Page 1

Part No. XXXXXXX Rev. 0 JAN 2011

If your pressure washer is not working properly or if there are parts missing or

broken, please DO NOT RETURN IT TO THE PLACE OF PURCHASE. Contact our

customer service department at www.power-washer.us or 1-800-381-0999.

Si su lavadora a presión no trabaja correctamente ó encuentra partes rotas

ófaltantes, por favor NO LA REGRECE AL LUGAR DONDE LA COMPRO.

Contáctese con nuestro Departamento de Servicio al Cliente llamando al www.

power-washer.us o 1-800-381-0999.

Save thiS manual for future reference.

VEA EL ESPAÑOL EN LA CONTRAPORTADA.

INSTRUCTIVO DE OPERACIÓN, CENTROS DE SERVICIO

Y PÓLIZA DE GARANTÍA. ADVERTENCIA: LÉASE ESTE

INSTRUCTIVO ANTES DE USAR EL PRODUCTO.

INSTRUCTION MANUAL

MANUAL DE INSTRUCCIONES

Pressure Washer • Lavadora a presión

Model • Modelo 11BDE-315

Go to www.power-washer.us to register your new product.

Vaya a www.power-washer.us para registrar su nuevo producto.

ON OFF

Page 2

EASY INSTALLATION

WARNING: CAREFULLY READ THE OPERATORS INSTRUCTIONS BEFORE USING

THE PRESSURE WASHER FOR THE FIRST TIME.

ALWAYS STORE YOUR PRESSURE WASHER IN A LOCATION WHERE THE

TEMPERATURE WILL NOT FALL BELOW 40°F (4°C) . FREEZE DAMAGE IS NOT

COVERED BY THE WARRANTY.

INSTALACIÓN FÁCIL

AVERTENCIA: LEA ATENTAMENTE EL MANUAL DE INSTRUCCIONES ANTES DE

PONER EL EQUIPO POR PRIMERA VEZ EN FUNCIONAMIENTO.

TIENE QUE PONER SIEMPRE LA MÁQUINA DE LAVAR A PRESIÓN EN UN SITIO

DONDE LA TEMPERATURA NO DIMINUE BAJO 4°C (40°F). LOS DAÑOS QUEL EL

HIELO PROVOCA NO SON REMBOLSDADO DE LA GARANTIA.

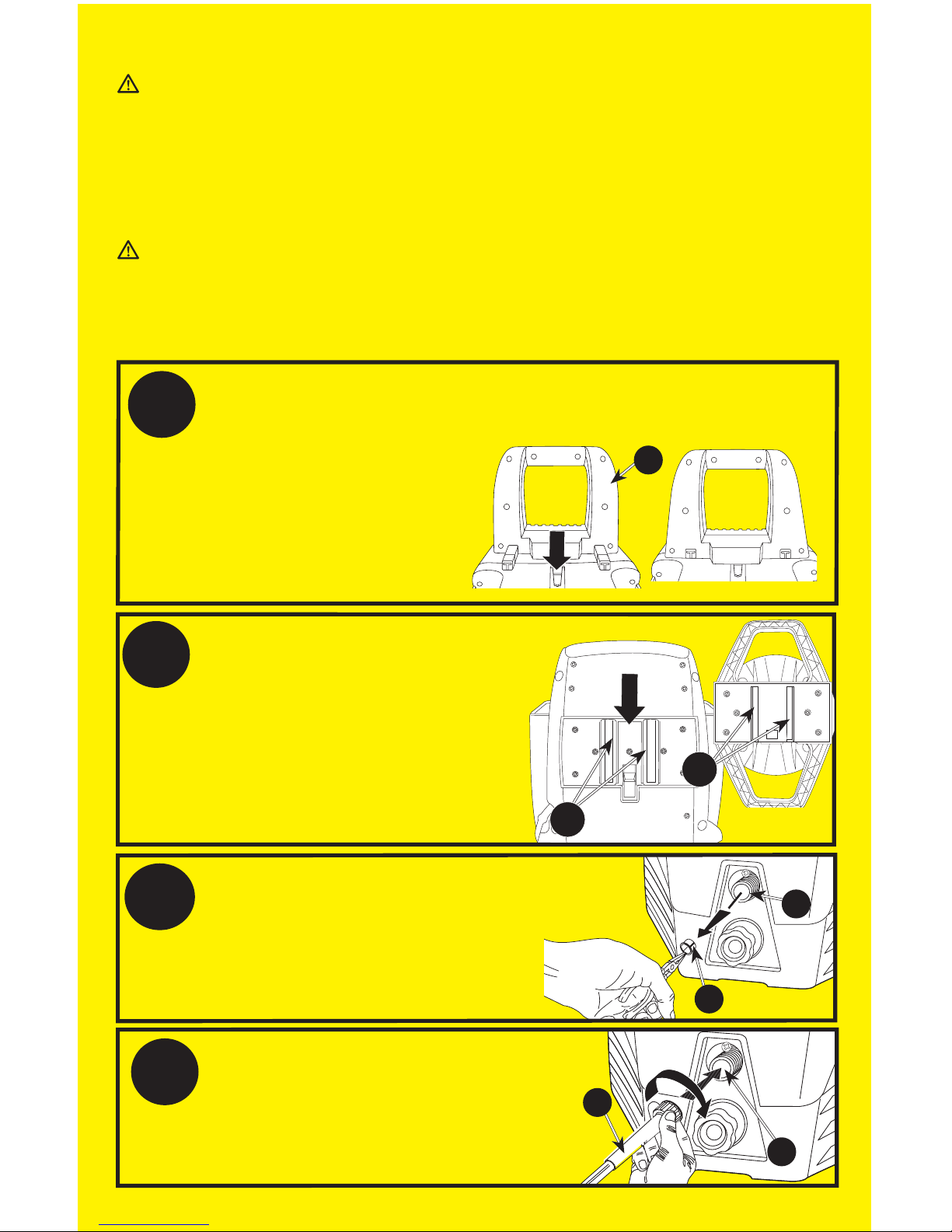

WITH HANDLE ORIENTED AS SHOWN, ALIGN GROOVES IN CARRY HANDLE (P)

WITH RAILS ON TOP OF PRESSURE WASHER AND SLIDE INTO PLACE. PUSH AS

SHOWN TO FURTHER LOCK CARRY HANDLE INTO PLACE.

