Page 1

MT1100A MT1100A-DC

JULY 2003

E1/T1 Rate Converters

MT1100C MT1101A

MT1101A-DC MT1102A

MT1102A-DC MT1102C

CUSTOMER

SUPPORT

INFORMATION

Order toll-free in the U.S.: Call 877-877-BBOX (outside U.S. call 724-746-5500)

FREE technical support 24 hours a day, 7 days a week: Call 724-746-5500 or fax 724-746-0746

Mailing address: Black Box Corporation, 1000 Park Drive, Lawrence, PA 15055-1018

Web site: www.blackbox.com • E-mail: info@blackbox.com

Page 2

Page 3

Contents

Chapter 1. Introduction

1.1 Overview..................................................................................................................... 1-1

Versions................................................................................................................................ 1-1

Application ...........................................................................................................................1-1

1.2 Functional Description................................................................................................. 1-2

Functional Block Diagram..................................................................................................... 1-2

Timing Reference..................................................................................................................1-2

Diagnostics ........................................................................................................................... 1-2

1.3 Technical Specifications............................................................................................... 1-3

Chapter 2. Installation and Setup

2.1 Site Requirements and Prerequisites ............................................................................ 2-1

2.2 Package Contents ........................................................................................................2-1

2.3 Configuring Standalone Unit........................................................................................ 2-2

Setting the Jumpers............................................................................................................... 2-2

Connecting the Interfaces .....................................................................................................2-5

Connecting the Power ..........................................................................................................2-5

Chapter 3. Operation

3.1 Front Panel Indicators .................................................................................................. 3-1

3.2 Operating Instructions ................................................................................................. 3-2

Turning On........................................................................................................................... 3-2

Operating the Unit ...............................................................................................................3-2

Turning Off........................................................................................................................... 3-2

Chapter 4. Troubleshooting and Diagnostics

4.1 Performing Local Analog Loopback.............................................................................. 4-1

Activating Local Analog Loopback .........................................................................................4-1

Deactivating Local Analog Loopback ..................................................................................... 4-2

4.2 Troubleshooting........................................................................................................... 4-2

Chapter 5. MT1100C, MT1102C Cards

5.1 Rack Nest 2/14 Card Cage ........................................................................................... 5-1

Line Connector.....................................................................................................................5-1

DTE Connector.....................................................................................................................5-1

5.2 Power Supply .............................................................................................................. 5-2

AC Supply ............................................................................................................................5-2

DC Supply............................................................................................................................5-2

Power Supply with Redundancy............................................................................................5-2

5.3 Front Panel .................................................................................................................. 5-3

5.4 Installing MT1100C, MT1102C.................................................................................... 5-5

Setting Internal Jumpers and Switches ................................................................................... 5-5

Installing MT1100C, MT1102C into the Rack Nest 2/14 Card Cage ....................................... 5-6

Connecting the Interfaces .....................................................................................................5-6

Appendix A. Interface Connector Wiring

i

Page 4

Table of Contents

List of Figures

1-1. Typical Application................................................................................................................ 1-1

