Page 1

1

E NGLISH

WARNING: IMPORTANT SAFETY WARNINGS

AND INSTRUCTIONS

TO REDUCE RISK OF INJURY:

• Before any use, be sure everyone using this tool reads and understands all

safety instructions and other information contained in this manual.

• Save these instructions and review frequently prior to use and in instructing

others.

WARNING: When using electric tools, basic safety precautions should

always be followed to reduce risk of fire, electric shock,

and personal injury, including the following

READ ALL INSTRUCTIONS

GENERAL SAFETY WARNINGS AND INSTRUCTIONS

FOR ALL TOOLS

• KEEP WORK AREA CLEAN. Cluttered areas and benches invite injuries.

• CONSIDER WORK AREA ENVIRONMENT. Don’t expose power tools to rain.

Don’t use power tools in damp or wet locations. Keep work area well lit. Do not

use in presence of flammable liquids or gases. Motors in these tools normally

spark, and the sparks may ignite the fumes.

• GUARD AGAINST ELECTRIC SHOCK. Prevent body contact with grounded

surfaces. For example; pipes, radiators, ranges, refrigerator enclosures. Use

extreme caution when drilling, driving, or cutting into walls, floors, ceilings or

other areas or wherever live electrical wires may be contacted, do not touch any

metal parts of the tool. Hold the tools only by the plastic handle to prevent

electric shock.

• KEEP CHILDREN AWAY. Do not let children and visitors contact tool or extension

cord. All children and visitors should be kept away from work area.

• STORE IDLE TOOLS. When not in use, tools should be stored in dry, and high or

locked-up place–out of reach of children.

• DON’T FORCE TOOL. It will do the job better and safer at the rate for which it

was intended.

1-800-544-6986

INSTRUCTION

MANUAL

4-1/2" (115mm ) Angle Grinder

TV800

KEY INFORMATION YOU SHOULD KNOW

•Wait until grinding wheel reaches full speed before

applying to work.

•Hold grinder at proper angle, as shown in figure 4.

VEA EL ESPAÑOL EN LA CONTRAPORTADA.

POUR LE FRANÇAIS, VOIR LA COUVERTURE ARRIÈRE.

SAVE THIS

MANUAL FOR

FUTURE REFERENCE.

If you have any questions, call

1-800-544-6986.

INSTRUCTIVO DE OPERACIÓN, CENTROS DE SERVICIO Y PÓLIZA DE

GARANTÍA. ADVERTENCIA: LÉASE ESTE INSTRUCTIVO ANTES DE USAR EL

PRODUCTO.

*TV800 / 386239 11/18/03 11:36 AM Page 1

Page 2

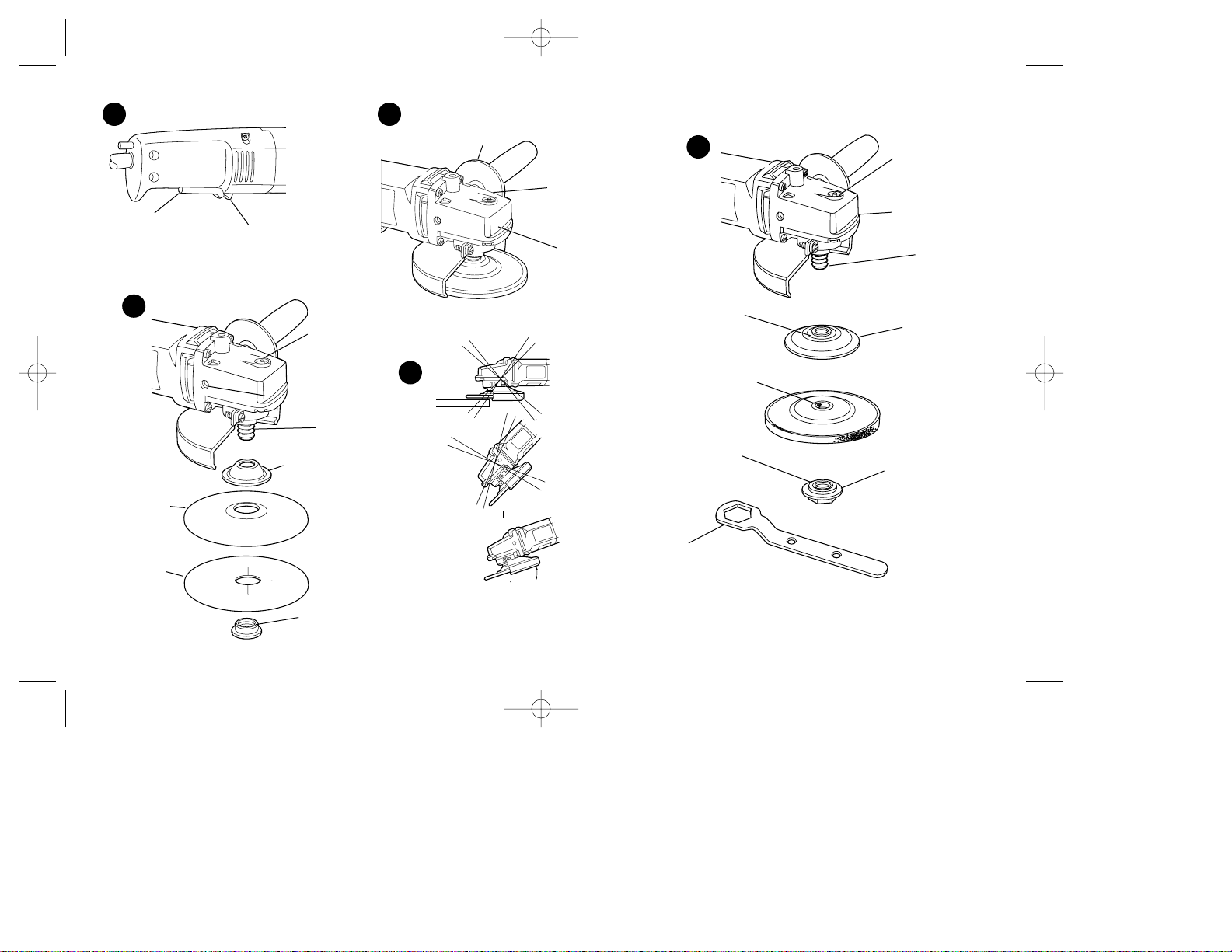

Disc nut hub

Moyeu de l'écrou du disque

Cubo de la tuerca del disco

Sanding disc

Disque abrasif

Disco de lija

Spindle Lock Pin

Tige de verrouillage de l'arbre

Perno de seguro de la flecha

Spindle

Arbre

Flecha

Disc nut

Écrou du disque

Tuerca del disco

Backing disc

Disque d'appui

Disco de respaldo

Trigger switch

Interrupteur à détente

Gatillo interruptor

Switch lock-off button

Bouton de verrouillage en mode hors tension

Botón de seguro de apagado

1

3

2

Gear case

Carter d'engrenages

Caja de engranes

Auxiliary handle

Poignée auxiliaire

Mango auxiliar

Spindle lock pin

Tige de verrouillage de l'arbre

Perno de seguro de la flecha

WRONG

INCORRECT

INCORRECTO

RIGHT

CORRECT

CORRECTO

10° to 15°

De 10° à 15°

10° a 15°

WRONG

INCORRECT

INCORRECTO

4

Wrench

Fourches

Llave

Spindle

Arbre

Flecha

Raised portion of flange toward spindle

Portion soulevée de la bride vers l'arbre

Porción elevada de la arandela hacia la flecha

Backing flange

Bride d'appui

Disco de respaldo

Spindle lock pin

Tige de verrouillage de l'arbre

Perno de seguro de la flecha

Gear case

Carter d'engrenages

Caja de engranes

Clamp washer

Rondelle de blocage

Roldana de sujeción

Raised portion of wheel toward flange

Portion soulevée de la meule vers la bride

Porción elevada del disco hacia la arandela

Raised shoulder toward wheel

Épaulement soulevé vers la meule

Hombro levantado hacia el disco

5

*TV800 / 386239 11/18/03 11:36 AM Page 2

Page 3

3

• USE RIGHT TOOL. Don’t force small tool or attachment to do the job of a

heavy-duty tool. Don’t use tool for purposes not intended.