CON LA MANIJA ORIENTADA

COMO SE MUESTRA, ALINEE LOS

SURCOS ADENTRO EL AGARADOR DE

LA MAQUINA (P) CON LOS CARRILES

ENCIMA DE LA MAQUINA DE PRESIÓN Y

RESBALAN DENTRO DE LUGAR. EMPUJE

COMO SE MUESTRA A CONECTAR EL

AGARADOR DE LA MAQUINA.

1

P

AA

BB

ALIGN SLOTS (BB) ON BACK OF STORAGE

RACK WITH RIBS (AA) ON BACK OF

PRESSURE WASHER. SLIDE STORAGE

RACK DOWN UNTIL IT LOCKS INTO PLACE.

2

ALINE LAS LINEAS (BB) ATRAS DEL ALMACENAMIENTO CON LAS LINEAS (AA) ATRAS

DE LA LAVADORA DESLICE EL ALMACENAMIENTO PARA ABAJO, HASTA QUE ESTE

SEGURO.

ON OFF

L

K

3

REMOVE AND DISCARD THE SHIPPING

PLUG (L) FROM THE OUTLET (K) ON

THE FRONT OF THE MACHINE.

EXTRAER EL TAPÓNES (L) DE

TRANSPORTE DEL EMPALME DE LA

MÁQUINA (K) Y ELIMINARLO.

4

ON OFF

E

K

CONNECT THE HIGH PRESSURE

HOSE (E) TO THE MACHINE

OUTLET (K).

CONNECT EL TUBO DE ALTO

PRESIÓN (E) A LA SALIDA DE LA

MÁQUINA (K).

Page 3

ON OFF

D

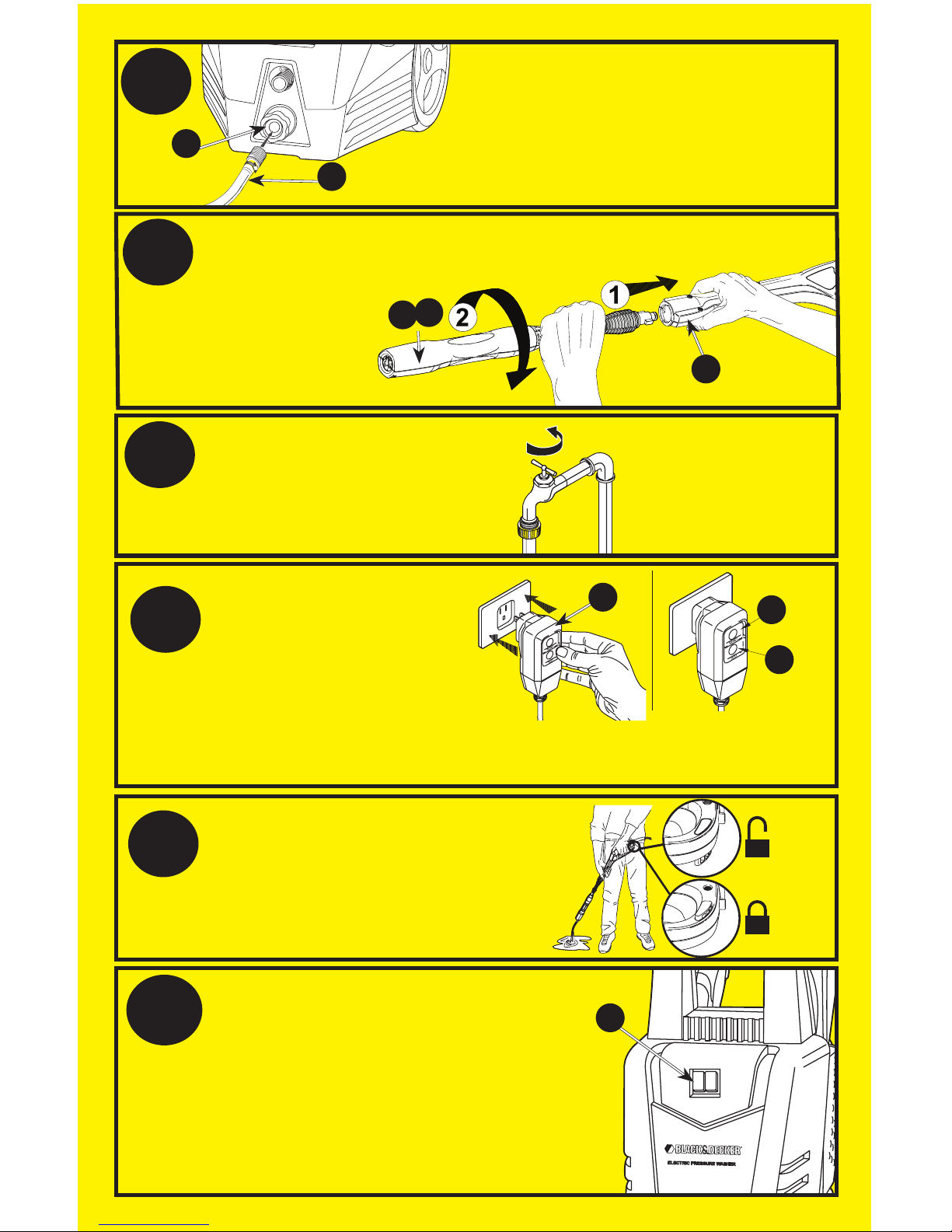

CONNECT THE GARDEN HOSE (Y) TO THE

CONNECTOR (D) ON THE FRONT OF THE

MACHINE.

CONECTE LA MANGUERA DEL JARDÍN (Y)

AL CONECTOR (D) CORRESPONDIENTE

ACOPLADO A LA ENTRADA DE LA

MÁQUINA.

