Page 1

HAMMER

TOOLS

STAR DRILLS

F®r V4" to V* hole sizes (Taper "A" Shank). Use witn and 1" Ham

mers. Can also be used with IVii" Hammer, (requires an extra Chuck

Wrench No. 22749).

Cat

Ni.

Till

7168

7160

7189

7161

9364

7170

For 11/18" to IVi" hole sizes (Taper “B"

IViz" Hammer. Can also be used with V

Chuck Wrench No. 23806).

24873

23081

23082

23083

7172

7087

9388

§390

For IV4“ to 2" hole sizes (Shank No. 2). Use with IW’

Requires additional Turning Handle No. 21726.

21942

21943

21944

21948

-----

Point

Diam.

V4“"

5/16"

%“

7/16“

Ml”

9/16“

11/16“

13/16“

7/fe“

IV4“ 18“

IV4“ 30“

1%“ 18“

m”

Over

all

Lgth.

5W

5“

5“

5“

9"

18“

9“

9“

9“

18“

24“

9“

9“

18“

24“

18“

Qty.

in

box

6

6

6

6

6

1

6

1

1

1

1

I

Cat

No.

7162

9372

7171

7163

9380

9382

50058

50062

Shank). Mainly for use with

Hammer (requires additional

7173

15/16“

7098

9396

9398

10751

10981

50065

50069

21947

21948

21950

21951

Point

Diam.

%“ 9“

w 18“

11/16“

%“

1“

1“

1“

r

m"

IW'

1V4 "

m“

m”

1¥4“

2“

2“

Over

all

Lgth.

9"

9“

18"

24*

9"

9“

9“

9“

18“

24“

12“

24“

14

14“

30“

18“

18“

30“

hammers.

CHUCK WRENCHES, HEAD

& TURNING HANDLE

No. 22587 Chuck

Wraneh — shown

with No. 17746

Dust Shield

attached.

Cat

No.

22587

23808

22749

22754 Chuck Wrench

22510

21728

item

Chuck Wrench

Chuck Wrench

Chuck Wrench

Chuck Head

Turning Handle*

Shank

No.

1

1

2

2

2

No. 22510 Chuck

Head with No.

21726 T urnine

Handle.

Takes

Use with Hammer

Taper

A

V2” & 1“

B

W & 1“

A

B

i

1^“

m”

m”

m”

Scaling

Chisels

No. 11108

Cold

Chisels

Flat

Wood

Chisels

Bushing No. 11624

Seam No. 17232

Clay

Spade

Tool

Blanks

%"x8"

9"

No. 11107

10"

No. 22887

2W'xl2"

No.7095

7/fe"x9"

No. §405

7/fe"K20"

No. 9039

2“x9"

N@.9040

9“

No. 9035

9“

No. 53557

4VS?"

No. 7267

12"

ACCESSORIES

Each accessory and attachment

found suitable for use with

your tool is identified in this

owner’s manual.

CAUTION; The use of any other

accessory or attachment might

be Hazardous.

IMPORTANT

To assure product SAFETY and

RELIABILITY repairs, mainte

nance (excluding brush inspec

tion & replacement) and ad

justments should be performed

by BLACK & DECKER Service

Center or other qualified service

organizations, always using

BLACK & DECKER replacement

parts.

SAFETY RULES FOR POWER TOOLS

1 KEEP WORK AREA CLEAN. Cluttered areas and benches invite accidents.

2. AVOID DANGEROUS ENVIRONMENT. Don't expose power tools to rain. Don’t use power tool in

damp or wet locations. And keep work area well lit.

3. KEEP CHILDREN AWAY. All visitors should be kept safe distance from work area.

4. STORE IDLE TOOLS. When not in use, tools should be stored in dry, high or locked*up place-

out of reach of children.

5. DON'T FORCE TOOL. It will do the job better and safer at the rate for which it was designed.

6. USE RIGHT TOOL. Don't force small tool or attachment to do the job of a heavy duty tool.

7. WEAR PROPER APPAREL. No loose clothing or jewelry to get caught in moving parts. Rubber

gloves and footwear are recommended when working outdoors.

