Page 1

NOVEMBER 2000

TS655A

RX2

TX1

ON/OFF

F1

F2

Escape

SETUP

Power Meter

SOURCE

Enter

Shift

AUTOTEST

SET REFERENCE

PAGE UP

PAGE DOWN

CertiFiber

CertiFiber

CertiFiber™

CUSTOMER SUPPORT INFORMATION

Order toll-free in the U.S.: Call 877-877-BBOX (outside U.S. call 724-746-5500)

FREE technical support 24 hours a day, 7 days a week: Call 724-746-5500 or

fax 724-746-0746

Mailing address: Black Box Corporation, 1000 Park Drive, Lawrence, PA 15055-1018

Web site: www.blackbox.com • E-mail: info@blackbox.com

Page 2

NORMAS OFICIALES MEXICANAS (NOM)

ELECTRICAL SAFETY STATEMENT

INSTRUCCIONES DE SEGURIDAD

1. Todas las instrucciones de seguridad y operación deberán ser

leídas antes de que el aparato eléctrico sea operado.

2. Las instrucciones de seguridad y operación deberán ser

guardadas para referencia futura.

3. Todas las advertencias en el aparato eléctrico y en sus

instrucciones de operación deben ser respetadas.

4. Todas las instrucciones de operación y uso deben ser

seguidas.

5. El aparato eléctrico no deberá ser usado cerca del agua—por

ejemplo, cerca de la tina de baño, lavabo, sótano mojado o

cerca de una alberca, etc..

6. El aparato eléctrico debe ser usado únicamente con carritos o

pedestales que sean recomendados por el fabricante.

7. El aparato eléctrico debe ser montado a la pared o al techo

sólo como sea recomendado por el fabricante.

8. Servicio—El usuario no debe intentar dar servicio al equipo

eléctrico más allá a lo descrito en las instrucciones de

operación. Todo otro servicio deberá ser referido a personal

de servicio calificado.

9. El aparato eléctrico debe ser situado de tal manera que su

posición no interfiera su uso. La colocación del aparato

eléctrico sobre una cama, sofá, alfombra o superficie similar

puede bloquea la ventilación, no se debe colocar en libreros o

gabinetes que impidan el flujo de aire por los orificios de

ventilación.

10. El equipo eléctrico deber ser situado fuera del alcance de

fuentes de calor como radiadores, registros de calor, estufas u

otros aparatos (incluyendo amplificadores) que producen

calor

.

11. El aparato eléctrico deberá ser connectado a una fuente de

poder sólo del tipo descrito en el instructivo de operación, o

como se indique en el aparato.

12. Precaución debe ser tomada de tal manera que la tierra fisica

y la polarización del equipo no sea eliminada.

13. Los cables de la fuente de poder deben ser guiados de tal

manera que no sean pisados ni pellizcados por objetos

colocados sobre o contra ellos, poniendo particular atención a

los contactos y receptáculos donde salen del aparato.

3

NOM STATEMENT

Page 3

14. El equipo eléctrico debe ser limpiado únicamente de acuerdo

a las recomendaciones del fabricante.

15. En caso de existir, una antena externa deberá ser localizada

lejos de las lineas de energia.

16. El cable de corriente deberá ser desconectado del cuando el

equipo no sea usado por un largo periodo de tiempo.

17. Cuidado debe ser tomado de tal manera que objectos

liquidos no sean derramados sobre la cubierta u orificios de

ventilación.

18. Servicio por personal calificado deberá ser provisto cuando:

A: El cable de poder o el contacto ha sido dañado; u

B: Objectos han caído o líquido ha sido derramado dentro

del aparato; o

C: El aparato ha sido expuesto a la lluvia; o

D: El aparato parece no operar normalmente o muestra un

cambio en su desempeño; o

E: El aparato ha sido tirado o su cubierta ha sido dañada.

CERTIFIBER™

4

Page 4

CONTENTS

1. Specifications ............................................ 7

2. Introduction ........................................... 10

2.1 The Complete Fiber Solution ......... 10

2.2 Standard Features ........................... 11

2.3 The CertiFiber Illustrated ............... 12

2.4 The CertiFiber Main Unit ............... 14

2.4.1 The User Interface ................ 14

2.4.2 The Keypad ........................... 15

2.5 The CertFiber Remote .................... 17

2.5.1 The LEDs .............................. 17

2.5.2 The Keypad ........................... 18

2.6 The Unit’s Batteries ........................ 19

2.7 Displaying Product Information

About CertiFiber .......................... 19

2.8 Editing with CertiFiber ................... 20

2.9 Getting Started ................................ 21

2.10 Display Contrast.............................. 22

2.11 Calibrating CertiFiber ................... 23

3. Configuration ......................................... 24

3.1 Autotests ........................................... 24

3.1.1 Selecting an

Autotest Standard ............... 24

3.1.2 Editing Autotests ................... 25

3.1.3 Test Mode ............................... 27

3.1.4 Job Names .............................. 28

3.2 Length Measurements:

Meters vs. Feet............................... 29

3.3 Time/Date ........................................ 29

3.4 Owner’s Name ................................. 31

3.5 Fiber GRI ......................................... 32

3.6 Language ......................................... 33

3.7 Upload to PC ................................... 33

5

TABLE OF CONTENTS

Page 5

CONTENTS (continued)

4.

Operation: Automatic Measurements

...... 34

4.1 Setting the Reference ...................... 34

4.1.1 In Normal Operation ............ 34

4.1.2 In Loopback Mode ................ 36

4.2 Regular Autotesting ......................... 37

4.2.1 The Autotest Results

Screen .................................. 41

4.2.2 Saving a Autotest ................... 42

4.2.3 Viewing Results ..................... 43

4.2.4 Storing Results ....................... 46

4.2.5 Deleting Results ..................... 47

4.2.6 Uploading Results to a PC .... 48

4.2.7 Printing Results ..................... 49

4.2.8 Sample Autotest-

Certification Report ........... 49

4.3 Loopback-Mode Autotesting ........... 52

5. Operation: Manual Measurements ....... 54

5.1 Power Loss ....................................... 54

5.2 Loopback .......................................... 55

5.3 Light Source .................................... 56

5.3.1 Local ...................................... 56

5.3.2 Remote ................................... 58

6. Troubleshooting ..................................... 59

6.1 Calling Black Box ............................ 59

6.2 Shipping and Packaging ................. 60

Appendix: PASS/FAIL Criteria .................... 61

Legal Information ........................................ 62

CERTIFIBER™

6

Page 6

1. Specifications

Compliance —

CE

Standards —

LAN: IEEE 802.3 Ethernet v. 2

Interfaces —

Fiberoptic: Multimode;

Serial: TIA-574 (DB9) subset of TIA RS-232, DCE

Standards Autotested Against —

TIA-568-A,

ISO 11801, ATM155, ATM155SWL, ATM622,

10BASE-F, 100BASE-F, 100BASE-SX,

100BASE-LX, FDDI, Fiber Channel, Token Ring,

or user-defined

Autostest Results Reported —

850- and 1300-nm

loss, pass/fail margin, and optical link budget;

length; propagation delay; and overall pass/fail

analysis, all for each of the two attached fibers

Wavelengths —

850 and 1300 nm

Transmit Level —

Greater than –20 dBm for both

850 and 1300 nm

Dynamic Range —

Loss: +3 to –55 dBm;

Length: 1 to 2000 m (3 to 6562 ft.);

Propagation delay: 10 to 10,000 ns

Resolution —

Power/loss: 0.01 dB/dBm;

Length:1mor1ft.;

Propagation delay: 1 ns

Accuracy/Linearity —

±0.25 dBm

7

CHAPTER 1: Specifications

Page 7

Optical Link Budget —

Automatically calculated

based on measured length, number of mated

connections, number of splices, and user-selected

standard to be tested against

Internal Memory —

Nonvolatile flash RAM for

storing autotest results for as many as 1000 fibers

User Controls —

ScanLink PC software (on included 3.5" PC-

format diskette);

All others front-mounted:

Main unit:

(12) Pushbuttons for power and test options;

Remote:

(2) Pushbuttons for power and battery test

Indicators —

All front-mounted:

Main unit: (1) 640-x-128-pixel graphical LCD;

Remote: (4) LEDs for pass/fail and wavelength

Connectors —

Fiberoptic: (2) ST female with indium gallium

arsenide (InGaAs) photodiodes;

Serial: (1) DB9 female

Leads Supported —

DB9: All

Power —

Both main unit and remote:

From (3) AA batteries (included)

Battery Life —

Varies depending on use and

battery quality; on average, long enough to test at

least 500 cables

CERTIFIBER™

8

Page 8

Temperature Tolerance —

Operating: 32 to 113˚ F (0 to 45˚ C);

Storage: –4 to 140˚ F (–20 to 60˚ C)

Humidity Tolerance —

Operating: 5 to 90% noncondensing;

Storage: 5 to 95% noncondensing

Size —

Both main unit and remote:

7.1"H x 3.1"W x 1.6"D (18 x 7.9x4cm)

Weight —

Main unit: 14.9 oz. (0.9 lb., 422 g, 0.4 kg);

Remote: 13.4 oz. (0.8 lb., 380 g, 0.4 kg)

9

CHAPTER 1: Specifications

Page 9

2. Introduction

2.1 The Complete Fiber Solution

CertiFiber™ is an advanced handheld

certification tool for fiber links, and is designed

to be the complete solution for professional

cable installers, service providers, and network

administrators.

With the push of a button, CertiFiber

certifies two multimode fibers simultaneously at

both wavelengths.

Rather than just providing a number,

CertiFiber analyzes the fiber link and

determines whether cabling and network

standards are met.

The CertiFiber main unit and CertiFiber

Remote have an optical source that provides a

consistent calibrated dual-wavelength light.