5

Y

INSERT THE SPRAY LANCE (B, R) INTO THE GUN (A). TWIST SPRAY LANCE

90° COUNTERCLOCKWISE TO SECURELY LOCK IN PLACE.

A

B

6

PARA INSERTAR LA LANZA

(B, R) EN LA PISTOLA (A).

TUERZA LA LANZA 90° DEL

AEROSOL A LA IZQUIERDA

A CON SEGURIDAD SE

TRABAN EN LUGAR.

R

FULLY OPEN

ABRA COMPLETAMENTE

7

TURN INCOMING WATER ON.

NOTE: USE COLD WATER ONLY.

GIRE EL AGUA ENTRANTE.

NOTA: UTILIZAR SÓLO AGUA FRÍA

PLUG GFCI (C) INTO POWER

RECEPTACLE. FIRMLY PRESS

AND RELEASE THE TEST

BUTTON (Z), THEN PRESS AND

RELEASE THE RESET BUTTON

(X). THE LIGHT ON THE GFCI SHOULD

BE ILLUMINATED.

X

Z

C

8

ENCHUFE EL GFCI (C) A UN TOMACORRIENTE. PRESIONE CON FIRMEZA Y SUELTE

EL BOTÓN DE PRUEBA (TEST) (Z), Y LUEGO PRESIONE Y SUELTE EL BOTÓN DE

REINICIO (RESET) (X). SE DEBE ENCENDER LA LUZ DEL GFCI.

SQUEEZE AND HOLD TRIGGER

UNTIL WATER FLOW IS STEADY.

RELEASE THE TRIGGER.

MANTENGA PULSADO EL

ACCIONADOR HASTA QUE EL CAUDAL DE

AGUA SE VUELVA CONSTANTE. SUELTE EL

ACCIONADOR.

9

ON OFF

TURN SWITCH TO ON POSITION (I) AND

SQUEEZE TRIGGER TO START MOTOR AND

WATER FLOW. NOTE: motor only runs when

trigger is depressed and water is spraying.

SITUAR EL INTERRUPTOR EN LA POSICIÓN DE ON (I)

Y APRETAR EL GATILLO PARA PONER EN MARCHA EL

MOTOR Y EL FLUJO DE AGUA. NOTA: el motor funciona

solamente cuando se presiona el disparador y el agua está

rociando.

I

10

Page 4

4- ENG

SAFETY GUIDELINES - DEFINITIONS

This manual contains information that is important for you to know and understand.

This information relates to protecting YOUR SAFETY and PREVENTING EQUIPMENT

PROBLEMS. To help you recognize this information, we use the symbols below.

Please read the manual and pay attention to these symbols.

DANGER: Indicates an imminently hazardous situation which, if not avoided,

will result in death or serious injury.

WARNING: Indicates a potentially hazardous situation which, if not avoided,

could result in death or serious injury.

CAUTION: Indicates a potentially hazardous situation which, if not avoided, may

result in minor or moderate injury.

NOTICE: Indicates a practice not related to personal injury which, if not avoided,

may result in property damage.

CONSUMER SAFETY INFORMATION

WARNING: This product contains chemicals known to the State of California

to cause cancer, and birth defects or other reproductive harm. In addition, some

cleaning products and dust contain chemicals know to the State of California to

cause cancer, and birth defects or other reproductive harm. Wash hands after

handling.

IMPORTANT SAFETY INSTRUCTIONS

WARNING: Please read this

entire manual before attempting

to assemble, operate or install the

product. If you have any questions

regarding the product, please contact

our customer service department

at www.power-washer.us or

1-800-381-0999.

WARNING: This unit was designed

for specific applications. It should

not be modified and/or used for any

application other than that which it was

designed.

NOTICE: Always store your pressure

washer in a location where the

temperature will not fall below 40° F

(4°C). freeze damage is not covered by

the warranty.

read and Save theSe

inStructionS

WARNING: When using this product

basic precautions should always be

followed, including the following:

1. Read all the instructions before

using the product.

2. To reduce the risk of injury, do not

operate near children or animals.

3. Know how to stop the product

and bleed pressures quickly.

Be thoroughly familiar with the

controls.

4. Stay alert - watch what you are

doing.

5. Do not operate the product when

fatigued or under the influence of

alcohol or drugs.

6. Keep operating area clear of all

persons.

7. Do not overreach or stand on

unstable support. Keep good

footing and balance at all times.

8. Follow the maintenance instructions

specified in the manual.

Page 5

5 - ENG

9. This product is provided with a

Ground Fault Circuit Interrupter

built into the power cord plug. If

replacement of the plug or cord

is needed, use only identical

replacement parts.

10. Do not touch plug or outlet with

wet hands.

11. Avoid accidental starts. Move

switch on unit to OFF position

before connecting or disconnecting

cord to electrical outlets.

12. Water spray must never be

directed towards any electric

wiring or directly towards the

pressure washer machine itself or

fatal electric shock may occur.

13. Never carry your pressure washer

by the cord. Do not pull on the cord

to disconnect from the outlet.

14. To prevent damage, the cord

should not be crushed, placed next

to sharp objects or near a heat

source.

15. Check power cords before using.

Damaged cords can reduce

performance of pressure washer or

cause a fatal electrical shock.

16. The narrow pin point stream is very

powerful. It is not recommended

for use on painted surfaces, wood

surfaces or items attached with an

adhesive backing.

17. Keep operating area clear of all

persons and ani mals.

18. Always use both hands when

operating pressure washer to

maintain complete control of the

wand.

19. Do not touch nozzle or water spray

while operating. Never place hands

in front of nozzle.

20. Wear safety goggles while

operating. Wear protective clothing

and footwear to protect against

accidental spraying.

21. Disconnect power plug from the

outlet when not in use and prior to

the detaching of the high pressure

hose.

22. Never tie knots or kink the high

pressure hose as da mage could

result. Inspect the high-pressure

hose regularly. Replace the hose

immediately if it is damaged, worn

or shows any signs of cracks,

bubbles, pinholes, or other leakage.

