Page 1

1000 Park Drive • Lawrence, PA 15055-1018 • 724-746-5500 • Fax 724-746-0746

© Copyright 1998. Black Box Corporation. All rights reserved.

Page 2

CUSTOMER

SUPPORT

INFORMATION

To order or for technical support: Call 724-746-5500 or fax 724-746-0746

Technical support and fax orders 24 hours a day, 7 days a week

Phone orders 24 hours, 7 A.M. Monday to midnight Friday; Saturday 8 to 4 (Eastern)

Mail order: Black Box Corporation, 1000 Park Drive, Lawrence, PA 15055-1018

S↔P (Serial↔Parallel) Converter (128K)

SERIAL

↔

PARALLEL CONVERTER II

FEBRUARY 1998

PI035A

PI035AE

Page 3

FEDERAL COMMUNICATIONS COMMISSION

AND

CANADIAN DEPARTMENT OF COMMUNICATIONS

RADIO FREQUENCY INTERFERENCE STATEMENTS

This equipment generates, uses, and can radiate radio frequency

energy and if not installed and used properly, that is, in strict

accordance with the manufacturer’s instructions, may cause

interference to radio communication. It has been tested and

found to comply with the limits for a Class A computing device

in accordance with the specifications in Subpart J of Part 15 of

FCC rules, which are designed to provide reasonable protection

against such interference when the equipment is operated in a

commercial environment. Operation of this equipment in a

residential area is likely to cause interference, in which case the

user at his own expense will be required to take whatever

measures may be necessary to correct the interference.

Changes or modifications not expressly approved by the party

responsible for compliance could void the user’s authority to

operate the equipment.

This digital apparatus does not exceed the Class A limits for radio

noise emission from digital apparatus set out in the Radio

Interference Regulation of the Canadian Department of

Communications.

Le présent appareil numérique n’émet pas de bruits radioélectriques

dépassant les limites applicables aux appareils numériques de

classe A prescrites dans le Règlement sur le brouillage

radioélectrique publié par le ministère des Communications du

Canada.

TRADEMARKS USED IN THIS MANUAL

IBM and AT are registered trademarks of International Business

Machines Corporation. PC/XT is a trademark of International

Business Machines Corporation.

Centronics is a registered trademark of Centronics Corporation.

HP and LaserJet are registered trademarks of Hewlett-Packard.

Page 4

Contents

Chapter Page

1.0 Specifications ........................................................................................ 1

2.0 Introduction ......................................................................................... 2

3.0 Installation ............................................................................................ 3

3.1 What You’ll Need .......................................................................... 3

3.2 Installation Procedures .................................................................. 8

4.0 Operation ........................................................................................... 13

5.0 Troubleshooting ................................................................................. 14

5.1 Common Concerns ...................................................................... 14

5.2 Calling Us ..................................................................................... 19

5.3 Shipping and Packaging .............................................................. 19

Appendix: Connector Pinouts ................................................................. 20

S↔P (SERIAL↔PARALLEL) CONVERTER (128K)