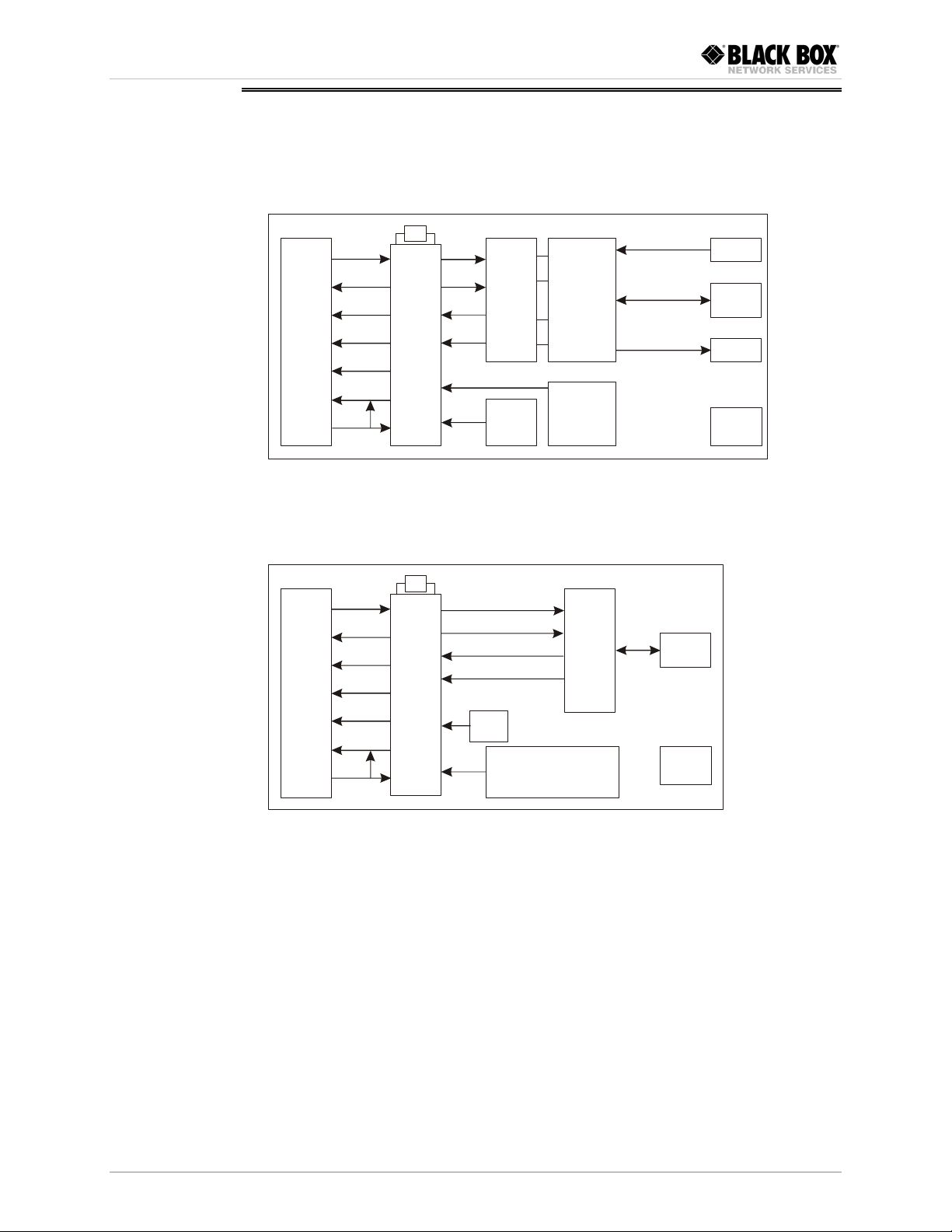

1-2. Block Diagram, E1 Converter................................................................................................. 1-2

1-3. Block Diagram, T1 Converter ................................................................................................ 1-2

2-1. Jumper Locations, E1 Converter ............................................................................................ 2-3

2-2. Jumper Locations, T1 Converter ............................................................................................ 2-3

3-1. E1 Converter Front Panel....................................................................................................... 3-1

3-1. T1 Converter Front Panel ...................................................................................................... 3-1

4-1. Running Local Loopback ....................................................................................................... 4-1

5-2. MT1100C, MT1102C Front Panels ........................................................................................ 5-3

5-5. Rack Nest 2/14 Front Panel ................................................................................................... 5-4

5-6. PCB Layout ........................................................................................................................... 5-5

List of Tables

2-1. Jumper Settings, E1 Converter ............................................................................................... 2-4

2-2. Jumper Settings, T1 Converter ............................................................................................... 2-4

3-1. Front Panel LED Indicators .................................................................................................... 3-1

4-1. Troubleshooting .................................................................................................................... 4-2

5-1. Jumper Settings ..................................................................................................................... 5-5

ii

Page 5

Versions

Chapter 1

Introduction

1.1 Overview

MT1100A, MT1100A-DC, MT1100C, MT1101A, MT1101A-DC, MT1102A,

MT1102A-DC, MT1102C are interface converters. They convert unframed HDB3,

AMI or B8ZS data of ITU G.703 E1/T1 balanced or unbalanced interface into a

V.35 or RS-530 DTE interface.

The units operate at 1544 kbps or 2048 kbps. It extracts data and the clock from

the G.703 interface via a jitter attenuator to meet ITU G.823 requirements.

RIC-E1 acts as a line transceiver. It provides protection from over-voltage and

over-current stress caused by lightning, power crosses and other noise sources.

