Page 1

Order toll-free in the U.S.: Call 877-877-BBOX (outside U.S. call 724-746-5500)

FREE technical support 24 hours a day, 7 days a week: Call 724-746-5500 or fax 724-746-0746

Mailing address: Black Box Corporation, 1000 Park Drive, Lawrence, PA 15055-1018

Web site: www.blackbox.com • E-mail: info@blackbox.com

CUSTOMER

SUPPORT

INFORMATION

MARCH 1996

MX400A MX404C

MX401C MX406C

MX402C MX407C

MX403C MX410C

Multiserver 500

TM

VA

RS

RD LS

TD

IS

PO

EXE

MULTISERVER 500

Page 2

FCC AND IC RFI STATEMENTS

FEDERAL COMMUNICATIONS COMMISSION

AND

CANADIAN DEPARTMENT OF COMMUNICATIONS

RADIO FREQUENCY INTERFERENCE STATEMENTS

This equipment generates, uses, and can radiate radio frequency energy and if not installed and used

properly, that is, in strict accordance with the manufacturer’s instructions, may cause interference to radio

communication. It has been tested and found to comply with the limits for a Class A computing device in

accordance with the specifications in Subpart J of Part 15 of FCC rules, which are designed to provide

reasonable protection against such interference when the equipment is operated in a commercial

environment. Operation of this equipment in a residential area is likely to cause interference, in which case

the user at his own expense will be required to take whatever measures may be necessary to correct the

interference.

Changes or modifications not expressly approved by the party responsible for compliance could void the

user’s authority to operate the equipment.

This digital apparatus does not exceed the Class A limits for radio noise emission from digital apparatus set out in the

Radio Interference Regulation of the Canadian Department of Communications.

Le présent appareil numérique n’émet pas de bruits radioélectriques dépassant les limites applicables aux appareils

numériques de la classe A prescrites dans le Règlement sur le brouillage radioélectrique publié par le ministère des

Communications du Canada.

Page 3

MULTISERVER 500

2

Trademarks

AT&T®is a registered trademark of American Telephone and Telegraph Company.

UL

®

is a registered trademark of Underwriters Laboratories Incorporated.

Page 4

CONTENTS

3

Chapter 1: Specifications.......................................................................................................................................7

Chapter 2: Introduction .......................................................................................................................................10

2.1 Multiplexing and the Multiserver 500........................................................................................................10

2.2 Description of the Multiserver 500.............................................................................................................10

2.3 Block Diagram .............................................................................................................................................12

2.3.1 Voice/Fax Interface Module.........................................................................................................13

2.3.2 Digital Processing Module.............................................................................................................13

2.3.3 Serial Interface Module.................................................................................................................13

2.3.4 LCD ................................................................................................................................................13

2.3.5 Power Supply..................................................................................................................................13

2.4 Interfaces......................................................................................................................................................13

2.4.1 Data Channel .................................................................................................................................13

2.4.2 Voice/Fax Channel........................................................................................................................13

2.4.3 Composite Channel .......................................................................................................................13

2.4.4 Command Port...............................................................................................................................13

2.5 Options14

2.6 Modules Covered in This Manual ..............................................................................................................14

Chapter 3: Installation.........................................................................................................................................15

3.1 Unpacking the Multiserver 500 ..................................................................................................................15

3.2 Installing the Multiserver ............................................................................................................................16

3.2.1 Selecting an Installation Site.........................................................................................................16

3.2.2 Cable and Power Connections ......................................................................................................16

3.3 Setting the Composite Transmit Clock ......................................................................................................17

3.4 Installing the Voice/Fax Interface Module ...............................................................................................18

3.5 Setting the Time and Date..........................................................................................................................19

Chapter 4: Using the LCD and Keypad..............................................................................................................21

Chapter 5: Using the Command Port.................................................................................................................28

5.1 Factory Defaults ...........................................................................................................................................28

5.2 Connecting Asynchronous Terminals ........................................................................................................30

5.2.1 Conecting a Single Multiserver 500 ..............................................................................................30

5.2.2 Connecting Multiple Multiserver 500s .........................................................................................31

5.3 Impedance Strapping..................................................................................................................................32

5.4 CMD IN and CMD OUT Connectors.........................................................................................................33

5.5 Accessing the Command Port.....................................................................................................................34

Chapter 6: Operation ..........................................................................................................................................41

6.1 LED Indicators.............................................................................................................................................41

6.2 The LCD and the Keypad ...........................................................................................................................43

6.3 Default Configuration Settings...................................................................................................................43

Contents

Page 5

MULTISERVER 500

4

6.4 Operating the Multiserver 500 ...................................................................................................................44

6.4.1 Establish a Data Connection .........................................................................................................44

6.4.2 To Make a Telephone Call.............................................................................................................44

6.4.3 To Send a Fax Message ..................................................................................................................47

Chapter 7: Diagnostics and Troubleshooting ....................................................................................................48

7.1 Automatic Self-Test......................................................................................................................................48

7.2 User-Initiated Tests ......................................................................................................................................48

7.2.1 Suggested Test Sequence...............................................................................................................50

7.2.2 EEPROM Test.................................................................................................................................50

7.2.3 Self-Test...........................................................................................................................................50

7.2.4 Local Data Loopback Test .............................................................................................................50

7.2.5 Local Composite Loopback Test...................................................................................................51

7.2.6 Remote Composite Loopback Test...............................................................................................54

7.2.7 Remote Data Loopback .................................................................................................................57

Appendix A: FXS Voice/Fax Interface Module.................................................................................................58

A.1 Connectors on the Back Panel ...................................................................................................................59

A.2 Strapping......................................................................................................................................................61

A.3 Removing or Replacing the Module ..........................................................................................................61

A.4 Specifications ...............................................................................................................................................61

Appendix B: FXO Voice/Fax Interface Module................................................................................................63

B.1 Connectors on the Back Panel ...................................................................................................................64

B.2 Strapping......................................................................................................................................................66

B.3 Removing or Replacing the Module ..........................................................................................................67

B.4 Specifications ...............................................................................................................................................67

Appendix C: E&M Voice/Fax Interface Module...............................................................................................68

C.1 Differences Between Models.......................................................................................................................68

C.2 Telephone-Interface Connectors................................................................................................................69

C.3 Connecting the Telephone-Interface Cable ..............................................................................................69

C.4 E&M Lead States..........................................................................................................................................71

C.5 Connection Diagrams..................................................................................................................................71

C.6 Strapping......................................................................................................................................................75

C.7 Removing or Replacing the Module ..........................................................................................................76

C.8 Specifications ...............................................................................................................................................76

Appendix D: Changing the Data Interface Types..............................................................................................77

D.1 Removing the Top Cover ............................................................................................................................78

D.2 Configuring the Interfaces..........................................................................................................................78

D.3 Replacing the Top Cover.............................................................................................................................80

Appendix E: Agency and Telephone-Company Requirements ........................................................................82

E.1 Requirements for Operation with the Telephone Company....................................................................82

E.2 Equipment Attachment Limitations for Operation in Canada ................................................................82

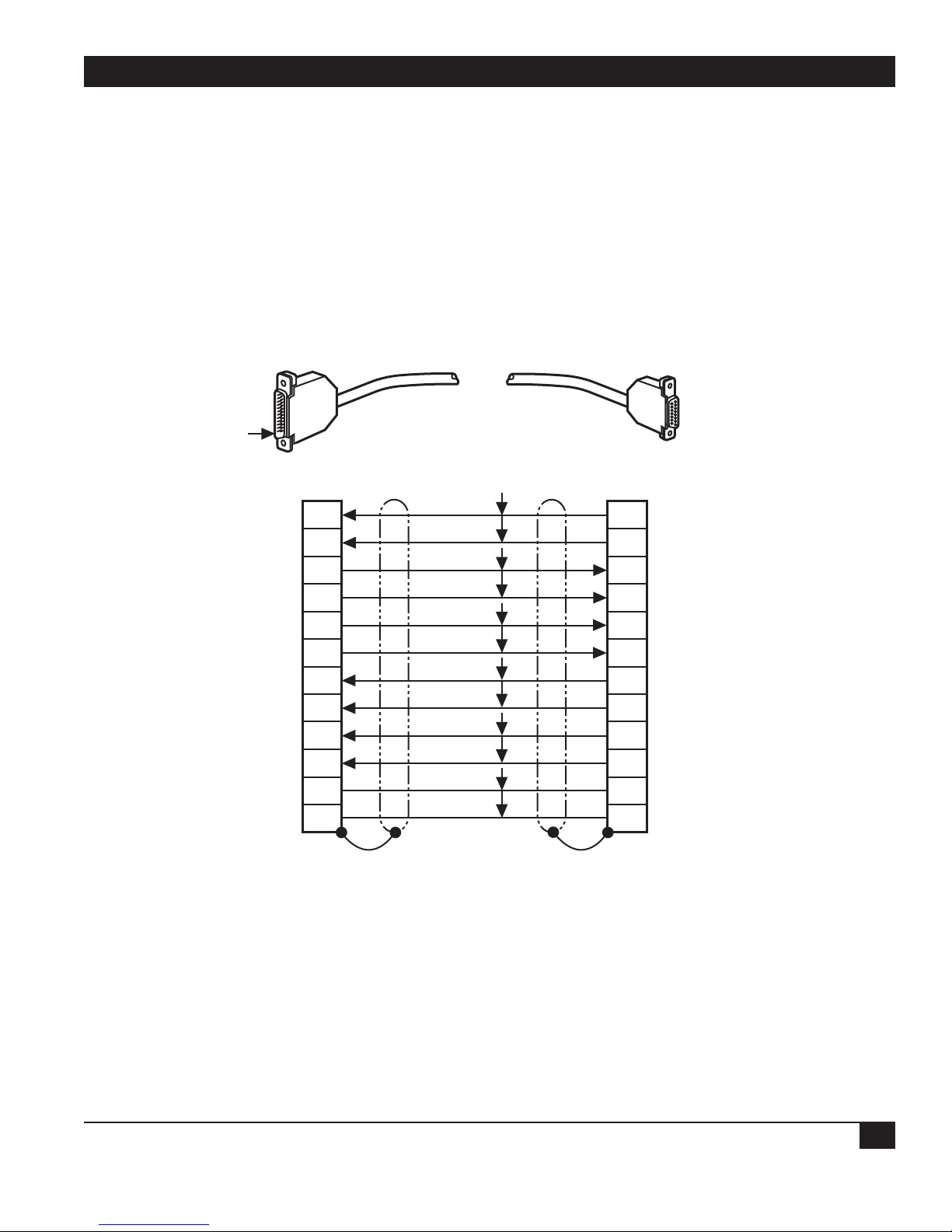

Appendix F: Cabling and Pin Assignments........................................................................................................84

F.1 Cables for the Composite Interface ...........................................................................................................84

F.2 Data-Channel Interface Cables...................................................................................................................92

Page 6

CONTENTS

5

Glossary .................................................................................................................................................................97

Index....................................................................................................................................................................102

Figures

2-1 Typical Multiserver 500 Application...........................................................................................................10

2-2 Multiserver 500, Front and Rear Views ......................................................................................................11

2-3 Multiserver 500 Block Diagram ..................................................................................................................12

3-1 Cable and Power Connectors......................................................................................................................16

3-2 Clocking with Multiserver 500 Connected to a DCE Device ....................................................................17

3-3 Installing or Removing the Voice/Fax Interface Module.........................................................................18

3-4 Setting the Time and Date..........................................................................................................................20

5-1 Reconfiguring the Command-Port Parameters .........................................................................................29

5-2 Connecting the Asynchronous Terminal ...................................................................................................30

5-3 Typical Three-Multiserver Daisychain Topology........................................................................................31

5-4 Setting the Data Rate and Device Number ................................................................................................31

5-5 Location of Command Port Impedance Header E5-on the Serial Interface Module ............................32

5-6 CMD IN CMD OUT Connector Pin Assignments (RS-422 Interface).....................................................33

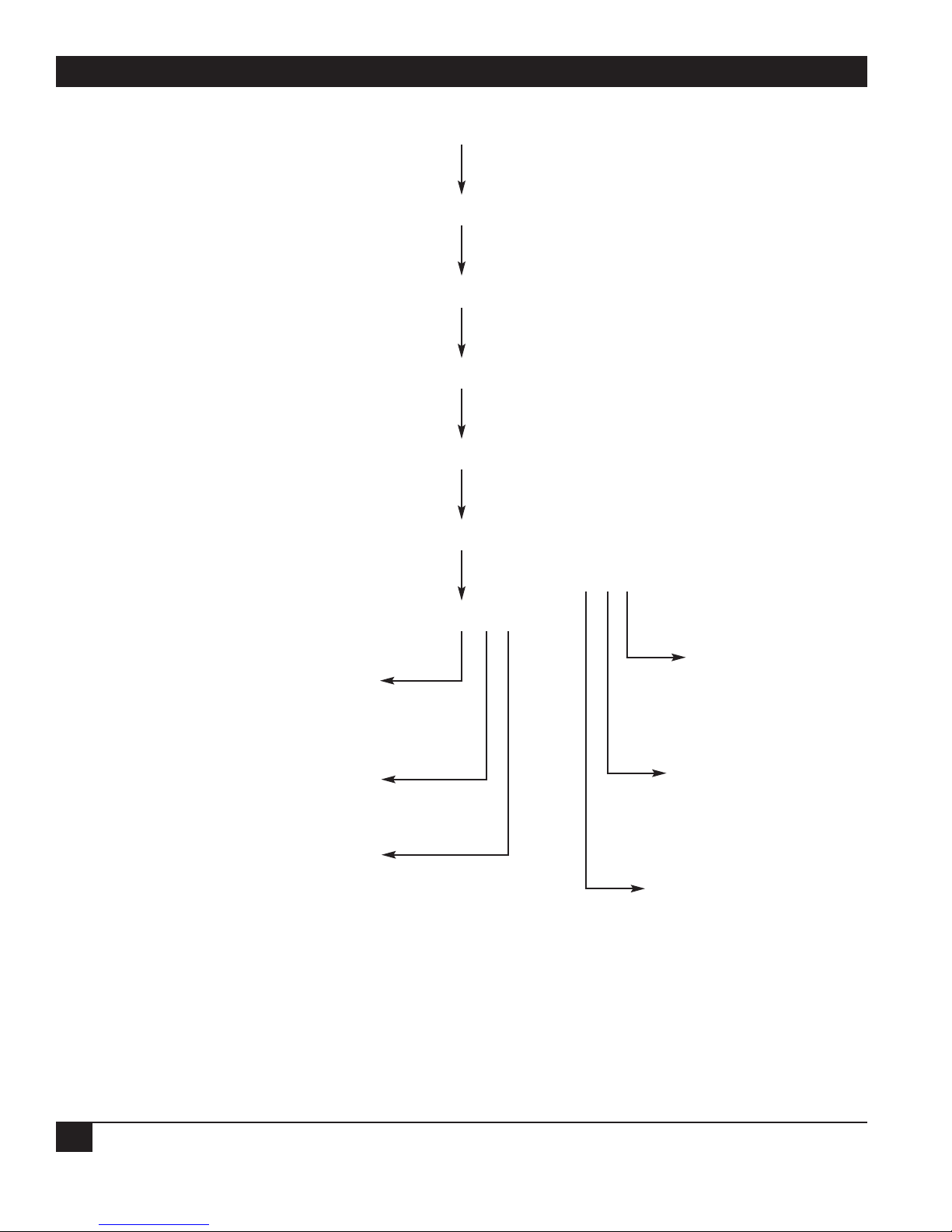

5-7 Flowchart for Accessing the Command Port .............................................................................................34

6-1 The Front Panel of the Multiserver 500 .....................................................................................................41

6-2 Telephone Calls from Local FXS Interfaces ..............................................................................................45

6-3 Telephone Calls from Local FXO or E&M Interfaces...............................................................................46

7-1 Clocking, with Multiserver 500s Connected in a Back-to-Back Hookup..................................................48

7-2 Tests in the Diagnostics Menu ....................................................................................................................49

7-3 Local Data Loopback Test...........................................................................................................................51

7-4 Local Composite Loopback Test.................................................................................................................52

7-5 FXO and E&M Voice/Fax Connections.....................................................................................................52

7-6 Setting Up a Remote Composite Loopback Test.......................................................................................55

7-7 Setting Up a Remote Data Loopback Test .................................................................................................56