Page 5

1

CHAPTER 1: Specifications

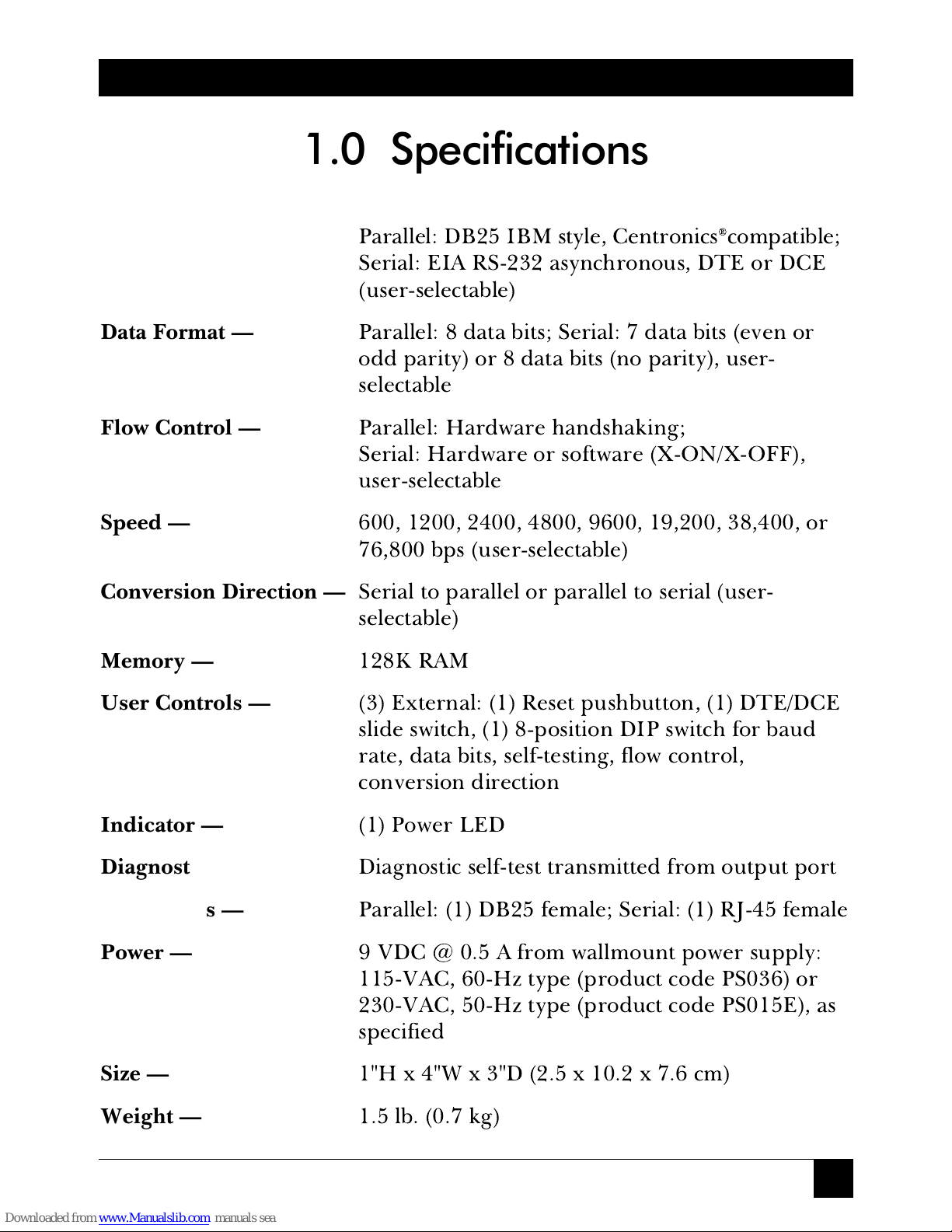

Interface —

Parallel: DB25 IBM style, Centronics®compatible;

Serial: EIA RS-232 asynchronous, DTE or DCE

(user-selectable)

Data Format —

Parallel: 8 data bits; Serial: 7 data bits (even or

odd parity) or 8 data bits (no parity), user-

selectable

Flow Control —

Parallel: Hardware handshaking;

Serial: Hardware or software (X-ON/X-OFF),

user-selectable

Speed —

600, 1200, 2400, 4800, 9600, 19,200, 38,400, or

76,800 bps (user-selectable)

Conversion Direction —

Serial to parallel or parallel to serial (user-

selectable)

Memory —

128K RAM

User Controls —

(3) External: (1) Reset pushbutton, (1) DTE/DCE

slide switch, (1) 8-position DIP switch for baud

rate, data bits, self-testing, flow control,

conversion direction

Indicator —

(1) Power LED

Diagnostic —

Diagnostic self-test transmitted from output port

Connectors —

Parallel: (1) DB25 female; Serial: (1) RJ-45 female

Power —

9 VDC @ 0.5 A from wallmount power supply:

115-VAC, 60-Hz type (product code PS036) or

230-VAC, 50-Hz type (product code PS015E), as

specified

Size —

1"H x 4"W x 3"D (2.5 x 10.2 x 7.6 cm)

Weight —

1.5 lb. (0.7 kg)

1.0 Specifications

Page 6

2

S↔P (SERIAL↔PARALLEL) CONVERTER (128K)

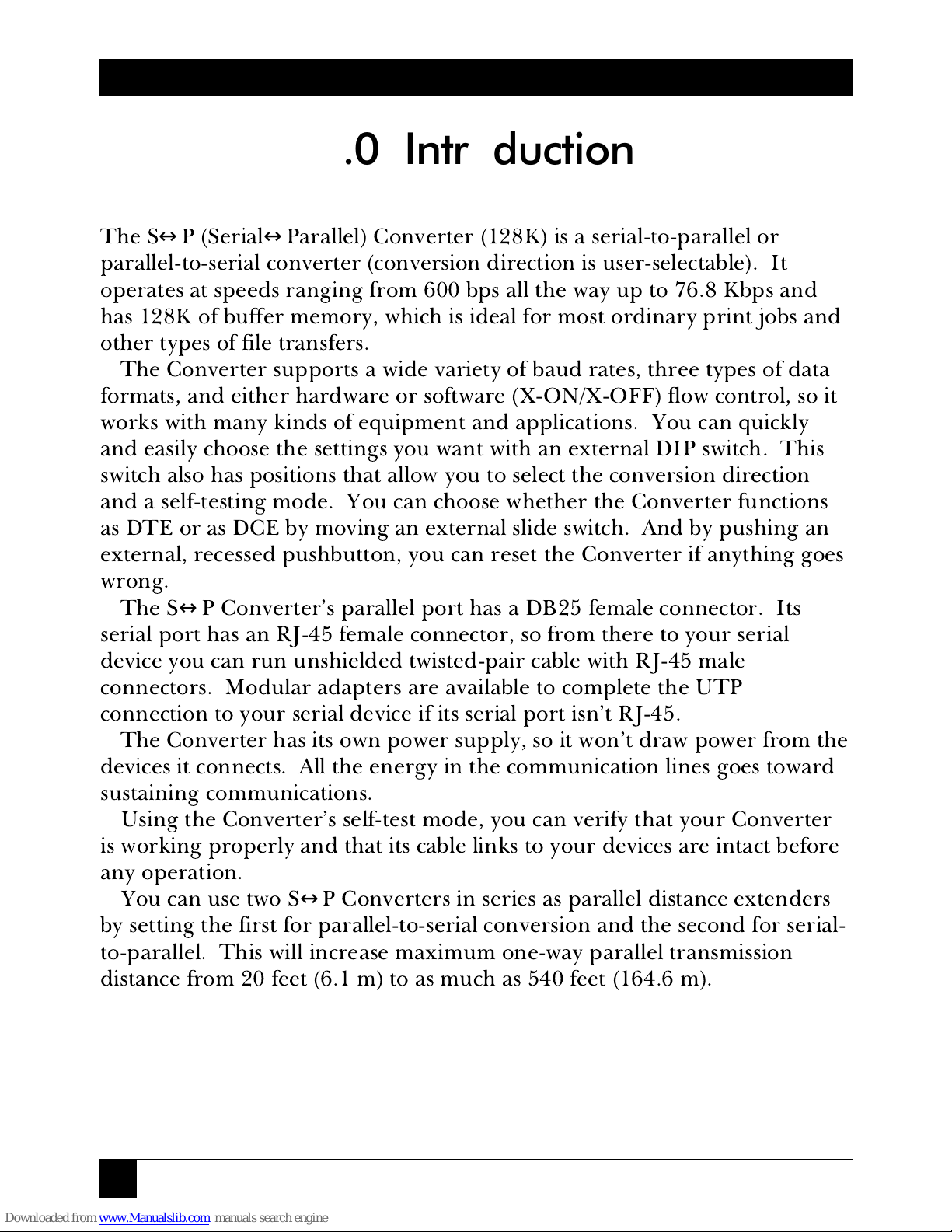

The S↔P (Serial↔Parallel) Converter (128K) is a serial-to-parallel or

parallel-to-serial converter (conversion direction is user-selectable). It

operates at speeds ranging from 600 bps all the way up to 76.8 Kbps and

has 128K of buffer memory, which is ideal for most ordinary print jobs and

other types of file transfers.

