Page 1

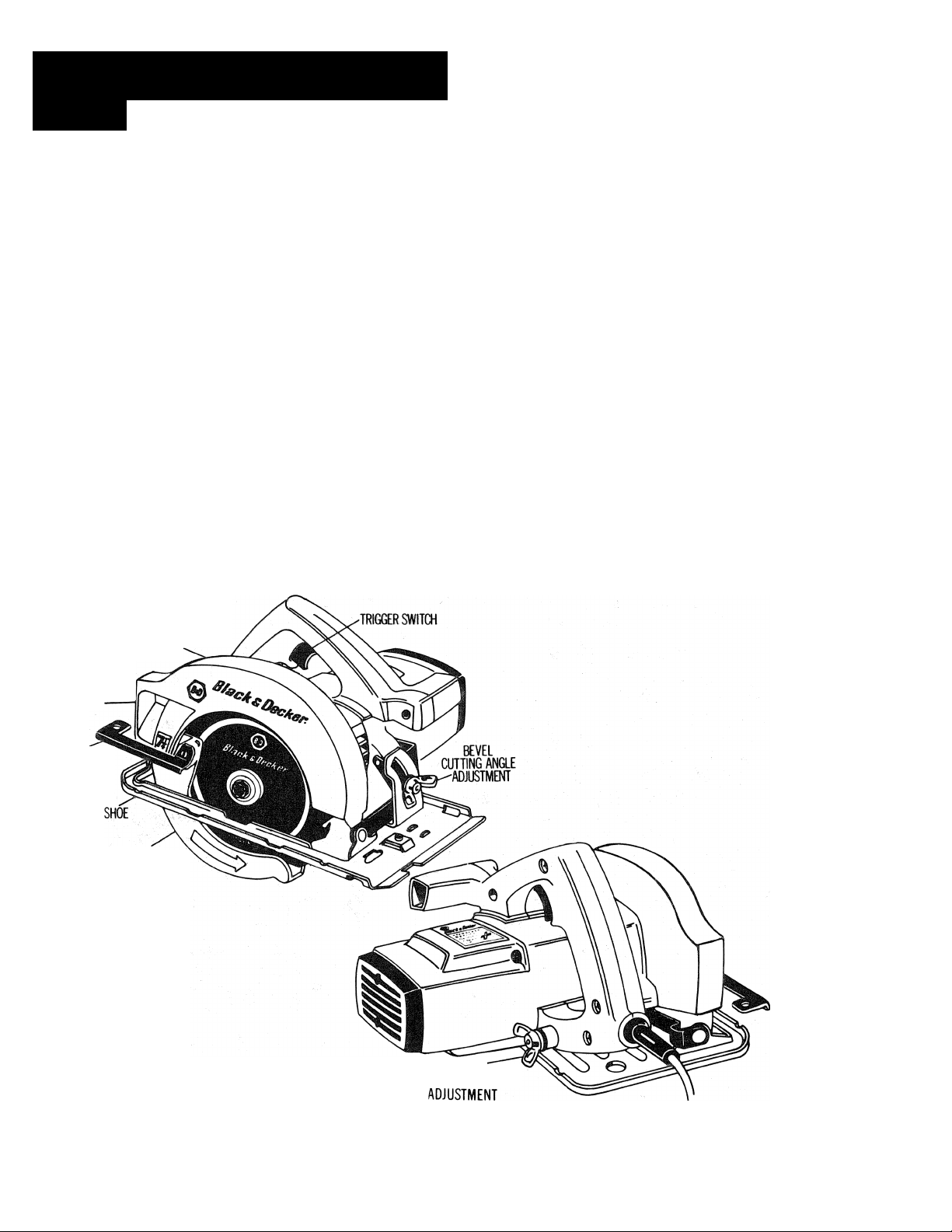

BIACK&DEGKER

#

NO. 3027-09 & 3027-90

7V4" SAWCAT® CIRCULAR SAW

Featuring:

1) Double Insulated construction with 3-wire, grounding 10 foot rubber power

cord.

2) Motor brushes are easily serviced.

3) Good visibility of blade and cutting line from operating position. Adjustable

cutting guide.

4) Rolled edge on shoe facilitates using guide strip for accurate cutting.