A-1 A Typical FXS Application ..........................................................................................................................58

A-2 Connectors on the Back Panel of the FXS Interface Module ..................................................................59

A-3 Wiring of the Connectors on the Back Panel ............................................................................................59

A-4 Cable Connections ......................................................................................................................................60

B-1 A Typical FXO Application .........................................................................................................................63

B-2 Back Panel of the FXO Analog Interface Module.....................................................................................64

B-3 Wiring of the Connectors on the Back Panel ............................................................................................64

B-4 Cable Connections ......................................................................................................................................65

B-5 Locations of the Straps on the FXO Interface Module.............................................................................66

C-1 Connections for the E&M Voice/Fax Interface Module ..........................................................................68

C-2 Connectors on the Back Panel ...................................................................................................................69

C-3 Connecting the E&M Cable........................................................................................................................70

C-4 Type I Interface Connection.......................................................................................................................72

C-5 E&M Type II Interface Connection............................................................................................................73

C-6 E&M Type V Interface Connection Diagram.............................................................................................74

C-7 Where the Straps Are on the E&M Module...............................................................................................75

D-1 Removing the Top Cover ............................................................................................................................77

D-2 Configuring the Composite Interface........................................................................................................79

D-3 Configuring the Data-Channel Interface...................................................................................................81

F-1 Pin Assignments for the RS-232 COMPOSITE and DATA CHANNEL Connectors ...............................84

Page 7

MULTISERVER 500

6

F-2 RS-232-to-RS-232 DCE Crossover Cable (EZ423-0015) .............................................................................85

F-3 Pin Assignments for the V.35 COMPOSITE and DATA CHANNEL Connectors....................................86

F-4 V.35-to-DCE Crossover Cable (EHN070-005M).........................................................................................87

F-5 Pin Assignments for the RS-530 COMPOSITE and DATA CHANNEL Connectors ...............................88

F-6 RS-530-to-RS-530 DCE Crossover Cable .....................................................................................................89

F-7 RS-530-to-RS-449 DCE Crossover Cable .....................................................................................................90

F-8 RS-530-to-X.21 DCE Crossover Cable.........................................................................................................91

F-9 RS-232-to-DTE Straight Cable (EDN16C-xxxx-MF) ..................................................................................92

F-10 V.35-to-DTE Straight Cable (EHN071-005M) ............................................................................................93

F-11 RS-530-to-RS-530 DTE Straight Cable ........................................................................................................94

F-12 RS-530-to-RS-449 DTE Straight Cable ........................................................................................................95

F-13 RS-530-to-X.21 DTE Straight Cable ............................................................................................................96

Tables

1-1 Allowable Rate Combinations.......................................................................................................................8

5-1 Impedance-Strapping Requirements .........................................................................................................32

6-1 LED Indicators.............................................................................................................................................42

C-1 E&M Lead States..........................................................................................................................................71

D-1 List of Configuration Items for the Composite Interface.........................................................................78

D-2 List of Configuration Items for the Data Channel Interface....................................................................80

Page 8

CHAPTER 1: Specifications

7

Composite Interface

Type — RS-232 (CCITT V.24/V.28) serial

synchronous, internal/external clocking; fullduplex interfaces to support optional V.35,

RS-530, RS-449, and X.21 standards

Connector — DB25 female

Configured as — DCE

Speeds (bps) — 7200, 9600, 14,400, 19,200,

38,400, 56,000, 64,000, 72,000

NOTE: The Multiserver 500 will not operate with

clock rates, internal or external, other than

those specified above.

Data-Channel Interface

Number of Channels — 1

Type — RS-232 (CCITT V.24/V.28) serial

synchronous/asynchronous, full-duplex

interfaces to support optional V.35, RS-530, RS449 and X.21 standards.

Connector — DB25 female connector

Configured as — DCE

Sync Channel Data Rates — 1200 bps to

72,000 bps

Sync-Channel Bandwidth Allocation — Fixed rate

or dynamic rate

Fixed Rate: Always operates at guaranteed rate

Dynamic Rate: Operates at either a maximum

configured rate or guaranteed configured rate,

depending on voice/fax activity and DBA

configuration

Dynamic Rate

Switching Status — On-hook/off-hook, or

idle/active voice/fax traffic

Maximum Rate — Composite rate minus

overhead

Async Channel

Data Rates — 1200 bps to 57,600 bps

Data Bits — 7 or 8 data bits plus 1 parity bit

Parity — Space, mark, even, odd, none

Stop Bits — 1, 1.5, and 2 per character

Flow Control — RTS/CTS and X-ON/X-OFF;

must be configured the same way at each end

EIA Controls: — 4 full-duplex control signals

supported

Voice/Fax Channel

Interface Types — E&M, FXS, or FXO, depending

on the type of voice/fax interface card installed

Digitizing Rates — Fixed rates of 4000, 4800,

6400, 7200, 8000, 9600, 12,000, 12,800, 14,400,

and 16,000. The voice/fax channel is

automatically assigned the highest fixed rate

within the available bandwidth. Available

bandwidth equals composite rate minus

guaranteed sync channel rate minus overhead.

Overhead is 400 bps for composite rates of less

than 56 Kbps, and 800 bps for composite rates

of 56 Kbps and above.

Specifications for Voice/Fax Modules — See

Appendixes A, B, and C

Command Port Interface

Type — RS-232 (CCITT V.24/V.28) serial

asynchronous

Connector — 8-position modular jack wired as RJ-

1D DCE

Speeds — 1200 bps to 19,200 bps

Data Bits — 7 or 8 data bits plus 1 parity bit

Parity — Space, mark, even, odd, none

1. Specifications

Page 9

MULTISERVER 500

8

Stop Bits — 1, 1.5, and 2 per character

Flow Control — X-ON/X-OFF

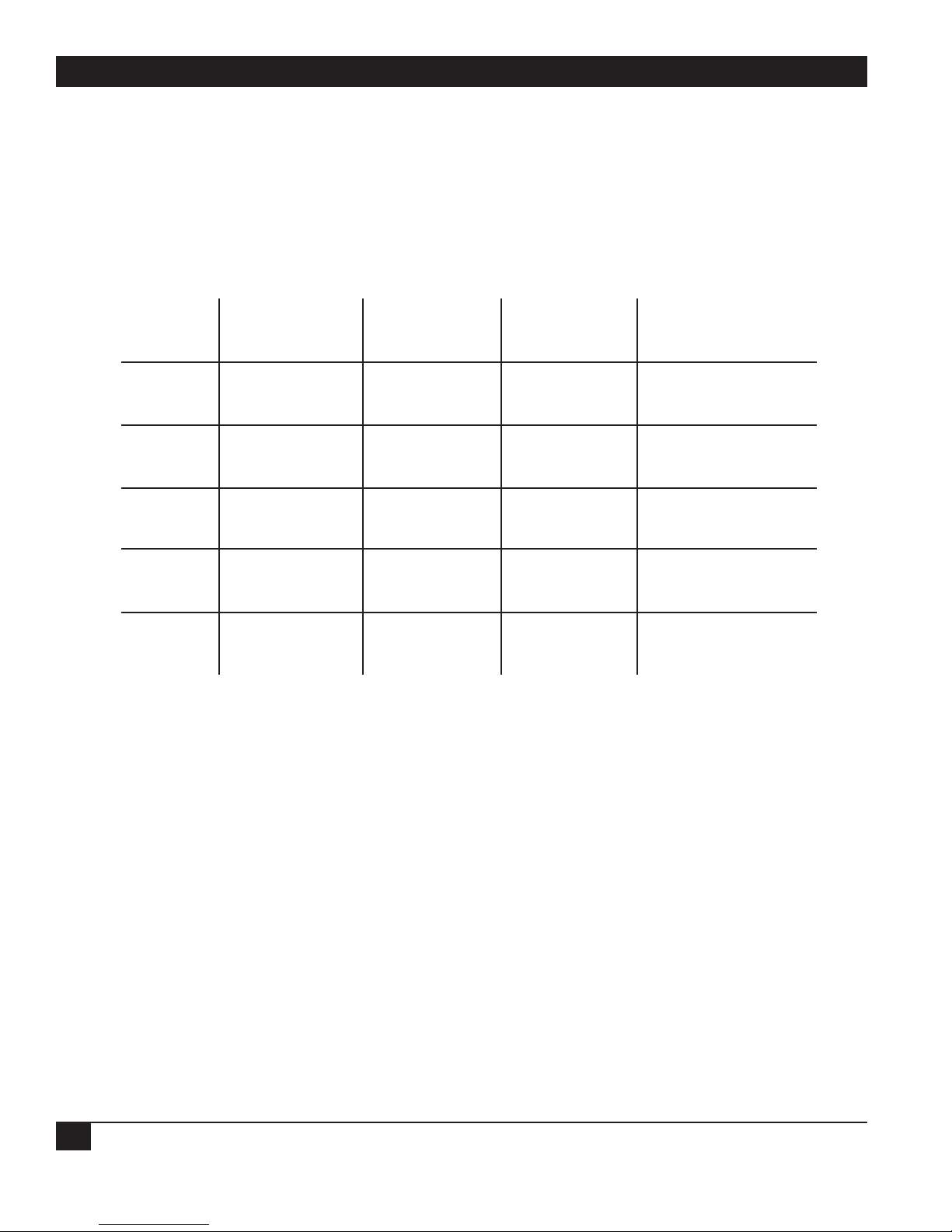

Allowable Rate Combinations

Table 1-1 shows the allowable combinations of

composite and data channel rates.

Table 1-1. Allowable Rate Combinations

Composite Sync Data DBA Max Maximum

Rate Rate Sync Rate Async Rate

---------------------------------------------------------------------------7200 1200 6800 3600

2400 6800

3600 6800

---------------------------------------------------------------------------9600 1200 9200 4800

2400 9200

3600 9200

4800 9200

----------------------------------------------------------------------------

14400 1200 14400 9600

2400 14000

3600 14000

4800 14000

7200 14000

9600 14000

----------------------------------------------------------------------------

19200 1200 14000 14000

2400 14000

3600 19200

4800 19200

7200 19200

9600 19200

12000 19200

14400 19200

Composite Sync Data DBA Max Maximum

Rate Rate Sync Rate Async Rate

---------------------------------------------------------------------------38400 1200 14400 28800

2400 14400

3600 19200

4800 19200

7200 19200

9600 19200

12000 28800

14400 28800

19200 33600

28800 38000

33600 38000

---------------------------------------------------------------------------56000 1200 14400 38400

2400 14400

3600 19200

4800 19200

7200 19200

9600 19200

12000 28800

14400 28800

19200 33600

28800 38400

33600 48000

38400 55200

46400 55200

48000 55200

51200 55200

Page 10

CHAPTER 1: Specifications

9

Composite Sync Data DBA Max Maximum

Rate Rate Sync Rate Async Rate

---------------------------------------------------------------------------64000 1200 14400 38400

2400 14400

3600 19200

4800 19200

7200 19200

9600 19200

12000 28800

14400 28800

19200 33600

28800 38400

33600 48000

38400 56000

46400 56000

48000 63200

51200 63200

56000 63200

57600 63200

---------------------------------------------------------------------------72000 1200 14400 38400

2400 14400 with 8-bit data

3600 19200

4800 19200

7200 19200

9600 19200 57600

12000 28800 with 7-bit data

14400 28800

19200 33600

28800 38400

33600 48000

38400 56000

46400 56000

48000 64000

51200 64000

56000 71200

57600 71200

64000 71200

Indicators — Self-test, EEPROM test, local and

remote data loopback tests, and local and

remote composite loopback tests

Power Requirements — 100-250 VAC, @ 0.9A, 50-

60Hz

Power Supply — External, provided with the

Multiserver

Size — 11.25″L × 8.5″W × 3″H (29 × 22 × 8 cm)

Weight — 3.4 lb. (1.5 kg)

Operating Environment —

Temperature: 32 to 114° F (0 to 45.5° C)

operating; -40 to 158° F (-40 to 70° C) storage

Relative Humidity: 25% to 75%

Atmospheric Pressure: 12.47 to 15.37 psi (86 KPA

to 106 KPA)

Agency Compliance

FCC Part 15, Class A

FCC Part 68

C.R.C., C. 13744

VDE 0871 Level B

CSA Standard C.22.2 No. 950 M-89

UL 1950

BABT 340, Issue 6

TÜV/GS-EN 60950/VDE 0805

DOC CS-03

Page 11

MULTISERVER 500

10

2.1 Multiplexing and the Multiserver 500

The Multiserver 500 is a standalone voice/fax/data

multiplexor. It converts analog voice into low-bitrate digital format, and multiplexes the digitized

voice with data into a composite digital stream. The

composite stream is transmitted over a leased line

to a remote site.

At the remote site, another Multiserver 500

demultiplexes the composite stream into data and

digitized voice, and reconverts the digitized voice

into analog form.

It’s the low bit rates that allow voice signals to

share a leased line with data. When you add

digitized voice to an already existing data link, you

don’t pay anything more than your existing leasing

costs; the voice gets a free ride.

In addition to accepting analog voice signals for

digital conversion, the Multiserver 500 can also

process analog signals from a fax machine. When

the mux detects fax signals, the firmware switches

into fax mode. In this mode, signals are

demodulated into fax symbols and passed as data to

the remote end. At the remote end the symbols are

remodulated to the correct standards.