• DRESS PROPERLY. Do not wear loose clothing or jewelry. They can be

caught in moving parts. Rubber gloves and non-skid footwear are

recommended when working outdoors. Wear protective hair covering to

contain long hair.

• USE SAFETY GLASSES AND OTHER SAFETY EQUIPMENT. Use safety

goggles or safety glasses with side shields, complying with applicable

safety standards and, when needed, a face shield. Also use face or dust

mask if cutting operation is dusty. This applies to all persons in the work

area. Also use a hard hat, hearing protection, gloves, safety shoes and

dust collection systems when specified or required.

• DON’T ABUSE CORD. Never carry tool by cord or yank it to disconnect from

receptacle. Keep cord from heat, oil, and sharp edges.

• SECURE WORK. Use clamps or a vise to hold work. It’s safer than using your

hand and it frees both hands to operate tool.

• DON’T OVERREACH. Keep proper footing and balance at all times.

• MAINTAIN TOOLS WITH CARE. Keep tools sharp and clean for better and safer

performance. Follow instructions for lubricating and changing accessories.

Inspect tool cords periodically and if damaged, have repaired by authorized

service facility. Inspect extension cords periodically and replace if damaged.

Keep handles dry, clean, and free from oil and grease.

• DISCONNECT TOOLS. Unplug the tool when not in use, when moving tool from

place to place, before servicing, and when changing accessories (such as

blades, bits, cutters) or making adjustments.

• REMOVE ADJUSTING KEYS AND WRENCHES. Form habit of checking to see

that keys and adjusting wrenches are removed from tool before turning it on.

• AVOID UNINTENTIONAL STARTING. Don’t carry tool with finger on switch. Be

sure switch is off when plugging in.

• EXTENSION CORDS. Make sure your extension cord is in good condition.

When using an extension cord, be sure to use one heavy enough to carry the

current your product will draw.An undersized cord will cause a drop in line

voltage resulting in loss of power and overheating. The following table shows

the correct size to use depending on cord length and nameplate ampere rating.

If in doubt, use the next heavier gage. The smaller the gage number, the heavier

the cord.

• OUTDOOR USE EXTENSION CORDS. When tool is used outdoors, use only

extension cords intended for use outdoors and so marked.

• STAY ALERT. Watch what you are doing. Use common sense. Do not operate

tool when you are tired or otherwise impaired.

• CHECK DAMAGED PARTS. Before further use of the tool, a guard or other part

that is damaged should be carefully checked to determine that it will operate

properly and perform its intended function. Check for alignment of moving

parts, binding of moving parts, breakage of parts, mounting, and any other

conditions that may affect its operation. A guard or other part that is damaged

should be properly repaired or replaced by an authorized service center unless

otherwise indicated elsewhere in this instruction manual. Have defective

switches replaced by authorized service center. Do not use tool if switch does not

turn it on and off.

ADDITIONAL SAFETY INSTRUCTIONS FOR GRINDERS

ALWAYS WEAR EYE PROTECTION.

KEEP GUARDS IN PLACE.

• Use only grinding wheels having a maximum operating speed at least high as

“No Load RPM” marked on the tool’s nameplate.

• Before using, inspect recommended accessory for cracks or flaws. If such a

crack or flaw is evident, discard the accessory. The accessory should also be

inspected whenever you think the tool may have been dropped.

• When starting the tool (with a new or replacement wheel installed) hold the tool

in a well protected area and let it run for one minute. If the wheel has an

Minimum Gage for Cord Sets

Volts Total Length of Cord in Feet

120V 0-25 26-50 51-100 101-150

240V 0-50 51-100 101-200 201-300

Ampere Rating

More Not more American Wire Gage

Than Than

0-6 18 16 16 14

6-10 18 16 14 12

10 - 12 16 16 14 12

12 - 16 14 12 Not Recommended

E NGLISH

*TV800 / 386239 11/18/03 11:36 AM Page 3

Page 4

4

E NGLISH

undetected crack or flaw, it should burst in less than one minute. Never start the

tool with a person in line with the wheel. This includes the operator.

• In operation, avoid bouncing the wheel or giving it rough treatment. If this

occurs, stop the tool and inspect the wheel.

• Always use guards with depressed center wheels or flaring cup grinding wheels.

• Clean your tool out periodically.

• CAUTION: Some wood contains preservatives such as copper chromium

arsenate (CCA) which can be toxic. When sanding these materials extra care

should be taken to avoid inhalation and minimize skin contact.

SAVE THESE INSTRUCTIONS

Motor Brushes

Master Mechanic uses an advanced brush system which automatically stops the

tool when the brushes wear out. This prevents serious damage to the motor.

Spindle Lock Pin Operation (Fig. 2)

Depress spindle lock pin and rotate the spindle until the lock pin engages to lock

the spindle.

NOTE: Never depress the spindle lock pin when the tool is running or coasting.

Damage to the gear and lock pin will result.

Auxiliary Handle (Fig. 2)

An auxiliary handle is furnished with your grinder and can be screwed into

either side or the top of the gear case. This handle SHOULD BE USED AT ALL

TIMES to maintain complete control of the tool.

Sanding With Abrasive Discs (Fig. 3)

Sanding accessories shown are available at extra cost.

TO INSTALL SANDING DISCS:

Be sure that the tool is turned off and unplugged. Push the hub of the disc nut

through the center of the sanding disc, as far as it will go, and also through the

backing disc.

Put the assembled discs on the tool spindle and engage the disc nut into the disc

nut hub. Thread the assembly clockwise, completely down on the spindle.

Engage the lock pin to lock the spindle in place. When using an abrasive disc,

hold the tool so that an angle of 10° to 15° exists between the disc and the work,

as shown in Figure 4. If only the outer edge of the sanding disc is pressed flat

against the work, the sanding action will be irregular and bumpy, and the tool

will be difficult to control.

PRECAUTIONS TO TAKE WHEN SANDING PAINT

1. Sanding of lead based paint is NOT RECOMMENDED due to the difficulty

of controlling the contaminated dust. The greatest danger of lead poisoning

is to children and pregnant women.

2. Since it is difficult to identify whether or not a paint contains lead without a

chemical analysis, we recommend the following precautions when sanding

any paint:

PERSONAL SAFETY

a. No children or pregnant women should enter the work area where the paint

sanding is being done until all clean-up is completed.

b. A dust mask or respirator should be worn by all persons entering the work

area. The filter should be replaced daily or whenever the wearer has

difficulty breathing.

NOTE: Only those dust masks suitable for working with lead paint dust and

fumes should be used. Ordinary painting masks do not offer this protection.

See your local hardware dealer for the N.I.O.S.H. approved proper mask.

c. NO EATING, DRINKING or SMOKING should be done in the work area to

prevent ingesting contaminated paint particles. Workers should wash and

clean up BEFORE eating, drinking or smoking. Articles of food, drink, or

smoking should not be left in the work area where dust can settle on them.