The following versions of the converters are available:

Application

• MT1100A – standalone T1 to V.35 converter, AC power supply

• MT1100A-DC – standalone T1 to V.35 converter, DC (-48 VDC) power supply

• MT1100C – converter card for Rack Nest 2/14 modem nest, T1 to V.35

• MT1102A – standalone T1 to RS-530 converter, AC power supply

• MT1102A-DC – standalone T1 to RS-530 converter, DC (-48 VDC) power

supply

• MT1102C – converter card for Rack Nest 2/14 modem nest, T1 to RS-530

• MT1101A – standalone E1 to V.35 converter, AC power supply

• MT1101A-DC – standalone E1 to V.35 converter, DC (-48 VDC) power supply.

Converters are typically used to connect between a G.703 network and a DTE.

The DTE can be a multiplexer, a bridge, a router etc. Figure 1-1 illustrates a typical

application.

Network

E1 or T1

MT 11 00A, MT 11 00A- D C,

MT 11 01A, MT 11 01A- D C,

MT1102A or MT1102A-DC,

Figure 1-1. Typical Application

V.35 or RS-530

DTE

Overview 1-1

Page 6

Chapter 1 Introduction

1.2 Functional Description

Functional Block Diagram

Figure 1-2 shows the functional block diagram of MT1101A and MT1101A-DC.

Interchangable Interfaces

Txd

Rxd

Txclk

Rxclk

Loss

Ts t

Ana

X

LIU

Transformers

Clock

Gen.

Select

IMP

Tx & Rx Code

AMI

HDB3

Unbalanced

Balanced

Unbalanced

BNC

RJ - 45

BNC

P. S .

Figure 1-2. Block Diagram, E1 Converter

Figure 1-2 shows the functional block diagram of MT1100A, MT1100A-DC,

MT1100C, MT1102A, MT1102A-DC, and MT1102C.

X

Txd

Interchangable Interfaces

Rxd

Txclk

Transformers

RJ - 45

Timing Reference

Converters support three clock modes:

• Internal, derived from its internal oscillator

• External, supplied by the attached DTE

• Receive, recovered from the received line signal.

Diagnostics

Converters support a V.54 (loop 3) local loopback activated by the internal jumper

of the standalone unit, front panel pushbutton of the rack card or via

corresponding pin of the DTE interface connector. For more information, refer to

Chapter 4.

Rxclk

Loss

Ts t

Ana

LIU

Tx & Rx Code

AMI

B8ZS

Clock GEN.

Figure 1-3. Block Diagram, T1 Converter

P. S .

1-2 Functional Description

Page 7

Chapter 1 Introduction

1.3 Technical Specifications

E1 Interface

T1 Interface

Coding

Framing

Bit Rate

Impedance

RCV Signal Level

XMT Signal Level

Connectors

Return Loss

Coding

Framing

Bit Rate

Impedance

RCV Signal Level

HDB3 or AMI

Unframed

2.048 Mbps

120Ω, balanced

75Ω, unbalanced

0 to -10 dB

3V (±10%), balanced

2.37V (±10%), unbalanced

RJ-45, 8-pin, balanced

Two BNC coaxial, unbalanced

Better than 15 dB

B8ZS, AMI

Unframed

1.544 Mbps

100Ω, balanced

0 to -10 dB

DTE Interface

Timing

Indicators

XMT Signal Level

Connector

Return Loss

Type

Control Signals

PWR (green)

TXD (yellow)

RXD (yellow)

LOS (red)

3V (±10%), balanced

RJ-45, 8-pin, balanced

Better than 15 dB

• V.35: 34-pin, female

• RS-530: 25-pin, D-type female

• CTS follows RTS

• DCD follows E1 state

• DSR is constantly ON

Derived from three alternative sources:

• Internal oscillator

• External, from the attached DTE

• Receive, derived from the received signal

On – Power on

On – Data is being transmitted to the link

On – Data is being received from the link

On – No E1/T1 data is received from the link

Technical Specifications 1-3

TST (red)

On – The local loopback is active

Page 8

Chapter 1 Introduction

Diagnostics

Power

Physical

Local Loopback

AC Source

DC Source

Power Consumption

Fuses

Standalone

Height

Width

Depth

Complies with ITU V.54 (loop 3)

Activated by:

• Internal jumper (standalone unit)

• Front panel pushbutton (rack card)

• DTE circuit 141

100 to 240 VAC (± 10%), 50 or 60 Hz

-48 VDC (-42 to -60 VDC)

• Standalone: 3W, max

• Card: 5.2W

Standalone: 250 mA 250V slowblow

Card: 500 mA 250V slowblow

39.5 mm / 1.5 in

190 mm / 7.4 in

160 mm / 6.2 in

Environment

Weight

Card

Temperature

Humidity

0.6 kg / 1.3 lb

Fits one slot in the Rack Nest 2/14

0–50°C (32–122°F)

Up to 90%, non-condensing

1-4 Technical Specifications

Page 9

Chapter 2

Installation and Setup

This chapter explains how to configure and install MT1100A, MT1100A-DC,

MT1101A, MT1101A-DC, MT1102A, and MT1102A-DC converters.

After the installation is complete, refer to Chapter 3 for information about

operating standalone units.

Refer to Chapter 4 for troubleshooting and diagnostics information.

2.1 Site Requirements and Prerequisites

MT1100A, MT1101A, MT1102A units should be installed within 1.5m (5 ft) of an

easily-accessible grounded AC outlet capable of furnishing the required supply

voltage, in the range of 100 to 240 VAC.

MT1100A-DC, MT1101A-DC and MT1102A-DC units require a -48 VDC power

source, which must be adequately isolated from the mains supply. In order to

prevent a fire hazard, a suitable fuse must be installed in the live DC line.

Allow at least 90 cm (36 in) of frontal clearance for operator access and at least

10 cm (4 in) clearance at the rear of the unit for interface cable connections.

The ambient operating temperature should be 0 to 50°C (32 to 122°F), at a

relative humidity of up to 90%, non-condensing.

2.2 Package Contents

The package includes the following items:

• Standalone unit or rack card

• The AC power cord or DC power supply connector kit for standalone unit

• Installation and operation manual on a CD

• Rack installation kit (if ordered).

Package Contents 2-1

Page 10

Chapter 2 Installation and Setup

2.3 Configuring Standalone Unit

This section provides information on the functions and locations of internal

jumpers. Use this information to select the correct setting for your particular

application.

To install a standalone unit:

1. Determine the required configuration, according to your application, and set

the internal jumpers accordingly. For more information, refer to Setting the

Jumpers on page 2-2.

2. Connect the DTE and G.703 link interfaces, as explained in Connecting the

Interfaces on page 2-5.

3. Connect the power to the unit. For more information, refer to Connecting the

Power on page 2-5.

Setting the Jumpers

This section explains how to set the internal jumpers according to your

requirements. Figure 2-1 and Figure 2-2 show the jumper locations.

Avoid adjusting, maintaining or repairing unit while it is connected to the

power source.

Adjusting, maintaining and repairing unit, while connected to power supply

Warning

should only be done by a skilled technician aware of the hazards involved.

Capacitors inside the instrument may still be charged even after the

instrument has been disconnected from its source of supply.

To set the jumpers:

1. Disconnect the power cable from the mains outlet.

2. Slide the blue side panel forward to detach it from the case.

3. Unscrew the two screws located on the bottom panel at the rear end of the

unit.

4. Separate the two halves of the case by lifting the top cover at the end of the

unit and sliding it forward.

5. Adjust the internal jumpers, as described in Table 2-1 and Table 2-2. Figure 2-1

and Figure 2-2 show the jumper locations.

6. Reinstall the cover and tighten the screws.

2-2 Configuring Standalone Unit

Page 11

Chapter 2 Installation and Setup

JP1

JP2

JP3

JP4

BAL

BNC

BAL

JP6

BNC

J4

RCV

EXT

INT

TX & RX CO DE

AMI

JP9

HDB3

JP11

LOC

DTE

ANA LOOP

Figure 2-1. Jumper Locations, E1 Converter

J4

RCV

EXT

INT

JP9

JP11

B8ZS

AMI

JP7

B8ZS

AMI

TX CODE RX CODE

LOC DTE

ANA LOOP

Figure 2-2. Jumper Locations, T1 Converter

Configuring Standalone Unit 2-3

Page 12

Chapter 2 Installation and Setup

Table 2-1. Jumper Settings, E1 Converter

Jumper Description Values Default Setting

JP1, JP2, JP3, JP4,

JP6

TX & RX CODE,

JP9

TIMING, J4 Selects the clock reference RCV (pin 4) – Receive clock

ANA LOOP, JP11 Controls the local analog

Select the E1 interface type BAL – Balanced interface

(RJ-45 connector)

