Page 1

NOVEMBER 1997

MT632A-ST35

MT632A-ST232

MT632A-SM35

MT632A-SM232

SFOM-HS2

CUSTOMER SUPPORT INFORMATION

Order toll-free in the U.S. 24 hours, 7 A.M. Monday to midnight Friday: 877-877-BBOX

FREE technical support, 24 hours a day, 7 days a week: Call 724-746-5500 or fax 724-746-0746

Mail order: Black Box Corporation, 1000 Park Drive, Lawrence, PA 15055-1018

Web site: www.blackbox.com • E-mail: info@blackbox.com

SFOM-HS2

R

E

M

N

O

R

A

N

A

P

W

R

TS

T

C

D

TD

Page 2

1

TRADEMARKS

TRADEMARKS USED IN THIS MANUAL

UL is a registered trademark of Underwriters

Laboratories Incorporated.

ST is a registered trademark of AT&T.

Any other trademarks mentioned in this manual are

acknowledged to be the property of the trademark owners.

Page 3

2

SFOM-HS2

FEDERAL COMMUNICATIONS COMMISSION

AND

INDUSTRY CANADA

RADIO FREQUENCY INTERFERENCE STATEMENTS

This equipment generates, uses, and can radiate radio frequency energy

and if not installed and used properly, that is, in strict accordance with the

manufacturer’s instructions, may cause interference to radio communication. It has been tested and found to comply with the limits for a Class A

computing device in accordance with the specifications in Subpart J of

Part 15 of FCC rules, which are designed to provide reasonable protection

against such interference when the equipment is operated in a commercial

environment. Operation of this equipment in a residential area is likely

to cause interference, in which case the user at his own expense will be

required to take whatever measures may be necessary to correct the

interference.

Changes or modifications not expressly approved by the party responsible

for compliance could void the user’s authority to operate the equipment.

This digital apparatus does not exceed the Class A limits for radio noise emission

from digital apparatus set out in the Radio Interference Regulation of Industry

Canada.

Le présent appareil numérique n’émet pas de bruits radioélectriques dépassant les

limites applicables aux appareils numériques de classe A prescrites dans le Règlement

sur le brouillage radioélectrique publié par Industrie Canada.

Page 4

3

NOM STATEMENT

NORMAS OFICIALES MEXICANAS (NOM)

ELECTRICAL SAFETY STATEMENT

INSTRUCCIONES DE SEGURIDAD

1. Todas las instrucciones de seguridad y operación deberán ser leídas

antes de que el aparato eléctrico sea operado.

2. Las instrucciones de seguridad y operación deberán ser guardadas

para referencia futura.

3. Todas las advertencias en el aparato eléctrico y en sus instrucciones

de operación deben ser respetadas.

4. Todas las instrucciones de operación y uso deben ser seguidas.

5. El aparato eléctrico no deberá ser usado cerca del agua—por

ejemplo, cerca de la tina de baño, lavabo, sótano mojado o cerca de

una alberca, etc..

6. El aparato eléctrico debe ser usado únicamente con carritos o

pedestales que sean recomendados por el fabricante.

7. El aparato eléctrico debe ser montado a la pared o al techo sólo

como sea recomendado por el fabricante.

8. Servicio—El usuario no debe intentar dar servicio al equipo eléctrico

más allá a lo descrito en las instrucciones de operación. Todo otro

servicio deberá ser referido a personal de servicio calificado.

9. El aparato eléctrico debe ser situado de tal manera que su posición

no interfiera su uso. La colocación del aparato eléctrico sobre una

cama, sofá, alfombra o superficie similar puede bloquea la

ventilación, no se debe colocar en libreros o gabinetes que impidan

el flujo de aire por los orificios de ventilación.

Page 5

4

SFOM-HS2

10. El equipo eléctrico deber ser situado fuera del alcance de fuentes

de calor como radiadores, registros de calor, estufas u otros aparatos

(incluyendo amplificadores) que producen calor.