ENVIRONMENTAL SAFETY

a. Paint should be removed in such a manner as to minimize the amount of

dust generated.

b. Areas where paint removal is occurring should be sealed with plastic

sheeting of 4 mils thickness.

*TV800 / 386239 11/18/03 11:36 AM Page 4

Page 5

5

E NGLISH

c. Sanding should be done in a manner to reduce tracking of paint dust

outside the work area.

CLEANING AND DISPOSAL

a. All surfaces in the work area should be vacuumed and thoroughly cleaned daily

for the duration of the sanding project. Vacuum filter bags should be changed

frequently.

b. Plastic drop cloths should be gathered up and disposed of along with any dust

chips or other removal debris. They should be placed in sealed refuse

receptacles and disposed of through regular trash pick-up procedures. During

clean-up, children and pregnant women should be kept away from the

immediate work area.

c. All toys, washable furniture and utensils used by children should be washed

thoroughly before being used again.

Removing Disc

TURN OFF AND UNPLUG TOOL.

Using a cloth or glove to protect your hand, turn the disc assembly counter-

clockwise to remove it from the tool spindle. Hold the spindle in place by

engaging the lock pin.

Grinding With Depressed Center Wheels (5/8"—11 Spindle)

Depressed center wheels may be used for moderate metal removal on flat or

contoured surfaces.

CAUTION: Never use depressed center wheels without the proper guard.

To install depressed center wheels:

1. Be sure tool is disconnected from power supply and switch is in “OFF”

position.

2. Be sure the guard assembly is securely attached to the gear case.

3. Put the backing flange onto the tool spindle as shown in Figure 5.

4. Check rated speed on depressed center wheel. Never use wheel with rated

speed lower than the speed on the nameplate of the tool.

5. Place the depressed center wheel on the tool spindle as shown.

6. Thread the clamp washer on tool spindle as shown. Hold the tool spindle by

engaging the spindle lock pin, and tighten clamp washer with wrench.

When using a depressed center wheel, hold the tool so that an angle of

approximately 30° exists between the wheel and the work.

Wire Cup and Knotted Wire Wheel Brushes.

1. Disconnect tool from power source and make sure switch is "OFF". Rest

grinder on its back with spindle facing up.

2. Ensure that the rated speed of the wire brush is equal to or higher than the

rated speed of the grinder found on the nameplate.

3. Thread brush onto spindle and tighten.

Common applications for knotted wire cup brushes include cleaning welds,

angles, corners and removing paint.

Usage of the knotted wire wheel brush is the same as the wire cup brush. They

can also be used to finish irregular surfaces and corners.

MAINTENANCE

Use only mild soap and a damp cloth to clean the tool. Never let any liquid get

inside the tool; never immerse any part of the tool into a liquid.

IMPORTANT: To assure product SAFETY and RELIABILITY, repairs, maintenance

and adjustment should be performed by authorized service centers or other

qualified service organizations, always using identical replacement parts.

Lubrication

MASTER MECHANIC tools are properly lubricated at the factory and are ready

for use.

Cleaning

Blowing dust and grit out of the motor housing using compressed air is a

necessary regular maintenance procedure. Dust and grit containing particles

from metal grinding often accumulate on interior surfaces and could create an

electrical shock hazard if not frequently cleaned out.

CAUTION: Never use solvents or other harsh chemicals for cleaning the nonmetallic parts of the tool. Use clean, dry rag only.

*TV800 / 386239 11/18/03 11:36 AM Page 5

Page 6

6

Accessories

A full array of accessories for use with your tool are available from your local

dealer or authorized service center.

CAUTION: The use of any accessory or attachment other than those

recommended in this manual may be hazardous.

ACCESSORY TYPE NOTES USAGE

DEPRESSED Use Guard Use for moderate

CENTER Supplied with metal & masonry

WHEEL Tool removal on flat or

contoured surfaces

SANDING Use for smoothing

DISCS welds, and sharp

edges, and automotive

body parts

WIRE Max. 4" (100mm) Knotted Wheel Use for rust removal

BRUSHES Max. 3" (76mm) Cup Wheel and surface preparation

before painting

* Depressed center grinding wheels must fit within the confines of the guard and

must be rated higher than the recommended speed as marked on the nameplate.

WARNING — To reduce the risk of injury, always use proper guards when

grinding and wear eye protection.

Two Year Quality Guarantee

This product is warranted for two years against any defects in material and

workmanship, If defective, the product will be repaired or replaced free of

charge. Simply provide proof of purchase and return the tool to your place of

purchase. Normal wear or damage due to abuse, mishandling or unauthorized

repair is not covered. This warranty does not apply to accessories, This warranty

gives you specific legal rights and you may have other rights which vary from

state to state.

30 Day Satisfaction Guarantee

If, for any reason, you are not completely satisfied with the performance or

results of this product, within thirty days of original purchase, it will be repaired

or replaced free of charge. Simply provide proof of purchase and return the tool

to your place of purchase.

If your tool requires out of warranty repairs, you may send or take your tool to a

Black & Decker owned Service Center. Black & Decker Service Centers are listed

under “Tools-Electric” in the yellow pages of the phone directory or you may call

1-800-544-6986 for information on your nearest Service Center.

TruServ

8600 W. Bryn Mawr Ave.

Chicago, IL 60631-3505

E NGLISH

*TV800 / 386239 11/18/03 11:36 AM Page 6

Page 7

F RANÇAIS

7

GUIDE

D’UTILISATION

RENSEIGNEMENTS IMPORTANTS

•Attendre le plein régime de la meule avant de déposer la

rectifieuse sur la pièce à ouvrer.

•Saisir la rectifieuse à l'angle approprié, comme le montre

la figure 4.

CONSERVER LE PRÉSENT

GUIDE À TITRE DE

RÉFÉRENCE.

1 800 544-6986

Rectifieuse coudée de

115 mm (4 1/2 po)

Modèle TV800

Pour obtenir de plus amples

renseignements, composer le

1 800 544-6986.

AVERTISSEMENT : IMPORTANTES MESURES

DE SÉCURITÉ

AFIN DE RÉDUIRE LES RISQUES DE BLESSURES :

•Avant toute utilisation, s’assurer que tous ceux qui se servent de l’outil lisent et

comprennent toutes les mesures de sécurité et tout autre renseignement contenu

dans le présent guide.

• Conserver ces mesures et les relire fréquemment avant d’utiliser l’outil et d’en

expliquer le fonctionnement à d’autres personnes.

AVERTISSEMENT : Afin de réduire les risques d’incendie, de secousses

électriques ou de blessures lorsqu’on utilise des outils

électriques, il faut toujours respecter les mesures de

sécurité suivantes.

LIRE TOUTES LES DIRECTIVES.

MESURES DE SÉCURITÉ POUR TOUS LES OUTILS

• BIEN DÉGAGER LA SURFACE DE TRAVAIL. Des surfaces et des établis

encombrés peuvent être la cause de blessures.

• TENIR COMPTE DU MILIEU DE TRAVAIL. Protéger les outils électriques de la

pluie. Ne pas s’en servir dans des endroits humides ou mouillés. Bien éclairer la

surface de travail. Ne pas se servir de l’outil en présence de liquides ou de

vapeurs inflammables. En effet, le moteur de tels outils génère habituellement

des étincelles et celles-ci peuvent enflammer les vapeurs.