BNC – Unbalanced interface (BNC

coax connectors)

Selects the transmit and

receive coding

loopback activation

AMI – Jumper plug is installed

HDB3 – Jumper plug is not installed HDB3

EXT (pin 5) – External clock

INT (pin 6) – Internal clock

LOC – Activates the local analog

loopback

DTE – Allows the activation of the

local analog loopback via DTE

BAL

RCV

DTE

Table 2-2. Jumper Settings, T1 Converter

Jumper Description Values Default Setting

TX & RX

CODE,

JP9 & JP7

Selects the transmit and

receive coding

AMI – Jumper plug is installed

B8ZS – Jumper plug is not installed

B8ZS

TIMING, J4 Selects the clock

reference

ANA LOOP,

JP11

Controls the local

analog loopback

activation

Selecting the E1 Impedance

When using the balanced interface:

• Terminate the impedance of G.703 link to 120Ω.

• Use only the RJ-45 connector to transmit full duplex data to the G.703

network over UTP or STP cable.

When using the unbalanced interface:

• Terminate the impedance of G.703 link to 75Ω.

• Use only the coaxial BNC connectors to transmit to the G.703 network via two

coaxial cables.

RCV (pin 4) – Receive clock

EXT (pin 5) – External clock

INT (pin 6) – Internal clock

LOC – Activates the local analog loopback

DTE – Allows the activation of the local

analog loopback via DTE

RCV

DTE

2-4 Configuring Standalone Unit

Page 13

Chapter 2 Installation and Setup

Closing the Case

After completing the internal settings, close the unit case.

To close the case:

1. Position the lower half of the case on the flat surface.

2. Install the top cover making sure the top cover guides enter the corresponding

recesses at the end of the unit.

3. Secure the two screws located at the end of the unit.

4. Fit the inside tabs of the blue side panel into the unit case grooves, and slide

the side panel until snaps into place.

Connecting the Interfaces

Connecting the E1 Line

E1 link interface terminates in balanced and unbalanced connectors, marked

LINK.

To connect the balanced interface:

• Use RJ-45 male connector and connect it to the RJ-45 port of converter.

Appendix A lists the balanced connector pin assignment.

To connect the unbalanced interface:

1. Connect the receive line to the back panel connector designated TX.

2. Connect the transmit line to the back panel connector designated RX.

Do not connect both balanced and unbalanced connectors.

Warning

Connecting the T1 Line

T1 link interface terminates in balanced RJ-45 connector, marked LINK.

To connect the balanced interface:

• Use RJ-45 male connector and connect it to the RJ-45 port of converter.

Appendix A lists the balanced connector pin assignment.

Connecting the DTE

Converters support V.35 and RS-530 data channel interfaces. The DTE equipment

can be connected directly to the RIC-E1 DTE port. Connector pin allocations and

cable wiring data appear in Appendix A.

Connecting the Power

Refer to the appropriate section below depending on the unit’s version – AC or

DC.

Configuring Standalone Unit 2-5

Page 14

Chapter 2 Installation and Setup

Connecting the AC Power

AC power should be supplied to the MT1100A, MT1101A, MT1102A units

through the 1.5m (5 ft) standard power cable terminated with a standard 3-prong

plug. The cable is provided with the unit.

Before connecting power to the unit, verify that the socket outlet is provided

with a protective ground contact. If you are using an extension cord (power

cable) make sure it is grounded as well

Warning

Interrupting the protective (grounding) conductor (inside or outside the unit),

or disconnecting the protective ground terminal can make this unit dangerous.

Make sure that only fuses of the required rating (0.250A, 250V) are used for

replacement. Do not use repaired fuses or short-circuit the fuse holder. Always

disconnect the mains cable before removing or replacing the fuse. If there is a

chance that the fuse protection has been damaged, make the unit inoperative.

To connect AC power:

1. Connect the power cable to the power connector on the rear panel.

2. Plug the power cable to the mains outlet.

The unit turns on automatically upon connection to the mains.