11. El aparato eléctrico deberá ser connectado a una fuente de poder

sólo del tipo descrito en el instructivo de operación, o como se

indique en el aparato.

12. Precaución debe ser tomada de tal manera que la tierra fisica y

la polarización del equipo no sea eliminada.

13. Los cables de la fuente de poder deben ser guiados de tal manera

que no sean pisados ni pellizcados por objetos colocados sobre o

contra ellos, poniendo particular atención a los contactos y

receptáculos donde salen del aparato.

14. El equipo eléctrico debe ser limpiado únicamente de acuerdo a las

recomendaciones del fabricante.

15. En caso de existir, una antena externa deberá ser localizada lejos

de las lineas de energia.

16. El cable de corriente deberá ser desconectado del cuando el equipo

no sea usado por un largo periodo de tiempo.

17. Cuidado debe ser tomado de tal manera que objectos liquidos no

sean derramados sobre la cubierta u orificios de ventilación.

18. Servicio por personal calificado deberá ser provisto cuando:

A: El cable de poder o el contacto ha sido dañado; u

B: Objectos han caído o líquido ha sido derramado dentro

del aparato; o

C: El aparato ha sido expuesto a la lluvia; o

D: El aparato parece no operar normalmente o muestra

un cambio en su desempeño; o

E: El aparato ha sido tirado o su cubierta ha sido dañada.

Page 6

5

UL LISTING REQUIREMENTS, EXIGENCES UL

UL Listing Requirements

IMPORTANT SAFETY INSTRUCTIONS

For North American Users

The SFOM-HS2 is powered by an external power supply

(product code PS632). To reduce the risk of shock, fire,

and injury, use it only with a UL

®

listed and CSA

Certified Class 2 power supply rated 9 VDC, 300 mA.

Exigences UL

INSTRUCTIONS IMPORTANTS DE SÉCURITÉ

Pour les utilisateurs Nord Americains

Le SFOM-HS2 est renforcé par un transformateur

extérieur (code produit PS632). Afin de réduire le risque

d’électrocution, d’incendie ou de blessure, utiliser

seulement avec un transformateur 9 VDC, 300 mA

Certifié classe 2 CSA et repris sur la liste UL

®

.

Page 7

6

SFOM-HS2

TÜV Certification Requirements

Installation – User Instructions

Electrical ratings: 9 VDC, 300 mA

The following instructions are intended to guarantee the

basic operation of the equipment concerning safety.

CAUTION!

1. To reduce the risk of electric shock, use only with a

power supply which is approved for the lastest

version of EN 60950.

2. For continuous protection against risk of fire, do not

operate the equipment with the enclosure completely

or partially removed.

3. Do not install the equipment with indicators facing down.

TÜV-Zertifizierungsanforderungen

Installation – Bedieningsanleitung

Leistungsaufnahme: 9 VDC, 300 mA

Die nachfolgenden Anleitungen sollen den Grundbetrieb

der Anlage hinsichtlich Sicherheit gewährleisten.

ACHTUNG!

1. Um das Risiko eines elektrischenSchlages oder

Brandes so weit wie möglich zu vermeiden verwenden

Sie nur ein Netzteil, das gemäß der neuesten Version

des Standards EN 60950 zugelassen ist.

2. Als ständigen Schutz vor Brand betrieben Sie die Anlage

nie mit ganz oder teilweise entfernter Abdeckung.

3. Installieren Sie de Anlage nicht mit nach unten

weisenden Anzeigeelementen.