The Converter supports a wide variety of baud rates, three types of data

formats, and either hardware or software (X-ON/X-OFF) flow control, so it

works with many kinds of equipment and applications. You can quickly

and easily choose the settings you want with an external DIP switch. This

switch also has positions that allow you to select the conversion direction

and a self-testing mode. You can choose whether the Converter functions

as DTE or as DCE by moving an external slide switch. And by pushing an

external, recessed pushbutton, you can reset the Converter if anything goes

wrong.

The S↔P Converter’s parallel port has a DB25 female connector. Its

serial port has an RJ-45 female connector, so from there to your serial

device you can run unshielded twisted-pair cable with RJ-45 male

connectors. Modular adapters are available to complete the UTP

connection to your serial device if its serial port isn’t RJ-45.

The Converter has its own power supply, so it won’t draw power from the

devices it connects. All the energy in the communication lines goes toward

sustaining communications.

Using the Converter’s self-test mode, you can verify that your Converter

is working properly and that its cable links to your devices are intact before

any operation.

You can use two S↔P Converters in series as parallel distance extenders

by setting the first for parallel-to-serial conversion and the second for serial-

to-parallel. This will increase maximum one-way parallel transmission

distance from 20 feet (6.1 m) to as much as 540 feet (164.6 m).

2.0 Introduction

Page 7

3

CHAPTER 3: Installation

3.1 What You’ll Need

Before you attach any cables or turn anything on, make sure you have

everything necessary to set up your S↔P Converter (128K) system.

Each S↔P Converter comes with its own power supply and a 6-foot

(1.8-m) flat satin cable with RJ-45 male connectors. This cable can connect

the Converter to an RJ-45 serial port—or to a modular adapter attached to

a different type of serial port—on a nearby device.

What other equipment is necessary depends on whether you’re using a

single Converter

for parallel-to-serial conversion or serial-to-parallel

conversion (see the list in

Section 3.1.1

)ora

pair of Converters

as parallel

distance extenders (see the list in

Section 3.1.2

).

3.1.1 A

DDITIONALEQUIPMENTNECESSARY TO ASINGLE-CONVERTERSYSTEM

:

A.

One parallel cable

.

For

parallel-to-serial conversion:

Cable running from the Converter to a

PC’s parallel port should be fully pinned straight-through DB25-male-to-

DB25-male extension cable, up to 20 feet (6.1 m) long, that does

not

have

Pin 1 tied to the shield. Our product code for this cable is ECN25C.

For

serial-to-parallel conversion:

Cable running to a printer’s parallel

port should be standard IBM®parallel printer adapter cable. Our product

code for this cable is EYN600.

B. If the Converter is within 6 feet (1.8 m) of the serial port you need to

connect, you can use the flat satin cable that came with your unit.

Otherwise, you’ll need

one serial cable

.

Cable running from the Converter to the serial port of a device that’s

between 6 feet (1.8 m) and 50 feet (15.2 m) away should be RJ-45-male-to-

RJ-45-male unshielded twisted-pair (

not

flat satin!). Our product code for

this cable is EYN730MS-MM. If you need to connect a serial port further

away than 50 feet (15.2 m), contact us for extended distance data cable

(“EDDC”), one or more modular adapters, and the maximum cable length

you can run (this will depend on the speed of your serial device).

3.0 Installation

Page 8

4

S↔P (SERIAL↔PARALLEL) CONVERTER (128K)

Pinning

DB25 to RJ-45

2 -------------------------------------------------------------- 5

3 -------------------------------------------------------------- 6

5, 6, 8 ------------------------------------------------------- 3

7 -------------------------------------------------------------- 4

9 -------------------------------------------------------------- 8

20 ------------------------------------------------------------ 7

(For more detail, see the Appendix)

Figure 3-1. DB25 Male and Female Adapters and

Required Pinning.

FA080-R2 (Male)

FA081-R2 (Female)