The level of light injected into or emerging

from the fiber network can be measured at any

point so that the performance of fiberoptic

transmission paths and equipment can be

accessed quickly and accurately.

The CertiFiber helps you identify faulty

patch cables, failing splices, and bad couplers

and connectors.

CertiFiber also accurately tests the link’s

propagation delay, which is then used to

calculate length.

CertiFiber incorporates a graphical user

interface, display, menus, arrow keys and

descriptive menu options that guide you

CERTIFIBER™

10

Page 10

11

quickly and easily through the completely

automated process of certifying or trouble-

shooting fiberoptic cabling systems.

2.2 Standard Features

•Certifies a duplex fiber link (two fiber

cables) simultaneously.

•Measures Optical Power Loss in the

direction of data transmission for both

multimode wavelengths on two fiber

cables without changing connectors.

•Measures Length and Propagation Delay

for a dual fiber cable.

•Makes bidirectional measurements for

duplex fiber links.

•Utilizes preprogrammed test templates to

easily certify fiberoptic cabling to industry

or network standards.

•Pinpoints the margin available on the

tested cable above and beyond the

PASS/FAIL requirements.

•Stores a thousand autotest results in

memory with user-friendly alphanumeric

names, job names, and unique time- and

date-stamps.

•

Transmits light continuously or modulated.

•Downloads stored test results to a

computer database for printing and

professional record management.

•

Includes a custom-tailored, non-removable

impact cover for added protection.

CHAPTER 2: Introduction

Page 11

CERTIFIBER™

12

2.3 The CertiFiber Illustrated

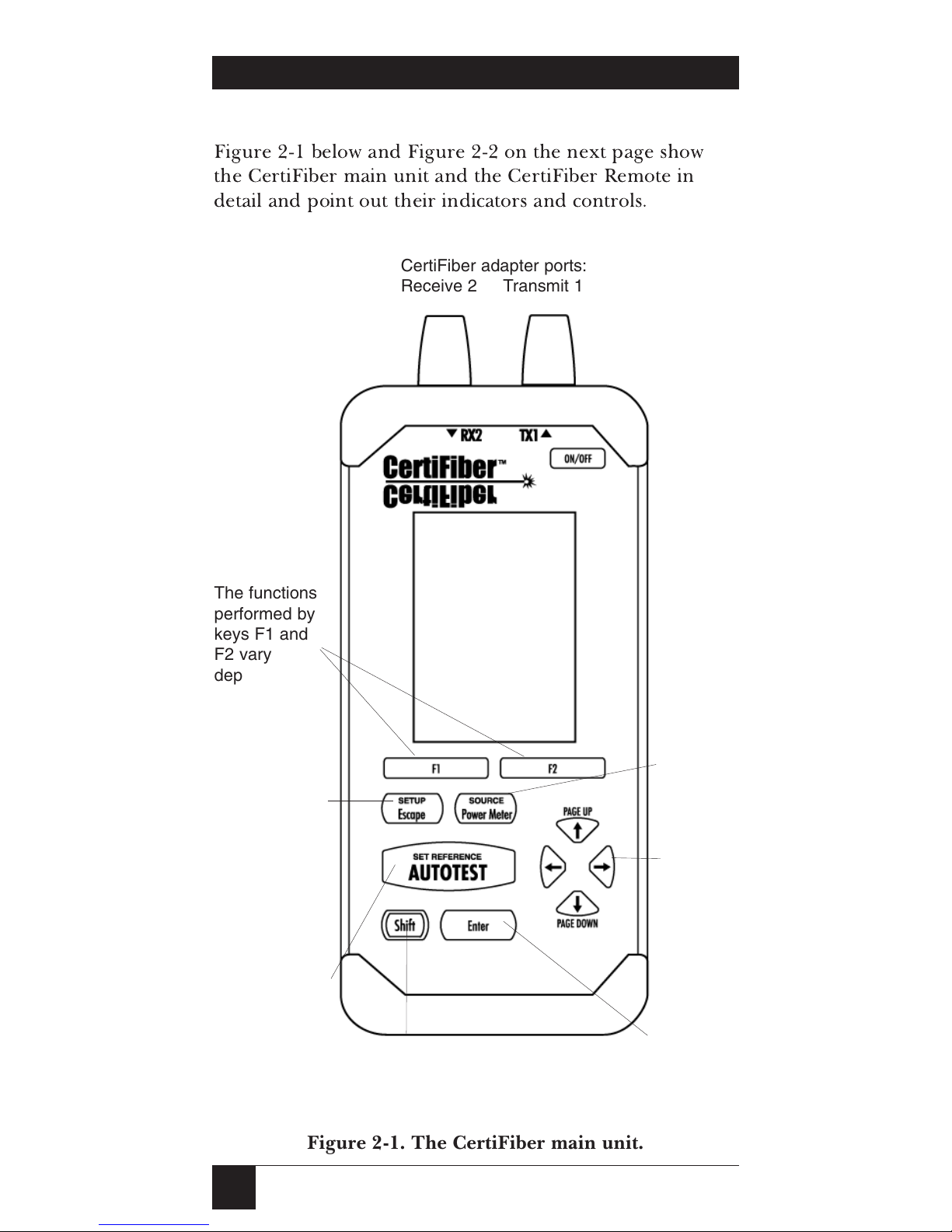

Figure 2-1 below and Figure 2-2 on the next page show

the CertiFiber main unit and the CertiFiber Remote in

detail and point out their indicators and controls.

Figure 2-1. The CertiFiber main unit.

CertiFiber adapter ports:

Receive 2 Transmit 1

The functions

performed by

keys F1 and

F2 vary

depending on

the screen

being

displayed.

Graphical

LCD panel

The Escape

key exits the

current display

or function;

Shirt + Escape

opens the

SETUP

screen.

Press the

Autotest key to

perform tests,

or Shirt +

Autotest to set

the reference.

Press the Shift key

together with other keys

for extended functions.

Use the Arrow

keys to

navigate

among the

displays.

Press Enter to

execute a command.

Use the Power

Meter key for

nonautomated

measurements;

Shift + Power

Meter activates

the unit’s light

source.

Page 12

13

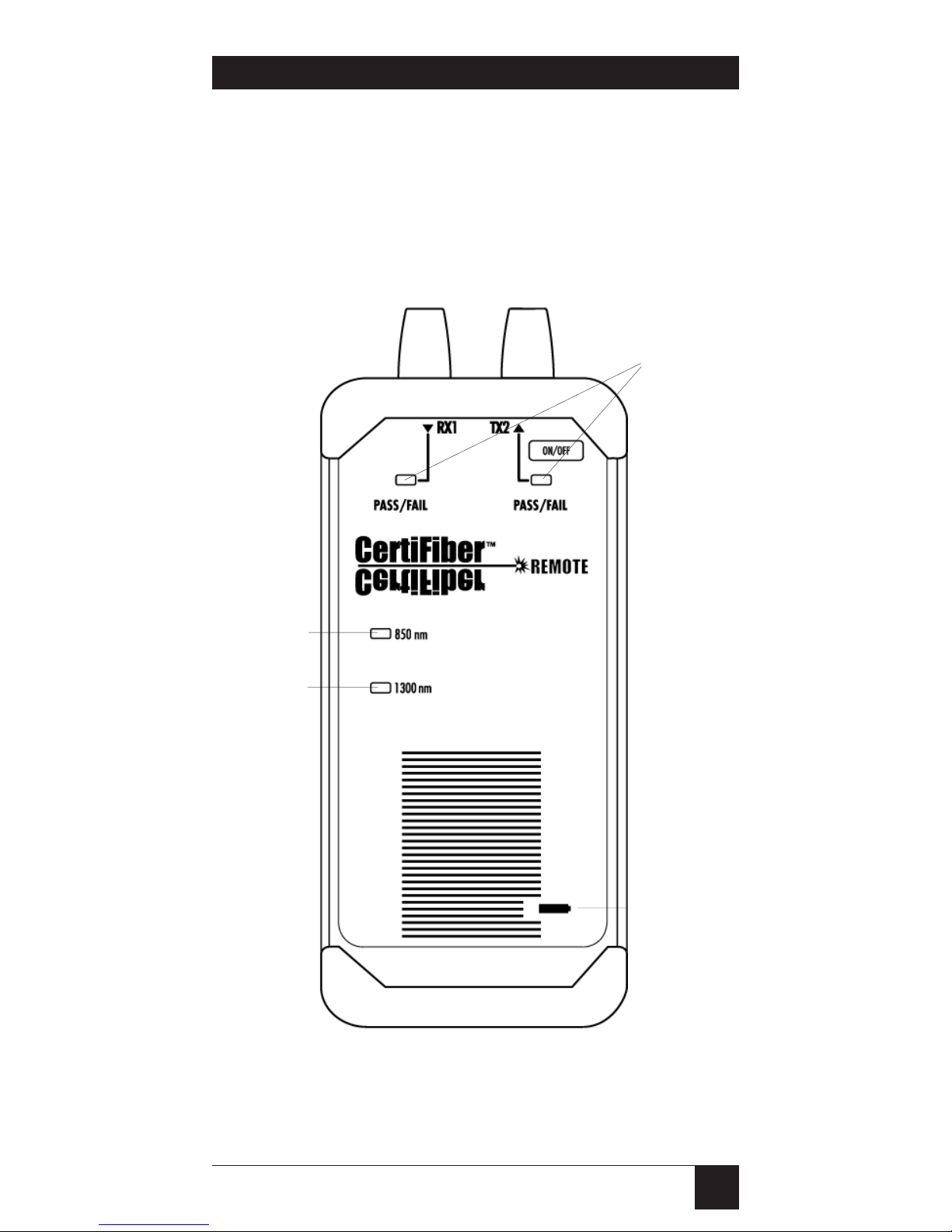

Figure 2-2. The CertiFiber Remote.

