Page 1

Decker, jvd' sawcat

s

ûl

8

IX

û-

X

m

m

Z

O

ci

<

m

Ü

O

>

O

CM

PJJ. SAFETY RULES

+

^ FOR POWER TOOLS

MOTOR

Your Black and Decker tool is powered by a B&D-built motor.

Be sure your power supply agrees with voltage marked on name

plate. Volts AC means Alternating Current (25 to 60 cycles) only.

1. KNOW YOUR POWER TOOL - Read owner's manual care

fully. Learn its applications and limitations as well as the

specific potential hazards peculiar to this tool.

GROUND ALL TOOLS - UNLESS DOUBLE-INSULATED. If

2.

tool is equipped with three-prong plug, it should be plugged

Volts AC/DC means it will also operate on Direct Current (single

speed unit only). Voltage variation of more than 10% will cause

loss of power and over-heating. All B&D tools are factory-tested.

If this tool does not operate, check the power supply line for

blown fuses and the plug and receptacle for proper contact.

into a three-hole electrical receptable. If adapter is used to

accommodate two-prong receptacle, the adapter wire must

be attached to a known ground. Never remove third prong.

3. KEEP GUARDS IN PLACE and in working order.

4. KEEP WORK AREA CLEAN. Cluttered areas and benches

invite accidents.

5. AVOID DANGEROUS ENVIRONMENT. Don't use power tool

in damp or wet locations. And keep work area well lit.

6. KEEP CHILDREN AWAY. All visitors should be kept safe dis

tance from work area.

7. STORE IDLE TOOLS. When not in use, tools should be

stored in dry, high or locked-up place — out of reach of

children.

8. DON'T FORCE TOOL. It will do the job better and safer at

the rate for which it was designed.

9. USE RIGHT TOOL. Don't force small tool or attachment to

do the job of a heavy duty tool.

10. WEAR PROPER APPAREL. No loose clothing or jewelry to

get caught in moving parts. Rubber gloves and footwear are

recommended when working outdoors.

11. USE SAFETY GLASSES with most tools. Also face or dust

mask if cutting operation is dusty.

12. DON'T ABUSE CORD. Never carry tool by cord or yank it to

disconnect from receptacle. Keep cord from heat, oil and

sharp edges.

13. SECURE WORK. Use clamps or a vise to hold work. It's

safer than using your hand and it frees both hands to

operate tool.

14. DON'T OVERREACH. Keep proper footing and balance at all

GROUNDING

These units are equipped with approved 3-conductor power cord

and 3-prong grounding type attachment plug to be used with the

proper grounding type receptacle, in accordance with the National

Electrical Code, Canadian Electrical Code, and Underwriters'

Laboratories specifications. The green colored conductor in the

cord is the grounding wire. It is connected to the metal frame

of the unit inside the housing and to the longest prong of the

attachment plug.

terminal.

If your unit requires less than 150 volts it has a plug that looks

like Fig. "A". It will fit directly into the proper type of 3-wire

grounding receptacle. The unit is then grounded automatically

each time it is plugged in.

Shown In Fig. "B” is a special grounding adapter (not allowed

in Canada by the Canadian Electrical Code) which is available

from your dealer and will permit using a 2-wire receptacle. The

green grounding wire extending from the side of the adapter

must be connected to a Permanent Ground.

If the unit requires from 150 to 250 volts, it has a plug like Fig.

“C”. No adapter is available and the plug must be used in the

proper 3-wire grounding receptacle.

If you use an extension cord, be sure that it is a 3-conductor,

grounding type cord. Grounding must be continuous from the

tool plug to the grounded receptacle.

Never connect the green wire to a 'live”

times.

15. MAINTAIN TOOLS WITH CARE. Keep tools sharp at all

times, and clean for best and safest performance. Follow

instructions for lubricating and changing accessories.

16. DISCONNECT TOOLS. When not in use, before servicing,

when changing accessories such as blades, bits, cutters, etc.

17. REMOVE ADJUSTING KEYS AND WRENCHES. Form habit

of checking to see that keys and adjusting wrenches are

GROUNDED OUTLET BOX

/

GROUNDING

PRONG IS

LONGEST OF

THE 3 PRONGS A

OUTLET BOX

ADAPTER

GROUNDED

GROUNDED OUTLET BOX^

o

GROUNDING

PRONG IS

LONGEST OF

THE 3 PRONGS c

®

©

removed from tool before turning it on.

18. AVOID ACCIDENTAL STARTING. Don't carry plugged-in tool

with finger on switch.

