Page 1

Order toll-free in the U.S. 24 hours, 7 A.M. Monday to midnight Friday: 877-877-BBOX

FREE technical support, 24 hours a day, 7 days a week: Call 724-746-5500 or fax 724-746-0746

Mail order: Black Box Corporation, 1000 Park Drive, Lawrence, PA 15055-1018

Web site: www.blackbox.com • E-mail: info@blackbox.com

CUSTOMER

SUPPORT

INFORMATION

APRIL 1999

PCA35A-R3

PCA35AE-R2

PS035A

PS034E

PQ-6 PLUS (RO)

Receive-only printer interface for IBM®System 3X and AS/400

LINE

SYNC

DTR

DATA

OUT

TEST PWR

PQ-6 Plus (RO)

START

STOP

TEST

LF

FF

Page 2

PQ-6 PLUS (RO)

1

FEDERAL COMMUNICATIONS COMMISSION

AND

INDUSTRY CANADA

RADIO FREQUENCY INTERFERENCE STATEMENTS

This equipment generates, uses, and can radiate radio frequency energy and if not installed and used

properly, that is, in strict accordance with the manufacturer’s instructions, may cause interference to radio

communication. It has been tested and found to comply with the limits for a Class A computing device

in accordance with the specifications in Subpart J of Part 15 of FCC rules, which are designed to provide

reasonable protection against such interference when the equipment is operated in a commercial

environment. Operation of this equipment in a residential area is likely to cause interference, in which

case the user at his own expense will be required to take whatever measures may be necessary to correct

the interference.

Changes or modifications not expressly approved by the party responsible for compliance could void the

user’s authority to operate the equipment.

This digital apparatus does not exceed the Class A limits for radio noise emission from digital apparatus set out in the

Radio Interference Regulation of Industry Canada.

Le présent appareil numérique n’émet pas de bruits radioélectriques dépassant les limites applicables aux appareils

numériques de la classe A prescrites dans le Règlement sur le brouillage radioélectrique publié par Industrie Canada.

Page 3

PQ-6 PLUS (RO)

2

INSTRUCCIONES DE SEGURIDAD (Normas Oficiales Mexicanas Electrical Safety Statement)

1. Todas las instrucciones de seguridad y operación deberán ser leídas antes de que el aparato eléctrico sea operado.

2. Las instrucciones de seguridad y operación deberán ser guardadas para referencia futura.

3. Todas las advertencias en el aparato eléctrico y en sus instrucciones de operación deben ser respetadas.

4. Todas las instrucciones de operación y uso deben ser seguidas.

5. El aparato eléctrico no deberá ser usado cerca del agua—por ejemplo, cerca de la tina de baño, lavabo, sótano

mojado o cerca de una alberca, etc..

6. El aparato eléctrico debe ser usado únicamente con carritos o pedestales que sean recomendados por el fabricante.

7. El aparato eléctrico debe ser montado a la pared o al techo sólo como sea recomendado por el fabricante.

8. Servicio—El usuario no debe intentar dar servicio al equipo eléctrico más allá a lo descrito en las instrucciones de

operación. Todo otro servicio deberá ser referido a personal de servicio calificado.

9. El aparato eléctrico debe ser situado de tal manera que su posición no interfiera su uso. La colocación del aparato

eléctrico sobre una cama, sofá, alfombra o superficie similar puede bloquea la ventilación, no se debe colocar en

libreros o gabinetes que impidan el flujo de aire por los orificios de ventilación.

10. El equipo eléctrico deber ser situado fuera del alcance de fuentes de calor como radiadores, registros de calor,

estufas u otros aparatos (incluyendo amplificadores) que producen calor.

11. El aparato eléctrico deberá ser connectado a una fuente de poder sólo del tipo descrito en el instructivo de

operación, o como se indique en el aparato.

12. Precaución debe ser tomada de tal manera que la tierra fisica y la polarización del equipo no sea eliminada.

13. Los cables de la fuente de poder deben ser guiados de tal manera que no sean pisados ni pellizcados por objetos

colocados sobre o contra ellos, poniendo particular atención a los contactos y receptáculos donde salen del aparato.

14. El equipo eléctrico debe ser limpiado únicamente de acuerdo a las recomendaciones del fabricante.

15. En caso de existir, una antena externa deberá ser localizada lejos de las lineas de energia.

16. El cable de corriente deberá ser desconectado del cuando el equipo no sea usado por un largo periodo de tiempo.

17. Cuidado debe ser tomado de tal manera que objectos liquidos no sean derramados sobre la cubierta u orificios de

ventilación.

18. Servicio por personal calificado deberá ser provisto cuando:

A: El cable de poder o el contacto ha sido dañado; u

B: Objectos han caído o líquido ha sido derramado dentro del aparato; o

C: El aparato ha sido expuesto a la lluvia; o

D: El aparato parece no operar normalmente o muestra un cambio en su desempeño; o

E: El aparato ha sido tirado o su cubierta ha sido dañada.

Page 4

PQ-6 PLUS (RO)

3

TRADEMARKS

The trademarks mentioned in this manual are the sole property of their owners.

Page 5

PQ-6 PLUS (RO)

4

CONTENTS

1. Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

2. Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2.1 Application . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2.2 Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

3. Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

3.1 Initial Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

3.1.1 Installing a Supported Printer. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

3.1.2 Power Supply and Grounding of the PQ-6 PLUS (RO) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

3.1.3 Off-Line Test of PQ-6 (RO) and Printer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

3.2 System Configuration and Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

3.2.1 PQ-6 PLUS (RO) Address Selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

3.2.2 System Configuration Reset. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

3.2.3 Printer Codes for Pitch and Density . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

3.3 Placing the PQ-6 in Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

4. Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

4.1 Operator Controls and Indicators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

4.1.1 Function Switches. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

4.1.2 Indicator Lights . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

4.2 Setup Mode. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

4.3 Command Pass Through . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

4.4 Buffer Print Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

4.4.1 Printout Format . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

4.4.2 Data Interpretation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

4.4.3 Notes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

4.5 Functions and Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Appendix A: PQ-6 PLUS (RO) EBCDIC to ASCII Translation Table. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Appendix B: Quick Reference Guide for PQ-6 PLUS (RO) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Page 6

PQ-6 PLUS (RO)

5

1. Specifications

Controls—PCA35A-R3, PCA35AE-R2: Reset, Start, Stop, LF, FF, Test

Speed—Serial port, 50 bps to 19.2 kbps

Interface—IBM twinaxial; RS-232/V.24 DCE asynchronous or Centronics type parallel