CHAPTER 2: Introduction

CertiFiber Remote adapter ports:

Receive 1 Transmit 2

Press the

Battery Test

key to get a

rough idea

how much life

is left in your

batteries.

Test

PASS/FAIL

LEDs.

The Wavelength LEDs

show which

fiber wavelength (850

or 1300 nm)

is currenty

selected.

Page 13

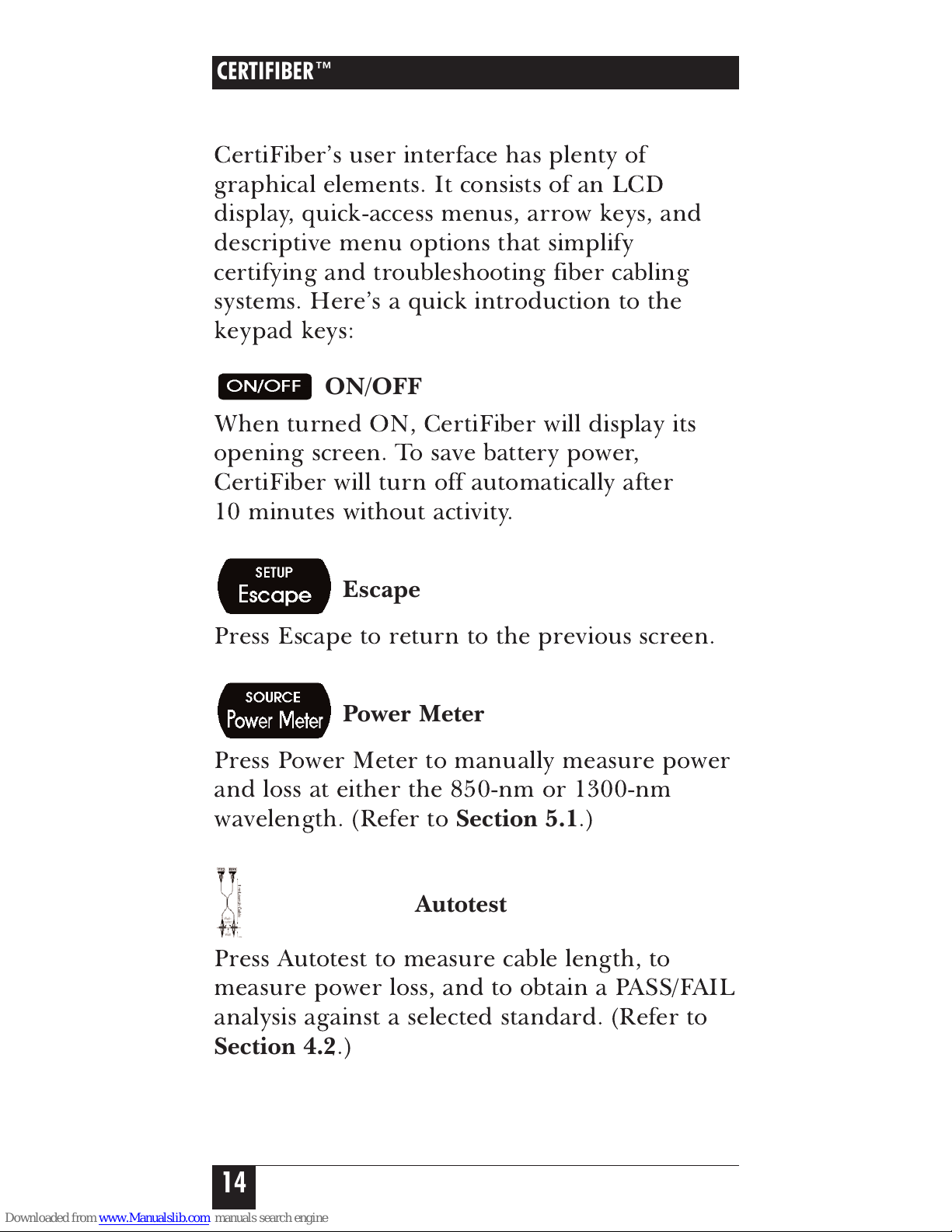

2.4 The CertiFiber Main Unit

CertiFiber’s user interface has plenty of

graphical elements. It consists of an LCD

display, quick-access menus, arrow keys, and

descriptive menu options that simplify

certifying and troubleshooting fiber cabling

systems. Here’s a quick introduction to the

keypad keys:

ON/OFF

When turned ON, CertiFiber will display its

opening screen. To save battery power,

CertiFiber will turn off automatically after

10 minutes without activity.

Escape

Press Escape to return to the previous screen.

Power Meter

Press Power Meter to manually measure power

and loss at either the 850-nm or 1300-nm

wavelength. (Refer to

Section 5.1

.)

Autotest

Press Autotest to measure cable length, to

measure power loss, and to obtain a PASS/FAIL

analysis against a selected standard. (Refer to

Section 4.2

.)

CERTIFIBER™

14

Page 14

Shift

To execute one of CertiFiber’s extended

functions, press Shift along with Autotest,

Power Meter, Escape, or one of the arrow keys.

Enter

Press Enter to execute the current screen

command.

Arrow Keys

The up and down arrows in the display area

indicate that more information is available by

pressing the up- or down-arrow keys. Press

Shift and use the up- and down-arrow keys for

page-up and page-down navigation. Use the

left or right arrow key to move left or right

within a string of characters for editing

purposes.

+ = Source

In addition to the fully automated test

functions, CertiFiber can be operated in a

manual mode. Press Shift + Power Meter to

quickly transform CertiFiber into a manual

light source. Source Mode also allows you to

change the light source from steady to

modulated. (Refer to

Section 5.2

.)

15

CHAPTER 2: Introduction

Page 15

+ = Set Reference

Press Shift + Autotest to set the Reference

value for calculating the loss measurement.

(Refer to

Section 4.1

.)

+ = Setup

Press Shift + Escape to configure (customize)

CertiFiber. From any screen, press Shift +

Escape to quickly return to the Setup menu.

(Refer to

Chapter 3

.)

CERTIFIBER™

16

Page 16

2.5 The CertiFiber Remote

The CertiFiber Remote is an active and

intelligent far-end device that works with the

CertiFiber main unit to verify optical-cable

transmission quality. All information is

processed and transferred to the main unit.

Both units provide a consistent, calibrated light

source that increases the ease and effectiveness

of fiberoptic testing.

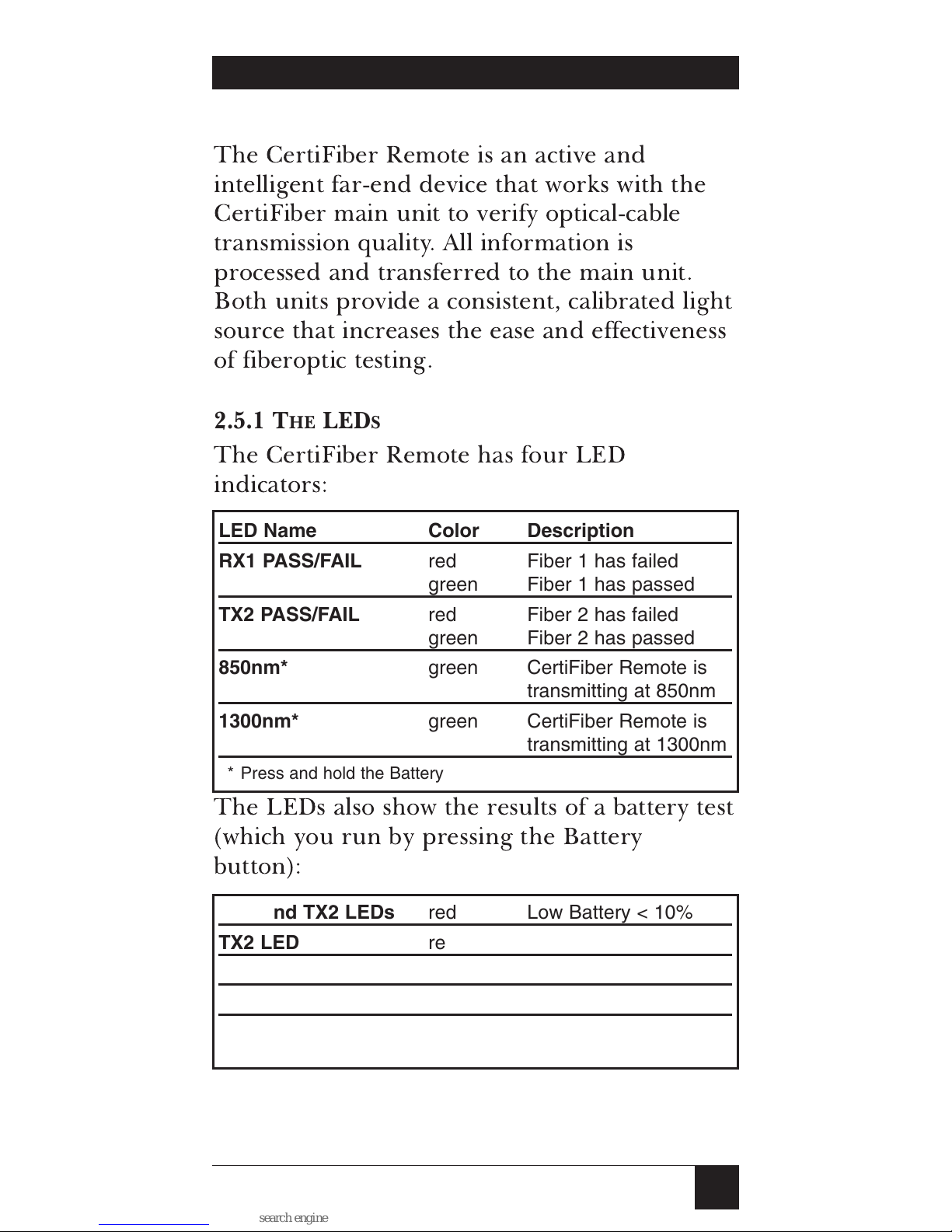

2.5.1 THELED

S

The CertiFiber Remote has four LED

indicators:

LED Name Color Description

RX1 PASS/FAIL red Fiber 1 has failed

green Fiber 1 has passed

TX2 PASS/FAIL red Fiber 2 has failed

green Fiber 2 has passed

850nm* green CertiFiber Remote is

transmitting at 850nm

1300nm* green CertiFiber Remote is

transmitting at 1300nm

* Press and hold the Battery button.

