Page 1

1000 Park Drive • Lawrence, PA 15055-1018 • 724-746-5500 • Fax 724-746-0746

© Copyright 1999. Black Box Corporation. All rights reserved.

Page 2

CUSTOMER

SUPPORT

INFORMATION

Order toll-free in the U.S. 24 hours, 7 A.M. Monday to midnight Friday: 877-877-BBOX

FREE technical support, 24 hours a day, 7 days a week: Call 724-746-5500 or fax 724-746-0746

Mail order: Black Box Corporation, 1000 Park Drive, Lawrence, PA 15055-1018

Web site: www.blackbox.com • E-mail: info@blackbox.com

APRIL 1999

MT160A PS462A

MT161C-25 PS463A

MT161C-V35 RM202

PS460A RM204

PS460AE RM208

PS461A RM216

MicroCSU/DSU Cards

MicroRACK

ON

OFF

Power

MicroRack System

AC Power Supply

Page 3

Page 4

1

TRADEMARKS

TRADEMARKS USED IN THIS MANUAL

AT&T is a registered trademark of AT&T.

MCI is a registered trademark of MCI Telecommunications Corporation.

Sprint is a registered trademark of U.S. Sprint Communications Ltd.

Any trademarks used in this manual are acknowledged to be the property of the

trademark owners.

Page 5

2

MicroCSU/DSU Cards and MicroRacks

FEDERAL COMMUNICATIONS COMMISSION

AND

INDUSTRY CANADA

RADIO FREQUENCY INTERFERENCE STATEMENTS

This equipment generates, uses, and can radiate radio frequency energy and if not

installed and used properly, that is, in strict accordance with the manufacturer’s

instructions, may cause interference to radio communication. It has been tested

and found to comply with the limits for a Class A computing device in accordance

with the specifications in Subpart J of Part 15 of FCC rules, which are designed to

provide reasonable protection against such interference when the equipment is

operated in a commercial environment. Operation of this equipment in a

residential area is likely to cause interference, in which case the user at his own

expense will be required to take whatever measures may be necessary to correct

the interference.

Changes or modifications not expressly approved by the party responsible

for compliance could void the user’s authority to operate the equipment.

This digital apparatus does not exceed the Class A limits for radio noise emission from

igital apparatus set out in the Radio Interference Regulation of Industry Canada.

Le présent appareil numérique n’émet pas de bruits radioélectriques dépassant les limites

applicables aux appareils numériques de la classe A prescrites dans le Règlement sur le

brouillage radioélectrique publié par Industrie Canada.

Page 6

3

NOM STATEMENT

NORMAS OFICIALES MEXICANAS (NOM)

ELECTRICAL SAFETY STATEMENT

INSTRUCCIONES DE SEGURIDAD

1. Todas las instrucciones de seguridad y operación deberán ser leídas antes de

que el aparato eléctrico sea operado.

2. Las instrucciones de seguridad y operación deberán ser guardadas para

referencia futura.

3. Todas las advertencias en el aparato eléctrico y en sus instrucciones de

operación deben ser respetadas.

4. Todas las instrucciones de operación y uso deben ser seguidas.

5. El aparato eléctrico no deberá ser usado cerca del agua—por ejemplo, cerca

de la tina de baño, lavabo, sótano mojado o cerca de una alberca, etc..

6. El aparato eléctrico debe ser usado únicamente con carritos o pedestales que

sean recomendados por el fabricante.

7. El aparato eléctrico debe ser montado a la pared o al techo sólo como sea

recomendado por el fabricante.

8. Servicio—El usuario no debe intentar dar servicio al equipo eléctrico más allá

a lo descrito en las instrucciones de operación. Todo otro servicio deberá ser

referido a personal de servicio calificado.

9. El aparato eléctrico debe ser situado de tal manera que su posición no

interfiera su uso. La colocación del aparato eléctrico sobre una cama, sofá,

alfombra o superficie similar puede bloquea la ventilación, no se debe colocar

en libreros o gabinetes que impidan el flujo de aire por los orificios de

ventilación.

10. El equipo eléctrico deber ser situado fuera del alcance de fuentes de calor

como radiadores, registros de calor, estufas u otros aparatos (incluyendo

amplificadores) que producen calor.

11. El aparato eléctrico deberá ser connectado a una fuente de poder sólo del

tipo descrito en el instructivo de operación, o como se indique en el aparato.

Page 7

4

MicroCSU/DSU Cards and MicroRacks

12. Precaución debe ser tomada de tal manera que la tierra fisica y la polarización

del equipo no sea eliminada.

13. Los cables de la fuente de poder deben ser guiados de tal manera que no

sean pisados ni pellizcados por objetos colocados sobre o contra ellos,

poniendo particular atención a los contactos y receptáculos donde salen

del aparato.

14. El equipo eléctrico debe ser limpiado únicamente de acuerdo a las

recomendaciones del fabricante.

15. En caso de existir, una antena externa deberá ser localizada lejos de las lineas

de energia.

16. El cable de corriente deberá ser desconectado del cuando el equipo no sea

usado por un largo periodo de tiempo.

17. Cuidado debe ser tomado de tal manera que objectos liquidos no sean

derramados sobre la cubierta u orificios de ventilación.

18. Servicio por personal calificado deberá ser provisto cuando:

A: El cable de poder o el contacto ha sido dañado; u

B: Objectos han caído o líquido ha sido derramado dentro del aparato; o

C: El aparato ha sido expuesto a la lluvia; o

D: El aparato parece no operar normalmente o muestra un cambio en su

desempeño; o

E: El aparato ha sido tirado o su cubierta ha sido dañada.

Page 8

5

CONTENTS

Contents

Chapter Page

1. Specifications ........................................................................................................6

2. Introduction ........................................................................................................10

2.1 Overview ....................................................................................................10

2.2 Features......................................................................................................11

3. Before You Begin ................................................................................................12

3.1 Dedicated DDS Configuration ................................................................12

3.2 Campus Area Short-Haul Configuration ................................................12

3.3 Network Interface Connection ................................................................12

4. Configuration ......................................................................................................13

4.1 Front-Panel LEDs ......................................................................................13

4.2 Source of Configuration ..........................................................................14

4.2.1 Hardware Switches ..........................................................................15

4.2.2 Software Switches ............................................................................21

4.3 Rear Card Configuration..........................................................................29

4.3.1 MicroCSU/DSU DB25 Rear Strap Settings ..................................31

4.3.2 MicroCSU/DSU V35 Rear Strap Settings ....................................32

5. Installation ..........................................................................................................34

6. DDS Testing ........................................................................................................38

6.1 Local Analog Loopback Testing ..............................................................38

6.2 Remote Digital Loopback Testing ..........................................................39

6.3 V.52 BER Test Generator..........................................................................40

6.4 Telco Testing ............................................................................................40

6.4.1 CSU Loop ........................................................................................41

6.4.2 DSU Loop ........................................................................................41

Appendix A. Cable Recommendations ..................................................................42

Appendix B. Interface Pin Assignment ..................................................................43

B.1 DDS Interface ............................................................................................43

B.2 M/34 Connector, Terminal Interface ....................................................43

B.3 DB25 Connector, Terminal Interface ....................................................44

Appendix C. Transmitter Clock Source During Test Loops ................................45

Page 9

6

MicroCSU/DSU Cards and MicroRacks

1. Specifications

MicroCSU/DSUs (MT160A, MT161C-25, MT161C-V35)

