Page 1

Page 2

Page 3

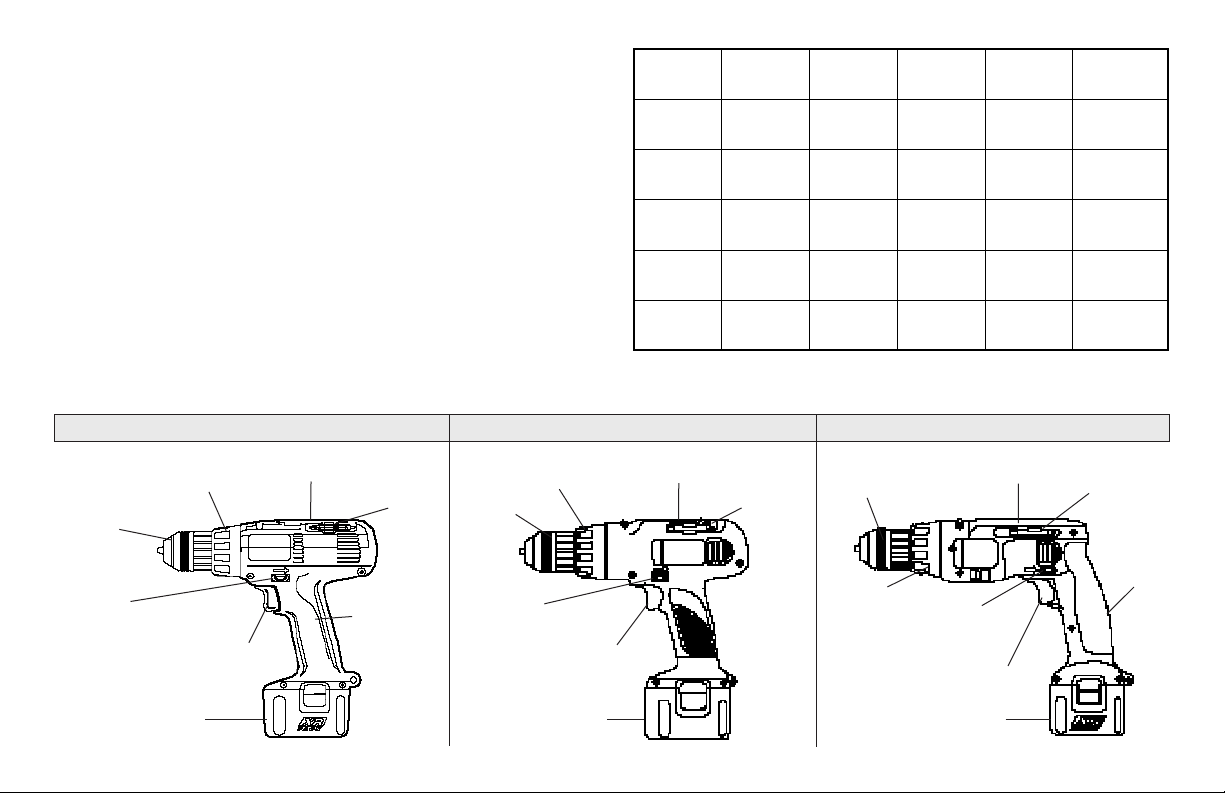

Getting the most out of your tool.

Cat # Voltage

Grip

Style

Chuck

Capacity

Battery

Pack

RPM

2755

2840

2852

2757

2861

9.6V

9.6V

12.0V

12.0V

12.0V

Mid

Standard

Pistol

Rubber

Mid

Rubber

Mid

Standard

Pistol

Rubber

3/8"

3/8"

3/8"

3/8"

3/8"

Standard

XR Pack™

XR Pack™

Standard

XR Pack™

0-400/0-1100

0-400/0-1200

0-450/0-1400

0-400/0-1200

0-450/0-1400

Please take time to read this manual and pay particular attention to the safety

rules we’ve provided for your protection. Don’t forget to send in your owner’s

registration card. If you have any questions about your tool please call:

1-800-9-BD TOOL

(1-800-923-8665)

Ergonomics that make a difference

Your driver/drill has been designed with concern for work conditions which

have quite an effect on the operator. The innovative design of this tool allows

for comfort in handling, neutral wrist positions, balanced weight, excellent

gripping, and low trigger pressure.

MMIIDD HHAANNDDLLEE RRUUBBBBEERR GGRRIIP

TORQUE ADJ.

COLLAR

KEYLESS

CHUCK

FWD/REV.

CONTROL BUTTON

TRIGGER SWITCH

BATTERY PACK

GEAR SHIFTER

P

RUBBER GRIP

BIT

HOLDER

MMIIDD HHAANNDDLLEE SSTTAANNDDAARRD

TORQUE ADJ.