The LEDs also show the results of a battery test

(which you run by pressing the Battery

button):

RX1 and TX2 LEDs red Low Battery < 10%

TX2 LED red Battery 10 to 25%

RX1 LED green Battery 25% to 75%

RX1 and TX2 LEDs green Good Battery > 75%

RX1 and TX2 LEDs* yellow Part 1 of Two Way

Autotest completed

*Switch fiber connectors: RX2 to TX1, TX1 to RX2, RX1 to

TX2, TX2 to RX1.

17

CHAPTER 2: Introduction

Page 17

2.5.2 THEK

EYPAD

ON/OFF (CertiFiber Remote)

When you turn it on, CertiFiber Remote will

flash the LCD power-up sequence. To save

battery power, CertiFiber Remote will turn off

automatically after 30 minutes without activity.

Battery (CertiFiber Remote)

CertiFiber Remote has a battery-level indicator

that allows you to check the battery if

CertiFiber Remote is not connected to the

CertiFiber main unit. Press the Battery button

to illuminate the RX1 and TX2 LEDs on the

CertiFiber Remote unit. If both LEDs blink

red, the batteries are low and should be

replaced. If the LEDs blink green, the remote

unit’s batteries are good and testing can

proceed.

CertiFiber and CertiFiber Remote each require

three AA alkaline batteries. If CertiFiber and

CertiFiber Remote will be stored for more than

one month, the batteries should be removed.

To conserve battery life, CertiFiber will turn off

automatically when no key has been used for

10 minutes.

NOTES

CertiFiber and CertiFiber Remote will not function

properly with carbon batteries. Alkaline batteries are

required.

Stored Autotests and setup parameters are stored in

flash memory. They are not affected by the battery

status.

CERTIFIBER™

18

Page 18

19

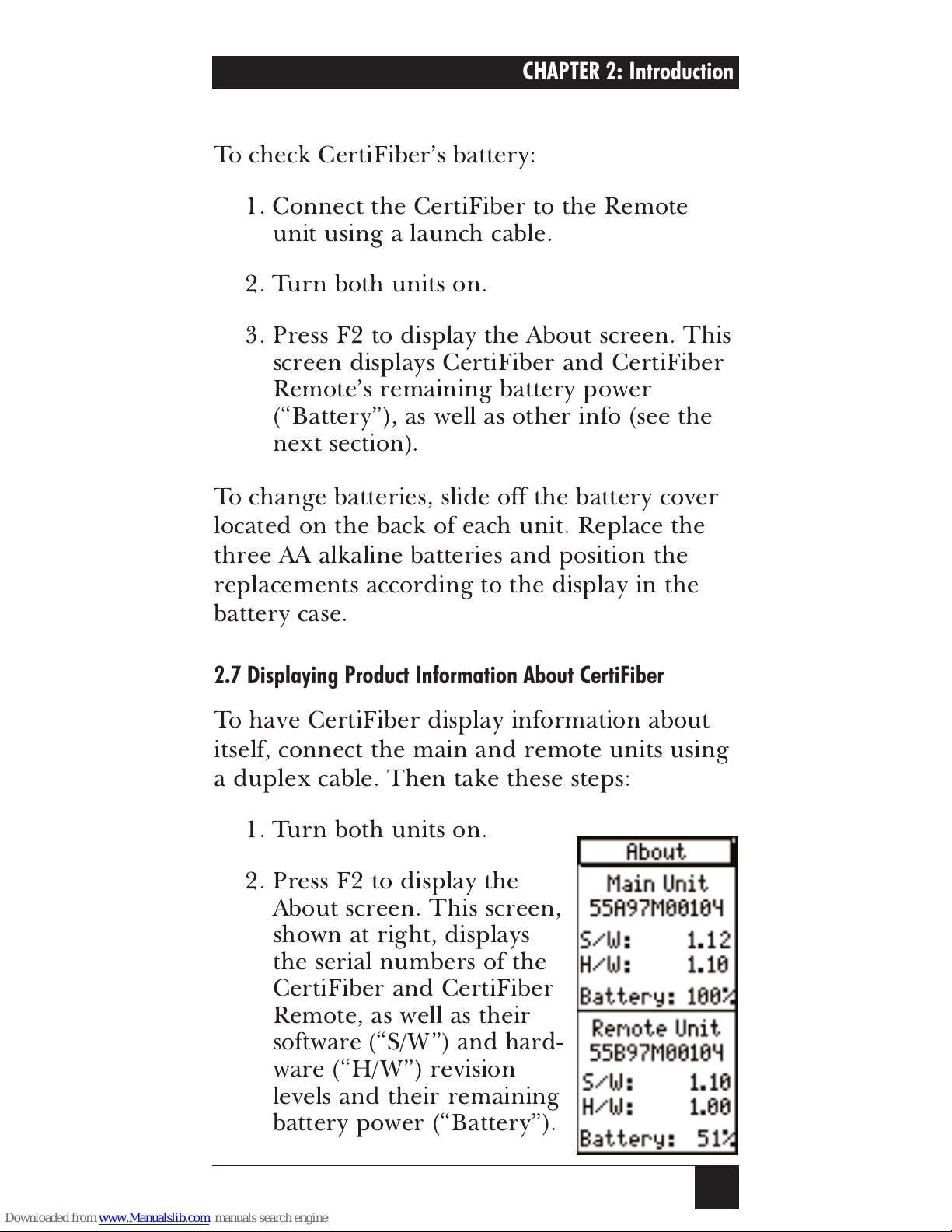

2.6 The Unit’s Batteries

To check CertiFiber’s battery:

1. Connect the CertiFiber to the Remote

unit using a launch cable.

2. Turn both units on.

3. Press F2 to display the About screen. This

screen displays CertiFiber and CertiFiber

Remote’s remaining battery power

(“Battery”), as well as other info (see the

next section).

To change batteries, slide off the battery cover

located on the back of each unit. Replace the

three AA alkaline batteries and position the

replacements according to the display in the

battery case.

2.7 Displaying Product Information About CertiFiber

To have CertiFiber display information about

itself, connect the main and remote units using

a duplex cable. Then take these steps:

1. Turn both units on.

2. Press F2 to display the

About screen. This screen,

shown at right, displays

the serial numbers of the

CertiFiber and CertiFiber

Remote, as well as their

software (“S/W”) and hard-

ware (“H/W”) revision

levels and their remaining

battery power (“Battery”).

CHAPTER 2: Introduction

Page 19

3. Press Escape to return to the Setup

screen.

