Page 1

B/ack& Decken.

fl V ' f M

This booklet is provided for your convenience in

the use and care of your new Black & Decker tool.

These instructions include operation, safety pre

cautions, preventive maintenance, maintenance

and other pertinent data to assist you in assuring

long life and dependable service.

SAFETY

SEALGÜI

power tool institute

Ho. 12

SCREWDRIVER Cit. Nos.

35a402,2ll45’5/2.

2055’57a2035’№

Page 2

SAFETY RULES

FOR POWER TOOLS

1. KNOW YOUR POWER TOOL—Read owner’s manual

carefully. Learn its applications and limitations as well

as the specific potential hazards peculiar to this tool.

2. GROUND ALL TOOLS—UNLESS DOUBLE-INSUUTED.

If tool is equipped wth three-prong plug, it should be

plugged into a three-hole electrical receptacle. If adapter

is used to accommodate two-pronged receptacle, the

adapter wire must be attached to a known ground. Never

remove third prong.

3. KEEP GUARDS IN PLACE and in working order.

4. KEEP WORK AREA CLEAN. Cluttered areas and benches

invite accidents.

5. AVOID DANGEROUS ENVIRONMENT. Don't use power

tool In damp or wet locations. And keep work area well lit.

6. KEEP CHILDREN AWAY. All visitors should be kept safe

distance from work area.

7. STORE IDLE TOOLS. When not in use, tools should be

stored in dry, high or locked-up place—out of reach of

children.

8. DON'T FORCE TOOL. It will do the job better and safer

at the rate for which it was designed.

9. USE RIGHT TOOL. Don't force small tool or attachment

to do the job of a heavy duty tool.

10. WEAR PROPER APPAREL. No loose clothing or jewelry to

get caught In moving parts. Rubber gloves and footwear

are recommended when working outdoors.

11. USE SAFETY GLASSES with most tools. Also face or

dust mask if cutting operation is dusty.

12. DON'T ABUSE CORD. Never carry tool by cord or yank H

to disconnect from receptacle. Keep cord from heat, oil

and sharp edges.

13. SECURE WORK. Use clamps or a vise to hold work, ft's

safer than using your hand and it frees both hands to

operate tool.

14. DON'T OVERREACH. Keep proper footing and balance

at all times.

15. MAINTAIN TOOLS WITH CARE. Keep tools sharp at all

times, and clean for best and safest performance. Follow

Instructions for lubricating and changing accessories.

16. DISCONNECT TOOLS. When not in use, before servicing;

when changing accessories such as blades, bits, cutters,

etc.

17. REMOVE ADJUSTING KEYS AND WRENCHES. Form

habit of checking to see that keys and adjusting wrenches

are removed from tool before turning it on.

18. AVOID ACCIDENTAL STARTING: Don't carry plugged-in

tool with finger on switch.

SWITCHES

Pulling the Trigger Switch turns the tool "ON"; releasing the

trigger turns the tool "OFF" To lock switch "ON", depress

trigger, hold In locking button, and release trigger. Release but

ton and tool will stay "ON". To then turn tool "OFF", depress

and release trigger.

The reversing switch is mounted on the top of the tool and for

driving fasteners is placed in the forward position. To reverse

rotation for fastener removal, first release trigger to turn tool

"OFF", then move toggle switch back to reverse tool.

For maximum tool life avoid excessive reverse operation. For

those operations where the tool is used primarily in reverse, see

your Black and Decker Distributor or Black and Decker Service

Center.

MOTOR

Your Black and Decker tool is powered by a B&D built motor.

Be sure your power supply agrees with nameplate marking.

Volts AC means Alternating Current (25 to 60 cycles) ONLY.

VOLTS AC/DC means it will also operate on Direct Current.

Voltage variation of more than 10% will cause loss of power

and over-heating. All B&D tools are factory-tested; if this tool

does not operate, check the following: Supply line for blown

fuses; plug and receptacle for contact; carbon brushes for

contact.