5) Knobs control bevel and cutting depth adjustments.

6) Enclosed lower guard return spring. Separate, removable switch handle, if re

placement ever needed.

MAXIMUM CUTTING DEPTH at 90°—2yu"; at 45°—1%"

120 Volts, 10 Amps. 5500 R.P.M.

STATIONARY

UPPER BLADE

GUARD

SMXJST

EJECTW

CHUTE

LEVER FOR

RETRACTIf«

LOWER BLADE

OJARD

LOWER

BLADE

GUARD

CUTTING-

DEPTH

INSTRUCTION MANUAL

Page 2

IMPORTANT SAFETY INSTRUCTIONS

WARNING; When using Electric Tools, basic safety precautions should always be

followed to reduce risk of fire, electric shock, and personal injury, including the following:

READ ALL INSTRUCTIONS

1. KEEP WORK AREA CLEANXIuttered areas and benches invite injuries.

2. CONSIDER WORK AREA ENVIRONMENT. Don’t expose power tools to rain. Don’t

use power tools in damp or wet locations. Keep work area well lit.

3. GUARD AGAINST ELECTRIC SHOCK. Prevent body contact with grounded surfaces.

For example: pipes, radiators, ranges, refrigerator enclosures.

4. KEEP CHILDREN AWAY. All visitors should be kept away from work area. Do not let

visitors contact tool or extension cord.

5. STORE IDLE TOOLS. When not in use, tools should be stored in dry, and high or

locked-up place—out of reach of children.

6. DON’T FORCE TOOL. It will do the job better and safer at the rate for which it was

intended.

7. USE RIGHT TOOL. Don’t force small tool or attachment to do the job of a heavy-duty

tool. Don’t use tool for purpose not intended, for example, don’t use circular saw for

cutting tree limbs or logs.

8. DRESS PROPERLY. Do not wear loose clothing or jewelry. They can be caught in

moving parts. Rubber gloves and non-skid footwear are recommended when working

outdoors. Wear protective hair covering to contain long hair.

9. USE SAFETY GLASSES. Also use face or dustmask if cutting operation is dusty.

10. DON’T ABUSE CORD. Never carry tool by cord or yank it to disconnect from

receptacle. Keep cord from heat, oil, and sharp edges.

11. SECURE WORK. Use clamps or a vise to hold work. It’s safer than using your hand

and it frees both hands to operate tool.

12. DON’T OVERREACH. Keep proper footing and balance at all time-.

13. MAINTAIN TOOLS WITH CARE. Keep tools sharp and clean for better and safe

performance. Follow instructions for lubricating and changing accessories. Inspect

tool cords periodically and if damaged have repaired by authorized service facility. In

spect extension cords periodically and replace if damaged. Keep handles dry, clean,

and free from oil and grease.

14. DISCONNECT TOOLS. When not in use, before servicing, and when changing

accessories, such as blades, bits, cutters.

15. REMOVE ADJUSTING KEYS AND WRENCHES. Form habit of checking to see that

keys and adjusting wrenches are removed from tool before turning it on.

16. AVOID UNINTENTIONAL STARTING. Don’t carry plugged-in tool with finger on

switch. Be sure switch is off when plugging in.

17. OUTDOOR USE EXTENSION CORDS. When tool is used outdoors, use only extension

cords intended for use outdoors and so marked.

Page 3

18. STAY ALERT. Watch what you are doing. Use common sense. Do not operate tool

when you are tired.

19. CHECK DAMAGED PARTS. Before further use of the tool, a guard or other part that

is damaged should be carefully checked to determine that it will operate properly and

perform its intended function. Check for alignment of moving parts, binding of mov

ing parts, breakage of parts, mounting, and any other conditions that may affect its

operation. A guard or other part that is damaged should be properly repaired or

replaced by an authorized service center unless otherwise indicated elsewhere in

this instruction manual. Have defective switches replaced by Authorized Service

Center. Do not use tool if switch does not turn it on and off.

20. DO NOT OPERATE portable electric tools near flammable liquids or in gaseous or

explosive atmospheres. Motors in these tools normally spark, and the sparks might

ignite fumes.