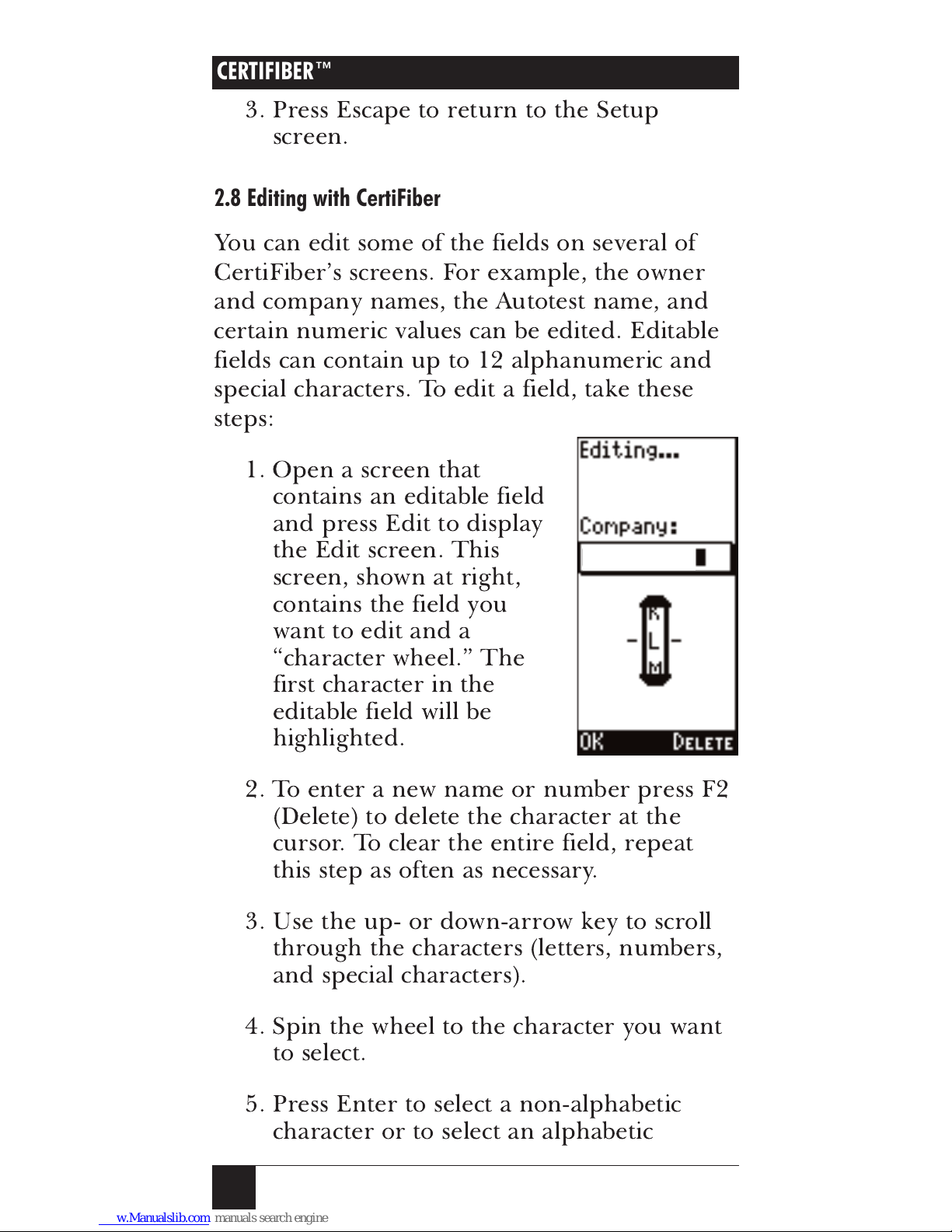

2.8 Editing with CertiFiber

You can edit some of the fields on several of

CertiFiber’s screens. For example, the owner

and company names, the Autotest name, and

certain numeric values can be edited. Editable

fields can contain up to 12 alphanumeric and

special characters. To edit a field, take these

steps:

1. Open a screen that

contains an editable field

and press Edit to display

the Edit screen. This

screen, shown at right,

contains the field you

want to edit and a

“character wheel.” The

first character in the

editable field will be

highlighted.

2. To enter a new name or number press F2

(Delete) to delete the character at the

cursor. To clear the entire field, repeat

this step as often as necessary.

3. Use the up- or down-arrow key to scroll

through the characters (letters, numbers,

and special characters).

4. Spin the wheel to the character you want

to select.

5. Press Enter to select a non-alphabetic

character or to select an alphabetic

CERTIFIBER™

20

YOUR_CO

Page 20

21

character as a

lowercase

letter, or press

Shift + Enter to select an alphabetic

character as an

uppercase

letter. The

highlight will move to the next position in

the field automatically. If you make a

mistake, press F2 (Delete) to erase the

character and back up.

6. Repeat steps 3 through 5 until the field is

completed.

7. Press F1 (OK) or Escape to exit the Edit

screen.

2.9 Getting Started

With CertiFiber, you can certify a fiber link in

seconds using the one-button Autotest. To run

an Autotest, take these steps (see

Section 4.2

for more detailed information):

1. Set the reference value (refer to

Section 4.1

).

2. Remove the covers from the

ST connectors on the CertiFiber and

CertiFiber Remote.

CAUTION!

Both units come with covers on their ST connectors to

protect the connectors from dirt and other foreign

matter. Keep the connectors covered when the units

are not in use. This helps to ensure that contaminants

do not affect test measurements.

3. Attach the cable to be tested to CertiFiber

and CertiFiber Remote’s ST connectors.

Run one fiber from RX2 to TX2, the

other from TX1 to RX1.

CAUTION!

Improperly polished or manufactured fiber-connector

ferrules can damage the CertiFiber’s transmit LED. To

avoid out-of-warranty repairs, please use cables with

clean, properly polished ST connectors.

CHAPTER 2: Introduction

Page 21

3. Select a fiber standard. TIA-568-A and

ISO 11801 are the most widely used fiber

standards.

4. Press the Autotest button.

5. Enter the number of splices and

connectors.

6. Press F1 (Run). CertiFiber will now run

the length, propagation delay, and dual

fiber-loss measurements for 850 nm and

1300 nm and provide a PASS/FAIL

analysis based on the chosen fiber

standard.

7. Press F1 (Save) to name and store the test

result for each fiber.

8. Press F2 (View) to display test results and

move between fibers.

9 Put the covers back on the

ST connectors on the CertiFiber and

CertiFiber Remote.

Test results can now be viewed in the Results

screen. To print test results, they need to be

uploaded to a PC using the included

ScanLink®software. Refer to

Section 4.2.3

.

2.10 Display Contrast

CertiFiber’s display contrast can be adjusted.

From the logo screen, press Shift + up-arrow

or down-arrow to increase or decrease the

contrast.

CERTIFIBER™

22

Page 22

NOTE

The display contrast returns to the default setting when

the unit is turned off.

2.11 Calibrating CertiFiber

CertiFiber and CertiFiber Remote should be

calibrated annually by the manufacturer with

specialized equipment. Contact Black Box

Technical Support for information on

calibration and service requirements.

23

CHAPTER 2: Introduction

Page 23

24

3. Configuration

Press

+

to

display the main Setup screen.

Use the up- or down-arrow

keys to highlight a setup

feature. Press Enter to display

the relevant setup screen. Press

Escape to return to the

CertiFiber logo screen.

3.1 Autotests

3.1.1 S

ELECTING ANAUTOTESTSTANDARD

CertiFiber certifies fiber links

based on the common standard

TIA-568-A and the international

standard ISO 11801, as well as

common LAN cabling

standards such as FDDI, Fiber

Channel and other application-

specific fiber requirements. (See

the

Standards Autotested

Against

specification in

Chapter 1

for a complete list of

supported network types.) To

select an Autotest standard, take these steps:

1 To display the Autotest screen, highlight

Autotest in the Setup screen and press

Enter or F1 (Select).

2. Use the up- or down-arrow keys to scroll

through the list of Autotests.

CERTIFIBER™

Page 24

3. Highlight the preferred Autotest and

press F1 (Select) to select it as the Autotest

to run and to return to the Setup screen.

3.1.2 E

DITINGAUTOTESTS

In addition to the pre-programmed

certification standards, CertiFiber allows you to

customize Autotest settings and to develop new

custom Autotests by specifying the PASS/FAIL

limits to be used. To edit an Autotest, take

these steps:

1. From the Autotest setup

screen, use the up- or

down-arrows to highlight

the Autotest you want to

customize and then press

F2 (Edit). A screen like

the one shown at right

appears. If you are

editing an existing

Autotest, the test name

will be preceded with an

asterisk (“*”).

2. With the Test Name field highlighted,

press F1 (Edit) to name the Autotest.

Refer to

Section 2.8

.

3. Edit the other test values. (Editable fields

for an

equation-based

Autotest are the Test

Name, the Loss per Connector, the Loss

per Splice, the Loss per Kilometer for

both wavelengths, the Length, and the

Delay. Editable fields for an Autotest with

fixed PASS/FAIL criteria

are the Test Name,

the Loss per Kilometer for both

wavelengths, the Length and the Delay.)

25

CHAPTER 3: Configuration

Page 25

First press F2 (Select) to highlight the

value you want to edit. Then use the up-

and down-arrow keys to change the

displayed values in small increments such

as 0.1 dB or 1 m, or use the left- and

right-arrow keys to change the displayed

values in large increments such as 1 dB

or 100 m.

4. Press F1 (Save) to open the Overwrite

Autotest screen. It contains a list of four

user-definable Autotest names (User 1,

User 2, User 3, and User 4).

5. Use the up- and down-arrow keys to

highlight one of the four Autotest names

you want to overwrite with the new

testname and settings. (To ensure that the

default Autotests are not overwritten, the

asterisk preceding the names of edited

existing Autotests cannot be removed.)

6. Press F1 (Select) to save the Autotest and

list the new test name in the Autotest

screen.

7. Press F1 (Select) to select the highlighted

Autotest as the test to run and return to

the Autotest-Setup screen.

CERTIFIBER™

26

Page 26

3.1.3 T

ESTMODE

CertiFiber allows you to control the test

direction. Dual fibers can be tested in opposite

single direction or in both directions. Choose

One Way

to measure a duplex fiber link or

choose

Two Way

to measure a duplex fiber

link in both directions (bidirectional test).

1. To display the

Test Mode

screen, use the up-arrow

to scroll to

Test Mode

in

the

Setup

screen and

press

Enter

or

F1

(Select)

.

The display shows the

currently selected test

mode.

2. Press

F2 (Change)

to

change the test mode.

3. Press

F1 (Save)

to save the setting and

return to the

Setup

screen.

27

CHAPTER 3: Configuration

Page 27

3.1.4 JOBN

AMES

CertiFiber allows you to assign predefined or

customized Job Names so that you can

uniquely identify different job sites, for

example, Project 1 has 102 fiber test results

stored, etc.

1. To display the

Job

Names

setup screen,

use the up-arrow to

scroll to

Job Names

in

the

Setup

screen and

press

Enter

or

F1

(Select)

.

2. Use the up-arrow or

down-arrow to scroll

through the list of job

names.

3. Highlight a Job Name and press

(F2) Edit

to customize it with up to 10 characters.

4. Highlight the Job Name you want to use

and press

Enter

or

F1 (Save)

to save the

list of Job Names.

If you choose not to use Job Names, the first

item in the Job Name list will automatically

default to

Not Used

when an Autotest is saved.

CERTIFIBER™

28

Page 28

3.2 Length Measurements: Meters vs. Feet

You can change CertiFiber’s

length-measurement unit from

meters to feet and vice versa.

To do so, take these steps:

1. To display the Meters/Feet

setup screen, use the

down-arrow key to scroll

to Meters/Feet in the main

Setup screen and press

Enter or F1 (Select). The

display will show the

currently selected

measurement unit.

2. Press F2 to toggle the measurement

setting between meters and feet, or use

the up- or down-arrow keys to change the

measurement unit.

3. Press F1 (Save) to save the setting and

return to the main Setup screen.