COLLAR

KEYLESS

CHUCK

FWD/REV.

CONTROL BUTTON

TRIGGER SWITCH

BATTERY PACK

GEAR SHIFTER

D

BIT

HOLDER

PPIISSTTOOLL HHAANNDDLLEE RRUUBBBBEERR GGRRIIP

KEYLESS

CHUCK

TORQUE

ADJ.

COLLAR

GEAR SHIFTER

FWD/REV.

CONTROL

BUTTON

TRIGGER SWITCH

BATTERY PACK

P

BIT HOLDER

RUBBER

GRIP

Page 4

FOR YOUR SAFETY- ALL TOOLS

WWAARRNNIINNG

G

: When using electric tools, basic safety precautions should always be

followed to reduce risk of fire, electric shock, and personal injury, including the

following:

RREEAADD AALLLL IINNSSTTRRUUCCTTIIOONNSS.

KKEEEEPP WWOORRKK AARREEAA CCLLEEAAN

1.

CCOONNSSIIDDEERR WWOORRKK AARREEAA EENNVVIIRROONNMMEENNT

2.

Don’t use power tools in damp or wet locations. Keep work area well lit.

KKEEEEPP CCHHIILLDDRREENN AAWWAAY

3.

not let visitors contact tool.

SSTTOORREE IIDDLLEE TTOOOOLLS

4.

high or locked-up place – out of reach of children.

DDOONN’’TT FFOORRCCEE TTOOOOLL.

5.

was intended.

UUSSEE RRIIGGHHTT TTOOOOL

6.

heavy-duty tool. Don’t use tool for purpose not intended, for example, don’t

use circular saw for cutting tree limbs or logs.

DDRREESSSS PPRROOPPEERRLLY

7.

caught in moving parts. Non-skid footwear is recommended when working

outdoors. Wear protective hair covering to contain long hair.

UUSSEE SSAAFFEETTYY GGLLAASSSSEES

8.

SSEECCUURREE WWOORRK

9.

hand and it frees both hands to operate tool.

DDOONN’’TT OOVVEERRRREEAACCH

10.

MMAAIINNTTAAIINN TTOOOOLLSS WWIITTHH CCAARRE

11.

.

N

. Cluttered areas and benches invite injuries

T

. Don’t expose power tools to rain.

Y

. All visitors should be kept away from work area. Do

S

. When not in use, tools should be stored in dry, and

.

It will do the job better and safer at the rate for which it

L

. Don’t force small tool or attachment to do the job of a

Y

. Do not wear loose clothing or jewelry. They can be

S

. Also use face or dustmask if operation is dusty.

K

. Use clamps or a vise to hold work. It’s safer than using your

H

. Keep proper footing and balance at all times.

E

. Keep tools sharp and clean for better and

safe performance. Follow instructions for lubricating and changing

accessories. Keep handles dry, clean, and free from oil and grease.

LLOOCCKK OOFFFF TTOOOOL

12.

accessories.

RREEMMOOVVEE AADDJJUUSSTTIINNGG KKEEYYSS AANNDD WWRREENNCCHHEES

13.

that keys and adjusting wrenches are removed from tool before turning it on.

AAVVOOIIDD UUNNIINNTTEENNTTIIOONNAALL SSTTAARRTTIINNG

14.

SSTTAAYY AALLEERRTT.

15.

operate tool when you are tired.

CCHHEECCKK DDAAMMAAGGEEDD PPAARRTTSS.

16.

service center. Do not use tool if switch does not turn it on and off.

DDOO NNOOTT OOPPEERRAATTE

17.

gaseous or explosive atmospheres. Motors in these tools normally spark, and

the sparks might ignite fumes.

BBEE AAWWAARRE

18.

not have to be plugged into an electrical outlet. Keep the switch control lever

in the lock “OFF” position, as shown in Figure 5c, when you are not using the

tool.

CCAAUUTTIIOONN:

19.

electrical wires may be encountered, DO NOT TOUCH ANY FRONT METAL

PARTS OF THE TOOL! Hold the tool only by the plastic handle to prevent

shock if you drill or drive into a “live” wire.

L

when not in use, before servicing, and when changing

S

. Form habit of checking to see

G

. Don’t carry tool with finger on switch.

.

Watch what you are doing. Use common sense. Do not

.