COMMUTATOR AND BRUSHES

Inspect carbon brushes often. Replace when brushes are worn

down to the identifying letter or groove or when spring exerts

insufficient pressure to hold brush against commutator. Keep

brushes clean and sliding freely in guides. Inspect commutator

for dirt and exessive wear. If dirty or rough, clean lightly with

very fine sandpaper (not emery cloth). If badly worn or

grooved, send tool to our nearest service station for repair

(see back page).

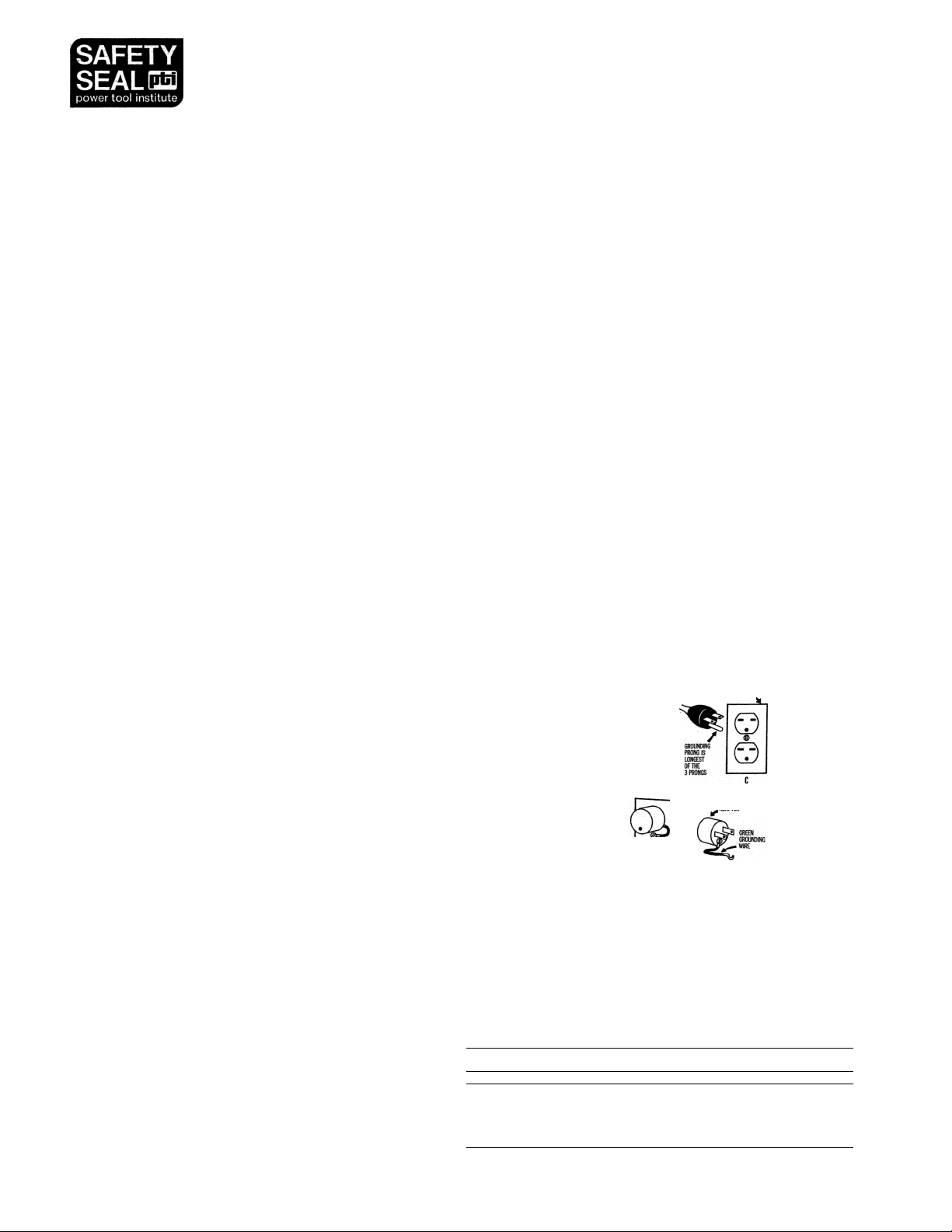

GROUNDING

These units are equipped with approved 3-conductor cord and

3-prong grounding type attachment plug to be used with the

proper grounding type receptacle, in accordance with the

National Electrical Code and Canadian Electrical Code.