Page 8

7

TABLE OF CONTENTS

Contents

1. Specifications ..................................................... 9

2. Introduction ..................................................... 13

3. Installation and Configuration ....................... 16

4. Operation ......................................................... 19

4. Troubleshooting .............................................. 23

4.1 Diagnostic Loopback Tests ...................... 23

4.2 Calling Black Box ..................................... 25

4.3 Shipping and Packaging ........................ 26

Page 9

8

SFOM-HS2

1. Specifications

Compliance — FCC Class B, IC Class/

classe B; UL®, CSA, TÜV

Interfaces — Device side:

“–Sx232” models:

TIA RS-232/ITU-TSS V.24;

“–Sx35” models:

ITU-TSS V.35;

Line side:

Multimode fiberoptic

Protocols —

Synchronous or asynchronous

(user-selectable)

Clock Source — Internal, external (from

device side), or recovered

(from line-side receive

signal)

Data Format — Async: 1 start bit (fixed); 5, 6,

7, or 8 data bits; even, odd,

or no parity; and 1, 1.5, or

2 stop bits (user-selectable),

with a minimum of 8 and a

maximum of 11 total bits

Page 10

9

CHAPTER 1: Specifications

Frequency Allowance — Async: Stop bit can be

shortened on the receive

end to accommodate a

frequency difference

between the SFOM-HS2

and the attached device,

either by 12.5% (allows a

–2.5% to +1% difference)

or by 25% (allows a –2.5%

to +2.3% difference), userselectable

Carrier — Constantly ON or follows

RTS (user-selectable)

Operation — Full-duplex over duplex

fiberoptic cable

Data Rates —

56 or 64 Kbps (user selectable)

Optical Output

(Transmit Level)— 100/140µ fiber: –26 dBm;

62.5/125µ fiber: –28 dBm;

50/125µ fiber: –32 dBm

Receiver Sensitivity — –43 dBm

Page 11

10

SFOM-HS2

Optical Wavelength — 850 nm

Maximum Distance — 2.5 miles (4 km)

User Controls — (1) Top-mounted three-

position slide switch for

test selection;

(10) Internal DIP-switch

positions for protocol, data

rate, data format, stop-bit

shortening, carrier, and

interface-based loop control

Diagnostics — Local analog and remote

digital loopback, controlled

with top-panel switch or

optionally with interface

signals

Indicators — (4) Top-mounted LEDs:

PWR (power), TST (test),

CD, and TD

Page 12

11

CHAPTER 1: Specifications

Connectors — Device side: (1) Front-

mounted DB25 female;

V.35 models include a

17.5" (45-cm) adapter cable

that patches this to an M/34

(34-pin M-block) female;

Line side:

“-SMxxx” models:

(2) SMA 906 female;

“-STxxx” models:

(2) ST female

Power — From wallmount power

supply PS632 (not included):

Input: 115-VAC, 60 Hz;

Output: 9 VDC, 300 mA

Size — 5.1"H x 2.1"W x 1.2"D

(13 x 5.3 x 3 cm)

Weight — 0.2 lb. (0.1 kg)

Page 13

12

SFOM-HS2

2. Introduction

The SFOM-HS2 is a high-speed fiberoptic local

(short-haul) modem. You can use pairs of SFOMHS2s to make extended-distance, full-duplex

connections across fiberoptic cable between

synchronous or asynchronous terminals, PCs, or

controllers on one end and high-speed computers

on the other.

There are four models of SFOM-HS2 available (see

Table 2-1 below). Each has fiberoptic connectors on

one side for attaching fiberoptic cable, and a DB25

connector on the other side for attaching your

data-terminal equipment (DTE). (The V.35 models

include a special adapter cable that patches the

DB25 connector to a 34-pin M-block connector

more appropriate for most V.35 equipment.)

Table 2-1. The SFOM-HS2 Models and their Interfaces

Product Code Fiber Connectors DTE Interface Standard

MT632A-ST35 ST®Style V.35

MT632A-ST232 ST Style RS-232

MT632A-SM35 SMA Style V.35

MT632A-SM232 SMA Style RS-232

Page 14

13

CHAPTER 2: Introduction

Each SFOM-HS2 converts the electrical data signal

from the DTE interface into light pulses for transmission across the fiber interface. It can operate

at 56 or 64 Kbps, and can transmit data as far as

2.5 miles (4 km); see Figure 2-1 below.

Figure 2-1. A typical SFOM-HS2 application.

Each unit also supports two ITU V.54 industrystandard loop tests for easy, convenient diagnostics

(see Section 4.3).