Connectors—(1) DB15 male with twinax V, (1) DB25 female

Indicators—(5) LEDs: DTR, Line Sync, Power, Test, Data Out

Temperature—Operating: 40 to 100 °F (5 to 42 °C);

Storage: -40 to 140 °F (-40 to 60 °C)

Humidity—0 to 95% noncondensing

MTBF—50,000 hours

Power—PCA35A-R2: 115-VAC, 60-Hz wallmount transformer (part number PS035A);

PCA35AE-R2: 230-VAC, 50-Hz (part number PS034E)

Size—PCA35A-R3, PCA35AE-R2: 2.1"H x 8.8"W x 11.5"D (5.3 x 22.4 x 29.2 cm)

Weight—PCA35A-R3, PCA35AE-R2: 4 lb. (1.9 kg)

Page 7

PQ-6 PLUS (RO)

6

2. Introduction

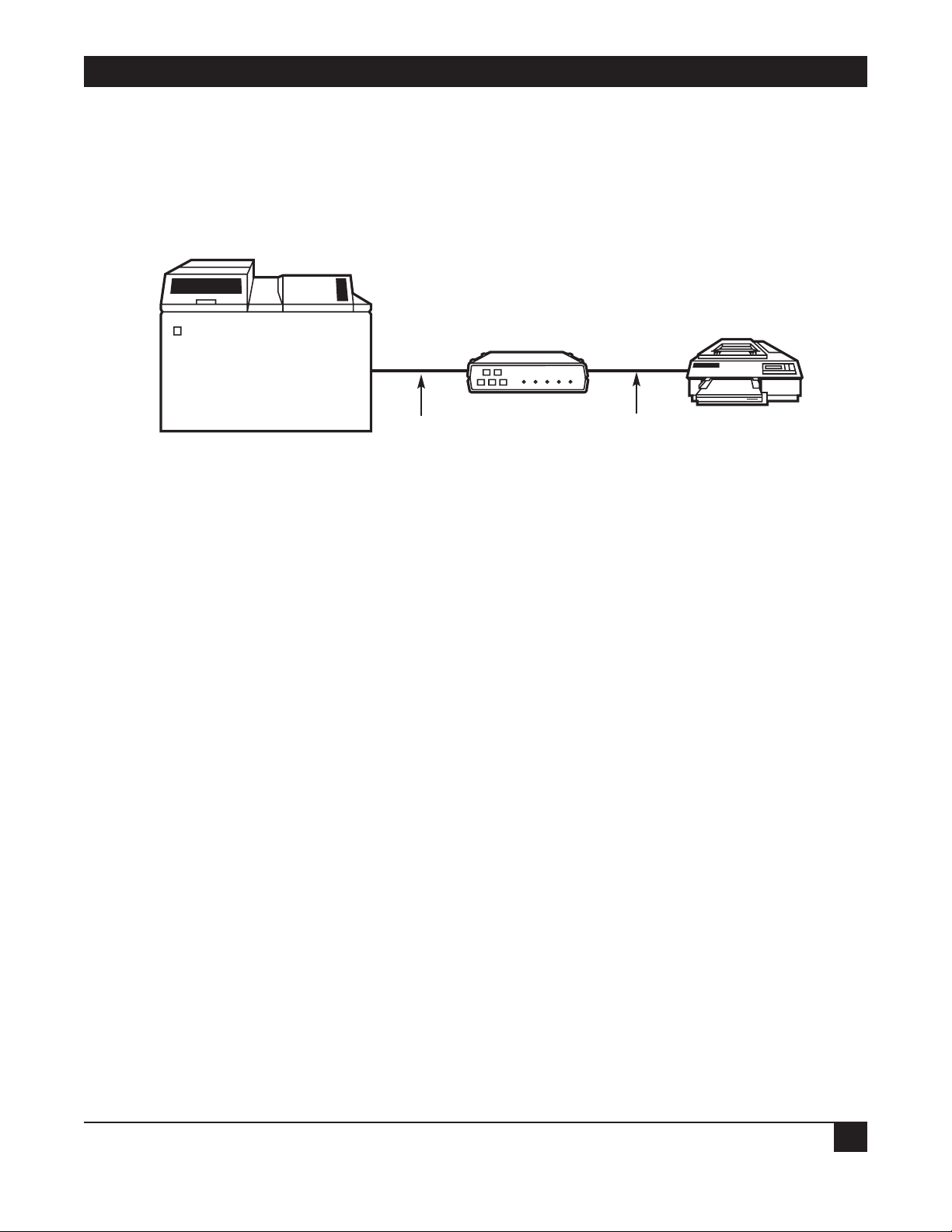

2.1 Application

The PQ-6 PLUS (RO) is a “receive-only” microprocessor-based printer interface for the IBM System/34,

System/36, and System/38 computers. It allows a printer with an RS-232 or Centronics compatible port to

interface with IBM twinaxial cable via a male DB15 and twinax “pigtail” cable. Device address and serial or

parallel output are switch selectable, and the baud rate is selectable in 16 settings from 50 to 19,200 bps.

XON/XOFF and DTR are supported by the PQ-6 PLUS (RO) for buffer control. Data format is 7 bits, space

parity, 1 stop or 8 data bits, no parity, 1 stop bit.

2.2 Description

Data and commands are received from the twinax cable serially (1-MHz clock) by the proprietary front-end

processor of the PQ-6 PLUS (RO). Those commands and data addressed to the PQ-6 PLUS (RO) as

determined by the device address selection switches, are passed to the Z-80A microprocessor for further

processing. The Z-80A CPU converts EBCDIC to ASCII and makes the protocol conversions it needs to change

the high-speed synchronous twinax input into an asynchronous RS-232 ASCII output or Centronics compatible

output. You may bypass the EBCDIC to ASCII controller to the printer using the PQ-6 PLUS (RO) commandpassthrough feature (see Section 4.3).

Input data from the controlling host consists of data and command sequences normally interpreted by an

IBM 5256, 5224, and 5225 printer. In addition to printable characters and carriage-control characters (such as

new line, carriage return, and line feed), the controlling host can send command sequences to control output

format. These commands include page width, page length, characters-per-inch, and horizontal and vertical

carriage-positioning sequences. The PQ-6 PLUS (RO) interprets these command sequences and outputs ASCII

characters to perform the appropriate function. For example, when a form length command is received, the

value is stored internally in the PQ-6 PLUS (RO); when it receives a request for a form feed or for an absolute

move to line one of the next page, the PQ-6 PLUS (RO) will cause the paper in the attached printer to eject a

form of the previously specified form length. Since some commands issued to IBM printers cannot be easily

implemented on RS-232 ASCII printers, these commands are interpreted by the PQ-6 PLUS (RO) and

discarded. For example, a command to set the lines per inch to seventy-two is accepted by the PQ-6 PLUS

(RO), but no corresponding ASCII sequence is output, since the PQ-6 PLUS (RO) cannot know in advance

whether the attached printer can accommodate such a command and how to implement it.

