Page 1

CUSTOMER

SUPPORT

INFORMATION

Order toll-free in the U.S.: Call 877-877-BBOX (outside U.S. call 724-746-5500)

FREE technical support 24 hours a day, 7 days a week: Call 724-746-5500 or fax 724-746-0746

Mailing address: Black Box Corporation, 1000 Park Drive, Lawrence, PA 15055-1018

Web site: www.blackbox.com • E-mail: info@blackbox.com

MAY 1995

ME758C-RJ11

ME758C-RJ45

ME759C-RJ11

ME759C-RJ45

Multi-Function LD Cards

Power

TD

RD

RTS

CD

Error

Analog

511

Remote

511/E

Test

Page 2

1

FCC STATEMENTS

FEDERAL COMMUNICATIONS COMMISSION

AND

INDUSTRY CANADA

RADIO FREQUENCY INTERFERENCE STATEMENTS

This equipment generates, uses, and can radiate radio-frequency energy, and if not

installed and used properly, that is, in strict accordance with the manufacturer’s

instructions, may cause interference to radio communication. It has been tested

and found to comply with the limits for a Class A computing device in accordance

with the specifications in Subpart B of Part 15 of FCC rules, which are designed to

provide reasonable protection against such interference when the equipment is

operated in a commercial environment. Operation of this equipment in a

residential area is likely to cause interference, in which case the user at his own

expense will be required to take whatever measures may be necessary to correct

the interference.

Changes or modifications not expressly approved by the party responsible

for compliance could void the user’s authority to operate the equipment.

This digital apparatus does not exceed the Class A limits for radio noise emission from

digital apparatus set out in the Radio Interference Regulation of Industry Canada.

Le présent appareil numérique n’émet pas de bruits radioélectriques dépassant les limites

applicables aux appareils numériques de la classe A prescrites dans le Règlement sur le

brouillage radioélectrique publié par Industrie Canada.

TRADEMARKS USED IN THIS MANUAL

AT&T is a registered trademark of American Telephone and Telegraph

Company.

Littelfuse is a registered trademark of Littelfuse, Inc.

Any other trademarks mentioned in this manual are acknowledged to be the property of the

trademark owners.

Page 3

2

MULTI-FUNCTION LD CARD

NORMAS OFICIALES MEXICANAS (NOM)

ELECTRICAL SAFETY STATEMENT

INSTRUCCIONES DE SEGURIDAD

1. Todas las instrucciones de seguridad y operación deberán ser leídas antes de

que el aparato eléctrico sea operado.

2. Las instrucciones de seguridad y operación deberán ser guardadas para

referencia futura.

3. Todas las advertencias en el aparato eléctrico y en sus instrucciones de

operación deben ser respetadas.

4. Todas las instrucciones de operación y uso deben ser seguidas.

5. El aparato eléctrico no deberá ser usado cerca del agua—por ejemplo, cerca

de la tina de baño, lavabo, sótano mojado o cerca de una alberca, etc..

6. El aparato eléctrico debe ser usado únicamente con carritos o pedestales que

sean recomendados por el fabricante.

7. El aparato eléctrico debe ser montado a la pared o al techo sólo como sea

recomendado por el fabricante.

8. Servicio—El usuario no debe intentar dar servicio al equipo eléctrico más allá

a lo descrito en las instrucciones de operación. Todo otro servicio deberá ser

referido a personal de servicio calificado.

9. El aparato eléctrico debe ser situado de tal manera que su posición no

interfiera su uso. La colocación del aparato eléctrico sobre una cama, sofá,

alfombra o superficie similar puede bloquea la ventilación, no se debe colocar

en libreros o gabinetes que impidan el flujo de aire por los orificios de

ventilación.

10. El equipo eléctrico deber ser situado fuera del alcance de fuentes de calor

como radiadores, registros de calor, estufas u otros aparatos (incluyendo

amplificadores) que producen calor.

11. El aparato eléctrico deberá ser connectado a una fuente de poder sólo del

tipo descrito en el instructivo de operación, o como se indique en el aparato.

Page 4

3

NOM STATEMENTS

12. Precaución debe ser tomada de tal manera que la tierra fisica y la polarización

del equipo no sea eliminada.

13. Los cables de la fuente de poder deben ser guiados de tal manera que no

sean pisados ni pellizcados por objetos colocados sobre o contra ellos,

poniendo particular atención a los contactos y receptáculos donde salen del

aparato.

14. El equipo eléctrico debe ser limpiado únicamente de acuerdo a las

recomendaciones del fabricante.

15. En caso de existir, una antena externa deberá ser localizada lejos de las lineas

de energia.

16. El cable de corriente deberá ser desconectado del cuando el equipo no sea

usado por un largo periodo de tiempo.

17. Cuidado debe ser tomado de tal manera que objectos liquidos no sean

derramados sobre la cubierta u orificios de ventilación.

18. Servicio por personal calificado deberá ser provisto cuando:

A: El cable de poder o el contacto ha sido dañado; u

B: Objectos han caído o líquido ha sido derramado dentro del aparato; o

C: El aparato ha sido expuesto a la lluvia; o

D: El aparato parece no operar normalmente o muestra un cambio en su

desempeño; o

E: El aparato ha sido tirado o su cubierta ha sido dañada.

Page 5

4

MULTI-FUNCTION LD CARD

Contents

Chapter Page

1. Specifications ............................................................................................. 5

2. Introduction ............................................................................................... 8

2.1 Overview .............................................................................................. 8

2.2 Features ............................................................................................... 8

3. Configuration ........................................................................................... 10

3.1 Setting the Switches on the Main Module ....................................... 10

3.2 Setting the Jumpers on the Interface Module ................................ 17

4. Installation ................................................................................................ 22

4.1 The MicroRacks: An Overview ......................................................... 22

4.2 The MicroRacks’ Power Supply ....................................................... 23

4.3 Installing the Multi-Function LD Card in the MicroRack .............. 24

4.4 The RS-232 Serial Cables and Connectors ...................................... 25

4.5 The Modem-to-Modem Line Cables and Connectors .................... 26

4.6 Multipoint Applications .................................................................... 28

5. Operation and Diagnostics ...................................................................... 29

5.1 Status LEDs ........................................................................................ 29

5.2 Diagnostic Testing Using the Error LED ........................................ 31

5.3 Power-Up ........................................................................................... 32

5.4 V.54 and V.52 Diagnostic Tests ........................................................ 33

6. Troubleshooting ...................................................................................... 36

6.1 Calling Your Supplier ....................................................................... 36

6.2 Shipping and Packaging ................................................................... 36

Appendix: Cable Recommendations ............................................................. 37

Page 6

5

CHAPTER 1: Specifications

1. Specifications

Hardware

Required — Cards can be installed only in MicroRacks (see

Section 4.1)

Cable Required — For modem-to-modem line: Two- or four-wire

unconditioned twisted-pair, 19 to 26 AWG (see

the Appendix), pinned as shown in Section 4.5

Compliance — FCC Part 15 Class A, DOC Class/MDC classe A

Interfaces — Serial:

ME758C models: EIA/TIA-561 (compatible with

EIA RS-232 and ITU-TSS [CCITT] V.24);