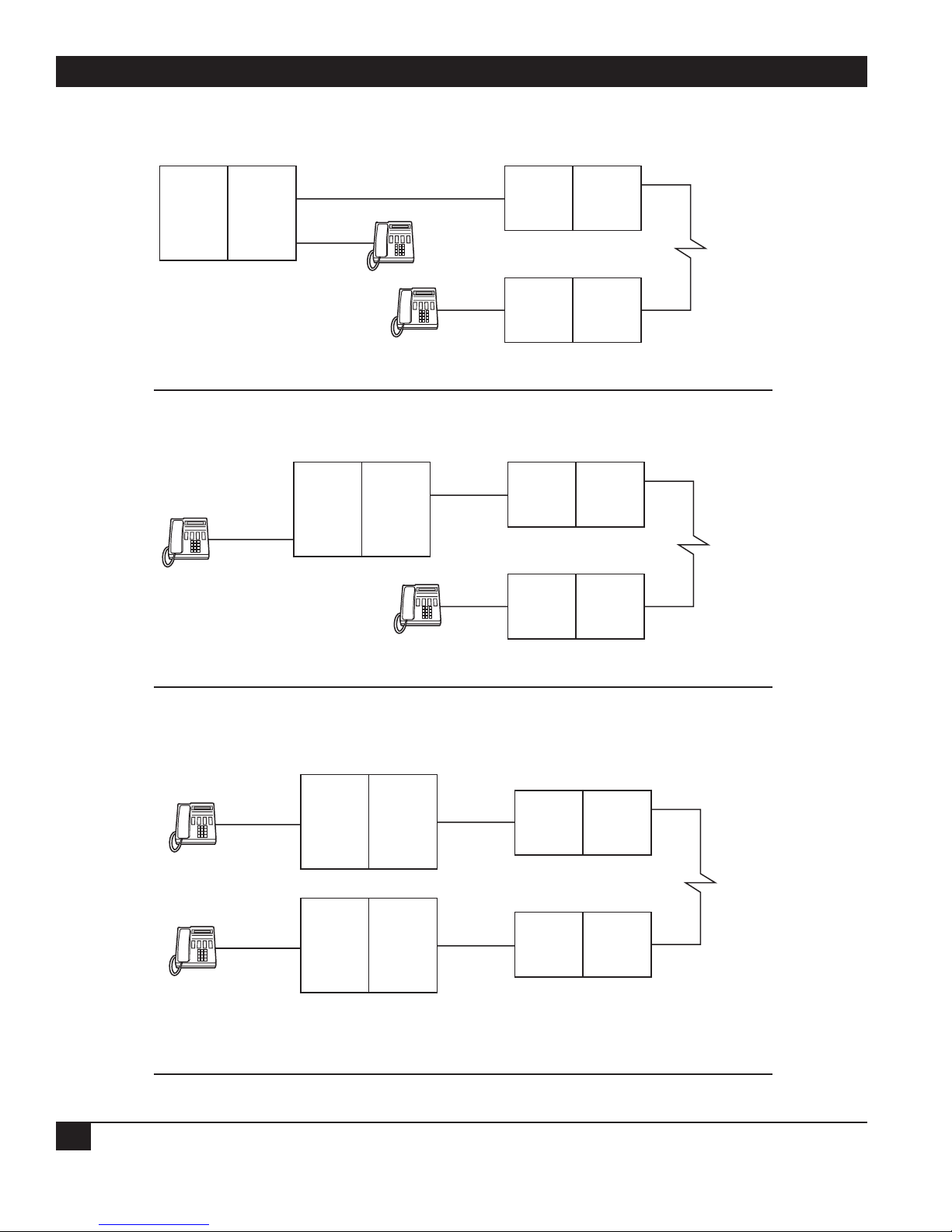

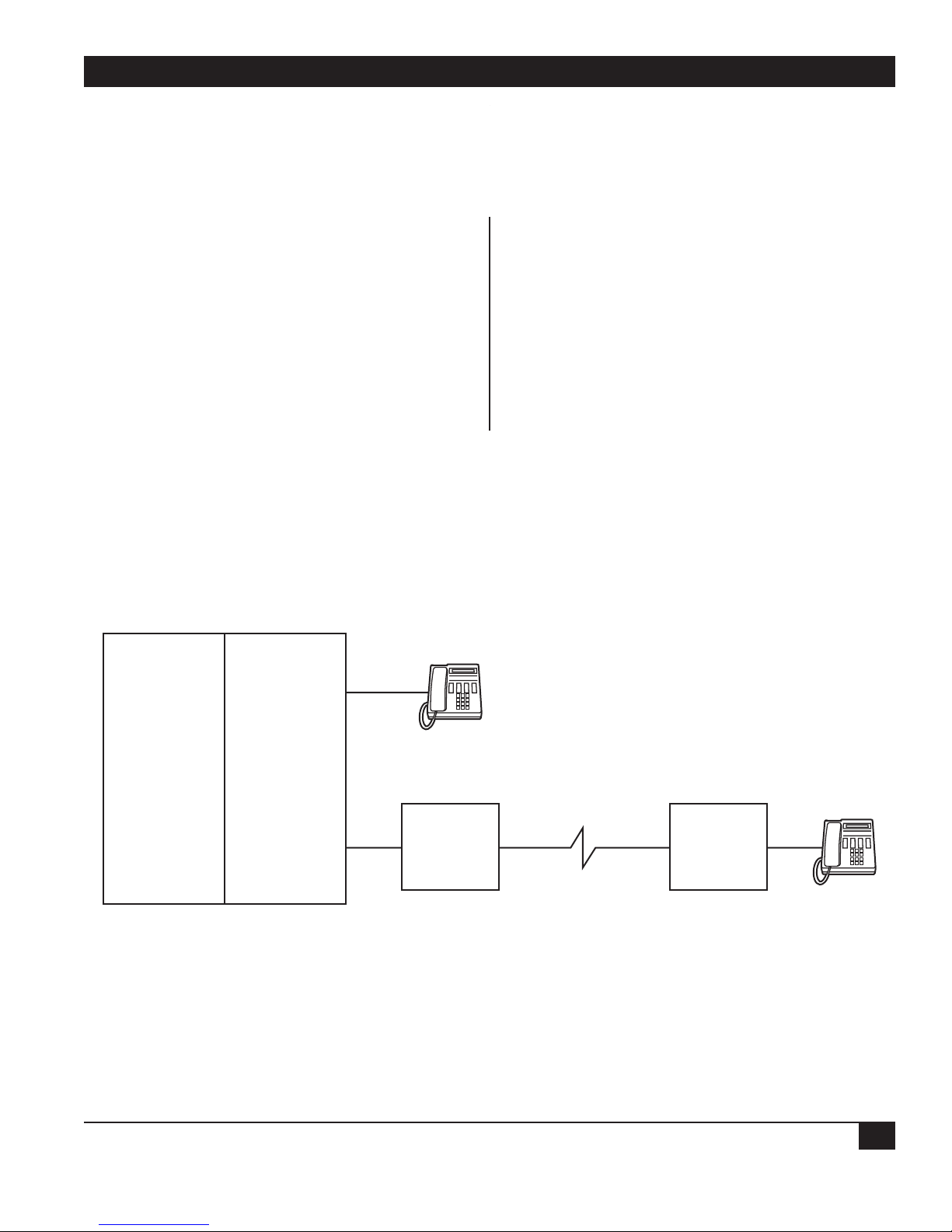

A typical Multiserver 500 application is shown in

Figure 2-1.

2.2 Description of the Multiserver 500

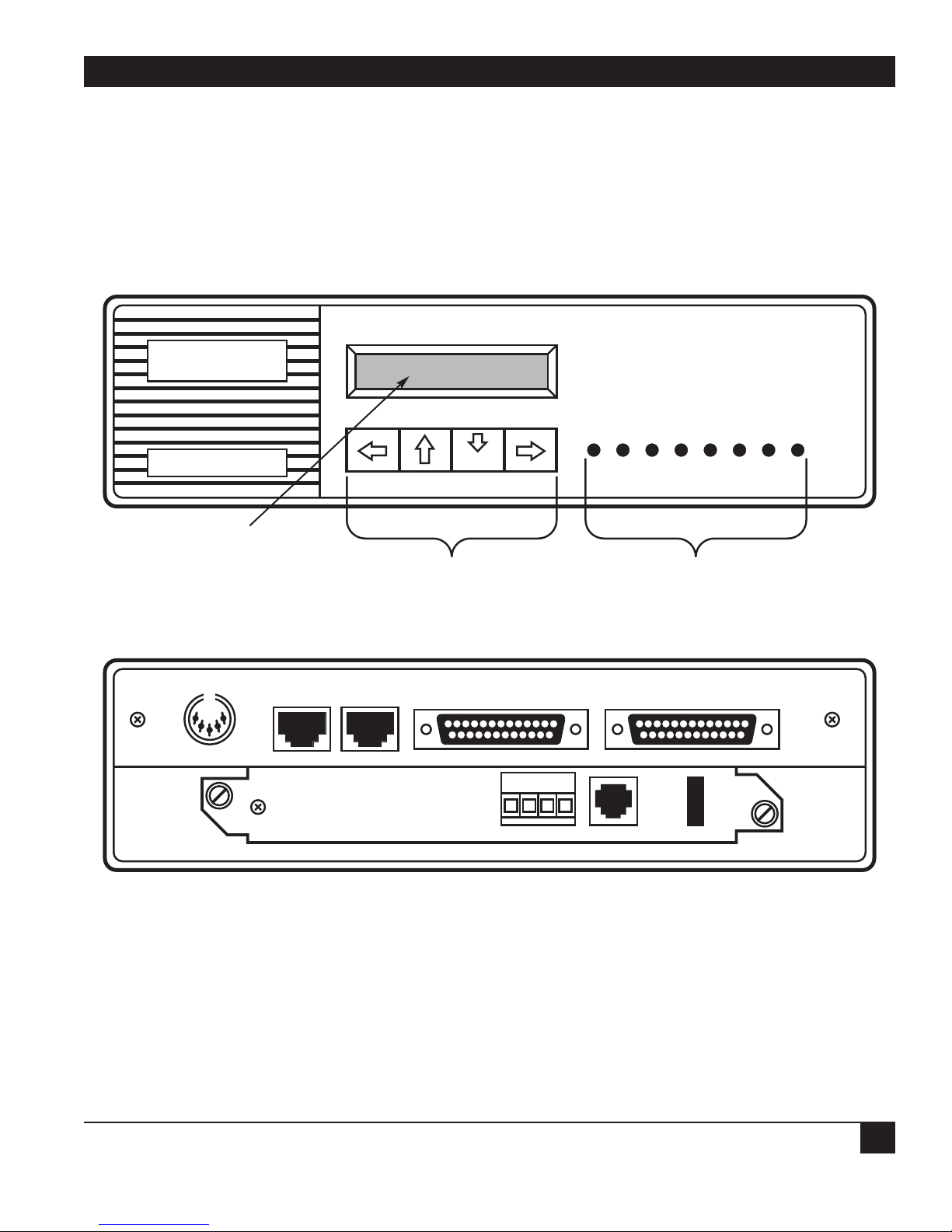

Physically, the Multiserver 500 is an assembly of

printed circuit boards—one data

channel/composite channel and one voice/fax

module—housed in a rectangular enclosure (see

Figure 2-2). The front of the unit includes an LED

display, an LCD display, and a keypad.

The LED display monitors power status, self-test

results, link conditions, and voice and data channel

activities.

The LCD display provides status, events, and

messages, and together with the keypad is used for

configuration, diagnostics, and administration

functions.

The physical ports for connecting the Multiserver

500 to the various interfaces are on the back of the

unit.

2. Introduction

Figure 2-1. Typical Multiserver 500 Application.

PBX

MAINFRAME

LOCAL

MULTISERVER 500

COMPOSITE

LINK

REMOTE

MULTISERVER 500

VOICE

Page 12

CHAPTER 2: Introduction

11

Figure 2-2. Multiserver 500, Front and Rear Views.