Have defective switches replaced by authorized

E

portable electric tools near flammable liquids or in

E

that this tool is always in an operating condition because it does

:

When drilling or driving into walls, floors or wherever “live”

SAVE THESE INSTRUCTIONS FOR FUTURE USE

1

Page 5

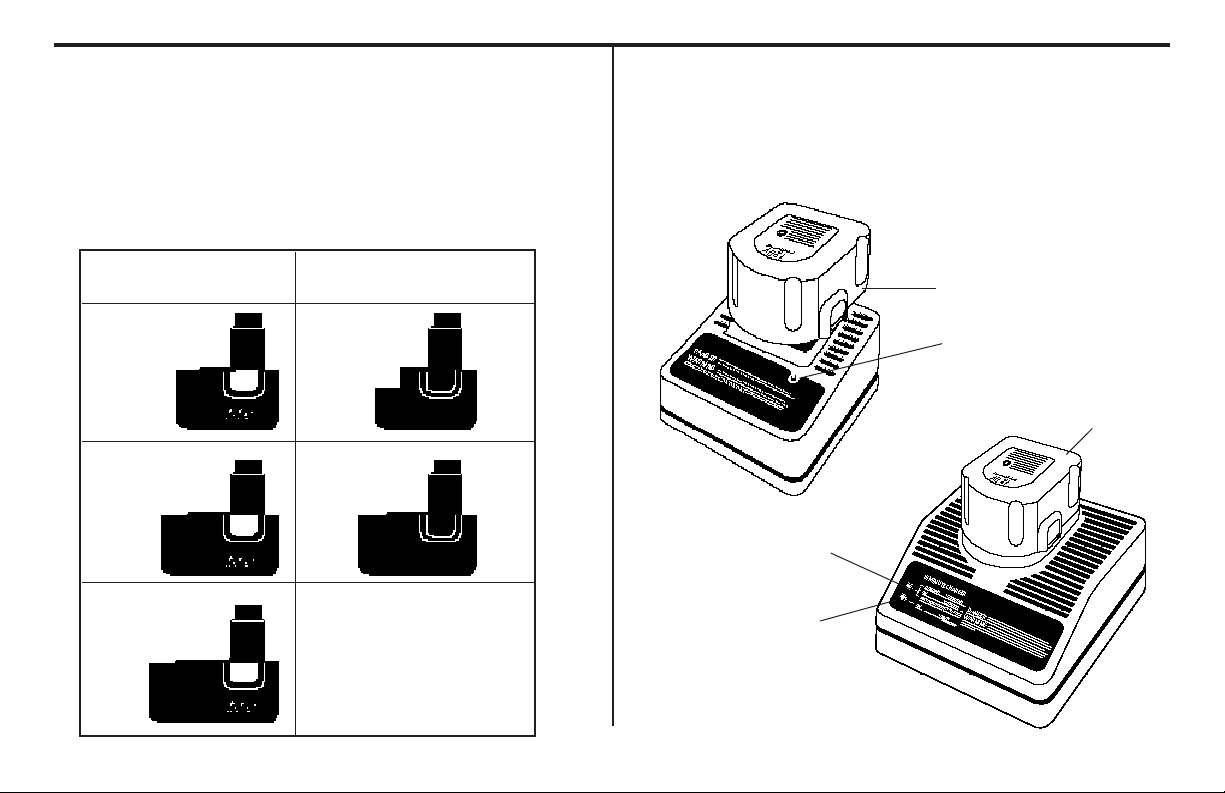

Battery Packs

Your tool uses a 9.6 Volt, a 12.0 Volt, or a 14.4 Volt battery pack. When

ordering replacement battery packs, be sure to include catalog number and

voltage.

XR PACK™ Extended Run-Time battery packs deliver 25% more run-time

than standard battery packs.

Battery Chargers (98014, 97014 & 98020)

Your battery can be charged in the

998800220

0

(15 Minute Charger). Be sure to read all safety instructions before

using your charger. (see page 5 for charging procedure)

9988001144,, 9977001144

98014/ 97014

1 HOUR CHARGERS

(1 Hour Chargers) or the

EExxtteennddeedd RRuunn--TTiimme

BBaatttteerryy PPaacckks

9.6V

97148

12.0V

97150

14.4V

97152

s

e

SSttaannddaarrdd BBaatttteerryy PPaacckks

9.6V

97048

97046

12.0V

97050

NNOOTTE

E

: Your tool will accept

either standard or Extended Run

Time battery packs. However,

you must be sure to select the

proper voltage.

s

BATTERY PACK

RED LIGHT

BATTERY PACK

RED LIGHT

YELLOW LIGHT

98020

15 MINUTE CHARGER

2

Page 6

SAFETY RULES FOR CHARGERS

1. Before using charger, read all instructions and cautionary markings on (1)

charger, (2) battery pack, and (3) product using battery pack.

DDAANNGGEERR:

2.

conductive objects. Danger of electric shock or electrocution.

3. If battery pack case is cracked or damaged, do not insert into charger.

Danger of electric shock or electrocution.

4. The charger and battery pack are specifically designed to work together. DO

NOT attempt to charge the battery pack with any chargers other than the

ones in this manual.

