Page 1

Important Safety Instructions

WARNING: For your own safety read instruction manual before operating miter saw.

Polarized Plugs

REPLACEMENT P ARTS. When servicing, use only identical replacement parts.

To reduce the risk of electric shock, this equipment has a polarized plug (one blade is wider than

the other). This plug will fit in a polarized outlet only one way. If the plug does not fit fully into the

outlet, reverse the plug. If it still does not fit, contact a qualified electrician to install the proper

outlet. Do not change the plug in any way . Units rated for 220 volts will have a different style plug

that will not fit the outlet and is not polarized.

Important Safety Instr uctions

• KEEP GUARDS IN PLACE and in working order.

• REMOVE ADJUSTING KEYS AND WRENCHES. Form habit of checking to see that keys and adjusting

wrenches are removed from tool before turning it on.

• KEEP WORK AREA CLEAN. Cluttered areas and benches invite injuries.

• DON’T USE IN DANGEROUS ENVIRONMENT. Don’t use power tools in damp or wet locations, or

expose them to rain. Keep work area well lighted.

• KEEP CHILDREN AWAY. All visitors should be kept safe distance from work area.

• MAKE WORKSHOP KID PROOF with padlocks, master switches, or by removing starter keys.

• DON’T FORCE TOOL. It will do the job better and safer at the rate for which it was designed.

• USE RIGHT TOOL. Don’t force tool or attachment to do a job for which it was not designed.

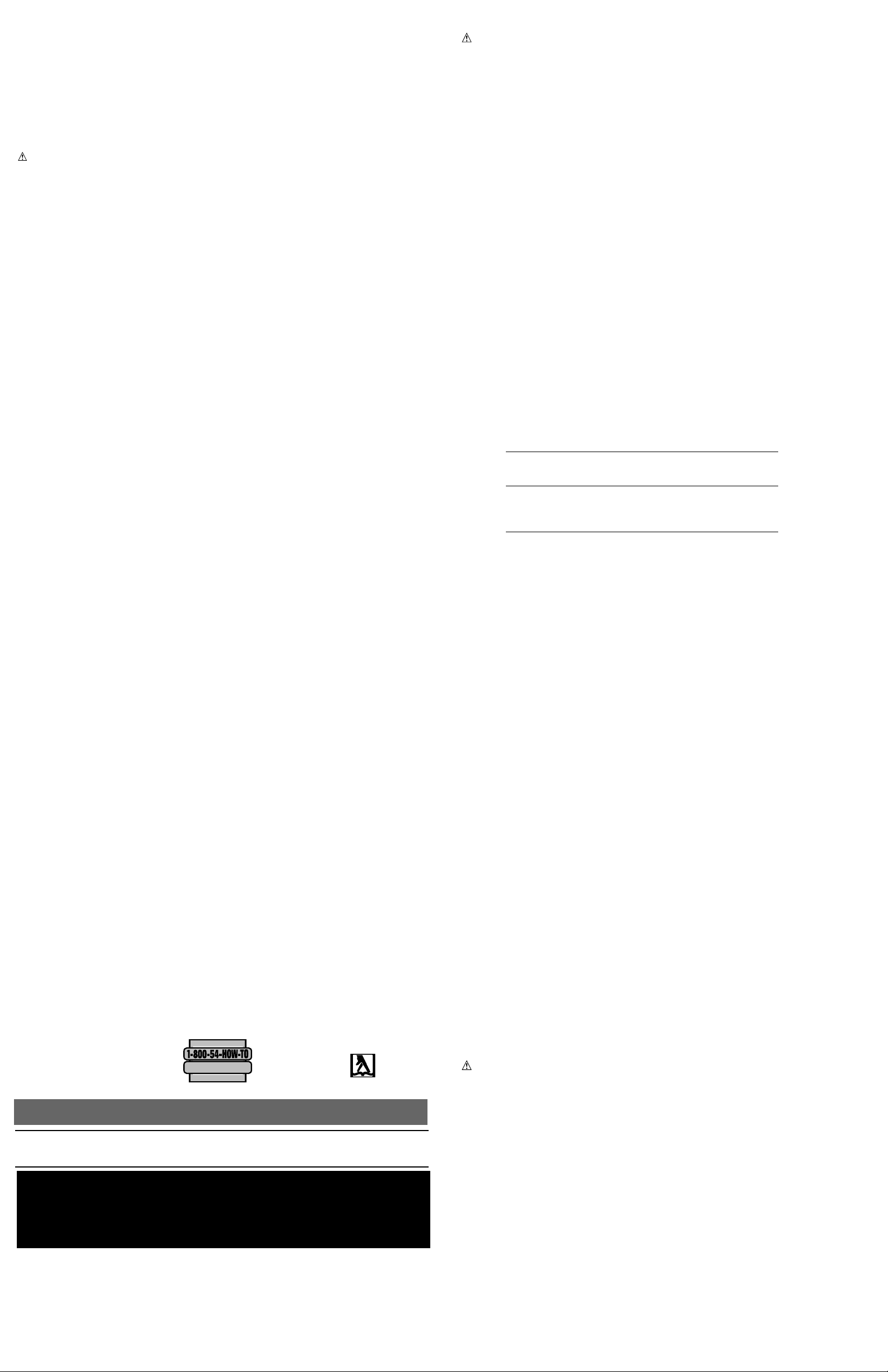

• USE PROPER EXTENSION CORD. Make sure your extension cord is in good condition. When using an

extension cord, be sure to use one heavy enough to carry the current your product will draw. An undersized cord will cause a drop in line voltage resulting in loss of power and overheating. The table shows

the correct size to use depending on cord length and nameplate ampere rating. If in doubt, use the next

heavier gage. The smaller the gage number, the heavier the cord.

• WEAR PROPER APPAREL. Do not wear loose clothing, gloves, neckties, rings, bracelets, or other jewel-

ry which may get caught in moving parts. Nonslip footwear is recommended. Wear protective hair covering to contain long hair.

• ALWAYS USE SAFETY GLASSES. Also use face or dust mask if cutting operation is dusty. Everyday eye-

glasses only have impact resistant lenses, they are NOT safety glasses.

• SECURE WORK. Use clamps or a vise to hold work when practical. It’s safer than using your hand and

it frees both hands to operate tool.

• DON’T OVERREACH. Keep proper footing and balance at all times.

• MAINTAIN TOOLS WITH CARE. Keep tools sharp and clean for best and safest performance. Follow

instructions for lubricating and changing accessories.

• DISCONNECT TOOLS before ser vicing; when changing accessories, such as blades, bits, cutters, and

the like.

• REDUCE THE RISK OF UNINTENTIONAL ST AR TING. Make sure switch is in off position before plugging

in.

• USE RECOMMENDED ACCESSORIES. Consult the instruction manual for recommended accessories. The

use of improper accessories may cause risk of injury to persons.

• NEVER STAND ON TOOL. Serious injury could occur if the tool is tipped or if the cutting tool is unin-

tentionally contacted.

• CHECK DAMAGED P ARTS. Before further use of the tool, a guard or other part that is damaged should

be carefully checked to determine that it will operate properly and perform its intended function–check

for alignment of moving parts, binding of moving parts, breakage of parts, mounting, and any other

conditions that may affect its operation. A guard or other part that is damaged should be properly

repaired or replaced.

• NEVER LEAVE TOOL RUNNING UNATTENDED. TURN POWER OFF. Don’t leave tool until it comes to a

complete stop.

Additional Safety Rules for Miter Saw

• Wear eye protection.

• Keep hands out of path of saw blade.

• Do not operate saw without guards in place.

• Do not perform any operation freehand.

• Never reach in back of saw blade.

• Turn of f tool and wait for saw blade to stop before moving workpiece or changing settings.

• Disconnect power before changing blade or servicing.

• Blade adjustment is to be made only with the power off and the blade stopped.

• Rated saw blade diameter is 10".

• No load speed is 5,500 R.P.M.

Additional Safety Instructions for Miter Saws

CAUTION:Do not connect unit to electrical power source until complete instructions are read and

understood.

• DO - Protect electric supply line with at least a 15 ampere time delay fuse or a circuit breaker.

• DO - Make cer tain the blade rotates in the correct direction and that the teeth at the bottom of

the blade are pointing to the rear of the miter saw.

• DO - Be sure all clamp handles are tight before starting any operation.

• DO - Be sure all blade and clamp washers are clean and recessed sides of collars are against

blade. Tighten arbor screw securely.

• DO - Keep saw blade sharp.

• DO - Keep motor air slots free of chips and dirt.

• DO - Support long work with an outboard tool rest.

• DON’T - Attempt to operate on anything but designated voltage.

• DON’T - Wedge anything against fan to hold motor shaft.

• DON’T - Cut ferrous metals (those with any iron or steel content) or any masonry.

• DON’T - Use abrasive wheels. The excessive heat and abrasive particles generated by them will

damage the saw.

• DON’T - Allow anyone to stand behind saw.

• DON’T - Apply lubricants to the blade when it’s running.

• DON’T - Use blades rated less than 5500 R.P.M.

• DON’T - Attempt to cut pieces smaller than 6" (153mm) without clamping.

• DON’T - Perform any operation freehand.

• DON’T - Reach underneath the saw unless it is turned off and unplugged. The saw blade is exposed

on the underside of the saw.

• DON’T - Move either hand from saw or workpiece or raise arm until blade has stopped.

• DON’T - Use any blade which is not 10" (254mm) in diameter.saw.

CAUTION: Some wood contains preservatives such as copper chromium arsenate (CCA) which

can be toxic. When cutting these materials extra care should be taken to avoid inhalation and

minimize skin contact.

CAUTION: WHEN SERVICING ALL TOOLS, USE IDENTICAL REPLACEMENT PAR TS. REPAIR OR

REPLACE DAMAGED CORDS.

• DON’T - Tie, tape or other wise hold guard open when operating saw.

SAVE THESE INSTRUCTIONS

For your convenience and safety, the following warning labels are on your miter saw.

ON GUARD: (DANGER - KEEP AWAY FROM BLADE.) ON TABLE: (2 PLACES)

ON FIELD CASE:

Electrical Connection

Be sure your power supply agrees with the nameplate marking. 120 volts, AC only means that

your saw is operated on alternating current only and never on direct current. A voltage decrease of

10 percent or more will cause a loss of power and overheating. All B&D tools are factory tested. If

this tool does not operate, check the power supply .