8. USE SAFETY GLASSES with most tools. Also face or dust mask if cutting operation is dusty.

9. DON'T ABUSE CORD. Never carry tool by cord or yank it to disconnect from receptacle. Keep

cord from heat, oil and sharp edges.

10. SECURE WORK. Use clamps or a vise to hold work. It’s safer than using your hand and it

frees both hands to operate tool.

11. DON'T OVERREACH. Keep proper footing and balance at all times.

12. MAINTAIN TOOLS Will CAil. Keep tools sharp at all times, and clean for best and safest

performance. Follow instructions for lubricating and changing accessories.

13. DISCONNECT TOOLS. When not in use, before servicing; when changing accessories such as

blades, bits, cutters, etc.

14. REMOVE ADJUSTING KEYS AND WRENCHES. Form habit of checking to see that keys and

adjusting wrenches are removed from tool before turning it on.

15. AVOID ACCIDENTAL STARTING. Don't carry plugged-in tool with finger on switch. Be sure

switch is off when plugging in.

16. OUTDOOR USE EXTENSION CORDS—When tool is used outdoors, use only extension cords

suitable for use outdoors and so marked.

17. DO NOT OPERATE portable electric tools in gaseous or explosive atmospheres. Motors in

these tools normally spark, and the sparks might ignite fumes.

ADDITIONAL SAFETY RULES WHEN USING HAMMERS

1. Wear safety goggles or other eye protection.

2. Wear ear protectors when hammering for extended periods.

3. Always lock the too! retainer before using Hammer.

4. Don’t overreach with the Hammer. Maintain a firm, balanced working stance. When

necessary, use only properly positioned, safe platforms, ladders and scaffolds, to do the

job SAFELY!

5. Hammer bits and tools get hot in operation. Wear gloves when touching them.

THE BLACK & DECKER MFC. CO., TOWSON, MD. 21204, U.SA. WWW/t!', electric HAMMERS

Fornì No. 44502-0?

/«rrTR77 r Pii

Printed in U.S.A.