• SE PROTÉGER CONTRE LES SECOUSSES ÉLECTRIQUES. Éviter tout contact avec

des objets mis à la terre, comme des tuyaux, radiateurs, cuisinières,

réfrigérateurs et autres objets du genre. Prendre soin lorsqu’on perce, visse ou

coupe des murs, planchers, plafonds ou autres endroits qui pourraient cacher

des fils électriques sous tension. Ne pas toucher aux composants métalliques de

l’outil. Saisir celui-ci seulement par sa poignée en plastique afin d’éviter les

secousses électriques.

• ÉLOIGNER LES ENFANTS. Tous les visiteurs doivent être tenus à l’écart de l’aire

de travail et il faut les empêcher de toucher à l’outil ou au cordon de rallonge.

• RANGER LES OUTILS INUTILISÉS. Il faut ranger les outils dans un endroit sec,

situé en hauteur ou fermé à clé, hors de la portée des enfants.

*TV800 / 386239 11/18/03 11:36 AM Page 7

Page 8

F RANÇAIS

8

• ENLEVER LES CLÉS DE RÉGLAGE. Prendre l’habitude de vérifier si les clés de

réglage ont été retirées avant de faire démarrer l’outil.

• ÉVITER LES DÉMARRAGES ACCIDENTELS. Ne pas laisser le doigt sur

l’interrupteur lorsqu’on transporte l’outil. S’assurer que l’interrupteur est à la

position hors circuit lorsqu’on branche l’outil.

• CORDONS DE RALLONGE. S’assurer que le cordon de rallonge est en bon état.

Lorsqu’on se sert d’un cordon de rallonge, s’assurer qu’il est de calibre

approprié pour la tension nécessaire au fonctionnement de l’outil. L’utilisation

d’un cordon de calibre inférieur occasionne une baisse de tension entraînant

une perte de puissance et la surchauffe. Le tableau suivant indique le calibre

approprié selon la longueur du cordon et les mentions de la plaque signalétique

de l’outil. En cas de doute, utiliser un cordon de calibre supérieur. Le chiffre

indiquant le calibre est inversement proportionnel au calibre du cordon.

• CORDONS DE RALLONGE PRÉVUS POUR L’EXTÉRIEUR. Lorsque l’outil est utilisé

à l’extérieur, ne se servir que d’un cordon de rallonge conçu pour l’extérieur et

portant la mention appropriée.

• DEMEURER VIGILANT. Travailler avec vigilance et faire preuve de bon sens. Ne

pas se servir de l’outil lorsqu’on est fatigué ou autrement affaibli.

• VÉRIFIER LES PIÈCES ENDOMMAGÉES. Avant de continuer à utiliser l’outil, il

faut vérifier si le protecteur ou toute autre pièce endommagée remplit bien la

fonction pour laquelle il a été prévu. Vérifier l’alignement et les attaches des

pièces mobiles, le degré d’usure des pièces et leur montage, ainsi que tout autre

facteur susceptible de nuire au bon fonctionnement de l’outil. Faire réparer ou

remplacer tout protecteur ou toute autre pièce endommagée dans un centre de

service autorisé. Ne jamais se servir d’un outil dont l’interrupteur est défectueux.

Calibre minimal des cordons de rallonge

Tension Longueur totale du cordon en pieds

120 V De 0 à 25 De 26 à 50 De 51 à 100 De 101 à 150

240 V De 0 à 50 De 51à 100 De 101 à 200 De 201 à 300

Intensité (A)

Au Au Calibre moyen de fil

moins plus

0-6 18 16 16 14

6-10 18 16 14 12

10 - 12 16 16 14 12

12 - 16 14 12 Non recommandé

• NE JAMAIS FORCER L’OUTIL. Afin d’obtenir un rendement sûr et efficace,

utiliser l’outil à son rendement nominal.

• UTILISER L’OUTIL APPROPRIÉ. Ne jamais exiger d’un petit outil ou d’un

accessoire le rendement d’un outil de fabrication plus robuste. Se servir de

l’outil selon l’usage prévu.

• PORTER DES VÊTEMENTS APPROPRIÉS. Éviter de porter des vêtements amples

et des bijoux qui peuvent être happés par les pièces en mouvement. Porter des

gants de caoutchouc et des chaussures à semelle antidérapante pour travailler à

l’extérieur. Protéger la chevelure si elle longue.

• PORTER DES LUNETTES DE SÉCURITÉ ET AUTRE ÉQUIPEMENT DE SÉCURITÉ.

Porter des lunettes de protection ou de sécurité à écrans latéraux, conformément

aux normes de sécurité appropriées, et, au besoin, un écran facial. Porter

également un masque respiratoire si le travail de coupe produit de la poussière.

La présente mesure vaut pour toute personne dans la zone de travail. Il faut

également porter un casque, des protège-tympans, des gants et des chaussures

de sécurité ainsi qu’utiliser des systèmes de dépoussiérage lorsque spécifié ou

exigé.

• NE PAS MANIPULER LE CORDON DE FAÇON ABUSIVE. Ne pas transporter

l’outil par le cordon ni tirer sur ce dernier pour le débrancher de la prise.

Éloigner le cordon des sources de chaleur, des flaques d’huile et des arêtes

tranchantes.

• ASSUJETTIR LA PIÈCE. Immobiliser la pièce à l’aide de brides ou d’un étau. On

peut alors se servir des deux mains pour faire fonctionner l’outil, ce qui est plus

sûr.

• NE PAS DÉPASSER SA PORTÉE. Toujours demeurer dans une position stable et

garder son équilibre.

• PRENDRE SOIN DES OUTILS. Conserver les outils propres et affûtés pour qu’ils

donnent un rendement supérieur et sûr. Suivre les directives concernant la

lubrification et le remplacement des accessoires. Inspecter régulièrement le

cordon de l’outil et le faire réparer au besoin à un atelier d’entretien autorisé.

Inspecter régulièrement les cordons de rallonge et les remplacer lorsqu’ils sont

endommagés. S’assurer que les poignées sont toujours propres, sèches et libres

de toute tache d’huile ou de graisse.

• DÉBRANCHER LES OUTILS. Débrancher l’outil lorsqu’on ne s’en sert pas, qu’on

doit le déplacer d’un endroit à un autre et qu’on doit le réparer, en changer un

accessoire (comme une lame, un foret ou un couteau) ou le régler.

*TV800 / 386239 11/18/03 11:36 AM Page 8

Page 9

F RANÇAIS

9

MESURES DE SÉCURITÉ ADDITIONNELLES : RECTIFIEUSES

TOUJOURS PORTER DES LUNETTES DE SÉCURITÉ.

S'ASSURER QUE LES PROTECTEURS SONT EN PLACE.

• Utiliser seulement des meules dont le régime maximal équivaut au moins au

régime à vide indiqué sur la plaque signalétique de l'outil.

•Avant de s'en servir, vérifier si les accessoires recommandés ne renferment

aucune fêlure ni défaut. Le cas échéant, jet l'accessoire. Il faut également

inspecter l'accessoire lorsque l'outil est tombé.

• Au moment du démarrage (après avoir installé une nouvelle meule), saisir l'outil

dans un endroit bien protégé et le laisser fonctionner pendant une minute. Si la

meule renferme une fêlure ou un défaut non décelé, elle éclatera en moins de

une minute. Ne jamais mettre l'outil en marche lorsqu'une personne se trouve

dans la trajectoire de la lame. Cette mesure vaut également pour l'utilisateur.

• Pendant les travaux, éviter de faire sauter la meule ou de la maltraiter. Le cas

échéant, arrêter l'outil et inspecter la meule.

•Toujours utiliser des protecteurs avec des meules à moyeu creux ou des meules

boisseau coniques.

• Nettoyer l'outil régulièrement.