DDS Type — Dedicated DDS

Transmission Format — Asynchronous, synchronous

Internal Interface — Connection to rack chassis via a 50-pin male card edge

External Interface — DB25 female, M/34 female, RJ-48S

Standards — AT&T 62310 compliant

DDS Line Rates — 2.4, 4.8, 9.6, 19.2, 56, and 64 Kbps

DTE Rates — 2.4, 4.8, 9.6, 19.2, 38.4, 56, 57.6, and 64 Kbps

Leads Supported — MT160A, MT161C-V35: B, C, D, E, F, H, L, M, N, P, R, S, T, U,

V, W, X, Y, AA; MT161C-25: 1–9, 11, 12, 14–18, 20, 21, 24, 25

Control Port — Configuration and diagnostics

Transmission Line — 4-wire

Applications — DDS point-to-point or multipoint; campus-area point-to-point

Indicators — (10) LEDs: POWER, TD, RD, CTS, CD, DTR, NS, OS, ER, and TM

Operation — Full duplex

Clocking — Internal, External, Recovered

Diagnostics — V.54 compliant local and remote loopback tests; V.52 compliant 511

BER test, telco CSU and DSU loops

Power Supply — Rackmount power supply is switchable between 120 and 240 VAC;

chassis supplies 10 VAC to the MicroCSU/DSU, typical consumption is 1.5W per

slot

Fuse — 400 mA for 120V applications; 200 mA for 240V applications

Operating Temperature — 32° to 114°F (0° to 45°C)

Page 10

7

CHAPTER 1: Specifications

Storage Temperature — -40° to 176°F (-40° to 80°C)

Humidity — Up to 95%, noncondensing

Size — MT160A: 2.5"H x 5"W x 1"L (6.4 x 12.7 x 2.5 cm); MT161C-25, MT161C-

V35: 2.5"H x 4.5"W x 1"L (6.4 x 11.4 x 2.5 cm)

Weight — 1 lb. (0.5 kg)

MicroRacks (RM202, RM204, RM208, RM216)

Indicators — Indicators are on the front card (MT160A)

Number of Slots — RM202: 2; RM204: 4; RM208: 8; RM216: 16

Power Source — Internal

Input Voltage — 120 VAC

Input Current/Amps — 200 mA

Input Connector Type — IEC 950

Connector Style — On the CSU/DSU rear cards

Operating Temperature — 32° to 114°F (0° to 45°C)

Storage Temperature — -40° to 176°F (-40° to 80°C)

Humidity — 0 to 95%, noncondensing

Size — RM202: 3.5"H x 3.5"W x 7.5"D (8.9 x 8.9 x 19.1 cm); RM204: 3.5"H x 5.5"W

x 7.5"D (8.9 x 14 x 19.1 cm); RM208: 3.5"H x 9.5"W x 7.5"D (8.9 x 24.1 x 19.1 cm);

RM216: 3.5"H x 19"W x 7.5"D (8.9 x

48.3 x 19.1 cm)

Weight — RM202, RM208, RM216: 5 lb. (2.2 kg); RM204: 4 lb. (1.8 kg)

Power Supply (PS460A)

Power Source — Internal

Input Voltage — 110 volts AC

Page 11

8

MicroCSU/DSU Cards and MicroRacks

Power Supply (PS460AE)

Power Source — Internal

Fuses — (4) Included (2 in the drawer and 2 spares)

Input Voltage — 115 or 230 volts AC, autosensing

Power Supply (PS461A)

Power Source — Internal

Input Voltage — 48 volts DC

Input Connector Type — PS461A: Terminal screw connections

Indicators — Power, DC input

Size — 3.5"H x 1.5"W x 7"D (8.9 x 3.8 x 17.8 cm)

Weight — 1 lb. (0.5 kg)

Power Supplies (PS462A and PS463A)

F

RONT

P

OWER-SUPPLYCARD

Power Supply — PS462A: 24 VDC; PS463A: 12 VDC

Input Voltage — PS462A: 13–36VDC; PS463A: 10–20 VDC

Input Protection — PS462A: Triggered at 39 VDC; PS463A: Triggered

at 22 VDC

Maximum Input

Current — PS462A: 2A @ 18 VDC; PS463A: 4A @ 10 VDC

Isolation Voltage — 500V RMS, input to output

Output Voltage — 12 VAC @ 2A

Output Power — 24W

Switches — Power on/off

Indicators — Power, DC Input

Page 12

9

CHAPTER 1: Specifications

R

EARPOWER-SUPPLYCARD

Connection — Cage-clamp terminal block with +DC In, -DC In, Frame

Ground, Alarm, Alarm C, +DC Out, -DC Out

Wire — 26-14 solid or stranded cable

Alarm — Opens when power is attached and closes when power

is disconnected

Page 13

10

MicroCSU/DSU Cards and MicroRacks

2. Introduction

2.1 Overview

The MicroCSU/DSU operates either synchronously or asynchronously and

supports data rates to 64 Kbps. An easily accessible control port allows the user to

enable diagnostic utilities, including V.54 and V.52 test. Ten easy-to-read LEDs

monitor data and control signals.

The Cards are AT&T

®

compliant and are fully compatible with DDS, Clear

Channel 64, and other digital services available from major service providers

including AT&T, Sprint

®

, and MCI®. They can also be used as high-speed modems

for private twisted pair.

In order for your MicroCSU/DSU to function properly, you will need one front

card (MT160A), one rear card (MT161C-25 or MT161C-V35), one power supply

(PS460A, PS461A, PS462A, or PS463A), and one MicroRack (RM202, RM204,

RM208, or RM216).

The MicroCSU/DSU Cards are designed to mount in any size MicroRack.

Depending on which model MicroRack you choose, it will hold up to 16 cards.

Measuring only 3.5 inches high, the Card is designed to occupy only 2U in a 19inch rack. The MicroRacks are powered by either the MicroRack AC Power Supply

(PS460A) or a MicroRack DC Power Supply (PS461A, PS462A, or PS463A). The

MicroRacks use mid-plane architecture (the front card can be plugged into

different rear cards). Therefore, the MicroCSU/DSU Cards can have several

interface options and can be switched with other short-haul cards.

The table on the next page lists the names and codes of the products described

in this manual.

Page 14

11

CHAPTER 2: Introduction

Code Product Name

MT160A MicroCSU/DSU Front Card

MT161C-25 MicroCSU/DSU DB25 Rear

MT161C-V35 MicroCSU/DSU V35 Rear

PS460A MicroRack AC Power Supply

PS461A MicroRack 48-VDC Power Supply

PS462A MicroRack 24-VDC Power Supply

PS463A MicroRack 12-VDC Power Supply

RM202 MicroRack 2

RM204 MicroRack 4

RM208 MicroRack 8

RM216 MicroRack 16

2.2 Features

• Operates over dedicated digital lines.

• Supports rates of 56 and 64 Kbps and all sub-rates.

• Provides both RS-232 and V.35 interfaces.

• Features V.52 and V.54-compliant tests.

• Easy-to-read LEDs monitor data and line signals.

• AT&T 62310 compliant.

• Can be used as a high-speed modem for private twisted pair.

Page 15

12

MicroCSU/DSU Cards and MicroRacks

3. Before You Begin

This chapter describes how to install the MicroCSU/DSU for dedicated operation

or for use as a campus-area short-haul modem.

3.1 Dedicated DDS Configuration

The MicroCSU/DSU can easily be configured for dedicated DDS operation by

means of the DIP switches on the bottom of the enclosure. Set the Line Rate

to match the rate of service to which you subscribe. Set the Mode switches for

Network Clocking. The Rate Converter and Data Format options should be set

as required for your application. The remaining options may also need to be set

depending on your terminal equipment and your application.

3.2 Campus Area Short-Haul Configuration

The unit can also be used for campus area point-to-point short-haul applications

on private twisted-pair wires. Set the Line Rates the same on both units. Set the

Mode switch for the appropriate Transmit Clock Mode for your application.