5. Do not expose charger to rain or snow.

6. These chargers are not intended for any uses other than charging Univolt™

or Cyclone Series™ rechargeable batteries. Any other uses may result in risk

of fire, electric shock or electrocution.

7. To reduce risk of damage to electric plug and cord, pull by plug rather than

cord when disconnecting charger.

8. Make sure cord is located so that it will not be stepped on, tripped over, or

otherwise subjected to damage or stress.

9. An extension cord should not be used unless absolutely necessary. Use of

improper extension cord could result in risk of fire, electric shock, or

electrocution.

10. Two wire cords can be used with 2 or 3 wire extension cords. Only round

jacketed extension cords should be used, and we recommend that they be

listed by Underwriters Laboratories (U.L.) (C.S.A. in Canada.) The letters WA

on the cord jacket indicate that the cord is suitable for outdoor use.

11. An extension cord must have adequate wire size (AWG or American Wire

Gauge) for safety. The smaller the gauge number of the wire, the greater the

capacity of the cable, that is 16 gauge has more capacity than 18 gauge.

When using more than one extension to make up the total length, be sure

each individual extension contains at least the minimum wire size.

:

120 volts present at charging terminals. Do not probe with

CHART FOR MINIMUM WIRE SIZE (AWG) OF EXTENSION CORDS

NAMEPLATE RATING AMPS - 0 - 10.0

Total Extension Cord Length (feet) 25 50 75 100 125 150 175

Wire Gauge 18 18 16 16 14 14 12

12. The charger is ventilated through slots in the top and the bottom of the

housing. Do not place any object on top of the charger or place the charger

on a soft surface that might block the ventilation slots and result in excessive

internal heat. Place the charger in a position away from any heat source.

13. Do not operate charger with damaged cord or plug — have them replaced

immediately.

14. Do not operate charger if it has received a sharp blow, been dropped, or

otherwise damaged in any way; take it to an authorized B&D service center.

15. Do not disassemble charger; take it to an authorized B&D service center

when service or repair is required. Incorrect reassembly may result in a risk

of electric shock, electrocution or fire.

16. To reduce risk of electric shock, unplug charger from outlet before

attempting any cleaning. Removing the battery pack will not reduce this risk.

17. NEVER attempt to connect 2 chargers together.

18. DO NOT store or use the tool and battery pack in locations where the

temperature may reach or exceed 105°F (such as outside sheds or metal

buildings in summer).

19. The charger is designed to operate on standard household electrical power

(120 volts). Do not attempt to use it on any other voltage!

SAVE THESE INSTRUCTIONS FOR FUTURE USE

3

Page 7

SAFETY RULES FOR BATTERIES

The batteries in your new battery pack are not fully charged out of the

carton! First read the safety instructions below. Then follow charging notes

and procedures.

WWAARRNNIINNG

always be followed to reduce risk of fire, electric shock, and personal injury,

including the following:

1. Read all instructions.

2. Do not incinerate the battery pack even if it is severely damaged or is

3. A small leakage of liquid from the battery pack cells may occur under

4. Never attempt to open the battery pack for any reason. If the plastic

5. Do not carry extra battery packs in aprons, pockets, or tool boxes along

G

: When using electric tools, basic safety precautions should

completely worn out.The battery pack can explode in a fire.

extreme usage or temperature conditions. This does not indicate a

failure. However, if the outer seal is broken and this leakage gets on your

skin:

a. Wash quickly with soap and water.

b. Neutralize with a mild acid such as lemon juice or vinegar.

c. If battery liquid gets into your eyes, flush them with clean water for a

minimum of 10 minutes and seek immediate medical attention.

(Medical note: The liquid is 25-35% solution of potassium hydroxide.)

housing of the battery pack breaks or cracks, immediately discontinue

use and do not recharge.

with other metal objects. Battery pack could be short circuited causing

damage to the battery pack and possibly causing severe burn or fire.

6. Charge the battery packs listed on page 2 only in Univolt™ or Cyclone

Series™ chargers.

NNOOTTEE:

7.

:

Review and observe all of the “Important Charging Notes” in the

charger instruction section of this manual.

NNOOTTEE::

After several years of normal use, the batteries in your battery

pack will no longer accept a charge. This is a normal occurrence and

signifies that the batteries have reached the end of their useful life.

Replacement battery packs are available at extra cost from your local

B&D service center. Your battery pack contains nickel cadmium

batteries. The Environmental Protection Agency considers cadmium to

be toxic material that can do severe damage to the environment. Check

with your state Environmental Protection agency to find out how to

properly recycle or dispose of cadmium, or you can turn in expired

battery packs to your local B&D service center for proper recycling or

disposal.

SAVE THESE INSTRUCTIONS FOR FUTURE USE

Introduction

998800114

The

about 1 hour. The

about 15 minutes.