ME759C models: EIA RS-232/ITU-TSS V.24

Line: Two- or four-wire telco;

Internal: Card-edge for module↔MicroRack

interconnection

Protocol — Synchronous or asynchronous

Clock Source — Internal, external (from DTE) or received (from

other Card) (user-selectable)

Data Format — Word length (including start bit, data bits, stop bits,

and parity bit) must equal 8, 9, 10, or 11 bits (user-

selectable)

Flow Control — Transparent to all types of software (X-ON/X-OFF,

robust X-ON/X-OFF, etc.) flow control; can be set

to support hardware flow control

Operating Mode — Two-wire half-duplex or four-wire full- or half-

duplex (user-selectable)

Page 7

6

MULTI-FUNCTION LD CARD

Data Rates — 57.6, 38.4, 28.8, 19.2, 14.4, 9.6, 7.2, 4.8, 3.6, 2.4, or

1.2 kbps (user-selectable)

Maximum

Distance — See the maximum distance chart in the Appendix

Isolation — 1500 volts RMS minimum using custom transformers

Surge-Protection

Method — Silicon Avalanche Diodes

Surge-Response

Time — 1 ps

Maximum Surge

Protection — 600 watts dissipated after 1 ms

User Controls — (2) Front-panel toggle switches:

Remote or (local) Analog loopback;

511 or 511/E V.52 diagnostics;

(3) 8-position DIP switches on main module:

(1) for data rate, clock source, protocol, and carrier

control;

(1) for 2- or 4-wire operation, diagnostics, RTS/CTS

delay, signaling-rate range, and word length;

(1) for input impedance, point-to-point or

multipoint operation, remote loopback-test

initiation, and antistream control;

(3) Frame-ground-connection jumpers on interface

module:

To Line Shield, DTE Shield (Protective Ground),

and Signal Ground

Indicators — (11) Front-panel LEDs:

(1) each for Power, Test, Error;

(2) each for TD, RD, RTS, and CD

Diagnostics — ITU-TSS V.54 remote digital and local analog

loopbacks; ITU-TSS V.52 BERT testing

Connectors — On main module:

All models:

Page 8

7

CHAPTER 1: Specifications

(1) 50-position card-edge male (to MicroRack);

On interface module:

All models:

(1) 50-position card-edge male (to MicroRack);

ME758C-RJ11:

(1) 6-pin RJ-11 female for modem-to-modem line,

(1) DB25 female for modem-to-DTE line;

ME758C-RJ45:

(1) RJ-45 female for modem-to-modem line,

(1) DB25 female for modem-to-DTE line;

ME759C-RJ11:

(1) 6-pin RJ-11 female for modem-to-modem line,

(1) 10-pin RJ female for modem-to-DTE line;

ME759C-RJ45:

(1) RJ-45 female for modem-to-modem line,

(1) 10-pin RJ female for modem-to-DTE line

Power — From MicroRack’s power supply (see Section 4.2):

Input 120 VAC or 240 VAC (user-selectable);

Output: 10 VAC;

Consumption: 1.8 watts typical

Fuse — On MicroRack (see Section 4.2.2):

400 mA when power supply is set to 120-VAC input;

200 mA when power supply is set to 240-VAC input

Temperature — 32 to 122˚F (0 to 50˚C)

Humidity — Up to 95% noncondensing

Maximum

Altitude — 15,000 ft. (4572 m)

Size — Main (front) module: 3.1"H x 1"W x 5.4"D

(7.9 x 2.5 x 13.7 cm);

Interface (rear) module: 3.5"H x 1"W x 2.9"D

(8.9 x 2.5 x 7.4 cm)

Weight — Total for main and interface modules: 0.2 lb. (0.1 kg)

Page 9

8

MULTI-FUNCTION LD CARD

2. Introduction

2.1 Overview

The Multi-Function LD Card is a short-range modem on a dual rack card (it

has a main [front] module and an interface [rear] module). The Card

operates across two wires (half-duplex) or four wires (full- or half-duplex),

communicating synchronously or asynchronously, up to a maximum range of

20 miles (32.2 km). You can set the Card to any of twelve data rates from 1.2

to 57.6 kbps. Local and remote modems on Multi-Function LD Cards always

communicate with each other synchronously. When connected to an

asynchronous RS-232 device, the Card performs synchronous↔asynchronous

conversion.

The Card has several features that enhance its overall performance,

including automatic equalization, automatic gain control, an antistreaming

timer, transformer isolation, and Silicon Avalanche Diode surge protection.

The Card also has strong diagnostics: It features V.52-compliant bit-error-rate

(BERT) pattern tests and two V.54 test modes. With the Card’s 11 easy-to-read

front-panel LEDs, you can easily monitor the status of data transmission and

diagnostic testing.

The Multi-Function LD Card is fabricated using the latest surface-mount

technology, so you get high-quality short-range-modem performance on a

convenient rack card. The Card is available with either DB25 or 10-pin RJ-style

serial-interface connectors, and either RJ-11 or RJ-45 line-interface

connectors, on its interface (rear) module. It fills one function-card slot in

our MicroRacks (RM202, RM204, RM208, or RM216).

2.2 Features

• Convenient rack-card design

• Synchronous or asynchronous communication

• Data rates up to 57.6 kbps, distances up to 20 miles (32.2 km)

• 2-wire/half-duplex or 4-wire/full- or half-duplex operation

• Point-to-point or multipoint operation

Page 10

9

CHAPTER 2: Introduction

• Internal, external, or received loopback clocking

• Hardware or software flow control

• Automatic equalization and gain control

• Anti-streaming timer

• Built-in transformer isolation and high-speed surge protection

• V.52 and V.54 test modes

• Eleven LED indicators show you status at a glance

• Error LED lights when Card detects broken or inferior cable

Page 11

10

MULTI-FUNCTION LD CARD

This chapter describes the locations and posssible settings of the MultiFunction LD Card’s configuration controls, and provides detailed instructions

for setting them. Section 3.1 tells you about the three 8-position DIP switches

on the Card’s main (front) module. Section 3.2 tells you about the three

jumpers (“straps”) on the Card’s interface (rear) module. Once you’ve

configured the Multi-Function LD Card, it is designed to operate

transparently, without needing to be frequently reconfigured. Just set it and

forget it!