• MISE EN GARDE : Certaines essences de bois renferment des agents de

conservation (comme de l'arséniate de cuivre et de chrome) qui peuvent être

toxiques. Lorsqu'on doit poncer de tels matériaux, prendre des mesures

supplémentaires afin d'éviter d'inhaler les vapeurs toxiques et de minimiser les

contacts avec la peau.

CONSERVER CES MESURES.

Balais du moteur

Les outils Master Mechanic comportent un système de pointe de vérification des

balais qui arrête automatiquement l'outil lorsque les balais sont usés. On

prévient de la sorte de graves dommages au moteur.

Tige de verrouillage de l'arbre (Fig. 2)

Enfoncer la tige de verrouillage de l'arbre et faire tourner l'arbre jusqu'à ce que

la tige de verrouillage s'enclenche dans l'arbre.

NOTE : Ne jamais enfoncer la tige de verrouillage de l'arbre lorsque l'outil

fonctionne au risque d'endommager les engrenages et la tige de verrouillage.

Poignée auxiliaire (Fig. 2)

La rectifieuse comporte une poignée auxiliaire qui peut être vissée d'un côté ou

de l'autre de l'outil ou sur le dessus du carter d'engrenages. La poignée DOIT

ÊTRE UTILISÉE EN TOUT TEMPS afin de bien maîtriser l'outil.

Ponçage à l'aide de disques abrasifs (Fig. 3)

Les accessoires de ponçage illustrés sont vendus séparément.

INSTALLATION DES DISQUES ABRASIFS

S'assurer que l'outil est hors tension et débranché. Enfoncer le moyeu de l'écrou

du disque à fond au centre du disque abrasif et du disque d'appui.

Placer les disques ainsi assemblés sur l'arbre de l'outil et insérer l'écrou du

disque sur le moyeu de l'écrou du disque. Serrer l'assemblage dans le sens

horaire jusqu'au bout de l'arbre. Enfoncer la tige de verrouillage de l'arbre.

Lorsqu'on utilise un disque abrasif, saisir l'outil de manière à laisser un angle de

10 à 15° entre le disque et la pièce à ouvrer (fig. 4). Lorsque le rebord extérieur

du disque abrasif est appuyé à plat contre la pièce, le mouvement abrasif sera

irrégulier et inégal. En outre, l'outil sera difficile à maîtriser.

MESURES À PRENDRE LORS DU PONÇAGE DE PEINTURE

1. IL N'EST PAS RECOMMANDÉ de poncer de la peinture à base de plomb

puisqu'il est difficile d'en maîtriser la poussière contaminée. Ce genre de

ponçage présente de sérieux risques d'empoisonnement au plomb pour les

femmes enceintes et les enfants.

2. Puisqu'il est difficile de déterminer si la peinture renferme du plomb sans en

faire une analyse chimique, il est conseillé de se conformer aux mesures

suivantes lors du ponçage de tout type de peinture.

SÉCURITÉ PERSONNELLE

a. Ne laisser aucun enfant ni aucune femme enceinte entrer dans la pièce où il

y a ponçage de peinture jusqu'à ce que la pièce soit nettoyée.

*TV800 / 386239 11/18/03 11:36 AM Page 9

Page 10

F RANÇAIS

10

dans le sens antihoraire afin de l'enlever de l'arbre de l'outil. Bloquer l'arbre en

place en actionnant la tige de verrouillage.

Ponçage à l'aide de meules à moyeu creux (arbre de

5/8 po — 11)

On peut se servir de meules à moyeu creux pour poncer modérément des

surfaces métalliques planes ou recourbées.

MISE EN GARDE : Ne jamais se servir de meules à moyeu creux sans le

protecteur approprié en place.

Faire ce qui suit pour installer les meules à moyeu creux.

1. S'assurer que l'outil est débranché et hors tension.

2. S'assurer que le protecteur est bien fixé au carter d'engrenages.

3. Placer la bride d'appui sur l'arbre de l'outil (fig. 5).

4. Vérifier le régime nominal des meules à moyeu creux. Ne jamais se servir

d'une meule dont le régime nominal est inférieur à celui indiqué sur la

plaque signalétique de l'outil.

5. Placer la meule à moyeu creux sur l'arbre de l'outil de la façon illustrée.

6. Visser la rondelle de blocage sur l'arbre de la façon illustrée. Bloquer l'arbre

en actionnant la tige de verrouillage et serrer la rondelle de blocage à l'aide

d'une fourches.

Lorsqu'on se sert d'une meule à moyeu creux, saisir l'outil de sorte qu'il y ait un

angle d'environ 30° entre la meule et la pièce à ouvrer.

Meules boisseau à fils d'acier et meules à fils d'acier

torsadés

1. S'assurer que l'outil est débranché et hors tension. Déposer la rectifieuse à

l'envers (l'arbre vers le haut).

2. S'assurer que le régime nominal de la meule à fils d'acier est égal ou

supérieur à celui de l'outil (voir la plaque signalétique de l'outil).

3. Visser la meule sur l'arbre et serrer.

On se sert habituellement des meules boisseau à fils d'acier pour nettoyer des

soudures, des angles, des coins et pour enlever de la peinture.

La meule à fils d'acier torsadés sert aux mêmes utilisations que la meule

boisseau à fils d'acier. On peut également s'en servir pour finir des surfaces et

des coins irréguliers.

b. Toute personne entrant dans la pièce de travail devrait porter un masque ou

un appareil respiratoire. L'utilisateur devrait remplacer le filtre chaque jour

ou dès qu'il éprouve de la difficulté à respirer. NOTE : Il faut seulement

utiliser des masques conçus pour le travail en présence de poussières ou de

vapeurs de plomb. Les masques ordinaires ne sont pas conçus à cet effet.

Consulter le quincaillier pour choisir le masque approprié.

c. IL EST INTERDIT DE MANGER, DE BOIRE ET DE FUMER dans la pièce de

travail afin de ne pas ingérer des particules contaminées. L'utilisateur doit se

laver et se nettoyer AVANT de manger, de boire ou de fumer. Il ne faut pas

laisser dans la pièce de travail de la nourriture, des boissons ou des

cigarettes car de la poussière pourrait se déposer sur ces articles.

PROTECTION DE L'ENVIRONNEMENT

a. Il faut enlever la peinture de manière à produire un minimum de poussière.

b. Il faut sceller la zone de travail à l'aide de feuilles de plastique d'une

épaisseur minimale de 4 mils.

c. Il faut poncer de façon à réduire la propagation de la poussière hors de la

pièce de travail.

NETTOYAGE ET DÉCHETS

a. Il faut bien aspirer toutes les surfaces de la pièce de travail et les nettoyer

à fond chaque jour pendant la durée des travaux. Il faut remplacer

fréquemment le filtre de l'aspirateur.

b. Ramasser les feuilles de plastique et les jeter avec la poussière et les autres

débris dans des contenants étanches à placer avec les ordures ménagères

pour l'enlèvement. Tenir les enfants et les femmes enceintes à l'écart de la

zone de travail pendant les travaux de nettoyage.

c. Il faut nettoyer à fond les jouets, les meubles et les ustensiles des enfants

avant de les utiliser de nouveau.

Retrait du disque

METTRE L'OUTIL HORS TENSION ET LE DÉBRANCHER.

Se protéger la main à l'aide d'un chiffon ou d'un gant et faire tourner le disque

*TV800 / 386239 11/18/03 11:36 AM Page 10

Page 11

F RANÇAIS

11

ENTRETIEN

Nettoyer l'outil seulement à l'aide d'un savon doux et d'un linge humide. Ne

laisser aucun liquide s'infiltrer dans l'outil et ne jamais immerger l'outil.