LCD DISPLAY

KEYPAD

FRONT VIEW

REAR VIEW

LED INDICATORS

PO IS TD RD LS RS VA TM

MULTISERVER 500

DC POWER CMD

PORT-IN

EXE

CMD

PORT-OUT COMPOSITE DATA CHANNEL

FXS

SG R T

FXS

Page 13

MULTISERVER 500

12

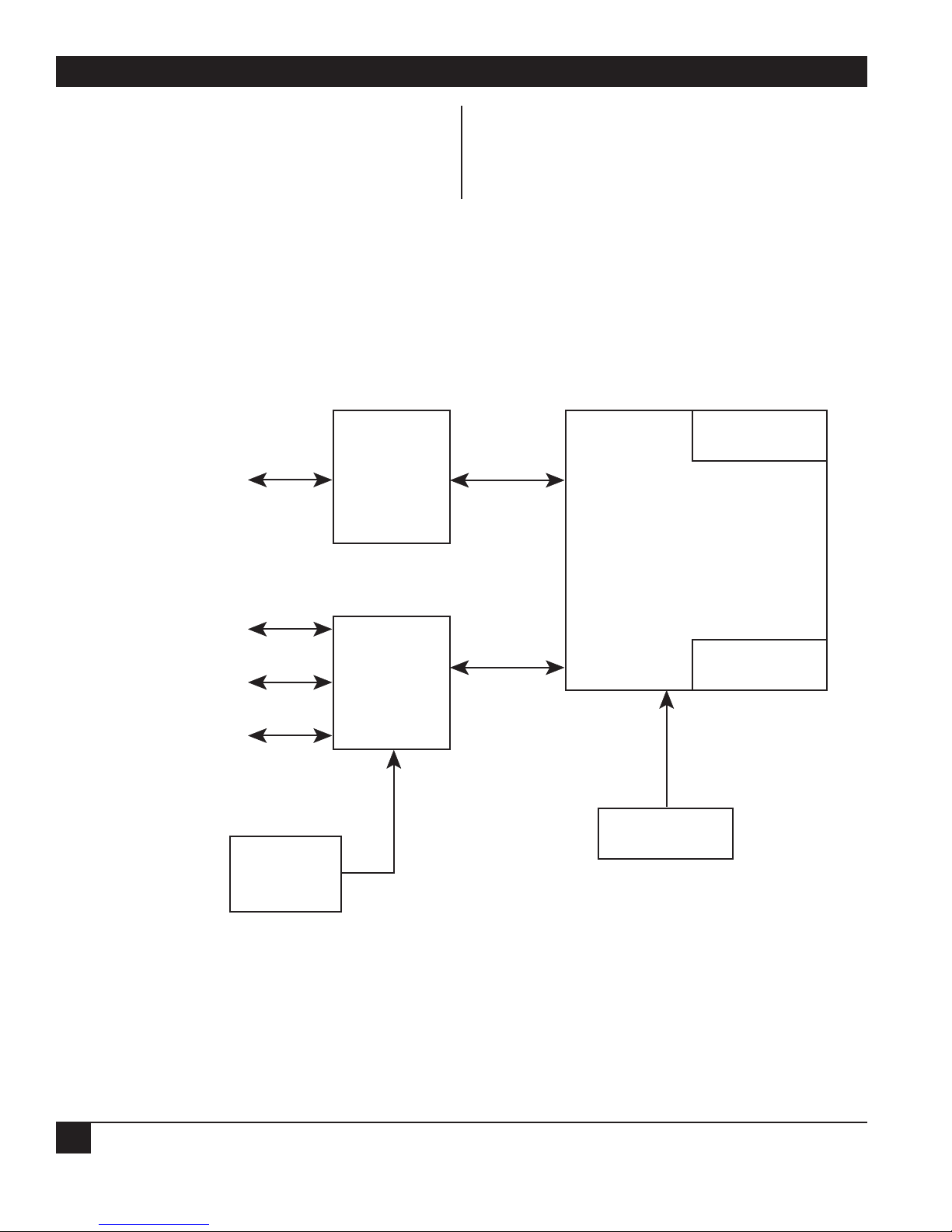

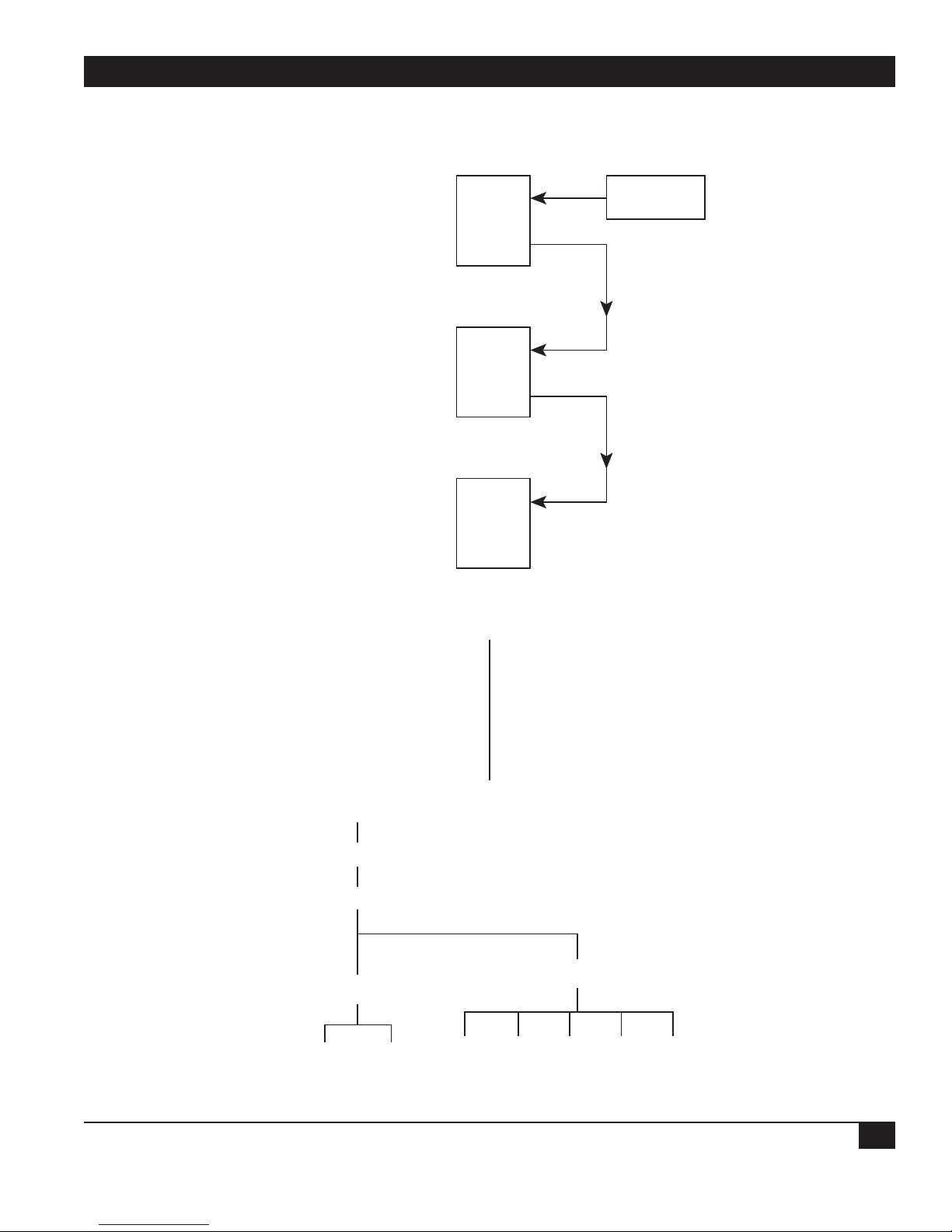

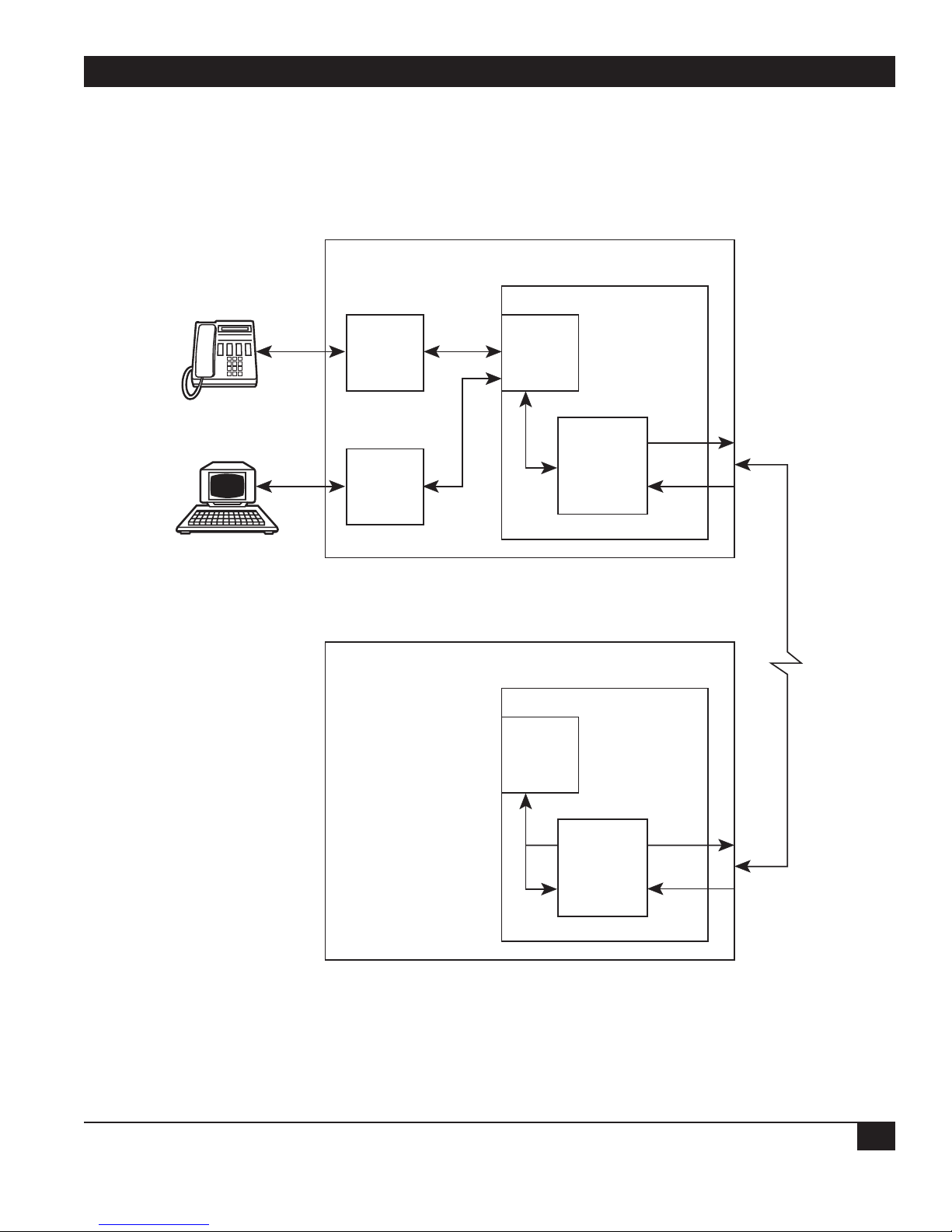

2.3 Block Diagram

Figure 2-3 is a diagram of the basic building blocks

that make up the Multiserver 500: the digital

processing module, the voice/fax interface module,

and the serial interface module. Attached to the

basic building blocks are the LCD display and

power-supply unit.

Figure 2-3. Multiserver 500 Block Diagram.

-

VOICE/FAX

INTERFACE MODULE DIGITAL PROCESSING MODULE

VOICE/FAX

SERIAL INTERFACE

MODULE

LED

DATA

COMPOSITE

COMMAND PORT

AC

POWER

POWER

SUPPLY

UNIT

KEYPAD

RIBBON

CABLE

LCD

Page 14

CHAPTER 2: Introduction

13

2.3.1 VOICE/FAX INTERFACE MODULE

The main function of the voice/fax interface

module is to convert the analog signals from the fax

machine or telephone equipment into digital form,

so they can be used by the digital processing

module. In addition, the voice/fax interface

module supplies impedance matching and signaling

conversion between the analog interface and the

Multiserver 500.

2.3.2 D

IGITAL PROCESSING MODULE

The digital processing module is the main

processing unit of the Multiserver 500. Its functions

include voice compression and multiplexing. In

addition, the LCD display and the keypad form part

of the digital processing module.

2.3.3 S

ERIAL INTERFACE MODULE

The serial interface module provides physical

connections for the data, composite, and Command

Port interfaces. It also contains the clockgenerating circuits derived either from internal or

external sources.

2.3.4 LCD

With the keypad, the LCD lets you configure and

monitor the Multiserver 500. It physically connects

to the digital processing module by a ribbon cable.

2.3.5 P

OWER SUPPLY

Power is supplied from a detachable power supply

through a connector at the back of the

Multiserver 500.

2.4 Interfaces

There are four interfaces that connect to the

Multiserver 500: data channel, voice/fax channel,

Command Port, and composite ichannel nterface.

2.4.1 D

ATA CHANNEL

The data channel interface is an RS-232 interface

terminated in a DB25 connector wired as DCE.

Support for V.35, RS-449/RS-530, and X.21 physical

levels is available on an optional basis, implemented

by daughterboards that plug into the serial

interface module.

The mux can accept both synchronous data

ranging from 1200 bps to 72,000 bps, and

asynchronous data ranging from 1200 bps to 57,600

bps.

2.4.2 VOICE/FAX CHANNEL

Depending on the type of telephone equipment (or

other analog equipment) interfacing with the

voice/fax channel, the voice/fax channel conforms

with one of three common types of signaling

conventions:

•FXS (Foreign Exchange Station)—Loop Start

•FXO (Foreign Exchange Office)—Loop Start

•E&M (E-lead and M-lead)—Tie Line Trunk

You can easily match the Multiserver 500 with the

correct telephone interface with a set of three

optional analog interface modules: FXS, FXO, and

E&M.

For more detailed information on the analog

interface modules, refer to Appendixes A, B, and C.

2.4.3 C

OMPOSITE CHANNEL

The composite is a synchronous channel ranging

from 7200 bps to 72,000 bps. Physically, the

composite channel is an RS-232 port terminated in

a DB25 connector wired as DCE. Support for V.35

RS-449/RS-530, and X.21 physical levels is also

available, implemented by daughterboards that

plug into the serial interface module.

2.4.4 C

OMMAND P

ORT

The Command Port is one way to access the

command facility of the Multiserver 500. Use the

command facility to issue commands and to

monitor status.

Physically, the Command Port is a set of two RJ-45

connectors at the back panel. It’s used to connect

an external asynchronous terminal to the

Multiserver 500.

In a single Multiserver 500 application, the CMD

PORT-IN connector is used for connection to the

terminal.

When several muxes are controlled by a single

terminal, the CMD PORT-IN connector connects to

the previous Multiserver 500 (or terminal, if it is the

first unit in line) and the CMD PORT-OUT

connector connects to the next Multiserver 500 in

Page 15

MULTISERVER 500

14

line.

2.5 Options

As described earlier, the composite port and data

channel interface connectors are wired, as

standard, for interfacing with RS-232 type devices.

You can change the interface with a conversion kit.

See the next section for the part numbers.

For additional information, refer to Appendixes D

and F.

2.6 Models Covered in This Manual

The basic Multiserver 500 is part number MX400A232/232. You might also have ordered it in any of

the optional configurations:

MX400A-35/35: V.35 composite interface, V.35 data

interface

• Base unit (MX400A-232/232)

• Two MX410C-35 Interface Cards

MX400A-422/422: RS-422 (X.21) composite interface,

RS-422 (X.21) data interface

• Base unit (MX400A-232/232)

• Two MX410C-422 Interface Cards

MX400A-422/35: RS-422 (X.21) composite interface,

V.35 data interface

• Base unit (MX400A-232/232)

• MX410C-422 Interface Card

• MX410C-35 Interface Card

MX400A-35/232: V.35 composite interface, RS-232 data

interface

• Base unit (MX400A-232/232)

• MX410C-35 Interface Card

MX400A-422/232: RS-422 composite interface, RS-232

data interface

• Base unit (MX400A-232/232)

• MX410C-422 Interface Card

In addition to the Multiserver 500 (MX400), this

manual covers the following voice/fax interface

card models:

• MX401C: Standard E&M Interface Module

• MX402C: Enhanced E&M Interface Module

• MX403C: Standard FXO Interface Card

• MX404C: Enhanced FXO Interface Module

• MX406C: Standard FXS Interface Card

• MX407C: Enhanced FXS Interface Module

Page 16

CHAPTER 3: Installation

15

Use the following procedures as a setup guide.

3.1 Unpacking the Multiserver 500

Unpack and inspect the equipment. Report any

physical damage to the shipping carrier. Save the

packing material. You may need it if you need to

return the unit for repair.

Check the contents of the equipment against the

packing slip. Verify that you have received the

following:

• The Multiserver 500

• If applicable, one modular cable for connecting

your FXS or FXO interface module to

telephone equipment

• One RJ-45-to-DB25 adapter

• One 8-conductor modular cable for use with the

adapter

• One power supply

Appendix F contains wiring diagrams for the above

cables. You may use them to construct your own

interface cables. Refer to Appendixes A, B, and C

for telephone interface cabling details.

3. Installation

Page 17

MULTISERVER 500

16

3.2 Installing the Multiserver

3.2.1 SELECTING AN INSTALLATION SITE

You can place the unit on a tabletop or shelf large

enough to accommodate it. Allow enough space to

get to the cables easily and remove the cover, and

make sure there is unobstructed air flow from the

sides of the unit.

3.2.2 C

ABLE AND POWER CONNECTIONS

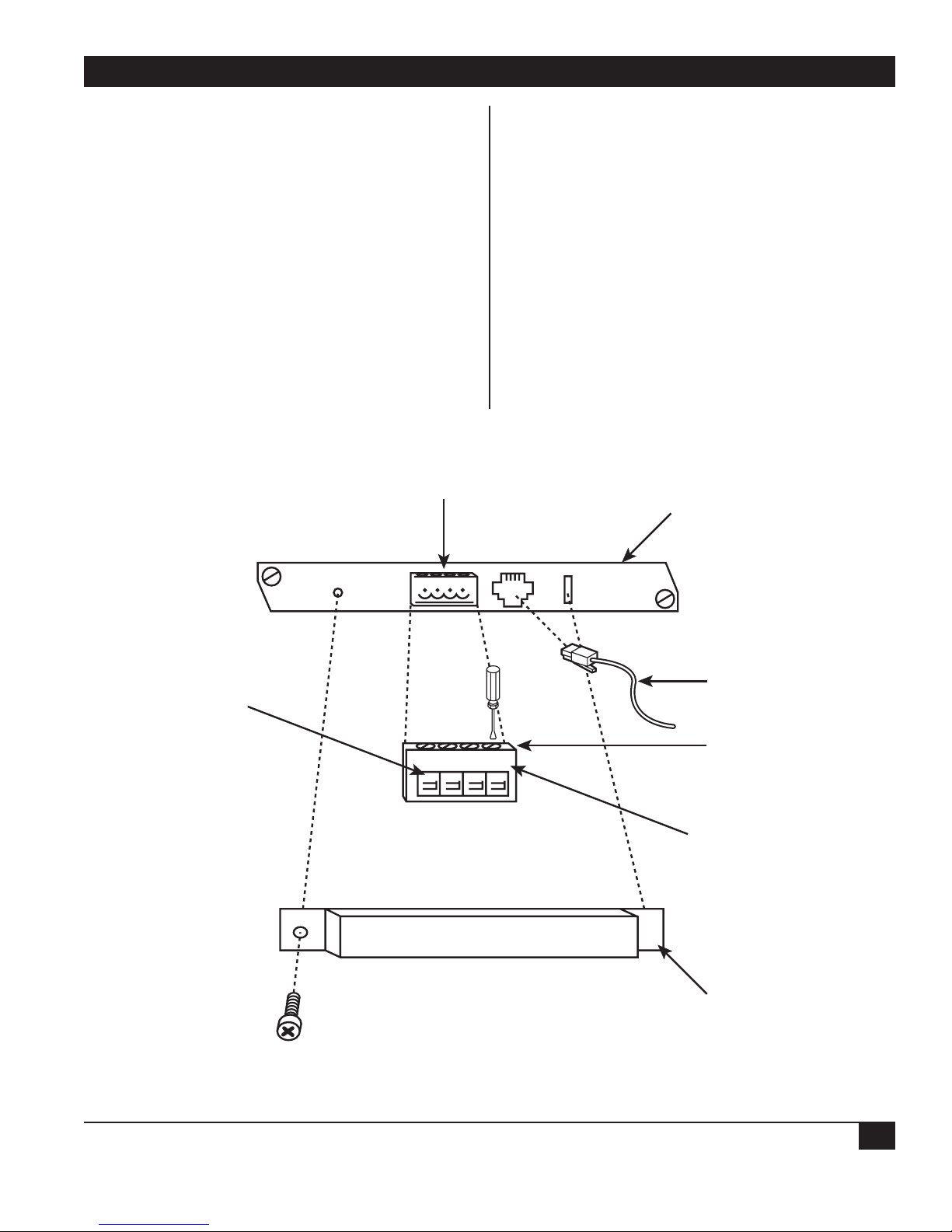

Figure 3-1 shows the rear panel of the

Multiserver 500.

1. Composite Interface

Use a crossover cable appropriate for your

installation. (See Section F.1 in Appendix F.)

Connect one end to the COMPOSITE connector

and the other end to the DCE device.

2. Data Channel Interface

Use a straight cable appropriate for your

installation. (See Section F.2.) Connect one end to

the DATA CHANNEL connector and the other end

to the DTE device.

3. Telephone Interface

Requirements vary with the type of telephone

equipment you’re connecting to—and with the type

of voice/fax interface module installed in the

Multiserver 500. Refer to Appendixes A through C

for details.

4. Power Connection

Connect the power supply output directly into the

DC POWER connector of the Multiserver 500.

Connect the other end to an AC wall outlet.

Figure 3-1 Cable and Power Connectors.

ASYNCHRONOUS

TERMINAL

CONNECT TO

DCE DEVICE

CONNECT TO

DTE DEVICE

DC POWER CMD

PORT-IN

CMD

PORT-OUT COMPOSITE DATA CHANNEL

SG R T

FXS

FXS

Page 18

CHAPTER 3: Installation

17

WARNING!

Do not use any power supply other

than the one provided with your Multiserver 500, as illustrated in Figure 3-1.

Any other power supply could damage

the Multiserver 500.

5. Connecting a Terminal to the Command Port

See Chapter 6 for information on setting up and

using your terminal.

3.3 Setting the Composite Transmit Clock

If your composite interface is connected to a DCE

device as in Figure 3-2, verify that the composite

clock is set to external. You can do that from the

LCD/keypad:

Main Menu

Configure Parameter

Composite Link

External Clock

NOTE: As shown in Figure 3-2, the Multiserver 500

provides transmit and receive clocks to the

synchronous data interface.

CAUTION!

Once a pair of Multiserver 500s,

configured for external clocking, have

established communications, the

clocking rate provided from the link

DCE device cannot be changed. If the

DCE rate is changed you must either

cycle the power off and on on the

Multiserver 500 or disconnect the link

cable and then reconnect.

You can use two Multiserver 500s as a diagnostics

tool. Simply connect two Multiserver 500s back to

back and bench-test them. To do this, set both

muxes to internal clock and select a composite

clock rate.

