il s’agit d’une situation normale qui ne pose aucun problème.

3. Lorsque l’ensemble de piles n’est pas bien chargé, (1) vérifier l’alimentation de la prise en y

branchant une lampe ou un autre appareil, (2) vérifier si la prise est reliée à un interrupteur

pour l’éclairage qui met la prise hors circuit lorsqu’on éteint les lumières, (3) déplacer

l’ensemble de piles et le chargeur dans une pièce où la température ambiante se situe

entre 18 °C et 24 °C (65 °F et 75 °F), (4) si le problème persiste, il faut confier l’outil,

l’ensemble de piles et le chargeur au centre de service de la région.

4. Il faut charger l’ensemble de piles lorsqu’il ne fournit plus la puissance nécessaire pour

effectuer les tâches avec autant de facilité qu’auparavant. NE PLUS S’EN SERVIR dans

ces conditions. Suivre les directives relatives au chargement. On peut également charger

en tout temps un ensemble de piles chargé en partie.

5. Les ensembles de piles Black & Decker portant la mention «NiMH» devraient seulement

être utilisés avec des chargeurs portant la mention «NiMH» ou «NiCd/NiMH».

6. Dans certaines conditions, lorsque le chargeur est branché, des corps étrangers peuvent

court-circuiter les contacts de chargement à découvert. Il faut donc éloigner les creux de

chargement du chargeur les corps étrangers de nature conductive, comme la laine d’acier,

le papier d’aluminium ou tout autre accumulation de particules métalliques. Toujours

débrancher le chargeur lorsqu’il n’y a pas d’ensemble de piles dans le chargeur et avant de

le nettoyer.

Capuchon du bloc-pile

Page 6

7. Ne pas immerger le chargeur de pile dans l’eau ou tout autre liquide.

ASSEMBLAGE / RÉGLAGE

AVERTISSEMENT : toujours retirer la pile de l'outil avant de procéder aux opérations

suivantes.

INSTALLATION ET RETRAIT DE LA LAME

REMARQUE : la première fois qu'on retire l'écrou de rétention de la lame alors que

cette dernière n'est pas encore installée, il pourrait s'avérer nécessaire de mettre la

clé de réglage sur l'écrou et le frapper d'un coup sec vers la gauche.

Escamoter le protège-lame inférieur et assembler la lame et les rondelles de fixation, tel

qu'illustré à la figure 8. Afin d'empêcher la lame de tourner pendant qu'on serre la vis, on doit

soulever le protège-lame inférieur et déposer la lame sur une retaille, tel qu'illustré à la figure

9A; en s'enfonçant dans le bois, les dents empêcheront la lame de bouger. Utilisant la clé

fournie, serrer fermement la vis de serrage de la lame. La figure 9B présente une autre

façon de serrer et de desserrer la lame en insérant un tournevis dans le trou de cette

dernière pour l'empêcher de bouger. REMARQUE : la clé de réglage de la lame est rangée

dans la plaque amovible, tel qu'illustré à la figure 8.

RÉGLAGE DE LA PROFONDEUR DE COUPE

Utilisant le levier approprié (figures 5 et 6), on peut régler la profondeur de coupe à la valeur

désirée; serrer fermement ce levier une fois le réglage effectué.

RÉGLAGE DE L'ANGLE DE BISEAU

Utilisant le bouton approprié et l'échelle de biseau (figure 7), on peut régler l'angle de biseau

à la valeur désirée; serrer fermement ce bouton une fois le réglage effectué.

RÉGLAGE DE LA PLAQUE AMOVIBLE