Page 1

IMPORTANT

To assure product SAFETY and RELIABILITY, repairs, maintenance and adjust

ment, (including brush inspection and replacement) should be performed by

Black <Sc Decker Service Centers or other qualified service organizations, always

using Black & Decker replacement parts.

COMMERCIAL/INDUSTRIAL USE WARRANTY

Black & Decker warrants this product for one year from date of purchase. We will

repair without charge, any defects due to faulty material or workmanship. Please

return the complete unit, transportation prepaid, to any Black & Decker Service

Center or Authorized Service Station listed under "Tools Electric” in the yellow

pages. This warranty does not apply to accessories or damage caused where

repairs have been made or attempted by others.

OWNER’S MANUAL

Your Black & Decker Electric SCRUGUN® is a

heavy-duty tool, capable of continuous produc

tion service on assembly operations. For dis

assembly work, there is a reversing switch con

veniently located on the handle back, opposite

the trigger switch. A wide variety of 1/4" hex

drive accessories—bits, sockets, nutsetters, ex

tensions, etc., permit this tool to drive or remove

many types of threaded fasteners.

For personal safety and for proper operation of

the Scrugun®, please take the time to carefully

read all of the safety rules and instructions in

this booklet. Don’t forget to send In the owner

registration card.

Form No. 740228-02

BLACK & DECKER (U.S.) INC.,

626 Hanover Pike, Hampstead, Maryland 21074

(APR83-CD)

Printed in U.S.A.

THANK YOU for buying BLACK & DECKER!

. DOUBLE INSULATED .

HEAVY-DUTY

SCRUGUN*

SCREWDRIVERS

Cat. Nos.

2020-10 POSITIVE CLUTCH

2025-10 VERSA-CLUTCH®

2033- 10 DRYWALL

2034- 10 DRYWALL

2022-10 POSITIVE CLUTCH

2032-10 DRYWALL

2034-15 DRYWALL

Page 2

ACCESSORY ASSEMBLY & ADJUSTMENTS

The 1/4' HEX DRIVE QUICK CHANGE CHUCK (Fig. 3)

is used on all positive and versa-clutch units. A bail retainer pro

vides positive locking of ail accessories in the chuck. Push for

ward on the ball retainer and hold while inserting or removing ac

cessories. Release for positive accessory retention.