Once you’ve selected a composite clock rate, you

must set both the local and remote muxes to the

same rate. The procedure is as follows (see

Figure 3-3 ):

2. Set the clock rate (9600) of the local unit to

external:

>COM C=EX R=9600 <cr>

Figure 3-2. Clocking with Multiserver 500 Connected to a DCE Device

DATA SOURCE MULTISERVER 500 DCE DEVICE

RxC

RxD

RxC

RxD

Set for

External

TxD

TxC

Clock

TxD

TxC

Page 19

Figure 3-3. Installing or Removing the Voice/Fax Interface Module.

MULTISERVER 500

18

3. Save the clock rate:

>SA

4. At the remote unit, repeat steps 2 and 3.

NOTE: Both the local and the remote Multiserver

500s must be set to the same composite

clock rate. Otherwise, the system will lock

up.

3.4 Installing the Voice/Fax Interface Module

Normally, the Multiserver 500 is shipped with the

voice/fax interface module already installed. If it

was shipped separately, or if you need to change the

existing module, see Figure 3-3 and proceed as

follows:

Tool Required: Medium-sized flat-head screwdriver.

To install:

1. Facing the rear of the Multiserver 500, place the

voice/fax interface module in the card guides,

then slide it toward the rear until it is firmly

seated in its mating connector in the digital

module.

DC POWER CMD

PORT-IN

CMD

PORT-OUT COMPOSITE DATA CHANNEL

FXS

SG R T

VOICE/FAX

INTERFACE MODULE

SCREW (2)

FXS

CAPTIVE

Page 20

CHAPTER 3: Installation

19

2. Secure the module with the two spring-loaded

captive screws. For further information,

including cable installation, refer to Appendix

A, B, or C.

To remove:

1. Using a medium-sized flat-head screwdriver,

unscrew the two spring-loaded captive screws.

2. Grasp the interface module firmly and slide it

slowly toward you until it’s free of its mating

connector, then slide it out of the

Multiserver 500.

3.5 Setting the Time and Date

To set the time of day and date from the Command

Port terminal, enter:

>U T=hh:mm:ss (set)

>U D=dd/mm/yy (set)

Note that time and date are not stored in EEPROM

(non-volatile memory), and must be set again each

time the Multiserver is powered up.

See Chapter 6 for additional Command Port

details.

To set the time of day and date from the

LCD/keypad, follow the diagram in Figure 3-4.

Page 21

MULTISERVER 500

20

Refer to Chapter 4 for additional LCD/keypad details.

Multiserver 500

Time 00:00:00

MAIN MENU

CONFIGURE PARAM

VOICE CHANNEL

SET TIME AND DATE

SET TIME

SET DATE

DATE: 01/01/00

SET

YEAR

DIGITS

LAST

SET

MONTH

DIGITS

NEXT

SET

DAY

DIGITS

FIRST

TIME: 00:00:00

Set hours digits first. Use up arrow to go

forward, use the down arrow to go

backward. When you’re finished, press

right arrow to advance to minutes.

Set minutes digits next. Use up/down

arrows. Press right arrow to advance to

seconds.

Set seconds digits last. Use right arrow to

return to main menu.

press down arrow

press down arrow

press down arrow

press left arrow twice

press down arrow

press down arrow

Figure. 3-4. Setting the Time and Date.

Page 22

CHAPTER 4: Using the LCD and Keypad

21

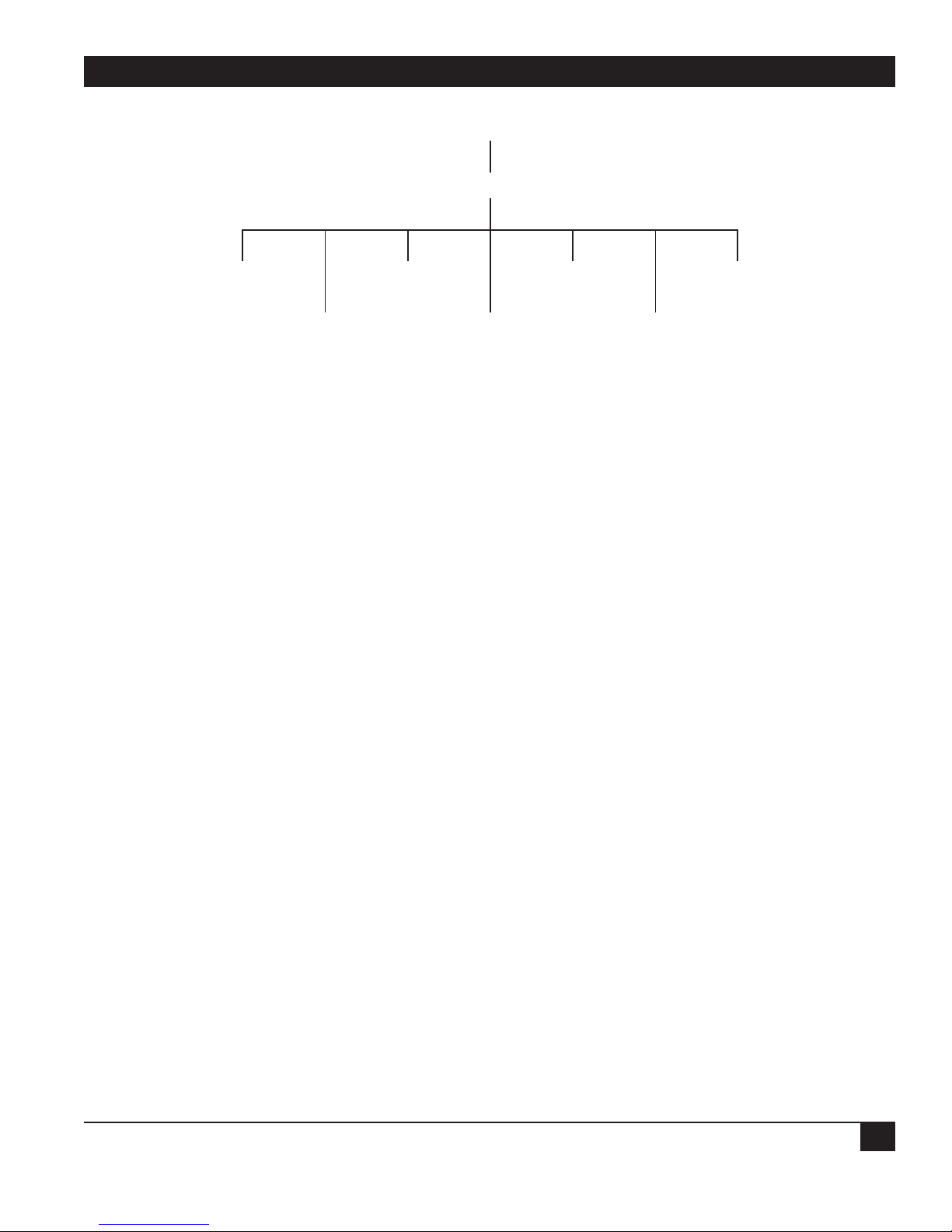

One of the ways to configure and monitor the

Multiserver 500 is to use the LCD/keypad. For the

Command Port method, see Chapter 5.

* NLP = Non-linear processing, which suppresses residual echo. In E&M 4-wire applications, voice quality

may be improved by disabling NLP.

Parameters shown in bold are default values.

4. Using the LCD and Keypad

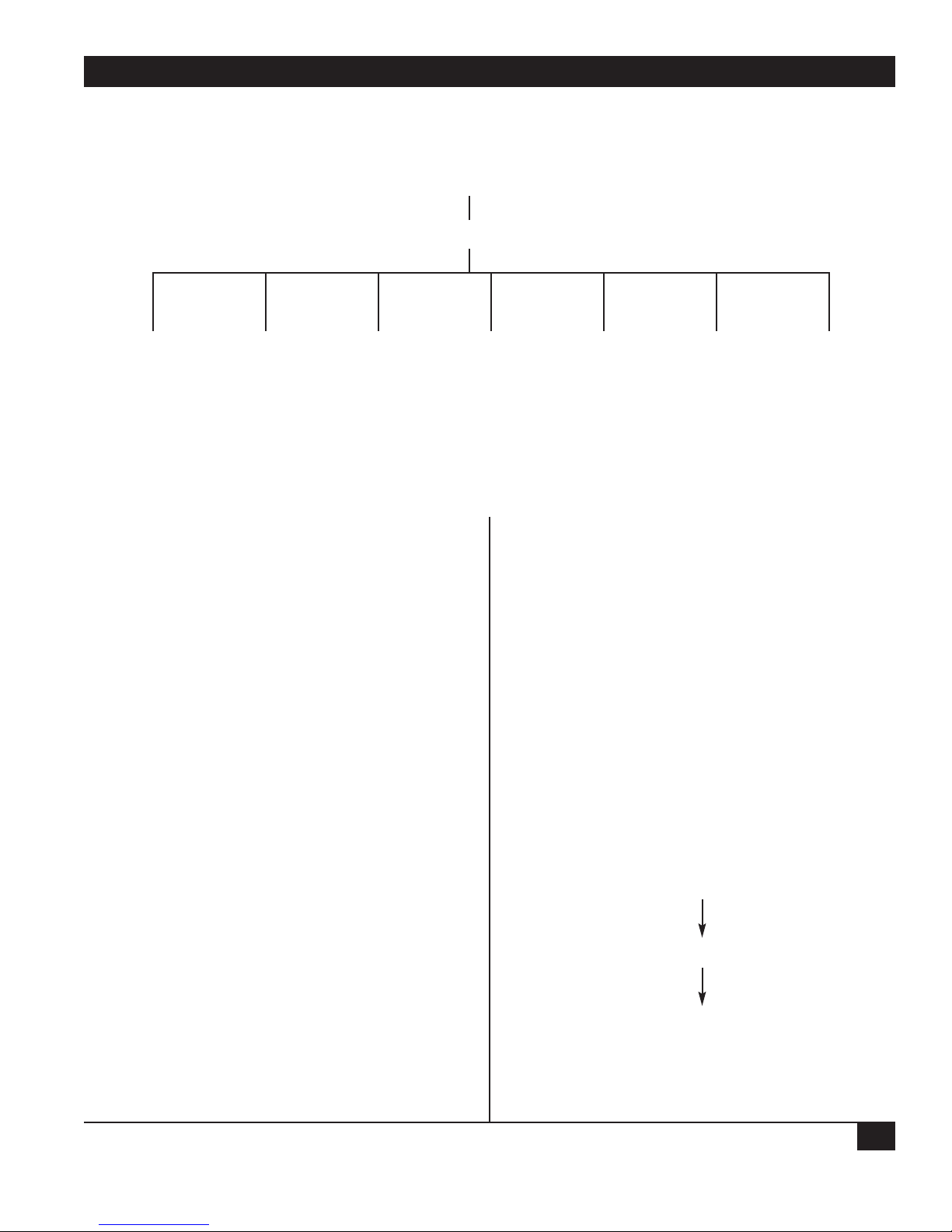

Main Menu

Status Diagnostics Reset Configure

Voice

Channel

Interface

Analog

Busy

State

Composite

Link

Data

Channel

Background Fax

Param

Command

Port

Factory

Default

Load

From

Mode

Save

EEPROM

Set

Password

Set Time

and Date

NLP Mode*

Silence

Disable EnableOn SystemOff

Regenerated Disable Enable

Page 23

MULTISERVER 500

22

* If you operate your equipment in the U.S.A. or Canada, input gain and output attenuation levels must be

set to 0 dB. In other countries, follow the standards of the country where the equipment is being used. If

there are no specific standards, set the input and output levels of your equipment to match the interfacing

telephone equipment.

Parameters shown in bold are default values.

Configure Param (cont.)

Analog Interface

Ringing

Frequency

Signalling

Format

DC Pulsed

DC

AC-15

Input Gain* Output

3 2 1 0 -1 -2 -3

4

5

6

7

8

9 10 19 20

Operation Extra Gain

2-Wire 4-Wire None 7

-4

-5

-6

22

21

25_Hz 50_Hz

Attenuation*

Interrupted

3 2 1 0 28 27 26

4

5

6

7

8

Ring Type Impedance

2-4

Interrupted

Repeated

1-2

600 Ohms Complex

25

24

23

22

21

9 10 19 20

Page 24

CHAPTER 4: Using the LCD and Keypad

23

NOTE: When you change these Command Port parameters, they become effective after you select a Save

and then a Reset.

* Does not include parity bit.

Parameters shown in bold are default values.

Configure Param (cont.)

Command Port

Parity Stop

Bits

1 21.5

Auto

1200

Data*

Bits

2400

4800

9600

Data

Rate

19200

Flow

Control

None Xon/Xoff 0........8

Enable Disable7 8

Local

Echo

Device

Number

None Even Odd Mark Space

Page 25

MULTISERVER 500

24

* Does not include parity bit.

Parameters shown in bold are default values.

(see next page for

parameters)

Configure Param (cont.)

Data Channel

Echo Flow

None Even Odd Mark Space

Enable Disable

1200

2400

1 1.5

3600

2 7 8

4800

7200

Asynchronous Synchronous

Data RateData Bit*Stop BitsParity

Control

Xon/Xoff

None

9600

14400

19200

28800

38400

EIA

Signal

CTS/

RTS

57600

RI DSR Control DCD Control CTS Control CTS

On

Off

Link

Off

On

Status

Remote

DTR

On

Off

Remote

RTS

On

RTS

Delay

Off

Local

RTS

125 ms 150 ms100 ms75 ms50 ms25 msNone

Page 26

CHAPTER 4: Using the LCD and Keypad

25

NOTE: The Multiserver 500 will not operate with clock rates, internal or external, other than those specified

above.

* Refer to Section 6.4.1 for a definition of Dynamic Bandwidth Allocation.

Parameters shown in bold are default values.

Configure Param (cont.)

Data Channel (cont.)

Synchronous

Rate Max

1200

(rate)

2400

3600

4800

7200

Transmit

Rate

12000

14400

9600

Internal Clock External Clock

28800

19200

Clock

Internal External

46400

33600

38400

Composite Link

48000

Off

56000

51200

Dynamic*

Bandwidth

Silence

57600

64000

Hook

72000

(maxrate)

9600

7200

14400

Clock Rate

19200

38400

56000

72000

64000

Page 27

MULTISERVER 500

26

* Shows status of all configuration parameters, as selected.

Main Menu (cont.)

Status

self test passed

self test active

checksum failed

ram failed

eeprom passed

eeprom failed

Analog

Interface

H/W Rev.

Dash No.

Configuration

Type

S/W Rev.

Dash No.

Remote Comp.

Local Comp.

Remote Data

Local Data

Comp. Loop

Data Loop

DSP

Dash No.

H/W

Rev.

Serial

Board

H/W Rev.

SystemDiagnosticsCurrent*

Type

Voice

Channel

I/F

Link

Status

CompositeSelf Test Analog

Clock

Rate

Data

Channel

Out

Level

Algorithm

Verification

I/F Type

Rate

PROM

Algorithm

Ver.

PROM

I.D.

Local

On/Off

Hook

Remote

On/Off

Hook

In

Level

Receive

Clock

Transmit

Clock

EIA

Signal

B0=

CTS

RTS

DCD

DTR

RI

DSR

UNA

Flow

Control

=

=

=

=

=

=

=

Page 28

CHAPTER 4: Using the LCD and Keypad

27

Main Menu (cont.)

Diagnostics

Composite

Remote

Composite

Local

Data

Remote

Data

Self

Test

TerminateLocal

EEPROM

Page 29

MULTISERVER 500

28

In addition to performing all of the functions from

the LCD/keypad, you can also do the same thing

with an asynchronous terminal connected to the

Command Port (with the exception of setting the

device number). This section describes how to

configure and strap the Command Port and how to

connect the asynchronous terminal to the

Command Port.

Once you’ve configured the Command Port and

connected the asynchronous terminal, you can use

the Command Port to configure and monitor the

Multiserver 500. See Section 6.3 for default details.

5.1 Factory Defaults

The factory defaults of the Command Port are as

follows:

Data Rate: Automatic Baud Rate

(ABR)

Number of Data Bits: 8

Parity: None

Number of Stop Bits: 1

Flow Control: None

Device Number: 0

Local Echo: Enabled

If your terminal meets all of the above parameters

(with the exception of device number), including

any of the compatible ABR rates, your Command

Port is ready for operation. ABR is compatible with

1200, 2400, 4800, 9600, and 19,200 bps.