Connecting the DC Power

To connect DC power:

• Refer to the DC power supply connection supplement.

2-6 Configuring Standalone Unit

Page 15

Chapter 3

Operation

This chapter describes how to operate converters. Installation procedures

explained in Chapter 2 must be completed and checked before attempting to

operate the unit.

3.1 Front Panel Indicators

Figure 3-1 and Figure 3-2 show front panels of the E1 and T1converters,

respectively. The front panel indicators are described in Table 3-1.

PWR

724-746-5500

E1 Rate Converter

TST

TXD

RXD

LOS

Figure 3-1. E1 Converter Front Panel

PWR

724-746-5500

T1 Rate Converter

TST

TXD

RXD

LOS

Figure 3-2. T1 Converter Front Panel

Table 3-1. Front Panel LED Indicators

Designation Color Function

PWR Green ON – The unis is powered up

TXD Yellow ON – Data is being transmitted to the link

RXD Yellow ON – Data is being received from the link

LOS Red ON – No E1/T1 data is received from the link

TST Red ON – The local loopback is active

Front Panel Indicators 3-1

Page 16

Chapter 3 Operation

3.2 Operating Instructions

Turning On

The unit starts operating as soon as AC or DC power is connected. Always connect

the power cable to the power connector first and then to the mains outlet.

The PWR LED lights when power is connected.

Operating the Unit

Converters operate entirely unattended except when performing system tests.

Turning Off

To turn the unit off, disconnect the power cable from the mains outlet.

3-2 Operating Instructions

Page 17

Chapter 4

Troubleshooting and

Diagnostics

4.1 Performing Local Analog Loopback

E1/T1 rate converters support activation of a V.54 diagnostic (loop 3) local

loopback.

This loopback checks the communication and connection between the unit and

the attached DTE, as shown in Figure 4-1. When converter performs a local

loopback, the data received from the local transmitter is both transmitted on the

line and looped back to the local receiver at the digital level. This checks the

operation of all local digital circuitry.

DTE Line

Tx

Rx

E1/T1 Rate Convert er

Figure 4-1. Running Local Loopback

Activating Local Analog Loopback

You can activate the local analog loopback via DTE interface circuit 141.

Note

Warning

When activating the local analog loopback via interface of the DTE connected to the

rack card, make sure to set the ALB DTE jumper (JP4) to EN.

Alternatively, you can initiate the loopback via internal jumper of the standalone

unit or by pressing the ANA pushbutton on the rack card panel.

Do not touch any components other than ANA LOOP (JP11) jumper plug while

activating the local loopback from the standalone unit, in order to avoid

electrical shock.

Tx

G. 7 0 3

Network

Rx

Performing Local Analog Loopback 4-1

Page 18

Chapter 4 Troubleshooting and Diagnostics

To activate the local analog loopback from the standalone unit:

1. Open the unit’s case, as described in Chapter 2.

2. Set the JP11 jumper to LOC.

The analog loopback is activated and the TST indicator on the front panel

turns on.

To activate the local analog loopback from rack card:

• Press the ANA pushbutton on the card’s front panel.

Make sure that the PNL SW jumper (JP5) on the card’s board is set to EN.

The TST indicator on the front panel turns on.

Deactivating Local Analog Loopback

To deactivate the local analog loopback from the DTE:

• Lower the circuit 141 pins of the DTE interface.

To deactivate the local analog loopback from the standalone unit:

• Set the JP11 jumper to DTE.

The TST indicator on the front panel turns off.

To deactivate the local analog loopback from the rack card:

• Press the ANA pushbutton again to return it to the previous position.

4.2 Troubleshooting

Table 4-1 contains troubleshooting information to help you identify and correct

problems.

Table 4-1. Troubleshooting

Trouble Symptoms Probable Cause Corrective Measures

All front panel indicators

are OFF

2. Blown fuse Disconnect power cable from both ends

LOS indicator is ON 1. Receive line fuses are blown Disconnect power cable from both ends

1. No power Check that both ends of the power cable

are properly connected.

and replace the fuse with another fuse of

proper rating.

and replace the fuses with new fuses of

proper rating.

2. Line cables are not properly

connected

3. Unbalanced BNC connectors

are reversed

4. The transformer is damaged Replace the unit.

Check and adjust both ends of the line

cables.

Switch the two BNC connectors.