As shipped from the factory, the PQ-6 PLUS (RO) is configured to emulate an IBM 5256 printer. If the PQ-6

PLUS (RO) is to emulate the 5224 or 5225 printer, you need to set the appropriate switch on the printed circuit

board (see Section 4.5).

Serial transmission speed is switch-selectable via printed-circuit-board switches, up to 19,200 bps. Output data

is asynchronous with one start bit, seven data bits, space parity, and one stop bit.

The PQ-6 PLUS (RO) supports both software flow control via XON/XOFF characters and hardware flow

control via the DTR RS-232 input lead. The PQ-6 PLUS (RO) will suspend printing whenever the DTR signal

drops and will resume printing when DTR is asserted. Similarly, when it receives an XOFF character (hex 13),

the PQ-6 PLUS (RO) suspends printing; when it receives an XON (hex 11), it will resume printing. Both

methods are always enabled. No configuration is required.

Page 8

PQ-6 PLUS (RO)

7

The Centronics parallel interface is a 25-pin, parallel byte interface. It has eight lines that carry their

respective binary bits in parallel. The transmission of these data bits is controlled by the computer-supplied

STROBE pulse. Handshaking (flow control) is achieved by asserting or deasserting either the ACKNLG or

BUSY signal from the printer.

Figure 2-1. Typical Application.

S/3X, AS/400 or remote controller

PQ-6 PLUS (RO)

Printer

ASCII data serial

or parallel

Twinaxial

Serial EBCDIC

data and

commands

(1 MHz bit rate)

Page 9

PQ-6 PLUS (RO)

8

3. Installation

The installation procedure is divided into three sections:

• Section 3.1, Initial Setup, explains how to position the PQ-6 (RO) after unpacking it, plug in the power

supply, and run off-line tests.

• Section 3.2, System Configuration and Connection, covers the considerations for setting up the PQ-6 PLUS

(RO). Items covered include setting the device address and all corresponding physical connections.

• Section 3.3, Placing the PQ-6 PLUS (RO) into Operation, details online testing procedures that you should

implement after completely installing the unit. This section also contains recovery procedures that you can

use if the PQ-6 PLUS (RO) malfunctions.

3.1 Initial Setup

3.1.1 INSTALLING A SUPPORTED PRINTER

CAUTION

Connecting a device to the DB25 connector without properly configuring the P3

jumper inside the box may cause damage to the PQ-6 PLUS (RO) and/or the attached

device.

Page 10

PQ-6 PLUS (RO)

9

Figure 3-1. Board Layout.

Reset

Power

DB25 Female DB15 Male

Serial

Parallel

+5 Ground

EPROM

Test

Data Out

DTR Line Sync

Power

ON

SW1

1 2 3 4 5 6 7 8

1 2 3 4 5 6 7 8

SW2

Page 11

PQ-6 PLUS (RO)

10

Installing an RS-232 Printer

Connect the 6-pin connector from the power supply to the 6-pin connector on the back of the PQ-6 PLUS

(RO). Remove the top cover of the PQ-6 PLUS (RO). Do not plug it into the AC outlet at this time. Locate

switch SW1 to set the baud rate and port configuration. Select the serial transmission speed (baud rate) for the

PQ-6 PLUS (RO) output port using the four switches labeled Rate 4, Rate 3, Rate 2, and Rate 1 on the printed

circuit board according to Table 3-1.

Table 3-1. Baud Rate.

Switch Baud Rate

S5 S6 S7 S8

OFF OFF OFF OFF 50

0=OFF OFF OFF OFF ON 75

1=ON OFF OFF ON OFF 110

OFF OFF ON ON 134.5

OFF ON OFF OFF 150

OFF ON OFF ON 300

OFFONONOFF600

OFF ON ON ON 1200

ON OFF OFF OFF 1800

ON OFF OFF ON 2000

ON OFF ON OFF 2400

ON OFF ON ON 3600

ON ON OFF OFF 4800

ON ON OFF ON 7200

ON ON ON OFF 9600

ON ON ON ON 19200

Select the port configuration for RS-232 serial operation by setting Opt 3 to the “ON” position.

Place the large internal jumper strip on P3 (P2 on boards with revision levels below C) in the “B-C” position

to select RS-232 output. Make sure that the cable to the PQ-6 PLUS (RO) is wired for DCE and contains wires

for pins 1, 2, 3, 7, and 20, connecting at the PQ-6 PLUS (RO) with a male DB25 connector. The signals are

shown in Table 3-2.

Table 3-2. Signals on the DCE cable.

Pin Signal Name Source

1 Chassis Ground —

2 Receive Data Printer

3 Transmit Data PQ-6 PLUS (RO)

7 Signal Ground —

20 Data Terminal Ready Printer

Place the supported printer close to the PQ-6 PLUS (RO). Connect the printer RS-232 cable to the DB25

connector on the back panel of the PQ-6 PLUS (RO). Proceed to Section 3.2.3.

Page 12

PQ-6 PLUS (RO)

11

Installing a Centronics compatible printer

Connect the 6-pin connector from the power supply to the 6-pin connector on the back of the PQ-6 PLUS

(RO). Do not plug it into the AC outlet at this time.

Place the large jumper strip at P3, in the “A-B” position for parallel output.

The Centronics DB25 pinout is a standard DB25 to Centronics cable (Black Box part number EYN600) that

connects the PC to the printer. This cable’s pinning is shown in Table 3-3.

Table 3-3. Centronics to RS-232 Cable Wiring.

Pin No. Signal Source Description

1 Strobe PQ-6 PLUS (RO) Data strobe pulse to printer.

2 Data 1 PQ-6 PLUS (RO)

3 Data 2 PQ-6 PLUS (RO) 8 bits of parallel data.

4 Data 3 PQ-6 PLUS (RO)

5 Data 4 PQ-6 PLUS (RO)

6 Data 5 PQ-6 PLUS (RO)

7 Data 6 PQ-6 PLUS (RO)

8 Data 7 PQ-6 PLUS (RO)

9 Data 8 PQ-6 PLUS (RO)

10 Acknlg Printer Indicates data received and ready to accept other

data.