BALL GROOVE

1/4" HEX DRIVE

BALL

RETAINER

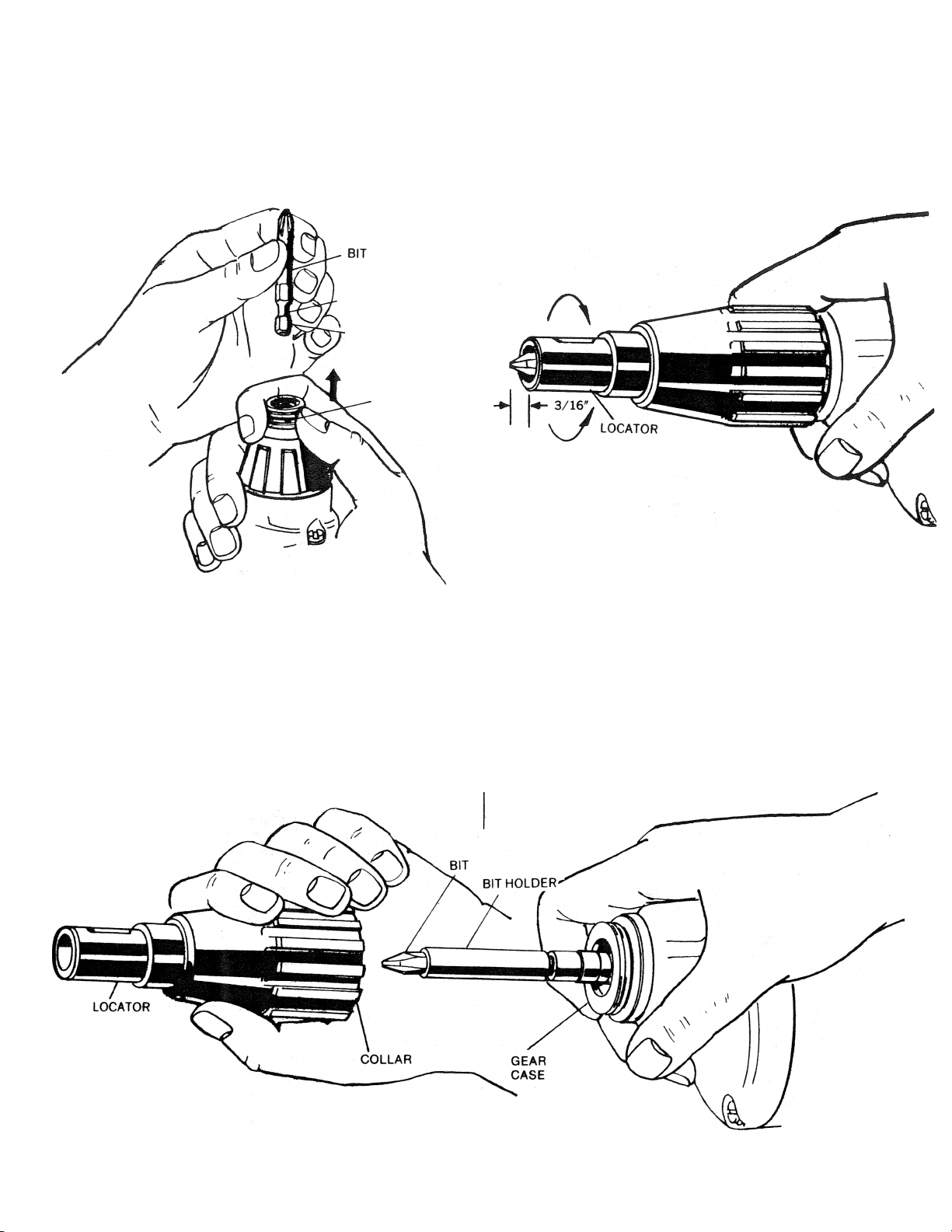

DEPTH ADJUSTMENT ON DRYWALL UNITS (Fig. 5)

1. Turn locator until end of bit extends 3/16" beyond end of

locator.

2. Test drive a fastener in scrap material to determine if

fastener is correctly seating.

3. Further adjustment may be necessary to Increase or

decrease the fastener depth.

Figure 5

Figure 3

ACCESSORY ASSEMBLY & ADJUSTMENT FOR DRYWALL UNITS (Fig. 4)

The 1/4" HEX DRIVE BALL LOCK CHUCK is used on all drywall

screwdrivers.

To change Bit Holders on Drywall Units

1. Unscrew collar AND locator assembly from gear case (left

hahd thread).

NOTE: There is no need to unscrew locator from collar.

2. Pull bit holder straight out with pliers, if it is difficult to

remove.

3. Push new bit holder Into spindle until ball lock snaps in

groove In bit holder shank.

4. Replace collar and locator assembly.

TO INCREASE, turn the locator so that end of bit extends further

from end of locator.

TO DECREASE, turn the locator so that end of bit Is closer to end

of locator.

Black & Decker Drywall Units have very fine depth settings, each

“detent” is .0052" or one revolution of the locator equals .083"

change in depth setting.

Figure 4

Page 3

SCREWDRIVER ACCESSORIES continued

Hex Drive Shank Extensions

*For use with 1/4" square drive sockets—1/4" hex.

Sockets for the above:

FOR DRIVING £jQl

HEX NUTS AND NonSHEET METAL

SCREWS 1/4" Sq. Drive

3,4 3,4

5 5 6

6 6

8 8

10

12,14,1/4

12

10,12

14,16, 1/4

14,1/4

SHANK SIZE

1/4"=^

1/4"^

TYPE

Magnetic 3/8"

Magnetic

SOCKET SIZE

1/4"

5/16"

1/4"

5/16"

3/8" 9/16"

4,5 3

8

10

12

1/4

1/4

SQ. DR.

1/4"

1/4" 6"

DIAM.

1/2"

1/2"

9/16"

7/16"

1/2"

4 5

5

6.8

10

12,1/4

12

LENGTH

2"

LENGTH

7/8"

7/8"

15/16"

7/8"

7/8"

7/8"

4

6

8

10

12,1/4 10

12

3,4

5.6

2

_

8

10

1/4" Hex Bits With Rotating Finder For Use With Any 1/4" Hex Drive

Power Tool

4.5

8

8

10

12

Mise. SCREWDRIVER ACCESSORIES

i* Hex Bit Extifision

For yst with 1/4* Hex Shanks and/or

other extensions.