These chargers require no adjustment and are designed to be as easy as

possible to operate. Simply place your battery pack into the receptacle of a

plugged in charger, as shown in Figure 1, and it will automatically charge the

pack.

9977001144

4

and

chargers are designed to charge battery packs in

9988002200

charger is designed to charge battery packs in

4

Page 8

Charging Procedure

9988001144//9977001144 ((11 HHoouurr CChhaarrggeerrss)) oonnllyy

1. Plug the charger into an appropriate AC power outlet.

2. Insert the battery pack into the charger, as shown in Figure 1, making

sure the pack is fully seated in the charger. The red (charging) light will

blink continuously indicating that the charging process has started.

3. The battery pack will be fully charged in about 1 hour under most

conditions. The completion of charge will be indicated by the red light

remaining ON continuously. The pack is fully charged and may be used

at this time or left in the charger.

9988002200 ((1155 MMiinnuuttee CChhaarrggeerr)) oonnllyy

1. Plug the charger into an appropriate AC power outlet. The charger will

beep twice and the red light will blink and then go off.

2. Insert the battery pack into the charger, as shown in Figure 1, making

sure the pack is fully seated in the charger. The red light will blink and the

charger will beep once indicating the charging process has started.

3. The battery pack will be fully charged in less than 15 minutes under most

conditions. This will be indicated by the red light remaining ON and 3

audible beeps. The pack is fully charged and may be used at this time or

left in the charger.

LLeeaavviinngg tthhee bbaatttteerryy ppaacckk iinn tthhee cchhaarrggeer

When the red light remains ON, the charger has switched to its “equalize

charge” mode which lasts approximately 4 hours, after which the charger

will switch to “maintenance charge” mode. The battery pack can be removed

at any time during these charge cycles, but will only be fully charged if the

red light is continuously ON. The charger and battery pack can be left

connected with the red light glowing indefinitely. The charger will keep the

r

battery pack fresh and fully charged.

NNOOTTE

E

: A battery pack will slowly lose

its charge when kept out of the

charger. If the battery pack has not

been kept on maintenance charge, it

may need to be recharged before

use. A battery pack may also slowly

lose its charge if left in a charger that

is not plugged into an appropriate AC

source.

TTrroouubbllee IInnddiiccaattoorrs

These chargers are designed to detect certain problems that can arise with

battery packs which would be indicated by the red light flashing at a fast rate

and continuous beeping. If this occurs, re-insert battery pack. If problem

persists, try a different battery pack to determine if the charger is OK. If the

new pack charges correctly, then the original pack is defective and should be

returned to a Service Center for recycling. If the new battery pack elicits the

same trouble indication as the original pack, have the charger tested at an

authorized Service Center.

WWeeaakk BBaatttteerryy PPaacckkss ((9988002200)) oonnlly

The charger can also detect a weak battery. Such batteries are still usable

but should not be expected to perform as much work. In such cases, about

10 seconds after battery insertion, the charger will beep rapidly 8 times to

indicate a weak battery condition. The charger will then go on to charge the

battery to the highest capacity possible.

5

s

y

FFiigguurree 1

1

Page 9

IMPORTANT CHARGING NOTES

1. Longest life and best performance can be obtained if the battery pack is

charged when the air temperature is between 65°F and 75°F (18°24°C). DO NOT charge the battery pack in an air temperature below

+40°F (+4.5°C), or above +105°F (+40.5°C). This is important and will

prevent serious damage to the battery pack.

2. The charger and battery pack may become warm to touch while

charging. This is a normal condition, and does not indicate a problem.

((9988002200 OOnnllyy))

3.

when exceeded, will temporarily stop the full charge current. This is

iinnddiiccaatteedd bbyy tthhee yyeellllooww lliigghhtt bbeeiinngg OONN..

resume when the temperature falls below the preset limit and will be

indicated by the yellow light turning OFF. The charge time may be

extended beyond the normal 15 minutes. Use the charger in normal

room temperatures whenever possible. To prevent overheating, do not

cover the charger and do not charge battery packs in direct sunlight or

near heat sources.

4. If the battery pack does not charge properly — (1) Check current at

receptacle by plugging in a lamp or other appliance, (2) Check to see if

receptacle is connected to a light switch which turns power off when

you turn out the lights. (3) Move charger and battery pack to a location

where the surrounding air temperature is approximately 65°F - 75°F

(18°- 24°C). (4) If charging problems persist, take or send the tool,

battery pack and charger to your local service center.

5. The battery pack should be recharged when it fails to produce sufficient

power on jobs which were easily done previously. DO NOT CONTINUE

to use under these conditions. Follow the charging procedure. You may

also charge a partially used pack whenever you desire with no adverse

affect on the battery pack.