11 Busy Printer Indicates printer cannot receive data.

12 Paper End Printer Indicates out of paper.

13 Select Printer Indicates printer is selected and ready to receive

data.

14 Auto Feed PQ-6 PLUS (RO) When this signal is low (Jumper J1), the paper is

automatically fed one line after printing. This

signal does not apply to all printers.

15 Fault Printer Indicates a printer fault condition such as out of

paper.

16 Input PQ-6 PLUS (RO) Clears the printer buffer and initializes the logic.

18, 19, Ground PQ-6 PLUS (RO) Logic ground.

23, 25

Connect the Centronics printer cable to the DB25 connector at the back of the PQ-6 PLUS (RO). Locate

SW1 and set switch option 3 (position 2) to the “OFF” position.

3.1.2 P

OWER AND GROUNDING OF PQ-6 PLUS (RO)

Plug the power supply into a suitably grounded AC receptacle.

Page 13

PQ-6 PLUS (RO)

12

3.1.3 OFF-LINE TEST OF PQ-6 PLUS (RO) AND PRINTER

Initial Power On Test

Once both the printer and the PQ-6 PLUS (RO) are plugged into the AC line, turn the printer power switch

“ON” and put it into an “on-line” condition. Make sure the connection between the printer and the PQ-6 PLUS

(RO) is complete. Run the following test to check the power and connections for both devices.

Table 3-4. Initial Test.

Initial Test Device Response Corrective Action

Plug the PQ-6 (RO) PLUS Power and DTR indicators. Proper response. No corrective

power supply into the AC line. action is necessary.

No response on power or Power supply not plugged into back

DTR indicators. connector of the PQ-6 (RO), or no AC

line power, or PQ-6 (RO) power supply

is defective.

DTR indicator blinking. If configured for serial: The attached

serial device is not providing Data

Terminal Ready (DTR) on Pin 20 of the

PQ-6’s DB25 connector. If configured for

parallel: The attached parallel printer is

not providing the select signal on Pin 13

of the PQ-6’s DB25 connector. Check

that the printer is “ON,” on-line, and the

cable is connected and configured

properly.

Page 14

PQ-6 PLUS (RO)

13

Self-Test

After running the power test successfully, you can run the self-test to check the PQ-6 PLUS (RO) program

memory (ROM) and buffer memory (RAM). You can perform the self-test via two different methods: internal

DIP switches or the front-panel test button. Either way, the printer will print the software revision level, address

selected, and printer emulated. The self-test will also send a printed barber-pole test pattern to the printer. The

amount of data in the barber pole is different between the two types of self-tests. The self-test procedures and

device response are shown in Table 3-5. Figure 3-1 illustrates a sample of a self-test printout.

Table 3-5. Self-Test Procedures and Device Responses.

Preliminary Initial Device Corrective

Condition Test Response Action

Both PQ-6 PLUS (RO) Two methods of 1. Printed verification 1. Proper response. No

and printer are “ON” performing the occurs as described corrective action necessary.

and the “Power ON” self-test: via switches above.

test has been or via the front-panel

conducted test button

successfully. Switch method: Set

SW2-4 ON, SW2-5 ON,

then press and release

the reset button on the

rear of the unit.

Front-panel method:

Press the front-panel

test button.

When performing either

method of self-test, the

front-panel LEDs will

flash once, then the

Data Out LED will

flash rapidly

(depending on the

baud rate if serial)

while data is being

sent to the attached

printer.

2. No response 2. Check that the printer is

from printer or random on-line and the cable is

or garbage characters configured properly. Incorrect

are printed. baud rate, parity, or stop bits if

using serial interface.

3. Printed verification 3. Locate Jumper (J1) on PC

has blank line between board and position jumper from

printed lines. the +5V pin to the center pin.

After the self-test is successfully performed, set SW2 position 5 to “OFF” and press the reset switch.

Page 15

PQ-6 PLUS (RO)