Never grasp a high-pressure hose

that is leaking or damaged.

23. Do not operate or store this product

in temperatures below 40°F (4°C).

Freeze damage is not covered by

the warranty.

24. Carefully observe all chemical

instructions and warnings

before using. Use only approved

pressure washer cleaners. Do

not use bleach, chlorine, or any

cleaners containing acids. Always

follow manufacturer’s label

recommendations for proper use

of cleaners. Always protect eyes,

skin and respiratory system from

cleaners.

25. The pressure washer should not

be used in areas where gas vapors

may be present. An electric spark

could cause an explosion or fire.

26. To minimize the amount of water

getting into the pressure washer,

the unit should be placed as far

as possible from the cleaning site

during operation.

27. To prevent accidental discharge,

the spray gun should be secured

by locking the trigger when not in

use.

28. To allow free air circulation, the

pressure washer should NOT be

covered during operation.

29. Never touch, grasp or attempt to

cover a pinhole or similar water

leak on the high-pressure hose.

The stream of water IS under high

pressure and WILL penetrate skin.

30. Use only hoses and accessories

rated for pressure higher than

your pressure washer's psi. Never

use with any other manufacturer’s

accessories or components.

Page 6

6- ENG

31. Never defeat the safety fea tures of

this product.

32. Do not op er ate machine with

missing, broken or un au tho rized

parts.

33. Never spray flammable liquids

or use pressure washer in areas

containing combustible dust,

liquid, or vapors.

WARNING: Risk of injection or

injury. Do not direct discharge stream

at persons.

Save theSe

inStructionS

SAFETY FEATURES

AUTOMATIC TOTAL STOP

®

The pressure washer is equipped with

a stop device which will sense when

the trigger on the gun is released. It will

open the power circuit to the motor and

cause the pressure washer to stop.

WARNING: If Automatic Total Stop

fails to operate, DO NOT USE THE

MACHINE. Contact our customer

service department. Further use will

damage the machine and/or cause

personal injury.

WARNING: The pressure washer

is also equipped with a main power

ON/OFF switch located on the unit. It

should always be moved to the OFF

position when the pressure washer is

not being used to prevent possible

injury or damage.

MOTOR OVERLOAD

The electric motor in this pressure washer

is equipped with an overload protection

device which will automatically shut off

the motor in the event the motor draws

excessive current or overheats. The

device will automatically reset itself and

resume normal operation after a short

period of time.

GROUND-FAULT CIRCUIT

INTERRUPTER PROTECTION

This pressure washer is provided with a

Ground-Fault Circuit-Interrupter (GFCI)

built into the plug of the power supply

cord. This device provides additional

protection from the risk of electric

shock. Should replacement of the plug

or cord become necessary, use only

identical replacement parts that include

GFCI protection.

SERVICING A DOUBLE INSULATED

APPLIANCE

In a double-insulated product,

two systems of insulation are

provided instead of grounding.

No grounding means is

provided on a double-insulated product,

nor should a means for grounding be

added to the pressure washer.

Servicing a double-insulated product

requires extreme care and knowledge

of the system, and should be done only

by qualified service personnel.

Replacement parts for a doubleinsulated product must be identical to

the parts they replace.

A double-insulated product is marked

with the words “DOUBLE-INSULATION”

or “DOUBLE-INSULATED”. The symbol

above may also be marked on the

product.

POWER SUPPLY AND

ELECTRICAL INFO

GROUND-FAULT CIRCUIT

INTERRUPTER PROTECTION

The pressure washer is factoryequipped with an electrical cord and a

Ground Fault Circuit Interrupter (GFCI)

power plug. This cord should only

be connected to an electrical outlet

installed in accordance with local safety

regulations.

NOTE: The power supply must be

120V, 60 Hz and a minimum 15 amp

dedicated circuit.

Page 7

7 - ENG

A. Inspect cord before using. Do not

use if cord is damaged.

B. Keep all connections dry and off

the ground.

C. Do not touch plug with wet hands.

D. The pressure washer is provided

with a ground fault circuit interrupter

built into the power plug.

If replacement of the plug or cord is

needed, use only identical replacement

parts. Contact customer service for

proper replacement parts.

WARNING: Test GFCI before each

use. DO NOT use pressure washer if

test below fails.

GFCI Test Procedures:

1. Plug GFCI into power receptacle.

Indicator light should illuminate.

2. Press test button (Z). Light should

turn off.

3. Press reset button (X) for use.

Indicator light should illuminate.

X

Z

1

Do not use if above test fails.

NOTE: The GFCI must be reset each

time the pressure washer is connected

to an electrical outlet. Reset by simply

pushing the reset button on the GFCI

power plug.

EXTENSION CORDS

Use only extension cords that are

intended for outdoor use. These

extension cords are identified by a

marking “Acceptable for use with

outdoor appliances: store indoors

while not in use”. Use only extension

cords having an electrical rating not

less than the rating of the product.

Do not use damaged extension cords.

Examine extension cord before using

and replace if damaged. Do not abuse

extension cord and do not yank on any

cord to disconnect.

Keep cord away from heat and

sharp edges. Always disconnect the

extension cord from the receptacle

before disconnecting the product from

the extension cord.

When using an extension cord, observe

the specification below:

Cable Length Wire Gauge

Up to 25 ft.

(7.5 m)

12 AWG Outdoor

WARNING: To reduce the risk of

electrocution, keep all connections dry

and off the ground. Do not touch plug

with wet hands.

Save theSe

inStructionS

Page 8

8- ENG

GET TO KNOW THE PRESSURE WASHER

NOTE: Photographs and line drawings

used in this manual are for reference

only and do not represent a specific

model.

Compare the illustrations with your unit

to familiarize yourself with the location

of various controls and adjustments.

Save this manual for future reference.