EXTENSION CORD

When using the tool at a considerable distance from power

ADDITIONAL SAFETY RULES FOR SAWS

DISCONNECT PLUG from power supply before changing

1.

blades, making cutting depth or cutting angle adjustments,

lubricating, inspecting, or when saw is not being used.

WHEN RETRACTING the lower blade guard, always use the

2.

retracting lever on the guard.

NEVER TIE BACK the lower blade guard or its retracting knob.

3.

WHEN SAWING never reach underneath the material.

4.

KEEP BLADE SHARP. Dull blades may cause the saw to

5.

swerve or stall under pressure.

IF YOU DROP or damage the saw, unplug it first; then check

6.

+

to see if the blade and lower blade guard operate freely be

fore resuming operations.

IF SAW STALLS, release the trigger and disconnect plug from

7.

power supply before attempting to loosen the unit.

source, a 3-conductor, grounding-type extension cord of ade

quate size must be used for safety, and to prevent loss of power

and over-heating. Use the table below for 120-volt tools. For

220-volt tools, see same chart but use a wire size corresponding

to an extension cord length shown which is % the length of

extension to be used.

P.T.I. Safety Rule #12 applies to Extension Cords as well as the

Tool Power Cord. Before using cords, inspect them for loose or

exposed wires and damaged insulation. Make any needed repairs

or replacement before using your power tool.

Ampere rating

(on nameplate)

Ext. Cable length

25 ft. 18

50 ft. 18

75 ft.

100 ft. 18

150 ft.

200 ft.

0 to

2.0

18

16

16

2.10 to 3.5 to

3.4

18

18 18

18

16

14 12

14 12 10

5.0

Wire Size (A.W.G.)

18

16 14

14

5.10 to

7.0

18

16

12

12

7.10 to

12.1 to

12.0 16.0

16

14

12

10

_

____

_

—

14

12

10

_

____

_

____

_

.—

Form No. 97717.m

Page 2

MOUNTING SAW BLADES

BEVEL ANGLE ADJUSTMENT

POCKET CUTTING

SAW ACCESSORIES:

%

1. BE SURE THE SAW IS DISCONNECTED FROM THE POWER

SUPPLY!

2. To remove blade clamping screw;

— a. ON NEW SAWS (without blade attached), turn screw

counter-clockwise with blade wrench provided. If screw does

not loosen easily from spindle, tap the outer end of the

wrench sharply in a counter-clockwise direction with a piece

of wood to "free" the screw threads. Remove screw and outer

clamp washer.

- b. ON SAWS WITH BLADE ATTACHED, turn the blade so

that the single hole In the rim is exposed at the front of the

saw. Put a nail through this hole and turn the blade counter

clockwise until the nail is against the housing and stops the

blade from turning. Turn the blade clamping screw counter

clockwise with the blade wrench and remove the screw and

outer clamp washer.

3. To attach the blade, retract the lower blade guard and slip

the blade over the saw spindle against the inner clamp washer

with printed side of blade out (teeth at bottom of blade

pointing forward). Place outer clamp washer or spindle so

that "flats" in washer fit "flats" on spindle. Thread on clamp

ing screw to hold washer in position. Place a nail through

hole in blade rim so that nail rests on front of saw base and

keeps blade from turning. Tighten clamping screw (clock

wise) securely with the blade wrench.