IF YOUR UNIT REQUIRES LESS THAN 150 VOLTS IT HAS A

PLUG THAT LOOKS LIKE FIG. "A". It will fit directly into the

proper type of 3-wire grounding receptacle. The unit is then

grounded automatically each time it Is plugged in.

Shown in Fig. "B" is a special grounding adaptor (not allowed

in Canada by the Canadian Electrical Code) which is available

from your dealer and will permit using a 2-wire receptacle.

The green grounding wire extending from the side of the

adapter must be connected to a PERMANENT GROUND.

IF THE UNIT REQUIRES FROM 150 TO 250 VOLTS, IT HAS A

PLUG LIKE FIGURE "C". No adapter is available and it should

be used in the proper standard matching 3-wire grounding

receptacle.

fflOMIDOllTlBll »

WlM»(WTLETKa ■

©

nWNGB

CffW

CABLE

The cable is the "life line" of your tool—keep it clean by

wiping it off occasionally. Keep it out of oils and greases which

ruin the rubber. Coil it neatly when not in use and avoid

dragging it across sharp surfaces or using it as a handle to lift

the tool. When using the tool at a considerable distance from

power source, an extension cable of adequate size must be

used to prevent loss of power and over-heating. Use the table

below for 115-volt tools. For 220-volt tools, use wire size corres

ponding to an extension length of V2 the contemplated length.

Ampere rating

(on nameplate) 2.0

Ext. Cable length Wire Size (A.W.G.)

25 ft. 18

50 ft. 18 18

75 ft.

100 ft.

150 ft.

200 ft.

©

aKUWEDOOTiireox.

2.10 to 3.5 to

0 to

18 18

18

16

16 14

3.4

16

14

11

5.10 to 7.10 to 12.1 to

7.0

5.0

18

18

18 16 14

16

14 12

12

___ ___

12.0

18

14

12

10

16.0

16

12 10

10

.—

—

14

12

—

,—.

Page 3

OPERA TION-CLUTCHES

In all Black and Decker Scruguns, a clutch provides a "dead”

or stationary front spindle to permit the driving accessory to

"locate” the screw slot or nut. Forward pressure then engages

the clutch and drives the fastener.

No. 12 Scruguns are equipped with either a "Positive” or

"Adjustable” clutch. Operation of these clutches is as follows:

CLEANING

With the tool motor running, blow dirt and dust out of all air

vents with dry air at least once a week. Also blow any dirt out of

Switches, Quick-change Chuck or Screw Depth Locator. If your tool

has a Locator, it should be disassembled after each day's work

and all parts cleaned with kerosene or other cleaning solvent.

Preferably, dry parts with an air hose with the motor running.

Positive Clutch—With the positive clutch, output torque of the

screwdriver Is directly controlled by operator pressure against the

fastener. A heavy forward pressure will hold the clutch engaged

to a high torque; while light forward pressure allows the clutch to

disengage at a lower torque. Release of pressure completely

disengages the clutch. Maximum torque on a fastener is reached

by maintaining forward pressure on the tool and allowing the

clutch to ratchet momentarily; the resultant hammering will

further tighten the fastener.

Adjustable Clutch—The adjustable clutch mechanism allows the

operator to drive a series of fasteners to a pre-set uniform

torque. Torque output is controlled mechanically by a spring

loaded clutch mechanism and operator pressure on the tool has

no effect on output. The adjustable clutch mechanism is also

provided with a dead spindle so that complete release of pres

sure on tool will disengage output spindle.

To adjust the clutch, slide the locking ring toward the gear

case. This action unlocks the adjusting ring and allows it to be

rotated. Turning the adjusting ring so that it moves toward the

gear case will increase the output torque of the clutch.

