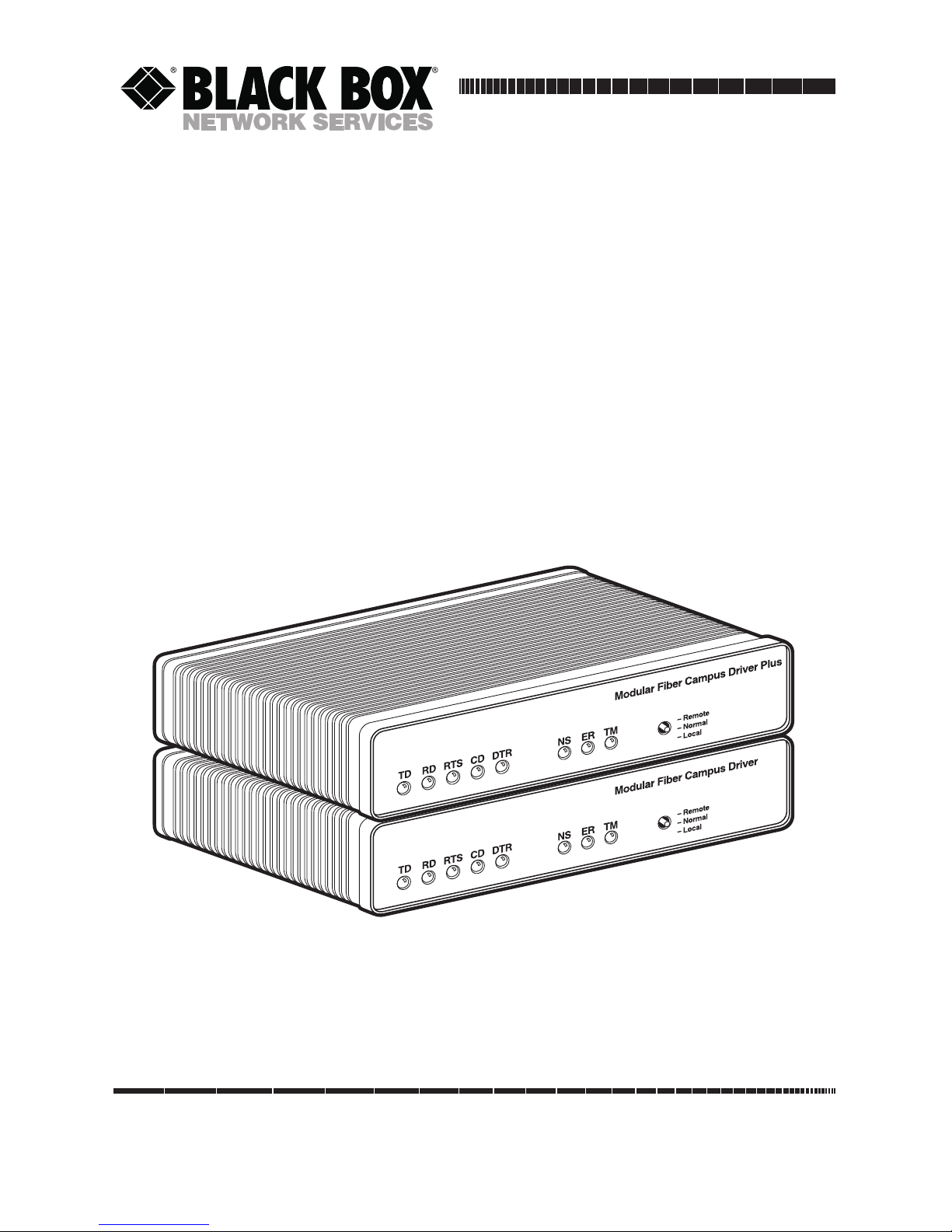

Page 1

OCTOBER 1998

ME620A

ME621A

Modular Fiber Campus Driver Plus-

256 kbps

Modular Fiber Campus Driver-128 kbps

CUSTOMER

SUPPORT

INFORMATION

Order toll-free in the U.S.: Call 877-877-BBOX (outside U.S. call 724-746-5500)

FREE technical support 24 hours a day, 7 days a week: Call 724-746-5500 or fax 724-746-0746