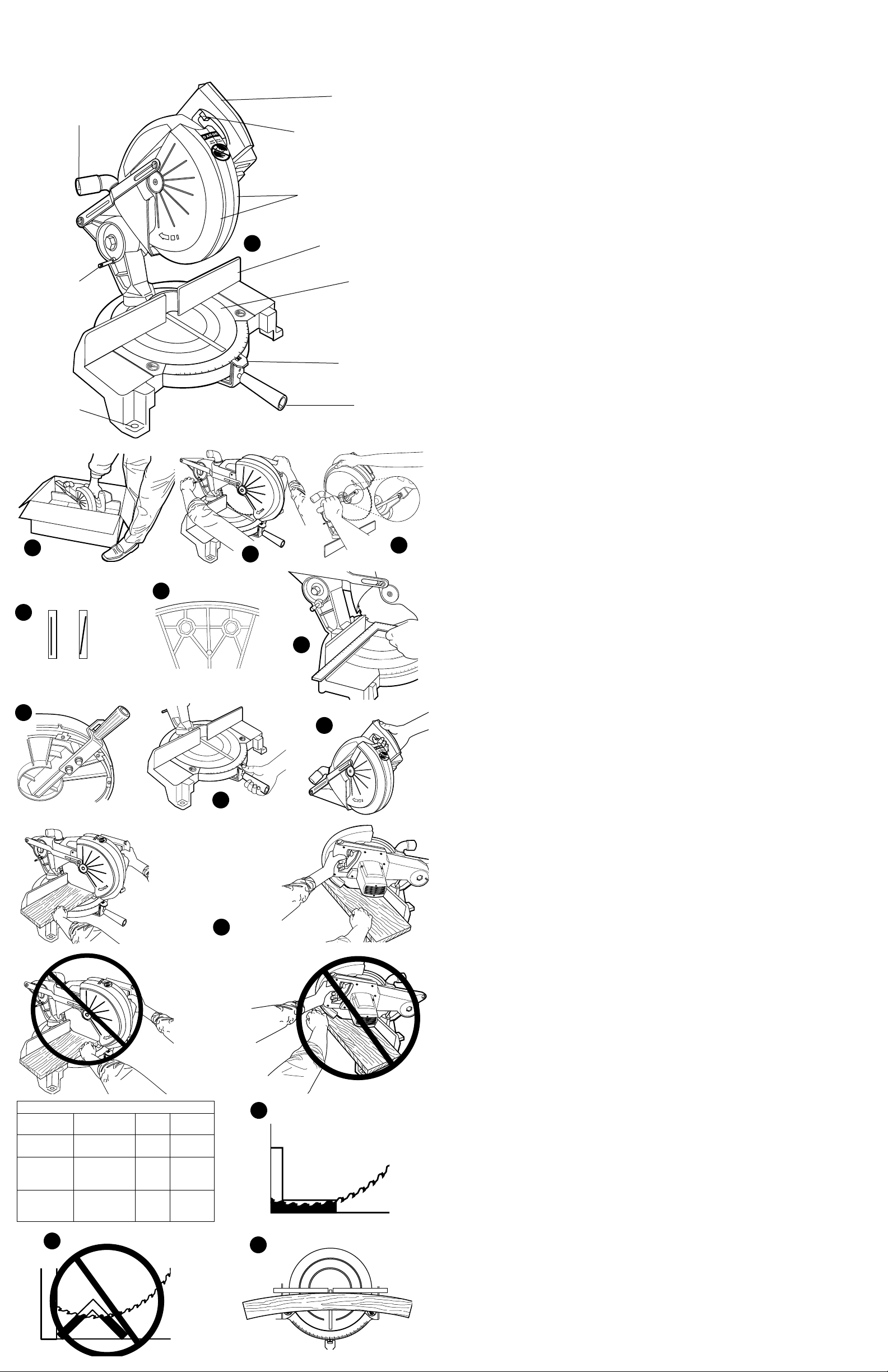

Familiarization

Your miter saw is fully assembled in the carton. Open the box and lift the saw out by the handle, as shown in Figure 1. Place the saw on a smooth, flat surface such as a workbench or

strong table.

Examine Figure A to become familiar with the saw and its various parts. The following section

on adjustments will refer to these terms and you must know what the parts are.

Press down lightly on the operating handle and pull out the lock down pin, as shown in Figure

2. Gently release the downward pressure and allow the arm to rise to its full height. Use the

lock down pin when carrying the saw from one place to another. Always use the handle to

transport the saw.

Bench Mounting

Holes are provided in all four feet to facilitate bench mounting. Always mount your saw firmly

to prevent movement. To enhance the tool’s portability, it can be mounted to a piece of 1/2"

(12.7mm) or thicker plywood which can then be clamped to your work support or moved to

other job sites and reclamped.

NOTE: If you elect to mount your saw to a piece of plywood, make sure the mounting screws

don’t protrude from the bottom of the wood. The plywood must sit flush on the work support.

When clamping the saw to any work surface, clamp only on the clamping bosses where the

mounting screw holes are located. Clamping at any other point will surely interfere with the

proper operation of the saw.

Changing the Blade

1. TURN OFF TOOL AND DISCONNECT FROM POWER SUPPLY.

2. With the saw arm in the upper position, raise the lower guard as far as possible.

3. Loosen (but do not remove) the guard bracket screw, shown in Figure 3 until the guard

bracket can be raised enough to permit access to the blade screw.

4. Push down on the saw arm to dig the saw blade teeth into a piece of scrap wood. Use the

blade wrench to remove (clockwise) the left hand threaded blade screw.

5. Remove outer clamp washer and saw blade.

6. Install the new blade making sure that the teeth at the bottom edge of the blade are pointing toward the back of the saw.

7. Replace the outer clamp washer and tighten the blade screw (counterclockwise) while hold-

VEA EL ESPAÑOL EN LA CONTRAPORTADA.

SAVE THIS MANUAL FOR FUTURE REFERENCE.

INSTRUCTIVO DE OPERACIÓN, CENTROS DE SERVICIO Y PÓLIZA DE

GARANTÍA. ADVERTENCIA: LÉASE ESTE INSTRUCTIVO ANTES DE USAR EL

PRODUCTO.

R

INSTRUCTION MANUAL

1710

11110000"""" ((((222255554444mmmmmmmm)))) MMMMiiiitttteeeerrrr SSSSaaaaww

ww

KEY INFORMA TION YOU SHOULD KNOW:

•Cut only with sharp blades. Dull blades cut poorly and overload the motor .

•If the saw does not cut accurately , refer to the TROUBLE SHOOTING chart in this

manual.

Cat # 1710 Form # 387479 MAR98-CD-1 Copyright © 1998 Black & Decker Printed in U.S.A.

Minimum Gage for Cord Sets

Volts Total Length of Cord in Feet

120V 0-25 26-50 51-100 101-150

240V 0-50 51-100 101- 200 201-300

Ampere Rating

More Not more American Wire Guage (AWG)

Than Than

0 - 6 18 16 16 14

6 - 10 18 16 14 12

10 - 12 16 16 14 12

12 - 16 14 12 Not Recommended

BEFORE RETURNING THIS PRODUCT

FOR ANY REASON PLEASE CALL

1-800-54-HOW-TO

IF YOU SHOULD EXPERIENCE A PROBLEM

WITH YOUR BLACK & DECKER PURCHASE,

CALL 1-800-54-HOW-TO.

IN MOST CASES, A BLACK & DECKER REPRESENTATIVE

CAN RESOLVE YOUR PROBLEM OVER THE PHONE.

IF YOU HAVE A SUGGESTION OR COMMENT,

GIVE US A CALL. YOUR FEEDBACK IS VITAL

TO THE SUCCESS OF BLACK & DECKER'S QUALITY

IMPROVEMENT PROGRAM.

0

4

5

3

0

3

5

2

0

2

15

0

1

5

0

5

0

1

5

1

0

2

5

2

30

4

3

5

5

0

4

DANGER

KEEP AWAY

FROM BLADE

!

WARNING:

For safe operation read instruction manual. Always

wear eye protection. Keep hands 6'' (153mm) from

path of saw blade. Do not operate saw without guards

in place. Keep guards in working order. Do not perform

any operation freehand. Never reach in back of saw

blade. Turn off tool, keep saw head down and wait for

saw blade to stop before moving work piece or

changing settings. Unplug tool before changing blade,

moving or servicing unit. Never cross arms in front of

blade. Secure unit before using.

WARNING: When servicing use only

identical replacement parts. Do not expose to

rain or use in damp locations.

AVERTISSEMENT : Pour

s'assurer du fonctionnement sûr, lire le guide

d'utilisation. Ne pas exposer à la pluie et ne pas

utiliser dans les emplacement humidies.

Black & Decker (U.S.) Inc., Towson, MD 21286 USA Made in USA

Page 2

ing the lower guard up and the saw blade teeth dug into the scrap wood.

8. AFTER INSTALLING THE SAW BLADE, REPOSITION GUARD BRACKET MAKING SURE IT

IS FULLY SEATED ON GUARD SCREW. FIRMLY TIGHTEN SCREW. FAILURE TO DO SO

WILL CAUSE SERIOUS DAMAGE TO THE SAW.

Adjustments

PERFORM ALL ADJUSTMENTS WITH THE MITER SAW UNPLUGGED!

NOTE: Your miter saw is fully and accurately adjusted at the factory. If readjustment is

required, follow the steps listed to adjust your saw.

PIVOT BOLT ADJUSTMENTS

Adjustments to the pivot bolt may be required as wear occurs. Adjustment must be made with the

saw fully assembled, including the blade. Loosen or tighten the pivot bolt by turning the hex head

located on the left side of the pivot assembly until nearly all play is removed and the motor moves

up smoothly when released.

BLADE TO FENCE SQUARENESS: Perform the steps listed:

NOTE: After adjustments, blade may not align with slot in table top.

1. With the saw unplugged, lower the pivot arm until tip of saw blade is even with top of saw

table. Blade should appear to be parallel to the sides of the slot. It is not important that the

blade be perfectly centered to the slot, but more importantly it should be reasonably parallel. See Figure 4.

If the blade appears to be parallel, proceed to "miter pointer adjustment" below. If not,

loosen (do not remove) the two bolts under the back edge of the saw table that hold the

pivot arm (see Figure 5) to the saw. Align the blade as necessary and tighten the bolts (2327 ft. lbs.). (DO NOT OVERTIGHTEN)

2. Check the squareness of the blade to the fence using a square. If the blade checks OK,

then saw is ready for use.

3. If blade and fence are not square (90°), the saw must be adjusted.

To adjust the squareness, loosen the two handle bar bolts, which are located underneath

the saw in the middle of the rotary table, (Figure 7). DO NOT REMOVE THESE BOLTS.

With the handle bar bolts loose and the rotary base set in the zero position, align the

blade square to the fence, (Figure 6).

Tighten the handle bar bolts (23-27 ft. lbs.) and your saw should be properly adjusted.

MITER POINTER ADJUSTMENT

TURN OFF TOOL AND DISCONNECT FROM POWER SUPPLY.

1. Loosen the miter clamp knob and squeeze the miter latch to move the miter arm to the 0

position, as shown in Figure 8.