1/4* oifware Drive Magnetic Socket

For driving 8 Poim^di and

Steel Headed Screws.

Heavy-Duty Tool Box

Cat. No. 50078

BIT

LENGTH

4.5

8 .

8

10

12

4,5.6 4.5 4.5

8,10

8,10 6 8

12

1/4

6

8.10 10 8.10

—

8

12

5.6

5.6

3-1/2"

3-1/2"

6"

3-1/2"

3-1/2"

Magnetic Bit Tip Holders

for Drywall Scruguns

1/r Hex Shank for 1/4» Hex Tip (3-3/32

tong) for use with all Drywall

SCRUGUNS® EXTRA LENGTH BIT TIP

DRIVE BODY.

1/4' Hex Shank for 1/4' Hex Tip (2-31/32

long) for use with all Drywall

SCRUGUNS® STANDARD LENGTH

STAINLESS STEEL BODY. (Standard

equipment on H.D. drywall SCRUGUNS®)

ggz

Scrugun® Holster Cat. No. 69590

attaches to belts up to 2-3/4" wide.

BELT CLIP Cat. No. 69600

For all H.D. SCRUGUN Screwdrivers.

(Standard equipment on H.D. drywall

SCRUGUNS®)

Page 4

VERSA-CLUTCH FOR DRIVING A

WIDE RANGE OF FASTENERS

RPM

SCREWS SCREWS SCREWS SCREWS SCREWS SCREWS

0-1200

1. Install proper fastener driving accessory and set screwdriver for

correct rotation.

2. Adjust clutch setting. See Fig. 4.

3. Place fastener in accessory, contact workpiece and apply

pressure to seat fastener keeping clutches engaged.

4. Upon fastener seating the clutches will ratchet. Disengage

screwdriver from fastener.

NOTE: With Versa-Clutch the operator has the ability to "override”

clutch ratchet if a fastener hits a wood knot, variable hardness in

steel workpieces or incorrect pilot holes. Increased operator

pressure will usually cause the clutches to "pick-up” and continue to

seat the fastener. Further, a quick twist of the collar will change the

clutch setting to overcome most driving difficulties and will provide

for immediate change in torque output giving the operator option to

drive a range of fastener sizes.

MAINTENANCE

NOMINAL CAPACITY

WOOD LAG DRILL CUTTING METAL MACHINE

#12

1/4" w/pilot hole

SELF THREAD SHEET

1/4" 1/4"

3/16" CRS

1/4"

1 /4"

CLEANING

With the motor running, blow dirt and dust out of all air vents with

dry air at least once a week. Wear safety glasses when performing

this.

Exterior plastic parts may be cleaned with a damp cloth and mild

detergent. Although these parts are highly solvent resistant, NEVER

use solvents.

CLUTCH FACE

CHANGING CLUTCHES (Fig. ?) FOR VERSA-CLUTCH ONLY

1. Remove clutch housing by unscrewing in direction of arrow

(left hand thread).

2. Clamp tool or clutch housing in a resilent clamp.

3. Remove round clutch retaining rings ■ with a very small

screwdriver or sharp pointed tool.

4. Install new clutches and new retaining rings.

NOTE: If the output spindle slides toward Inside of gear case,

remove dead spindle spring and thread a 5/16" -18 bolt or

cap.screw into end of spindle and lift up to expose retaining

ring groove. Re-assemble dead spindle spring allowing no

more than 1/4" projecting from end of spindle.

5. Relubricate clutches. (See lubrication'

CHANGING CLUTCHES (Fig. 8) FOR POSITIVE CLUTCH & DRYWALL UNITS ONLY

CLUTCH

OUTPUT

SPINDLE

RETAINING

RING

1. Remove three gear case screws from front and disassemble

^ gear case.

2. Clamp output spindle In a resilient clamp.

3. Remove round clutch retaining rlng^ with a very small

screwdriver or sharp pointed tool.

4. Install a new clutch and retaining ring.

5. Relubricate clutches and gearing. (See lubrication).

5/16"-18 SCREW

Figure 7

Figure 8

Loading...

Loading...