Otherwise, the Command-Port parameters must

be reconfigured from the LCD/keypad, as shown in

Figure 5-1.

5. Using the Command Port

Page 30

CHAPTER 5: Using the Command Port

29

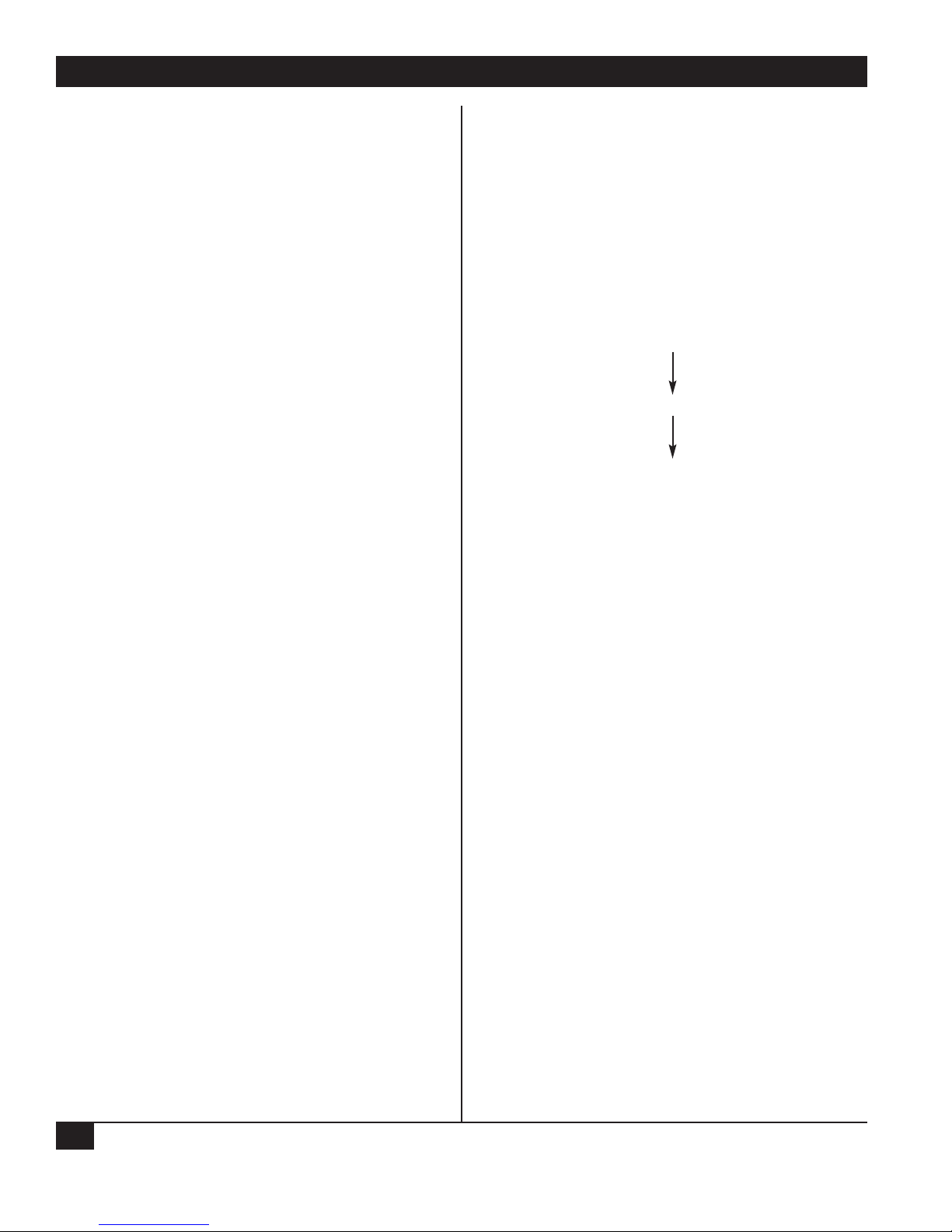

Main Menu

Figure 5-1. Reconfiguring the Command-Port Parameters.

Configure Parameter

Analog

I/F

Voice

Channel

Parity Stop Bit

121.5

Composite

Link

Data

Bits

Data

Channel

Command

Port

Data

Rate

Save

To

Load

From

Set Time

& Date

Flow

Control

None Xon/Xoff 0........8

Enable Disable8 7

Local

Echo

Set

Password

Device

Number

None Even Odd Mark Space

Auto

1200 2400 4800 9600 19200

Page 31

MULTISERVER 500

30

5.2 Connecting Asynchronous Terminals

The Command Port includes an interface

connector, so you can connect an asynchronous

terminal. The interface connector also lets you

control multiple Multiserver 500s from a single

terminal in a daisychain fashion.

5.2.1 C

ONNECTING A

SINGLE MULTISERVER 500

As shown in Figure 5-2, there are two RJ-45-type

Command Port connectors located on the rear

panel of the Multiserver 500: CMD IN and CMD

OUT. Cable requirements and pinouts are detailed

in Section 5.4. If your installation includes a single

Multiserver 500, connect the asynchronous terminal

to CMD IN. You will need an RJ-45 to DB25 adapter

to connect the cable to the asynchronous terminal.

NOTE: In a single-unit installation, the device

number must be left at its default value of 0,

and you must strap the Multiserver 500 for

the low-impedance position. Strapping

details are covered in Section 5.3.

5.2.2 C

ONNECTING MULTIPLE MULTISERVER 500S

Figure 5-2. Connecting the Asynchronous Terminal.

DC POWER CMD

PORT-IN

CMD

PORT-OUT COMPOSITE DATA CHANNEL

SG R T

FXS

FXS

Page 32

CHAPTER 5: Using the Command Port

31

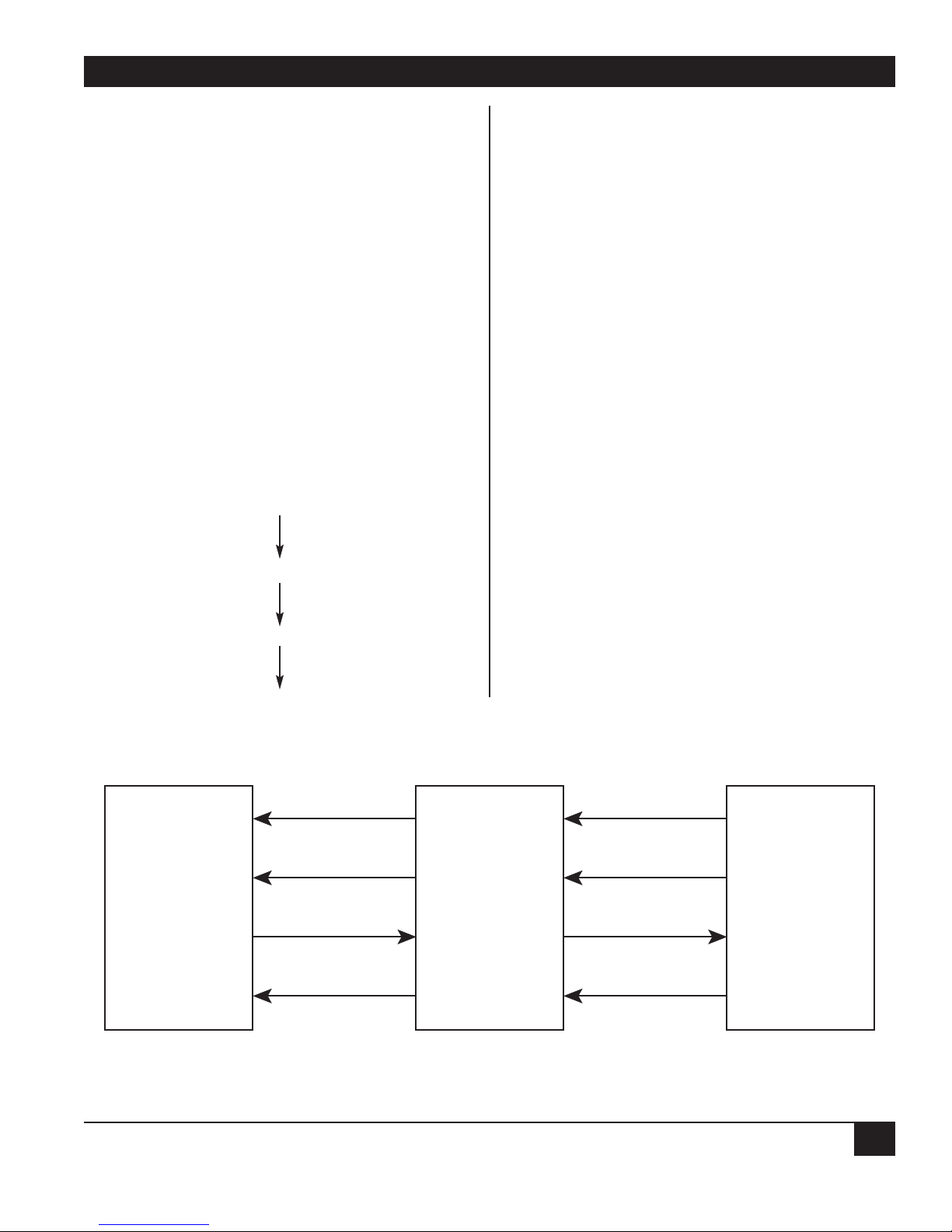

You can connect up to eight Multiserver 500s in a

daisychain and control the chain from a single

asynchronous terminal. Figure 5-3 shows the

topology for a typical three-Multiserver 500 local

installation. Before connecting them, you must

configure each Multiserver 500 with a fixed data

rate and then with a device number from the LCD

and keypad. (See Figure 5-4.) The default values are

8 data bits, 1 stop bit, no parity, autobaud, no flow

control, and local echo enabled.

At least one unit must be set to 1; each of the

other units may be set randomly to any number in

the range of 2 through 8, as long as no two units

have the same number.

5.3 Impedance Strapping

Multiserver 500

Figure 5-3. Typical Three-Multiserver Daisychain Topology.

Figure 5-4. Setting the Data Rate and Device Number.

Unit 1

Strap

for High Impedance

Multiserver 500

Strap

for High Impedance

Multiserver 500

Strap

for Low Impedance

Main Menu

Cmd

In

Cmd

Out

Unit 2

Cmd

In

Cmd

Out

Unit 3

Cmd

In

Cmd

Out

Async

Terminal

Configure Parameter

Command Port

Device Number

0.............8

Auto

Data Rate

1200 4800 9600 19200

Page 33

MULTISERVER 500

32

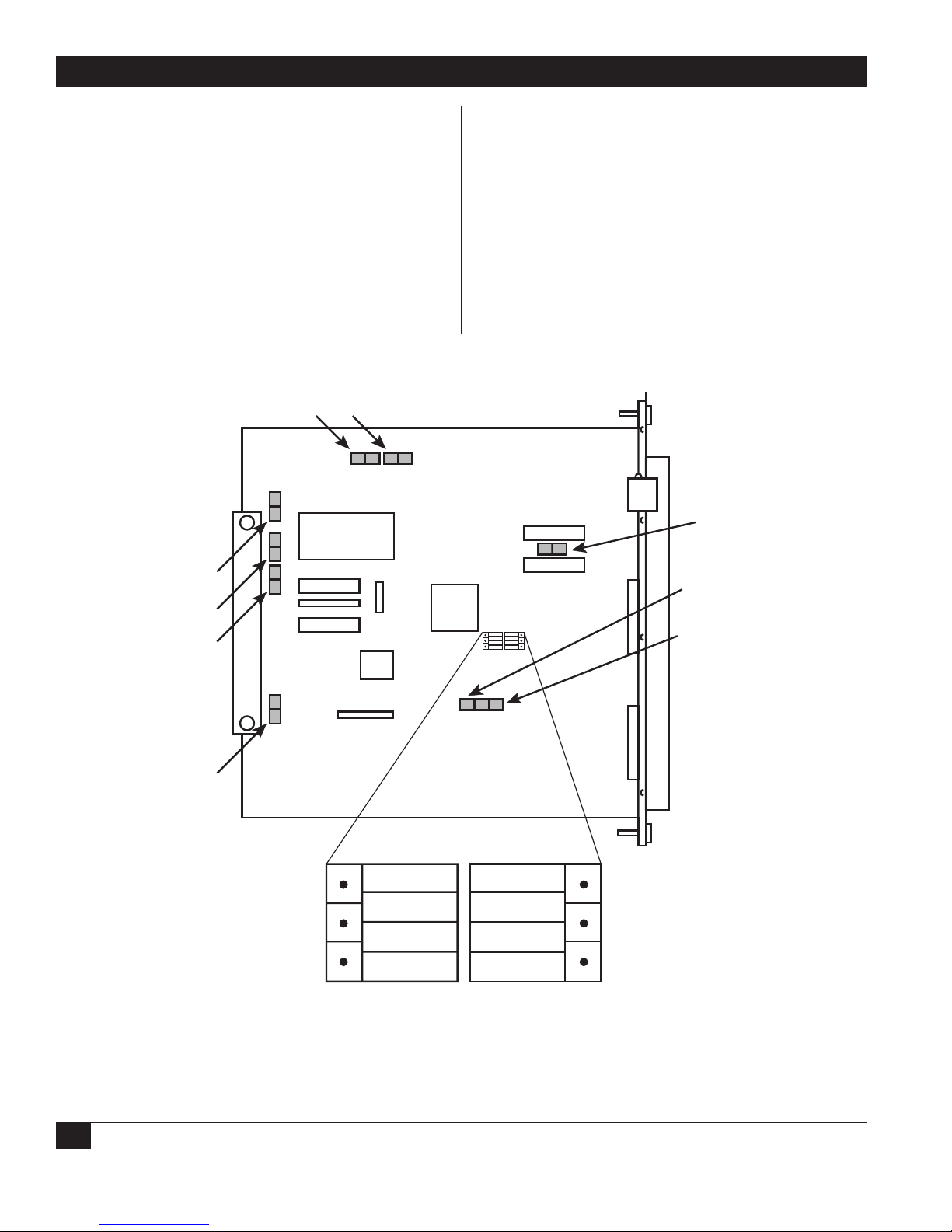

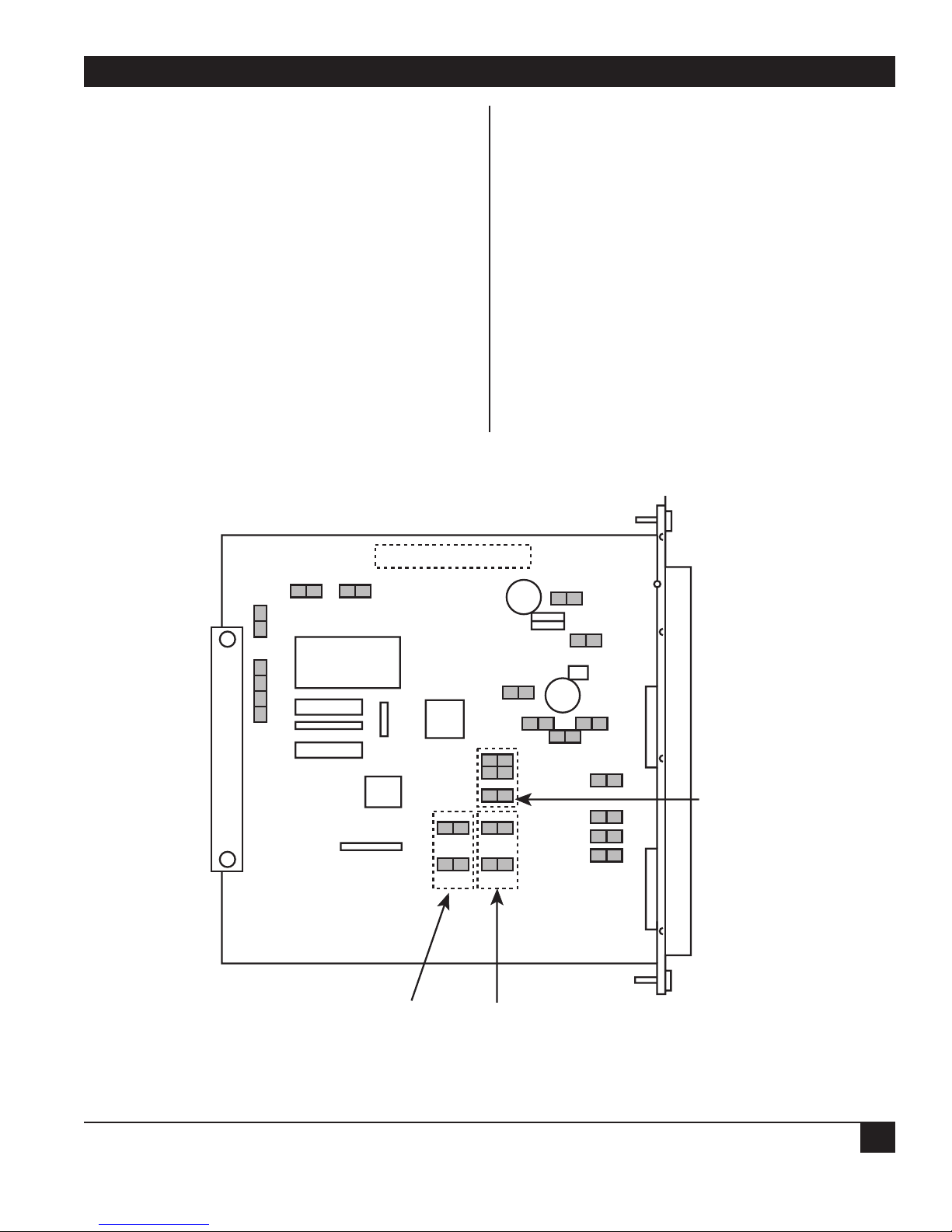

You can strap the Command Port receiver for either

high-impedance (30K Ω) or low-impedance (5K Ω)

termination, implemented by a three-position

header E5 and a 2-position jumper. Figure 5-5 shows

the location E5 on the serial interface module. See

Section D.1 for accessing the serial interface

module.