This charger has an

iinntteerrnnaall tteemmppeerraattuurree lliimmiit

The normal charge cycle will

t

that,

6. Under certain conditions, with the charger plugged into the power

supply, the exposed charging contacts inside the charger can be

shorted by foreign material. Foreign materials of a conductive nature

such as, but not limited to, steel wool, aluminum foil, or any buildup of

metallic particles should be kept away from charger cavities. Always

unplug the charger from the power supply when there is no battery

pack in the cavity. Unplug charger before attempting to clean.

7. Do not immerse charger in water or any other liquid.

WWAARRNNIINNGG::

8.

may result.

9. To facilitate the cooling of the battery pack after use, avoid placing the

charger or battery pack in a warm environment such as in a metal shed,

or an uninsulated trailer.

CCAAUUTTIIOON

10.

plastic housing of the battery pack breaks or cracks, return to a service

center for recycling.

Don’t allow any liquid to get inside charger. Electric shock

N

: Never attempt to open the battery pack for any reason. If the

Important!

This product is not user servicable. There are no user servicable parts inside

the charger. Servicing at an authorized service center is required to avoid

damage to static sensitive internal components.

RREEAADD AALLLL OOFF TTHHEE IINNSSTTRRUUCCTTIIOONNSS IINN TTHHEE BBAATTTTEERRYY CCHHAARRGGEERR SSEECCTTIIOON

OOFF TTHHIISS MMAANNUUAALL BBEEFFOORREE AATTTTEEMMPPTTIINNGG TTOO CCHHAARRGGEE TTHHEEBBAATTTTEERRYY PPAACCK

FFOORR YYOOUURR TTOOOOLL.

Always use correct battery pack (pack supplied with tool or replacement pack

exactly like it.) See chart on inside cover to determine correct battery pack

voltage. Never install any other battery pack. It will ruin your tool and may

create a hazardous condition.

6

.

N

K

Page 10

Removing and Installing the Battery Pack

TOOL OPERATION

NNOOTTEE:: YYOOUURR BBAATTTTEERRYY PPAACCKKWWIILLLL NNOOTT BBEE FFUULLLLYY CCHHAARRGGEEDD OOUUTT OOFF TTHHE

CCAARRTTOONN.

.

To install the battery pack into the tool handle, align the base of the tool with

the notch inside the tool’s handle and slide the battery pack firmly into the

handle until you hear the lock snap into place as shown in Figures 2 and 3.

To remove the battery pack from the tool, press the release buttons, as

shown in Figure 3, and firmly pull the battery pack out of the tool handle.

Insert it into the charger as described in the charger section of this

instruction manual.

FFiigguurree 2

2

RELEASE BUTTON

E

To turn the tool “ON,” squeeze the trigger switch. To turn the tool “OFF,”

release the trigger switch (Figure 4). Your driver/drill is equipped with a

brake. The chuck will stop as soon as the trigger switch is fully released.

Your driver/drill is equipped with a variable speed switch which enables you

to select the best speed for a particular application. The farther you squeeze

the trigger, the faster the tool will operate.

Use lower speeds for starting holes without a centerpunch, drilling in metals

or plastics, driving screws and drilling ceramics, or in any application

requiring high torque. Higher speeds are better for drilling in wood, wood

compositions and for using abrasive and polishing accessories. For

maximum tool life, use variable speed only for starting holes or fasteners.

NNOOTTE

E

: Continuous use in variable speed range is not recommended. It may

damage the switch and should be avoided.

FFiigguurree 4

VARIABLE SPEED

TRIGGER SWITCH

4

FFiigguurree 3

3

7

Page 11

Forward/Reverse Control Button

A forward/reverse control button determines the direction of the tool and

also serves as a “lock off” button. To select forward rotation, release the

trigger switch and depress the forward/reverse control button on the right

side of the tool, as shown in Figure 5a.

To select reverse, depress the forward/reverse control button on the left side

of the tool as shown in Figure 5b. The center position of the control button

locks the tool in the “OFF” position as shown in Figure 5c.

When changing the position of the forward/reverse control button, be sure

the trigger is released.

NNOOTTE

E

: The first time the tool is run after changing the direction of rotation,

you may hear a click on start up. This is normal and does not indicate a

problem.

DEPRESS FOR FORWARD

DEPRESS FOR REVERSE

Torque Adjustment Collar

Your driver/drill has an adjustable torque screwdriver mechanism for driving

and removing a wide array of fastener shapes and sizes.

Circling the collar are numbers ranging from 0 to 5, and a drill bit symbol.

These numbers (and half numbers designated by dots on the collar) are used

to set the clutch to deliver a torque range.

The higher the number on the collar, the higher the torque and the larger the

fastener which can be driven. To select any of the numbers, rotate until the

desired number aligns with the selector, shown in Figure 6.