A. Spray Gun

B. Click-N-Clean

®

Spray Lance

C. GFCI

D. Garden Hose Connector (factory

installed)

E. High-Pressure Hose

F. Safety Lock

G. Motor and Pump in Case

H. Power Supply Cord with GFCI

I. ON/OFF Switch

J. On-board Detergent Tank

K. High Pressure Outlet (metal)

L. Shipping Plug

M. Water Inlet (plastic)

N. On-Board Accessory Storage

Holsters

O. Water Inlet Filter Screen [factory

installed inside water inlet (M)]

P. Carry Handle

Q. Hose/Cord Storage Location

R. Powerswivel

®

Fan Spray Wand

ON OFF

P

H

K

L

J

C

O

E

F

A

B

G

2

M

Q

I

N

R

D

Page 9

9 - ENG

ASSEMBLY

INSTRUCTIONS (FIG. 3)

1. Locate and remove all loose parts

from the carton.

2. With handle oriented as shown,

align grooves in carry handle (P)

with rails on top of pressure washer

and slide into place.

3A

P

3. Push as shown to further lock carry

handle into place.

3B

4. Align slots (BB) on back of storage

rack with ribs (AA) on back of

pressure washer.

5. Slide storage rack down until it

locks into place.

3C

AA

BB

6. Remove and discard the shipping

plug (L) from the outlet (K) on the

front of the machine.

ON OFF

L

K

3D

OPERATING INSTRUCTIONS

PRESSURE WASHER

TERMINOLOGY

PSI: Pounds per Square Inch. The

unit of measure for water pressure.

Also used for air pressure, hydraulic

pressure, etc.

GPM: Gallons Per Minute. The unit of

measure for the flow rate of water.

CU: Cleaning Units. GPM multiplied by

PSI. GPM x PSI = CU

Detergent Injection System: Mixes

cleaners or cleaning solvents with the

water to improve cleaning effectiveness.

Water Supply: All pressure washers

must have a source of water. The

minimum requirements for a water

supply are 20 psi and 5 gallons per

minute. If your water source is a well,

the garden hose length can only be 30

ft. (9 m) max.

WARNING: To reduce the

possibility of contamination always

protect against backflow when

connected to a potable water system.

DANGER: Risk of fluid injection

and laceration. When using the highpressure setting, DO NOT allow

the high-pressure spray to come in

contact with unprotected skin, eyes,

or with any pets or animals. Serious

injury will occur.

• Your washer operates at fluid

pressures and velocities high

enough to penetrate human and

animal flesh, which could result in

amputation or other serious injury.

Page 10

10- ENG

Leaks caused by loose fittings or

worn or damaged hoses can result

in injection injuries. DO NOT TREAT

FLUID INJECTION AS A SIMPLE

CUT! See a physician immediately!

PRESSURE WASHER

OPERATING FEATURES

CLICK-N-CLEAN® SPRAY LANCE

(Fig. 4)

WARNING: Do not move the nozzle

to adjust spray while the trigger is

squeezed.

The Click-N-Clean

®

4 n 1 nozzle has

four spray settings. Turn the collar 90°

to the desired position.

S.

The Low Pressure

Soap position is

intended for dispensing detergent.

T.

The High Pressure Jet

Stream position is

intended for cleaning

with high pressure.

U.

The High Pressure

Wide Fan Spray

position is intended for

clea ning with high

pressure.

V.

The High Pressure

Turbo Spray position

is intended for optimal

cleaning.

NOTE: The pressure of the spray on

the surface you are cleaning increases

as you move the wand closer to the

surface.

S

U

V

T

4

NOTE: The pressure of the spray on

the surface you are cleaning increases

as you move the wand closer to the

surface.

CAUTION: The High Pressure

Jet Stream spray position is very

aggressive. We recommend that for

most cleaning applications a fan spray

pattern (U or V) be used to avoid

damage to the surface being sprayed.

POWERSWIVEL

®

FAN SPRAY WAND

(FIG. 5)

CAUTION: The red nozzle portion of

the lance pivots 360°. This adjustment

can only be made when the gun trigger

is completely released. Do not attempt

to adjust the nozzle when the machine

is in operation. Failure to follow this

instruction could result in personal

injury.

The nozzle pivots 360° and delivers a

high pressure fan spray pattern to clean

hard to reach areas.

R

5

USING DETERGENT (FIG. 6–7)

NOTICE: Use only approved pressure

washer cleaners. Do not use bleach,

chlorine, or any cleaners containing

acids.

NOTICE : Fill and flush the detergent

tank with clear water after use.

1. Insert the spray lance (B) into the

gun (A) by pushing firmly and

simultaneously twisting a 1/4 of a

turn counterclockwise until locked

into place.

Page 11

11 - ENG

6

A

B

2. Remove the tank cap (W) present

on the back of the machine.

3. Fill the tank (J) with suitable

cleaning solution.

7

W

J

4. Place the Click-N-Clean® spray

lance into the Low Pressure Soap

position (S, fig. 4).

5. Squeeze the trigger and the

detergent will automatically

be mixed with the water and

dispensed from the nozzle.

NOTE: When the Click-N-Clean

®

nozzle is moved to the High Pressure

Jet Stream, High Pressure Wide Fan

Spray or High Pressure Turbo Spray

position (T, U or V), detergent will not

be dispensed.

6. When you have completed the

use of detergent, Fill and flush the

detergent tank with clear water

after use. See Storage for correct

procedure.

7. See Storage section in this manual

for proper shutdown and storage

procedures

Cleaning techniques

When cleaning with the pressure washer,

some cleaning tasks can be solved with

water alone, but for most tasks it is

advantageous to use a detergent. A

detergent ensures a quick soaking of

the dirt allowing the high pressure water

to penetrate and remove the dirt more

effectively.

Application of detergent

CAUTION: Avoid working on hot

surfaces or in direct sunlight to minimize the chance of the soap damaging

painted surfaces.

CAUTION: Damage may occur to

painted surface if soap is allowed to dry

on the surface. Wash and rinse a small

section at a time.

1. Apply the solution to a DRY work

surface.