CIRCULAR SAW SAFETY INSTRUCTIONS

1. Disconnect plug from power supply before changing blades, making cutting depth or

cutting angle adjustments, inspecting, cleaning or when saw is not used.

2. Keep guards in place and in working order. Never wedge or tie lower guard open.

Check operation of lower guard before each use. Do not use if lower guard does not

close briskly over saw blade. CAUTION : If saw is dropped, lower guard may be bent,

restricting full return.

3. KEEP BLADES CLEAN AND SHARP. Sharp blades minimize stalling and kick back.

4. DANGER: KEEP HANDS AWAY FROM CUTTING AREA. (See fig. 7) Keep hands away

from blades. Do not reach underneath work while blade is rotating. Do not attempt to

remove cut material when blade is moving. CAUTION: Blades coast after turn off.

5. SUPPORT LARGE PANELS. Large panels must be supported as shown in FIGURE 8

tominimizethe risk of blade pinching and kick back. When cutting operation requires

the resting of the saw on the work-piece, the saw shall be rested on the larger portion

and the smaller piece cut off. (See FIGURE 7)

6. USE RIP FENCE. Always use a fence or straight edge guide when ripping.

7. GUARD AGAINST KICK BACK. Kick back occurs when the saw stalls rapidly and is

driven back towards the operator. Release switch immediately if blade binds or saw

stalls. Keep blades sharp. Support large panels as shown in FIGURE 8. Use fence or

straight edge guide when ripping. Don’t force tool. Stay alert, exercise control. Don’t

remove saw from work during a cut while the blade is moving.

8. LOWER GUARD. Raise lower guard with the retracting handle.

9. ADJUSTMENTS. Before cutting be sure depth and bevel adjustments are tight.

10. USE ONLY CORRECT BLADES IN MOUNTING. Do not use blades with incorrect size

holes. Never use defective or incorrect blade washers or bolts.

11. AVOID CUTTING NAILS. Inspect for and remove all nails from lumber before cutting.

SAVE THESE INSTRUCTIONS

Page 4

GROUNDING

This tool should be grounded while in use to protect the operator from electric

shock. The tool is equipped with an approved three-conductor cord and threeprong grounding type plug to fit the proper grounding type receptacle. The green

(or green and yellow) conductor in the cord is the grounding wire. Never connect

the green (or green and yellow) wire to a live terminal.

If your unit is for use on less than 150 volts, it has a plug like that shown in

Figure A. If it is for use on 150 to 250 volts, it has a plug like that shown in Figure

D. An adapter. Figures B and C, is available for connecting Figure A plugs to twoprong receptacles. The green-colored rigid ear, lug, etc., must be connected to a

permanent ground such as a properly grounded outlet box.

No adapter is available for a plug as shown in Figure D. Adapter shown in Figures

B & C is Not for Use in Canada.

GROUNDED OUTLET BOX ^

^ ADAPTER

©

GROUNDING

PRONG IS

LONGEST OF

THE 3 PRONGS

We recommend that you NEVER disassemble the tool or try to do any rewiring in

the electrical system. Any repairs should be performed only by B&D Service Cen

ters or other qualified service organizations. Should you be determined to make a

repair yourself, remember that the green colored wire is the “grounding” wire.

Never connect this green wire to a “live” terminal. If you replace the plug on the

power cord, be sure to connect the green wire only to the grounding (longest)

prong on a 3-prong plug, THESE INSTRUCTIONS

(0)

©

A. B. C. D.

GROUNDED

OUTLET BOX ^

( GROUNDING

MEANS

GROUNDED OUTLET BOX ^

©

m

GROUNDING

PRONG IS

LONGEST OF

THE 3 PRONGS

/

©

EXTENSION CORDS

Tools that have 3 wire cords requiring grounding must only be used with extension cords

that have 3-prong grounding type plugs and 3-pole receptacles. Only round jacketed

extension cords should be used, and we recommend that they be listed by Underwriters

Laboratories (U.L) (C.S.A. in Canada). If the extension will be used outside, the cord must be

suitable for outdoor use. Any cord marked as outdoor can also be used for indoor work.

An extension cord must have adequate wire size (AWG or American Wire Gauge) for

safety, and to prevent loss of power and overheating. The smaller the gauge number of

the wire, the greater the capacity of the cable, that is 16 gauge has more capacity than 18

gauge. When using more than one extension to make up the total length, be sure each

individual extension contains at least the minimum wire size.