IMPORTANT : Pour assurer la SÉCURITÉ D'EMPLOI et la FIABILITÉ de l'outil, n'en

confier la réparation, l'entretien et les rajustements qu'à un centre de service ou

à un atelier d'entretien autorisé qui n'utilise que des pièces de rechange

identiques.

Lubrification

Les outils MASTER MECHANIC sont lubrifiés en usine et prêts à être utilisés.

Accessoires

On peut se procurer une gamme complète d´accessoires pour l´outil chez le

détaillant ou au centre de service de la région.

MISE EN GARDE : L’utilisation de tout autre accessoire non recommandé pour

l’outil peut être dangereuse.

TYPE D'ACCESSOIRE NOTES UTILISATION

MEULE Se servir du Pour enlever modérément

À MOYEU protecteur compris du métal et de la

CREUX avec l'outil maçonnerie sur des

surfaces

planes et recourbées.

DISQUES Pour égaliser

ABRASIFS des soudures et des

rebords tranchants ainsi

que pour la carrosserie

MEULES 100 mm (4 po) max. Fils torsadés Pour enlever de la rouille

À FILS D'ACIER 76 mm (3 po) max. Boisseau et préparer les surfaces

avant de peindre

* Les meules à moyeu creux doivent s'insérer sous le protecteur et elles doivent

avoir un régime nominal supérieur à celui indiqué sur la plaque signalétique de

l'outil.

AVERTISSEMENT — Afin de minimiser les risques de blessures, toujours s'assurer

que les protecteurs appropriés sont en place et toujours porter des lunettes de

sécurité.

Garantie de qualité de deux ans

Une garantie de deux ans couvre le produit contre les vices de matière et de

fabrication. Si le produit est défectueux, il sera réparé ou remplacé sans frais. Il

suffit de fournir une preuve d'achat et de retourner le produit à l'endroit où il a

été acheté. La présente garantie ne s'applique pas aux avaries dues à une usure

normale, à une manœuvre négligente, au mauvais usage ni à une réparation

non autorisée. Elle ne vaut également pas pour les accessoires. Les modalités

de la présente garantie donnent des droits légaux spécifiques. L'utilisateur peut

se prévaloir d'autres droits selon l'état ou la province qu'il habite.

Garantie de satisfaction de 30 jours

Si, pour quelque raison que ce soit, l'utilisateur n'est pas complètement satisfait

du rendement du produit ou des résultats obtenus dans les trente jours suivant

l'achat du produit, il sera réparé ou remplacé sans frais. Il suffit de fournir une

preuve d'achat et de retourner le produit à l'endroit où il a été acheté.

Lorsque l'outil nécessite des réparations non garanties, on peut confier l'outil au

personnel d'un centre de service Black & Decker. Les centres de service Black &

Decker sont inscrits à la rubrique «Outils électriques» des Pages Jaunes ou

composer le 1 (800) 544-6986 pour obtenir des plus amples renseignements sur

le centre de service de la région.

TruServ

8600 W. Bryn Mawr Ave.

Chicago, IL 60631-3505

*TV800 / 386239 11/18/03 11:36 AM Page 11

Page 12

E SPAÑOL

12

LEA TODAS LAS INSTRUCCIONES

ADVERTENCIAS E INSTRUCCIONES GENERALES DE SEGURIDAD

PARA TODAS LAS HERRAMIENTAS.

• CONSERVE LIMPIA EL AREA DE TRABAJO. Las áreas y los bancos con objetos

acumulados en desorden propician los accidentes.

• OTORGUE PRIORIDAD AL AMBIENTE DE TRABAJO. No exponga las

herramientas eléctricas a la lluvia ni las utilice en lugares húmedos o

inundados. Ilumine bien la zona de trabajo. No utilice las herramientas

eléctricas en presencia de líquidos o gases inflamables. Los motores de estas

herramientas producen chispas, que pueden encender los vapores.

• PROTEJASE CONTRA EL CHOQUE ELECTRICO. Evite el contacto corporal con

superficies aterrizadas, por ejemplo; tuberías, radiadores, hornos, gabinetes de

refrigeración, etc. Tenga precaución extrema cuando taladre, atornille o corte

en muros, pisos, techos u otras áreas en donde pueda encontrar cables

eléctricos vivos, no toque ninguna parte metálica de la herramienta. Sujete las

herramientas solamente por las empuñaduras de plástico para evitar descargas

eléctricas.

• CONSERVE APARTADOS A LOS NIÑOS. No permita que niños ni otros

visitantes toquen la herramienta ni los cables de extensión. Todos los niños y

otros visitantes deben apartarse del área de trabajo.

• GUARDE LAS HERRAMIENTAS QUE NO EMPLEE. Siempre que no use las

herramientas, debe guardarlas en un lugar seco y elevado o bajo llave, fuera

del alcance de los niños.

• NO FUERCE LA HERRAMIENTA. Esta hará el trabajo mejor y de manera más

segura bajo las condiciones para las que se diseñó.

• EMPLEE LA HERRAMIENTA ADECUADA. No fuerce a una herramienta pequeña

o a sus dispositivos de montaje en una tarea destinada a una herramienta de

alto rendimiento. No utilice la herramienta para tareas para las que no ha sido

diseñada.

• VISTASE DE MANERA ADECUADA. No utilice ropas sueltas ni joyas, pueden

quedar atrapadas en las partes móviles. Se recomienda el uso de guantes y

calzado antiderrapante cuando trabaje a la intemperie. Cúbrase el cabello si lo

tiene largo.

• UTILICE GAFAS Y OTRO EQUIPO DE SEGURIDAD. Utilice anteojos de seguridad

MANUAL DE

INSTRUCCIONES

INFORMACION CLAVE QUE DEBE SABER

•Espere hasta que el disco de esmeril alcance la velocidad

máxima antes de aplicarlo al trabajo.

•Sujete la esmeriladora a un ángulo apropiado, como se

observa en la figura 4.

CONSERVE ESTE

MANUAL PARA

REFERENCIAS

FUTURAS

Esmeriladora angular de

115 mm (4-1/2")

TV800

ADVERTENCIA: ADVERTENCIAS E INSTRUCCIONES

IMPORTANTES DE SEGURIDAD

PARA REDUCIR EL RIESGO DE LESIONES:

• Antes de cualquier uso, asegúrese que cualquier persona que vaya a utilizar

esta herramienta lea y comprenda todas las instrucciones de seguridad y la

información contenida en este manual.

• Conserve estas instrucciones y repáselas con frecuencia antes de usar la

herramienta e instruir a otras personas.

ADVERTENCIA: Siempre que utilice herramientas eléctricas debe seguir

ciertas precauciones básicas de seguridad, a fin de

reducir los riesgos de incendio, choque eléctrico y

lesiones personales, entre las que se encuentran las

siguientes.

*TV800 / 386239 11/18/03 11:36 AM Page 12

Page 13

E SPAÑOL

13

con cubiertas protectoras laterales, que cumplan con los estándares de

seguridad aplicables y, cuando se requiera, una máscara. También utilice una

mascarilla contra polvo si la operación de corte lo produce. Esto se aplica a

todas las personas en el área de trabajo. Utilice también un casco, protección

para los oídos, guantes, calzado de seguridad y sistemas recolectores de polvo

cuando se especifiquen o se requieran.

• NO MALTRATE EL CORDON ELECTRICO. Nunca cargue la herramienta por el

cable ni tire de éste para desconectarlo de la toma de corriente. Aléjelo de

calor, aceite y bordes afilados.