Internal, External, and Looped Clock Modes are available. Set the remaining

options as needed by your terminal equipment or your application.

3.3 Network Interface Connection

The Network Interface is an 8-position modular connector. Connect this port to

the RJ-48S jack provided by the digital data service provider. If you are using the

MicroCSU/DSU for private short-haul communication, the twisted-pair cable will

connect to this port. See Appendix B for the pin assignments of this connector.

Page 16

13

CHAPTER 4: Configuration

4. Configuration

Before you can operate your MicroCSU/DSU, you must configure the unit. This

chapter describes reading the LED status monitors, setting the DIP switches, and

using the control port.

4.1 Front-Panel LEDs

There are ten front-panel status LEDs that indicate the condition of the CSU/DSU

and the communication link. Figure 1 shows the location of each LED. Following

Figure 1 is a description of each LED’s function.

Figure 1. The MicroCSU/DSU’s LEDs.

DTR Power

TD

RD

CD

CTS

NS

OS

TM

ER

Remote Analog

511 511/E

Page 17

14

MicroCSU/DSU Cards and MicroRacks

• POWER will glow red when the proper power is applied to the rack.

• TD and RD will glow red to indicate an Idle condition or Binary “1” data on

the respective terminal interface signals. Green indicates Binary “0” data.

• CTS will glow red to indicate an Off condition. Green indicates an On

condition. When on, the unit is ready to send data. If CTS remains off,

check the Forced RTS, Circuit Assurance, and Anti-Streaming Settings.

• CD will glow red to indicate that the Idle code is being received. Green

indicates that data is being received.

• DTR will glow to indicate that the DTR signal from the terminal is active.

• NS indicates No Signal. This means the MicroCSU/DSU receiver does not

detect a signal from the digital service provider (or, in the case of short-haul

operation, from the remote MicroCSU/DSU). If NS is lit, check for an

unplugged cable, broken wire, or an incorrect Line Rate selection.

• OS indicates Out-of-Service. This means the MicroCSU/DSU has received an

Out-of-Service signal from the digital service provider and indicates a problem

with the service provider’s equipment. If this condition persists, contact your

service provider.

• ER indicates the likelihood of a Bit Error in the received signal. ER will flash

if the MicroCSU/DSU receives illegal bi-polar violations. During the 511 or

511/E test, ER will flash to indicate that the Test Pattern Detector has detected

a bit error.

• TM indicates Test Mode. It will light if the unit is placed into a test mode. The

unit can be placed in test mode by the local user, by the remote user, or by the

service provider.

4.2 Source of Configuration

The unit defaults to the use of Hardware Switches for configuration. It can also be

set to use Soft Switches for configuration, in which case the Hardware Switches will

be ignored.

Page 18

15

CHAPTER 4: Configuration

4.2.1 H

ARDWARESWITCHES

It is possible to override the Soft Switches and force the unit to use the Hardware

Switches. To do this, powerup the unit once with the Line Rate (SW1-1, 1-2, 1-3)

set to OFF, OFF, OFF. Then set the Hardware Switches as you require and

powerup the unit again.

Figure 2. The MicroCSU/DSU Front Card, bottom view, showing the

location of the DIP switches.

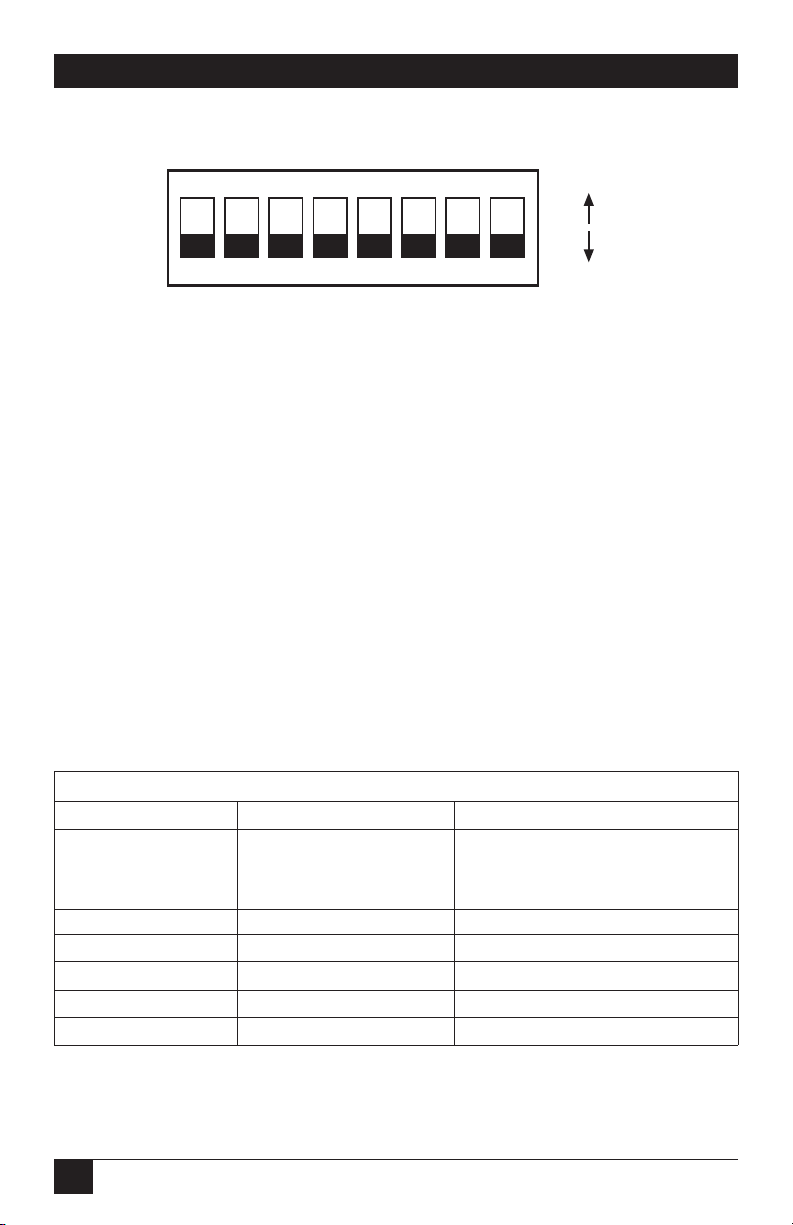

The sixteen DIP switches can be configured as either On or Off. Figure 3 shows the

orientation of the DIP switches with respect to ON/OFF positions.

SW2SW1

Front

Interface

Driver

Board

MSD LSD

Address Rotary

Switches

Page 19

16

MicroCSU/DSU Cards and MicroRacks

Figure 3. Close-up of DIP switches showing ON/OFF positions.

T

ERMINALINTERFACE

The MicroCSU/DSU supports RS-232 and V.35 terminal interface electrical

specifications by means of an interface driver board. Install this board by observing

the markings “This side up for RS-232,” “This side up for V.35,” and “Front.” (The

arrow should point toward the front panel.)

S

WITCHSET

1

The configuration switches on switch set 1 (SW1) allow you to specify Line Rate,

Circuit Assurance, Force RTS, Character Length, Data Format, and DSR System

Status. Table 1 (on the next page) summarizes the SW1 switch settings, including

the factory defaults. Following the chart is a description of each switch setting.

SWITCH SET 1 SUMMARY

Position Function Factory Default

Switch SW1-1 Line Rate Off 56,000 bps

Switch SW1-2 On

Switch SW1-3 On

Switch SW1-4 Circuit Assurance Off Disabled

Switch SW1-5 Force RTS Off Enabled

Switch SW1-6 Character Length Off 10-Bit

Switch SW1-7 Data Format Off Synchronous

Switch SW1-8 DSR System Status Off Disabled

Table 1. Summary of switch settings and factory defaults

12345678

ON

ON

OFF

Page 20

17

CHAPTER 4: Configuration

Line Rate

These switches control the signaling rate on the line or RJ-48S port of the unit.