FFiigguurree 6

6

TORQUE

ADJUSTMENT

COLLAR

DUAL RANGE

GEAR SHIFTER

FFiigguurree 55a

a

FFiigguurree 55c

CENTER POSITION: LOCKED OFF

FFiigguurree 55b

b

c

8

LOW SPEED/HIGH TORQUE

(position 1)

HIGH SPEED/LOW TORQUE

(position 2)

Page 12

Dual Range Gearing

The dual range feature of your driver/drill allows you to shift gears for

greater versatility.

To select the low speed, high torque setting, turn the tool off and permit the

unit to stop. Slide the gear shifter forward (towards the chuck - position 1),

as shown in Figure 6.

To select the high speed, low torque setting, turn the tool off and permit the

unit to stop. Slide the gear shifter back (away from chuck - position 2).

NNOOTTE

E

: Do not change gears when the tool is running.

Refer to the chart below to determine the available speeds of your model of

driver/drill.

Troubleshooting Tip!

If you are having trouble changing gears, make sure that the dual range gear

shifter is either completely pushed forward or completely pushed back.

Catalog No. Low Range High Range

2755 0 - 400 0 - 1100

2840 0 - 400 0 - 1200

2852 0 - 450 0 - 1400

2757 0 - 400 0 - 1200

2861 0 - 450 0 -1450

Keyless Chuck

Your tool features a keyless chuck for greater convenience. To insert a drill

bit or other accessory, follow the steps listed below.

1. Lock the trigger switch in the OFF position as shown in Figure 5c.

2. Grasp the rear half of the chuck with one hand and use your other hand

to rotate the front half counterclockwise, as shown in Figure 7. Rotate

far enough so that the chuck opens sufficiently to accept the desired

accessory.

3. Insert the bit or other accessory about 3/4” into the chuck and tighten

securely by holding the rear half of the chuck and rotating the front

portion in the clockwise direction.

To release the accessory, repeat step 2 listed above.

WWAARRNNIINNGG:

gripping the front part of the chuck and turning the tool on. Damage to the

chuck and personal injury may result. Always lock off trigger switch when

changing accessories.

FFiigguurree 7

9

:

Do not attempt to tighten drill bits (or any other accessory) by

7

HHeellppffuull HHiinntt!

Be sure to tighten chuck with two hands- one

on both the rear sleeve and the forward sleeve

for maximum tightness.

!

Page 13

Chuck Removal

AAllwwaayyss wweeaarr eeyyee pprrootteeccttiioonn.

Lock off the tool and turn the adjustment collar to the “drill” position and low

speed gear shifter to position 1. Tighten the chuck around the shorter end of

a hex key (not supplied) of 1/4” or greater size. Using a wooden mallet or

similar object, strike the longer end in the clockwise direction, as shown in

Figure 8. This will loosen the screw inside the chuck.

Open chuck jaws fully, insert screwdriver (or Torx tool if required) into front

of chuck between jaws to engage screw head. Remove screw by turning

clockwise (left-hand-thread). Place hex key in chuck and tighten, as shown

in Figure 9. Using a wooden mallet or similar object, strike key sharply in the

counter clockwise direction. This will loosen the chuck so that it can be

unscrewed by hand.

.

Chuck Installation

Lock off the tool. Screw the chuck on by hand as far as it will go. Tighten the

chuck around the shorter end of a 1/4” or larger hex key (not supplied) strike

the longer end in the clockwise direction with a wooden mallet, as shown in

Figure 8. Insert and tighten the screw by turning in a counter clockwise

direction.

FFiigguurree 8

8

FFiigguurree 9

9

Operation as a Drill

Turn the collar to the drill bit symbol. Install and tighten the desired drill bit

in the chuck. Select the desired speed/torque range using the dual range

gear shifter to match the speed and torque to the planned operation.

Follow these instructions for best results when drilling.

Drilling

1. Use sharp drill bits only. For WOOD, use twist drill bits, spade bits,

power auger bits, or hole saws. For METAL, use high speed steel twist

drill bits or hole saws. For MASONRY, such as brick, cement, cinder

block, etc., use carbide-tipped bits.

2. Be sure the material to be drilled is anchored or clamped firmly. If

drilling thin material, use a “back-up” block to prevent damage to the

material.

3. Always apply pressure in a straight line with the bit. Use enough

pressure to keep the drill bit biting, but do not push hard enough to

stall the motor or deflect the bit.

4. Hold tool firmly to control the twisting action of the drill.

IIFF DDRRIILLLL SSTTAALLLLS

5.

RREELLEEAASSEE TTRRIIGGGGEERR IIMMMMEEDDIIAATTEELLY

determine cause of stalling.