Page 9

5

CHAPTER 3: Installation

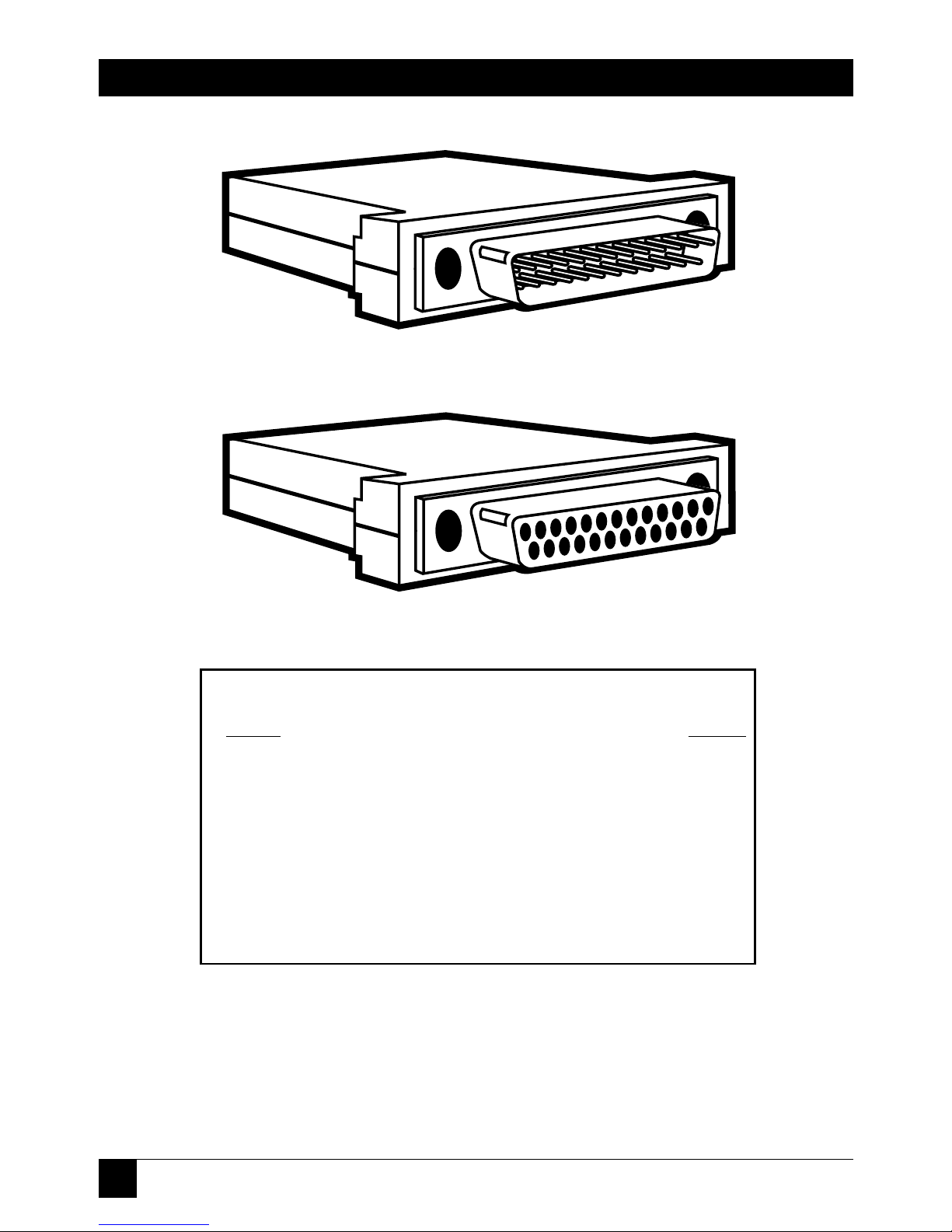

C. If the serial port you need to connect is not an RJ-45 female, you will

also need

one modular adapter

.

For

parallel-to-serial

conversion: To connect RJ-45 UTP to a printer’s

serial port, use an RJ-45-female-to-DB25-male adapter pinned as in

Figure 3-1. Our product code for this adapter is FA080-R2. Refer to

Figure 3-3 for a typical system setup using this adapter.

For

serial-to-parallel

conversion: To connect RJ-45 UTP to an IBM

PC/XT™ type computer’s serial port, use an RJ-45-female-to-DB25-female

adapter pinned as in Figure 3-1. Our product code for this adapter is

FA081-R2. To connect RJ-45 UTP to an IBM AT®type computer’s serial

port, use an RJ-45-female-to-DB9-female adapter pinned as in Figure 3-2.

Our product code for this adapter is FA082-R2. Refer to Figure 3-3 for

typical system setups using these adapters.

Pinning

DB9 to RJ-45

1, 6, 8 ------------------------------------------------------- 3

2 -------------------------------------------------------------- 6

3 -------------------------------------------------------------- 5

4 -------------------------------------------------------------- 7

5 -------------------------------------------------------------- 4

(For more detail, see the Appendix)

FA082-R2

Figure 3-2. DB9 Female Adapter and Required Pinning.

Page 10

6

S↔P (SERIAL↔PARALLEL) CONVERTER (128K)

PC

Up To 20 Ft.

(ECN25C)

Up To 50 Ft.

(EYN730MS-MM)

FROM

PARALLEL

PORT

SERIAL↔PARALLEL

CONVERTER (128K)

(PI035A*)

POWER SUPPLY

(PS035A)

SERIAL PRINTER

RJ-45 TO DB25

MALE ADAPTER

(FA080)

SIGNAL DIRECTION

PC

Up To 20 Ft.

(EYN600)

Up To 50 Ft.

(EYN730MS-MM)

SERIAL↔PARALLEL

CONVERTER (128K)

(PI035A*)

POWER SUPPLY

(PS035A)

PARALLEL PRINTER

RJ-45 TO DB25

MALE ADAPTER

(FA081)

FROM SERIAL PORT

SIGNAL DIRECTION

AT

Up To 20 Ft.

(EYN600)

Up To 50 Ft.

(EYN730MS-MM)

SERIAL↔PARALLEL

CONVERTER (128K)

(PI035A*)

POWER SUPPLY

(PS035A)

PARALLEL PRINTER

RJ-45 TO DB9

FEMALE ADAPTER

(FA082)

FROM SERIAL PORT

SIGNAL DIRECTION

Figure 3-3. Typical Setups for Each of the Three Adapters.

*NOTE: 230-VAC version is product code PI035AE. 230-VAC power supply is PS015E.