3.3 Time/Date

You can set the date and time

of the CertiFiber’s internal

clock. CertiFiber will maintain

these settings until either you

change them again or the unit’s

battery is removed for more

than one hour. To set the date

and time, take these steps:

1. To display the Time/Date

setup screen, use the

down-arrow key to scroll

29

CHAPTER 3: Configuration

Page 29

to Time/Date in the Setup screen and

press Enter or F1 (Select).

2. Use the left- and right-arrow keys to

scroll through the segments in the screen.

3. Select a portion of the time or date field

to change.

4. Use the up- or down-arrow key to change

the value in that field segment. (All fields

are editable in increments of 1 unit. Hold

down the up- or down-arrow key to scroll

through the possible values more quickly.)

5. CertiFiber has two time displays available:

12-hour (a.m./p.m.) or 24-hour (military-

time) clock. You can toggle back and forth

between these displays by moving the

cursor to the clock-type field. Use the up-

or down-arrow key to select the 12- or

24-hour option.

6. Press F1 (Save) to save the new settings

and return to the Setup screen.

30

CERTIFIBER™

Page 30

3.4 Owner’s Name

You can also change the owner

and company names that

appear on the logo screen of

the CertiFiber and on printed

reports. To do so, take these

steps:

1. To display the Owner

Name setup screen, use

the down-arrow key to

scroll to Owner Name in

the Setup screen and

press Enter or F1 (Select).

2. Use the up- or down-arrow key to

highlight the Company Name.

3. With the Company Name highlighted,

press F2 (Edit).

4. The Edit screen will appear with the

cursor in the Company Name field.

Follow the directions in

Section 2.8

to

edit this field as desired.

5. Now highlight the Operator Name and

press F2 (Edit).

6. The Edit screen will appear again, this

time with the cursor in the Operator

Name field. Follow the directions in

Section 2.8

to edit this field as desired.

7. Press F1 (Save) to save the names and

return to the Setup screen.

31

CHAPTER 3: Configuration

YOUR_CO

Page 31

32

3.5 Fiber GRI

The Graded Refractive Index

(GRI) of fiber cables differs

depending on the

manufacturer. So that you can

get accurate length results for

different cables, CertiFiber has

user-definable GRI values for

both test wavelengths.

The default GRI values used

for a 62.5-micron cable are

1.5014 at 850 nm and 1.4966 at

1300 nm. If you are using 50-micron cable and

do not have the GRI values published by the

fiber manufacturer, the defaults should be set

to 1.4897 at 850 nm and 1.4856 at 1300 nm.

The standard GRI values for 62.5-micron

fiber produced before 1994 are 1.478 at

850 nm and 1.422 at 1300 nm.

1. To display the Fiber GRI setup screen,

use the down-arrow key to scroll to Fiber

GRI in the Setup screen and press Enter

or F1 (Select).

2. Press F2 (Select) to highlight the GRI to

be changed.

3. Use the up- or down-arrow key to

increase or decrease the value by

.0001 dB, or use the left- or right-arrow

key to increase or decrease the value by

.01 dB.

4. Press F1 (Save) to save the settings and

return to the Setup screen.

CERTIFIBER™

Page 32

3.6 Language

CertiFiber offers a selection of

languages for the screen

display. To choose a different

display language, take these

steps:

1. To display the Language

setup screen, use the

down-arrow key to scroll

to Language in the Setup

screen and press Enter.

2. Use the up- or down-

arrow key to scroll to the appropriate

language.

3. Press Enter or F1 (Select) to select the

highlighted language as the default

language and return to the Setup screen.

3.7 Upload to PC

All test results can be uploaded to a PC using

the included ScanLink software. To display the

Upload to PC setup screen, use the down-

arrow key to scroll to Upload to PC in the

Setup screen and press Enter. For the rest of

the upload procedure, see

Section 4.2.5

.

33

CHAPTER 3: Configuration

Page 33

34

4. Operation: Automatic

Measurements

CAUTION!

All connectors and fiber-end faces need to be clean

prior to testing. Use the appropriate optical cleaning

supplies to keep connectors and adapters free from

contamination.

Both CertiFiber units come with covers on their ST

connectors to protect the connectors from dirt and

other foreign matter. Keep the connectors covered

when the units are not in use. This helps to ensure that

contaminants do not affect test measurements.

4.1 Setting the Reference

4.1.1 INN

ORMALOPERATION

+

Accurate, repeatable measurements of optical

power and signal loss are fundamental for the

installation and maintenance of fiber optics.

To make an accurate measurement, you need

to know the loss in your attached launch cable

and the power being transmitted. (The launch

cable used to set the reference value should be

the same type of fiber as the

cables to be tested and certified,

either 50/125 or 62.5/125.)

The reference value must be

stored before a loss

measurement can be calculated.

CertiFiber requires the

reference value to compensate

for the signal loss in the launch

cable. This value is then

subtracted from the actual

CERTIFIBER™

Page 34

measured value to determine loss.

Once the reference value is

established, consistent readings

for loss, delay, and length

measurements are ensured.

To set the reference value, take

these steps:

1. Connect CertiFiber and

CertiFiber Remote using

the ST-ST launch cables

and couplers as shown at

right.

2. Press Shift + Autotest to

record the reference

value. The Reference

screen shown below will

appear briefly. Once the

reference data has been

saved, the CertiFiber logo

screen will be displayed.

3. Remove the couplers.

NOTES

Once the reference value has been set, make sure that

both launch cables remain attached to the CertiFiber

units. Try to remove the coupler without disturbing

these connections.

If the test configuration changes, a new reference

value needs to be established.

35

CHAPTER 4: Operation: Automatic Measurements

1-m Launch Cable

1-m Launch Cable

Coupler

Page 35

CertiFiber will store a separate reference value

for each wavelength.

The new reference value will be subtracted

from the actual measured value to determine

loss.

CertiFiber will store reference data for up to

five CertiFiber Remote units and one loopback

setup (see the next section).

NOTE

To ensure consistently accurate measurements, the

reference value must be set each calendar day that

CertiFiber is used. The reference value expires each

day at midnight.

4.1.2 INL

OOPBACKMODE

If a single cable needs to be measured, the

reference value can be set for a single launch

cable. To do so, take these steps:

1. Attach one end of the cable

to the CertiFiber main

unit’s TX1 connector, and

the other end to the RX2

connector, as shown at

right.

2. Use a coupler to connect

the Launch cables.

3. Press Shift + Autotest to

record the reference value.

4. Remove the coupler without disturbing

the connection to the CertiFiber.

36

CERTIFIBER™

Coupler

RX2 TX1RX2 TX1

RX2 TX1

1 m Launch Cable

Page 36

4.2 Regular Autotesting

Using its completely automated Autotest

feature, CertiFiber runs cable

tests, checks test results against

standards, and displays a PASS/

FAIL indication.

An Autotest can be easily

customized to run the different

certification tests required for

your site or system.

Autotest supports many

different network types. The

tests and results vary

depending on the type of

network. (See the

Standards

Autotested Against

specification in

Chapter 1

for a

complete list of supported

network types.)

For certain Autotests, the

PASS/FAIL criteria need to be

customized in the Edit Autotest

screen. (Refer to

Section 3.1

.)

To run an Autotest, take

these steps:

1. Attach the cables to

CertiFiber and CertiFiber

Remote as shown at right.

37

CHAPTER 4: Operation: Automatic Measurements

Page 37

2. Press the Autotest key.

At this point, if you are running an equation-

based Autotest (TIA-568-A, ISO 11801, or

100BASE-F), a screen like the one shown below

will be displayed to allow for connector- and

splice-number editing. Take steps 3 through 5

only if

you need to customize the number of

connectors and splices.

3. Press F2 (Select) to toggle the highlight

between the number of connector pairs

and the number of splices.

4. Use the up- and down-arrow keys to

change the number of connector pairs

and splices.

5. After editing these numbers, press F1

(Run) to save the changes and run the

Autotest.

6. The Autotest Results screen (see the next

section) will be displayed while CertiFiber

is verifying both fiberoptic cables.

38

CERTIFIBER™

Page 38

7. To continue the two-way

test, switch the connectors

that attach to the cable

under test as shown in the

graphic.

NOTE

Do not switch the launch cable

connectors that are attached to the

units.

8. Press

F1 (Run)

to

complete the two-way test.

39

CHAPTER 4: Operation: Automatic Measurements

Page 39

During Autotesting, CertiFiber measures

a cable’s Loss, Length, and Delay:

Optical Power Loss is a measurement of the

signal loss in a cable. A signal is injected into

the fiber cable by the Remote unit. CertiFiber

measures the received signal to determine loss.

It displays the loss in decibels (dB), as well as

the margin values, for both wavelengths.

Length measurements are derived from the

propagation-delay results by using the cable’s

GRI (Graded Refractive Index) at the

appropriate wavelength. CertiFiber measures

the full length of the fibers under test. (See

Section 3.5

for information on how to change

the GRI values.) In the Autotest Results screen,

the length is displayed in meters or feet

depending on how your unit is set up. (See

Section 3.2

.)

Propagation Delay is a measurement of the

time required for a signal to advance from one

end of the circuit to the other. When

measuring propagation delay, CertiFiber

measures the round-trip delay through both

fibers, and then divides the result by two,

assuming that the cables are equal in length.

Propagation delay cannot be measured on a

single fiber; duplex fibers must be used. The

Autotest Results screen displays the

Propagation Delay in nanoseconds (ns).

CERTIFIBER™

40

Page 40

4.2.1 THEA

UTOTESTRESULTSSCREEN

The arrows at the top of the

screen indicate whether the

results are for a

One Way

or a

Two Way

test.

The Autotest Results screen

displays the loss for each fiber

at 850 and 1300 nm. For

bidirectional measurements the

Worst case loss is displayed.