2. With the miter clamp knob loose, allow the miter latch to snap into place as you rotate the

miter arm past 0.

3. Observe the pointer and miter scale through the viewing opening. If the pointer does not

indicate exactly 0, use a flat bladed screwdriver to gently push it left or right as required.

Guard Actuation and Visibility

The blade guard on your saw has been designed to automatically raise when the arm is

brought down and to lower over the blade when the arm is raised. The guard can be raised by

hand when installing or removing saw blades or for inspection of the saw. NEVER RAISE THE

BLADE GUARD MANUALLY UNLESS THE SAW IS TURNED OFF.

Switch

To turn the saw on, depress the trigger switch- Figure 9. To turn the tool off, release the switch.

There is no provision for locking the switch on, but a hole is provided in the trigger for insertion

of a padlock to lock the saw off.

Cutting with Your Saw

NOTE: Although this saw will cut wood and many nonferrous materials, we will limit our discussion to the cutting of wood only. The same guidelines apply to the other materials. DO NOT

CUT FERROUS METAL (IRON AND STEEL) OR MASONRY MATERIALS WITH THIS SAW. Do not

use any abrasive blades.

Set the miter arm at the desired angle. Be sure to tighten the miter clamp knob and hold the

wood on the table and firmly against the fence. Turn on the saw by squeezing the trigger switch

shown in Figure 9.

When the saw comes up to speed (about 1 second) lower the arm smoothly and slowly cut

through the wood. Let the blade come to a full stop before raising arm.

Quality of Cut

The smoothness of any cut depends on a number of variables. Things like material being cut,

blade type, blade sharpness and rate of cut all contribute to the quality of the cut.

When smoothest cuts are desired for molding and other precision work, a sharp (60 tooth or

greater) carbide blade and a slower, even cutting rate will produce the desired results.

Ensure that material does not creep while cutting, clamp it securely in place. Always let the

blade come to a full stop before raising the arm.

If small fibers of wood still split out at the rear of the workpiece, stick a piece of masking tape

on the wood where the cut will be made. Saw through the tape and carefully remove tape when

finished.

For varied cutting applications, refer to Table 2. Select the blade that best fits your needs.

Body and Hand Position (Figure 10)

Proper positioning of your body and hands when operating the miter saw will make cutting

easier , more accurate and safer. Never place hands near cutting area. Place hands no closer than

6" (153mm) from the blade. Hold the workpiece tightly to the table and the fence when cutting.

Keep hands in position until the trigger has been released and the blade has completely stopped.

ALWA YS MAKE DR Y RUNS (UNPOWERED) BEFORE FINISH CUTS SO THAT YOU CAN CHECK

THE P ATH OF THE BLADE. DO NOT CROSS HANDS IN FRONT OF BLADE AS SHOWN IN

FIGURE 10.

Keep both feet firmly on the floor and maintain proper balance. As you move the miter arm left

and right, follow it and stand slightly to the side of the saw blade.

Support for Long Pieces

TURN OFF TOOL AND DISCONNECT FROM POWER SUPPLY.

Support long workpieces using any convenient means, such as sawhorses or similar devices to

keep the ends from dropping.

Special Cuts

NEVER MAKE ANY CUT WITHOUT FIRMLY CLAMPING THE MATERIAL. ALWAYS USE PROPER

BLADE.

ALUMINUM CUTTING

Aluminum extrusions such as those used when making aluminum screens and storm windows

can easily be cut with your saw. Position the material so that you will be cutting the thinnest

cross section, as shown in Figure 11. Figure 12 illustrates the wrong way to cut these extrusions.

Use a wax lubricant when cutting aluminum such as Johnson’s Stick Wax No. 140. Apply the

stick wax directly to the saw blade before cutting. Never apply stick wax to a moving blade.

The wax, available at most hardware stores and industrial mill supply houses, provides proper

lubrication and keeps chips from adhering to the blade.

BOWED MATERIAL

When cutting bowed material always position it as shown in Figure 13. Positioning the material incorrectly will cause it to pinch the blade near the completion of the cut.

CUTTING PLASTIC PIPE

Plastic pipe can be easily cut with your saw. It should be cut just like wood andclamped or held

firmly to the fence to keep it from rolling.

45

25

20

1

5

1

0

5

0

5

1

0

1

5

20

2

5

30

35

40

35

4

0

30

DUST CHUTE

FENCE

LOCK DOWN PIN

TABLE

UPPER GUARD

SWITCH

SWITCH HANDLE

MOUNTING FOOT

MITER HANDLE

MITER LATCH

SPECIFICATIONS

120 Volts

1152 Watts

60 Hz

12 Amps

ORIFICE D'ÉVACUATION DE LA POUSSIÈRE

GUIDE

TIGE DE VERROUILLAGE

PROTECTEUR SUPÉRIEUR

INTERRUPTEUR

POIGNÉE D'INTERRUPTEUR

PATTE DE MONTAGE

POIGNÉE POUR ONGLETS

DISPOSITIF DE VERROUILLAGE POUR ONGLETS

TABLE

CANAL PARA POLVO

GUIA

PERNO DE TRABADO

MESA

GUARDA SUPERIOR

INTERRUPTOR

MANIJA DEL INTERRUPTOR

PIE DE MONTAJE

ASA ANGULAR

SEGURO DE ANGULO

FICHE TECHNIQUE

120 volts

1152 watts

60 Hz

12 A

ESPECIFICACIONES

Tensión de alimentación: 120 V~

Potencia nominal: 1152 W

Frecuencia de operacion: 60 Hz

Consumo de corriente: 12 A

A

1

2

3

4

5

6

4

5

2

5

2

0

1

5

1

0

5

0

5

1

0

1

5

2

0

2

5

3

0

3

5

4

0

3

5

4

0

3

0

7

8

9

45

25

2

0

1

5

1

0

5

0

5

1

0

15

2

0

2

5

3

0

3

5

4

0

35

4

0

30

4

5

25

2

0

1

5

1

0

5

0

5

10

1

5

20

25

3

0

3

5

4

0

3

5

4

0

3

0

10

11

APPLICATION

BLADE

DESCRIPTION

NO. OF

TEETH

TYPE

OF CUT

Fine Trim

Molding

Trim, Framing

Pressure Treated

Decking

Aluminum

Precision

Ground Carbide

Combination

Multi-Purpose

Non-Ferrous

Metal Cutting

Carbide

60-100

32-60

60-80

Very Smooth

Splinter Free

Smooth

Fast Cut

—

Table 2

12

13

0

5

1

0

1

5

2

0

2

5

3

0

35

40

4

5

45

4

0

35

3

0

25

20

15

1

0

5

40

35

30

5

2

0

2

5

1

0

1

5

0

5

10

5

1

0

2

5

2

0

3

5

3

0

4

4

5

Page 3

Maintenance

1 All bearings are sealed and lubricated for life. They need no fur ther maintenance.

2. Periodically clean all dust and wood chips from around AND UNDER the base and the

rotary table. Even though slots are provided to allow debris to pass through, some dust will

accumulate.

3. Use only mild soap and a damp cloth to clean the tool. Never let any liquid get inside the

tool; never immerse any part of the tool into a liquid.

Accessories

Recommended accessories for use with your tool are available at extra cost from your local

dealer or authorized service center.

CAUTION: The use of any accessor y not recommended for use with this tool could be haz-

ardous.

Important

To assure product SAFETY and RELIABILITY, repairs, maintenance and adjustment (including

brush inspection and replacement) should be performed by authorized service centers or other

qualified service organizations, always using identical replacement parts.

Trouble Shooting Guide

BE SURE TO FOLLOW SAFETY RULES AND INSTRUCTIONS

TROUBLE! SAW WILL NOT START

WHAT’S WRONG? WHAT TO DO…

1. Saw not plugged in. 1. Plug in saw.

2. Fuse blown or circuit breaker tripped. 2. Replace fuse or reset circuit breaker.

3. Cord damaged. 3. Have cord replaced by authorized ser vice

center.

4. Brushes worn out. 4. Have brushes replaced by authorized

service center.

TROUBLE! SAW MAKES UNSATISFACTORY CUTS

WHAT’S WRONG? WHAT TO DO…

1. Dull blade. 1. Replace blade.

2. Blade mounted backwards. 2. Turn blade around.

3. Gum or pitch on blade. 3. Remove blade and clean with turpen-

tine and coarse steel wool or household

oven cleaner.

4. Incorrect blade for work being done. 4. Change the blade.

TROUBLE! BLADE DOES NOT COME UP TO SPEED

WHAT’S WRONG? WHAT TO DO…

1. Extension cord too light or too long. 1. Replace with adequate size cord.

2. Low house current. 2. Contact your electric company.

TROUBLE! MACHINE VIBRATES EXCESSIVELY

WHAT’S WRONG? WHAT TO DO…

1. Saw not mounted securely to stand or work 1. Tighten all mounting hardware.

bench.

2. Stand or bench on uneven floor. 2. Reposition on flat level surface.

3. Damaged saw blade. 3. Replace blade.

TROUBLE! DOES NOT MAKE ACCURATE MITER CUTS

WHAT’S WRONG? WHAT TO DO…

1. Miter scale not adjusted correctly. 1. Check and adjust.

2. Blade is not square to fence. 2. Check and adjust.

3. Blade is not perpendicular to table. 3. Check and adjust fence.

4. Workpiece moving. 4. Clamp workpiece to fence or glue 120

grits and paper to fence with rubber

cement.

TROUBLE! MATERIAL PINCHES BLADE

WHAT’S WRONG? WHAT TO DO…

1. Cutting bowed material. 1. Position bowed material as shown

Service Information

Black & Decker offers a full network of company-owned and authorized service locations

throughout North America. All Black & Decker Service Centers are staf fed with trained personnel to provide customers with efficient and reliable power tool service.

Whether you need technical advice, repair, or genuine factory replacement par ts, contact the

Black & Decker location nearest you.

To find your local service location, refer to the yellow page directory under "Tools—Electric" or

call: 1-800-54-HOW TO.

Full Two-Year Home Use Warranty

Black & Decker (U.S.) Inc. warrants this product for two years against any defects in material

or workmanship. The defective product will be replaced or repaired at no charge in either of

two ways:

The first, which will result in exchanges only, is to return the product to the retailer from whom

it was purchased (provided that the store is a participating retailer). Returns should be made

within the time period of the retailer’s policy for exchanges (usually 30 to 90 days after the

sale). Proof of purchase may be required. Please check with the retailer for their specific return

policy regarding returns that are beyond the time set for exchanges.

The second option is to take or send the product (prepaid) to a Black &Decker owned or

authorized Service Center for repair or replacement at our option. Proof of purchase may be

required. Black & Decker owned and authorized service centers are listed under "Tools-Electric"

in the yellow pages of the phone directory.