They should be set to match the speed of your digital service.

SW1-1 SW1-2 SW1-3 Setting

On On On 2.4 Kbps

On On Off 4.8 Kbps

On Off On 9.6 Kbps

On Off Off 19.2 Kbps

Off On On 56 Kbps

Off On Off 64 Kbps

Off Off Off Force configuration

pointer to default to

Hardware Switches

Circuit Assurance

The transmitter and the CTS output can be configured to go On only when a

working communication circuit is established. If Circuit Assurance is used, enable

it on only one end of the communication link.

SW1-4 Circuit Assurance Description

On Enabled CTS will go low and the transmitter will be

held off if the receiver is in the No Signal

state or CD is low

Off Disabled The transmitter and CTS will operate

without regard to the receiver state

Force RTS

The RTS input can be forced on, ignoring the terminal’s RTS signal. RTS controls

the transmitter by either sending the user’s data or sending an idle code.

SW1-5 RTS Forced On Description

Off Enabled An On (high) condition is transmitted

regardless of the state of this unit’s RTS

input

On Disabled The RTS input controls the transmitter

Page 21

18

MicroCSU/DSU Cards and MicroRacks

Character Length

In asynchronous data format, 10- and 11-bit characters are supported. This setting

is ignored in synchronous data format.

Character Description

SW1-6 Character Length Start Data bits Parity Stop bits

Off 10-bit 1 8 None 1 or more

1 7 1 1 or more

1 7 None 2

On 11-bit 1 8 1 1 or more

1 9 None 1 or more

Data Format

The data-format selection controls whether an async-to-sync conversion is

performed.

SW1-7 Data Format

On Asynchronous

Off Synchronous

DSR System Status

The behavior of the DSR output during performance of a local loop can be

controlled.

SW1-8 DSR System Status Description

On Enabled DSR remains high (On) during the

Analog Loop

Off Disabled DSR goes low (Off) during the Analog

Loop

Page 22

19

CHAPTER 4: Configuration

S

WITCHSET

2

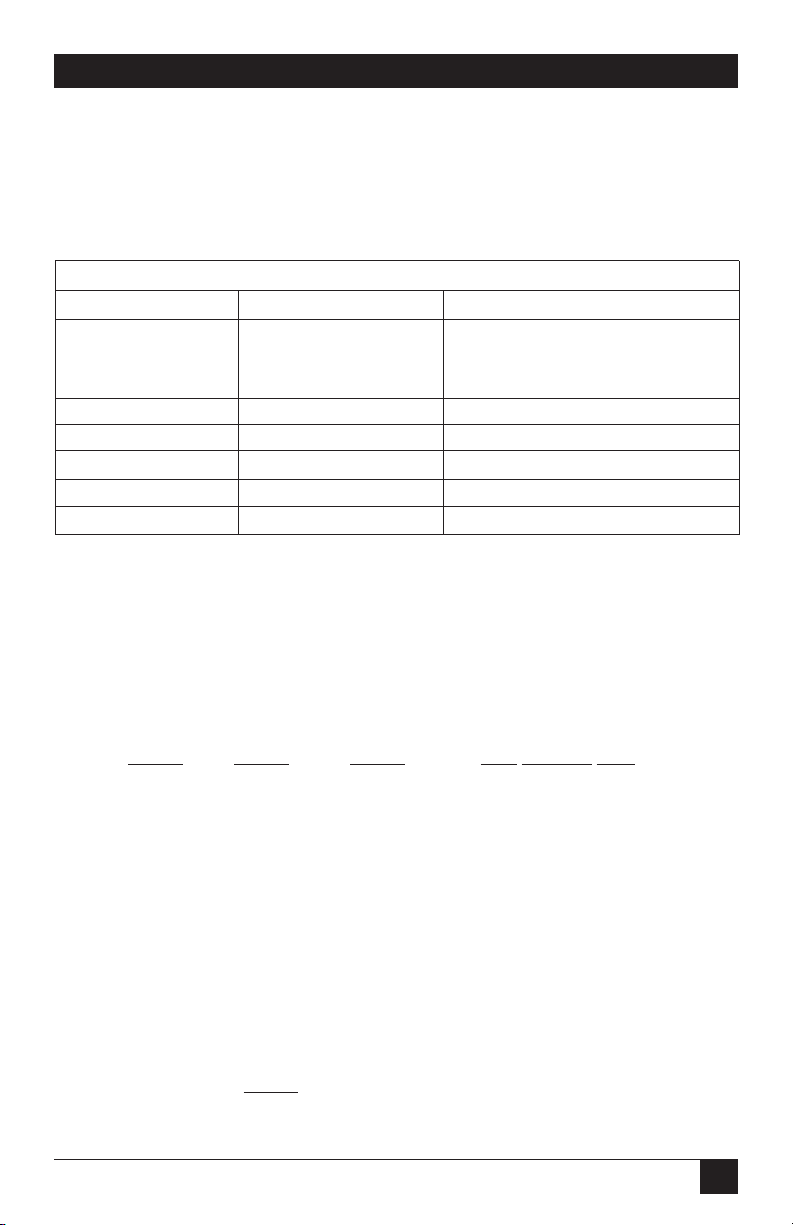

The configuration switches on switch set 2 (SW2) control the Rate Converter,

Loop Control from Terminal, Mode of Operation, Anti-Stream Timer, and CTS

Delay. Table 2 summarizes SW2 switch settings, including the factory defaults.

Following Table 2 is a description of each switch setting.

SWITCH SET 2 SUMMARY

Position Function Factory Default

Switch SW2-1 Rate Converter Off Disabled

Switch SW2-2 Off

Switch SW2-3 Off

Switch SW2-4 Loop Control from DTE Off Disabled

Switch SW2-5 Mode Off Network

Switch SW2-6 Off Clock

Switch SW2-7 Anti-Streaming Timer On Disabled

Switch SW2-8 CTS Display Off Normal

Table 2. Summary of switch settings and factory defaults

Rate Converter

The rate converter allows a 56 or 64K line rate to be used for operation at slower

data rates. If the rate converter is disabled, the DTE interface rate is the same as

the line rate.

SW2-1 SW2-2 SW2-3 DTE Interface Rate

On On On 2.4 Kbps

Off On On 4.8 Kbps

On Off On 9.6 Kbps

Off Off On 19.2 Kbps

On On Off 38.4 Kbps

Off Off Off Disabled

Loop Control from Terminal

The local loop and remote loop can be activated from the DTE interface using

signals LL and RL.

SW2-4

On Enabled LL and RL inputs

Off Disable

Page 23

20

MicroCSU/DSU Cards and MicroRacks

Mode

The mode of operation, Switched or Dedicated, is selected with these switches. The

appropriate transmitter clocking modes can be selected for Dedicated DDS or

campus-area (private) operation.

SW2-5 SW2-6 Mode Description

On Off External Clock Mode Transmit Clock derived from

terminal interface

Off Off Network Clock Mode Transmit Clock derived from

(Looped Clock Mode) from the received line signal; Use

this mode for Dedicated DDS

operation

On On Internal Clock Mode Transmit Clock derived internally

Anti-Stream Timer

The anti-stream timer protects multidrop networks from a drop that is

continuously transmitting. If the terminal keeps RTS raised for more than 30

seconds, the timer forces RTS off internally. This allows the rest of the multidrop

network to resume operation. The CSU/DSU remains in the forced-off condition

until the terminal drops RTS.