• ASEGURE LAS PIEZAS DE TRABAJO. Utilice prensas para sujetar su pieza de

trabajo; es más seguro que usar su mano y le deja ambas manos libres para

operar la herramienta.

• NO SE SOBREEXTIENDA. Apoye bien los pies y conserve el equilibrio siempre.

• CUIDE SUS HERRAMIENTAS. Conserve sus herramientas limpias y afiladas para

un rendimiento mejor y más seguro. Siga las instrucciones de lubricación y

cambio de accesorios. Revise la herramienta periódicamente y si está dañada,

hágala reparar por una estación de servicio autorizada. Revise los cables de

extensión periódicamente y reemplácelos si están dañados. Conserve las

empuñaduras secas, limpias y libres de aceite y grasa.

• DESCONECTE LAS HERRAMIENTAS. Desconecte la herramienta cuando no la

utilice, cuando la cambie de lugar, antes de darle servicio y cuando le cambie

accesorios (como brocas, puntas, cortadores) o le haga ajustes.

• QUITE LAS LLAVES DE AJUSTE Y LAS HERRAMIENTAS DE MANO.

Acostúmbrese a verificar que se hayan retirado todas las llaves antes de

encender la unidad.

• EVITE EL ENCENDIDO ACCIDENTAL. No acarree la herramienta con el dedo en

el interruptor. Asegúrese que el interruptor esté en posición de apagado antes

de conectar la unidad.

• CORDONES DE EXTENSION. Asegúrese que su extensión esté en buenas

condiciones. Cuando utilice una extensión, asegúrese que tenga el calibre

suficiente para conducir la corriente que su herramienta necesita. Una

extensión con calibre menor al necesario causará una caída en el voltaje de la

línea, resultando en pérdida de potencia y sobrecalentamiento. La tabla

siguiente muestra el calibre correcto para usarse, de acuerdo con la longitud de

la extensión y el amperaje en la placa de identificación. Si tiene dudas, utilice el

calibre siguiente. Mientras menor sea el número del calibre, mayor será la

capacidad del cable.

• CORDONES DE EXTENSION PARA INTEMPERIE. Cuando utilice la herramienta

a la intemperie, utilice únicamente extensiones destinadas para este uso y

marcadas así.

• ESTE ALERTA. Concéntrese en lo que hace. Utilice el sentido común. No opere

la herramienta si está cansado o discapacitado de alguna manera.

• REVISE LAS PARTES DAÑADAS. Antes de seguir usando la herramienta, debe

revisar las guardas y otras partes para determinar realizarán su función

adecuadamente. Revise la alineación de las partes móviles, la manera en que

están sujetas, que no haya piezas o soportes rotos, y cualesquiera otras

condiciones que puedan afectar la operación. Una guarda u otra pieza que

esté dañada debe ser reparada o reemplazada en un centro de servicio

autorizado. No use la herramienta si el interruptor no enciende y apaga.

INSTRUCCIONES DE SEGURIDAD ADICIONALES

PARA ESMERILADORAS

LLEVE PUESTOS SIEMPRE ANTEOJOS DE SEGURIDAD.

CONSERVE LAS GUARDAS EN SU SITIO.

• Utilice exclusivamente ruedas de esmeril que tengan indicada en la etiqueta

una velocidad máxima de operación de por lo menos las "RPM" (revoluciones

Calibre mínimo para cordones de extensión

Volts Longitud total del cordón en metros

120V 0-7.62 7.63-15.24 15.25-30.48 30.49-45.72

240V 0-15.24 15.25-30.48 30.49-60.96 60.97-91.44

AMPERAJE

Más No más Calbre del cordón

de de

0-6 18 16 16 14

6-10 18 16 14 12

10 - 12 16 16 14 12

12 - 16 14 12 No Recomendado

*TV800 / 386239 11/18/03 11:36 AM Page 13

Page 14

E SPAÑOL

14

la parte frontal del mismo. Debe usted EMPLEAR ESTE MANGO SIEMPRE para

conservar el control total de la herramienta.

Lijado con discos abrasivos (fig. 3)

Se encuentran a su disposición accesorios de lijado con cargo extra.

INSTALACION DE DISCOS DE LIJA:

Asegúrese que la herramienta esté apagada y desconectada. Empuje el cubo de

la tuerca del disco a través del centro del mismo, y también a través del disco de

respaldo, hasta que asiente bien.

Coloque los discos ensamblados en la flecha de la herramienta e inserte la

tuerca del disco al cubo. Atornille el montaje en el sentido de las manecillas del

reloj hasta llegar al tope. Trabe el pasador de seguridad. Cuando utilice un

disco abrasivo sujete la herramienta de modo que se produzca un ángulo de 10

a 15 grados entre el disco y el material sobre el que está trabajando, como se

ilustra en la figura 4. Si sólo se emplea el borde exterior del disco de lijado, el

resultado será una superficie áspera. Si se hace presión con el disco totalmente

aplanado contra el objeto de trabajo, la acción de lijado resultará irregular y a

saltos, y será difícil controlar la unidad.

PRECAUCIONES A TOMAR CUANDO LIJE PINTURA

1. NO SE RECOMIENDA el lijado de pintura con base de plomo, por la

dificultad para controlar el polvo contaminado. Los niños y las mujeres

embarazadas son las personas con mayor peligro de sufrir envenenamiento

por plomo.

2. Ya que es difícil identificar si una pintura contiene plomo sin un análisis

químico, recomendamos seguir las precauciones que siguen cuando se lije

cualquier tipo de pintura.

SEGURIDAD PERSONAL

a. No deben tener acceso al área de trabajo niños ni mujeres embarazadas

hasta que ésta se encuentre perfectamente limpia.

b. Todas las personas que ingresen en el área de trabajo deberán utilizar

máscara contra polvo o un respirador. El filtro deberá reemplazarse

diariamente o en el momento en que el usuario perciba dificultad para

por minuto: NO LOAD RPM) indicadas en la placa de identificación de la

unidad.

• Antes de usar la herramienta, revise siempre todos los accesorios en busca de

cuarteaduras o defectos. ¡Descarte de inmediato la pieza si tiene un desperfecto

de esta clase! Deberá revisar, del mismo modo, la rueda cuando sospeche que

la unidad ha caído o se ha golpeado.

• Al accionar la herramienta (con una rueda nueva o de reemplazo instalada),

sujétela bien dentro de una zona protegida adecuadamente y déjela funcionar

durante un minuto. Si la rueda tiene una cuarteadura o una hendidura

inadvertidas, deberá romperse en pedazos en menos de un minuto. Nunca

accione una herramienta cuando haya una persona alineada con la rueda: esto

incluye al propio operador.

• Evite que la rueda opere a saltos o se maltrate mientras funciona. Si sucediera

así, apague y desconecte la herramienta y revise la rueda.

• Emplee siempre guardas cuando utilice discos con centro hendido o piedras de

esmerilado de copa.

• PRECAUCION: Algunos tipos de maderas contienen conservadores como el

arsenato cúprico de cromo (CCA) que pueden ser tóxicos. Cuando lije estos

materiales tenga cuidado extremo para evitar la inhalación y minimizar el

contacto con la piel.

CONSERVE ESTAS INSTRUCCIONES

Carbones del motor

Master Mechanic utiliza un avanzado sistema de carbones que detiene

automáticamente el motor del taladro cuando se desgastan estas piezas. Esto

impide que el motor se dañe seriamente.

Operación del seguro de la flecha (fig. 2)

Oprima el seguro de la flecha y gire ésta última hasta que el perno se enganche

para asegurar la flecha.