14

PQ6.PLUS

REV1.41 SOFTWARE

RAM OK

ROM OK

DEVICE ADDRESS 0

Printer = 5256

.<(+|& !$*);^-/,%>? -:#@'="abcdefghi jklmnopqr -stuvwxyz {ABCDEFGHI }JKLMNOPQ

<(+|& !$*);^-/,%>? -:#@'="abcdefghi jklmnopqr -stuvwxyz {ABCDEFGHI }JKLMNOPQ

.<(+|& !$*);^-/ ,%>? -:#@'="abcdefghi jklmnopqr -stuvwxyz {ABCDEFGHI }JKLMNOPQ

<(+|& !$*);^-/ ,%>? -:#@'="abcdefghi jklmnopqr -stuvwxyz {ABCDEFGHI }JKLMNOPQR

<(+|& !$*);^-/ ,%>? -:#@'="abcdefghi jklmnopqr -stuvwxyz {ABCDEFGHI }JKLMNOPQR

.<(+|& !$*);^-/ ,%>? -:#@'="abcdefghi jklmnopqr -stuvwxyz {ABCDEFGHI }JKLMNOPQR

<(+|& !$*);^-/ ,%>? -:#@'="abcdefghi jklmnopqr -stuvwxyz {ABCDEFGHI }JKLMNOPQR

+\& !$*);^-/ ,%>? -:#@'="abcdefghi jklmnopqr -stuvwxyz {ABCDEFGHI }JKLMNOPQR

& !$*);^-/ ,%>? -:#@'="abcdefghi jklmnopqr -stuvwxyz {ABCDEFGHI }JKLMNOPQR

!$*);^-/ ,%>? -:#@'="abcdefghi jklmnopqr -stuvwxyz {ABCDEFGHI }JKLMNOPQR

!$*);^-/ ,%>? -:#@'="abcdefghi jklmnopqr -stuvwxyz {ABCDEFGHI }JKLMNOPQR

!$*);^-/ ,%>? -:#@'="abcdefghi jklmnopqr -stuvwxyz {ABCDEFGHI }JKLMNOPQR

!$*);^-/ ,%>? -:#@'="abcdefghi jklmnopqr -stuvwxyz {ABCDEFGHI }JKLMNOPQR

!$*);^-/ ,%>? -:#@'="abcdefghi jklmnopqr -stuvwxyz {ABCDEFGHI }JKLMNOPQR

*);^-/ ,%>? -:#@'="abcdefghi jklmnopqr -stuvwxyz {ABCDEFGHI }JKLMNOPQR

^-/ ,%>? -:#@'="abcdefghi jklmnopqr -stuvwxyz {ABCDEFGHI }JKLMNOPQR

-/ ,%>? -:#@'="abcdefghi jklmnopqr -stuvwxyz {ABCDEFGHI }JKLMNOPQR

,%>? -:#@'="abcdefghijklmnopqr -stuvwxyz {ABCDEFGHI }JKLMNOPQR

,%>? -:#@'="abcdefghijklmnopqr -stuvwxyz {ABCDEFGHI }JKLMNOPQR

,%>? -:#@'="abcdefghijklmnopqr -stuvwxyz {ABCDEFGHI }JKLMNOPQR

,%>? -:#@'="abcdefghijklmnopqr -stuvwxyz {ABCDEFGHI }JKLMNOPQR

,%>? -:#@'="abcdefghijklmnopqr -stuvwxyz {ABCDEFGHI }JKLMNOPQR

%>? -:#@'="abcdefghijklmnopqr -stuvwxyz {ABCDEFGHI }JKLMNOPQR

>? -:#@'="abcdefghi jklmnopqr -stuvwxyz {ABCDEFGHI }JKLMNOPQR

-:#@'="abcdefghi jklmnopqr -stuvwxyz {ABCDEFGHI }JKLMNOPQR

-:#@'="abcdefghi jklmnopqr -stuvwxyz {ABCDEFGHI }JKLMNOPQR

-:#@'="abcdefghi jklmnopqr -stuvwxyz {ABCDEFGHI }JKLMNOPQR

-:#@'="abcdefghi jklmnopqr -stuvwxyz {ABCDEFGHI }JKLMNOPQR

-:#@'="abcdefghijklmnopqr -stuvwxyz {ABCDEFGHI }JKLMNOPQR

-:#@'="abcdefghijklmnopqr -stuvwxyz {ABCDEFGHI }JKLMNOPQR

-:#@'="abcdefghijklmnopqr -stuvwxyz {ABCDEFGHI }JKLMNOPQ

:#@'="abcdefghijklmnopqr -stuvwxyz {ABCDEFGHI }JKLMNOPQR

@'=" abcdefghijklmnopqr -stuvwxyz {ABCDEFGHI }JKLMNOPQR

=" abcdefghijklmnopqr -stuvwxyz {ABCDEFGHI }JKLMNOPQR

abcdefghijklmnopqr -stuvwxyz {ABCDEFGHI }JKLMNOPQR

bcdefghijklmnopqr -stuvwxyz {ABCDEFGHI }JKLMNOPQR

defghijklmnopqr -stuvwxyz {ABCDEFGHI }JKLMNOPQR

fghijklmnopqr -stuvwxyz {ABCDEFGHI }JKLMNOPQR

hijklmnopqr -stuvwxyz {ABCDEFGHI }JKLMNOPQR

jklmnopqr -stuvwxyz {ABCDEFGHI }JKLMNOPQR

jklmnopqr -stuvwxyz {ABCDEFGHI }JKLMNOPQR

jklmnopqr -stuvwxyz {ABCDEFGHI }JKLMNOPQR

jklmnopqr -stuvwxyz {ABCDEFGHI }JKLMNOPQR

klmnopqr -stuvwxyz {ABCDEFGHI }JKLMNOPQR

Figure 3-1. Sample Self-Test Printout.

Page 16

PQ-6 PLUS (RO)

15

3.2 System Configuration and Connection

At this point, the PQ-6 PLUS (RO)’s serial or parallel port has been tested off-line and verified to be in working

condition. However, before attaching to the host system, you must consider the overall system layout to establish

the relative device positioning, port selection, cabling, device addressing, and unit identification.

3.2.1 PQ-6 PLUS (RO) A

DDRESS SELECTION

Determine the correct device address number for the PQ-6 to use by contacting the person responsible for

assigning workstation and device addresses.

Locate the printer-options/address-selection DIP switches by removing the top half of the enclosure. The

switches are labeled SW2: ADR4 (POS 6), ADR2 (POS 7), and ADR1 (POS 8).

Set the three switches on the right of the DIP switch to arrive at the proper twinax address. When the switch

is OFF, it represents a zero. Conversely, when the switch is ON, it represents a one. The three switches are

labeled ADR 4, 2, and 1, representing a binary value. Therefore, any address, zero to six, can be represented by

an appropriate on-off configuration of the switches. Examples are given in Table 3-6.

Table 3-6. Printer Options/Address Selection DIP Switch.

Device Address

Decimal SW6 ADR4 SW7 ADR2 SW 8 ADR1

0 OFF OFF OFF

1 OFF OFF ON

2 OFF ON OFF

3 OFF ON ON

4ONOFFOFF

5 ON OFF ON

6 ONONOFF

7 ON ON ON (ON=ILLEGAL)

3.2.2 SYSTEM CONFIGURATION REQUEST

Physically, the PQ-6 PLUS (RO) is now properly addressed and cabled to the host system or remote controller.

However, before the System 3X or AS/400 system will recognize the PQ-6 PLUS (RO), you must: 1) make sure

the PQ-6 PLUS (RO) is emulating the proper system device and 2) perform a system configuration (unless the

PQ-6 PLUS (RO) is replacing an existing printer or you have auto-config enabled).

As shipped from the factory, the PQ-6 PLUS (RO) is configured to emulate an IBM 5256 printer. On the

inside of the PQ-6 PLUS (RO) are two DIP switches labeled ID1 and ID2 SW2, positions 1 and 2. They select

the IBM printer to be emulated (5256, 5224, or 5225). Table 3-7 gives the proper settings for selecting the

desired printer type.

Table 3-7. Settings for Printer Type.

ID2 SW2-1 ID1 SW2-2 Printer Type

OFF OFF 5256

OFF ON 5224

ON OFF 5225

ON ON UNUSED

Page 17

PQ-6 PLUS (RO)

16

You must configure the system at a console to inform the operating system of the new device port, address,

and unit ID assignments.

NOTE

You don’t have to configure the system if a previously existing 5256, 5224, or 5225

printer was replaced by the PQ-6 PLUS (RO) or if you have auto-config enabled on the

AS/400. If the PQ-6 PLUS (RO) is replacing an existing device, printer ID and device

addressing must remain as established for the removed device.

3.2.3 PRINTER CODES FOR PITCH AND DENSITY

The printer control ode feature in the PQ-6 PLUS (RO) allows the host to control the horizontal pitch (10 and

15 CPI) and vertical pitch (6 and 8 LPI) for certain attached ASCII printers. You can find the list of printers on

page 20.