®

(FA080-R2)

(FA081-R2)

FROM SERIAL PORT

Up to 20 ft. (6.1 m)

(ECN25C)

Up to 20 ft. (6.1 m)

(EYN600)

Up to 20 ft. (6.1 m)

(EYN600)

Up to 50 ft. (15.2 m)

(EYN730MS-MM)

Up to 50 ft. (15.2 m)

(EYN730MS-MM)

Up to 50 ft. (15.2 m)

(EYN730MS-MM)

(FA082-R2)

FROM SERIAL PORT

(PS036*)

(PS036*)

(PS036*)

Page 11

7

CHAPTER 3: Installation

3.1.2 A

DDITIONALEQUIPMENTNECESSARY TO ACONVERTER-PAIRSYSTEM

:

A.

One parallel input cable

.

Cable running from one Converter to a PC’s parallel port should be

fully pinned straight-through DB25-male-to-DB25-male extension cable, up

to 20 feet (6.1 m) long, that does

not

have Pin 1 tied to the shield. Our

product code for this cable is ECN25C.

B.

One parallel output cable

.

Cable running from the other Converter to a printer’s parallel port

should be standard IBM PC parallel printer adapter cable up to 20 feet

(6.1 m) long. Our product code for this cable is EYN600.

C. If your Converters are 6 feet (1.8 m) or less away from each other,

cable running between them can be one of the flat satin cables that came

with your units. Otherwise, you’ll need

one serial cable

.

If the Converters are from 6 feet (1.8 m) to 50 feet (15.2 m) apart,

cable running between them should be RJ-45-male-to-RJ-45-male

unshielded twisted-pair (

not

flat satin!). Our product code for this cable is

EYN730MS-MM.

If the Converters are from 50 feet (15.2 m) to 500 feet (152.4 m)

apart, cable running between them should be DB25-male-to-DB25-male

extended distance data cable (“EDDC”). Our product code for this cable is

PC

Up To 20 Ft.

(ECN25C)

Up To 50 Ft.

(EYN730MS-MM)

FROM

PARALLEL

PORT

SERIAL↔PARALLEL

CONVERTER (128K)

(PI035A*)

POWER

SUPPLY

(PS035A)

PARALLEL PRINTER

Up To 20 Ft.

(EYN600)

SERIAL

↔

PARALLEL

CONVERTER (128K)

(PI035A*)

Figure 3-4. A Pair of Converters Used As

Parallel Distance Extenders.

*NOTE: 230-VAC version is product code PI035AE. 230-VAC Power supply is PS015E.

SIGNAL DIRECTION

Up to 20 ft. (6.1 m)

(ECN25C)

Up to 20 ft. (6.1 m)

(EYN600)

Up to 50 ft. (15.2 m)

(EYN730MS-MM)

(PS036*)

Page 12

8

S↔P (SERIAL↔PARALLEL) CONVERTER (128K)

EDN25C. Two DB25-female-to-RJ-45-female adapters pinned as in

Figure 3-1 should be connected to the EDDC, one at each end. Our

product code for these adapters is FA081-R2. Cable running from the

Converters’ serial ports to these modular adapters could be the two flat

satin cables that came with your units. If your system consistently garbles

transmissions or loses data, however, you might have to replace the flat

satin with two short lengths of modular UTP (the cable specified in the

previous paragraph).

3.2 Installation Procedures

To complete the installation of your S↔P Converter (128K) system, follow

the steps listed in

Section 3.2.1

if you’re using a single Converter or those

listed in

Section 3.2.2

if you’re using a pair of Converters as parallel

distance extenders.

3.2.1 S

INGLE-CONVERTERPROCEDURES

1. First locate your S↔P Converter within 20 feet (6.1 m) of your parallel

device, close to a power outlet.

2. Run your parallel cable from the parallel device to the Converter’s

parallel (DB25 female) port.

3. Run UTP or the included flat satin serial cable from the S↔P

Converter’s serial (RJ-45 female) port to the RJ-45 female serial port on:

• your serial device (if it has one),

• the appropriate adapter for a serial device that has a different type of

serial port (see Figure 3-3), or

• an RJ-45-female-to-DB25-female adapter pinned as in Figure 3-1

(FA081-R2) to convert to EDDC for a long cable run.

3A. If you haven’t already, complete the link from the Converter to your

serial device:

• If you’re running flat satin/UTP, plug the adapter into the device’s

serial port.

Page 13

9

CHAPTER 3: Installation

• If you’re running EDDC, attach the EDDC to the Converter-end

adapter and run it to your serial device. Attach its free end to the DB25

female serial port on the device or to the DB25 female connector on a

second adapter. Attach any additional cable or adapters needed at the

device end.

4. Now you’re ready to set the switches on your S↔P Converter (128K).

First set its external DTE/DCE slide switch. For the great majority of appli-

cations, this switch should be set to DCE (towards the RJ connector). Only

select DTE (switch towards the parallel connector) if your serial device is

DCE (communications equipment). For example, choose DTE if remote

users will be calling in over a modem to reach a parallel printer.

Set the Converter’s DIP switch (see Table 3-1 on the next page) for the

baud rate, data bits, and flow control settings that match those of your serial

device. (Positions are ON when down and OFF when up.) Set position 6 to

ON for the self-test mode. Set position 8 to OFF if the conversion direction

is serial to parallel or set it to ON if the direction is parallel to serial.

5. Test your setup. Make sure the output device is plugged in and

turned on, then plug in the Converter. If its DIP switch posistion 6 is ON,

the Converter will perform a diagnostic self-test and send the results to the

output device. Data sent includes the name of the Converter, the settings of

its switches, and verification of a proper cable link with its output port.

After this point the unit performs a continuous “barber pole” test, which

you can watch as it scrolls on your output device’s printout or screen. If

something seems to be wrong, see

Chapter 5: Troubleshooting

. If you’re

satisfied that the system is working properly, go on to Step 6.