To determine the minimum wire size required, refer to the chart below:

CHART FOR MINIMUM WIRE SIZE (AWG) OF EXTENSION CORDS

NAMEPUtTE

IÀTING-AMPS 25

0 -10.0

10.1 -13.0 16

13.1 -15.0

Before using an extension cord, inspect it for loose or exposed wires, damaged insulation,

and defective fittings. Make any needed repairs or replace the cord if necessary. Black &

Decker has extension cords available that are U.L (C.SA in Canada) listed for outdoor use.

18 18 16

14 14 12 12

50 75 100 125

16

MOTOR

Your Black & Decker tool is powered by a B & D-built motor. Be sure your power

supply agrees with the nameplate marking.

Volts 50/60 Hz or “AC only” means your tool must be operated only with alter

nating current and never with direct current. Volts DC-60Hz or AC/DC means your

tool may be operated with either alternating or direct current.

Voltage decrease of more than 10% will cause loss of power and over-heating. All B&D

tools are factory-tested; if this tool does not operate, check the power supply.

TOTAL EXTENSION CORD LENGTH ■ FEET

150 175

14 14 14 12

16

14

12 12

14 12

12

12

200

12

12

—

Page 5

MAINTENANCE

It is recommended that, once a year, you take or send the tool to a B&D Service

Center for a thorough cleaning, inspection and lubrication of the gear case. Service

Center addresses are shown on the owner registration card packed with your tool.

RETRACTING

LEVER

FIGURE 1

MOlfITING

HOLE

SCREW WASHER

CLAMPING

SCREW OUTER CLAMP

WASHER

FIGURE 2

ATTACHING & REMOVING BLADES

1. BE SURE SAW IS DISCONNECTED FROM POWER SUPPLY!

2. To remove blade clamping screw (Fig. 1):

—a. ON NEW SAWS (without blade attached). Turn screw counter-clockwise with

blade wrench provided. If screw does not loosen easily from spindle, tap the outer

end of the wrench sharply in a counter-clockwise direction with a piece of wood

to "free” the screw threads. Remove screw and outer clamp washer.

—b. ON SAWS WITH BLADE ATTACHED. Using the retracting lever, retract the

lower blade guard and place the Saw on a piece of scrap lumber as shown in

Figure 2. Press down on the Saw so that the blade teeth dig slightly into the lum

ber and prevent the blade from turning. Then, with the blade wrench provided,

turn the clamping screw counter-clockwise and remove the screw and outer clamp

washer. Disengage the blade teeth from the lumber, and with the lower blade

guard still retracted, lift off the blade.

3. To attach the blade: Place inner clamp washer on spindle if previously re

moved. Retract lower blade guard and place blade over inner clamp washer with

printed side of blade out (teeth at bottom of blade pointing forward). Fit outer

clamp washer onto spindle . . . “flats” on the outer washer must mesh with the

“flats” on the spindle. Thread on clamping screw firmly by hand to hold washers

in position. Place Saw on piece of scrap lumber as shown in Figure 2 and press

down on the Saw so that blade teeth dig slightly into wood and prevent the blade

from turning. Tighten clamping screw (clockwise) firmly with the blade wrench.

NOTE: An alternate way to keep the blade from turning, when tightening or loosen

ing the blade screw, is to hold a large nail through the hole in the blade and

against the forward part of the shoe. Rest the nail on top of the shoe when tight

ening, against the bottom when loosening. CAUTION: Remove nail before con

necting plug.

Page 6

FIGURE 3

CUTTING DEPTH ADJUSTMENT

DISCONNECT PLUG FROM POWER SUPPLY BEFORE MAKING THIS OR ANY

OTHER ADJUSTMENT.

For the most efficient cutting action, set the Depth Adjustment so that one tooth

of the blade will project below the material to be cut. This distance is from the

tip of the tooth to the bottom of the gullet in front of it. This keeps blade friction

at a minimum, removes sawdust from the cut, and results in cooler, faster sawing.

NOTE; When using Carbide-Tipped Blades, make an exception to the above rule

and allow only one-half of a tooth to project below the material being cut.