Timer Value in Sec. at Various Line Rates

SW2-7 Timer 56 19.2 9.6 4.8 2.4

On Disabled — — — — —

Off Enabled 2 4 8 15 30

CTS Delay

The RTS/CTS turn-on delay can be set to Normal or Extended.

Delay in mSec. at Various Line Rates

SW2-8 CTS Delay 56 19.2 9.6 4.8 2.4

Off Normal 0.3 0.9 1.9 3.8 7.5

On Extended 1.3 3.8 7.5 15 30

Page 24

21

CHAPTER 4: Configuration

4.2.2 S

OFTWARESWITCHES

The MicroCSU/DSU Front Card has an internal control port that allows software

configuration. Control port signals are carried to each card in the rack along the

power bus board inside the rack chassis. Access to all rack card control ports is

provided by a single control card.

Accessing the Software Control Port

Once you have set each Card’s address, plugged each front card into the rack

chassis, and properly installed the control card, you are ready to access the Main

Menu. Follow these steps:

1. Connect the serial RS-232C port of a VT100 terminal (or similar RS-232 DTE

with terminal emulation) to the EIA-561 control port on the control card.

2. Power on the terminal and set its RS-232C port as follows:

9600 baud

8 data bits, 1 stop bit, no parity

local echo

CR=CR/LF on inbound data

ANSI, VT100 emulation

3. Press [CTRL+B] on the terminal, then enter the address of the card you wish

to configure, and press [RETURN].

NOTE

Do not use the universal address [99]. Configure only one card at a

time.

The Main Menu should then display on the terminal screen.

MAIN MENU—Esc to exit menu mode

1. Select Hardware/Software Switch Control

2. Read Hardware/Software Configuration

3. Set Software Switch Parameters

4. Display Line/Loop Status

5. Set Switched 56 Parameters

Figure 4. Main Menu.

Page 25

22

MicroCSU/DSU Cards and MicroRacks

Using the Software Menu System

The Menu System operates as follows:

1. All selections must be followed by [RETURN].

2. To make a selection from any menu, enter the option number at the prompt

and press [RETURN].

3. To exit any menu without making a selection, press [ESC] followed by

[RETURN].

NOTE

You can also exit by just pressing [RETURN]. However, doing this in the

Store Phone Number Menu will clear the buffer of the currently stored

number.

Verifying Software Switch Control

In order to use software switches for configuration, you must disable the hardware

switch settings. To do this, use the following procedure.

NOTE

If this procedure is omitted, your software configurations will be

overridden by the hardware switch settings.

1. On the Main Menu, choose item 1, “Select Hardware/Software Switch

Control.” The following screen will appear:

HARDWARE/SOFTWARE CONTROL MENU—Esc to exit

1. Use Hardware Switch Control

2. Use Software Switch Control

Figure 5. Hardware/Software Control Menu.

2. In the Hardware/Software Control menu, select item 2 to enable software

switch control.

3. The Main Menu will automatically reappear after your selection is entered.

Page 26

23

CHAPTER 4: Configuration

Setting Software Switch Parameters

From the Main Menu, selecting item 3, “Set Software Switch Parameters” will take

you to the Software Switch Menu (below). From this screen, you can soft configure

the Card parameters.

SOFTWARE SWITCH MENU—Esc to exit

1. Line Rate 8. DTE Loop Control

2. Circuit Assurance 9. Clock Mode

3. RTS A. Anti-Stream Timer

4. Character Length B. RTS/CTS Delay

5. Data Frmt (Sync/Async) C. 511 Test Pattern

6. DSR Loop Status D. Remote Digital Loop

7. Rate Adapter/DTE Rate E. Local Line Loop

Figure 6. Software Switch Menu.

For each screen described next, selecting a numbered option and pressing

[RETURN] stores that option setting and returns you to the Software Switch

Menu.

NOTE

All lettered options must be entered in lower case.

Line Rate

Choosing option 1 in the Software Switch Menu takes you to the Line Rate Menu.

This option controls the signaling rate on the line. Set it to match the speed of

your digital service. For line rates of 56 or 64 Kbps, it is possible to operate the DTE

interface at a lower rate. To do this, set the line rate to 56 or 64 Kbps. Then set the

DTE Speed as required (Software Switch Menu option 7).

Page 27

24

MicroCSU/DSU Cards and MicroRacks

LINE RATE MENU—Esc to exit

1. 2400 bps 4. 19.2 Kbps

2. 4800 bps 5. 56 Kbps (DEFAULT)

3. 9600 bps 6. 64 Kbps

Figure 7. Line Rate Menu.

Circuit Assurance

Choosing option 2 in the Software Switch Menu takes you to the Circuit Assurance

Menu. On dedicated (DDS) circuits, the transmitter and the CTS output can be

configured to go ON only when a working communication circuit is established. If

you use Circuit Assurance with DDS services, enable it on only one end of the

communications link. For Switched-56 services, enable Circuit Assurance on both

ends of the circuit. When Circuit Assurance is disabled, the transmitter and CTS

operate without regard to the receiver state.

CIRCUIT ASSURANCE MENU—Esc to exit

1. Enable Circuit Assurance

2. Disable Circuit Assurance (DEFAULT)

Figure 8. Circuit Assurance Menu.

Force RTS

Choosing option 3 in the Software Switch Menu takes you to the RTS Menu. The

RTS input can be forced ON, ignoring the RTS signal from the DTE. When RTS is

forced ON, the transmitter is always enabled and the user may send data.

RTS Menu—Esc to exit

1. RTS Forced On (DEFAULT)

2. RTS Follows DTE Signal

Figure 9. RTS Menu.

NOTE

When the Line Rate (Software Switch Menu option 1) is 64 Kbps, RTS is

always forced ON, regardless of the Force RTS switch setting.

Page 28

25

CHAPTER 4: Configuration

Character Length

Choosing option 4 in the Software Switch Menu takes you to the Character Length

Menu. In asynchronous data format, the Card supports 10-bit and 11-bit character

lengths. Set this option according to the characteristics of the data being

transmitted.

CHARACTER LENGTH MENU—Esc to exit

1. 10 Bit Character Length (DEFAULT)

2. 11 Bit Character Length

Figure 10. Character Length Menu.

DTE Data Format

Choosing option 5 in the Software Switch Menu takes you to the Data Format

Menu. This option controls whether an async-to-sync conversion is performed

between the DTE and the Card. (Data is always transferred synchronously between

two Cards.) For an asynchronous DTE, select the asynchronous data format. For a

synchronous DTE, select the synchronous data format.

DATA FORMAT MENU—Esc to exit

1. Asynchronous Data Format

2. Synchronous Data Format (DEFAULT)

Figure 11. Data Format Menu.

NOTE

The async rate of 57.6 Kbps is supported at the 56 Kbps line rate,

provided the DTE equipment is configured to transmit two stop bits. The

extra stop bit reduces the DTE’s effective data rate to allow

synchronization with the 56 Kbps line speed. Set the Card for two stop

bits by selecting “11 bit character length” in the Character Length Menu.

NOTE

You can use the Card to transmit lower-speed asynchronous data (up to

9.6 Kbps) over synchronous circuits by simple over-sampling. To do

this, select the synchronous data format and set the line Line Rate

(Software Switch Menu option 1) to at least four times that

asynchronous data rate you wish to send. For example, use a Line Rate

of 9.6 Kbps or higher for 2.4 Kbps async data.

Page 29

26

MicroCSU/DSU Cards and MicroRacks

DSR Status During Local Loopback

Choosing option 6 inn the Software Switch Menu takes you to the DSR Loop Status

Menu. This option controls the behavior of the DSR output during local loopback.

To force DSR high (ON) during local loopback, enable this option. To force DSR

low (OFF) during a local loopback, disable it.