6. Reset the Converter. Either (1) unplug it, set DIP switch position 6 to

OFF, and plug it back in, or (2) set position 6 to OFF while it’s still plugged

in and then hit the reset button.

7. Make sure the input device is plugged in and turned on. Your S↔P

Converter (128K) system is now ready for continuous operation.

Page 14

10

S↔P (SERIAL↔PARALLEL) CONVERTER (128K)

Option Switch Position*

1234567 8

Baud Rate

76800 OFF OFF OFF

38400 ON OFF OFF

19200 OFF ON OFF

9600 ON ON OFF

4800 OFF OFF ON

2400 ON OFF ON

1200 OFF ON ON

600 ON ON ON

Data Bits/Parity

8, no parity OFF OFF

or

ON OFF

7, odd parity OFF ON

7, even parity ON ON

Self-Test

Normal Operation OFF

Self-Test ON

Flow Control

Hardware OFF

X-ON/X-OFF ON

Direction

Serial to Parallel OFF

Parallel to Serial ON

*Positions are ON when down and OFF when up.

Table 3-1. DIP Switch Settings for

S↔P (Serial↔Parallel) Converter (128K)

Page 15

11

CHAPTER 3: Installation

3.2.2 C

ONVERTER-PAIRPROCEDURES

1. First locate each Converter within 20 feet (6.1 m) of its associated

parallel device, close to a power outlet.

2. Run your parallel input cable from the PC (or whatever device is

transmitting) to the input-side Converter’s parallel (DB25 female) port.

3. Run UTP or the included flat satin serial cable from the input-side

Converter’s serial (RJ-45 female) port to the RJ-45 female serial port on:

• the output-side S↔P Converter, or

• an RJ-45-female-to-DB25-female adapter pinned as in Figure 3-1

(FA081-R2) to convert to EDDC for a long cable run.

3A. If you’re running EDDC, complete the link between the Converters.

Run the EDDC, attach the output-side FA081-R2 adapter, and run the

second length of UTP or flat satin.

4. Finish your cabling installation by running your parallel ouput cable

from the output-side Converter to the parallel printer (or whatever device

is receiving).

5. Now you’re ready to set the switches on your S↔P Converters (128K).

First set their external DTE/DCE slide switches to complement each other:

one as DCE (switch towards the RJ connector) and the other as DTE (switch

towards the parallel connector; it doesn’t matter which Converter gets

which setting). Then set their DIP switches (see Table 3-1; positions are

ON when down and OFF when up).

Set positions 1 through 5 and 7 identically: Whichever settings you

choose for one Converter should be the same on the other. It won’t make

much difference whether you choose hardware or software flow control.

We recommend 9600 baud for distances up to 500 feet (152.4 m), but if you

don’t need to transmit that far, you may be able to use higher speeds;

contact your dealer for assistance in determining your maximum baud rate.

Finally, using 8 bits with no parity will give you slightly higher throughput

than 7-bit word structures.

Page 16

12

S↔P (SERIAL↔PARALLEL) CONVERTER (128K)

Set DIP switch position 8 to ON (parallel to serial conversion) on the S↔P

Converter connected to the input (transmitting) device and to OFF (serial

to parallel conversion) on the Converter connected to the output (receiving)

device. Set switch position 6 to ON for self-test mode on the output-side

Converter and to OFF for normal operation on the input-side unit (setting

both to ON at the same time might yield misleading self-test results).

6. Test your setup. Make sure the output device is plugged in and

turned on, then plug in the output-side Converter. It will perform a

diagnostic self-test and send the results to the output device. Data sent

includes the name of the Converter, the settings of its switches, and

verification of a proper cable link with its output port. After this point the

unit performs a continuous “barber pole” test, which you can watch as it

scrolls on your output device’s printout or screen. If something seems to be

wrong, see

Chapter 5: Troubleshooting

. If you’re satisfied that the output

side of the system is working properly, go to Step 7.

7. Unplug both Converters, reverse the settings of switch position 6 on

both units, replug the output-side Converter and then the input-side one.

Observe the input-side unit’s self-test. If something doesn’t seem right, see

Chapter 5

. Otherwise, go to Step 8.

8. Reset the input-side Converter. Either (1) unplug it, set DIP-switch

position 6 to OFF, and plug it back in, or (2) set position 6 to OFF while it’s

still plugged in and then hit the reset button.

9. Make sure the input device is plugged in and turned on. Your S÷P

Converter (128K) system is now ready for continuous operation.

Page 17

13

CHAPTER 4: Operation

Once you’ve installed the S↔P Converter (128K), run a few test

transmissions. If one or more don’t get through intact, see

Chapter 5:

Troubleshooting

.

If at any time something goes wrong with a transmission, you can press

the Reset button to reset the Converter without having to unplug it or

restart your devices. Also see

Chapter 5

for troubleshooting suggestions.

After the Converter is up and working properly, few adjustments should

be necessary. Every so often, especially (1) at system boot time if your

system is powered down frequently or (2) any time your system performance

seems to deteriorate, you might want to set the Converter to perform its

self-test (DIP switch position 6 to ON). The self-test could reveal, or make it

easier to diagnose, a problem. If a problem does become evident, see

Chapter 5

.

Any time you upgrade or replace a serial device connected to your S↔P

Converter, reposition the Converter’s baud-rate, word-structure, flow-

control, and DTE/DCE switches as necessary.

4.0 Operation

Page 18

14

S↔P (SERIAL↔PARALLEL) CONVERTER (128K)

5.1 Common Concerns

This section lists some problems that might come up during installation or

operation of the S↔P Converter (128K), along with some solutions.

5.1.1 THEC

ONVERTER’SPOWER

LED D

OESN’TLIGHTUP

1. Make sure the Converter’s power supply is firmly mounted in the

outlet. If it is, go to Step 2.