To adjust the cutting depth:

1. BE SURE THE SAW IS DISCONNECTED FROM THE POWER SUPPLY!

2. Place the saw in the position shown in Figure 3 and loosen depth adjustment

knob ‘‘A".

3. Place a scrap piece of the material to be cut along the side of the blade as

shown. Raise or lower the shoe until the blade projects from the shoe the

desired distance. Retighten knob.

SWITCH

Pull the trigger switch to turn the motor “ON". Releasing the trigger instantly

turns the motor "OFF”. For safer operation, this tool has no provision to lock

the switch in the “ON” position.

6

Page 7

FIGURE 4

BEVEL ANGLE ADJUSTMENT

DISCONNECT THE SAW FROM THE POWER SUPPLY BY PULLING THE PLUG,

BEFORE MAKING THIS, OR ANY OTHER ADJUSTMENT! On the front of the saw

is a bevel angle adjustment device (Figure 4) consisting of calibrated quadrant

“E” and a knob “D”. To set the saw for a bevel cut, loosen knob and tilt shoe

to angle desired. Retighten knob firmly.

CAUTION: When making bevel cuts, place one hand on the motor housing as

shown in Figure 4. Exert only enough pressure in the direction of the arrow to

keep the saw shoe flat on the work. This will insure an accurate bevel cutting

angle and help prevent the blade from binding in the cut.

GUIDE ALONG PENCILLED GUTTING LINE

SO KERF FALLS IN WASTE STOCK —

GUIDE EDGES

Guide along the penciled cut

ting line so that the kerf falls

into the waste or surplus

material—See Figure 5.

An Adjustable Guide on

the front of the saw

shoe has two guide

edges (Figure 6)—one

for vertical cutting, and

one for 45‘’bevel cut

ting. These edges en

able you to guide the

saw along penciled lines,

and the edges line up

with the left (inner) side

of the saw blade. This

makes the slot or "kerf"

cut by the moving blade

fall to the right of the

guide mark.

DESIRED

- LENGTH -

OF STOCK

WASTE

SURPLUS

-KERF

OR

STOCK

FIGURE 5

45* BEVEL CUT 1 GUIDE

0* VERTICAL CUTJ EDGES

FIGURE 6

Page 8

OPERATION

Figure 7 shows proper sawing

position. Note that hands are

kept away from cutting area,

safety glasses are worn, power

cord is kept clear of cutting

area and positioned so that it

will not be caught on the work

piece while cutting and that

clothing is not loose to the point

where it might get caught in

moving parts.

When operating the saw, keep

the cord away from the cutting

area and prevent it from becom

ing hung up on the work piece.

WARNING: It is impor

tant to support the work

properly and to hold the

saw firmly to prevent

loss of control which

could cause personal in

jury. Figure 7 illustrates

typical hand support of

the saw.

TO AVOID KICKBACK. DO

SUPPORT BOARD OR

PANEL NEAR THE CUT.

FIGURE 8

8

Page 9

OPERATION

WARNING: It is important to support the work properly and to hold the saw

firmly to prevent loss of control which could cause personal injury.

ALWAYS DISCONNECT SAW BEFORE MAKING ANY ADJUSTMENTS! Place the work

with its "good” side—the one on which appearance is most important—down.

The saw cuts upward, so any splintering will be on the work face that is up when

you saw it.

Support the work so that the cut will be on your right. Place the wider portion of

the saw shoe on that part of the work piece which is solidly supported, not on the

section that will fall off when the cut is made. As examples. Figure 9 illustrates

the RIGHT way to cut off the end of a board, and Figure 10 the WRONG way. If

the work is short or small, clamp it down. Don't try to hold short pieces by hand!

FIG. 9 -RIGHT

Draw the required guide lines. Then rest the front of the saw shoe on the work

with the guide edge lined up with the drawn guide line. Before starting the motor,

push the blade lightly against the edge of the work and then back off about

Now, start the motor, and when the blade gains full speed, push the saw forward

and begin sawing. As you begin cutting, the lower blade guard will automatically

begin to telescope into the upper blade guard. This telescoping action will continue

as you advance the saw until it reaches the position in Figure 9

Push the saw forward at a speed which allows the blade to cut without laboring.