4-2 Troubleshooting

Page 19

Chapter 5

MT1100C, MT1102C Cards

This chapter describes the card version of the T1 converter, designed for

installation in the Rack Nest 2/14 card cage. The chapter contains the following

sections:

• The Rack Nest 2/14 card cage

• MT1100C, MT1102C cards

• Power supply to the cards

• Installing the cards.

5.1 Rack Nest 2/14 Card Cage

The Rack Nest 2/14 card cage contains one or two power supplies and up to

14 plug-in cards.

For each of the 14 cards, the rear panel contains a male connector for the terminal

block and a DB-25 connector. A protection cover protects the terminal block

connectors.

Line Connector

The line is to be attached to the rear panel terminal block connectors. It contains

screws for connecting the transmit and receive pairs and ground, if present.

The Rack Nest 2/14 is also available with BNC coaxial unbalanced or RJ-45

balanced line connectors.

DTE Connector

The 25-pin D-type female interface connector provides all interface signals for the

digital interfaces. Units with V.35 interface require an external mechanical

adapter.

Rack Nest 2/14 Card Cage 5-1

Page 20

Chapter 5 MT1100C, MT1102C Cards

5.2 Power Supply

Power is supplied to the converter cards from the Rack Nest 2/14 power supply via

the chassis. Each converter card has two fuses (F5 and F6), which protect the

entire system against power failure resulting from a short circuit in one card. The

rating of the fuses is 500 mA, 250V, slowblow (see Figure 5-3).

The Rack Nest 2/14 card cage can accept both AC or DC power supplies. LED

indicators located on the Rack Nest 2/14 front panel (see Figure 5-2) show activity

when the power supply is connected to the mains plug. The power supply

supports the full card cage with any combination of cards.

AC Supply

The AC power supply of the Rack Nest 2/14 is 100, 115, or 230 VAC, ±10%,

47 to 63 Hz.

Optional DC Supply

The DC power supply is -48 VDC (-36 to -72 VDC) or 24 VDC (18 to 32 VDC). It

uses a DC/DC converter module to provide the power required for the cards.

Power Supply with Redundancy

This special ordering option is equipped with two separate power supplies,

operating together and sharing the load of the whole card cage. If either of the

power supplies fails, the other one will continue to supply power to the full card

cage.

Two LED indicators show activity of each power supply. They should both light

when mains power is provided.

Note

It is possible to combine AC and DC power supplies in the same cage.

5-2 Power Supply

Page 21

Chapter 5 MT1100C, MT1102C Cards

5.3 Front Panel

Figure 5-1 shows the card front panel. The LEDs of the card version with serial DTE

interface are identical in their functionality to those of the standalone device,

except for the ANA pushbutton. The ANA pushbutton serves for activation of the

local analog loopback, see Chapter 4 for the details.

PWR

TXD

RXD

TST

LOS

ANA

Figure 5-1. MT1100C, MT1102C Front Panels

Front Panel 5-3

Page 22

Chapter 5 MT1100C, MT1102C Cards

Figure 5-2. Rack Nest 2/14 Front Panel

5-4

Page 23

Chapter 5 MT1100C, MT1102C Cards

5.4 Installing MT1100C, MT1102C

Setting Internal Jumpers and Switches

Figure 5-3 illustrates location of the internal jumpers on the PCB.

EN EN

DIS DIS

ALB DTE

JP4

PNL SW

J2

INT

EXT

JP5

RCV

TIMING SEL

B8ZS

AMI

TX&RX CODE

JP6

CHASS-GND

CON

DISCON

J3

F5

F6

Figure 5-3. PCB Layout

Table 5-1. Jumper Settings

Jumper Description Values Default Setting

ALB DTE, JP4 Enables local analog

loopback activation from

the DTE (via pin 18 for

RS-530 or via pin “JJ” for

V.35)

EN – The local analog loopback

activation from the DTE is

enabled

DIS – The local analog loopback

activation from the DTE is

DIS

disabled

PNL SW, JP5 Enables activation of the

local analog loopback via

the front panel pushbutton

EN – The LLB can be activated via

the front panel

DIS – The LLB cannot be

EN

activated via the front

panel

TX&RX CODE, JP6 Selects the data receive

and transmit coding

Installing MT1100C, MT1102C 5-5

B8ZS

AMI

B8ZS

Page 24

Chapter 5 MT1100C, MT1102C Cards

Table 5-1. Jumper Settings (Cont.)