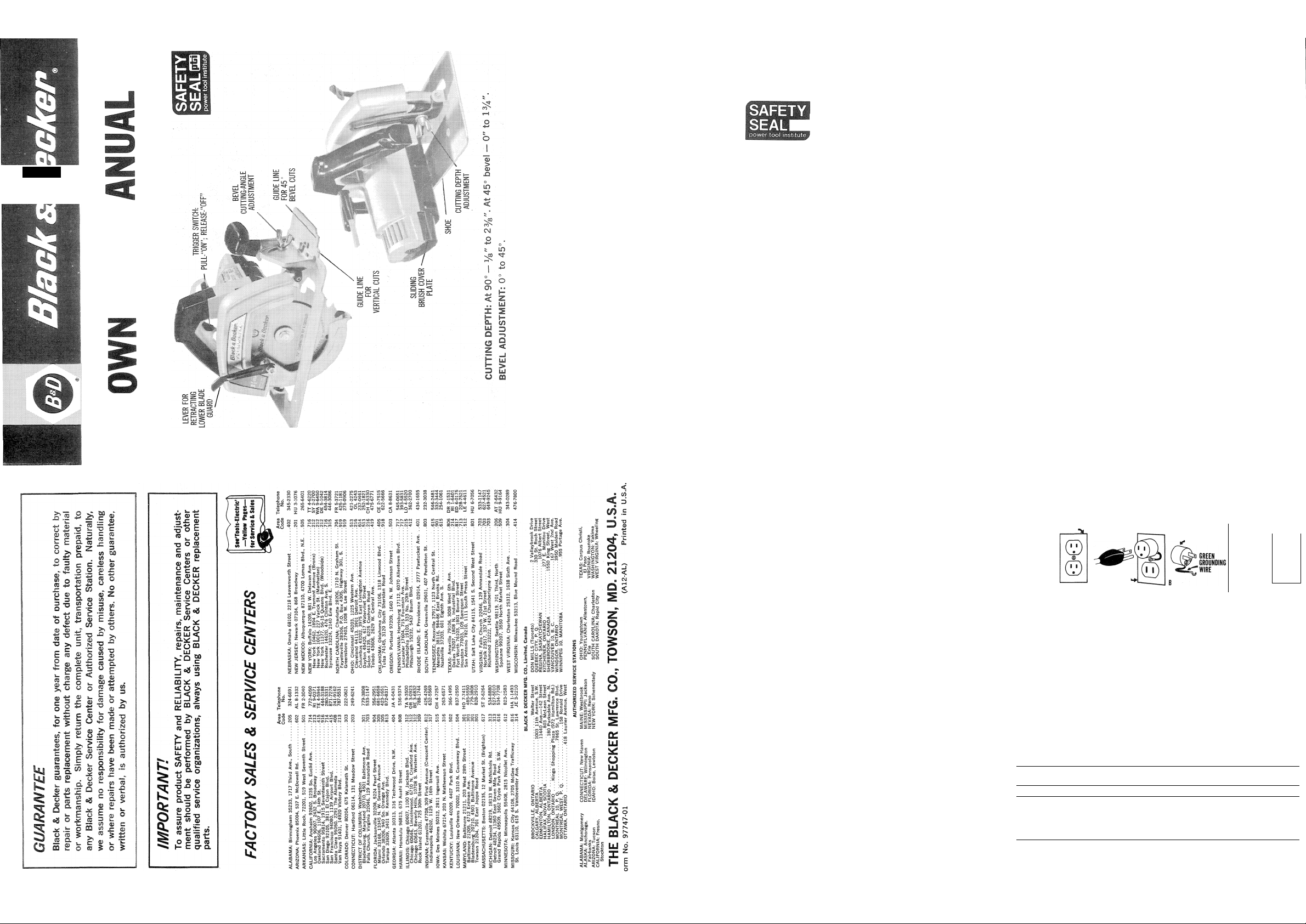

BE SURE SAW IS UNPLUGGED. When cutting any material with

steel blades, the most efficient depth adjustment is one that

permits the blade tooth depth only to project below the bottom

of the material (except when using Carbide Tipped Blades, where

only 1/2 oi the tooth tip should project below the material). This

keeps blade friction at a minimum, removes sawdust from the

cut and results In cooler, faster sawing. Correct cutting depth is

obtained by: (1) Place the saw in the position shown above and

loosen the wing nut on the inside of the blade guard. (2) Raise

or lower the base until the blade projects from the base the de

sired distance. Retighten wing nut securely.

DISCONNECT PLUG FROM POWER SUPPLY BEFORE MAKING

THIS OR ANY OTHER ADJUSTMENT. The adjustable base (shoe)

permits bevel cutting at any angle between 45° and 90°, The

quadrant on the front of the saw is calibrated for accurate

adjustment. To set saw for bevel angle cut, loosen wing nut and

tilt base to angle desired. Retighten wing nut securely.

SWITCH

Pull the trigger switch to turn the motor "ON". Releasing the

trigger instantly turns the motor "OFF," but the blade will

continue to rotate for a short time. For safer operation, this tool

has no provision to lock the switch in the "ON" position.

OPERATION

ALWAYS DISCONNECT THE SAW BEFORE MAKING ANY AD-

JUSTMENTS. Place the work with its "good” side — the one on

which appearance is msore important — down. The saw cuts

upward, so any splintering will be on the face that is up when

you saw it. Support the stock so that the cut will be on your

right, with the wider base portion of the saw base on that part

of the work piece which is solidly supported, not on the section

that will fall off when the cut is made. If the stock is short or

small, clamp it down. Don’t try to hold short pieces by hand.