3.1 Setting the Switches on the Main Module

3.1.1 W

HERE THESWITCHESARE

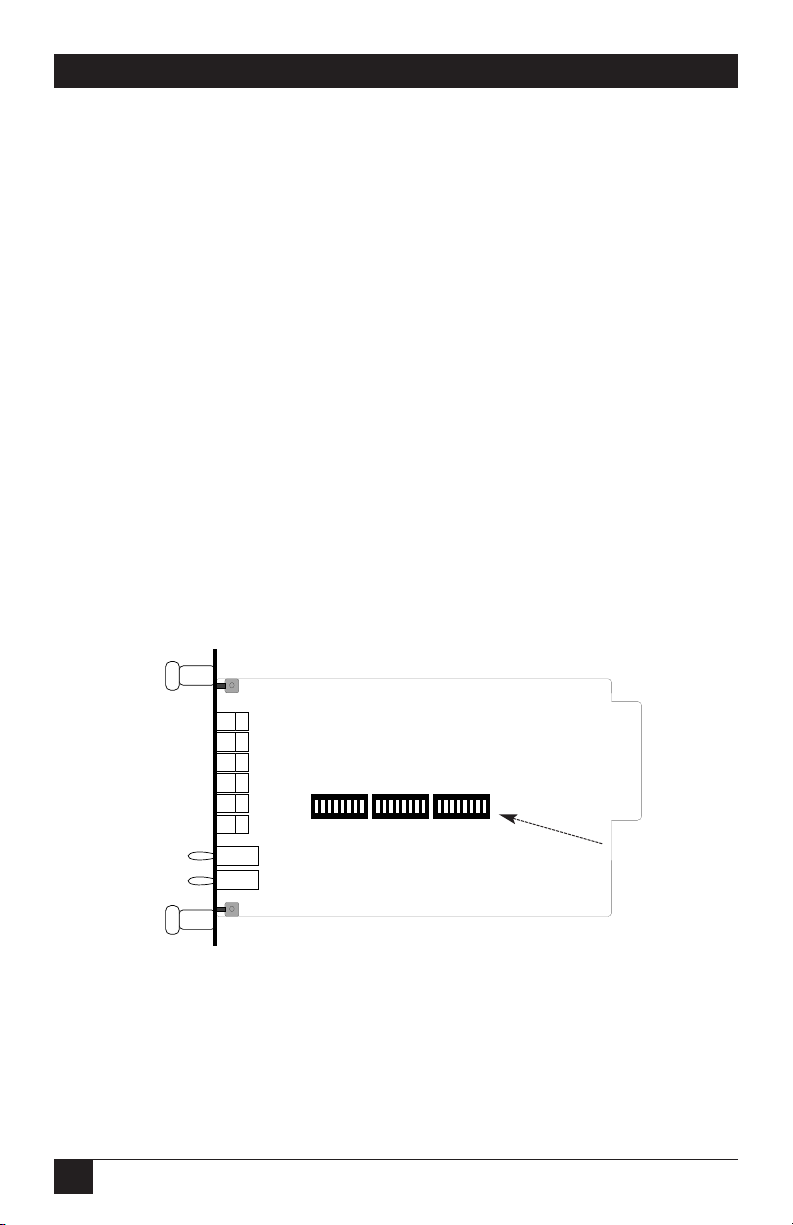

The Multi-Function LD Card has three 8-position DIP switches—S1, S2, and

S3—mounted on the circuit board of its main (front) module, as shown in

Figure 3-1 below. These configuration switches allow you to select data rates,

clocking methods, V.52 and V.54 tests, word lengths, extended signaling rates,

sync or async protocol, 2- or 4-wire operation, antistream control, and input

impedance. As shown in Figure 3-2 on the next page, the “ON” and “OFF”

points are the same for all of the switch positions.

Figure 3-1. The main-module switches.

S1 S2

S3

(on other

side of

board)

Page 12

11

CHAPTER 3: Configuration

3.1.2 C

ONFIGURATION

S

WITCH

“S1”

Use the individual positions on DIP switch S1 to set data rate, clock source,

sync vs. async protocol, and carrier-control method. The factory-default

settings are summarized in Table 3-1 below.

Table 3-1. Switch S1 Summary

Position Function Default Setting

S1-1 Data Rate On

S1-2 Data Rate Off

9600 bps

S1-3 Data Rate Off

S1-4 Data Rate On

S1-5 Clock Source On

Internal

S1-6 Clock Source On

S1-7 Protocol On Asynchronous

S1-8 Carrier Control Off Constantly ON

Figure 3-2. The ON and OFF settings of the DIP switches.

12345678

ON

ON

OFF

Page 13

12

MULTI-FUNCTION LD CARD

S1 Positions 1 through 4: Data-Rate Setting

Set positions 1 through 4 of switch S1 to determine the data rate (valid for

both synchronous and asynchronous protocols) of the Multi-Function LD

Card.

S1-1 S1-2

S1-3 S1-4 Data Rate

On On On On 1.2 kbps

Off On On On 1.8 kbps

On Off On On 2.4 kbps

Off Off On On 3.6 kbps

On On Off On 4.8 kbps

Off On Off On 7.2 kbps

On Off Off On 9.6 kbps (default)

Off Off Off On 14.4 kbps

On On On Off 19.2 kbps

Off On On Off 28.8 kbps

On On Off Off 38.4 kbps

Off On Off Off 57.6 kbps

S1 Positions 5 and 6: Clock Source

Set positions 5 and 6 of switch S1 to determine which transmit-clock source

the Multi-Function LD Card uses.

S1-5

S1-6 Clock Source

On On Internal transmit clock (default)

Off On Receive-recover clock

On Off External transmit clock

S1 Position 7: Protocol

Set position 7 of switch S1 to determine whether the Multi-Function LD Card

operates synchronously or asynchronously.

S1-7 Protocol

On Asynchronous (default)

Off Synchronous

Page 14

13

CHAPTER 3: Configuration

S1 Position 8: Carrier-Control Method

Set position 8 of switch S1 to determine whether the carrier is “constantly on”

or “controlled by RTS.” In the “controlled by RTS” setting, the Switch can

support switched-carrier, multipoint, or hardware flow-control applications.

S1-8 Carrier

Off Constantly ON (default)

On Controlled by RTS

3.1.3 C

ONFIGURATIONSWITCH

“S2”

Use the individual positions on DIP switch S2 to set word length, signalingrate range, RTS/CTS delay, or 2- or 4-wire operation, as well as to control

diagnostic testing. The factory-default settings are summarized in Table 3-2

below.

Table 3-2. Switch S2 Summary

S2 Position 2: 2-Wire vs. 4-Wire Operation

Set position 2 of switch S2 to determine whether the Multi-Function LD Card

operates in 2-wire or 4-wire mode.

S2-2 Operation

Off 4-wire (full- or half-duplex) (default)

On 2-wire (half-duplex only)

Position Function Default Setting

S2-1 Not Used N/A

S2-2 2-Wire/4-Wire Off 4-Wire

S2-3 V.52, V.54 Tests Off Normal Operation

S2-4 RTS/CTS Delay On

7 ms

S2-5 RTS/CTS Delay On

S2-6 Signaling-Rate Range On -2.5 to +1%

S2-7 Word Length Off

10 bits

S2-8 Word Length Off

Page 15

14

MULTI-FUNCTION LD CARD

S2 Position 3: V.52 and V.54 Diagnostic Testing

To reset the V.54 circuit, turn switch S2 position 3 ON, then back OFF.

S2-3 Test Mode

Off Normal Operation (default)

On Test Disabled

S2 Positions 4 and 5: RTS/CTS Delay

Set positions 4 and 5 of switch S2 to determine the amount of time the MultiFunction LD Card waits after it “sees” RTS before it sends CTS. Possible

settings are no delay, 7 ms, or 53 ms.

S2-4

S2-5 RTS/CTS Delay

On On 7 ms (default)

On Off 53 ms

Off On No delay

Off Off No delay

S2-6: Signaling-Rate Range

Set position 6 of switch S2 to determine the degree of asynchronous data-rate

fluctuation that the Multi-Function LD Card will accept (that is, how much

variance from a given frequency level the Card will tolerate).