NOTE

There is a ±0.25dB margin of error in

all PASS/FAIL indications.

Length and Propagation Delay

will be measured. The values

will then be compared against

the preprogrammed

PASS/FAIL limits and

CertiFiber will provide a

indication for both fibers.

The first page of the screen

displays the results for Fiber 1.

Use the right-arrow key to

highlight and display the

results for Fiber 2.

To save the highlighted

Autotest result, press

F1 (Save)

.

To view all results for the highlighted Autotest,

press

F2 (View)

.

41

CHAPTER 4: Operation: Automatic Measurements

Page 41

4.2.2 S

AVING ANAUTOTEST

To save the results of an Autotest, take these

steps:

1. Highlight Fiber 1 on the RX side or Fiber

2 on the TX side and press F1 (Save) to

name and store the measured values with

a time stamp.

2. The Job Name screen will be displayed.

3. Highlight a Job name and press F1

(Select).

The performed Autotest

will now be saved under

the selected Job Name.

If you do not want to use

CertiFiber’s Job Name

feature, highlight the first

item on the list (Not

Used), and press F1

(Select).

4. If the Job Name you wish

to use was not predefined

in the Job Name setup

screen, CertiFiber allows

you to edit one by

pressing F2 (Edit).

5. The Save Circuit ID

screen will be displayed

with an arrow in the

titlebar indicating which

fiber the test result is for.

The overall Test Result is

located right below the

arrow.

CERTIFIBER™

42

Page 42

6. The last saved Autotest name is displayed

in the Circuit ID field with the cursor on

the last character. Modify the Circuit ID.

CertiFiber allows entering of up to 10

alphabetic and special characters.

7. Press F1 (OK) when the Circuit ID is

modified or a new Circuit ID is entered.

8. The Save Circuit ID screen for the other

Fiber is now displayed.

9. Edit the Circuit ID and press F1 (OK).

NOTE

If you choose a bidirectional test, the data for both

directions is automatically stored in the Autotest test

record for that fiber.

4.2.3 V

IEWINGAUTOTESTRESULTS

Once the Autotest has been saved, CertiFiber

returns to the Autotest Result screen. F2 (View)

is available.

The arrow on the titlebar shows whether the

fiber was tested one way or bidirectional. For a

one way test, the arrow has one pointer; for a

bidirectional test, the arrow has two pointers.

1. Press F2 (View).

The overall test result is

displayed right below the

arrow.

The Autotest name that

was specified in Setup as

the test to run is shown.

The worst case difference

between the PASS/FAIL

43

CHAPTER 4: Operation: Automatic Measurements

Page 43

value and the actual measurement for

each fiber will be displayed as Margin. A

positive margin indicates that the

measured loss was less than the

PASS/FAIL value. A negative margin

indicates a fail, and shows how much the

measurement exceeded the maximum

allowable PASS/FAIL amount.

NOTE

If the overall result is FAIL, the failed parameters will be

marked with a reverse highlight.

During Autotest, CertiFiber measures a cable’s

Loss, Length, and Delay. The results are shown

in the top part of the screen.

Optical Power Loss measures

the signal loss in a cable. A

signal is injected into the fiber

cable by the remote unit.

CertiFiber measures the

received signal to determine

loss. The loss in decibel (dB)

and the margin values are

displayed for both wavelengths.

Length measurements are

derived from the propagation

delay results using the GRI

(Graded Refractive Index) at

the appropriate wavelength.

CertiFiber measures the full

length of the fibers under test.

In the Autotest Results screen,

the length is displayed in

meters or feet depending on

your unit’s setup.

CERTIFIBER™

44

Page 44

Propragation Delay is the measure of the time

required for a signal to advance from one end

of the circuit to the other. When measuring

propagation delay, CertiFiber measures the

round trip delay through both fibers, and then

divides the result by two, assuming that the

cables are equal in length. Propagation delay

cannot be measured on a single fiber; duplex

fibers must be used.

2. To view results for

bidirectional Autotests,

press F1 (Direction) to

switch between the results

measured for each

direction. The arrow in

the titlebar will indicate

the direction in which the

fiber was measured.

3. Use the up and down

arrow keys to scroll to the

bottom part of the

Autotest results screen.

The Job Name, the

Circuit ID, the number of

Connector Pairs and

Splices used for the

Autotest are revealed.

Each test is stored with a

date and time stamp.

4. Use the left- or right-

arrow keys to toggle

between results for Fiber

1 and Fiber 2.

45

CHAPTER 4: Operation: Automatic Measurements

Page 45

5. Press Escape to exit the Autotest Results

screen.

4.2.4 S

TORINGRESULTS

CertiFiber will store 1000 Autotest results.

1. To display the Results

screen, press F1 (Results)

from the logo screen.

The results screen will be

displayed with all stored

test results sorted by

reverse date, where the

oldest test is at the top of

the list.

2. To quickly move to the

last page of the list, use

the right-arrow key. Use the left-arrow

key to return to the first page.

3. To view detailed test results, use the up-

arrow or down-arrow keys to highlight

the appropriate item and press Enter.

The Results screen will be displayed with

the overall test result in the titlebar. The

type of Autotest used, the Circuit ID (Test

name), the loss for both wavelengths, the

length, the delay, the number of

connectors and splices, the overall test

number, and the time and date the test

was taken will be shown in the scrollable

screen.

4. Press Escape to return to the Results

screen.

CERTIFIBER™

46

Page 46

4.2.5 D

ELETINGRESULTS

CertiFiber allows you to delete selected

Autotest results. To do so, take these steps:

1. Display the Results screen and use the

up- and down-arrow keys to highlight the

Autotest result you want to delete.

2. Press F2 (Mark) to mark the Autotest

name with a large arrow

on the right side, as

shown at right. The

highlight will

automatically advance to

the next line.

3. To manually select several

test results, press F2

(Mark) continuously until

all the Autotest names to

be deleted are marked

with arrows.

4. To automatically select several test results,

turn on block mode by pressing Shift +

F2 (Block). Each highlighted Autotest will

automatically be marked with the arrow.

5. Press Shift + down-arrow once to page

down and automatically mark each test in

the block. Pressing Shift + down-arrow

continuously will rapidly mark several

pages of Autotest names. Press Shift +

up-arrow to unmark a page of Autotest

names.

6. If tests were accidentally marked and

should not be deleted, press F2 (Block)

once more to turn the mark or block

47

CHAPTER 4: Operation: Automatic Measurements

Page 47

mode off. Unselect the Autotests by

pressing F2 (Unmark).

7. Press F1 (Delete) to delete all tests that

are currently marked.

8. A confirmation screen will prompt you.

Make the appropriate choice and

continue.

4.2.6 U

PLOADINGRESULTS TO A

PC

Test results can be uploaded to a PC using the

included ScanLink software. To do so, take

these steps:

1. Connect CertiFiber’s serial port to the

serial port on your PC with the included

communications cable, as shown at right.

2. Turn CertiFiber on to

display the logo

screen.

3. Press Shift + Escape

to display the Setup

screen.

4. Highlight Upload to

PC and press F1

(Select). CertiFiber is

now in upload mode.

5. Run the ScanLink software.

6. Click on the software’s Upload button (it

shows an arrow pointing from a

CertiFiber to a PC) to establish

communications between ScanLink and

CertiFiber. Autotests that are stored in

CERTIFIBER™

48

Com 1 or

Com 2

DB9 to DB9

Serial Cable

Page 48

CertiFiber’s memory will be transferred

directly to the PC. Consult the ScanLink

Help file for further instructions for

uploading and storing test results.

Additionally, the collected data can be

easily transferred into the MT Crimp for

Windows database, where CertiFiber

Autotests can be viewed in detail,

managed, saved, printed, and distributed.

NOTE

MT Crimp for Windows products are available

separately.

7. Turn CertiFiber off when the transfer is

completed.

4.2.7 P

RINTINGTESTRESULTS

Uploaded Autotest results can be printed from

the PC to a printer. ScanLink or MT Crimp for

Windows can be used to save and print the

data. Consult the ScanLink Help file for

further information about printing test results.

4.2.8 S

AMPLEAUTOTESTCERTIFICATIONREPORT

The information on your Autotest printout

varies depending on the type of Autotest that

was used.

The name of the Autotest that was used to run

the test is displayed right below the company

name, and the report title.

The heading provides information on the

Circuit ID, the overall test result, etc. The

number of connections and splices used in the

link will only appear when the Autotest

performed was equation-based.

49

CHAPTER 4: Operation: Automatic Measurements

Page 49

The Test Direction depends on your scanner

setup. Choices are CertiFiber-->Remote,

Remote-->CertiFiber, Bidirectional.

The Actual Results vary depending on your

scanner setup. For bidirectional tests, the

results will be displayed as follows: 1.20/1.40,

where the first number represents a

measurement from CertiFiber to CertiFiber

Remote. The second number indicates a

measurement from CertiFiber Remote to

CertiFiber. Margin and Pass/Fail results are

based on the worst of the two values.

Networks also supported by CertiFiber’s test

results are listed on the bottom of the printout.

A sample certification report is shown on the

next page.