2. Try a different outlet, or test the outlet you have been attempting to

use by plugging another device into it. If the outlet isn’t supplying power,

it might have to be repaired before you can use it.

3. If the problem isn’t solved, the power supply might be bad. If you

have another power supply that supplies the same voltage and has a

compatible type of output plug, try replacing the original.

4. If the problem still isn’t solved, call us.

5.1.2 THEC

ONVERTER’SPOWER

LED L

IGHTSUP

, B

UT ATRANSMISSIONWAS

G

ARBLED ORDIDN’TGETTHROUGHATALL

or

IP

RESSED THERESETBUTTONBUTNOTHINGHAPPENED

A. Single-Converter Systems Only:

1. Make sure the attached devices are plugged in and turned on. If

they are, go to Step 2.

2. Make sure all of your cables are firmly seated at both ends. Make

sure any adapter you have plugged directly into a device’s serial port is also

firmly seated. If all cable and adapter connections are solid, go to Step 3.

3. The transmitting device or its software might have crashed. If the

transmitting device and its application appear to be functioning normally,

go to Step 4.

5.0 Troubleshooting

Page 19

15

4. Check the Converter’s DTE/DCE slide switch and the word-

structure and flow-control settings of its DIP switch. If they are correctly set

for communication with your serial device, go to Step 5.

5. A cable run may be too long. Cable length for parallel communica-

tion must not exceed 20 feet (6.1 m) between any pair of devices; serial

cable length must not exceed 50 feet (15.2 m) for UTP or 500 feet (152.4 m)

for extended distance data cable. If either of your devices is too far from

the S↔P Converter, move the Converter or move the device.

6. If the problem isn’t solved, run the Converter’s self-test by setting

its DIP switch position 6 to ON. If the self-test data is not transmitted

properly to the output device, you can concentrate on the ouput device and

cable as you search for the cause of the problem. If the data is transmitted

properly, you can concentrate on the input device, its software, and the

input cable. go to Step 7.

7. A cable might be broken. Visually inspect the length of your cables

or continuity-test them. You can also try replacing the cable with identical

cable you know is OK.

8. If the problem isn’t solved, a cable or an adapter may be pinned

incorrectly. Any parallel cable connecting the parallel ports of your

Converter and a PC (RS-232 extension cable), as well as any UTP or EDDC

serial cable, should be pinned straight-through. This means that a single

wire connects Pin 1 at one end to Pin 1 at the other end. Likewise Pin 2 is

wired to Pin 2, 3 to 3, and so on. Also, the RS-232 extension cable must not

have Pin 1 tied to the shield.

If you’re using an adapter compatible with one of those shown in

Figures 3-1 and 3-2, compare the pinning in the charts in Figure 3-1 or 3-2

and in the Appendix with the pinning listed in your adapter’s

documentation (do

not

disassemble the adapter). If you’re unable to

determine the pinning of your adapter, or if you’re using an adapter with a

different type of connector, call us.

9. If the problem isn’t solved, check the hardware and software

configurations of the attached devices. If possible, test both of your devices

by detaching them from the S↔P Converter and connecting them to

different equipment (serial device to serial device, parallel device to parallel

device). Attempt communication through the same serial or parallel port

you were using when the problem occurred. If possible, use the same serial

CHAPTER 5: Troubleshooting

Page 20

16

S↔P (SERIAL↔PARALLEL) CONVERTER (128K)

or parallel cable, or an identical cable you know is OK. If communication

goes smoothly for both of your devices and their associated cables when the

Converter isn’t involved, go to Step 10.

If there is still a problem after you make these substitutions, any of

several device-related difficulties may be occurring. Some examples:

• One of the attached devices might be set up to communicate

through the wrong port.

• One of the device ports is broken.

• One of the attached devices or its software may be hitting a fault

(a bug in its programming) when it tries to communicate.

• A software package or a driver on one device might be incompatible

with the other device.

The problem could also be highly application-specific. For example,

the polarity option on HP®LaserJet®printers is often set incorrectly. You

might want to consult the manuals of the devices and software involved in

the problem as you carefully investigate your application.

10. If the problem still isn’t solved, call us.

B. Converter-Pair (Parallel Distance Extension) Systems Only

1. Make sure the attached devices are plugged in and turned on. If

they are, go to Step 2.

2. Make sure all of your cables are firmly seated at both ends. If all

cable connections are solid, go to Step 3.

3. The transmitting device or its software might have crashed. If the

transmitting device and its application appear to be functioning normally,

go to Step 4.

4. Check the Converters’ DTE/DCE slide switches and the word-

structure and flow-control settings of their DIP switches. If they are

correctly set for communication with each other (see

Section 3.2.2, Step 5

),

go to Step 5.

Page 21

17

5. A cable run may be too long. Cable length for parallel communica-

tion must not exceed 20 feet (6.1 m) between any pair of devices; serial

cable length must not exceed 50 feet (15.2 m) for UTP or 500 feet (152.4 m)

for extended distance data cable. If either of your devices is too far from

the S↔P Converter it’s directly attached to, move the Converter or move

the device. If your Converters are too far from each other, move one of

them and, if necessary, its attached device.

6. If the problem isn’t solved, run the self-test on the output-side

Converter by setting its DIP switch position 6 to ON. If the self-test data is

not transmitted properly to the output device, you can concentrate on the

ouput device and cable as you search for the cause of the problem—turn

the self-test off and go to Step 8. If the data is transmitted properly, go to

Step 7.

7. Reverse the settings of position 6 on the two Converters, so that the

one on the output side is back to normal operation and the one on the

input side runs the self test. If the input-side self-test data is transmitted

properly, you can concentrate on the input device, its software, and the

input cable as you search for the cause of the problem. If the data is not

transmitted properly, you can concentrate on the cable and any adapters

between the Converters. Turn the self-test off and go to Step 8.