The SFOM-HS2 can get its transmit timing from

any of three sources: its own oscillator (internal

clock), the attached DTE (external clock), or

the receive signal (recovered clock).

Mainframe

Controller

Up to 2.5 miles

(4 km)

Duplex Fiberoptic Cable

SFOM-HS2

SFOM-HS2

Page 15

14

SFOM-HS2

You can also choose whether carrier is constantly

ON or switched. In switched mode, the carrier is

controlled by the RTS signal so you can transfer

a control signal end-to-end.

9-VDC power for the unit comes from the external

wallmout AC power supply PS632 (sold separately).

Page 16

15

CHAPTER 3: Installation and Configuration

3. Installation and Configuration

Each SFOM-HS2 has a three-position loop-activation

switch on the front panel, plus ten internal DIP

switches (see Figure 3-1 below). Use these switches

to configure the SFOM-HS2 prior to installation.

(See Chapter 4 for more about configuration options.)

Figure 3-1. The internal DIP switches.

To set the DIP switches in an SFOM-HS2:

1. Use a small screwdriver to gently pry open each

of the unit’s four locking tabs and open the

plastic case (see Figure 3-2 on the next page).

ON ON

1

ON

23456

7

8

9

10

Number of Bits (async)

Stop Bit (async)

Data Rate

Transmit Timing

Carrier

Loop Control

Page 17

16

SFOM-HS2

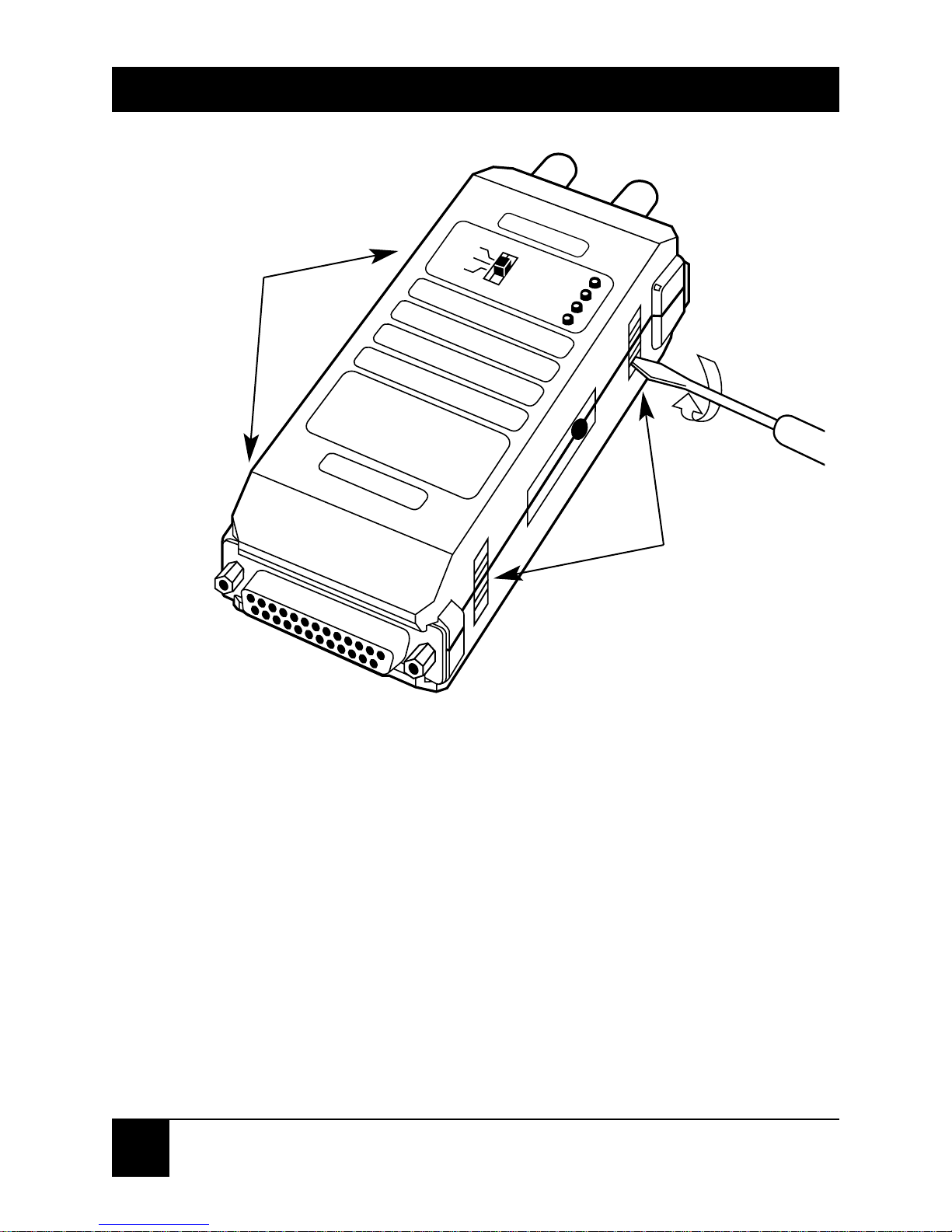

Figure 3-2. Opening the plastic cover.

2. Set the DIP switches to match your

application’s requirements. Table 3-1 on the

next page lists the possible settings. (A similar

table is printed inside the unit’s plastic case,

for reference during field installations.) See

pages 18 and 19 for the recommended settings

for most synchronous and asynchronous

applications respectively.