This warranty does not apply to accessories. This warranty gives you specific legal rights and

you may have other rights which vary from state to state. Should you have any questions, contact the manager of your nearest Black & Decker Service Center.

Importantes mesures de sécurité

AVERTISSEMENT : Par mesure de sécurité personnelle, lire le guide d’utilisation avant de se

servir de l’outil.

Fiche polarisée

Afin de réduire les risques de secousses électriques, l’outil est muni d’une fiche polarisée (une lame

plus large que l’autre). Ce genre de fiche n’entre que d’une façon dans une prise polarisée.

Lorsqu’on ne peut insérer la fiche à fond dans la prise, il faut tenter de le faire après avoir inversé

les lames de côté. Si la fiche n’entre toujours pas dans la prise, il faut communiquer avec un électricien certifié. Il ne faut en aucun cas modifier la fiche.

Importantes mesures de sécurité

•LAISSER LES PROTECTEURS EN PLACE et s’assurer qu’ils sont toujours en bon état.

• ENLEVER LES CLÉS DE RÉGLAGE. Prendre l’habitude de vérifier si les clés de réglage ont été

retirées de l’outil avant de le faire démarrer.

•BIEN DÉGAGER LA SURFACE DE TRAVAIL. Des surfaces et des établis encombrés peuvent être

la cause de blessures.

• TENIR COMPTE DU MILIEU DE TRAVAIL. Ne pas se servir des outils électriques dans des endroits

humides ou mouillés. Les protéger de la pluie. Bien éclairer la surface de travail.

• ÉLOIGNER LES ENFANTS. Tous les visiteurs doivent être tenus à l’écart de l’aire de travail.

• GARDER L’ATELIER À L’ÉPREUVE DES ENFANTS en y installant des cadenas, des interrupteurs

généraux ou en retirant les clés des démarreurs.

• NE JAMAIS FORCER L’OUTIL. Afin d’obtenir un rendement sûr et efficace, utiliser l’outil à son

rendement nominal.

• UTILISER L ’OUTIL APPROPRIÉ. Ne jamais exiger d’un petit outil ou d’un accessoire le rendement

d’un outil de fabrication plus robuste. Se servir de l’outil selon l’usage prévu.

• UTILISER LES CORDONS DE RALLONGE APPROPRIÉS. S’assurer que le cordon de rallonge est

en bon état. Lorsqu’on se sert d’un cordon de rallonge, s’assurer qu’il est de calibre approprié

pour la tension nécessaire au fonctionnement de l’outil. L’utilisation d’un cordon de calibre

inférieur occasionne une baisse de tension entraînant une perte de puissance et la surchauffe.

Le tableau suivant indique le calibre approprié selon la longueur du cordon et les mentions de

la plaque signalétique de l’outil. En cas de doute, utiliser un cordon de calibre supérieur. Le

chiffre indiquant le calibre est inversement proportionnel au calibre du cordon.

Calibre minimal des cordons de rallonge

Tension Longueur totale de la rallonge en pieds

120 V 0-25 26-50 51-100 101-150

240 V 0-50 51-100 101-200 201-300

Intensité nominale (A)

Plus Moins Calibre moyen de fil (AWG)

de de

0-6 18 16 16 14

6 - 10 18 16 14 12

10 - 12 16 16 14 12

12 - 16 14 12 Non recommandé

• PORTER DES VÊTEMENTS APPROPRIÉS. Éviter de porter des vêtements amples, des gants, des

cravates, des bagues, des bracelets ou tout autre bijou qui peuvent être happés par les pièces

en mouvement. Il est conseillé de porter des chaussure à semelle antidérapante. Protéger la

chevelure si elle est longue.

• TOUJOURS PORTER DES LUNETTES DE SÉCURITÉ. Porter également un masque respiratoire si

le travail de coupe produit de la poussière. Les lentilles des verres correcteurs résistent seulement

aux chocs; ce ne sont pas des lunettes de sécurité.

• NE P AS DÉPASSER SA PORTÉE. Toujours demeurer dans une position stable et garder son équili-

bre.

• PRENDRE SOIN DES OUTILS. Conserver les outils propres et affûtés pour qu’ils donnent un rendement supérieur et sûr. Suivre les directives concernant la lubrification et le remplacement des

accessoires.

• DÉBRANCHER LES OUTILS avant de les réparer ou d’en changer un accessoire (comme une

lame, un foret ou un couteau).

• ÉVITER LES DÉMARRAGES ACCIDENTELS. S’assurer que l’interrupteur est en position hors ten-

sion (OFF) lorsqu’on branche l’outil.

• UTILISER LES ACCESSOIRES RECOMMANDÉS. Consulter le guide d’utilisation pour connaître la

liste des accessoires recommandés. L’utilisation d’accessoires inappropriés peut présenter des

risques de blessures.

• NE JAMAIS SE TENIR SUR L’OUTIL. Cela présente des risques de blessures graves si l’outil bas-

cule ou si on touche à la lame par inadvertance.

• VÉRIFIER LES PIÈCES ENDOMMAGÉES. Avant de continuer à utiliser l’outil, il faut vérifier si le

protecteur ou toute autre pièce endommagée remplit bien la fonction pour laquelle il a été prévu.

Vérifier l’alignement et les attaches des pièces mobiles, le degré d’usure des pièces et leur montage, ainsi que tout autre facteur susceptible de nuire au bon fonctionnement de l’outil. Faire

réparer ou remplacer tout protecteur ou toute autre pièce endommagée.

• TOUJOURS SURVEILLER L’OUTIL. LE METTRE HORS TENSION. Laisser l’outil seulement lorsqu’il

est complètement immobilisé.

• PIÈCES DE RECHANGE. Lors de l’entretien, utiliser seulement des pièces de rechange identiques.

Mesures de sécurité additionnelles relatives aux scies à onglets mixtes

coulissants

• Porter des lunettes de sécurité.

• Éloigner les mains du tracé de la lame. NE JAMAIS COUPER UNE PIÈCE AVEC UNE MAIN À

MOINS DE 152 mm (6 po) DE LA LAME.

• Ne pas se servir de la scie sans les protecteurs en place.

• Ne faire aucune manœuvre à main levée.

• Ne jamais placer les mains derrière la lame de la scie.

• Mettre l’outil hors tension et attendre l’immobilisation complète de la lame avant de déplacer la

pièce à ouvrer ou de modifier les réglages.

• Débrancher l’outil avant d’en remplacer la lame ou d’en faire l’entretien.

• Régler la lame seulement lorsque l’outil est hors tension et que la lame est immobile.

• Ne jamais utiliser la scie sans la plaque rainurée.

• Remplacer la plaque lorsque la largeur de la rainure dépasse 3 mm (1/8 po).

• Afin de réduire les risques de blessures, remonter la scie en position arrière complète après

chaque coupe en travers.

MISE EN GARDE : LE NON-RESPECT DES PRÉSENTS AVERTISSEMENTS PEUT PRÉSENTER DES

RISQUES DE BLESSURES ET DE DOMMAGES IMPORTANTS.

• PROTÉGER le circuit électrique avec un fusible à action différée ou un disjoncteur d’au moins

15 ampères.

• S’ASSURER que la lame tourne dans le bon sens et que les dents du bas de la lame pointent

vers l’arrière de la scie à onglets mixtes coulissants.

• SE SERVIR des stabilisateurs en tout temps.

• VÉRIFIER si tous les boutons et les poignées de serrage sont bien fixés avant de commencer à

se servir de la scie.

• S’ASSURER que les rondelles de la lame et de l’arbre sont propres et que le côté en retrait des

collets repose contre la lame. Bien serrer la vis de l’arbre.

• VEILLER à ce que la lame soit bien affûtée et réglée.

• S’ASSURER que les orifices d’aération du moteur sont propres et libres de copeaux.

• UTILISER en tout temps les protecteurs de la lame.

• ÉLOIGNER les mains du tracé de la lame.

• METTRE la scie hors tension, débrancher le cordon d’alimentation et attendre l’immobilisation

complète de la lame avant d’entretenir ou de régler l’outil.

• SOUTENIR les grandes pièces à découper à l’aide de chevalets ou d’un établi.

• NE PAS essayer de faire fonctionner l’outil à une tension autre que la tension nominale.

• NE PAS faire fonctionner la scie à onglets si les boutons de serrage ne sont pas bien fixés.

• NE PAS utiliser de lame dont le diamètre est inférieur ou supérieur à celui recommandé.

• NE RIEN coincer dans le ventilateur pour soutenir l’arbre du moteur.

• NE PAS forcer la coupe. (Le blocage partiel ou complet du moteur peut causer des dommages

irrémédiables. Laisser le moteur atteindre son régime nominal avant de commencer à couper.)

• NE PAS couper des métaux ferreux (ceux qui renferment du fer ou de l’acier) ni de la maçon-

nerie.

See ‘Tools-Electric’

– Yellow Pages –

for Service & Sales

Imported by

Black & Decker (U.S.) Inc.,

701 E. Joppa Rd.

Towson, MD 21286 U.S.A.

SSSScccciiiieeee àààà oooonnnngggglllleeeettttssss ddddeeee 222255554444 mmmmmmmm ((((11110000 ppppoooo))

))

RENSEIGNEMENTS IMPORTANTS

•Couper seulement avec des lames affûtées. Des lames émoussées coupent mal et

surchargent le moteur.

•Lorsque la scie ne coupe pas bien, consulter le guide de dépannage

GUIDE D’UTILISATION

CONSERVER LE PRÉSENT GUIDE À TITRE DE RÉFÉRENCE.

AVANT DE RETOURNER LE PRODUIT, PEU IMPORTE LA RAI-

SON PRIÈRE DE COMPOSER

1 800 544-6986

YOU'VE GOT THE TOOL

http://www.blackanddecker.com

NOW GET THE KNOW-HOW

Page 4

• NE PAS utiliser des meules abrasives. La chaleur excessive et les particules abrasives dégagées

abîmeraient la scie.

• NE PAS utiliser des lames abrasives.

• NE permettre à personne de rester derrière la scie.

• NE PAS lubrifier la scie lorsqu’elle fonctionne.

• NE PAS mettre les mains près de la lame lorsque la scie est branchée.

• NE PAS se servir de lames conçues pour fonctionner à un régime inférieur à 5500 trs/min.

• NE PAS essayer de découper de petites pièces (152 mm - 6 po) non fixées.

• NE PAS se servir de la scie sans les protecteurs.

• NE PAS utiliser la scie sans la tenir d’au moins une main.

• NE PAS placer les mains près de la lame de la scie.

• NE PAS placer les mains à moins de 152 mm (6 po) de la lame.

• NE PAS placer les mains sous la scie sauf si celle-ci est hors tension et débranchée.

• NE P AS déplacer les mains de la scie ni de la pièce à découper et ne pas soulever les bras avant

l’immobilisation complète de la lame.