AANN AATTTTEEMMPPTT TTOO SSTTAARRTT AA SSTTAALLLLEEDD DDRRIILLLL –– TTHHIISS CCAANN DDAAMMAAGGEE TTHHE

DDRRIILLLL.

.

6. To minimize stalling on breaking through the material, reduce pressure

on drill and ease the bit through the last fractional part of the hole.

7. Keep the motor running when pulling the bit back out of a drilled hole.

This will help prevent jamming.

8. With variable speed drills there is no need to center punch the point to

be drilled. Use a slow speed to start the hole and accelerate by

squeezing the trigger harder when the hole is deep enough to drill

10

without the bit skipping out. Operate at full on after starting the bit.

S

, it is usually because it is being overloaded.

Y

, remove drill bit from work, and

DDOO NNOOTT CCLLIICCKK TTRRIIGGGGEERR OOFFFF AANNDD OONN IIN

N

E

Page 14

Drilling in Wood

Holes in wood can be made with the same twist drills used for metal. These

bits may overheat unless pulled out frequently to clear chips from the flutes.

For larger holes, use low speed wood bits. Work that is likely to splinter

should be backed up with a block of wood.

MAINTENANCE

CLEANING: With the motor running, blow dirt and dust out of all air vents

with dry air at least once a week. Wear safety glasses when performing this.

Exterior plastic parts may be cleaned with a damp cloth and mild detergent.

Although these parts are highly solvent resistant, NEVER use solvents.

Drilling in Metals

Use a cutting lubricant when drilling metals. The exceptions are cast iron and

brass which should be drilled dry. The cutting lubricants that work best are

sulphurized cutting oil or lard oil; bacon grease will also serve the purpose.

Drilling in Masonry

Use carbide tipped masonry bits at low speeds. Keep even force on the drill

but not so much that you crack the brittle materials. A smooth, even flow of

dust indicates the proper drilling rate.

Operation as a Screwdriver

Select the desired speed/torque range using the dual range gear shift lever

on the top of tool to match the speed and torque to the planned operation.

Insert the desired fastener accessory into the chuck as you would any drill

bit. Set the torque adjustment collar (Figure 6). Make a few practice runs in

scrap or unseen areas to determine the proper position of the clutch collar.

Charger Cleaning Instructions:

WWAARRNNIINNGG::

and grease may be removed from the exterior of the charger using a cloth or

soft non-metallic brush. Do not use water or any cleaning solutions.

Disconnect the charger from the AC outlet before cleaning. Dirt

Accessories

Recommended accessories for use with your tool are available at extra cost

from your distributor or local service center. A complete listing of service centers is included with your tool.

CCAAUUTTIIOONN::

If you need any assistance in locating any accessory call 1-800-9-BD TOOL

(1-800-923-8665) or contact Black & Decker (U.S.) Inc., Consumer Services

Department, P.O. Box 618, 626 Hanover Pike, Hampstead, MD 21074.

The use of any non-recommended accessory may be hazardous.

Maximum Recommended Capacities

Low Range- 1 High Range- 2

BITS, METAL DRILLING 3/8" 1/4"

WOOD, FLAT BORING 1" 5/8"

11

Page 15

IMPORTANT!

To assure product safety and reliability, particularly for Double Insulated tools,

repairs, maintenance and adjustment (excluding maintenance described in

this manual) should be performed by B&D service centers or authorized service centers, using identical B&D replacement parts.

EEvveerryy BB&&DD ttooooll iiss ooff tthhee hhiigghheesstt qquuaalliittyy.

IIff yyoouu wwiisshh ttoo ccoonnttaacctt uuss rreeggaarrddiinngg tthhiiss pprroodduucctt,, pplleeaassee ccaallll ttoolll

ffrreeee bbeettwweeeenn 88::0000aamm aanndd 88::0000ppmm EETT,, sseevveenn ddaayyss aa wweeeekk:

.

l

:

1-800-9-BD TOOL

(1-800-923-8665)

One Year Service/Safety Check

All B&D tools for Industry and Construction are covered under a service/safety check program where B&D will inspect your tool for safety and provide necessary maintenance or repairs, including normal wear and tear parts, for one

year, FREE OF CHARGE.

Full Warranty

All B&D tools for Industry and Construction are warranted to be free of any

defects in materials or workmanship. Upon thorough examination of tool,

B&D will repair or replace, at our option, any product that is determined to be

defective.

Conditions

The service/safety check and the warranty do not apply to: repairs made or

attempted by anyone other than an authorized B&D service location; misuse,

abuse, neglect, improper application of the tool; missing parts; or normal wear

and tear (after first year of ownership). Please return the complete unit, transportation prepaid, to any B&D factory owned or B&D authorized service center

location (list provided with tool or see Yellow Pages under “Tools Electric”).

Loading...

Loading...