R

EM

N

O

R

ANA

PW

R

TST

CD

TD

Locking

Tabs

Locking

Tabs

Page 18

17

CHAPTER 3: Installation and Configuration

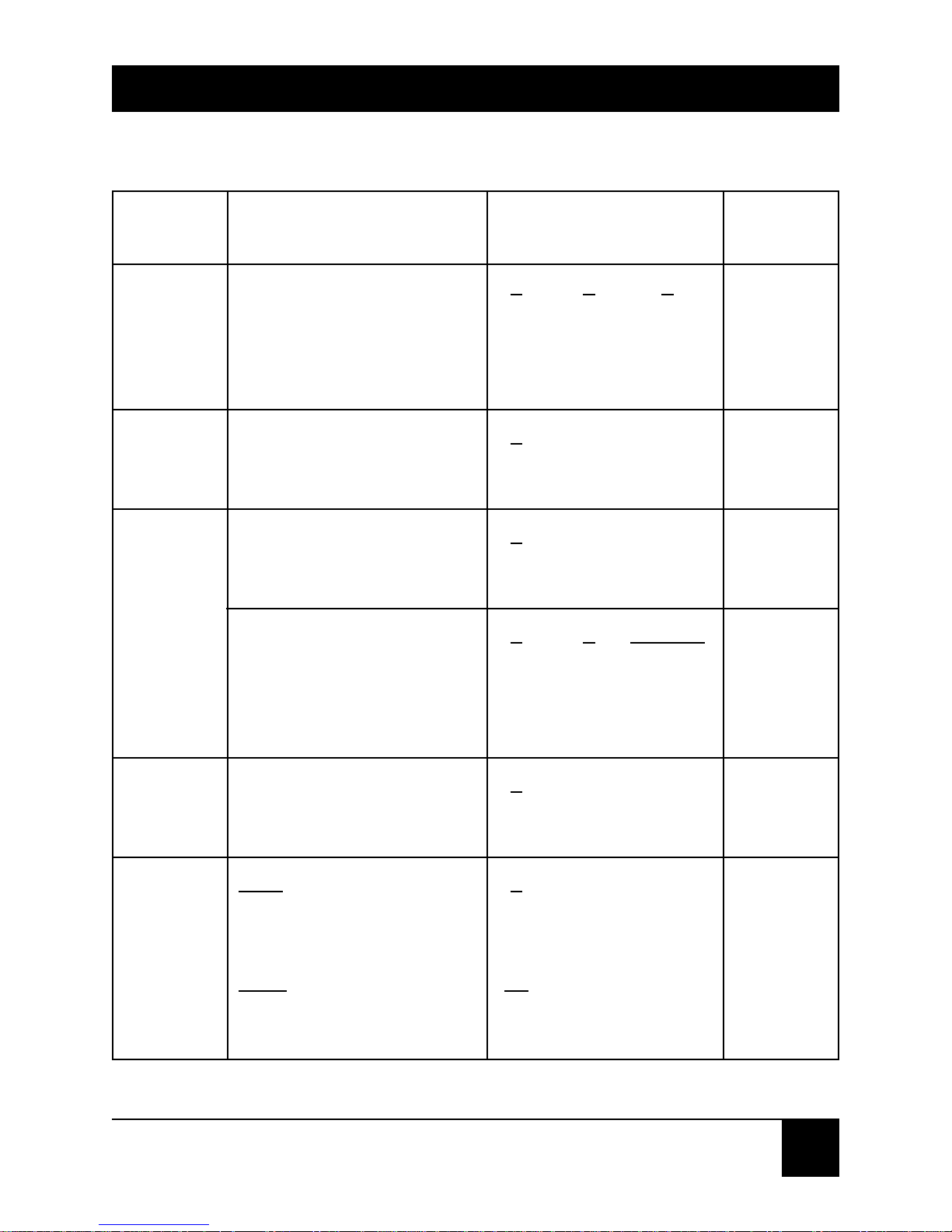

Transmit

Timing

Data

Rate

Async

Data

Format

(Word

Length)

Carrier

Loop

Activation

from the

DTE

Interface

(Loop

Control)

Determines sync clock

source or async mode

Determines datatransmission rate

Determines the amount

of stop-bit shortening to

be used in async mode

Determines word length

in async mode (see

Appendix A)

Determines carrier—

constantly on, or

controlled by RTS

ANA

Determines DTE control

of analog loop

REM

Determines DTE control

of remote digital loop

1

2 3

ON OFF OFF

OFF OFF OFF

OFF OFF ON

OFF ON OFF

4

ON—56 Kbps

OFF—64 Kbps

5

ON—12.5%

OFF—25%

6

7 # of bits

OFF OFF 8

OFF ON 9

ON OFF 10

ON ON 11

8

ON—Constantly ON

OFF—Controlled

9

ON—Enable

OFF—Disable

10

ON—Enable

OFF—Disable

External

Internal

Receive

Async

64 Kbps

25%

10 bits

ON

Disable

Disable

Feature Function Possible DIP Switch Default

Settings Settings

Table 3-1. DIP-Switch Functions, Settings, and Defaults

Page 19

18

SFOM-HS2

• Follow these steps to configure your

SFOM-HS2 for synchronous operation.

(Note that DIP switches 5, 6, and 7 are

not relevant for sync operation.)

a. Use switches 1, 2, and 3 to set XMT timing

to INT (internal), EXT (external), or RCV

(recovered).

b. Use switch 4 to set the data rate

to 56 or 64 Kbps.

c. Use switch 8 to set carrier to constantly

on or controlled by RTS.

For example, DIP switch settings on an

SFOM-HS2 configured for internal clocking,

64 Kbps, and constant carrier would be:

1, 2, 3 = OFF 4 = OFF 8 = ON

Page 20

19

CHAPTER 3: Installation and Configuration

•Follow these steps to configure your

SFOM-HS2 for for asynchronous operation.

a. Use switches 1, 2, and 3 to select “async”

(turn XMT timing off).

b. Use switch 4 to set the data rate.

c. Use switches 5, 6, and 7 to set frequency

allowance and character length (if necessary,

refer to Table 3-1 on page 17, Figure 3-1 on

page 15).

d. Use switch 8 to set carrier to constantly

on or controlled by RTS.