MISE EN GARDE : Ne pas brancher l’outil avant d’avoir bien lu et compris toutes les mesures

de sécurité.

MISE EN GARDE : Certaines essences de bois renferment des agents de conservation (comme

de l’arséniate de cuivre et de chrome) qui peuvent être toxiques. Lorsqu’on doit couper de tels

matériaux, prendre des mesures supplémentaires afin d’éviter d’inhaler les vapeurs toxiques et de

minimiser les contacts avec la peau.

À titre de commodité et de sécurité, les étiquettes suivantes se trouvent sur la scie à onglets mixtes

coulissants.

Connexion électrique

Il faut s’assurer que la source d’alimentation utilisée est conforme aux inscriptions qui figurent

sur la plaque signalétique. La mention 120 volts c.a. seulement signifie que l’outil utilise seulement du courant alternatif et jamais du courant continu. Une baisse de tension de plus de

10 p. 100 provoque une perte de puissance et la surchauffe de l’outil. Tous les outils

Black & Decker sont vérifiés à l’usine. Si l’outil ne fonctionne pas, vérifier la source d’alimentation.

Familiarisation

La scie à onglets est complètement assemblée dans l’emballage. Il suffit d’ouvrir la boîte et d’en sortir la

scie en la soulevant par sa poignée, comme le montre la figure 1. Déposer la scie sur une surface uniforme

et plate (comme un établi ou une table solide).

Examiner les figures qui se trouvent sur la page couverture intérieure avant du présent guide afin de

mieux connaître la scie et ses composantes. La rubrique suivante relative aux réglages utilise les termes

indiqués sur les figures et il faut les connaître.

Appuyer légèrement sur la poignée de fonctionnement et retirer la tige de verrouillage (fig. 2). Relâcher

doucement la pression exercée vers le bas et laisser le bras remonter à sa position de service. Utiliser la

tige de verrouillage pour transporter la scie. Toujours saisir la scie par sa poignée pour le transport.

Montage sur établi

Les quatre pattes de l’outil sont pourvues d’un trou afin d’en faciliter le montage sur établi.

Toujours installer la scie solidement afin d’éviter qu’elle ne bouge. Afin de pouvoir transporter

la scie facilement, il est conseillé de fixer l’outil à un morceau de contreplaqué d’au moins

12,7 mm (1/2 po) d’épaisseur qu’on pourra ensuite fixer à un établi ou à un autre endroit

lorsqu’on a à se déplacer.

NOTE : Lorsqu’on fixe la scie sur un morceau de contreplaqué, s’assurer que les vis ne

dépassent pas sous le bois. Le contreplaqué doit reposer à plat sur la surface de travail.

Lorsqu’on fixe la scie à une surface quelconque, il faut installer les brides de serrage seulement

aux épaulements où se trouvent les trous des vis de montage. L’installation des brides à tout

autre endroit nuira au bon fonctionnement de la scie.

Remplacement de la lame

1. METTRE L’OUTIL HORS TENSION ET LE DÉBRANCHER.

2. Lorsque le moteur de la scie est en position élevée, soulever au maximum le protecteur

inférieur.

3. Desserrer (sans l’enlever) la vis de la patte d’attache du protecteur illustrée à la figure 3

jusqu’à ce qu’on puisse soulever la patte d’attache du protecteur suffisamment pour

accéder à la vis de la lame.

4. Abaisser le bras de la scie jusqu’à ce que les dents de la lame s’enfoncent dans un bout de

bois. Utiliser la clé pour enlever (dans le sens horaire) la vis de la lame (filet à gauche).

5. Retirer la rondelle de fixation extérieure et la lame de la scie.

6. Installer la nouvelle lame en s’assurant que les dents au bas de la lame pointent vers l’arrière de la scie.

7. Remettre en place la rondelle de fixation extérieure et serrer la vis de la lame (dans le sens

antihoraire) tout en retenant le protecteur inférieur en position élevée et les dents de la

lame coincées dans un bout de bois.

8. BIEN RABAISSER LA PATTE D’ATTACHE DU PROTECTEUR ET SERRER FERMEMENT LA VIS

DE LA PATTE D’ATTACHE DU PROTECTEUR APRÈS AVOIR INSTALLÉ LA LAME, SINON LA

SCIE SERA ENDOMMAGÉE.

Réglages

S’ASSURER QUE LA SCIE À ONGLETS EST DÉBRANCHÉE AVANT DE LA RÉGLER.

NOTE : La scie à onglets est complètement et précisément réglée en usine. Lorsqu’on doit la

régler de nouveau, se conformer aux consignes suivantes.

RÉGLAGE DU BOULON DE PIVOT

Il peut être nécessaire de régler le boulon de pivot en raison de l’usure. Il faut effectuer ce

réglage lorsque la scie est complètement montée, y compris la lame. Desserrer ou serrer le

boulon de pivot en faisant tourner la tête hexagonale située à gauche du pivot jusqu’à ce qu’il

n’y ait plus de jeu et que le moteur monte doucement lorsqu’on le relâche.

LAME PERPENDICULAIRE AU GUIDE- Faire ce qui suit.

NOTE : Après ce réglage, la lame peut ne plus s’aligner sur la rainure de la plaque.

1. Lorsque la scie est débranchée, abaisser le bras de pivot jusqu’à ce que le rebord de la

lame soit à égalité avec le dessus de la plaque rainurée. La lame doit alors sembler être

parallèle aux côtés de la plaque rainurée. La lame ne doit pas nécessairement être parfaitement au centre de la plaque rainurée, mais elle doit y être parallèle, dans la mesure

du possible (fig. 4).

Lorsque la lame semble parallèle, effectuer le réglage de l’indicateur d’onglets décrit.

Sinon, desserrer (mais ne pas enlever) les deux boulons qui se trouvent sous le rebord

arrière de la table de la scie retenant le bras de pivot (fig. 5) à la scie. Aligner la lame au

besoin et resserrer les boulons (couple de 23 à 27 lb-pi). (ÉVITER DE TROP SERRER.)

2. Vérifier si la lame est perpendiculaire au guide à l’aide d’une équerre. Le cas échéant, on

peut se servir de la scie.

3. Lorsque ce n’est pas encore le cas, il faut régler la scie.

Pour la régler, desserrer les deux boulons de la barre de poignée qui se trouvent sous la

scie, au centre de la table rotative (fig. 7). NE PAS RETIRER CES BOULONS.

Lorsque les boulons de la barre de poignée sont lâches et que la base rotative est réglée à

la position zéro, placer la lame perpendiculaire au guide (fig. 6).

Serrer les boulons de la barre de poignée (couple de 23 à 27 pi-lb) et la scie devrait être

bien réglée.

RÉGLAGE DE L’INDICATEUR D’ONGLETS

METTRE L ’OUTIL HORS TENSION ET LE DÉBRANCHER.

1. Desserrer le bouton de serrage pour onglets et serrer le dispositif de verrouillage pour onglets

afin de déplacer l’indicateur d’onglets à la position 0, comme le montre la figure 8.

2. Laisser le bouton pour onglets desserré et faire enclencher le dispositif de verrouillage pour

onglets en faisant tourner l’indicateur d’onglets au-delà de zéro.

3. Examiner l’indicateur et l’échelle d’onglets par l’ouverture. Lorsque l’indicateur ne montre pas

exactement le zéro, le déplacer doucement vers la gauche ou la droite à l’aide d’un tournevis

à lame plate.

Fonctionnement du protecteur et visibilité

Le protecteur de la scie est conçu pour se soulever automatiquement lorsqu’on abaisse le

moteur et pour se rabaisser sur la lame lorsque le moteur remonte. On peut le soulever à la

main lors de l’installation et du retrait de la lame ou pour effectuer l’inspection de la scie. NE

JAMAIS SOULEVER LE PROTECTEUR À LA MAIN LORSQUE LA SCIE EST SOUS TENSION.

Interrupteur

Pour mettre la scie en marche, enfoncer l’interrupteur à détente (fig. 9). Pour arrêter l’outil,

relâcher l’interrupteur. Il n’est pas possible de verrouiller la scie en marche, mais la détente est

dotée d’un trou permettant d’y insérer un cadenas afin de bloquer la scie en position d’arrêt.

Coupe

NOTE : Même si la scie peut couper le bois et de nombreux métaux non-ferreux, le présent

guide ne traite que de la coupe du bois. Les mêmes directives valent pour les autres matériaux.

NE PAS UTILISER LA SCIE POUR COUPER DES MÉTAUX FERREUX (COMME LE FER ET L’ACIER)

NI DE LA MAÇONNERIE. Ne pas utiliser de lame abrasive.

Régler l’indicateur d’onglets à l’angle voulu. Bien serrer le bouton de verrouillage pour

onglets et bien retenir le bois contre la table en l’appuyant fermement contre le guide. Mettre

la scie en marche en enfonçant la détente de l’interrupteur (fig. 9).

Lorsque la scie atteint son régime de fonctionnement (en environ 1 seconde), abaisser le

moteur doucement et couper le bois lentement. Attendre l’immobilisation complète de la lame

avant de soulever le moteur.

Qualité de la coupe

La qualité de la coupe dépend d’un certain nombre de facteurs. Il peut s’agir du type de

matériau à couper, du type de lame utilisé, de l’affûtage de la lame et de la vitesse de coupe.

Ces éléments influencent tous la qualité de la coupe.

Lorsqu’on veut une coupe douce pour une moulure ou tout autre travail de précision, une lame

tranchante (d’au moins 60 dents, au carbure) ainsi qu’une vitesse de coupe lente et uniforme

procurent les résultats voulus.

Afin d’éviter que le matériau ne glisse pendant la coupe, bien le fixer en place. Toujours

attendre l’immobilisation complète de la lame avant de soulever le moteur de la scie.

Lorsque de petites fibres de bois éclatent encore à l’arrière de la pièce à découper, coller du

ruban-cache sur le bois sur la ligne de coupe. Découper dans le ruban-cache et le retirer à la

fin des travaux.

Consulter le tableau 2 pour les lames recommandées pour les diverses applications de la scie.

Choisir celle qui convient le mieux à la tâche.

Position du corps et des mains

(Figure 10)

Une bonne position du corps et des mains facilite l’utilisation de la scie tout en donnant de

meilleurs résultats de façon sûre. Ne jamais placer les mains près de la zone de coupe. Les

tenir à plus de 153 mm (6 po) de la lame. Bien placer la pièce à découper contre la plaque et

le guide pendant la coupe. Ne pas déplacer les mains jusqu’à ce qu’on ait relâché la détente

et que la lame ne s’immobilise complètement. TOUJOURS FAIRE DES ESSAIS À BLANC (AVEC

L’OUTIL HORS TENSION) AVANT LES COUPES DE FINITION AFIN DE VÉRIFIER LA TRAJECTOIRE DE LA LAME. NE PAS CROISER LES MAINS, COMME LE MONTRE LA FIGURE 10.