Jumper Description Values Default Setting

TIMING SEL, J2 Selects the clock reference RCV – Receive clock

EXT – External clock

INT – Internal clock

CHASS GND, J3 Controls the connection

between the signal ground

of the card and the frame

(chassis) ground

CON – Signal ground is

connected to the frame

ground

DISCON – Signal ground is

disconnected from the

frame ground

RCV

CON

Installing MT1100C, MT1102C into the Rack Nest 2/14 Card Cage

To install MT1100C, MT1102C card into the Rack Nest 2/14 card cage:

1. Install the Rack Nest 2/14 card cage in the 19-inch rack.

2. Insert the MT1100C or MT1102C card into one of the Rack Nest 2/14 slots.

3. Push the card into the cage until it is fully inserted into the edge connector

inside the rack.

4. Tighten the screws on front panel of the modem card.

Connecting the Interfaces

Warning

MT1100C and MT1102C use the Rack Nest 2/14 rear panel terminal block ports for

the line connections. The 25-pin D-type female connector serves as a DTE port.

1. Remove the protection cover from the terminal block connectors.

2. Connect the terminal block to the Rack Nest 2/14 terminal block connector.

3. Connect the line to the terminal block as follows: connect transmit pair to the

terminals marked XMT, the receive pair to the terminals marked RCV, and the

fifth screw to ground (optional).

4. If required, attach the appropriate interface adapter to the DB-25 connector

on the card cage rear panel.

5. Connect the DTE cable to the DB-25 connector or other side of the interface

adapter (depending on your version of the card interface).

6. Connect power to the Rack Nest 2/14 card cage:

To connect AC power, connect the power cable to the mains supply.

To connect DC power, refer to DC power supply connection supplement

of the Rack Nest 2/14 installation and operation manual.

The Rack Nest 2/14 card cage has no power switch. Operation starts when the

power is applied to the rear panel POWER connector. When applying power,

first connect the plug of the power cord to the Rack Nest 2/14 POWER

connector and then to the mains power source (outlet).

5-6 Installing MT1100C, MT1102C

Page 25

Appendix A

Interface Connector Wiring

A.1 V.35 and RS-530 Interface Connectors

Table A-1 lists the pin assignments of the V.35 and RS-530 interface connectors.

Table A-1. V.35 and RS-530 Interfaces, Pin Assignments

Signal

Function

Protective

Ground

Signal

Ground

Transmitted

Data

Received

Data

Request to

Send

Clear to

Send

Data Set

Ready

Data

Terminal

Ready

Carrier

Detect

V.35, 34-Pin RS-530, DB-25

Pin

A Frame 101 1 101

B

P

S

R

T

C RTS 105 4

D CTS 106 5

E DSR 107 6

H DTR 108 20

F DCD 109 8

Signal

GND

TD(A)

TD(B)

RD(A)

RD(B)

Circuit Pin

102 7 AB 102

103

103

104

104

2

14

3

16

19

13

22

23

10

BA(A)

BA(B)

BB(A)

BB(B)

CA(A)

CA(B)

CB(A)

CB(B)

CC(A)

CC(B)

CD(A)

CD(B)

CF(A)

CF(B)

Circuit

103

103

104

104

105

106

107

108

109

External

Transmit

Clock

Transmit

Clock

Receive

Clock

Local Analog

Loop

Test

Indicator

Line Interface Connector A-1

U

W

Y

AA

V

X

jj LLB 141 18 LL 141

kk TM 142 25 TM 142

SCTE(A)

SCTE(B)

SCT(A)

SCT(B)

SCR(A)

SCR(B)

113

113

114

114

115

115

24

11

15

12

17

9

DA(A)

DA(B)

DB(A)

DB(B)

DD(A)

DD(B)

113

113

114

114

115

115

Page 26

Appendix A Interface Connector Wiring

A.2 Line Interface Connector

The E1/T1 line interface terminates in 8-pin balanced RJ-45 connector, wired in

accordance with Table A-2.

Table A-2. Balanced RJ-45 Line Interface Connector, Pin Assignment

Pin Function

1, 2 Transmit

4, 5 Receive

3, 6 GND

A-2 Line Interface Connector

Loading...

Loading...