DSR LOOP STATUS MENU—Esc to exit

1. DSR On During Local Line Loop

2. DSR Off During Local Line Loop (DEFAULT)

Figure 12. DSR Loop Status Menu.

Rate Converter/DTE Rate

Choosing option 7 in the Software Switch Menu takes you to the Rate

Adapter/DTE Rate Menu. The Card rate converter adapts a 56 Kbps or 64 Kbps

line rate to slower DTE data rates. Set the Rate Converter to match the DTE data

rate. If the DTE data rate is the same as the line rate, disable rate conversion by

selecting item 6 on this menu.

RATE ADAPTER/DTE RATE MENU—Esc to exit

1. Line=56/64, DTE=2.4

2. Line=56/64, DTE=4.8

3. Line=56/64, DTE=9.6

4. Line=56/64, DTE=19.2

5. Line=56/64, DTE=38.4

6. Line Rate=DTE Rate (DEFAULT)

For 57.6, use Line Rate=DTE Rate, set Line Rate to

56 Kbps, config DTE for 2 Stop bits and set Char

Length accordingly.

Figure 13. Rate Adapter/DTE Rate Menu.

Page 30

27

CHAPTER 4: Configuration

NOTE

For DTE data rates of 56 Kbps or 64 Kbps, set the rate adapter to “Line

Rate=DTE Rate,” and set the Line Rate to 56 or 64 Kbps, respectively.

For DTE rate of 57.6 Kbps, set rate adapter to “Line Rate=DTE Rate,” set

line rate to 56 Kbps, set DTE for two stop bits, and set CSU/DSU

character length to “11 bits.”

DTE Loop Control

Choosing option 8 in the Software Switch Menu takes you to the DTE Loop

Control Menu. The local and remote loopbacks on the Card can be controlled

from the DTE interface by raising or lowering the LL and RL signals. To allow the

DTE to control these loopbacks in this manner, enable this option. Disable if you

want the Card to ignore these signals.

DTE LOOP CONTROL MENU—Esc to exit

1. Enable DTE Loop Control

2. Disable DTE Loop Control (DEFAULT)

Figure 14. DTE Loop Control Menu.

Clock Mode

Choosing option 9 in the Software Switch Menu takes you to the Clock Mode

Menu.

CLOCK MODE MENU—Esc to exit

1. Internal (Master) Clock

2. Network (Looped) Clock (DEFAULT)

3. External (DTE) Clock

4. Switched 56 Clock

Figure 15. Clock Mode Menu.

Page 31

28

MicroCSU/DSU Cards and MicroRacks

Set this option as follows:

• Internal (Master): To use the Card internal reference clock as the timing

source, select item 1. Use internal timing in point-to-point applications where

the Card is being used as a limited distance modem. (Set the far-end Card for

looped timing as described below.)

• Network (Looped): To have the Card derive a transmit clock from the

incoming data stream from the network, select item 2. This is the default

setting and appropriate for most applications.

• External (Terminal Timing): To have the Card use the DTE-supplied transmit

clock (pin 24 on an RS-232/V.24 interface or pins U and W on a V.35

interface), select item 3. Use external timing for tail-circuit applications, in

which the RS-232 or V.35 ports of two Cards are interconnected.

• Switched 56: When using a Card with Switched 56 service, select item 4.

Anti-Streaming Timer

Choosing option “a” (options “a” through “e” must be entered in lower-case

letters) in the Software Switch Menu takes you to the Anti Stream Timer Menu.

This option lets you enable or disable the anti-streaming timer, which protects

multidrop networks from a drop that is continuously transmitting. If the DTE

asserts RTS for a period of time exceeding the timer interface, the timer forces

RTS off internally. This allows the rest of the multidrop network to resume

operation. The Card holds RTS off until the terminal drops RTS. The timer

interval decreases as the line rate increases.

ANTI-STREAM TIMER MENU—Esc to exit

1. Enable Anti-Stream Timer

2. Disable Anti-Stream Timer (DEFAULT)

Figure 16. Anti-Stream Timer Menu.

Page 32

29

CHAPTER 4: Configuration

RTS/CTS Delay

Choosing option “b” in the Software Switch Menu takes you to the RTS/CTS Delay

Menu. This option lets you set the RTS/CTS turn-on delay to Normal or Extended.

The delay interval decreases as the line rate increases.

RTS/CTS DELAY MENU—Esc to exit

1. Normal RTS/CTS Delay (DEFAULT)

2. Extended RTS/CTS Delay (4xNormal)

Figure 17. RTS/CTS Delay Menu.

4.3 Rear Card Configuration

The MicroCSU/DSU Front Card has two interface card options: the

MicroCSU/DSU DB25 Rear (DB25/RJ-48S) and the MicroCSU/DSU V35 Rear

(M/34/RJ-48S). Each of these options supports one interface connection and one

4-wire connection. Figure 18 illustrates the two interface options.

Figure 18. The interface cards.

RJ-48 RJ-48

DB25 F M/34 F

MicroCSU/DSU

DB25 Rear

MicroCSU/DSU

V35 Rear

Page 33

30

MicroCSU/DSU Cards and MicroRacks

Prior to installation, you will need to examine the rear card you have selected and

make sure it is properly configured for your application. Each rear card is

configured by setting straps located on the PC board.

To configure the rear cards, you must set the configuration straps. Figure 19 shows

the orientation of these straps. Each strap can either be on pegs 1 and 2, or on

pegs 2 and 3. Sections 4.3.1 and 4.3.2 describe the strap locations and possible

settings for each rear card.

Figure 19. Orientation of interface card straps.

123 123 123

Page 34

31

CHAPTER 4: Configuration

4.3.1 M

ICRO

CSU/DSU DB25 R

EARSTRAPSETTINGS

Figure 20 shows strap locations for the MicroCSU/DSU DB25 Rear (DB25/RJ48S). These straps determine various grounding characteristics for the terminal

interface and twisted-pair lines.

Figure 20. DB25/RJ-48S strap locations.

Table 3 provides an overview of interface strap functions for the rear interface

cards. Following this overview is a detailed description of each strap’s function.

Strap Function Position 1 & 2 Position 2 & 3

JB3 DTE Shield (Pin 1) & FRGND Connected Open*

JB4 FRGND & SGND Connected Open*

NOTE: * indicates factory default

Table 3. Summary of strap settings

JB2

(Not Used)

JB3

(Peg 1 on top)

JB4

(Peg 1 on left)

Page 35

32

MicroCSU/DSU Cards and MicroRacks

DTE Shield (Pin 1) & FRGND (JB3)

In the connected position, this strap links DB25 pin 1 and frame ground. In the

open position, pin 1 is “lifted” from frame ground.

JB3

Position 1 & 2 = DTE Shield (Pin 1) and FRGND Connected

Position 2 & 3 = DTE Shield (Pin 1) and FRGND Not Connected

SGND & FRGND (JB4)

In the connected position, this strap links DB25 pin 7 (Signal Ground) and frame

ground. In the open position, pin 1 is “lifted” from frame ground.

JB4

Position 1 & 2 = SGND (Pin 7) and FRGND Connected

Position 2 & 3 = SGND (Pin 7) and FRGND Not Connected

4.3.2 M

ICRO

CSU/DSU V35 R

EARSTRAPSETTINGS

Figure 21 shows the strap location for the MicroCSU/DSU V35 Rear (M/34/RJ48S). This strap determines whether Signal Ground and Frame Ground will be

connected.

Figure 21. M/34/RJ-48S strap locations.

Page 36

33

CHAPTER 4: Configuration

SGND & FRGND (JB4)

In the connected position, this strap links Signal Ground and Frame Ground.