Laisser les deux pieds sur le plancher et garder un bon équilibre. Lorsqu’on déplace la scie à

onglets à gauche et à droite, la suivre et se tenir un peu sur le côté de la lame. Regarder par

les volets du protecteur pour suivre un tracé au crayon

Soutien des grandes pièces

METTRE L’OUTIL HORS TENSION ET LE DÉBRANCHER.

Soutenir les grandes pièces à l’aide de chevalets ou de tout autre dispositif semblable qui

empêchera les bouts de tomber.

Coupes particulières

NE JAMAIS COUPER LE MATÉRIAU AVANT DE L’AVOIR BIEN FIXÉ. TOUJOURS UTILISER LA

LAME APPROPRIÉE .

COUPE DE L’ALUMINIUM

La scie peut facilement couper des profilés d’aluminium comme ceux utilisés dans la fabrication de moustiquaires et de contre-fenêtres. Placer le matériau de façon à couper la partie

transversale la plus mince, comme le montre la figure 11. La figure 12 illustre une façon incorrecte de découper ces profilés.

Utiliser une cire lubrifiante pour couper l’aluminium (comme la cire en bâtons n° 140 de

Johnson). Appliquer le bâton de cire directement sur la lame de la scie avant la coupe. Ne

jamais enduire de cire une lame en mouvement.

La cire (vendue dans la plupart des quincailleries et des centres de fournitures industrielles)

assure la lubrification adéquate de l’outil et empêche l’adhésion d’éclats à la lame.

MATÉRIAU ARQUÉ

Toujours placer les matériaux arqués de la façon illustrée à la figure 13. Lorsque le matériau

n’est pas bien placé, il se coince sur la lame avant la fin de la coupe.

DANGER

KEEP AWAY

FROM BLADE

SUR LE BOÎTIER DU CHAMP :

SUR LE PROTECTEUR :

DANGER –

ÉLOIGNER

DE LA LAME.

CONSERVER CES MESURES À TITRE DE RÉFÉRENCE.

UTILISATION

DESCRIPTION DE

LA LAME

NOMBRE

DE DENTS

TYPE

DE COUPE

Moulure

délicate

Moulure,

cadrage et bois

traité

Aluminium

Au carbure,

évidée et précise

De60

à100

De32

à60

De60

à80

Très douce;

sans éclat

Douce;

coupe rapide

—

Tableau 2

Universelle

À usages

multiples

À métaux

non-ferreux

Au carbure

!

WARNING: When servicing use only

identical replacement parts. Do not expose to

rain or use in damp locations.

AVERTISSEMENT : Pour

s'assurer du fonctionnement sûr, lire le guide

d'utilisation. Ne pas exposer à la pluie et ne pas

utiliser dans les emplacement humidies.

Black & Decker (U.S.) Inc., Towson, MD 21286 USA Made in USA

WARNING:

For safe operation read instruction manual. Always

wear eye protection. Keep hands 6'' (153mm) from

path of saw blade. Do not operate saw without guards

in place. Keep guards in working order. Do not perform

any operation freehand. Never reach in back of saw

blade. Turn off tool, keep saw head down and wait for

saw blade to stop before moving work piece or

changing settings. Unplug tool before changing blade,

moving or servicing unit. Never cross arms in front of

blade. Secure unit before using.

Page 5

Tuyau en plastique et autre matériau rond à coupe transversale

La scie coupe facilement les tuyaux en plastique et autres matériaux semblables. Ils se coupent

comme le bois et il faut BIEN LES SAISIR OU LES FIXER AU GUIDE POUR LES EMPÊCHER DE

ROULER SURTOUT LORSQU’ON COUPE EN ANGLE.

Entretien

1. Tous les roulements sont scellés et ils sont lubrifiés en permanence et ne nécessitent aucun

entretien.

2. Nettoyer régulièrement la poussière et les copeaux qui se trouvent autour ET EN DESSOUS

du socle et de la plaque tournante. Même s’il y a des fentes pour laisser passer les débris,

ceux-ci s’accumulent.

3. Utiliser seulement un savon doux et un chiffon humide pour nettoyer l’outil. Ne laisser

aucun liquide s’infiltrer dans l’outil et ne jamais l’immerger.

Accessoires

Les accessoires recommandés pour l´outil sont vendus chez le détaillant ou au centre de ser-

vice autorisé de la région.

MISE EN GARDE : L’utilisation de tout autre accessoire non recommandé pour l’outil peut être

dangereuse.

Important

Pour assurer la SÉCURITÉ D’EMPLOI et la FIABILITÉ de l’outil, n’en confier la réparation, l’entretien et les rajustements (y compris l’inspection et le remplacement des balais) qu’à un centre

de service ou à un atelier d’entretien autorisé n’utilisant que des pièces de rechange identiques.

Guide de dépannage

SE CONFORMER AUX MESURES DE SÉCURITÉ ET AUX DIRECTIVES.

PROBLÈME : LA SCIE NE DÉMARRE PAS.

VÉRIFIER SI : SOLUTION

1. La scie est branchée. 1. Brancher la scie.

2. Le fusible a sauté ou le disjoncteur est enclenché. 2. Remplacer le fusible ou

enclencher le disjoncteur.

3. Le cordon est endommagé. 3. Faire remplacer le cordon au

centre de service autorisé.

4. Les balais sont usés. 4. Faire remplacer les balais au

centre de service autorisé

PROBLÈME : LA SCIE NE COUPE PAS BIEN.

VÉRIFIER SI : SOLUTION

1. La lame est émoussée 1. Remplacer la lame

2. La lame est installée à l’envers. 2. La replacer à l’endroit

3. Il y a de la gomme ou de la poix sur la lame. 3. Enlever la lame, la nettoyer

avec de la térébenthine et

une laine d’acier de gros cal

ibre ou à l’aide d’un nettoy

ant à fours.

4. La lame ne convient pas à la coupe. 4. Remplacer la lame.

PROBLÈME : LA SCIE N’ATTEINT PAS SON PLEIN RÉGIME.

VÉRIFIER SI : SOLUTION

1. Le cordon de rallonge est de trop faible calibre ou il est 1. Utiliser un cordon

trop long. de dimensions appropriées

2. Le courant domestique est trop faible. 2. Appeler la compagnie d’élec

tricité.

PROBLÈME : LA SCIE VIBRE DÉMESURÉMENT.

VÉRIFIER SI : SOLUTION

1. La scie n’est pas bien installée sur le soutien ou 1. Serrer toutes les ferrures de

sur l’établi montage

2. Le soutien ou l’établi se trouve sur un plancher inégal. 2. Replacer sur une surface

plane.

3. La lame est endommagée. 3. Remplacer la lame

PROBLÈME : LA SCIE NE COUPE PAS BIEN LES ONGLETS.

VÉRIFIER SI : SOLUTION

1. L’échelle pour onglets est bien réglé. 1. Vérifier et régler.

2. La lame n’est pas perpendiculaire au guide. 2. Vérifier et régler.

3. La lame n’est pas perpendiculaire à la plaque. 3. Vérifier et régler

4. La pièce à découper bouge. 4. Fixer la pièce au guide ou

coller du papier abrasif de

grain 120 sur le guide avec

une dissolution.

PROBLÈME : LE MATÉRIAU SE COINCE SUR LALAME.

VÉRIFIER SI : SOLUTION

1. On coupe un matériau arqué. 1. Placer les matériaux arqués

de la façon illustrée

Renseignements relatifs au service

Black & Decker exploite un réseau complet de centres de service et d’ateliers d’entretien autorisés par toute

l’Amérique du Nord. Le personnel de tous les centres de service Black & Decker a reçu la formation voulue

pour assurer l’entretien efficace et fiable des outils électriques.

Pour obtenir des renseignements d’ordre technique, des conseils relatifs aux réparations ou des pièces de

rechange d’origine, communiquer avec le centre de service Black & Decker de la région.

On peut trouver l’adresse du centre de service de la région dans l’annuaire des Pages Jaunes à la rubrique

«Outils électriques» ou en composant le numéro suivant : 1 800 544-6986

Garantie complète de deux ans pour utilisation domestique

Black & Decker garantit ce produit pour une période de deux ans contre les vices de matière ou

de fabrication. Le produit défectueux sera réparé ou remplacé sans frais conformément à l’une

des conditions suivantes.

Pour échanger l’outil, il suffit de le retourner au détaillant (si le détaillant participe au programme

d’échange rapide Black & Decker). Le retour doit être effectuer dans les délais impartis par la

politique de retour du détaillant (habituellement entre 30 et 90 jours suivant la date d’achat). Le

détaillant peut exiger une preuve d’achat. Prière de vérifier la politique de retour du détaillant

au-delà des délais impartis.

On peut également retourner l’outil port payé à un centre de service Black & Decker ou à tout

autre atelier d’entretien accrédité pour y être remplacé ou réparé, à notre gré. On peut exiger

une preuve d’achat. Les adresses des centres de service Black & Decker se trouvent à la rubrique

«Outils électriques» des Pages jaunes.La présente garantie ne vaut pas pour les accessoires. Les

modalités de la présente garantie donnent des droits légaux spécifiques. L ’utilisateur peut

également se prévaloir d’autres droits selon l’état ou la province qu’il habite. Pour obtenir de

plus amples renseignements, communiquer avec le directeur du centre de service Black & Decker

de la région.

INFORMACION CLAVE QUE DEBE SABER

•Corte únicamente con discos afilados. Los discos desafilados cortan pobremente y

sobrecargan el motor.

•Si la sierra no corta con precisión consulte la GUIA PARA SOLUCION DE

PROBLEMAS FRECUENTES

INSTRUCCIONES IMPORTANTES DE SEGURIDAD

ADVERTENCIA: Por su propia seguridad lea el manual de instrucciones antes de operar la sier-

ra de ángulo compuesto corrediza.

Clavijas polarizadas

Este equipo cuenta con una clavija polarizada (con una pata más ancha que la otra) para reducir

los riesgos de choque eléctrico. Este tipo de clavija, ajustará en un contacto polarizado solamente

de una manera. Si la clavija no ajusta completamente en su contacto, inviértala. Si aún así no

ajusta, llame a un electricista calificado para que le instale un contacto polarizado apropiado.

No modifique o haga cambios en la clavija por ningún motivo.

Instrucciones de seguridad importantes

• CONSERVE LAS GUARDAS EN SU SITIO y listas para el trabajo.

• RETIRE LAS LLAVES DE AJUSTE Y OTRAS HERRAMIENTAS. Hágase el hábito de revisar para

verificar que las llaves se hayan retirado de la herramienta antes de encenderla.