• To strap for low-impedance termination,

position the jumper over pins 2 and 3.

• To strap for high-impedance termination,

position the jumper over pins 1 and 2.

Impedance requirements are as listed in Table 5.1.

Figure 5-5. Location of Command-Port Impedance Header E5 on the Serial Interface Module.

Table 5-1. Impedance-Strapping Requirements

Number of Multiserver 500s Strapping Requirements

---------------------------------------------------------------------------------------------------------------------------------------------------------------1 Strap E5 for low impedance.

----------------------------------------------------------------------------------------------------------------------------------------------------------------

2 through 4 Strap E5 on end unit for low impedance. Strap E5 on all other

units for high impedance.

----------------------------------------------------------------------------------------------------------------------------------------------------------------

5 through 8 Strap E5 on all units for high impedance.

E4

J9 J8

E5

Low

3

2

1

J11 J10

E11

E5

Impedance

High

3

2

E5

1

Impedance

Page 34

CHAPTER 5: Using the Command Port

33

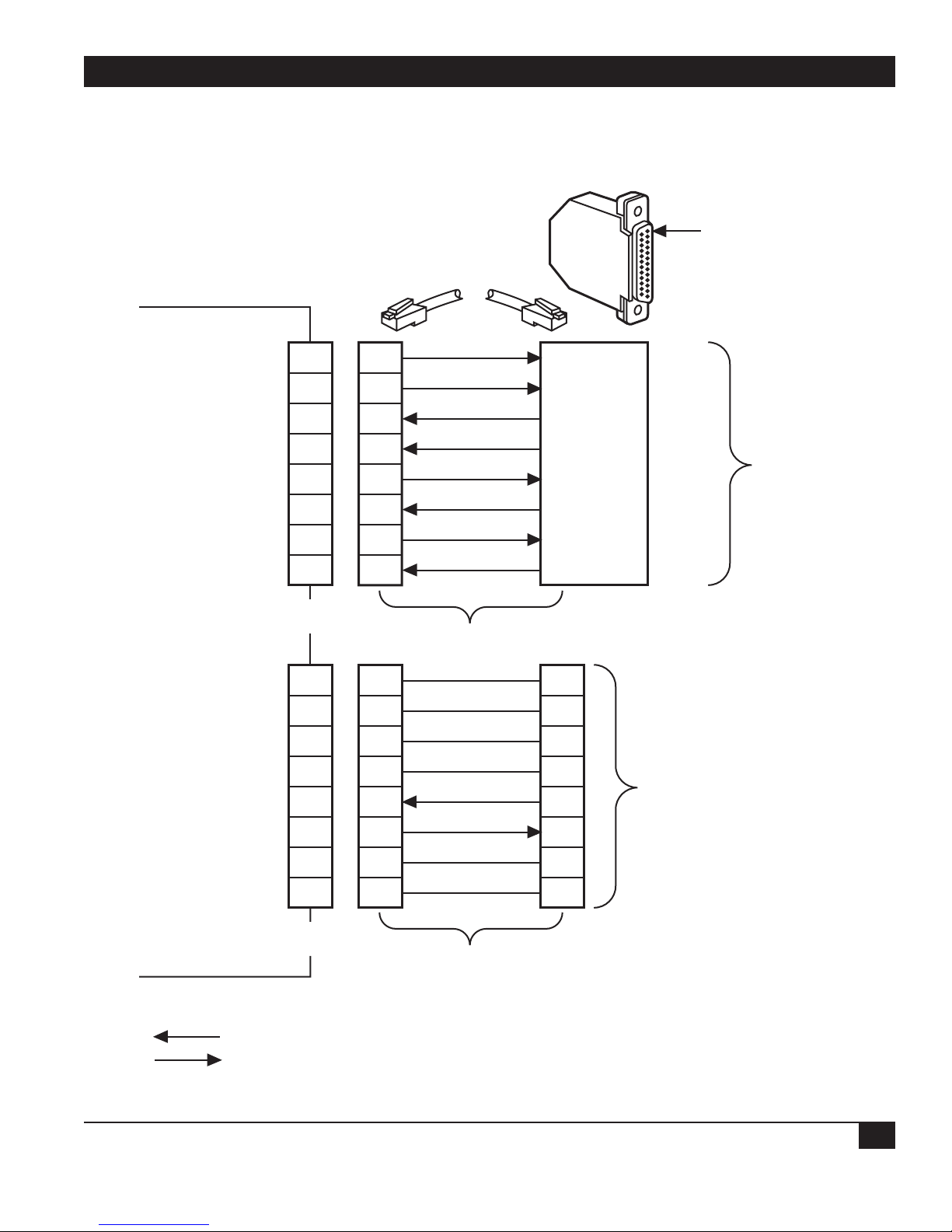

5.4 CMD IN and CMD OUT Connectors

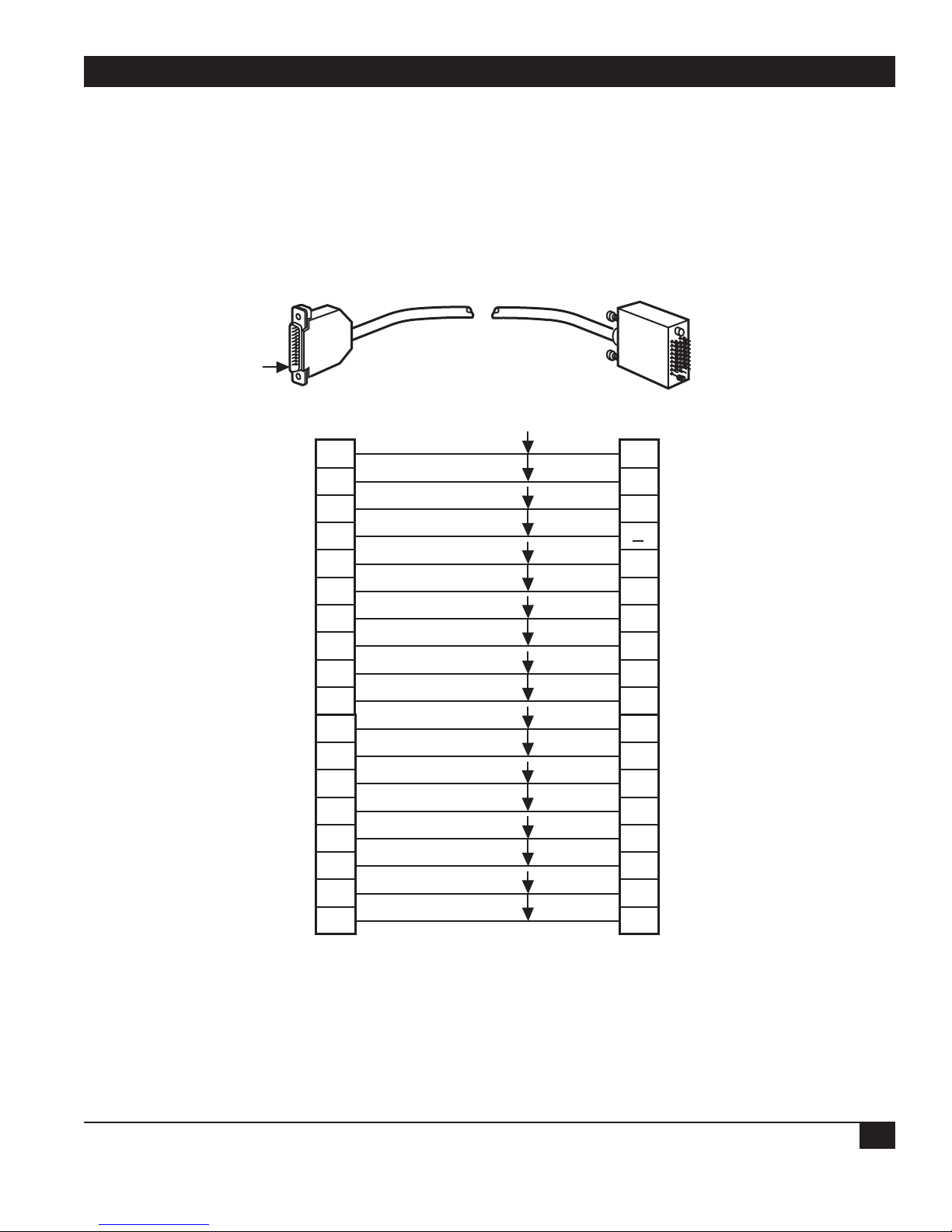

Figure 5-6 shows the pin assignments for the CMD

IN and CMD OUT connectors.

Figure 5-6. CMD IN and CMD OUT Connector Pin Assignments (RS-422 Interface).

Multiserver 500

PIN 1

n/c

force to mark

n/c

Ground

Command Data Out

Command Data In

force to mark

n/c

n/c

n/c

n/c

Ground

Daisy-chain Data In

1

2

3

4

5

6

7

8

CMD Port-In

Connector

1

2

3

4

5

1

2

3

4

1

2

3

4

22

8

20

7

RI

RLSD

DTR

Ground

To

5

6

7

8

Modular

Cable

1

2

3

4

5

5

6

7

8

RJ-45 to

DB25 Adapter

1

2

3

4

5

RD

3

TD

2

CTS

5

RTS

4

Terminal

To CMD Port-in of next

Multiserver 500 in daisy-chain

Daisy-chain Data Out

n/c

n/c

Legend:

= Input to Multiserver 500

= Output from Multiserver 500

6

7

8

CMD Port-Out

Connector

6

7

8

Modular

Cable

6

7

8

Page 35

MULTISERVER 500

34

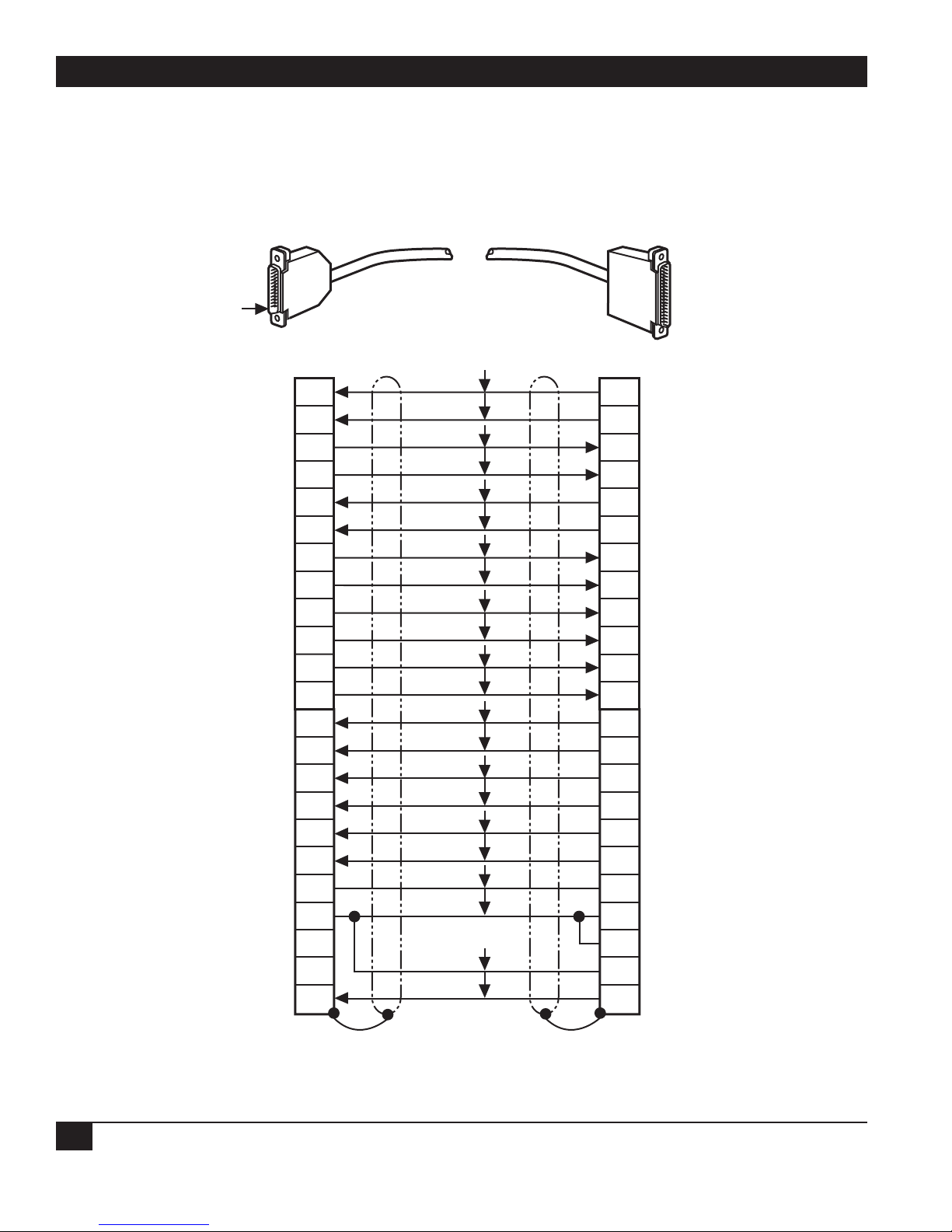

5.5 Accessing the Command Port

To access the Command Port from the asynchronous terminal, follow the flowchart in Figure 5-7.

Figure 5-7. Flowchart for Accessing the Command Port.

Power Up

N

N

Daisy

Chain

N

Command

Port

ABR

Y

Enter

<cr><cr>

in quick succession

Password

Configured

Y

Enter

<Ctrl> C

Enter

Device

Number

Multiserver 500 Display

Copyright (c) 1993

All rights reserved

Y

Enter

Password

1 2 3

Page 36

CHAPTER 5: Using the Command Port

35

Figure 5-7. Flowchart for Accessing the Command Port (continued).

* If daisychaining or reconfiguring Command Port, enter <Ctrl> C to end session. Otherwise, enter <exit>.

1

Start

Session

To Change to Remote

Command Port,

enter <Remote> command

To Return to Local

Command Port,

enter <Exit> command

N

Session

Completed

2 3

Y

Either* Or*

Enter

<Ctrl> C

Enter

<Exit>

Page 37

MULTISERVER 500

36

When you type a command, you need only type the

first few unique letters. In the lists of commands in

this manual, the capitalized part of a command is

the minimum you must type for the Multiserver to

recognize it.

Configuring the Prompt

When you first turn on the Multiserver 500, the

following prompt will appear on the terminal

screen: >.

You can change the prompt to whatever you like. To

change it to “Multiserver 500>,” enter:

UNit PRompt = Multiserver 500 <CR>

The prompt will change to:

Multiserver 500>

The prompt thus configured becomes automatically

active for the duration of the session. You can make

this permanent by issuing a SAve command.