Hardness and toughness can vary even in the same piece of material, and a

knotty or damp section can put a heavy load on the saw. When this happens, push

the saw more slowly, but hard enough to keep it working without much decrease

in speed. Forcing it beyond this makes for rough cuts, inaccuracy and overheating

of the motor.

Should your cut begin to go off the line, don’t try to force the saw back on. Re

lease trigger and allow blade to come to a complete stop. Then you can withdraw

the saw, sight anew, and start a new cut a trifle inside the wrong one. In any

event, withdraw the saw if you must shift the cut. Forcing a correction inside the

cut can stall the saw and perhaps spoil the work. IF SAW STALLS, RELEASE THE

TRIGGER, BACK THE SAW UNTIL IT IS LOOSE. BE SURE BLADE IS STRAIGHT IN

THE CUT BEFORE RESTARTING.

As you finish a cut, release the trigger and allow the blade to stop before lifting

the saw from the work. As you lift the saw the spring-tensioned telescoping guard

will automatically close under the saw. Remember the blade is exposed until this

occurs; never reach under the work for any reason whatsoever. When you have to

retract the telescoping guard manually (as is necessary for starting pocket cuts)

always use the retracting lever.

FIG. 10 - WRONG

Page 10

FIGURE 11

POCKET CUTTING

DISCONNECT SAW FROM POWER SUPPLY BEFORE MAKING CUTTING DEPTH

ADJUSTMENT! Set blade to desired cutting depth. Tilt saw forward and rest

front of shoe on material to be cut. Using the retracting lever, retract blade guard

to an upward position. Lower rear of shoe until blade teeth almost touch cutting

line. Now release the blade guard and its contact with the work will keep it in

position to open freely as you start the cut (Figure 11). Start the motor and

gradually lower the saw until its shoe rests flat on the material to be cut. Advance

saw along cutting line until cut is completed. Release trigger and allow blade to

stop completely before withdrawing the blade from the material. When starting

each new cut, repeat as above. Never tie the blade guard in a raised position.

ACCESSORIES

The accessories listed in this manual are available at extra cost from your local dealer

or Black & Decker Service Center. A complete listing of service centers is included

on the owner’s registration card packed with your tool.

If you need assistance in locating any accessory, please contact: Black & Decker (U.S.)

Inc., User Services Department, 10 North Park Drive, P.O. Box 857, Hunt Valley,

MD 21030-0857.

RIP FENCE. . . Attaches to top of Saw shoe. Permits rip

cuts without penciled guide lines.

B. SAW PROTRACTOR. . . Guides Saw for accurate cut-off

work. Adjusts from 0° to 70°.

CUT-OFF GUIDE. . For 90° or 45° cuts.

SAFETY GLASSES. . . Lightweight, one-piece, impact resis

tant, clear plastic safety glasses with side shields. Can be

worn directly over eyes or over prescription glasses.

Comfortable.

SAW CARRYING CASE

handy on the job.

CAUTION: Recommended accessories and saw blades for your Saw are listed

above and on the next page of this manual. The use of any other type of blade

or accessory might be hazardous.

. Protect your saw, keep saw accessories and extra blades

10

Page 11

BLACK & DECKER CIRCULAR SAW BLADES

A dull blade will cause slow, inefficient cutting and will overload the saw motor. It is a

good practice to keep extra blades on hand so that sharp blades are available while the dull

ones are being sharpened (See "SAWS—SHARPENING" in Yellow Pages). In fact, many lower

priced blades can be replaced with new ones at very little cost over the sharpening price. USE

ONLY 71/4", 7%" or 7" BLADES, WITH %" ARBOR HOLE, ON YOUR SAW.

Hardened gum on the blade will slow down the cutting. This gum can best be removed with

trichlorethylene, kerosene or turpentine. Remove blade before cleaning to prevent solvent from

damaging plastic parts of saw.

Black & Decker manufactures a complete line of saw blades and the following types are

available.

Standard; Outstanding value for the price. These blades are also available in bulk quantities.

Ask for quantity prices. (When sold in bulk, "-01" is added to catalog number).

Premium: Industrial chrome plating gives twice the cutting life of unplated blades.