NOTE: WETTING THE SURFACE

FIRST IS NOT RECOMMENDED,

AS IT DILUTES THE DETERGENT

AND REDUCES ITS CLEANING

ABILITY.

On a vertical surface, apply soap

horizontally from side to side

starting from the bottom to avoid

streaking.

2. Allow detergent to remain on the

surface for a short time before

rinsing.

3. Rinse with clean water under high

pressure. On a vertical surface,

first rinse from the bottom up, then

rinse from the top down. Hold

nozzle 6–8 in. (15–20 cm) from the

work surface at a 45° angle using

the flat spray as a peeling tool

rather than a scrub brush.

NOTE: Ensure that the detergent

injection system is completely clean

prior to switching from one detergent

to another.

Page 12

12- ENG

STARTING (FIG. 8–14)

DANGER: Risk of injury from spray.

Always engage the trigger lock when

gun is not in use. Failure to do so could

cause accidental spraying.

WARNING: Risk of Injury. Do not

direct discharge stream at self or others.

WARNING: Risk of unsafe operation.

Stand on a stable surface and grip gun/

spray wand firmly with both hands.

1. Connect the high pressure hose (E)

to the machine outlet (K). Ensure

the threads are aligned properly

and the connection is secure.

ON OFF

8

E

K

2. Connect the garden hose (Y) to the

connector (D) on the front of the

machine. Before connecting, run

water through the garden hose (not

supplied) to flush out any foreign

matter.

NOTE: If your water source is a

well, the garden hose length can

only be 30 ft. maximum.

ON OFF

9

D

Y

3. Insert the spray lance (B, R) into

the gun (A) by pushing firmly and

simultaneously twisting a 1/4 of a

turn counterclockwise until locked

into place.

10

A

B

R

WARNING: If the lance is not

securely locked into place, it could

be ejected under high pressure during

operation, possibly causing injury or

damage.

4. Turn incoming water on and fully

open valve to insure maximum

water flow to machine.

11

5. Plug GFCI (C) into power receptacle.

Firmly press and release the TEST

button (Z), then press and release

the RESET button (X). The light on

the GFCI should be illuminated.

NOTE: The power supply must be

120 V, 60 Hz and a minimum 15

amp dedicated circuit.

X

Z

C

12

6. Ensure the gun safety is unlocked

and squeeze the trigger until the air

has escaped and a steady flow of

low pressure water is coming from

the nozzle.

Page 13

13 - ENG

13

7. Turn switch to ON position(I). Note

that the motor will momentarily

start then stop.

ON OFF

14

I

8. Squeeze the trigger to start motor

and begin pressure washing.

NOTE: The motor only runs when

the gun trigger is depressed and

water is spraying.

SHUTTING DOWN

See Storage section in this manual

for proper shutdown and storage

procedures.

MAINTENANCE

WARNING: Risk of burn hazard.

When performing maintenance, you

may be exposed to hot surfaces,

water pressure or moving parts that

can cause serious injury or death.

To ensure efficient operation and longer

life of your pressure washer, a routine

maintenance schedule should be

prepared and followed. If the pressure

washer is used in unusual conditions,

such as high-temperatures or dusty

conditions, more fre quent maintenance

checks will be required.

CONNECTIONS

Connections on pressure washer hoses,

gun and spray wand should be cleaned

regularly and lubricated with light oil or

lithium grease to prevent leakage and

damage to the o-rings.

NOZZLE

The nozzles should be cleaned regularly.

Clogging of the nozzle causes

diminished performance and the pump

pressure to be too high and cleaning is

immediately required.

1. Remove the wand from the gun.

2. Clear the nozzle by forcing a stiff

wire or straightened out paper clip

(small size) through the center hole

of each nozzle.

3. Backflush the nozzle with water

from both ends.

4. Reconnect the wand to the gun.

Restart the pressure washer and

depress the trigger on the spray gun.

LUBRICATION

The pressure washer is designed

with a permanent lubrication system.

Conventional oil checks and changes

are not necessary.

NOTE: In case of oil leakage, contact

our customer service department at

www.power-washer.us or 1-800-381-

0999. A SMALL AMOUNT OF OIL

LEAKAGE IS NORMAL.

WATER SCREEN FILTER

The pressure washer is equipped with

a water inlet screen filter to protect

the pump. Never operate the pressure

washer without the screen filter in place.

CAUTION: If the screen filter is

not kept clean, the flow of water to the

pressure washer will be restricted and

the pump may be damaged.

• To clean the inlet water screen filter,

remove garden hose connector (D)

and remove the screen filter from

the inlet.

• Flush screen filter with warm water

to clean.

Page 14

14- ENG

• Replace screen filter, and garden

hose connector immediately to

prevent any foreign matter from

entering the pump.

CAUTION: Do not damage the

screen filter, while removing or cleaning.

Any foreign particles entering the pump

may damage the pump.

COOLING SYSTEM

The air vents, located in and around the

pressure washer, must be kept clean

and free of any obstructions to ensure

proper air cooling of the motor during

operation.

WARNING: Prevent water from

penetrating the vents of the pressure

washer to minimize the risk of damage

to the machine and to reduce the risk of

shock to the operator.

STORAGE

CAUTION: Prior to moving the unit,

always disconnect the garden hose via

the garden hose connector.

CAUTION: Always store your

pressure washer in a location where

the temperature will not fall below 40°F

(4° C). The pump in this machine is

susceptible to permanent damage if

frozen. FREEZE DAMAGE IS NOT

COVERED BY THE WARRANTY.

END OF USE AND WINTER

STORAGE INSTRUCTIONS

1. When finished using the pressure

washer, you must first drain and

rinse the detergent tank.

2. Run the pressure washer in low

pressure until all of the soap is

drained from the detergent tank.

3. Pour clear water into the tank and

run it through on low pressure as

though it were detergent.

NOTICE: Failure to clean properly will

cause bottle or suction tube to become

clogged and inoperable.

4. Turn the machine OFF and squeeze

the trigger to re lease the trapped

pressure inside of the machine.