8. A cable might have come loose. If all cables are firmly seated, go to

Step 9.

9. A cable might be broken. Visually inspect the length of your cables

or continuity-test them. You can also try replacing the cable with identical

cable you know is OK.

10. If the problem isn’t solved, a cable or an adapter may be pinned

incorrectly. Any parallel cable connecting the parallel ports of your

Converter and a PC (RS-232 extension cable), as well as any UTP or EDDC

serial cable, should be pinned straight-through. This means that a single

wire connects Pin 1 at one end to Pin 1 at the other end. Likewise Pin 2 is

wired to Pin 2, 3 to 3, and so on. Also, the RS-232 extension cable must not

have Pin 1 tied to the shield.

If you’re using a pair of adapters with EDDC, compare the FA081-R2

adapter pinning listed in Figure 3-1 and in the Appendix with the pinning

listed in your adapter’s documentation (do

not

disassemble the adapter). If

you’re unable to determine the pinning of your adapter, or if you’re using

an adapter with a different type of connector, call us.

CHAPTER 5: Troubleshooting

Page 22

18

S↔P (SERIAL↔PARALLEL) CONVERTER (128K)

11. If the problem isn’t solved, check the hardware and software

configurations of the attached devices. If possible, test both of your devices

by detaching them from the S↔P Converter and connecting them to each

other with your input or output cable. Attempt communication through

the same parallel ports you were using when the problem occurred. If

communication goes smoothly for both of your devices and their associated

cables when the Converter isn’t involved, go to Step 12.

If there is still a problem after you make these substitutions, any of

several device-related difficulties may be occurring. Some examples:

• One of the attached devices might be set up to communicate

through the wrong port.

• One of the parallel ports you are using is broken.

• One of the attached devices or its software may be hitting a fault

(a bug in its programming) when it tries to communicate.

• A software package or a driver on one device might be incompatible

with the other device.

The problem could also be highly application-specific. For example,

the polarity option on HP LaserJet printers is often set incorrectly. You

might want to consult the manuals of the devices and software involved in

the problem as you carefully investigate your application.

12. If the problem still isn’t solved, call us.

5.1.3 I’

MLOSINGDATA

1. Check the word-structure and flow-control settings of the Converter’s

DIP switch. If they are correctly set to match your serial device, go to

Step 2.

2. The transmission may have overflowed the buffer. There’s a very

good chance of this if you are sending files with lots of graphics. Try

breaking such files into smaller pieces.

3. If the problem isn’t solved, call us.

Page 23

19

CHAPTER 5: Troubleshooting

5.2 Calling Us

If your Serial↔Parallel Converter (128K) seems to be malfunctioning,

do not

attempt to alter or repair the unit.

Contact us; the problem might be solvable

over the phone.

Before you do, make a record of the history of the problem. We’ll be able

to provide more efficient and accurate assistance if you have a complete

description, including:

• the nature and duration of the problem

• when the problem occurs

• the components involved in the problem

• any particular application that, when used, appears to create the

problem or make it worse

5.3 Shipping and Packaging

If you need to transport or ship your Serial↔Parallel Converter (128K):

• Carefully package the Converter. We recommend that you use the

original container.

• If you are shipping the Converter for return or repair, make sure you

include its power supply and this manual. Before you ship, contact

your supplier to get a Return Materials Authorization (RMA) number.

Page 24

A.1 Serial Connectors of Converter and Adapters

The first column shows the pinning of the S↔P Converter’s RJ-45

connector, the second column shows the pinning of the DB25 connectors of

the FA080-R2 and FA081-R2 adapters, and the third column shows the

pinning of the FA082-R2 adapter’s DB9 connector. Straight-through-

pinned RJ-45 cable must be run between the Converter and any of these

adapters. This pinout is not affected by whether the Converter is set for

serial-to-parallel or parallel-to-serial operation.

Pin Numbers Signal Function Direction, Converter set as:

RJ-45 DB25 DB9 DCE DTE

3 5 1 CTS Flow Control From Converter To Converter

6 6 DSR

88 CD

4 7 5 SGD Signal Ground

5 2 3 RXD Receive Data To Converter From Converter

6 3 2 TXD Transmit Data From Converter To Converter

7 20 4 DTR Flow Control To Converter From Converter

8 9 +10V Steady Positive

Voltage

20

S↔P (SERIAL↔PARALLEL) CONVERTER (128K)

Appendix: Connector Pinouts

Page 25

21

APPENDIX: Connector Pinouts

A.2 The Converter’s Parallel Connector

This pinout is not affected by whether the Converter is set as DCE or DTE.

Pin No. Function Direction, Converter set for:

Serial to Parallel* Parallel to Serial

1 Strobe From Converter To Converter

2 Data Bit 1 From Converter To Converter

3 Data Bit 2 From Converter To Converter

4 Data Bit 3 From Converter To Converter

5 Data Bit 4 From Converter To Converter

6 Data Bit 5 From Converter To Converter

7 Data Bit 6 From Converter To Converter

8 Data Bit 7 From Converter To Converter

9 Data Bit 8 From Converter To Converter

10 Acknowledge To Converter From Converter

11 Busy To Converter From Converter

12 (Paper Empty) No Connection

13 Select Held High

14 No Connection

15 Fault Held High

16 Input Prime Held High

17 No Connection

18 Ground Ground

19 Ground Ground

20 Ground Ground

21 Ground Ground

22 Ground Ground

23 Ground Ground

24 Ground Ground

25 Ground Ground

*The strobe’s duration is 2 microseconds long in units with serial number

94010763, Version 1.2. If you have a problem with garbled data during

serial to parallel conversion, please contact us.

Page 26

NOTES

Loading...

Loading...