• CONSERVE LIMPIA EL AREA DE TRABAJO. Los lugares y los bancos desordenados propician

los accidentes.

• NO SE UTILICE EN AMBIENTES PELIGROSOS. No utilice herramientas eléctricas en lugares

húmedos o inundados, ni las exponga a la lluvia. Conserve el área de trabajo bien iluminada.

• CONSERVE APARTADOS A LOS NIÑOS. Todos los visitantes deben permanecer a distancia

segura del área de trabajo.

• HAGA SU TALLER A PRUEBA DE NIÑOS con candados, interruptores maestros o quitando las

llaves de encendido.

• NO FUERCE LA HERRAMIENTA. Esta hará el trabajo mejor y de manera más segura bajo las

especificaciones para las que se diseñó.

• UTILICE LA HERRAMIENTA ADECUADA. No fuerce a una herramienta o sus dispositivos a hacer

trabajos para los que no se han diseñado.

• UTILICE CABLES DE EXTENSION ADECUADOS. Asegúrese que su cable de extensión esté en

buenas condiciones. Cuando utilice una extensión, asegúrese que tenga el calibre necesario

para soportar la corriente que su herramienta requiere. Un cale con calibre menor causará una

caída en el voltaje de la línea, ocasionando pérdida de potencia y sobrecalentamiento. El

cuadro siguiente muestra el calibre correcto para usarse de acuerdo con la longitud y el amperaje descrito en la placa de identificación. Si tiene dudas, utilice el calibre siguiente. Mientras

más pequeño sea el número del calibre, mayor será su capacidad.

Calibre mínimo requerido (AWG) para cables de extensión

Volts Longitud total de la extensión (metros)

120 V 0 - 7.5 7.6 - 15.2 15.3 -30.4 30.5 - 45.7

240 V 0 - 15.2 15.3 - 30.4 30.5 - 60.8 60.9 - 121.2

Amperaje en la placa de identificación

Más No más Calibre promedio del alambrede

de de

0 - 6 18 16 16 14

6 - 10 18 16 14 12

10 - 12 16 16 14 12

12 - 16 14 12 No se recomienda

• UTILICE LAS ROPAS ADECUADAS. No utilice prendas flojas, guantes corbatas, anillos brazaletes ni otros artículos de joyería que pudiesen quedar atrapados por las piezas en movimiento. Se recomienda el uso de calzado antiderrapante. Cúbrase el cabello si lo tiene largo.

• SIEMPRE UTILICE ANTEOJOS DE SEGURIDAD. También utilice una máscara contra polvo si la

operación que efectuará lo produce. Los anteojos de diario solamente tienen lentes resistentes

al impacto, no son anteojos de seguridad.

• ASEGURE LAS PIEZAS DE TRABAJO. Utilice prensas para sujetar su trabajo cuando le sea práctico. Esto es más seguro que usar sus manos y le deja ambas libres para operar la herramienta.

• NO SE SOBREEXTIENDA. Conser ve los pies bien apoyados, lo mismo que el equilibrio.

• CUIDE SUS HERRAMIENTAS. Consérvelas afiladas y limpias para un rendimiento más seguro y

más eficaz. Siga las instrucciones para la lubricación y el cambio de accesorios.

• DESCONECTE LAS HERRAMIENTAS antes de darles servicio y cuando cambie de accesorios,

tales como discos, brocas, cuchillas, y otros similares.

• EVITE EL RIESGO DE ENCENDIDO ACCIDENTAL. Asegúrese que el interruptor esté en posición

de apagado antes de conectar la herramienta.

• UTILICE LOS ACCESORIOS RECOMENDADOS. Consulte el manual de instrucciones para conocer los accesorios recomendados. El empleo de accesorios no apropiados puede ocasionar riesgos de lesiones a las personas.

• NUNCA SE PARE EN LA HERRAMIENTA. Se puede lesionar gravemente si la herramienta se

vuelca o hace contacto accidental con la pieza de corte.

• REVISE LAS PARTES DAÑADAS. Antes de seguir utilizando la herramienta, una guarda u otra

pieza que esté dañada debe ser examinada cuidadosamente para determinar si funcionará

apropiadamente y cumplirá con su función. Revise la alineación de las piezas móviles, su montaje, la ruptura de las piezas, montajes y cualesquiera otras condiciones que pudiesen afectar

su operación. Una guarda u otra parte dañada debe ser reparada correctamente o reemplazada.

• SENTIDO DE ALIMENTACION. Alimente la pieza de trabajo hacia el disco únicamente en contra de su sentido de rotación.

• NUNCA DEJE LA HERRAMIENTA EN OPERACION DESATENDIDA. APAGUELA. No deje la herramienta hasta que se haya detenido completamente.

• PARTES DE REPUESTO. Utilice únicamente piezas de repuesto idénticas cuando haga servicio.

Instrucciones de seguridad adicionales para sierras angulares

PRECAUCION: No conecte la unidad a la toma de corriente hasta que haya leído y compren-

dido completamente las instrucciones.

• PROTEJA la alimentación eléctrica con un relevador o un interruptor de circuito de por lo

menos 15 amperes.

• ASEGURESE de que el disco gire en la dirección correcta y de que los dientes en la parte inferior apuntan hacia la parte trasera de la sierra.

• ASEGURESE de que todos los mangos de sujeción estén apretados antes de iniciar cualquier

operación.

• ASEGURESE de que el disco y las arandelas de sujeción estén limpias y los lados huecos de

los collarines estén contra el disco. Apriete firmemente el tornillo - eje.

• CONSERVE el disco afilado y correctamente dispuesto.

• CONSERVE las rendijas de ventilación del motor libres de mugre y virutas.

• COLOQUE soportes fuera de la mesa de trabajo para las piezas largas.

•NOintente operar la unidad con un voltaje diferente al designado.

•NOatore con ningún objeto el ventilador para detener el eje del motor.

•NOcorte metales ferrosos (aquellos con algún contenido de hierro o acero), ni piezas de

mampostería.

•NOutilice discos abrasivas. El calor excesivo y las partículas abrasivas generadas por ellas

dañarán la sierra.

Imported by / Importé par Black & Decker Canada Inc.

100 Central Ave. Brockville (Ontario) K6V 5W6

Voir la rubrique “Outils électriques”

des Pages Jaunes

pour le service et les ventes.

MANUAL DE INSTRUCCIONES

SSSSiiiieeeerrrrrrrraaaa aaaannnngggguuuullllaaaarrrr ddddeeee 222255554444mmmmmmmm ((((11110000""""))

))

CONSERVE ESTE MANUAL PARA REFERENCIAS FUTURAS

Page 6

•NOper mita que nadie se pare por detrás de la sierra.

•NOaplique lubricantes al disco cuando está funcionando.

•NOutilice discos cuya velocidad nominal sea menor a 5500 R.P.M.

•NOintente cortar piezas menores a 153mm (6") sin sujetarlas con una pr ensa.

•NOrealice ninguna operación a manos libres.

•NOacerque las manos a menos de153mm (6") del disco.

•NOse coloque por debajo de la sierra a menos que esté apagada y desconectada. El disco

se encuentra expuesto por la parte de abajo de la sierra.

•NOmueva ninguna de las manos de la sierra o la pieza en que esté trabajando, o levante los

brazos, hasta que el disco se haya detenido.

•NOutilice discos que no tengan 254mm (10") de diámetro.

PRECAUCION: Algunas maderas contienen conser vadores como el arsenato cúprico de

cromo (CCA) que pueden ser tóxicos. Cuando corte estos materiales debe tomar precauciones adicionales para evitar la inhalación y minimizar el contacto con la piel.

PRECAUCION: Cuando HAGA SERVICIO A SUS HERRAMIENTAS, UTILICE PARTES DE

REEMPLAZO IDENTICAS. REPARE O REEMPLACE LOS CORDONES ELECTRICOS

DAÑADOS.

•NOamarre, encinte o sujete de alguna otra manera la guarda para que permenezca abierta cuando opere la sierra.

EN LA GUARDA: EN LA CUBIERTA DEL CAMPO:

PELIGRO – ALEJE DEL DISCO.

Conexiones eléctricas

Asegúrese de que su toma de corriente concuerde con la marca en la placa de identificación.

120 volts CA significa que su sierra operará con corriente alterna, nunca corriente directa. Un

decremento en el voltaje de 10 por ciento o mayor causará una pérdida de potencia y sobrecalentamiento. Todas las herramientas B&D vienen probadas de origen. Si esta herramienta no

funciona, verifique la alimentación de corriente.

Desempacando su herramienta

Verifique el contenido de la caja de su sierra angular para asegurarse de que ha recibido

todas las partes. Además de este manual de instrucciones, la caja debe contener: una sierra

angular 1710.

Familiarícese con su herramienta

Su sierra angular viene completamente ensamblada en la caja. Abra la caja y levante la sierra tomándola por el asa, como se ilustra en la figura 1. Coloque la unidad en una superficie

plana, como un banco de trabajo o una mesa estable.

Examine las figuras del interior de la cubierta para familiarizarse con la sierra y sus partes.

La sección referente a los ajustes hace mención a esos términos, y usted debe cuales son y en

donde están estas partes.

Presione ligeramente hacia abajo el mango de operación y jale el perno de trabado, como se

ilustra en la figura 2. Libere suavemente la presión hacia abajo y permita que el brazo se levante hasta su altura total. Utilice el perno de trabado cuando transporte la sierra de un lugar a

otro. Emplee siempre el asa para transportar la unidad.

Montaje en banco

Las cuatro patas están provistas con perforaciones para facilitar el montaje en un banco.

Monte siempre su sierra firmemente para evitar movimiento. Para incrementar la portabilidad

de la unidad, puede montarse en un pieza de madera contraplacada de

12.7mm (1/2") o más gruesa, que puede sujetarse a su mesa de trabajo o moverse a otros

lugares y resujetarse.

NOTA: Si elige montar su sierra a una pieza de triplay, asegúrese de que los tornillos no

sobrepasan el fondo de la madera. La hoja de madera debe asentarse perfectamente en el

soporte de trabajo. Cuando monte la unidad a cualquier otra superficie, sujete sólo en los

lugares destinados a ello en la zona en donde se localizan los agujeros para los tornillos.

Sujetarse de cualquier otro lugar seguramente interferirá con la operación apropiada de la

sierra.

Cambio de disco

1. APAGUE LA HERRAMIENTA Y DESCONECTELA DE LA TOMA DE CORRIENTE.

2. Con el brazo de la sierra en la posición elevada, levante la guarda inferior tanto como sea

posible.

3. Afloje (pero no desarme) el tornillo de montaje de la guarda, ilustrado en la figura 3,

hasta que la montura de la guarda se pueda levantar lo suficiente para permitir el acceso

al tornillo del disco.