CERTIFIBER™

50

Page 50

Company Name

CertiFiber Certification Report

TIA 568 A

Circuit ID: MICRO-IDF-002 Test Date/Time: 20 Dec 97

14:34:09

Test Result: PASS # of fiber connectors: 2

CertiFiber S/N: 39PT7748322 # of splices: 1

Remote S/N: 39WT70288212 Fiber GRI@850nm: 1.4776

SW Version: V1.07 Fiber GRI@1300nm: 1.4719

Test Direction: Bidirectional

Test Expected Results Actual Results Margin Pass/Fail

C->R R->C

850 loss dB OLB = 2.6 1.2 +1.4 PASS

1300 loss dB OLB = 2.1 1.0 +1.1 PASS

Prop. Delay nS – 60 – n/a

Length m <2000 88 – PASS

Networks Supported:

TIA 568A IS 11801 ATM 155 ATM155SWL

ATM622 FDDI 100BASEF 100BASEFL

10BASEFB 1000BASESX 1000BASELX Token Ring

Fiber Chan

Signature: __________________________ Date: _______

51

CHAPTER 4: Operation: Automatic Measurements

Page 51

4.3 Loopback-Mode Autotesting

CertiFiber also allows you to run an Autotest

for a single cable. The results will be displayed

in the RX (left) side of the Autotest Results

screen. To perform a loopback autotest, take

these steps:

1. To quickly verify the

optical power loss of a

single fiber, attach one

end to CertiFiber’s TX1

connector and the other

end to the RX2

connector.

2. Press the Autotest key.

The results will be

displayed on the RX

(left) side of the Autotest

Results screen.

NOTE

When running Autotest for a single

fiber cable, only Optical Power Loss

will be measured. Length and Delay

cannot be determined without

connecting two fiber cables.

3. Press F1 (Save) to name

and store the measured

values for the cable with a Job Name, a

Circuit ID, and a time stamp.

52

CERTIFIBER™

Page 52

53

CHAPTER 4: Operation: Automatic Measurements

4. When viewing results

for bidirectional

Loopback Autotests,

press F1 (Direction) to

switch between the

measured results.

5. Press Escape to return

to the logo screen.

Page 53

5. Operation: Manual

Measurements

CAUTION!

All connectors and fiber-end faces need to be clean

prior to testing. Use the appropriate optical cleaning

supplies to keep connectors and adapters free from

contamination.

Both CertiFiber units come with covers on their ST

connectors to protect the connectors from dirt and

other foreign matter. Keep the connectors covered

when the units are not in use. This helps to ensure that

contaminants do not affect test measurements.

5.1 Power Loss

The proper operation of a fiber network can

be affected by the operation of its active

components, such as transmitters and

receivers. Excessive loss could actually be a

result of a transmitter launching light at an

unacceptable power level. Transmitters can also

deliver too much light into the fiberoptic cable,

causing the receiver to overload.

You can use CertiFiber’s Power Meter

function to quickly verify and correct cabling

and equipment problems. For both test

wavelengths, Power Meter reports the overall

power, the previously stored reference value,

and the loss.

To perform a Power Meter test, take these

steps:

1. Connect CertiFiber directly to a cable or

use a launch cable to connect to the

equipment to be tested.

CERTIFIBER™

54

Page 54

2. Press the Power Meter

button. The Power Meter

screen, shown at right,

will be displayed.

3. The test direction will be

indicated in the titlebar.

The power, reference, and

loss are displayed for each

wavelength.

4. Press Escape to exit the

Power Meter screen.

5.2 Loopback

Power and loss for both wavelengths can also

be measured in a Loopback.

1. Attach the cable to be

tested to the launch cable

as described in the

Loopback Autotest

section.

2. Press the Power Meter

button.

3. The direction of the

power flow will be

indicated in the titlebar.

4. Press Escape to exit the Power Meter

screen.

55

CHAPTER 5: Operation: Manual Measurements

Page 55

5.3 Light Source

+

5.3.1 L

OCAL

CertiFiber and CertiFiber Remote are designed

to provide a consistent, calibrated light source

for effectively measuring signal loss in

fiberoptic cables. The light can be transmitted

continuously or modulated: When testing loss,

use CertiFiber to function as a continuous-wave

(CW) light source; when identifying fiber cables

with a tone locator, use the 2-KHz modulated

mode.

To perform a loss test or fiber identification,

take these steps:

1. Attach the cable to the the TX1 connector

on the CertiFiber.

56

CERTIFIBER™

Page 56

2. Hold down the Shift key while pressing

Power Meter. The Source Mode screen

will be displayed. This display includes

the wavelength and the light-source

frequency, as shown below.

3. Press F2 to change the light-source

frequency only, or press F1 to change

both the wavelength and frequency, as

shown below:

4. Press Escape to exit the Source Mode

screen.

57

CHAPTER 5: Operation: Manual Measurements

Page 57

5.3.2 R

EMOTE

To use the calibrated light source in the

CertiFiber Remote for loss testing or fiber

identification, take these steps:

1. Press and hold the CertiFiber Remote’s

Battery button.

2. The RX1 and/or TX2 LEDs slowly flash

five times as the unit performs its battery

test.

3. The Wavelength LED then blinks rapidly

until the Battery button is released.

4. The unit steadily lights the Wavelength

LED to indicate that it is ready to

provude a consistent light source for the

currently selected wavelength.

5. Press and hold the Battery button if you

want to switch to the other wavelength.

6. Press the Battery button to turn the

light source off.

58

CERTIFIBER™

Page 58

6. Troubleshooting

6.1 Calling Black Box

If your CertiFiber seems to be malfunctioning,

do not attempt to alter or repair the unit

. It contains

no user-serviceable parts. Call Black Box

Technical Support at 724-746-5500; the

problem might be solvable over the phone.

Before you call, make a record of the history

of the problem. We will be able to provide

more efficient and accurate assistance if you

have a complete description, including:

•the nature and duration of the problem.

•when the problem occurs.

•the components involved in the problem.

•any particular application that, when

used, appears to create the problem or

make it worse.

•the results of any tests you’ve already

done.

59

CHAPTER 6: Troubleshooting

Page 59

6.2 Shipping and Packaging

If you need to transport or ship your

CertiFiber:

•Package it carefully. We recommend that

you use the original container.

•If you are returning the unit, make sure

you include everything you received with

it. If for whatever reason you are

shipping the unit back to us, contact

Black Box to get a Return Materials

Authorization (RMA) number.

60

CERTIFIBER™

Page 60

Appendix: PASS/FAIL Criteria

For the latest cable installation, international

standards, and conformance techniques, go to:

http://cabletesting.com/Fiber_Standards.html

61

APPENDIX: PASS/FAIL Criteria

Page 61

Legal Information

License Provisions

This manual and the product described in it

have been protected internationally by

copyright and other applicable laws with all

rights reserved. You may not remwe or conceal

any trademark, patent, or copyright notice

appearing on the product or in this manual.

The developer remains the sole owner of the

software programs that are part of this

product. The developer grants you a

nonexclusive license to use these software

programs. This license is for a single user only.

You may not make any copies of the software

other than as a backup copy for your own use.

You may not sell, rent, lease, lend, distribute,

or otherwise transfer copies of the software or

of this manual to others, except that you may

permanently transfer all copies of the software

in your possession (including any backups) and

all related materials as a set to another person

who accepts the terms of this license

agreement. You may not modify, transcribe,

translate, decompile, reverse-engineer or

reverse-assemble the software or create any

derivative works from it. The developer may

terminate this license at any time without

notice if you breach any of these terms. If any

provision of this license is held to be

unenforceable or contrary to any applicable

law, the validity of the remaining provisions

shall not be affected.

62

CERTIFIBER™

Page 62

U.S. Government Restricted Rights Notice

The software programs that are part of this product

are provided with Restricted Rights in accordance

with 48CFR§52.227-14 and may not be used,

reproduced, or disclosed by the Government except

that this software may be (1) used or copied for use

in or with the computer or computers for which it

was acquired, including use at any Government

installation to which such computer or computers

may be transferred; (2) used or copied for use in a

backup computer if any computer for which it was

acquired is inoperative; (3) reproduced for

safekeeping (archives) or backup purposes;

(4) modified, adapted, or combined with other

computer software, provided that the modified,

combined, or adapted portions of the derivative

software incorporating restricted computer software

are made subject to the same restricted rights;

(5) disclosed to and reproduced for use by support

service Contractors in accordance with

subparagraphs (1) through (4) of this clause,

provided the Government makes such disclosure or

reproduction subject to these restricted rights; and

(6) used or copied for use in or transferred to a

replacement computer. Notwithstanding the

foregoing, if this computer software is published

copyrighted computer software, it is licensed to the

Govemment, without disclosure prohibitions, with

the minimum rights set forth in this clause. Any

other rights or limitations regarding the use,

duplication, or disclosure of this computer software

are to be expressly stated in, or incorporated in, the

contract under which it is provided to the

Government. This Notice shall be marked on any

reproduction of this computer software, in whole or

in part.

63

LEGAL INFORMATION

Page 63

Warnings and Disclaimers

No part of this document may be photocopied,

reproduced, or translated into another

language without prior written consent.

The manufacturer and its authorized agents

make no warranty of any kind with regard to

this material, including, but not limited to, the

implied warranties of merchantability and

fitness for a particular purpose. Neither the

manufacturer nor its authorized agents shall be

liable for errors contained herein or for

incidental consequential damages in

connection with the fumishing, performance,

or use of this material.

Warning: This manual and the software

described herein are protected by United

States Copyright law (Title 17 United States

code). Unauthorized reproduction and/or sales

may result in imprisonment for up to one year

and fines of up to $10,000 (l 7 USC 506).

Copyright violators may also be subject to civil

liability.

The information in this document and the

software is subject to change without notice.

Trademarks Used in This Manual

ScanLink is a registered trademark, and

CertiFiber is a trademark, of Microtest, Inc.

Any other trademarks mentioned in this manual are

acknowledged to be the property of the trademark

owners.

CERTIFIBER™

64

Page 64

65

NOTES

Page 65

66

NOTES

Page 66

67

NOTES

Page 67

1000 Park Drive • Lawrence, PA 15055-1018 • 724-746-5500 • Fax 724-746-0746

© Copyright 2000. Black Box Corporation. All rights reserved.

Loading...

Loading...