JB4

Position 1 & 2 = SGND and FRGND Connected

Position 2 & 3 = SGND and FRGND Not Connected

Page 37

34

MicroCSU/DSU Cards and MicroRacks

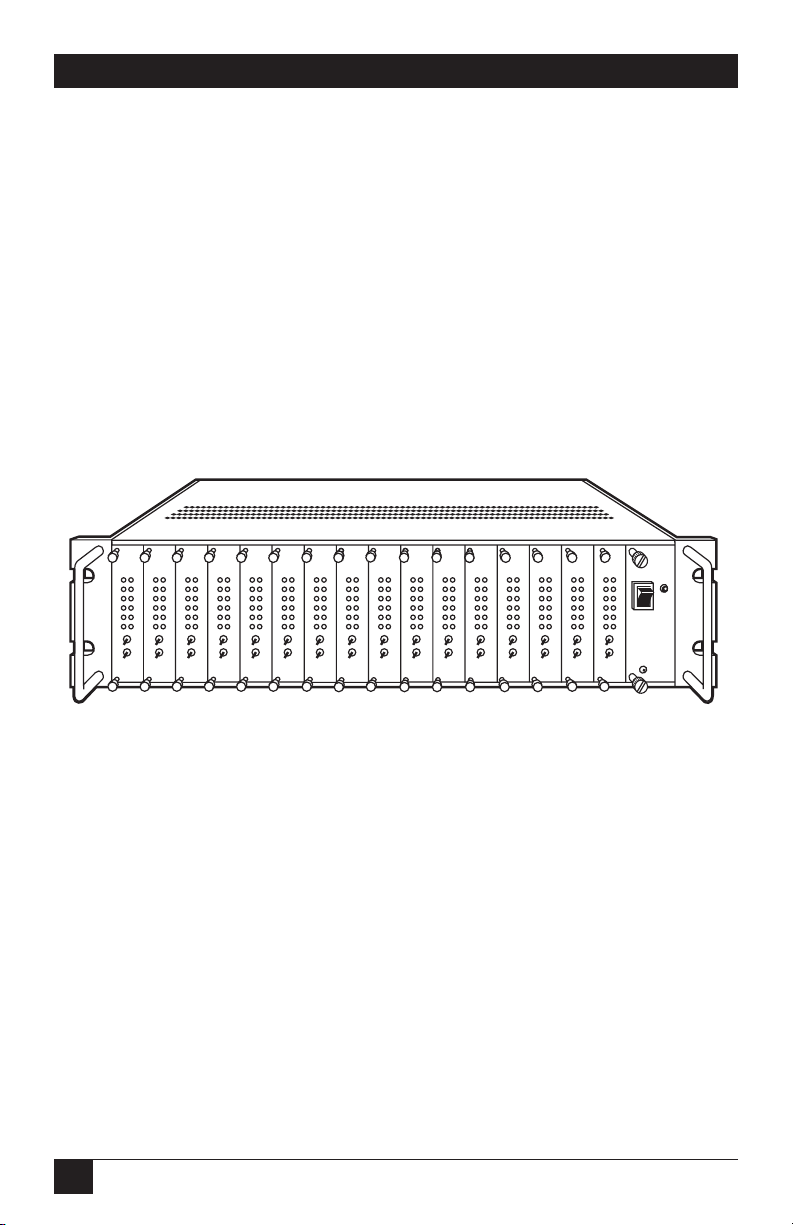

5. Installation

This chapter describes the functions of the MicroRack chassis, tells how to install

front and rear MicroCSU/DSU cards into the chassis, and provides diagrams for

wiring the interface connections correctly.

The MicroRacks come with two, four, eight, or sixteen short-range modem card

slots, plus its own power supply. Measuring only 3.5 inches high, the MicroRack

is designed to occupy only 2U in a 19-inch rack. Sturdy front handles allow the

MicroRack 16 to be extracted and transported conveniently.

Figure 22. The MicroRack 16.

The power supply consists of two cards: a front power-supply card and the rear

power entry card. The two cards meet inside the rack chassis and plug into each

other by means of a multipin connector. Use the steps on the next page as a guide

for installing the power-supply module.

ON

OFF

Power

MicroRack System

AC Power Supply

Page 38

35

CHAPTER 5: Installation

Rear (Power Entry) Card Installation

1. Attach the ground wire using the star washer and the #6-32 nut. Use a wrench

to tighten the nut securely.

2. Slide the power entry card into the back of the chassis along the metal guide

rails provided.

3. Secure the rear card using the #4-40 metal screws provided.

CAUTION

To avoid shock, do not connect power cables until the power-supply

module is fully assembled.

Front (Power Supply) Card Installation

1. Make sure the power switch is in the OFF position.

2. Slide the power-supply card into the front of the chassis. It should meet the

rear card when it’s almost all the way into the chassis.

3. Push the front card gently into the multipin connector on the rear card.

4. Secure the front card using the thumbscrews.

Rear Card Power Connection for the AC Power Supply

The PS460A rear card is equipped with a shrouded male IEC-320 AC power

interface. This interface accepts a domestic U.S. power cord or any number

of international power cords.

DC Rear Card Power Connection

The power supply’s rear card comes equipped with a cage-clamp terminal block.

The steps below will help you install the rear card.

CAUTION

Connect the equipment to a SELV DC supply source that is electrically

isolated from the AC power sources. The DC power source should also

be reliably connected to earth ground.

Page 39

36

MicroCSU/DSU Cards and MicroRacks

1. Strip back the insulation on each of the wires about a quarter of an inch.

2. Use a small flatblade screwdriver to open the cage clamp as shown in Figure

3-2. Insert the stripped portion of the wire into the opening and remove the

screwdriver. The cage clamp will clamp the wire, producing a reliable

connection. Make sure all strands of wire are captured and that there is no

exposed wire.

3. Connect the earth ground wire to the frame ground terminal.

4. Connect the +VDC power wire to the +DC In terminal. Connect the -VDC

power wire to the -DC In terminal. The power-supply card is protected against

accidental reversal of polarity. If the DC-Input LED does not light, check the

polarity of the input wiring.

5. Connect the Alarm contacts as needed by your application.

Figure 23. Connecting bare wires to the rear power-entry card.

Replacing the Power Supply Fuse

The rack chassis power supply uses a 400 mA fuse for 120-VAC circuits, and a 200

mA fuse for 240-VAC circuits. The fuse compartment is located just below the AC

socket on the rear card. To replace the fuse, follow the steps on the next page:

1) Turn the power switch off and remove the power cord.

2) Using a small screwdriver, pop the compartment open (it will slide open

like a drawer). Depending upon the exact part used, the drawer may slide

completely out of the fuse holder or it may stop partway out.

Page 40

37

CHAPTER 5: Installation

3) Note that there are two fuses in the drawer. The front fuse is the spare,

and the rear fuse is the “active” fuse.

4) If the active fuse appears to be blown, remove it from the clips and replace it

with the spare from the front compartment. Note the size and rating of the

blown fuse before discarding it.

5) Buy a replacement fuse at an electronics store. (Note: For continued

protection against the risk of fire, replace only with the same type and

rating of fuse.)

Switching the Power Supply Between 120 and 240 Volts

The power supply module should be installed in the rack chassis before any

CSU/DSU cards. Here are the steps to select the switch for the proper voltage

level.

1) Locate the two-position switch near the back of the card. Slide the switch to

the desired voltage. (Note: The actual values on the switch may be “110/220”

or “115/230.”)

2) Verify that the existing fuse is the correct value (400 mA for the 120-volt, 200

mA for the 240-volt).

3) Connect the power supply cord.

Wiring the MicroCSU/DSU

Each of the rear interface cards compatible with the MicroCSU/DSU has one

terminal interface port and one 4-wire (twisted pair) port. For specific interface

pinouts, refer to Appendix B.