3.3 Placing the PQ-6 in Operation

When notified that the system operator has completed the system configuration, you can power on the PQ-6

PLUS (RO) (and all other cabled-through devices) using the following procedure:

A. Plug the power supply into the AC line.

B. Place the AC power switch on the attached printer in the “ON” position and place the printer into

“on-line” mode. The DTR indicator should light.

C. The LINE SYNC indicator should light as soon as communications with the host are established. The PQ-6

PLUS (RO) should now be exercised online to verify the operational readiness. Simply execute a print

comand.

M

ALFUNCTION RECOVERY PROCEDURES

Table 3-8 describes the recovery procedures you can use if the machine malfunctions.

Table 3-8. Recovery Procedures.

Indicator Condition Probable Cause Recovery Action

Page 18

PQ-6 PLUS (RO)

17

No indicator lights Power supply not plugged Plug power supply cord into a suitable receptacle.

into AC or into PQ-6.

Line Sync light “OFF” Printer improperly addressed. Set correct address on SW2-6, 7, and 8; press

RESET. Check twinax connections.

DTR Flashing Attached printer OFF, in error Turn on attached printer or check for proper configuration.

condition, or switches and P2

jumper not in proper position.

Head moving printing No ribbon. Install new ribbon.

Defective ribbon. Install new ribbon.

No printing in test mode. Ribbon out. Install new ribbon.

Paper out. Install forms.

Printer AC off. Turn on printer power.

No DTR or select from printer. Check cables and printer power.

Test message printed Incorrect PQ-6(RO) baud rate. Set correct baud rate via switches on the board.

incorrectly. Bad cable connection to printer. Disconnect power supply, check cable for complete

insertion at both ends. Check for broken wires.

Page 19

PQ-6 PLUS (RO)

18

4. Operation

4.1 Operator Controls and Indicators

Use Figure 4-1 to locate the controls, indicators, and connectors described in this section.

Figure 4-1. Front-Panel Controls and Indicators.

4.1.1 F

UNCTION SWITCHES

• Test: Pressing this switch will cause the TEST light to blink and a test pattern to be printed. If the PQ-6

(RO) cannot detect the attached printer, the TEST light will blink repeatedly. You can clear this condition

by readying the printer.

• Line Feed: Pressing the LINE FEED switch will cause the paper to advance one line for each key you press.

The internal line counter will also be advanced. For continuous line feeds, hold this switch “ON.”

• Form Feed: Pressing the FORM FEED switch will cause the paper to move to the top of the next form.

• Stop: Pressing the STOP switch stops printing on the PQ-6 PLUS (RO) Plus. It also presents “unit not

available” status to the controller. The message “press start on printer Pn” will appear on the controlling

console.

• Start: Pressing the START switch will present “unit available” status to the controller and clear the STOP

message. Printing will resume on the PQ-6 Plus.

• Reset: Pressing the RESET switch (located on the rear panel) initializes all PQ-6 PLUS (RO) hardware.

START STOP

TEST LF FF

TEST DATA

OUT

DTR LINE

SYNC

PWR

Page 20

PQ-6 PLUS (RO)

19

4.1.2 INDICATOR LIGHTS

• Power: Indicates that AC power has been applied to the unit.

• Line Sync: Indicates that the PQ-6 is responding to host polls.

• DTR (Data Terminal Ready): This signal from the printer to the PQ-6 PLUS (RO) indicates that the printer

is ready. This signal must be present for printing to proceed. You can enable flow control from the PQ-6

PLUS (RO) to the printer via XON/XOFF characters (Hex 11/Hex 13) or by dropping DTR when the

printer is not able to accept more data. When used as a Centronics port, the DTR light indicates select from

the printer.

• Data Out: Shows the data sent to the printer from the PQ-6 PLUS.

• Test: Blinks to indicates that internal tests are running. Blinks repeatedly if the select signal from the printer

is not present.

NOTE

Initial setup of internal switch and jumper settings for baud rate, printer interface, etc.,

must have been done previously. See Section 3.1.

4.2 Setup Mode

You can configure the PQ-6’s twinax address, printer emulated, ASCII printer type, page select and command

pass-through by the front panel or the internal DIP switches.

NOTE

ASCII printer type is only selectable via the front panel.

To enable configuration via the front panel, set the internal DIP switch bank 2 position 4 to OFF. The

factory-default setting for this switch position is ON.

To place the PQ-6 PLUS (RO) in setup mode, press and hold in the test switch while pressing and releasing the

reset switch, then release the test switch. The PQ-6 PLUS (RO) will print the following menu on the attached

printer:

PQ-6 PLUS REV. 1.41 SOFTWARE SETUP MODE

Press START to select switch settings

Press STOP to print switch settings

Press LF to do Printer Test

Press FF to return to twinax mode

Press FF to accept switch setting

Press STOP to toggle switch setting

Page 21

PQ-6 PLUS (RO)

20

DEVICE ADDRESS 0

DEVICE ADDRESS 7

DEVICE ADDRESS 6

DEVICE ADDRESS 5

DEVICE ADDRESS 4

DEVICE ADDRESS 3

DEVICE ADDRESS 2

DEVICE ADDRESS 1

DEVICE ADDRESS 0

Printer=5224

Printer=5225

Page Eject is Form Feeds

Page Eject is Line Feeds

Command Pass Thru is Disabled

Command Pass Thru is Enabled

Current printer attached is Generic 3400h

Current printer attached is IBM Proprinter

Current printer attached is Okidata 2410

Current printer attached is Okidata 83/84

Current printer attached is MX-80

Current printer attached is T.I. 810/820

Current printer attached is NEC SpWr 3500

Current printer attached is FX-80

Press FF to save configuration

Press STOP to cancel configuration

S

ELECTING SWITCH SETTINGS

This mode lets you change the initial switch settings using the front panel instead of removing the top cover of

the PQ-6 PLUS.

Follow the instructions on the printed menu to select the different switch selections.

Upon exiting this mode, the switch selections will be stored in nonvolatile memory; the PQ-6 will retain

them until you change them using the front panel. On the next power-up, the PQ-6 PLUS will be configured to

the last stored setup. If no previous configuration was stored, the PQ-6 PLUS will default to the current switch

settings on the PC board, and the printer type will be Generic 3400h.

Page 22

PQ-6 PLUS (RO)

21

When selecting printer type, the following data is used by the PQ-6 PLUS:

6 LPI

8 LPI

10 CPI

15 CPI

If you select a generic printer, the data used is located at 3400H and must be entered in the EPROM (see

Section 3.3.3).