5. Remove both the garden hose and

high pressure hose from the unit.

6. Disconnect the lance from the gun.

7. Turn ON the machine and allow it

to run for 5 seconds. (This will clear

out most of the water trapped in

the pump).

8. Unplug machine .

9. Wrap high pressure hose and

power supply cord onto storage

rack and snap power supply cord

into place as shown.

15

10. Store the machine and accessories

in a dry, climate controlled

environment. Do not store the

machine or accessories in a place

where the temperature could drop

below 40°F (4°C).

ACCESSORIES

DANGER: Risk of fluid injection.

When using replacement lances or

guns with this pressure washer, DO

NOT use a lance and/or lance/gun

combination that is shorter in length

than what was provided with this

pressure washer as measured from

the nozzle end of the lance to the

gun trigger.

NOTICE: The use of any other

accessory not recommended for use

with this tool could be hazardous.

Use only accessories rated equal

to or greater than the rating of the

pressure washer.

Page 15

15 - ENG

SPECIFICATIONS

Model 11BDE-315

PSI Max* 1900 psi

GPM Max* 1.5 gpm

Electrical Requirements 120V,

15 A, 60 Hz

Electrical Cord 35 ft. (10.6m)

High Pressure Hose 25 ft. (7.6 m)

Minimum Amp Source 15 A

Presure of Inlet Water 20–100 psi

Inlet Water cold tap

Soap Consumption Rate 10% max

* Water flow and maximum pressure

ratings determined in accordance

with PWMA standard PW101.

SERVICE INFORMATION

Do not return this product to your

retailer. Please contact our customer

service department at www.powerwasher.us or 1-800-381-0999.

LIMITED WARRANTY

Limited Warranty

This product is warranted against

defects in material and workmanship for

a period of one year on all components

excluding the spray gun, high pressure

hose, lances, nozzles, and ground fault

circuit interrupter (GFCI) which are only

covered for 90 days; effective from

the date of retail purchase and is not

transferable.

This warranty excludes incidental/

consequential damages and failures

due to misuse, abuse or normal wear

and tear. This warranty applies only

to products used in consumer (home)

applications.

This warranty does not apply to

commercial or rental applications.

This warranty gives you specific rights,

and you may also have other rights,

which vary from state to state.

Please complete and return the

enclosed Customer Information Card.

Return of this card is not required to

validate this warranty. A store issued

receipt or credit card statement showing

the purchase date is an acceptable

warranty validation. Please retain one of

these documents in your records.

If you have any questions, please

contact our customer service

department at www.power-washer.us

or 1-800-381-0999.

What is covered: Replacement parts

and labor. Please note that we reserve

the right to repair or replace the product

as we deem appropriate.

What is not covered: This warranty

does not include such parts as

nozzles which must be replaced as

part of normal maintenance of the

equipment, rather than as the result

of a defect. Transportation charges to

warranty center for defective products.

Transportation charges to consumer for

repaired products. Damages caused

by abuse, accident, improper repair, or

failure to perform normal maintenance.

Use of improper chemicals or

noncompliance with the operator

manual's instructions. Sales outside

of the United States or Canada. Any

other expense including consequential

damages, incidental damages, or

incidental expenses, including damage

to property. Some states do not allow

the exclusion or limitation of incidental

or consequential damages, so the

above limitation or exclusion may not

apply to you. This warranty does not

cover damage resulting from failure to

observe any of the following conditions:

1) The inlet water pressure must be

between 20 and 100 p.s.i.

2) The inlet water temperature must

not exceed 90°F (32°C).

3) The unit should not be stored in

areas where temperatures may

drop below 40°F (4°C).

Page 16

16- ENG

Implied Warranties

Any implied warranties, including the

implied warranties of merchantability

and fitness for a particular purpose, are

limited in duration to one year on all

components excluding the spray gun,

high pressure hose, lance, and ground

fault circuit interrupter (GFCI) which are

only covered for 90 days; effective from

the date of retail purchase and is not

transferable. This warranty excludes

incidental/consequential damages and

failures due to misuse, abuse or normal

wear and tear. This warranty applies

only to products used in consumer

(home) applications. This warranty

does not apply to commercial or rental

applications. This warranty gives you

specific rights, and you may also have

other rights, which vary from state to

state.

Page 17

17 - ENG

TROUBLE SHOOTING GUIDE

OPERATIONAL

ISSUE

POSSIBLE

CAUSE

SOLUTION

Detergent is

not dispensing

Detergent is not

pressure washer

approved

Use only detergents, degreasers, waxes and

other cleaning solutions, that are designed

specifically for pressure washers. Cleaners

in this category will clearly state on the

label that they are meant for use in pressure

washers. Do NOT use any other type of

cleaning solution in your pressure washer.

Never use bleach, ammonia, any type of

acid, or hot water in your machine!

The suction

tube has

become

disconnected,

clogged or

kinked

Ensure the clear suction tube is not damaged

and is properly connected to the detergent

nozzle. Reconnect, clean or replace the tube

as needed.

Detergent nozzle

is clogged

with debris

Clean the nozzle according to the instructions

provided in the Nozzle paragraph under the

Maintenance section of this manual.

The ClickN-Clean (B)

spray lance

is not in the

Low Pressure

Soap position.

Follow the instructions provided in the Using

Detergent paragraph under the Operation

Instructions section of this manual.

Detergent to

Water ratio

The pressure washer draws detergent at

a maximum 10:1 water to detergent ratio.

Most pressure washer detergents are

concentrated within this range. If you feel you

are using more detergent than is required for

the application, you can dilute the detergent

with regular tap water.

Circuit breaker

trips or fuse

blown in

fuse box

Circuit overload Verify that the circuit is rated at 15 amps or

greater. Ensure no other appliance is drawing

power from the same circuit (dedicated

circuit).

Extension cord

too long or wire

gauge too small

We do not recommend the use of extension

cords with your pressure washer. If you

must use an extension cord, verify that it

meets the minimum requirements listed in the

Extension Cord paragraph under the Power

Supply & Electrical Info in this manual.