An increase in the force required to turn the adjusting ring

indicates that the clutch setting is Increasing.

Turning the ring so that it moves away from the gear case

will decrease the clutch setting. This is matched with a decrease

In effort required to turn the adjusting ring. CAUTION: Once

the adjusting ring is free from spring pressure additional loosen

ing has no. further effect on the clutch and should be avoided.

If the adjusting ring is loosened too far it will come off the

tool allowing the locking ring and spring also to come off. No

damage is done and these can be reassembled by operator.

SPRING MECHANISM

DEAD SPINDLE CLUTCH

ACCESSORIES

Number 12 Scrugun Models can utilize practically every type

of fastening accessory (bits, bit tip holders, shanks for sockets,

etc.) with a hex shank.

Your Tool will handle a wide variety of bits and other fastening

accessories. Some of these are listed below, but for the very

many other types and sizes of accessories please see your Black

& Decker Distributor, or refer to Black & Decker Catalog No. 1.

SQUARE DRIVE SHANKS —

1/4" HEX DRIVE SHANK

No. 20510 2" Overall Length, For Va"

Square Drive Sockets

No. 20511 6" Overall Length, For "

Square Drive Sockets

PHILLIPS HEAD BITS —

lv4" HEX DRIVE SHANKS

No. 54595 No. 1 Point, 1-15/16" Overall

Length

No. 54592 No. 2 Point, 1-15/16" Overall

Length

No. 54594 No. 3 Point, 1-15/16" Overall

Length

BIT TIP HOLDERS —

1/4" HEX DRIVE SHANKS

No. 61108 Non-Magnetic, For Va"

Bit Tips

No. 63957 Magnetic, For Vi" Bit Tips

w HEX BIT TIPS

No. 38403 Phillips, No. 1 Point

No. 38404 Phillips, No. 2 Point

No. 38405 Phillips, No. 3 Point

No. 61102 Phillips Pozedriv®, No. 2 Point

No. 61104 Phillips Pozedriv®, No. 3 Point

ADJUSTABLE CLUTCH

LUBRICATION

Black and Decker Tools are completely lubricated at factory and

are ready for use. Gears should be relubricated every 60 days

to 6 months depending upon use. To lubricate, remove gear

case, wipe out old grease, and refill gear case with B&D HeavyDuty Grease to the amount specified on the Parts List packed

with your tool.

It is also recommended that the clutch faces be given a light

greasing after every 50 hours of usage. Refer to "exploded"

parts bulletin (included with your tool) If you have any difficulty

in making the minor disassembly necessary to reach the clutch.

No. 38406 Frearson Type (Reed & Prince)

SOCKETS (Use with Square Drive Shanks)

G.

Cat. No.

20512

20514

20516

38420

38422

38424

Type

Non-Mag. 1/4"

Non-Mag. 5/16"

Non-Mag. 3/8"

Magnetic 1/4"

Magnetic

Magnetic

Hex

Diam.

Size

5/16" 1/2"

3/8"

1/2"

1/2"

9/16"

7/16"

9/16"

SLOTTED HEAD SCREWS are easily driven with "Bit and Finder”

accessories. Finder Sleeve No. 65879 adapts the thread on the

front of the clutch housing to hold all 719000 series Finders

which then become integral with the housing.

If you prefer, separate Bits with Rotating Finders are available

to mount directly in the Scrugun chuck. See your B&D Catalog

No. 1 for the complete selection of accessories.

Page 4

FACTORY SALES and SERVICE CENTERS

Area Telephone

ALABAMA; Birmingham 35233, 1717 Third Ave., South

ARIZONA: Phoenix 85004, 537 E. McDowell Rd

ARKANSAS: Little Rock, 72201, 519 West Seventh Street

CALIFORNIA: Anaheim 92802, 1235 So. Euclid Ave

Los Angeles 90007, 2432 S. Broadway

Oakland 94606, 1107 E. 14th St...................................................415 TE 4-5944

Sacramento 95814, 1915 Seventeenth Street..............................916 444-3188

San Diego 92105, 3811 El Cajon Blvd

San Francisco 94080, 1139 Airport Blvd

Santa Clara 95050, 2291 The Alameda

Van Nuys 91401, 14920 Victory Blvd

COLORADO: Denver 80204, 675 Kalamath St

CONNECTICUT; Hartford 06114, 131 Meadow Street

DISTRICT OF COLUMBIA: Washington

Bladensburg, Maryland 20710, 4501 Baltimore Ave

Falls Church, Virginia 22046, 129 Annandale Road

FLORIDA: Jacksonville 32208, 5224 Pearl Street..