To cancel a print job sent from the host, press and hold the STOP button on the PQ-6 Plus (RO) front

panel, and press the START button simultaneously. This sends a cancel request to the host, ending the print

job.

4.3 Command Pass-Through

The command pass-through feature in the PQ-6 PLUS (RO) lets you (or a programmer) control an attached

printer so that you can use special functions or features of the printer. It’s required because the IBM System 3X

operating software will not allow codes below Hex 40 to be transmitted on the twinax cable.

The method will transmit any 8-bit binary value from Hex 00 to Hex FF. The PQ-6 does not interpret or

translate data when in command pass-through mode.

To enter command pass-through mode, send the two-character sequence ampersand percent (&%) as part

of the normal printable data.

NOTE

Ampersand (&)=EBCDIC 50 Hex

Percent (%)=EBCDIC 6C Hex

After it enters command pass through mode, the PQ-6 PLUS (RO) takes characters from its internal print

buffer and outputs a single 8-bit binary value for every two EBCDIC characters it receives. The two EBCDIC

characters should embody the Hex representation of a legal 8-bit value.

Example: To send an ASCII escape character (1B Hex), send the two-character sequence ampersand percent

as a terminating character pair.

NOTE

No gaps or spaces should occur between any characters during command pass

through mode.

To send the sequence of ASCII characters “ABC (space) 1 2 3,” the following command pass-through

sequence would be sent:

EBCDIC - & % 4 1 4 2 4 3 2 0 3 1 3 2 3 3 & %

Hex - 50 6C F4 F1 F4 F2 F4 F3 F2 F0 F3 F1 F3 F2 F3 F3 50 6C

Page 23

PQ-6 PLUS (RO)

22

4.4 Buffer Print Mode

A buffer print listing interprets the actions of a printer or similar device on the twinax cable. All the data that is

received is listed as a hexadecimal printout. None of the formatting commands are executed; rather, they are

printed to aid in the interpretation.

4.4.1 P

RINTOUT FORMAT

The data transmitted on the twinax cable is sent in blocks. A block can be one byte to 256 bytes long. The PQ-6

does not interpret the poll requests and device commands (such as device status) in a buffer print listing, but

prints all of the data received in each of the blocks, grouped in its block. Each byte that the PQ-6 receives is

expanded into three characters. The first two characters are the hexadecimal representation of the data byte,

and the third is the printable character that the byte would print if any. The three characters that are printed

for the received byte are printed in a vertical line. The most significant nibble on the second line, and the

printable character, if any, appear on the third line.

Characters are printed in groups of three lines, each line containing up to 128 characters. Since each block

of data can be up to 256 bytes, the blocks are printed in one or two groups of three lines. At the beginning of

each block of data, a new group of three lines starts. Thus, the position of the data within each block can be

readily seen.

Take care here if you’re using a printer that will print only 80 character lines. The groups of three lines are

up to 128 characters long. If the printer used will only print 80 character lines, or has been set to print only 80

character lines, one of two things will occur depending on the printer. If the printer is set to not auto-new-line,

the printer does an auto-new-line after reaching its line length, and the end of each line will be interlaced

between each of the original lines. You can interpret this once you realize what is happening.

4.4.2 D

ATA INTERPRETATION

The data is received in IBM EBCDIC. The format commands, while almost exactly the same for all twinax

systems, may be somewhat different. It is always best to consult the IBM manual for the particular system.

Listed next is a representation of the buffer printout. This particular listing was copied from a printout for

the beginning of the System 34 printer diagnostic. A few comments follow that will assist in its interpretation.

EXAMPLE OF A BUFFER PRINT LISTING

0

C

2C002D02002D0802C082C042C040

B62CB2490AB1310B124B222B8201

F K J a A d B H

CCCCCCCCCDDDDDDDDDEEEEEEEE44444FFFFFFFFFF

12345678912345678923456789000000123456789

ABCDEFGHIJKLMNOPQRSTUVWXYZ 0123456789

Page 24

PQ-6 PLUS (RO)

23

4.4.3 NOTES

The first block contains a single byte (a hex 0C). In EBCDIC, that’s a formfeed. Note that it is not a printing

character and the space under the 0C is blank. The next block of data contains 28 bytes. It starts with a 2B,

which is a format command (similar to an ASCII escape sequence). The 2BC6 denotes set line density, 02 says 2

bytes after the 2BC6 are part of the command. The 0C designates 6 lines per inch. The C6 has an “F” under it.

If it occurred not in a format command, it would be printable “F,” but it does not print since it is part of a

command.

The 2B D2 04 29 00 0A is the format command to set the printer into 10 characters per inch.

The 2B D1 03 81 00 sets the printer into the international character set.

The 2B C1 is for setting the maximum print position. 02 again states that 2 bytes follow the 2BC1 command,

and 84 is hex for 132. Thus, it sets the maximum print position to 132.

The 2B C2 sets the maximum number of print lines per page. 02 42 specifies two following bytes and sets it

to 66 lines per page.

The 2B C8 states what the printer will do when it receives a character that is undefined. This sequence of 02

bytes sets the printer to print a hex 40 (which is a space), and the 01 indicates to continue without any error

action.

The next block of data is actual EBCDIC printable data (the first data that the printer actually prints). This

pattern is the alphabet and numbers.

4.5 Functions and Options

For easy setup, the new PQ-6 PLUS (RO) single-port device features slide-type DIP switches that you can access

by removing the top cover.

Page 25

PQ-6 PLUS (RO)

24

SWITCH DEFINITION TABLES

Table 4-1. Option Switch SW1 Baud Rate Selection (0=OFF, 1=ON).

Switch Bank 1 Baud Rate

5678

OFF OFF OFF OFF 50

OFF OFF OFF ON 75

OFF OFF ON OFF 110

OFF OFF ON ON 134.5

OFF ON OFF OFF 150

OFF ON OFF ON 300

OFFONONOFF600

OFF ON ON ON 1200

ON OFF OFF OFF 1800

ON OFF OFF ON 2000

ON OFF ON OFF 2400

ON OFF ON ON 3600

ON ON OFF OFF 4800

ON ON OFF ON 7200

ON ON ON OFF 9600

ON ON ON ON 19200

Option Select

1 (OPT4) ON=Buffer print mode.

2 (OPT3) ON=Serial OFF=Parallel

3 (OPT2) ON=Enable Command Passthrough

OFF=Disable Command Passthrough

4 (OPT1) OFF=Use FF (Form Feed) character for page eject.