S2-6

Signaling-Rate Range

Off -2.5% to +1% (default)

On -2.5% to +2.3%

S2-7 and S2-8: Word Length

Set positions 7 and 8 of switch S2 to determine the word length that the MultiFunction LD Card will expect for synchronous or asynchronous data. For

example, if you are using the most common data format (1 start bit,

8 data bits, 1 stop bit, and no parity), you would use the factory-default wordlength setting (10 bits).

S2-7

S2-8 Word Length

On Off 8 bits

On On 9 bits

Off Off 10 bits (default)

Off On 11 bits

Page 16

15

CHAPTER 3: Configuration

3.1.4 C

ONFIGURATION

S

WITCH

“S3”

Use the individual positions on DIP switch S3 to set antistream control,

receive (input) impedance, and point-to-point/multipoint, as well as to

enable or disable local and remote loopbacks. The factory-default settings are

summarized in Table 3-3 below.

Table 3-3. Switch S3 Summary

S3-1 and S3-2: Input Impedance

Set positions 1 and 2 of switch S3 to determine the Multi-Function LD Card’s

input impedance.

Choose the optimum impedance setting for your application. In longdistance applications, the impedance of the cable must match the impedance

of the load (or resistor) of the Multi-Function LD Card: Thicker-gauge cables

require a lower ohm setting, while thinner-gauge cables require a higher ohm

setting. Also, higher data rates call for a lower ohm setting, and lower data

rates dictate a higher ohm setting. Table 3-4 below lists our recommendations

for setting this switch.

S3-1

S3-2 Input Impedance

On On 130 ohms

On Off 200 ohms (default)

Off On 320 ohms

Off Off High (minimum 2000 ohms)

Position Function Default Setting

S2-1 Input Impedance On

200 ohms

S2-2 Input Impedance Off

S2-3 Reserved N/A

S2-4 Pt.-to-Pt./Multipoint On Point-to-Point

S2-5 DTE Local Loopback Off Disabled

S2-6 DTE Remote Loopback Off Disabled

S2-7 Antistream Control Off

Disabled

S2-8 Antistream Control Off

Page 17

16

MULTI-FUNCTION LD CARD

Table 3-4. Recommended Impedance Settings

S3-4: Mode Selection

Set position 4 of switch S3 to determine whether the Multi-Function LD Card

operates in point-to-point or multipoint mode.

S3-4 Operation

On Point-to-point (also multipoint as the “master”) (default)

Off Multipoint (as a “slave”)

S3-5: DTE RS-232 Initiation of Local Loopback Test

Set position 5 of switch S3 to determine whether or not the attached DTE can

initiate the Multi-Function LD Card’s local analog loopback test by raising the

Local Loopback (LL) signal on Pin 18 of the RS-232 interface.

S3-5

DTE Initiation of Local Loopback

On Enabled

Off Disabled (default)

S3-6: DTE RS-232 Initiation of Remote Loopback Test

Set position 6 of switch S3 to determine whether or not the Multi-Function

LD Card’s remote analog loopback test can be initiated by raising the Remote

Loopback (RL) signal on Pin 21 of the RS-232 interface.

S3-6 DTE Initiation of Remote Loopback

On Enabled

Off Disabled (default)

Cable Data Rates in kbps

Gauge 1.2 1.8 2.4 3.6 4.8 7.2 9.6 14.4 19.2 28.8 38.4 57.6

19 320 320 200 200 200 200 200 130 130 130 130 130

22 320 320 320 200 200 200 200 200 130 130 130 130

24 320 320 320 320 200 200 200 200 200 130 130 130

26 320 320 320 320 320 200 200 200 200 200 130 130

Page 18

17

CHAPTER 3: Configuration

S3-7 and S3-8: Antistream Control

Set positions 7 and 8 of switch S3 to determine the timeout period for the

Multi-Function LD Card’s antistream-control timer, or to disable the timer

entirely.

S3-7 S3-8 Setting

Off Off Disabled (default)

Off On 12.5 seconds

On Off 50 seconds

On On 12.5 seconds

3.2 Setting the Jumpers on the Interface Module

3.2.1 THEI

NTERFACE-MODULEOPTIONS

The Multi-Function LD Card has four interface-module options:

• The ME758C-RJ11 has a DB25 connector for an RS-232 serial port and an

RJ-11 modem-to-modem port.

• The ME758C-RJ45 has a DB25 connector for an RS-232 serial port and an

RJ-45 modem-to-modem port.

• The ME759C-RJ11 has a 10-pin RJ-style connector for an RS-232

compatible serial port and an RJ-11 modem-to-modem port.

• The ME759C-RJ45 has a 10-pin RJ-style connector for an RS-232

compatible serial port and an RJ-45 modem-to-modem port.

Page 19

18

MULTI-FUNCTION LD CARD

Figure 3-3, below, shows the rear panels of each of these interface modules.

Before you install the Card, you should examine the interface module you

have selected and make sure that it is configured for your application. Each

interface module has three jumpers on its circuit board, as described in the

following sections.

3.2.2 T

HECONFIGURATIONJUMPERSILLUSTRATED

Figure 3-4, below, shows the possible settings of the Multi-Function LD Card’s

jumpers. Each jumper can be either on pegs 1 and 2, as shown at left, or on

pegs 2 and 3, as shown at right.

Figure 3-4. The possible jumper settings.

123 123

Figure 3-3. The four interface modules.

ME758C-RJ11

Line: RJ-11

ME758C-RJ45

Line: RJ-45

ME759C-RJ45

Line: RJ-11

ME759C-RJ11

Line: RJ-45

Serial: DB25 Serial: DB25 Serial: 10-Pin RJ Serial: 10-Pin RJ

Page 20

19

CHAPTER 3: Configuration

3.2.3 W

HERE THE

J

UMPERSARE

Figure 3-5, below, shows the locations of the jumpers on the interface

modules (the locations are the same for both the -RJ11 and -RJ45 models).

These jumpers determine various grounding and signal characteristics for the

serial and modem-to-modem lines.

Figure 3-5. The jumper locations.

ME758C interface

module

JB2

(peg 1 on left)

JB3

(peg 1 on top)

JB4

(peg 1 on left)

JB2

(peg 1 on top)

JB3

(peg 1 on top)

JB4

(peg 1 on left)

ME759C interface

module

Page 21

20

MULTI-FUNCTION LD CARD

Table 3-5, below, provides a summary of the functions of these jumpers. The

functions are described in more detail afterward.

Table 3-5. Summary of Interface-Module Jumper Functions

Line Interface: Line Shield Connection to Frame Ground (JB2)

This jumper applies to the line interface. When this jumper is in positions 1

and 2, it links RJ-11 Pins 1 and 6 or RJ-45 Pins 2 and 7 on the corresponding

line to the interface module’s frame ground. (If you are using shielded

twisted-pair cable, the shield can be connected to these pins.) In positions 2

and 3, RJ-11 Pins 1 and 6 or RJ-45 Pins 2 and 7 remain connected to each

other, but are disconnected (“lifted”) from frame ground.

JB2

Positions 1 and 2 = Line Shield and FGND Connected

Positions 2 and 3 = Line Shield and FGND Not Connected (default)

CAUTION!