List of Commands

To get a list of commands, enter a question mark

(?) followed by a <cr>.

Multiserver 500>?<cr>

The following list will appear:

Command Function

AInterface* Configures the analog interface

portion of the voice/fax parameters.

ASyncport* Configures the async data port

parameters.

CMDport* Configures the Command Port’s

parameters.

COMPositelink* Configures the composite link

parameters.

<Ctrl>C Terminates all command sessions.

DAtaport* Configures the data port type and

controls.

Command Function

DIagnostics* Performs diagnostic tests.

Exit Terminates the current command

session.

LOAd Sets parameters to factory-default

values or last saved configuration

values.

Remote Accesses remote Command Port.

SAve Command to save modified

configuration in EEPROM (nonvolatile memory), replacing the

default parameters. Command will

take effect after unit is reset.

SHow* Displays selected information such

as status and statistics.

SYncport* Configures parameters for the sync

data port.

Unit* Changes system-level parameters.

Voiceport* Configures the digital portion of the

voice/fax parameters.

How to Enter Commands and Set Parameters

There are no menus when you use the command

port. Instead, you enter a command or a string of

commands that are specific to the parameter (or

parameters) you intend to set or change, bypassing

all intermediate steps.

• Commands are not case-sensitive.

• The upper-case letters shown in the list of

commands are for your information only. They

indicate the minimum number of characters

required to execute that command.

• Commands that require parameters are

followed by an asterisk (*). For more

information about a specific command’s

parameters, type the command name, followed

by a space, followed by a ?.

Example: >DA ? (Data port).

• A command without an asterisk will not display

* For these commands, you must enter parameters. To get a display of parameters available under each

command, type in the command name, followed by a space, followed by a question mark (?), followed by

<cr>. For example, to get the sync port parameters, type SY ?<cr>.

Page 38

CHAPTER 5: Using the Command Port

37

more information, but will be executed when

entered.

• Parameters of the same command may be

chained together as a single entry, with each

parameter separated by a space. The chain

cannot exceed 80 characters, including spaces.

Example: to configure CTS and DSR in the data

port async channel, you could enter the

following string: data=as cts=on dsr=on.

(NOTE: The equal sign = may be replaced by a

space.)

List of Parameters

Following is a list of parameters associated with each

of the commands marked with an asterisk in the list

of commands.

AInterface

INput_gain (dB) -6 through 22

Output_Attn (dB) 0 through 28

OPeration (E&M) 2_wire, 4_wire

Signalling_format (E&M) DC, AC-15, Pulsed_DC

IMpedance 600 ohms, Complex

RINGTYPE (FXS) 2-4_interrupted,

1-2_interrupted

RINGFreq (FXS) 25_Hz, 50_Hz

Extra_gain (E&M 4-wire) None, 7 dB

Example: >AI IN=-6 OUT=4 RING T=2-4

IMp=600<cr> will set the FXS input gain to -6 dB,

the output attenuation to 4, the ringing type to 2-4,

and the line impedance to 600 Ω

NOTE: If your equipment is operated in the U.S.A.

or Canada, input and output levels must be

set to 0 dB. In other countries, follow the

standards of the country wherein the

equipment is used. If there are no specific

standards, set the input and output levels of

your equipment to match the interfacing

telephone equipment.

Be sure to separate each command in the string by

a space.

The parameters above become effective

immediately when entered, but are not stored in

EEPROM (nonvolatile memory) until saved. To save

the newly set parameters in EEPROM, type >SA

<cr>.

ASyncport

Rate (bps) 1200, 2400, 3600, 4800,

7200, 9600, 14400,

19200, 28800, 38400,

57600

Data_bit 8, 7

Stop 1, 1.5, 2

Parity None, Even, Odd,

Mark, Space

Flow_control None, Xon/Xoff,

CTS/RTS

Echo Disable/Enable

Example: >AS RA=7200 D=7 P=O <cr> will

set the async channel rate to 7200 bps, the number

of data bits 7, and parity to odd.

Be sure to separate each command in the string

with a space.

To save the newly set parameters in EEPROM,

type >SA <cr>.

CMD port

Rate (bps) AUTO*, 1200, 2400,

4800, 9600, 19200

Data_bit 8, 7 (Does not include

parity bit)

Stop 1, 1.5, 2

Parity None, Even, Odd,

Mark, Space

Flow_control None, Xon/Xoff

Echo Enable, Disable

* The Automatic baud rate option is available only to terminals that use an 8-bit, no parity, 1 stop bit format.

Page 39

MULTISERVER 500

38

Device Number: 0 through 8

Example: >CMD RA=9600 will set the Command

Port rate to 9600.

Be sure to separate each command in the string

by a space. To save the newly set parameters in

EEPROM, type >SA <cr>.

COMpositelink

Clock External, Internal

Rate (bps) 7200, 9600, 14400,

19200, 38400, 56000,

64000, 72000

Example: >COM CL=EX RA=56000 <cr>, will set

the composite port clock to external, and the rate

to 56,000 bps. Rate selection applies to internal

clock only.

Be sure to separate each command in the string

by a space. To save the newly set parameters in

EEPROM, type >SA <cr>

DAtaport

Use this command to select the data port type and

parameters that are common to both the

synchronous and asynchronous data channels.

Parameters that are unique to the synchronous and

asynchronous channels are set by separate

commands for each type.

Type Asynchronous,

Synchronous

CTS ON, OFF, Local

(Follows local RTS)

CTSDelay None, 25, 75, 100, 125,

150 in msec

DCD ON, OFF, Remote

(follows remote RTS)

DSR ON, OFF, Remote

(follows remote DTR)

RI ON, OFF, Link (follows

link status)

Example: >DA TY=SY RI=OFF will set the data

port type to synchronous, and the ring indicator to

off.

Be sure to separate each command in the string

by a space. To save the newly set parameters in

EEPROM, type >SA <cr>.

DIAgnostics

SElftest Initiates a self-test

EEprom Initiates a nonvolatile

RAM check

LOCComp Initiates a local

composite loopback

REMComp Initiates a remote

composite loopback

LOCDat Initiates a local data

channel loopback

REMDat Initiates a remote data

channel loopback

TErminate Terminates test in

progress, such as selftest or loopback

Example: To initiate a remote-data-channel

loopback test, type: >DI REMD <cr>.

SHow

DATE Displays today’s date

Example: >SH DATE 03/11/94

Status Displays Multiserver

500’s current general

status, including selftest, loopback, and

hardware type and

revision.

Example: >SH S

System Status: 20 MHz DSP, 64K RAM,

no download capability

Main module 001 Voice & Data

Revision Level: B

Voice/Fax Interface Module: 002

Revision Level: 03

Interface Type: Enhanced FXS, Loop

start.

Page 40

CHAPTER 5: Using the Command Port

39

Serial Module 001 Voice & Data

Revision Level: B

Serial Module Type: Standard

Self-Test passed, EEPROM passed, No

active loopback

COMposite Displays the current

status of the composite

link, including rate,

clock, and link.

Example: >SH COMP

COMPOSITE LINK STATUS

Link Up, External Clock Rate = 19200

VOice Displays the current

status of the voice/fax

channel, including rate,

on-hook/off-hook,

input/output levels,

etc.

Example: >SH VO

Voice Channel Status

Local = on-hook, Remote = on-hook,

Level In = 0, Level Out = 0

Algorithm rate = 16000,

Algorithm ver. = 0,

Analog interface Status:

Interface Type = Enhanced FXS,

PROM version = 2A, PROM I.D. = 2196

DATA Displays the current

EIA status of the data

channel, including

type, rate, flow control

and EIA signal status.

Example: >SH DATA

Data Channel Status:

EIA SIGNAL

Input:

UNA = OFF, B0 = OFF, RTS = OFF,

DTR = OFF

Output:

DCD = OFF, RI = OFF, CTS =ON

DSR = OFF, for Synchronous Data:

Synchronous Tx Data Rate = 56000,

Rx Data Rate = 56000 for Asynchronous

Data:

Asynchronous data rate = 9600, flow

control = OFF

Time Displays current time

Example: >SH T

02:59:37

VErsion Displays the current

software revision.

Example: >SH VE

Software Revision: 907-2200-0

CONfiguration Displays the current

configuration of the

data channel,

Command Port,

composite link,

voice/fax channel, and

the analog interface

portion of the

voice/fax channel. See

the explanation below.

Example: >SH CON

Data Channel configuration

Type = Asynchronous, CTS = ON,

CTSDelay = None, DCD = Remote rts,

DSR = Remote dtr, RI = Link status,

Rate = 9600, Data_bit = 8, Stop =

1, Parity = None, Flow_control =

None, Echo = Disable

Command port configuration

device number = 1, Rate = 9600,

Data_bit = 8, Stop = 1, Parity =

None, Flow_control = None, Echo =

Page 41

MULTISERVER 500

40

Enable

Voice Channel configuration

BUSYstate = SYStem,

BACKground = Silence, FAX = Disable,

NLP = Enable

Composite Link configuration

Clock = External, Rate = 9600

Analog Interface configuration

INput_gain(dB) = 0, Output_attn

(dB) = 0, RINGType =

2-4_interrupted,

RINGFreq = 25_Hz,

IMpedance = 600 Ohms

Unlike SHow CONfiguration, SHow DATA always

displays the parameters currently stored in

EEPROM (nonvolatile memory).

To activate the newly set configuration, type >U R

<cr> (unit reset).

This message might appear:

Data and composite parameters

effective after unit reset.

When that message appears, the data and

composite parameters displayed have been recently

modified but not made effective. After you use the

save command and reset the unit, the modified

parameters will be stored in EEPROM (nonvolatile

memory) and the message above will disappear.

Unlike data and composite parameters, voice and

analog parameters take effect immediately when

you enter them.

SYnc port

Rate* or Maxrate (bps): 1200, 2400, 3600, 4800,

7200, 9600, 12000,

14400, 19200, 28800,

33600, 38400, 46400,

48000, 51200, 56000,

57600, 64000, 72000

Tx clock Internal/External

DBA OFF, SILENCE, HOOK

Example: >SY RA=38400 MAX=56000

DBA=HOOK <cr> will set the sync channel

minimum rate to 38,400 bps, maximum rate to

56,000 bps, and DBA (dynamic bandwidth

allocation) will follow the on-hook/off-hook state of

the voice/fax channel.

Be sure to separate each command in the string

by a space.

To save the newly set parameters in EEPROM,

type >SA <cr>. To activate the newly set

parameters, type: >U R <cr> (unit reset).

Unit

Available parameters are:

Date, Reset, Time, PAssword, PRompt

When you enter the parameters listed above, they

take effect immediately. Date and time cannot be

saved and will be lost when power is disconnected.

You must save password and prompt in order for

them to remain in effect after a power off/on cycle.

VOice Port

BUsy State OFF, ON, SYstem

BAckground Silence, Regenerated

Fax Disable, Enable

NLP† Disable, Enable

Example: >BUsy SY will set the busy state to

system-controlled.

Be sure to separate each command in the string

by a space. The above parameters become effective

immediately when entered, but are not stored in

EEPROM (nonvolatile memory) until saved. To save

the newly set parameters in EEPROM, type >SA

<cr>.

*Guaranteed rate. †NLP = Non-Linear Processing.

Page 42

CHAPTER 6: Operation

41

This section describes how the Multiserver 500

works. Indicators are described first, followed by

procedures for transmitting data, making telephone

calls, and sending fax messages.

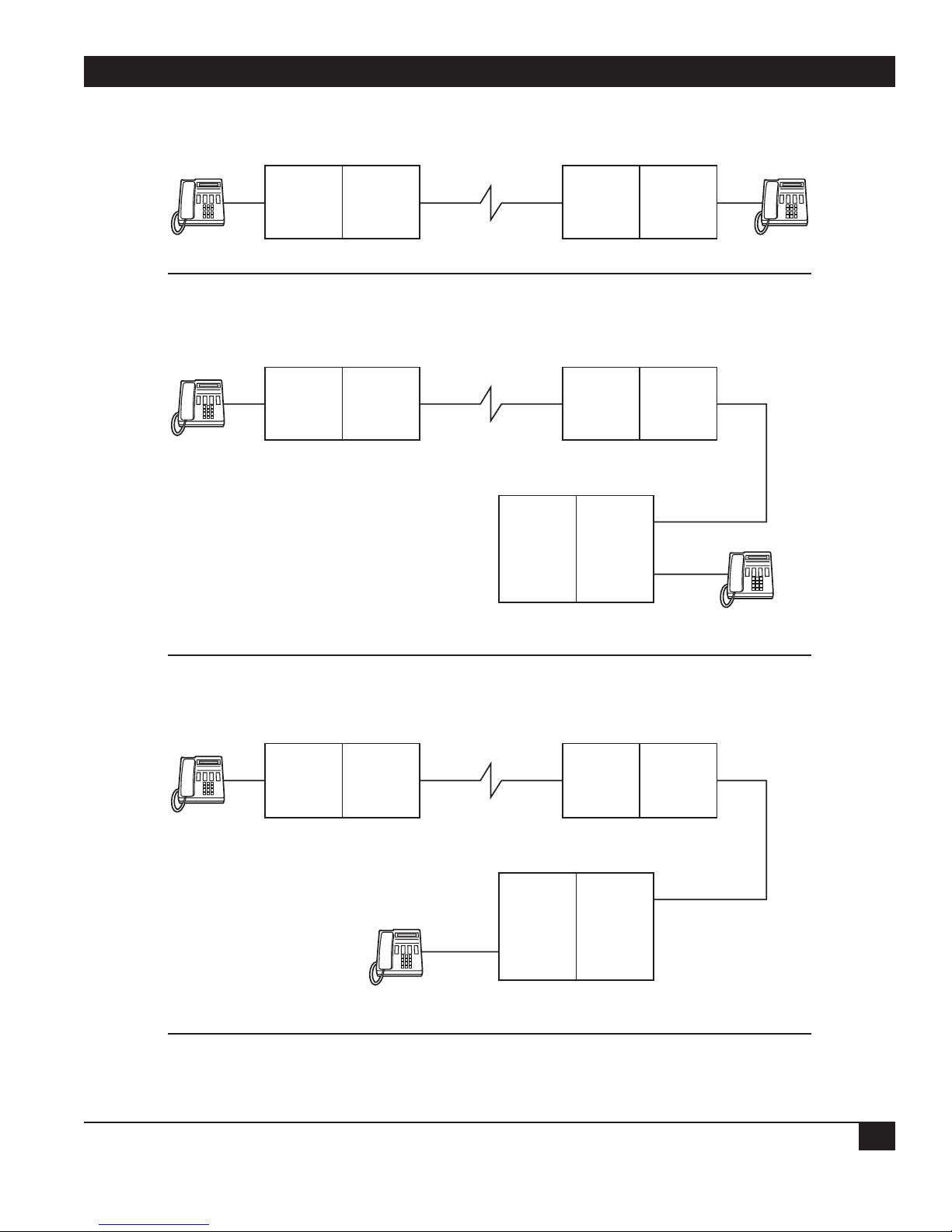

6.1 LED Indicators

LED indicators are on the front panel of the

Multiserver 500, as shown in Figure 6-1. Their

functions are summarized in Table 6-1.

6. Operation

Figure 6-1. The Front Panel of the Multiserver 500.

MULTISERVER 500

PO IS TD RD LS RS VA TM

EXE

KEYPAD LED INDICATORSLCD DISPLAY

Page 43

MULTISERVER 500

42

Table 6-1. LED Indicators

Indicator State Meaning

----------------------------------------------------------------------------------------------------------------------------------------------------------------

PO (Power On) On Unit is powered up and has passed the self-test.

Off Power is off.

Flashing Self-test failed.

----------------------------------------------------------------------------------------------------------------------------------------------------------------

IS (In Sync) On The local Multiserver 500 is in sync with the remote

Multiserver 500.

Off The local and remote Multiserver 500s are out of

sync.

----------------------------------------------------------------------------------------------------------------------------------------------------------------

TD (Transmit Data) Flickering Data channel is transmitting data.

Off Data channel is not transmitting.

----------------------------------------------------------------------------------------------------------------------------------------------------------------

RD (Receive Data) Flickering Data channel is receiving data.

Off Data channel is not receiving data.

----------------------------------------------------------------------------------------------------------------------------------------------------------------

LS (Local Speech) On Speech signal from local telephone interface present.

Off No local speech present.