Operating the Power Supply

The AC power supply has a single power LED on the front panel, which lights

when the power switch is turned on and the unit is connected to an AC power

source.

The DC power supplies feature two front-panel LEDs that indicate the condition of

the power line. The “Power ” LED will only light when the power switch is turned

on and the low voltage AC power is available to the function cards installed in the

rack. The “DC Input” LED will light whenever a power source is present (with

correct polarity), regardless of whether or not the power switch is turned on.

Page 41

38

MicroCSU/DSU Cards and MicroRacks

6. DDS Testing

The MicroCSU/DSU offers three tests to evaluate the condition of the CSU/DSUs

and the communication link: local analog loopback testing, remote digital

loopback testing, and telco testing. This section describes how to utilize each of

these test modes.

6.1 Local Analog Loopback Testing

The Local Analog Loopback (LAL) test checks the operation of the local

MicroCSU/DSU. Any data sent to the local MicroCSU/DSU in this test mode will

be echoed (returned) back to the user device. For example, characters typed on

the keyboard of a terminal will appear on the terminal screen. To perform an

Analog Loopback test, follow these steps:

1) Activate Analog Loopback. This may be done in one of two ways: by moving

the front-panel toggle switch to Analog or by raising signal LL on the terminal

interface. Once LAL is activated, the MicroCSU/DSU transmit output is

connected to its own receiver. The “test” LED should be lit.

2) Verify that the data terminal equipment is operating properly and can be used

for a test. If a fault is indicated, call your supplier.

3) Perform a BER (bit error rate) test on each unit. If the BER test equipment

indicates no faults but the data terminal indicates a fault, follow the

manufacturer’s checkout procedures for the data terminal. Also, check the

interface cable between the terminal and the MicroCSU/DSU.

CSU/DSU

Page 42

39

CHAPTER 6: DDS Testing

6.2 Remote Digital Loopback Testing

The Remote Digital Loopback (RDL) test checks the performance of both the

local and remote MicroCSU/DSUs, and the communication link between them.

Any characters sent to the remote MicroCSU/DSU in this test mode will be

returned back to the originating device. For example, characters typed on the

keyboard of the local terminal will appear on the local terminal screen after having

been passed to the remote MicroCSU/DSU and looped back. To perform an RDL

test, follow these steps:

1) Activate RDL. This may be done in two ways: by moving the front-panel toggle

switch to “Remote” or by raising the RL signal on the terminal interface.

2) Perform a BER (bit error rate) test on the system.

3) If the BER test equipment indicates a fault and the Local Analog Loopback

test was successful for both MicroCSU/DSU modems, you may have a problem

with the line between the CSU/DSUs. You should inspect the line for proper

connections.

DIGITAL

NETWORK

CSU/DSU

Page 43

40

MicroCSU/DSU Cards and MicroRacks

6.3 V.52 BER Test Generator

The MicroCSU/DSU has a built-in test pattern generator and detector. It can be

invoked at both ends of a link simultaneously, or it can be used with the Local

Analog or Remote Digital Loopback. The following example requires two

operators: one to initiate and monitor the test at the local MicroCSU/DSU

modem, and one at the remote MicroCSU/DSU modem. To use the V.52 BER

test by itself, both operators should simultaneously follow these steps:

1) Locate the “511/511E” toggle switch on the front panel of the

MicroCSU/DSU and move it to “511.” This activates the V.52 BER test mode

and transmits a “511” pseudorandom test pattern to the other unit. If any

errors are received, the receiving CSU/DSU’s red “Error” LED will blink

sporadically.

NOTE

For this test to function, the “511” switch on both MicroCSU/DSU

modems must be on.

2) If the test indicates no errors are present, move the V.52 toggle switch to the

“511/E” test. The 511/E test transmits the 511 pseudorandom test pattern and

periodically injects intentional errors. If the test is working properly, the

receiving CSU/DSU’s red “Error” LED will blink regularly. A successful 511/E

test will confirm that the link is in place, and that the MicroCSU/DSU’s builtin 511 generator and detector are working properly.

3) This test can be done by one operator by first activating the local analog loop

or remote digital loop.

6.4 Telco Testing

The digital service provider’s central office can perform CSU Loop and DSU Loop

diagnostic testing. These diagnostics allow the central office to evaluate circuit

operation without making visits to a customer’s premises.

Page 44

41

CHAPTER 6: DDS Testing

6.4.1 CSU L

OOP

The CSU Loop is activated when the central office reverses the DC sealing current

that flows between the TX pair and the RX pair. In this case, the MicroCSU/DSU

recognizes this and loops signals on the RX pair back to the central office on the

TX pair. While the CSU Loop is activated by the central office, the TM light is

illuminated.

6.4.2 DSU L

OOP

The DSU Loop is activated when the central office sends a DSU loop signal over

the twisted-pair wire. The MicroCSU/DSU senses this signal and loops the digital

data back to the central office. While the DSU Loop is activated, the TM light is

illuminated.

DSU CSU

DIGITAL

NETWORK

DSU CSU

DIGITAL

NETWORK

Page 45

42

MicroCSU/DSU Cards and MicroRacks

Appendix A. Cable

Recommendations

The MicroCSU/DSU has been tested using twisted-pair cable with the following

characteristics:

Wire Gauge Capacitance Resistance

19 AWG 83nf/mi or 15.72 pf/ft. 0.0163 ohms/ft.

22 AWG 83nf/mi or 15.72 pf/ft. 0.0326 ohms/ft.

24 AWG 83nf/mi or 15.72 pf/ft. 0.05165 ohms/ft.

For optimum performance from your MicroCSU/DSU, keep the following

guidelines in mind:

• Always use twisted-pair wire—this is not an option.

• Use twisted-pair wire with a capacitance of 20 pf/ft. or less.

• Avoid twisted-pair wire thinner than 26 AWG (in other words, avoid higher

AWG numbers than 26).

• Use of twisted pair with a resistance greater than the above specifications may

cause a reduction in maximum distance obtainable. Functionality should not

be affected.

• Many different environmental factors can affect the maximum distances

obtainable at a particular site

.

Page 46

43

APPENDIX B: Interface Pin Assignment

Appendix B. Interface Pin

Assignment

B.1 DDS Interface

The DDS Interface is an RJ-48S modular jack.

Pin # Signal

1 TX+

2 TX-

3 No connection

4 No connection

5 No connection

6 No connection

7 RX+

8 RX-

B.2 M/34 Connector, Terminal Interface

Pin # Signal

B SGND (Signal Ground)

C RTS

D CTS

E DSR

FCD

H DTR

L LL (Local Loop)

M TM (Test Mode)

N RL (Remote Loop)

PTD

RRD

S TD/

T RD/

Page 47

44

MicroCSU/DSU Cards and MicroRacks

M/34 Connector, Terminal Interface (continued)

U XTC

VRC

W XTC/

X RC/

YTC

AA TC/

B.3 DB25 Connector, Terminal Interface

Pins are assigned according to RS-232E and EIA-530 standards.

Pin # Signal

1 Frame Ground

2TD

3RD

4 RTS

5 CTS

6 DSR

7 SGND (Signal Ground)

8CD

9 /RC

11 /XTC

12 /TC

14 /TD

15 TC

16 /RD

17 RC

18 LL (Local Loop)

20 DTR

21 RL (Remote Loop)

24 XTC

25 TM (Test Mode)

Page 48

45

APPENDIX C: Transmitter Clock Source During Test Loops

Appendix C. Transmitter Clock

Source During Test Loops

Clock Analog Originating Receiving

Mode Normal Loop Remote Loop Remote Loop

Internal INT INT INT RC

External EXT INT EXT EXT

Network RC INT RC RC

RC = Receive Clock

Loading...

Loading...