If you connect shield to frame ground, make sure that RJ-11 Pins 1 and 6

or RJ-45 Pins 2 and 7, as well as the cable shield, are connected to

ground at one end of the cable only. Connecting them at both ends of the

cable will defeat the transformer isolation and will leave your system

open to damage from ground loops.

Jumper Function Pos. 1 & 2 Pos. 2 & 3

JB2 Line Shield and FGND Connected N/C*

JB3 PGND (DTE Pin 1) and FGND Connected N/C*

JB4 SGND and FGND Connected N/C*

*factory-default settings

Page 22

21

CHAPTER 3: Configuration

Serial Interface: DTE Shield (Pin 1) Connection to Frame Ground (JB3)

This jumper applies to the serial interface. In position 1 and 2, this jumper

links the Protective Ground (PGND) or “DTE Shield” lead (DB25 Pin 1 or 10pin RJ Pins 1 and 10) of the RS-232 line to the interface module’s frame

ground (FGND). When this jumper is in positions 2 and 3, the RS-232

Protective Ground on DB25 Pin 1 or RJ-45 Pins 1 and 10 is disconnected

(“lifted”) from frame ground.

JB5

Positions 1 and 2 = PGND and FGND Connected

Positions 2 and 3 = PGND and FGND Not Connected (default)

Serial Interface: Signal Ground and Frame Ground (JB4)

This jumper also applies to the serial interface. In position 1 and 2, this

jumper links the Signal Ground (SGND) lead (DB25 Pin 7 or 10-pin RJ

Pin 5) of the RS-232 line to the interface module’s frame ground (FGND).

When this jumper is in positions 2 and 3, RS-232 Signal Ground on DB25 Pin

7 or 10-pin RJ Pin 5 is disconnected (“lifted”) from frame ground.

JB5

Positions 1 and 2 = SGND and FGND Connected

Positions 2 and 3 = SGND and FGND Not Connected (default)

Page 23

22

MULTI-FUNCTION LD CARD

4. Installation

This chapter describes the functions of the MicroRacks, tells how to install the

front and rear modules of the Multi-Function LD Cards in them, and provides

diagrams for wiring the interface connections correctly.

4.1 The MicroRacks: An Overview

Multi-Function LD Cards are designed to be installed in our MicroRacks

(product codes RM202 for the 2-card models, RM204 for the 4-card models,

RM208 for the 8-card models, and RM216 for the 16-card models). You will

install Multi-Function LD Cards in any MicroRack the same way.

As an example of these products, the MicroRack 16, shown in Figure 4-1

below, features sixteen slots for short-range modem cards, plus its own power

supply. Measuring only 3.5" (8.9 cm) high, the MicroRack 16 is designed to

occupy only 2U in a 19" rack. Sturdy front handles allow the MicroRack 16 to

be extracted and transported conveniently.

Figure 4-1. The MicroRack 16 (shown with fifteen

Multi-Function LD Cards installed).

Page 24

23

CHAPTER 4: Installation

4.2 The MicroRacks’ Power Supply

The power supply included with the MicroRacks uses the same mid-plane

architecture as the line-driver cards. Slide the front module of the power

supply into the MicroRack from the front, and slide the rear module in from

the rear. The two modules plug into one another in the middle of the rack.

Secure the front module with thumbscrews and the rear module with

conventional metal screws; these screws and thumbscrews come with the rack.

4.2.1 S

WITCHING THE

P

OWERSUPPLYON ANDOFF

The MicroRack’s power switch is located on the power supply’s front panel.

When the MicroRack is plugged in and switched on, the power supply will

light the red LED on its front panel. Since the MicroRack is a “hot-swappable”

rack, you don’t have to install any cards before switching on the power supply. Also,

the power supply may be switched off at any time without harming the

installed cards, and you can install or remove cards without turning off the

power supply. However, you should always unplug the power cord before

removing, replacing, or switching the power supply or its fuses.

4.2.2 R

EPLACING THEPOWERSUPPLY’SFUSE

The MicroRack’s power supply uses a 400-mA fuse for 120-VAC circuits, and a

200-mA fuse for 240-VAC circuits. The fuse compartment is located just below

the AC socket on the power supply’s rear module. To replace the fuse, follow

these steps:

1. Making sure the rack is turned off and unplugged, use a small screwdriver to pop the compartment open: It will slide open like a drawer.

2. Notice that there are two fuses in the compartment: The rear fuse is

“active,” and the front fuse is the “spare.”

3. If the active fuse appears to be blown, remove it from the clips and

replace it with the spare from the front of the compartment. Note the

size and rating of the blown fuse before discarding it.

4. Order a new replacement fuse. Both the 400-mA fuses (Littelfuse

®

239.400 or equivalent) and the 200-mA fuses (Littelfuse 239.200 or

equivalent) measure 5 x 20 mm.

CAUTION!

For continued protection against the risk of fire, replace blown fuses

only with fuses of the same type and rating.

Page 25

24

MULTI-FUNCTION LD CARD

4.2.3 S

WITCHING THE

P

OWERSUPPLYBETWEEN

120

AND

240 V

OLTS

Although the MicroRack is shipped from the factory with a customer-specified

power-supply configuration, you may change the configuration yourself.

Follow these steps to switch the configuration of the power supply between

120 VAC and 240 VAC:

1. Making sure the rack is turned off and unplugged, remove the power

supply’s front module and locate the two-position switch (labeled either

“110/220” or “115/230”) near the back of the card. Slide the switch to

the setting corresponding to your desired voltage.

2. Replace the existing fuses with fuses of the correct type (see step 4 of

Section 4.2.2).

3. If necessary, replace the power-supply cord with a country-specific cord.

(For certain countries, your supplier might be able to give you a special

quote on country-specific cords.) Plug the cord back in.

4.3 Installing the Multi-Function LD Card in the MicroRack

The Multi-Function LD Card is made up of a main (front) module and an

interface (rear) module. The two cards meet inside the rack chassis; their

mating 50-pin card-edge connectors plug into each other. Use these steps to

install each Multi-Function LD Card into a MicroRack:

1. Slide the rear module into the back of the MicroRack on the metal rails.

2. Secure the rear module using the included metal screws.

3. Slide the front module into the front of the chassis. It should meet the

rear module when it is almost completely in the chassis.

4. Push the front module gently into the card-edge receptacle of the rear

module. It should “click” into place.

5. Secure the front module using the thumbscrews.

NOTE

Since the MicroRacks allow “hot swapping” of cards, it is not necessary to

power down the rack when you install or remove a Multi-Function LD

Card.

Page 26

25

CHAPTER 4: Installation

4.4 The RS-232 Serial Cables and Connectors

The Multi-Function LD Card’s RS-232 port is always the lower port on its

interface module. On ME758C models it is a standard DB25 connector

(pinout shown in Table 4-1 below, top). On ME759C models it is a 10-pin

female RJ-style connector (compatible with regular male RJ-45 cable

connectors), pinned according to a modified version of the EIA/TIA-561

standard, as shown in Table 4-2 below (bottom).