For example, DIP-switch settings on an SFOMHS2 configured for async operation, 64 Kbps,

and constant carrier would be:

1, 3 = OFF 2 = ON 4 = ON

6, 7 = OFF 8 = ON

NOTE

PCs working at high speeds in async mode operate at

57.6 Kbps (instead of 56 Kbps). In such cases, the PC

should be set to use two stop bits, and the SFOM-HS2

should be set to use one stop bit and to communicate

at 56 Kbps.

Page 21

20

SFOM-HS2

3. Carefully close the two halves of the unit’s

plastic case, pressing them together firmly

until the four locking tabs snap back into place.

4. If possible, plug the SFOM-HS2 directly into

your DTE’s DB25 connector (or, if your unit is

a V.35 model, run the included adapter cable

from the SFOM-HS2 to your DTE’s

M/34 [also

called “34-pin M-block”] connector).

If you have

to run an additional cable between the DTE

and the SFOM-HS2, keep it as short as possible.

Once you’ve made this connection, tighten the

connector screws to ensure a secure hold.

5. Remove the plastic dust caps from the

fiberoptic connectors and attach your

fiber cable to them:

• Connect the local SFOM-HS2’s TX port

to the remote unit’s RX port.

• Connect the local SFOM-HS2’s RX port

to the remote unit’s TX port.

Page 22

21

CHAPTER 3: Installation and Configuration

6. Connect the output cord of the included

external power supply to the SFOM-HS2’s

power jack, then plug the transformer into

a nearby AC wall outlet.

Page 23

22

SFOM-HS2

4. Troub leshooting

4.1 Diagnostic Loopback Tests

You can configure the SFOM-HS2 to perform either

of two test loops. V.54 Loop 3 (ANA, local analog

loopback) tests the local SFOM-HS2 by routing the

transmit signal the unit gets from the attached device

back to that device through its receiver (see Figure 4-1

below).

Figure 4-1. Local analog loopback (ANA).

V.54 Loop 2 (REM, remote digital loopback) tests

the local SFOM-HS2, the line, and the remote

SFOM-HS2 (see Figure 4-2 below).

Figure 4-2. Remote digital loopback (REM).

Page 24

23

CHAPTER 4: Troubleshooting

Both loops can be controlled either physically, with

the top-panel loop-selection switch, or electronically,

by having the DTE raise and lower the signals to

Pins 18 (ANA) and 21 (REM) of the SFOM-HS2’s

DB25 connector.

NOTE

To select loops electronically with the V.35 version of

the SFOM-HS2, use Pins JJ (ANA) and HH (REM) of the

adapter cable’s M/34 connector.

To activate loops from your DTE, DIP switches 9 and

10 must be set to ENABLE (see Figure 3-1 on page 15

and Table 3-1 on page 17).

Start the loop test by moving the top-panel loop-

selection switch to the desired test position or

raising

the appropriate signal on the DTE interface.

While a diagnostic loop is active, the top-panel

TST

LED will light and the Test Mode signal (DB25 Pin 25

or M/34 Pin KK)

will be held high (ON).

To return to normal operation, reset the top-panel

loop-selection switch to the center NOR position

or lower the controlling DTE-interface signal.

The TST LED and Test Mode signal will turn

OFF automatically.

Page 25

24

SFOM-HS2

4.2 Calling Black Box

If your SFOM-HS2 seems to be malfunctioning, do

not attempt to alter or repair the unit. It contains no user-

serviceable parts. Call Black Box Technical Support

at 724-746-5500. The problem might be solvable over

the phone.

Before you call, make a record of the history of the

problem. We will be able to provide more efficient

and accurate assistance if you have a complete

description, including:

• the nature and duration of the problem.

• when the problem occurs.

• the components involved in the problem.

• any particular application that, when used,

appears to create the problem or make it worse.

Page 26

25

CHAPTER 4: Troubleshooting

4.3 Shipping and Packaging

If you need to transport or ship your SFOM-HS2:

• Package it carefully. We recommend

that you use the original container.

• If the shipping is return- or repair-related,

pack the SFOM-HS2, its power supply, and

this manual together. Contact Black Box

to get a Return Materials Authorization

(RMA) number.

Page 27

NOTES

Loading...

Loading...