Mailing address: Black Box Corporation, 1000 Park Drive, Lawrence, PA 15055-1018

Web site: www.blackbox.com • E-mail: info@blackbox.com

Page 2

1

MODULAR FIBER CAMPUS DRIVER, MFCD PLUS

FEDERAL COMMUNICATIONS COMMISSION

AND

CANADIAN DEPARTMENT OF COMMUNICATIONS

RADIO FREQUENCY INTERFERENCE STATEMENTS

This equipment generates, uses, and can radiate radio frequency energy and if not

installed and used properly, that is, in strict accordance with the manufacturer’s

instructions, may cause interference to radio communication. It has been tested

and found to comply with the limits for a Class A computing device in accordance

with the specifications in Subpart B of Part 15 of FCC rules, which are designed to

provide reasonable protection against such interference when the equipment is

operated in a commercial environment. Operation of this equipment in a

residential area is likely to cause interference, in which case the user at his own

expense will be required to take whatever measures may be necessary to correct the

interference.

Changes or modifications not expressly approved by the party responsible for

compliance could void the user’s authority to operate the equipment.

This digital apparatus does not exceed the Class A limits for radio noise emission from digital

apparatus set out in the Radio Interference Regulation of the Canadian Department of

Communications.

Le présent appareil numérique n’émet pas de bruits radioélectriques dépassant les limites

applicables aux appareils numériques de la classe A prescrites dans le Règlement sur le

brouillage radioélectrique publié par le ministère des Communications du Canada.

The CE symbol on your equipment indicates that it complies with the

Electromagnetic Compatibility (EMC) directive and the Low Voltage Directive

(LVD) of the Union European (EU).

Page 3

2

MODULAR FIBER CAMPUS DRIVER, MFCD PLUS

NORMAS OFICIALES MEXICANAS (NOM)

ELECTRICAL SAFETY STATEMENT

INSTRUCCIONES DE SEGURIDAD

1. Todas las instrucciones de seguridad y operación deberán ser leídas antes de

que el aparato eléctrico sea operado.

2. Las instrucciones de seguridad y operación deberán ser guardadas para

referencia futura.

3. Todas las advertencias en el aparato eléctrico y en sus instrucciones de

operación deben ser respetadas.

4. Todas las instrucciones de operación y uso deben ser seguidas.

5. El aparato eléctrico no deberá ser usado cerca del agua—por ejemplo, cerca

de la tina de baño, lavabo, sótano mojado o cerca de una alberca, etc..

6. El aparato eléctrico debe ser usado únicamente con carritos o pedestales que

sean recomendados por el fabricante.

7. El aparato eléctrico debe ser montado a la pared o al techo sólo como sea

recomendado por el fabricante.

8. Servicio—El usuario no debe intentar dar servicio al equipo eléctrico más allá

a lo descrito en las instrucciones de operación. Todo otro servicio deberá ser

referido a personal de servicio calificado.

9. El aparato eléctrico debe ser situado de tal manera que su posición no

interfiera su uso. La colocación del aparato eléctrico sobre una cama, sofá,

alfombra o superficie similar puede bloquea la ventilación, no se debe colocar

en libreros o gabinetes que impidan el flujo de aire por los orificios de

ventilación.

10. El equipo eléctrico deber ser situado fuera del alcance de fuentes de calor

como radiadores, registros de calor, estufas u otros aparatos (incluyendo

amplificadores) que producen calor.

11. El aparato eléctrico deberá ser connectado a una fuente de poder sólo del

tipo descrito en el instructivo de operación, o como se indique en el aparato.

Page 4

3

MODULAR FIBER CAMPUS DRIVER, MFCD PLUS

12. Precaución debe ser tomada de tal manera que la tierra fisica y la polarización

del equipo no sea eliminada.

13. Los cables de la fuente de poder deben ser guiados de tal manera que no

sean pisados ni pellizcados por objetos colocados sobre o contra ellos,

poniendo particular atención a los contactos y receptáculos donde salen del

aparato.

14. El equipo eléctrico debe ser limpiado únicamente de acuerdo a las

recomendaciones del fabricante.

15. En caso de existir, una antena externa deberá ser localizada lejos de las lineas

de energia.