Table 4-1. Pinout of the RS-232 Interface

Table 4-2. Pinout of the 10-Pin RJ Interface

Pin ITU-TSS Signal Name/Description

Number V.24

Circuit

1 N/A Not Used

2 107 DCE Ready (DCR [DSR])

3 109 Received Line Signal Detector (RLSD [CD])

4 108/2 DTE Ready (DTR)

5 102 Signal Common (SCOM [SGND])

6 104 Receive Data (RD)

7 103 Transmitted Data (TD)

8 106 Clear to Send (CTS)

9 105 or 133 Request to Send (RTS) or Ready for Receiving (RR)

10 N/A Not Used

Pins 3 through 9 correspond to Pins 2 through 8 of the EIA/TIA-561 non-synchronous interface standard.

Pin 2 corresponds to Pin 1 of the EIA/TIA TSB-25 preliminary interface standard.

DIRECTION STANDARD RS-232/V.24 DCE PINNING DIRECTION

1 Protective Ground (PGND)

From Card Transmit Clock DCE (TCC) 15

2 Transmit Data (TD) To Card

3 Receive Data (RD) From Card

From Card Receive Clock DCE (RCC) 17

4 Request to Send (RTS) To Card

To Card Local Loopback (LL) 18

5 Clear to Send (CTS) From Card

6 Data Set Ready (DSR) From Card

To Card Data Terminal Ready (DTR) 20

7 Signal Ground (SGND)

To Card Remote Loopback (RL) 21

To Card Transmit Clock DTE (TCT) 24

From Card Test Mode (TM) 25

0 0 0 0 0 0 0 0 0 1

1 2 3 4 5 6 7 8 9 0

Page 27

26

MULTI-FUNCTION LD CARD

The Multi-Function LD Card is wired as a DCE (Data Communications

Equipment) device. Therefore, it would normally be connected to a DTE

(Data Terminal Equipment) RS-232 device. You might need to run a special

cable or use a special adapter if the serial port of the RS-232 device you want

to attach is not the same type of connector as the one on your Card. Even if

the serial ports on the Card and the DTE are both RJ-45 connectors, you

might still need to use a specially pinned cable. Call your supplier for

technical support with these issues, or if you want to attach a DCE device to

the Card.

4.5 The Modem-to-Modem Line Cables and Connectors

The Multi-Function LD Card’s line port is always the upper port on its

interface module. It is a 6-pin RJ-11 connector on the -RJ11 models or an

8-pin RJ-45 connector on the -RJ45 models, pinned for a standard telco-wiring

environment, as shown in Table 4-3 and Figure 4-2 on the next page.

The Multi-Function LD Card operates half-duplex over two wires (one

twisted pair) or full- or half-duplex over four wires (two twisted pairs). In all

applications, the twisted-pair wire must be 26 AWG or thicker, unconditioned,

dry, and metallic. Both shielded and unshielded cable yield favorable results.

NOTE

The Multi-Function LD Card can only communicate in a closed data

circuit with another Multi-Function LD Card. It will not work with dialup

analog circuits, such as those used with standard modems. For further

information about acceptable wire grades, refer to the recommendations

in the Appendix.

The modem-to-modem cable connection must be specially cross-pinned, as

shown in Table 4-3 and Figure 4-2 on the next page. If your cabling includes

punchdown blocks, you can easily do the cross-pinning at a punchdown block.

If you will be running cable directly between two Multi-Function LD Cards,

you can get a custom cable from your supplier as a special quote, or you can

use regular straight-through-pinned cable and repin one of the RJ connectors

(that is, rearrange the wiring connections between the terminal block and the

actual contacts). You might need special crimping tools or new connectors;

call your supplier for these items, or for technical support if you have

difficulty.

Page 28

27

CHAPTER 4: Installation

Table 4-3. Line-Cable Pinouts

RJ-11 (Four-Wire)

SIGNAL PIN# COLOR* COLOR* PIN# SIGNAL

GND** 1 Blue..................................................White 6 GND**

RCV–† 2 Yellow ..............................................Red 4 XMT–

XMT+ 3 Green...............................................Black 5 RCV+

XMT– 4 Red ..................................................Yellow 2 RCV–

RCV+ 5 Black................................................Green 3 XMT+

GND** 6 White................................................Blue 1 GND**

RJ-45 (Four-Wire)

SIGNAL PIN# COLOR* COLOR* PIN# SIGNAL

GND** 2 Orange.............................................Brown 7 GND**

RCV–† 3 Black ................................................Green 5 XMT–

XMT+ 4 Red ..................................................Yellow 6 RCV+

XMT– 5 Green...............................................Black 3 RCV–

RCV+ 6 Yellow ..............................................Red 4 XMT+

GND** 7 Brown...............................................Orange 2 GND**

RJ-11 (Two-Wire)

SIGNAL PIN# COLOR* COLOR* PIN# SIGNAL

XMT+† 3 Green ...............................................Green 3 XMT+

XMT– 4 Red ..................................................Red 4 XMT–

RJ-45 (Two-Wire)

SIGNAL PIN# COLOR* COLOR* PIN# SIGNAL

XMT+† 4 Red ..................................................Red 4 XMT+

XMT– 5 Green...............................................Green 5 XMT–

*Standard color codes—wire colors in your cable might be different

**Connection to ground is optional

†The Multi-Function LD Card is not sensitive to polarity

1 – Blue

1 – Blue 2 – Orange

2 – Yellow 3 – Black

3 – Green 4 – Red

4 – Red 5 – Green

5 – Black 6 – Yellow

6 – White 7 – Brown

8 – Slate

Figure 4-2. AT&T®standard modular color codes.

Page 29

28

MULTI-FUNCTION LD CARD

4.6 Multipoint Applications

The Multi-Function LD Card supports multipoint applications using

equipment arranged in a star topology. Maximum distance between the units

will vary based on the number of drops, data rate, wire gauge, etc. Call your

supplier’s technical support for distance estimates more specific to your

application. Figures 4-3 and 4-4 below show how to wire two-pair and one-pair

cables respectively for a Multi-Function LD Card star network.

HOST FIRST SLAVE SECOND SLAVE

XMT RCV

RCV

XMT RCV

RCV

RCV XMT

XMT

RCV XMT

XMT

Figure 4-3. Two-pair star wiring for host and slave Cards.

HOST FIRST SLAVE SECOND SLAVE

XMT XMT

XMT

XMT XMT

XMT

Figure 4-4. Single-pair star wiring for host and slave Cards.

Page 30

29

CHAPTER 5: Operation and Diagnostics

5. Operation and Diagnostics

Once you have configured each Multi-Function LD Card and connected the

cables, you are ready to operate the units. This chapter describes the Card’s

LEDs, the power-up procedure, and diagnostic testing.

5.1 Status LEDs

The Multi-Function LD Card features 11 front-panel status LEDs (shown in

Figure 5-1 below) that indicate the condition of the modem and the

communication link.

5.1.1 THETD

AND

RD I

NDICATORS

The TD and RD indicators (one red and one green LED for each signal)

blink when data activity occurs: The red LEDs indicate a low RS-232 logic

level, while the green LEDs indicate a high RS-232 logic level. Also, since RS232 devices idle in a low state, the red LED will be steadily lit if the

connections are correct and the RS-232 device is in an idle state.

Figure 5-1. The Card’s front panel.