Page 2

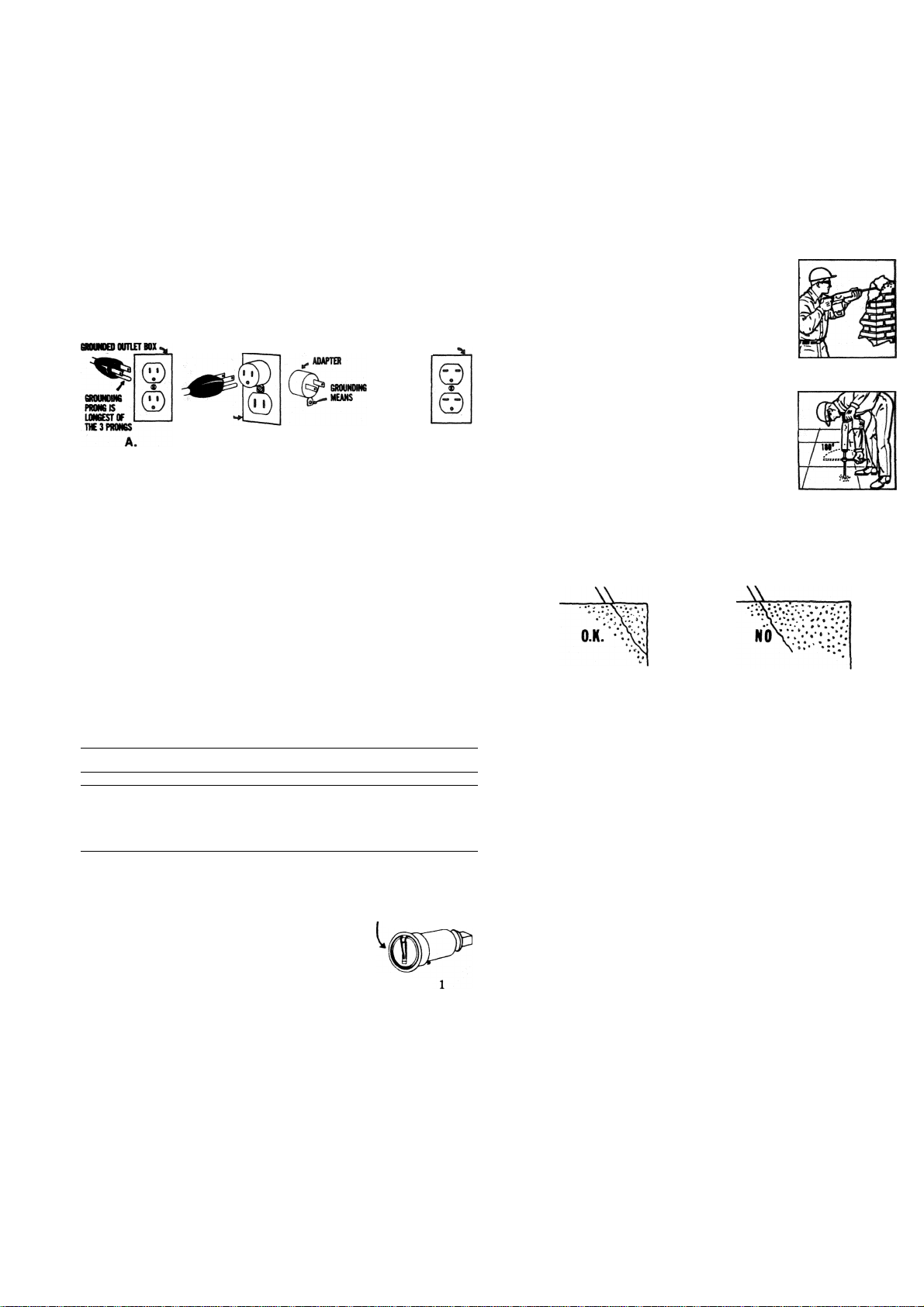

GROUNDING

This tool should be grounded while in use to protect the operator

from electric shock. The tool is equipped with an approved

three-conductor cord and three-prong grounding type plug to fit

the proper grounding type receptacle. The green (or green and

yellow) conductor in the cord is the grounding wire. Never

connect the green (or green and yellow) wire to a live terminal.

If your unit Is for use on less than 150 volts, it has a plug like

that shown in Figure A. If It is for use on 150 to 250 volts, it has

a plug like that shown in Figure D. An adapter, Figures B and C,

is available for connecting Figure A plugs to two-prong recep

tacles. The green-colored rigid ear, lug, etc,, must be connected

to a permanent ground such as a properly grounded outlet box.

No adapter is available for a plug as shown in Figure D. Adapter

shown in Figures B & C is Not for Use in Canada.

a«)U№Q) OUTLET gOK

/

GftoiMe

OUTLET BOX

B.

We recommend that you NEVER disassemble the tool or try to

do any rewiring in the electrical system. Any repairs should be

performed only by B&D Service Centers or other qualified

service organizations. Should you be determined to make a

repair yourself, remember that the green colored wire Is the

“grounding" wire. Never connect this green wire to a “live"

terminal. If you replace the plug on the power cord, be sure to

connect the green wire only to the grounding (longest) prong

on a 3-prong plug.

c.

6R0UNDIN6

PRONG IS

LOHKSTSH^

THE3PR0HGS

D.

ATTACHING HAMMER TOOLS

First, swing the Tool Retaining Spring (located in front of the

nose piece) to one side. Insert tool bit into nose piece until

shoulder on tool bit bottoms on nose piece. (NOTE: If tool bit

does not bottom, hold Hammer so that tool bit is touching the

ground, and push the Hammer sharply downward to seat the

tool bit.) Next, swing Tool Retaining Spring back into place so

that ft engages the shaft of the tool ‘bit.