Miami 33168, 13345 N. W. Seventh Avenue................................305 681-6658

Orlando 32806, 940 So. Orange Ave............................................305 423-1651

Tampa 33609, 3401 W. Kennedy Blvd

GEORGIA; Atlanta 30313, 316 Techwood Drive, N.W

HAWAII: Honolulu 96813, 675 Auahi Street.....................................808 536-9374

ILLINOIS: Chicago 60607, 1100 W. Jackson Blvd...........................312 TA 9-3500

Chicago 60646, Lincolnwood, 6710 N. Crawford Ave..................312 OR 3-0923

Chicago 60643, Beverly Hills, 10708 S. Western Ave

Rock Island 61201, 725 30th Street.............................................309 788-1744

INDIANA: Evansville 47708, 931 Bond Street

Indianapolis 46202, 1125 W. 16th Street

.........

602 AL 8-1332

.......................

.......................................

.........................................

......................................

.......................................

...........................................

...............................

...................

...................

.....................

..........................

.........................................

....................

.................................

.....................................

IOWA: Des Moines 50312, 2811 Ingersoll Ave............................. 515 CH 4-7257

KANSAS: Wichita 67214, 203 N. Mathewson Street

KENTUCKY: Louisville 40209, 4407 Park Blvd

LOUISIANA: New Orleans 70002, 3310 N. Causeway Blvd. ...504 837-2550

MARYLAND: Baltimore 21211, 203 West 28th Street

Baltimore 21205, 4712 Erdman Ave

Bladensburg 20710, 4501 Baltimore Avenue

MASSACHUSETTS; Boston 02135, 12 Market St (Brighton)..617 ST 2-6264

MICHIGAN: Detroit 48219, 18133 W. McNichols Rd

Detroit 48234, 11360 East Seven Mile Road................................313 527-5010

Grand Rapids 49509, 3662 Clyde Park Ave., S.W

MINNESOTA: Minneapolis 55408, 2815 Nicollet Ave

MISSOURI; Kansas City 64108 2705 McGee Trafficway

St Louis 63110, 615 S. Vandeventer Ave

BROCKVILLE, ONTARIO

CALGARY, ALBERTA

DON MILLS (Toronto)

EDMONTON, ALBERTA

HALIFAX, NOVA SCOTIA......................................803 McLean Street

HAMILTON, ONTARIO

LONDON, ONTARIO

ALABAMA, Montgomery

ALASKA, Anchorage

Fairbanks

ARIZONA, Tucson

CALIFORNIA, Fresno

Stockton

CONNECTICUT 06051, New Britain, 595 John Downey

GEORGIA 30354. Atlanta, 3271 Hamilton Blvd. S.W.

ILLINOIS 60018, Des Plaines, 2180 S. Woif Road

MARYLAND 21074, Hampstead, Phone.- 301-374-9046

MISSOURI 64116, N. Kansas City, 1343 Murray Drive

DISTRIBUTION CENTERS

CALIFORNIA 94804, Richmond, 1732 Wright Ave.

Phone: 415 235-4232

Drive, Phone: 203 225-8415

Phone: 404 762-1601 - 4

Phone: 312 827-7145

(Sales Office: 312 827-0083)

Phone: 816 842-6350

............................................

...................................................

...................................

............................................

...............................

....................................

...........................

CONNECTICUT, New Haven

DELAWARE, Wilmington

FLORIDA, Pensacola

IDAHO, Boise, Lewiston

.......................

.............................

.....................