Model 1080RC

Power

TD

RD

RTS

CD

Test

Remote

511/E

Error

Analog

511

Page 31

30

MULTI-FUNCTION LD CARD

5.1.2 T

HE

RTS

AND

CD I

NDICATORS

The RTS and CD indicators (again, one red and one green LED for each

signal) function much like the TD and RD LEDs: The red LEDs light for a

“low” signal, while the green LEDs light for a “high” signal. The RTS LEDs

light for an incoming RTS signal on the RS-232 side (DB25 Pin 4 or 10-pin RJ

Pin 9). The CD LEDs light for an incoming signal on the line side and the

resulting output signal on the RS-232 side (DB25 Pin 8 or 10-pin RJ

Pin 3).

5.1.3 THEP

OWERINDICATOR

The green Power LED lights to indicate that the Card is receiving power.

5.1.4 T

HE

T

ESTINDICATOR

The green Test LED lights to indicate that V.52 or V.54 tests are running.

5.1.5 THEE

RRORINDICATOR

The red Error LED has three functions:

A. When the Card is in test mode (green Test LED is lit), the Error LED

glows red when bit errors occur.

B. When the Card is not in test mode (green Test LEDis dark), the Error

LED is used to indicate an RTS streaming condition (see Section 5.2.2).

C. The Error LED can also indicate line-quality problems (see

Section 5.2.1) such as:

1. The improper use of “flat satin” (non-twisted-pair) cable, or lowquality twisted-pair cable, to connect the modems.

2. One or more broken wires in the 4-wire twisted-pair cable.

4. Broken or corroded connectors.

Page 32

31

CHAPTER 5: Operation and Diagnostics

5.2 Diagnostic Testing Using the Error LED

5.2.1 T

ESTINGCABLE

Q

UALITY

NOTE

The Error LED’s circuitry is designed to detect line quality across 4-wire

twisted-pair cable only, and might not function properly with 2-wire

cable.

If there is any question as to the quality of your line, we recommend the

following test:

1. Disconnect both local and remote modems from their attached RS-232

DTE devices. Make sure the red TD, RD, and RTS LEDs are all lit.

2. Set the input impedance of both modems to 200 ohms by setting switch

S3 position 1 “On” and S3 position 2 “Off.”

3. Set the data rate on both modems to 9.6 kbps by setting switch S1

position 1 “On,” S1 position 2 “Off,” S1 position 3 “Off,” and S1 position

4 “On.”

4. On the local modem, set carrier control for “Constantly on” by setting

switch S1 position 8 “Off.”

5. On the remote modem, set carrier control to “Controlled by RTS” by

setting switch S1 position 8 to “On.”

6. Move both front-panel toggle switches to the center (neutral) position.

(The Test LED should not light.)

7. Connect both modems to the 4-wire twisted-pair cable to be tested. (See

Section 4.5 for pinouts and guidelines for this type of cable.)

8. Here’s how to interpret the results:

A. If the quality of the line is good, neither modem’s Error LED will

light. The local modem’s red CD LED will light, and the remote

modem’s green CD LED will light.

B. If there is flat satin cable in the line somewhere between the modems,

the local modem’s Error LED and green CD LED will both light. On

the remote modem, the remote modem’s green CD LED will light,

but the Error LED will stay dark.

Page 33

32

MULTI-FUNCTION LD CARD

NOTE

We cannot guarantee that the Card will accurately detect small pieces of

flat satin cable in the line if they are farther than 1500 ft. (457.2 m) from

the local modem.

C. If one wire among the four twisted-pair wires is broken, the Error

LED and the green CD LED will both light on at least one of the

modems.

5.2.2 D

ETECTINGSTREAMINGERRORS

When the Multi-Function LD Card is not in test mode (its green Test LED is

dark), the front-panel Error LED can also indicate streaming errors. When

the Card’s antistreaming circuitry is enabled (one or both of switch S3

positions 7 and 8 set to “On”), the RTS signal from the attached DTE is timercontrolled. The timer begins to count down when the DTE raises RTS. If RTS

remains high for longer than the preset timeout period, the antistream circuit

will force RTS low. The Error LED will light, indicating a streaming condition

(RTS continually on). This feature prevents a malfunctioning terminal from

tying up a computer port in a multidrop or polling environment.

When the DTE drops RTS, the antistreaming timer is automatically reset

and the Error LED goes dark. The timeout period is user-selectable for 12.5

or 50 seconds. See Section 3.1.4.

5.3 Power-Up

There is no power switch on the Multi-Function LD Card: Power is

automatically applied to the Card whenever—and for as long as—its cardedge connector is plugged into the MicroRack’s mid-plane socket and the

MicroRack’s power supply is turned on.

NOTE

The Multi-Function LD Card is a “hot-swappable” card—it will not be

damaged by plugging it in or removing it while the rack is powered up.

Page 34

33

CHAPTER 5: Operation and Diagnostics

When the local and remote Multi-Function LD Cards are both powered up and

are passing data normally, the LEDs on the Cards will look like this:

• Power: Steadily lit

• TD and RD: Flashing red and green

• RTS and CD: Green steadily lit, red dark

• Test and Error: Dark

5.4 V.54 and V.52 Diagnostic Tests

The Multi-Function LD Card offers two V.54 test modes and two V.52 test

modes to evaluate the condition of the modems and the communication link.

Both sets of tests can be activated physically from the front panel. The V.54

test can also be activated from the RS-232 interface.

NOTE

V.54 and V.52 test modes on the Multi-Function LD Card are available for

point-to-point applications only.

5.4.1 L

OCALANALOGLOOPBACK

(LAL)

The Local Analog Loopback (LAL) test checks the operation of the local

Multi-Function LD Card, and is performed separately on each unit. Any data

sent to the local Multi-Function LD Card in this test mode will be echoed

(returned) back to the user device. For example, characters typed on the

keyboard of a terminal will appear on the terminal’s screen. To perform a

LAL test, follow these steps:

1. Activate LAL. You can do this in either of two ways. One is to move the

upper front-panel toggle switch labeled “Remote—Analog” to the

“Analog” (right-hand) position. The other is to raise the signal on

Pin 18 of the RS-232 interface (switch S3 position 5 must be “On”—see

Section 3.1.4). Once LAL is activated, the Card’s transmit output is

connected to its own receiver. The Test LED should light.

2. Verify that the attached DTE is operating properly and can be used for a

test.

3. Move the lower front-panel toggle switch labeled “511/E—511” to the

“511” (right-hand) position. This will activate the V.52 BERT test mode

and inject a 511 test pattern into the local loop. If any errors are present

in the loop, the Error LED will blink sporadically.

Page 35

34

MULTI-FUNCTION LD CARD

4. If the BERT test indicates no errors are present, move the “511/E—511”

toggle switch to the left-hand position to activate the “511/E” test with

periodic errors. If this test is working properly, the Error LED will blink

regularly. A successful 511/E test will confirm that the loop is in place,

and that the Multi-Function LD Card’s built-in 511 generator and

detector are working properly.

5. If the BERT test indicates that errors are present, make sure that the RS232 cable connecting the DTE to the Multi-Function LD Card is wired

straight-through, and is plugged in properly. Also, make sure that the

Card is configured properly. Then recheck your DTE equipment. If you

still get errors and can’t find the cause, call your supplier for technical

support (see Section 6.1).