Draw the required guide lines then rest the front of the saw base

(shoe) fiat on top of the work, with the guide notch correctly

aligned. Run the stationary blade lightly against the edge of the

work, back it off a little, and only then start the motor. Advance

the saw into the wood. The telescoping blade guard will swing

back by itself. Feed the tool at the speed at which the blade

cuts easily. Remember that hardness and toughness can vary

even in the same piece. A knotty or damp section can put a

heavy load on the saw; when this happens feed more slowly.

Feed the saw hard enough to keep it working without much

decrease in speed. Forcing it beyond this makes for rough cuts,

inaccuracy, and overheating of the motor.

Should your cut begin to go off the line, don’t try to force it

back on. It's best, of course to make errors on the waste side

of the line. Then you can withdraw the saw, sight anew, and

start a new cut a trifle inside the wrong one. In any event,

withdraw the saw if you must shift the cut. Forcing a correction

inside the cut can stall the saw and perhaps spoil the work. IF

SAW STALLS, RELEASE THE TRIGGER, DISCONNECT PLUG

FROM POWER SUPPLY AND THEN BACK THE SAW UNTIL IT

IS LOOSE. BE SURE BLADE CLEARS THE WORK BEFORE RE

STARTING CUTTING.

As you finish a cut, release the trigger and allow the blade to

stop before lifting the saw from the work. As you lift the saw

the spring-tensioned telescoping guard will automatically close

under the saw. Remember the blade is exposed until this occurs;

never reach under the work for any reason whatsoever. When

you have to retract the telescoping guard manually (as is neces

sary for starting pocket cuts) always use the retracting lever.

Adjust saw base (shoe) so blade cuts at desired depth. Tilt saw

forward and rest front of base on materia! to be cut. Using

lever, retract blade guard to an upward position. Lower rear of

base until blade teeth almost touch cutting line. Now release

the blade guard and its contact with the work will keep it in

position to open freely as you start the cut. Start the motor and

gradually iov^/er the saw until its base rests fiat on the material

to be cut. Advance saw along cutting line until cut is completed.

Release trigger and allow blade to stop completely before with

drawing the blade from the material. \Yhen starting each new

cut, repeat as above. Never tie the blade guard In a raised

position.

MOTOR BRUSHES

Carbon motor brushes

should be inspected fre

quently for wear. To in

spect brushes, FIRST, UN

PLUG SAW FROM POWER

SUPPLY. Then, with a

screwdriver, slide the

brush cover plates out

ward and the brush spring

will pop out Put the /

spring, with attached wire

extended out of the open

ing into the position

shown at right and tilt the

saw so that the carbon brush will drop out of the opening. If the

brush is worn down to the grooved line on its side, a new brush

is needed and can be obtained from any B&D Service Center

see "TOOLS, ELECTRIC" in Yellow Pages.

To reassemble, insert brush with worn end toward motor, or a

new brush with longest distance from end to grooved line toward

motor. Next, insert the

small brass plate behind the brush, and

then feed in the spring until the round spring cap fits flush with

the opening. This allows the cover plate to be pushed back into

the closed position.

LUBRICATION

Your tool was properly lubricated before leaving the factory. It is

recommended that, at least once a year, you take or send the

tool to a B&D Service Center for a thorough cleaning, inspec

tion and lubrication of the gear case.

RIP FENCE

The Rip Fence permits fast, smooth

rip-cuts without penciled lines. To

install, insert Rip Fence in front

slots, set Fence at desired dis

tance from blade and tighten

screw. The Rip Fence may also be

inserted from the opposite side of

the base slots. Cat. No. 55584

SAW PROTRACTOR

Guides accurate cross cuts at any

angle from 0° to 90°. Calibrated

in degrees. Has adjustable pointer.

Cat, No. 49531

t:

CUT-OFF GUIDES

One-piece guide for making accu

rate 90° or 45° cuts. Cat. No. 55582

CARRYING CASE

Gives easy portability and protec

tion for your saw. Has room for

extra blades, accessories and ex

tension cord. Cat. No. 55580

SMW BLMDES

Black & Decker manufacturers a complete line of blades which

are available from your Distributor. These include: COMBINATION

(crosscut & rip), CROSSCUT, PLYWOOD, PLANER, FLOORING,

CARBIDE-TIPPED, METAL CUTTING, PLYWOOD, FRICTION,

FRAMING, and RIPPING Blades.

Loading...

Loading...