...............................

........................

.......................

......................

.....................................

631 Commissioners Rd., East

Code No.

................

............

205 324-6691

501 FR 2-3040

714 772-4050

213 R1 9-0371

714 AT 1-3331

415 871-7278

408 241-9162

213 787-5531

303 222-0621

203 249-6241

301 779-3808

703 533-1147

904 356-2951

813 872-8317

404 JA 4-0431

.................

312 BE 3-6832

812 425-4269

317 632-5569

316 FO 3-6571

502 366-1495

301 HO 7-7411

301 485-5550

301 779-3808

313 534-8880

616 534-7708

..............

1003 11th Avenue, S. W.

11440 Ave.—142 Street

612 TA 3-5283

816 HA 1-1493

314 JE 3-2210

BLACK & DECKER MFG. CO., Umfted, Canada

Perth Street

2 Valleybrook Drive

180 Parkdale Ave., N.

AUTHORIZED SERVICE STATIONS

MAINE, Westbrook

MISSISSIPPI, Jackson

NEVADA, Reno, Las Vegas

NEW YORK, Schenectady

MANUFACTURING PLANTS

Fayetteville, North.Carolina;

Lancaster, Pa.; Solon, Ohio;

Towson, Md., Hampstead, Md., U. S. A.;

Brockville, Ontario, Can.; Harmondsworth

Middx., Maidenhead, Spennymoor, England;

Croydon, Vic., Australia; Lyon, France; Milan, Italy

NEBRASKA: Omaha 68102, 2218 Leavenworth Street.................402

NEW JERSEY: Newark 07104, 868 Broadway..............................201

NEW MEXICO: Albuquerque 87110, 4700 Lomas Blvd. N.E...505

NEW YORK: Buffalo 14209, 881 W. Delavan Ave..

New York 10462, 1894 E. Tremont Avenue (Bronx)

New York 10014, 227 Varick St (Manhattan).

New York 11377, 56-15 Queens Blvd. (Woodside)

Rochester 14620, 476 Clinton Ave. S......................

Syracuse 13224, 2140 Erie Blvd. E

NORTH CAROLINA: Charlotte 28206, 1710 N. Graham St

Fayetteville 28306, P.O. Box 4305, Highway 301,^ S...............919

Greensboro 27403, 1008 W. Lee Street....................................919

OHIO: Cincinnati 45203, 1225 Western Ave

Cleveland 44113, 3901 Detroit Ave

Columbus 43202, 3293 N. High Street

Dayton 45420, 617 Watervliet Street.............................

Solon 44139, 6225 Cochran Road.............................................216

Toledo 43606, 2629 W. Central Ave..........................................419

OKUHOMA: Oklahoma City 73106, 1318 Linwood Blvd

Tulsa 74145, 3120 South Sheridan Road..................................

...........................................

...........................................

.....................

................

..........................

.................

.................

..........

...................

......................................

..............

............

................

OREGON: Portland 97209, 1640 N. W. Johnson Street................503

PENNSYLVANIA: Harrisburg 17112, 6070 Allentown Blvd

Lancaster 17604, 715 Fountain Ave..........................................717

Philadelphia 19103, 333 No. 20th Street

Pittsburgh 15232, 5437 Baum Blvd

RHODE ISLAND: E. Providence 02914, 2777 Pawtucket Ave...401

SOUTH CAROLINA: Greenville 29601, 407 Pendleton St

TENNESSEE: Knoxville 37917, 1123 North Central St

Memphis 38116, 984-86 East Brooks Rd,...

Nashville 37203, 601 Eighth Ave. S...........................................615

TEXAS: Amarillo 79106, 3008 West 6th Ave

Dallas 75207, 1808 N. Industrial Blvd........................................214

Fort Worth 76103, 1801 Bomar Street.......................................817

Houston 77003, 105 Sampson Street........................................713

San Antonio 78210, 1111 South Presa Street

...................................

...........................................

..............................

.................................