ON=Use Multiple Line Feed for page eject.

Table 4-2. Option Switch SW2.

Switch Bank 2 Position Function

1, 2 Printer type select (00=5256, 01=5224, 10=5225, 11=illegal)

3 Parallel Print option (OFF=PQ-6 responds to the busy and acknowledge

signals from the printer. ON=PQ-6 responds to the busy signal only. This

setting increases the data transfer rate to the printer.)

4 Configuration option (ON=DIP switch, OFF=Front panel)

5 Self-Test

6, 7, 8 Address select (0-6) 0=OFF, 1=ON

When the auto-feed jumper is installed in the ground position, the paper is automatically fed one line after

printing. This signal does not apply to all printers.

Jumper (J1) applies either +5 or ground or pin 14 of the Centronics printer connector.

Page 26

PQ-6 PLUS (RO)

25

Appendix A: PQ-6 PLUS (RO)

EBCDIC to ASCII Translation Table

HEX EBCDIC HEX ASCII DESCRIPTION

05 09 Horizontal Tab

0B 08 Backspace

0C 0C Form Feed

00 00 Carriage Return

0F 20 |

15 0A Line Feed

16 08 Backspace

25 0A Line Feed

2F 07 Bel

40 20 Space

46 20 Carriage Return

47 20 Line Feed

48 20 Form Feed

49 20 Line Feed

4B 2E .

4C 3C <

4D 28 [

4E 2B 4F 7C |

50 26 &

5A 21

5B 24 $

5C 2A *

5D 29 ]

5E 3B ;

5F 5E ^

60 2D 61 2F /

6A 7C |

6B 2C ,

6C 25 %

6D 5F _

6E 3E >

6F 3F ?

79 60

7A 3A :

7B 23 =

7C 40 @

Page 27

PQ-6 PLUS (RO)

26

HEX EBCDIC HEX ASCII DESCRIPTION

7D 27 '

7E 3D =

7F 22 "

81 61 a

82 62 b

83 63 c

84 64 d

85 65 e

86 66 f

87 67 g

88 68 h

89 69 i

91 6A j

92 6B k

93 6C l

94 6D m

95 6E n

96 6F o

97 70 p

98 71 q

99 72 r

A1 7E

A2 73 s

A3 74 t

A4 75 u

A5 76 v

A6 77 w

A7 78 x

A8 79 y

A9 7A z

C0 7B [

C1 41 A

C2 42 B

C3 43 C

C4 44 D

C5 45 E

C6 46 F

C7 47 G

C8 48 H

C9 49 I

D0 7P ]

D1 4A J

D2 4B K

D3 4C L

D4 4D M

D5 4E N

Page 28

PQ-6 PLUS (RO)

27

HEX EBCDIC HEX ASCII DESCRIPTION

D6 4F O

D7 50 P

D8 51 Q

E9 52 R

E0 5C

E2 53 S

E3 54 T

E4 55 U

E5 56 V

E6 57 W

E7 58 X

E8 59 Y

E9 5A Z

F0 30 0

F1 31 1

F2 32 2

F3 33 3

F4 34 4

F5 35 5

F6 36 6

F7 37 7

F8 38 8

F9 39 9

NOTE

Any characters not shown are not used.

Page 29

Appendix B: PQ-6 PLUS (RO) Quick Setup Guide

Reset

Power

DB25 Female

DB15 Male

Serial

Parallel

+5

Ground

EPROM

Test

Data Out

DTR Line Sync Power

ON

SW1

1 2 3 4 5 6 7 81 2 3 4 5 6 7 8

SW2

Option Switch SW1.

Switch Bank 1 Baud Rate

5678

OFF OFF OFF OFF 50

OFF OFF OFF ON 75

OFF OFF ON OFF 110

OFF OFF ON ON 134.5

OFF ON OFF OFF 150

OFF ON OFF ON 300

OFF ON ON OFF 600

OFF ON ON ON 1200

ON OFF OFF OFF 1800

ON OFF OFF ON 2000

ON OFF ON OFF 2400

ON OFF ON ON 3600

ON ON OFF OFF 4800

ON ON OFF ON 7200

ON ON ON OFF 9600

ON ON ON ON 19200

Option Select

1 (OPT4) ON=Buffer print mode.

2 (OPT3) ON=Serial OFF=Parallel

3 (OPT2) ON=Enable Command Pass Thru

OFF=Disable Command Pass Thru

4 (OPT1) OFF=Use FF (Form Feed) character for page eject.

ON=Use Multiple Line Feed for page eject.

Option Switch SW2.

Switch Bank 2 Function

Position

1, 2 Printer type select (00=5256, 01=5224, 10=5225, 11=illegal)

3 Parallel Print option (OFF=PQ-6 responds to the busy and acknowledge

signals from the printer. ON=PQ-6 responds to the busy signal only. This

setting increases the data transfer rate to the printer.)

4 Configuration option (ON=DIP switch, OFF=Front panel)

5 Self-Test

6, 7, 8 Address select (0-6) 0=OFF, 1=ON

PQ-6 (RO) Board Layout.

Baud Rate.

Switch Baud Rate

S5 S6 S7 S8

OFF OFF OFF OFF 50

0=OFF OFF OFF OFF ON 75

1=ON OFF OFF ON OFF 110

OFF OFF ON ON 134.5

OFF ON OFF OFF 150

OFF ON OFF ON 300

OFF ON ON OFF 600

OFF ON ON ON 1200

ON OFF OFF OFF 1800

ON OFF OFF ON 2000

ON OFF ON OFF 2400

ON OFF ON ON 3600

ON ON OFF OFF 4800

ON ON OFF ON 7200

ON ON ON OFF 9600

ON ON ON ON 19200

Printer Options/Address Selection DIP Switch.

Device Address

Decimal SW6 ADR4 SW7 ADR2 SW 8 ADR1

0 OFF OFF OFF

1 OFF OFF ON

2 OFF ON OFF

3 OFF ON ON

4 ON OFF OFF

5 ON OFF ON

6ONONOFF

7 ON ON ON (ON=ILLEGAL)

Settings for Printer Type.

ID2 SW2-1 ID1 SW2-2 Printer Type

OFF OFF 5256

OFF ON 5224

ON OFF 5225

ON ON UNUSED

Page 30

1000 Park Drive • Lawrence, PA 15055-1018 • 724-746-5500 • Fax 724-746-0746

© Copyright 1999. Black Box Corporation. All rights reserved.

Loading...

Loading...