4. Empuje el brazo de la sierra hacia abajo para clavar los dientes del disco en un pedazo

de madera de desperdicio. Emplee la llave del disco para remover (en el sentido de las

manecillas del reloj) el tornillo del disco (cuerda izquierda).

5. Quite arandela de presión exterior y el disco de la sierra.

6. Instale el disco de la sierra asegurándose de que los dientes en la parte inferior del disco

apuntan hacia la parte trasera de la sierra.

7. Coloque la tuerca exterior del disco y apriete el tornillo (en sentido opuesto a las manecillas del reloj) mientras sostiene la guarda inferior hacia arriba y los dientes del disco permanecen enterrados en la pieza de madera de desperdicio.

8. DESPUES DE INSTALAR EL DISCO DE LA SIERRA, REPOSICIONE LA MONTURA DE LA

GUARDA ASEGURANDOSE DE QUE ASIENTA COMPLETAMENTE EN EL TORNILLO DE

LA GUARDA. APRIETE FIRMEMENTE EL TORNILLO. NO HACERLO CAUSARA DAÑOS A

LA UNIDAD.

Ajustes

¡REALICE TODOS LOS AJUSTES CON LA SIERRA ANGULAR DESCONECTADA!

NOTA: Su sierra angular viene ajustada completamente y con precisión de origen. Si se

requiere reajustarla, siga los pasos a continuación.

AJUSTE DEL EJE

Se pueden requerir ajustes en el eje conforme pase el tiempo. Se deben hacer los ajustes con

la sierra totalmente ensamblada, incluyendo el disco. Afloje o apriete el eje girando la cabeza

hexagonal situada del lado izquierdo del ensamble del eje hasta eliminar el juego y el motor se

mueva con suavidad cuando se libera.

AJUSTE EL DISCO A ESCUADRA CON LA GUIA: Realice los siguientes pasos:

NOTA: DESPUÉS DE LOS AJUSTES, EL DISCO PUEDE NO ESTAR ALINEADO CON LA RANURA

DE LA CUBIERTA DE LA MESA.

1. Con la sierra desconectada, baje el brazo hasta que la punta del disco quede al ras de la

cubierta. El disco debe quedar paralelo a los lados de la ranura. No es importante que el

disco esté perfectamente centrado en la ranura, pero debe estar razonablemente en paralelo, observe la figura 4.

Si el disco está paralelo, proceda con el "ajuste del indicador de ángulos" explicado más

adelante. Si no lo está, afloje (no quite) los dos tornillos que están situados debajo del

borde posterior de la mesa de la sierra que sujetan el brazo (observe la figura 5) a la sierra. Alinee el disco como lo requiera y apriete los tornillos (23-27 ft. lbs.). (NO SOBREAPRIETE.)

2. Verifique la alineación del disco con respecto a la guía utilizando una escuadra. Si el

disco está alineado correctamente, la sierra está lista para usarse.

3. Si el disco y la guía no están a escuadra (90º), debe ajustarse la sierra.

Para lograr el ajuste a escuadra, afloje los dos tornillos de la barra del asa, que se

encuentran debajo de la sierra, al centro de la base giratoria (figura 7). NO QUITE

ESTOS TORNILLOS.

Cuando los tornillos de la barra del asa estén flojos y la base giratoria esté colocada en la

posición cero, escuadre al disco con respecto ala guía (figura 6).

Apriete los tornillos de la barra del asa (23-27 ft. lbs.) y su sierra quedará ajustada correctamente.

AJUSTE DEL INDICADOR DE ANGULOS

APAGUE LA HERRAMIENTA Y DESCONECTELA DE LA TOMA DE CORRIENTE.

1. Afloje la perilla de fijación de ángulos y oprima el seguro para mover el brazo angular a

posición cero, como se ilustra en la figura 8.

2. Con la perilla de fijación de ángulos floja, permita que el seguro de ángulo se coloque en

su posición como usted vaya girando el brazo angular hasta 0.

3. Observe el indicador y el cuadrante a través de la mirilla. Si el indicador no está exactamente en 0, córralo suavemente a izquierda o derecha utilizando un destornillador de

punta plana.

Actuación de la guarda y visibilidad

La guarda del disco de su sierra ha sido diseñada para levantarse automáticamente cuando

se baje el brazo, y cubrir el disco cuando el brazo se levante. La guarda se puede levantar con

la mano cuando instale o remueva discos, o para inspeccionar la sierra. NUNCA LEVANTE LA

GUARDA DEL DISCO CON LA MANO A MENOS QUE LA SIERRA ESTE APAGADA.

La sección frontal de la guarda está enrejillada para permitir visibilidad mientras se corta.

Aunque la rejilla reduce en gran medida la salida de astillas, son aberturas, lo que implica que

deben utilizarse anteojos de seguridad siempre que se mire a través de las hendiduras.

Interruptor

Para encender la sierra, oprima el gatillo interruptor como se ilustra en la figura 9. Suéltelo

para apagarla. Esta herramienta no cuenta con dispositivo para trabar el interruptor en la

posición de encendido, pero éste tiene un orificio para que se inserte una chaveta de seguridad

en su interior a fin de trabarlo en posición de apagado.

Cortes con su sierra

NOT A:Aunque esta sierra cortará madera y muchos materiales no ferrosos, la descripción se

limitará aquí únicamente al corte de madera. Se aplican las mismas guías de referencia a los

otros materiales. NO CORTE MA TERIALES FERROSOS (HIERRO Y ACERO) O MAMPOSTERÍA CON

EST A SIERRA. No utilice ningún disco de tipo abrasivo.

Ajuste el brazo en el ángulo deseado, y sostenga la pieza de madera firmemente contra la guía.

Accione a continuación la sierra oprimiendo el interruptor como se ilustra en la figura 9.

Cuando la sierra alcanza su máxima velocidad (en cerca de un segundo), baje el brazo con

suavidad y lentamente para hacer el corte a través de la madera. Deje que el disco llegue hasta el

tope antes de levantar el brazo.

Calidad del corte

La lisura del corte dependerá de diversas variables. Contribuirán a la calidad del mismo

aspectos como material que se está cortando, tipo de disco de sierra, filo de éste y velocidad de

corte.

Cuando se desean los cortes más lisos para molduras y otros trabajos de precisión, se obtendrán

los resultados deseados con un disco filoso (de carburo de 60 dientes) y una velocidad de corte

suave y uniforme.

Asegúrese que el material no salte cuando lo está cortando, y para esta finalidad sujételo

bien en su sitio. Permita siempre que el disco de sierra llegue al tope para levantar el brazo.

Si aún saltan fibrillas de madera por la parte de atrás del disco, adhiera una tira de cinta de

enmascarillar sobre la línea de la pieza de madera sobre la que se está haciendo el corte.

Efectúe este sobre la cinta y quítela con cuidado una vez que haya acabado de cortar.

Consulte el cuadro 2 para las diferentes aplicaciones de corte. Seleccione el disco que mejor

se ajuste a sus necesidades.

Posición de cuerpo y manos (figura 10)

La colocación adecuada de cuerpo y manos cuando se está operando esta sierra facilitará el

corte y lo volverá más preciso y seguro. Nunca ponga las manos cerca del sitio de corte. No las

acerque a menos de 15 cm del disco de sierra. Conserve la pieza de trabajo sujeta firmemente

a la base y a la guía mientras la esté cortando. Conserve las manos en la posición adecuada

hasta que haya soltado el interruptor de gatillo y el disco se detenga por completo. EFECTUE

SIEMPRE ASCENSOS Y DESCENSOS DEL BRAZO SIN CORRIENTE ANTES DE REALIZAR LOS

CORTES, CON OBJETO DE VERIFICAR LA TRAYECTORIA QUE SIGUE EL DISCO. NO CRUCE

LAS MANOS SOBRE DICHA TRAYECTORIA, COMO SE ILUSTRA EN LA FIGURA 10.

Conserve ambos pies apoyados firmemente en el suelo y mantenga el equilibrio. Al mover el

brazo de inglete a izquierda y derecha, sígalo y párese ligeramente hacia un lado del disco de

la sierra. Mire a través de la guarda cuando siga una línea trazada con lápiz..

Sujeción de la pieza de trabajo

APAGUE LA HERRAMIENTA Y DESCONECTELA DE LA TOMA DE CORRIENTE.

PARA EVITAR LA PERDIDA DE CONTROL, SIEMPRE SUJETE LA MADERA A LA SIERRA, ESTO

ES AUN MAS IMPORTANTE CUANDO SE REQUIERA ACERCAR SU MANO A MENOS DE 15

cm DEL DISCO. Puede sujetar la pieza de cualquier lado del disco. Recuerde colocar la prensa

en una parte plana y sólida de la guía.

Soporte para piezas largas

AP AGUE LA HERRAMIENTA Y DESCONECTELA DE LA TOMA DE CORRIENTE.

Ofrezca soporte a las piezas largas utilizando un medio adecuado, como un sargento o algún

otro dispositivo para evitar que los extremos de la pieza caigan al suelo.

Cortes especiales

NUNCA HAGA UN CORTE SIN SUJETAR FIRMEMENTE EL MATERIAL. SIEMPRE UTILICE EL

DISCO ADECUADO (vea la cuadro 2)

CORTE DE ALUMINIO:

Los extruídos de aluminio tales como los que se utilizan para hacer pantallas y ventanas se

pueden cortar fácilmente con su sierra. Coloque el material de manera que corte la sección más

delgada, como se ilustra en la figura 11. La figura 12 muestra la manera incorrecta de cortar estos

perfiles.

Utilice un lubricante de cera cuando corte aluminio. Aplique la barra de cera directamente al

disco de la sierra antes de cortar . Nunca aplique la cera cuando el disco esté girando.

DANGER

KEEP AWAY

FROM BLADE

GUARDE ESTAS INSTRUCCIONES PARA REFERENCIAS FUTURAS

!

WARNING:

identical replacement parts. Do not expose to

rain or use in damp locations.

AVERTISSEMENT :

s'assurer du fonctionnement sûr, lire le guide

d'utilisation. Ne pas exposer à la pluie et ne pas

utiliser dans les emplacement humidies.

Black & Decker (U.S.) Inc., Towson, MD 21286 USA Made in USA

When servicing use only

Pour

WARNING:

For safe operation read instruction manual. Always

wear eye protection. Keep hands 6'' (153mm) from

path of saw blade. Do not operate saw without guards

in place. Keep guards in working order. Do not perform

any operation freehand. Never reach in back of saw

blade. Turn off tool, keep saw head down and wait for

saw blade to stop before moving work piece or

changing settings. Unplug tool before changing blade,

moving or servicing unit. Never cross arms in front of

blade. Secure unit before using.

Cuadro 2

APLICACION

Corte fino

Molduras

Recorte, marcos

Tratada a presión

Tableros

Aluminio

DESCRIPCION

DEL DISCO

Precisión