UTAH: Salt Lake City 84115, 1541 S. Second West Street

VIRGINIA: Fails Church 22046, 129 Annandale Road

Norfolk 23517, 337 W. 21st Street.............................................703

Richmond 23222, 1424 Chamberlayne Ave

WASHINGTON: Seattle 98119, 701 Third. North

Spokane 99207, 3550 North Market Street................................509

WEST VIRGINIA; Charleston 25312, 1638 Sixth Ave

WISCONSIN: Milwaukee 53213. 6301 Blue Mound Road

MONTREAL 10, P. Q

OTTAWA, ONTARIO...................................418 Laurier Avenue, West

QUEBEC CITY, P. Q

REGINA, SASKATCHEWAN...................................1076 Albert Street

SASKATOON, SASK

VANCOUVER 10, B. C

WINNIPEG 10, MANITOBA......................................934 St. James St.

.....................................

.............................................

..........

Diamond Ind. Center, Quebec & 33rd St.

.............................................

OHIO, Youngstown

PENNSYLVANIA, Allentown

Erie

SOUTH CAROLINA, Charleston

SOUTH DAKOTA, Rapid City

Vienna, Austria; Brussels, Belgium; Copenhagen, Denmark;

Helsinki, Finland; Idstein, Germany; Athens, Greece; Tokyo,

Japan; Mexico, D.F., Monterrey, Guadalajara, Mexico; Rotterdam,

Netherlands; Auckland, Wellington, Christchurch, New Zealand; Grorud,

Norway; Johannesburg, Cape Town, Durban, South Africa; Barcelona,

Spain; Goteborg, Sweden; Zurich, Switzerland; Caracas, Venezuela

BLACK & DECKER, INC., Urbanización Industrial Julia

..............................

SALES AND SERVICE SUBSIDIARIES

Caparra Heights, San Juan, Puerto -Rico

...........

............

.................

...........................

...........

..................

..........................

....................

.............

7865 St. Lawrence Blvd.

330 St. Roch Street

24 West 2nd Ave.

TEXAS, Corpus Christi

El Paso

VIRGINIA, Roanoke

WASHINGTON, Yakima

WEST VIRGINIA, Wheeling

Area

Code

716

212

212

212

716

315

704

513

216

614

513

405

918

717

215

412

803

615

901

806

512

801

703

703

206

304

414

Telephone

No.

345-2330

HU 3-1076

265-6401

TT 4-6220

SY 2-2700

WA 9-6450

DE 5-1042

454-3814

446-3086

FR 5-3721

425-1181

275-0906

421-2275

OL 1-4243

263-8884

252-1821

CH 8-5330

475-6771

CE 2-7515

622-5666

CA 8-8631

Kl 5-0651

393-5831

LO 4-5520

362-2700

434-1655

232-3038

546-2481

332-3444

254-1061

DR 3-1531

RI 1-6401

ED 6-0175

CA 8-7521

LE 4-4611

HU 6-7056

533-1147

627-6888

649-9245

AT 2-6432

HU 9-9164

343-0289

GR 6-7800

Guarantee

BLACK & DECKER GUARANTEES, FOR ONE YEAR FROM DATE OF PURCHASE, TO CORRECT BY

REPAIR OR PARTS REPLACEMENT WITHOUT CHARGE ANY DEFECT DUE TO FAULTY MATERIAL

OR WORKMANSHIP. SIMPLY RETURN THE COMPLETE UNIT, TRANSPORTATION PREPAID, TO

ANY BLACK & DECKER SERVICE CENTER OR AUTHORIZED SERVICE STATION. NATURALLY, WE

ASSUME NO RESPONSIBILITY FOR DAMAGE CAUSED BY MISUSE, CARELESS HANDLING OR

WHERE REPAIRS HAVE BEEN MADE OR ATTEMPTED BY OTHERS. NO OTHER GUARANTEE,

WRITTEN OR VERBAL, IS AUTHORIZED BY US.

THE BLACK AND DECKER MFG. CO. — TOWSON, MARYLAND 21204, U.S.A.

Form No. 97553 CD

Printed in U.S.A.

Loading...

Loading...