5.4.2 R

EMOTEDIGITALLOOPBACK

(RDL)

The Remote Digital Loopback (RDL) test checks the performance of both the

local and remote Multi-Function LD Cards, and the communication link

between them. Any characters sent to the remote Card in this test mode will

be echoed (returned) back to the originating device. For example, characters

typed on the keyboard of the local terminal will appear on the local terminal’s

screen after having been passed to the remote Multi-Function LD Card and

looped back. To perform an RDL test, follow these steps:

1. Activate RDL. You can do this in either of two ways. One is to move the

upper front-panel toggle switch labeled “Remote—Analog” to the

“Remote” (left-hand) position. The other is to raise the signal on

Pin 21 of the RS-232 interface (switch S3 position 6 must be “On”—see

Section 3.1.4). Once RDL is activated, the remote Card’s receive input is

connected to its own transmitter. The Test LED should light on both

Cards.

2. Verify that the DTE attached to the local Card is operating properly and

can be used for a test.

3. Move the lower front-panel toggle switch labeled “511/E—511” to the

“511” (right-hand) position. This will activate the V.52 BERT test mode

and inject a 511 test pattern into the remote loop. If any errors are

present in the loop, the Error LED will blink sporadically.

Page 36

35

CHAPTER 5: Operation and Diagnostics

4. If the BERT test indicates no errors are present, move the “511/E—511”

toggle switch to the left-hand position to activate the “511/E” test with

periodic errors. If this test is working properly, the Error LED will blink

regularly. A successful 511/E test will confirm that the loop is in place,

and that the Multi-Function LD Card’s built-in 511 generator and

detector are working properly.

5. If the remote BERT test indicates that errors are present, but the local

analog loopback BERT tests showed that both Multi-Function LD Cards

were functioning properly, there is probably a problem with the twistedpair communication line connecting the two modems. A common

problem is improper crossing of the pairs. Also, check the cable’s

pinning (see Section 4.5) and continuity. If you still get errors and can’t

find the cause, call your supplier for technical support (see Section 6.1).

5.4.3 U

SING THE

V.52 BERT T

ESTINDEPENDENTLY

The Multi-Function LD Card can perform its V.52 BERT test independently of

the V.54 loopback tests. This requires two operators: one to initiate and

monitor the test at the local Card, and one to do the same at the remote

Card. To use the V.52 BERT test by itself, both operators should

simultaneously follow these steps:

1. Move the lower front-panel toggle switch labeled “511/E—511” to the

“511” (right-hand) position. This will activate the V.52 BERT test mode

and transmit a 511 test pattern to the other unit. If any errors are

present, the receiving modem’s Error LED will blink sporadically.

NOTE

For this independent test to work properly, the “511/E—511” switch on

both Multi-Function LD Cards must be set the same way (that is, moved

to the “511” position for this step and to the “511/E” position for the next

step).

2. If the BERT test indicates no errors are present, move the “511/E—511”

toggle switch to the left-hand position to activate the “511/E” test with

periodic errors. If this test is working properly, the receiving modem’s

Error LED will blink regularly. A successful 511/E test will confirm that

the link is in place, and that the Multi-Function LD Cards’ built-in 511

generators and detectors are working properly.

Page 37

36

MULTI-FUNCTION LD CARD

6. Troubleshooting

6.1 Calling Your Supplier

If you determine that your Multi-Function LD Card is malfunctioning, do not

attempt to alter or repair it. Contact your supplier. The problem might be

solvable over the phone.

Before you do, make a record of the history of the problem. Your supplier

will be able to provide more efficient and accurate assistance if you have a

complete description, including:

• The nature and duration of the problem.

• When the problem occurs.

• The components involved in the problem.

• Any particular application that, when used, appears to create the problem

or make it worse.

6.2 Shipping and Packaging

If you need to transport or ship your Multi-Function LD Card:

• Package it carefully. We recommend that you use the original container.

• Before you ship a unit for repair or return, contact your supplier to

get a Return Authorization (RA) number, and make sure you include

everything you received with the unit when you ship it.

Page 38

37

APPENDIX: Cable Recommendations

Appendix: Cable Recommendations

The Multi-Function LD Card has been performance-tested using twisted-pair

cable with these characteristics:

Wire Gauge Capacitance Resistance

19 AWG 83 nf/mi. or 15.72 pf/ft.* 16.3 Ω/1000 ft. (53.5 Ω/km)

22 AWG 83 nf/mi. or 15.72 pf/ft.* 32.6 Ω/1000 ft. (107 Ω/km)

24 AWG 83 nf/mi. or 15.72 pf/ft.* 51.65 Ω/1000 ft. (169.5 Ω/km)

26 AWG 83 nf/mi. or 15.72 pf/ft.* 82.35 Ω/1000 ft. (270.2 Ω/km)

*Alternatively, 51.6 nf/km or 51.6 pf/m

If you use the Multi-Function LD Card with a different type of twisted-pair

cable, make sure that the cable has characteristics similar to, or better than,

those listed above (for example, lower capacitance or lower resistance).

Bench tests yield the following data-rate/maximum-distance results:

Data Rate Maximum Distance in miles (km)

in bps 19 AWG 22 AWG 24 AWG 26 AWG

57,600 12 (19.3) 7 (11.3) 5.3 (8.5) 4 (6.4)

38,400 13 (20.9) 7.5 (12.1) 6.2 (10) 4.2 (6.8)

28,800 14 (22.5) 8 (12.9) 6.6 (10.6) 4.6 (7.4)

19,200 16 (25.7) 8.5 (13.7) 7 (11.3) 5.1 (8.2)

14,400 17 (27.4) 11 (17.7) 9.2 (14.8) 6.5 (10.5)

9600 18.5 (29.8) 13 (20.9) 10.4 (16.7) 7.5 (12.1)

7200 19 (30.6) 13.5 (21.7) 10.9 (17.5) 8 (12.9)

4800 19.5 (31.4) 14 (22.5) 11.3 (18.2) 8.8 (14.2)

3600 20 (32.2) 14.5 (23.3) 11.5 (18.5) 8.8 (14.2)

2400 20.5 (33) 15 (24.1) 11.6 (18.7) 9 (14.5)

1800 20.5 (33) 15 (24.1) 11.5 (18.5) 8.9 (14.3)

1200 20 (32.2) 15 (24.1) 11.4 (18.3) 8.9 (14.3)

Many environmental factors can affect the maximum distances obtainable at a particular

site. Use this table as a general guideline only.

Page 39

38

MULTI-FUNCTION LD CARD

To gain optimum performance from the Multi-Function LD Card, please

keep these guidelines in mind:

• Always use twisted-pair cable—this is not an option.

• Use twisted-pair cable with a capacitance of 20 pf/ft. (65.6 pf/m) or less.

• Avoid twisted-pair cable thinner than 26 AWG (that is, avoid higher AWG

numbers than 26).

• Using twisted-pair cable with a resistance greater than that listed at the

top of this page might reduce the maximum distance you can run the

cable, but should not otherwise affect your system.

Page 40

1000 Park Drive • Lawrence, PA 15055-1018 • 724-746-5500 • Fax 724-746-0746

© Copyright 1995. Black Box Corporation. All rights reserved.

Loading...

Loading...