OPERATION

Grasp handle of Hammer with one hand, and

the barrel of Hammer with the other hand

(see Fig. 2). If using Star Drills, grasp Ham

mer handle and the Turning Handle (see Fig.

3). Place tool in working position and depress

trigger. When using Star Drills, swing Turning

Handle in a 180° arc about 30 times per min

ute to prevent binding and to remove cuttings;

exert firm even pressure for best results.

NOTE: Use Dust Shield for all overhead

drilling.

For best demolition performance always place

the end of the bit close to an edge of the

work, breaking the work away piece by piece

(Fig. 4). Trying to break away too large a chunk may cause the

bit to get stuck in the work and may also decrease demolition

rate.

Fig. 2

Fig. 3

t

4-

EXTENSION CORD

When using the tool at a considerable distance from power

source, a 3-conductor, grounding-type extension cord of ade

quate size must be used for safety, and to prevent loss of power

and over-heating. Use the table below to determine the mini

mum wire size required in an extension cord.

Use only three wire extension cords which have three-prong

grounding-type plugs and three-pole receptacles which accept

the tool's plug. Replace or repair damaged cords.

Ampere rating

(on nameplate)

Ext. Cable length

25 ft.

50 ft.

75 ft.

100 ft.

150 ft.

200 ft.

Oto

2.0

18

18

18

18

16

16

2.10 to

3.4

18

18

18

16

14

14

3.5 to

5.10 to 7.10 to

5.0

Wire Size (A.W.G.)

18

18

16

14

12

12

7.0 12.0

18 16

16

14 12

12 10

12

10

14

—

—

12.1 to

16.0

14

12

10

—

—<

MOTOR BRUSHES

Inspect carbon brushes regularly. First, unplug

the tool, then press together the two prongs

of the Retaining Spring (see Fig. 1) and re

move spring. Unscrew brush cap and remove

brush and spring assembly. Replace when

brushes are worn down to the identifying

letter or groove, or when spring exerts insuf

ficient pressure to hold brush against com

mutator. Keep brushes clean and sliding freely

in guides.

RETAINING SPRING

Fig.

COMMERCIAL/

INDUSTRIAL USE WARRANTY

Black & Decker warrants this product for one year from the

date of purchase. We will repair without charge, any defects

due to faulty material or workmanship. Please return the com

plete unit, transportation prepaid, to any Black & Decker Ser

vice Center or Authorized Service Station listed under “Tools

Electric" in the yellow pages. This warranty does not apply to

accessories or damage caused where repairs have been made

or attempted by others.

Fig. 4

LUBRICATION

The most important point in keeping your Electric Hammer freerunning and powerful Is regular oiling. Oil cups are located in

the gear case under the switch handle. Oil liberally (several

squirts from the can) after every 3 hours of Hammer operation.

In overhead work, oil Hammer, through the nose piece rather

than through the oil cups. Excess oiling will cause some leakage

around the tool shank, but this does no damage and Hammer

will clear Itself rapidly in operation.

Black & Decker Special Hammer Oil (See Hammer Supplies,

this booklet) has special qualities for adhering to high speed

working parts and will greatly prolong the life of the tool. In an

emergency, use high grade SAE No. 30 Oil.

In from 30 days to 3 months, depending upon use, your Ham

mer sould be sent to the nearest B&D Service Branch for a

complete cleaning and replacement of lubricant In the gear case.

Your Hammer will be returned to you completely cleaned and

adjusted with new parts installed where necessary.

HAMMER SUPPLIES

Cat. No. 51315 Special Hammer Oil, 1 pint can

Cat. No. 60541 Hammer Gear Grease, 1 lb. can

Cat. No. 7276 Drift Key (To remove tapered shank bits from

chuck)

Cat. No. 10909 Tool Retaining Spring, & 1" Hammers

Cat. No. 21750 Tool Retaining Spring, IVi" Hammer

Cat. No. 17746 Dust Shield for Wrenches Nos. 22587, 23806,

and Chuck Head 22510.

Cat. No. 17747 Dust Shield for Wrenches Nos. 22749, 22854

Loading...

Loading...