NOTA: Nunca oprima el perno de seguridad cuando la herramienta esté en

funcionamiento o el disco continúe girando.

Mango auxiliar (fig. 2)

Su esmeril incluye un mango auxiliar que se puede instalar a cualquier lado de

*TV800 / 386239 11/18/03 11:36 AM Page 14

Page 15

E SPAÑOL

15

respirar a través del dispositivo. NOTA: Sólo deben emplearse máscaras

contra polvo adecuadas para vapores y polvos originados en pintura que

contiene plomo. Las máscaras ordinarias para pintar no ofrecen ésta

protección. Consulte a su distribuidor local de ferretería para que le

recomiende el equipo adecuado.

c. NO se deberá COMER, BEBER NI FUMAR en el área de trabajo, para evitar

la ingestión de partículas de pintura contaminadas. El operador deberá

lavarse y limpiarse ANTES de comer, beber o fumar. No se deben dejar

artículos de estas clases en un área de trabajo en la que se puede asentar

polvo.

SEGURIDAD AMBIENTAL

a. La pintura debe removerse de manera que se minimice la cantidad

generada de polvo.

b. Se deben sellar los accesos a las áreas en donde se está removiendo

pintura con hojas de plástico cuyo espesor mínimo sea de 0.1 mm.

c. El lijado se debe realizar de manera que se reduzca la salida de polvo de

pintura fuera del área de trabajo.

LIMPIEZA Y DESECHO

a. Todas las superficies en el área de trabajo deben aspirarse y limpiarse

diariamente mientras dure el lijado. Se deben cambiar con frecuencia los

filtros de bolsa de la aspiradora.

b. Las telas plásticas de recolección se deben recoger y desechar con todos los

restos de polvo y de pintura. Se colocarán en recipientes desechables

sellados, y se desecharán por medio del servicio de recolección regular de

basura. Debe procurarse que, durante la limpieza, no haya niños ni

mujeres embarazadas en las proximidades del área de trabajo.

c. Todos los juguetes, mobiliario y utensilios usados por niños deben lavarse a

conciencia antes de que se vuelvan a utilizar.

Remoción del disco

APAGUE Y DESCONECTE LA HERRAMIENTA

Utilice un trapo o un guante para protegerse la mano, y gire el montaje del

disco en sentido contrario a las manecillas del reloj para desmontarlo de la

flecha de la unidad. Sujete la flecha con el perno de seguridad.

Esmerilado con ruedas de centro hendido (flecha 5/8"—11)

Se pueden emplear ruedas de esmerilar con centro realzado para la remoción

moderada de metal en superficies planas o contorneadas.

PRECAUCION: Nunca utilice ruedas de esmerilar de centro hendido sin la

guarda apropiada.

Para instalar las ruedas de esmerilar de centro hendido:

1. Asegúrese que la herramienta se encuentra desconectada de la toma de

corriente, y que el interruptor esté en la posición "apagado".

2. Verifique que el montaje de la guarda se encuentre bien sujeto sobre a la

caja de engranes.

3. Coloque la arandela de respaldo sobre el eje de la herramienta, como se

ilustra en la figura 5.

4. Verifique los límites velocidad indicados en la rueda de esmerilar de centro

realzado. Nunca utilice una rueda de menor velocidad que la señalada en

la placa de identificación de la herramienta.

5. Coloque la rueda de esmerilar en la flecha de la herramienta como se

muestra.

6. Atornille la roldana de seguridad en la flecha como se muestra. Sujete éste

valiéndose del perno de seguridad, y apriete la tuerca roldana con la llave.

Cuando emplee usted una rueda de esmerilar de centro hendido, sujete la

herramienta de modo que haga un ángulo aproximado de 30° entre la rueda y

la superficie de trabajo.

Cepillos cónicos de alambre y cepillos circulares de

alambre trenzado.

1. Desconecte la unidad de la corriente eléctrica y verifique que el interruptor

esté en posición de apagado. Deje descansar la esmeriladora sobre el

dorso, con la flecha orientada hacia arriba.

2. Asegúrese de que la velocidad de trabajo del cepillo de alambre sea igual

o superior a la velocidad indicada para la esmeriladora en la placa de

identificación.

*TV800 / 386239 11/18/03 11:36 AM Page 15

Page 16

E SPAÑOL

16

CEPILLOS Máx. 100 mm (4") Cepillo Para remover óxido

DE de alambre y preparación de

ALAMBRE Máx. 76 mm (3") Cepillo cónico superficies antes

de pintar

* Los discos de esmeril de centro hendido deben ajustarse dentro de los confines

de la guarda y deben estar clasificados para una velocidad mayor a la indicada

en la placa de identificación.

ADVERTENCIA — A fin de reducir el riesgo de lesiones, utilice siempre las

guardas apropiadas cuando esmerile, y también utilice protección para los ojos.

Garantía de calidad por dos años

Este producto está garantizado por dos años contra cualquier defecto en

materiales y mano de obra. Si resultara defectuoso, el producto será reparado o

reemplazado sin cargo alguno. Simplemente proporcione la prueba de compra

y devuelva la herramienta al lugar en que la adquirió. El desgaste normal y los

daños producidos por abuso, maltrato o reparaciones por personal no

autorizado no están cubiertos por esta garantía. Esta garantía no se aplica a los

accesorios. Esta garantía le otorga derechos legales espeícficos y usted puede

tener otros que pudieran variar de estado a estado.

Garantía de satisfacción sin riesgo por 30 días

Si, por cualquier motivo, usted no estuviera completamente satisfecho con el

desempeño o con los resultados de este producto, dentro de los treinta días

siguientes a la fecha original de compra, éste será reparado o reemplazado sin

cargo alguno. Simplemente proporcione prueba de compra y devuelva la

herramienta al lugar en que la adquirió.

TruServ

8600 W. Bryn Mawr Ave.

Chicago, IL 60631-3505

3. Atornille el cepillo en la flecha y apriétela.

Las aplicaciones más frecuentes de los cepillos cónicos de alambre son limpieza

de soldadura, ángulos y aristas, y remoción de pintura.

Los cepillos circulares de alambre trenzado tienen las mismas aplicaciones, pero

también se pueden utilizar para el acabado de superficies y aristas irregulares.

MANTENIMIENTO

Solamente utilice jabón suave y un trapo húmedo para limpiar la herramienta.

Nunca permita que ningún líquido se introduzca en la herramienta; nunca

sumerja ninguna parte de la herramienta en ningún líquido.

IMPORTANTE: Para garantizar la SEGURIDAD y la CONFIABILIDAD del

producto, las reparaciones, el mantenimiento y los ajustes deben ser realizados

por centros de servicio autorizados u otras organizaciones de servicio

calificadas, que siempre utilicen partes de repuesto idénticas.

Lubricación

Las herramientas MASTER MECHANIC se lubrican apropiadamente en la

fábrica y están listas para usarse.

Accesorios

El distribuidor o centro de servicio de su localidad cuentan con una gran

variedad de accesorios para emplearse con su herramienta.

PRECAUCION: El empleo de cualquier accesorio o dispositivo no recomendado

puede ser peligroso.

TIPO DE ACCESORIO NOTAS USO

DISCO Use la guarda Para remoción

DE CENTRO suministrada con moderada de metal

HENDIDO la herramienta y mampostería en

superficies planas

o contorneadas

DISCOS Para rebajar soldaduras,

DE LIJA afilar bordes y

piezas de carrocerías

automotrices

Cat. No. TV800 Form No. 386239 (OCT97-CD-1)

*TV800 / 386239 11/18/03 11:36 AM Page 16

Loading...

Loading...