Nozzle partially

blocked

Clean the nozzle according to the instructions

provided in the Nozzle paragraph under the

Maintenance section of this manual.

Page 18

18- ENG

OPERATIONAL

ISSUE

POSSIBLE

CAUSE

SOLUTION

GFCI Plug

Malfunction

For GFCI reset procedure see Ground-fault

Circuit Interrupter Protection paragraph

under Power Supply & Electrical Info in

this manual. To order a replacement GFCI

or for GFCI installation instructions, please

contact our customer service department at

www.power-washer.us or by calling

1-800-381-0999.

Spray gun,

lance or high

pressure hose

leaking water

Improperly

connected

accessory

Verify all components (gun, lance, high

pressure hose) are properly connected

according to instructions provided in this

manual.

Leaking oil/

water from

pump

NOTE: A small amount of leakage is normal.

If oil/ water leakage from pump is excessive,

please locate the specific source of the leak

and contact our customer service department.

Contact our customer service department at

www.power-washer.us or 1-800-381-0999.

NOTE: Have the pressure washer present

when calling with this issue.

Low / surging

pressure or

motor does

not stop when

spray gun trigger

is released

NOTE: The

Pressure washer

is NOT receiving

a full volume of

incoming water

The machine

requires a

pressurized

water source

capable of

sustaining a

minimum of

20psi at 5 gpm.

Faucet is not

fully open

Verify incoming water supply faucet is open

at the maximum setting.

Garden hose

is too long or

it is kinked /

restricted

Use a maximum garden hose length of

50 ft.(15.2 m) (city water) or 25 ft. (7.5 m)

(well water). Ensure the garden hose is laid

out flat and does not have any kinks or

leaks. Unwrap garden hose from reel or

hook (if applicable). Replace garden hose if

necessary.

Water inlet

filter screen

is clogged

Remove the filter screen (O) from the water

inlet (M) and clean it thoroughly. Replace the

filter screen.

Extension cord

is too long or

wire gauge

is too small

We do not recommend the use of extension

cords with your pressure washer. If you

must use an extension cord, verify that it

meets the minimum requirements listed in the

Extension Cord paragraph under the Power

Supply & Electrical Info in this manual.

Page 19

19 - ENG

OPERATIONAL

ISSUE

POSSIBLE

CAUSE

SOLUTION

No water

coming out

of nozzle

Nozzle is

clogged

Clean the nozzle according to the instructions

provided in the Nozzle paragraph under

Maintenance section of this manual.

Water inlet

filter screen

is clogged

Remove the filter screen (O) from the water

inlet (M) and clean it thoroughly. Replace the

filter screen.

Kink in the

garden hose

or hose is

wrapped on a

storage wheel

Use a maximum garden hose length of

50 ft.(15.2 m) (city water) or 25 ft. (7.5 m)

(well water). Ensure the garden hose is laid

out flat and does not have any kinks or

leaks. Unwrap garden hose from reel or

hook (if applicable). Replace garden hose if

necessary.

Spray Gun

Trigger will

NOT Move

Gun safety lock

is engaged

Release safety lock according to instructions

provided in the Starting paragraph under

Operation in this manual.

Unit will

NOT start

NOTE: Unit will

only start and

run when trigger

is depressed

and water is

spraying!

Unit is not

turned ON

Verify that the On/Off Switch (I) is fully

engaged in the ON position.

GFCI Plug is

not reset

Confirm the GFCI plug is reset and functioning

according to instructions provided in Ground-

Fault Circuit Interrupter Protection

paragraph under Power Supply & Electrical

info in this manual.

Motor stops

working during

normal operation

NOTE: Motor’s

thermal overload

switch is

tripping because

the motor is

overheated

Allow the motor

to cool for 20

minutes before

troubleshooting

and the switch

will automatically

reset.

Extension cord

is too long or

wire gauge

is too small

We do not recommend the use of extension

cords with your pressure washer. If you

must use an extension cord, verify that it

meets the minimum requirements listed in the

Extension Cord paragraph under the Power

Supply & Electrical Info in this manual.

Nozzle is

clogged

Clean the nozzle according to the instructions

provided in the Nozzle paragraph under

Maintenance section of this manual.

Defective

Spray Gun

Turn unit OFF, disconnect incoming water

from unit, and remove the gun and hose

assembly. Aim pressure washer away from

the electrical outlet, reconnect incoming

water, and switch the unit into the ON

position. If the motor starts and water flows

steadily out of the front (and you have

verified that the nozzle is not clogged), the

spray gun may be malfunctioning and need

to be replaced. Please contact our customer

service department at www.power-washer.

us or by calling 1-800-381-0999.

Page 20

20- ENG

OPERATIONAL

ISSUE

POSSIBLE

CAUSE

SOLUTION

Connecting and

Disconnecting

the Spray Lance

NOTE: Due

to the high

pressures

produced by

your pressure

washer, the

lance must

seal tightly to

the gun. As

the result of

normal operation

the lance can

become difficult

to attach or

remove and

this process

may require

considerable

force.

To attach the Lance – apply steady downward

pressure on the lance (In the direction of the

trigger) while simultaneously twisting the

lance 90° counterclockwise. It may help if

you set the gun vertically on a flat surface

with the lance pointing upwards. The two

tabs on the end of the lance must be fully

inserted in the gun before the lance will twist

and lock. If this does not work then remove

the bayonet o-ring from the end of the lance

and attach the lance to the gun without the

o-ring in place. If the lance attaches to the

gun without the o-ring in place you will need

to replace the o-ring. Please contact our

customer service department at www.power-

washer.us or by calling 1-800-381-0999.

To remove the Lance – release any trapped

pressure in the gun / hose by turning the unit

OFF and squeezing the gun trigger. Apply

steady downward pressure on the lance (In the

direction of the trigger) while simultaneously

twisting the lance 90° clockwise. It may help

if you set the gun vertically on a flat surface

with the lance pointing upwards.

Loading...

Loading...