TYPE OF BLADE

COMBINATION Chisel tooth configuration means this

blade is the fastest cutting blade in our line. Specifically

designed for general-purpose ripping and cross-cutting

where the finish of the cut is not critical.

FRAMING/RIP An all-purpose blade for smooth, fast

cutting in any direction. Rips, crosscuts, miters, etc.

Gives especially fast, smooth finishes when cutting with

the grain of both soft and hard woods.

METAL CUTTING Teeth shaped and set specifically for

cutting aluminum, copper, lead and other soft metals.

HOLLOW GROUND PLANER Specially ground for

satin-smooth finish cuts (cross-cuts, rips and miters) In

all solid woods. A professional quality blade for use In

cabinet work, furniture, etc. Specifically designed to

make extremely smooth cuts in wood.

CARBIDE TIPPED (8 tooth) Specially designed for cut

ting tough-to-cut materials such as: Transite, Cemesto

board, asbestos, Formica and Masonite. Will also cut

wood where speed and finish are not critical.

CARBIDE TIPPED (20 tooth) Chisel tooth combination

blade for fast general-purpose cutting in all types of

woods. Tips are of tungsten carbide material which out

lasts regular steel blades up to 10 to 1. Teeth are accu

rately set for ease of cutting.

TOOTH

SHAPE

>

FLOORING For use where nails or other metal objects

may be encountered, such as cutting reclaimed lumber,

flooring, opening crates. Allows crosscuts as well as

miters.

HOLLOW GROUND PLYWOOD Special taper grinding

on the sides of this thin-rim blade gives an absolutely

smooth cut in plywood, veneers and laminates, etc. Can

be used in crosscutting and mitering for a professional

finish on ail types of cabinet work.

STEEL CUTTING FRICTION Designed for cutting cor-

rugated or sheet roofing, black Iron, furnace pipe or

thin bar stock. Cuts faster with less filings than abra

sive blades. Cuts by friction action.

CROSS-CUT Specifically designed for smooth, fast cut

ting cross the grain of both hard and soft woods where

finish is an Important factor. May also be used for rip

and crosscuts on extremely hard woods.

ABRASIVE BLADES (Fiberglass Reinforced)

Aluminum Oxide cuts ferrous

metals and hardened non-ferrous

metals.

11

rry

Silicon Carbide cuts masonry

materials and soft non-ferrous

metals.

Page 12

CLEANING

Use only mild soap and a damp cloth to clean the tool. Many household cleaners

contain chemicals which could seriously damage the plastic. Also, do not use

gasoline, turpentine, lacquer or paint thinner, dry cleaning fluids or similar prod

ucts. Never let any liquid get inside the tool; never immerse any part of the tool

into a liquid.

IMPORTANT

To assure product SAFETY and RELIABILITY, repairs, maintenance and adjustment

(including brush inspection and replacement) should be performed by Black &

Decker Service Centers or other qualified service organizations, always using

Black & Decker replacement parts. When servicing Double-Insulated Tools, it is

extremely important that ONLY IDENTICAL REPLACEMENT PARTS BE USED and

that REASSEMBLY OF TOOL IS IDENTICAL TO THE ORIGINAL ASSEMBLY.

COMMERCIAL/INDUSTRIAL USE WARRANTY

Black & Decker (U.S.) Inc. warrants this product for one year from date of pur

chase. We will repair without charge, any defects due to faulty material or

workmanship. Please return the complete unit, transportation prepaid, to any

Black & Decker Service Center or Authorized Service Station listed under “Tools

Electric” in the yellow pages. This warranty does not apply to accessories or

damage caused where repairs have been made or attempted by others.

Like all Black & Decker tools, your Saw is listed by Underwriters’ Laboratories to en

sure that it meets stringent safety requirements.

This symbol on the nameplate means the product

is Listed by Underwriters' Laboratories, Inc,

See Tools-Electric’

7\

—Yellow Pages—

for Service & Sales

BLACK & DECKER (U.S.) INC.

U.S. Power Tools Group • 10 North Park Drive

P.O. Box 798 • Hunt Valley, MD 21030-0798

Form No. 740565-03

(AUG86-CD)

©1982 Printed in U.S.A.

Loading...

Loading...