16. El cable de corriente deberá ser desconectado del cuando el equipo no sea

usado por un largo periodo de tiempo.

17. Cuidado debe ser tomado de tal manera que objectos liquidos no sean

derramados sobre la cubierta u orificios de ventilación.

18. Servicio por personal calificado deberá ser provisto cuando:

A: El cable de poder o el contacto ha sido dañado; u

B: Objectos han caído o líquido ha sido derramado dentro del aparato; o

C: El aparato ha sido expuesto a la lluvia; o

D: El aparato parece no operar normalmente o muestra un cambio en su

desempeño; o

E: El aparato ha sido tirado o su cubierta ha sido dañada.

Page 5

4

MODULAR FIBER CAMPUS DRIVER, MFCD PLUS

TRADEMARKS

The trademarks mentioned in this manual are the sole property of their owners.

Page 6

5

MODULAR FIBER CAMPUS DRIVER, MFCD PLUS

Contents

Chapter Page

1. Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2. Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2.1 General Product Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2.2 Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

3. Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Configuration Switch S1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

4. Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

4.1 Connection to the Fiber Interface. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

4.2 Connection to the Serial Port . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

4.2.1 Changing Modules. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

4.2.2 Connection to a “DTE” Device . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

4.2.3 Connection to a “DCE” Device . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

4.2.4 Re-configuring the X.21 Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

4.3 Power Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

5. Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

5.1 Power-On . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

5.2 LED Status Monitors. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

5.3 Diagnostics. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

5.3.1 Local Analog Loopback. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

5.3.2 Remote Analog Loopback. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Appendix: Interface Pin Assignments. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Page 7

6

MODULAR FIBER CAMPUS DRIVER, MFCD PLUS

1. Specifications

Transmission—Asynchronous and synchronous

Clocking—Internal, external or derived from receive signal

Distance—Up to 3 miles (4.8 km)

ME621A Data Rates—Asynchronous: 0 to 19.2 kbps; Synchronous: 4.8, 9.6, 14.4,

19.2, 28.8, 32.0, 56.0, 64.0, 128.0 kbps

ME620A Data Rates—Asynchronous: 2.4 to 38.4 kbps; Synchronous: 2.4, 9.6,

14.4, 28.8, 38.4, 56.0, 64.0, 72.0, 128.0, 144.0, 192.0, 256.0 kbps

Handshaking—Software (XON/XOFF) or hardware (RTS/CTS); both modes

available at all time.

Connectors—(1) Fiber ST

Link Budget—12 dB (62.5 micron), 8 dB (50.0 micron)

Diagnostics—V.54 Compliant; Local Analog Loopback and Remote Digital

Loopback bit-error-rate pattern

Fiber Modes—Single 50- or 62.5-micron core, multi-mode fiberoptic cable

LED Indicators—TD, RD, RTS, DTR, ER, NS and TM

Interface Modules—EIA RS-232/CCITT V.24, RS-232/530, CCITT V.35, X.21,

Ethernet Bridge and G.703

Power—85 to 256 VAC universal-input power supply, 50/60 Hz

Regulatory Compliance—FCC part 15 Class A, UL 1950, EN60950 89/336/EEC,

73/23/EEC IEC 825 Class 1 equipment

Temperature Range—32 to 122°F (0 to 50°C)

Altitude—Up to 15,000 feet (4572 m)

Humidity—5 to 95% non-condensing

Size—1.6"H x 7.3"W x 6.6"D (4.1 x 18.5 x 16.8 cm)

Weight—2.02 lb. (1 kg)

Page 8

7

MODULAR FIBER CAMPUS DRIVER, MFCD PLUS

2. Introduction

2.1 Description

The Modular Fiber Campus Driver (ME621A) and the Modular Fiber Campus

Driver Plus (ME620A) are designed for high-speed RS-232 communication over a

single multi-mode fiber. Operating at up to 128 kbps synchronous and 19.2 kbps

asynchronous data rates, the ME621A is perfect for campus applications where

data integrity is a must. The ME620A is even faster at a bursty 256 kbps

synchronous or 38.4 kbps async. Synchronous clocking options include internal,

external, or receive recovered clock.

Both models feature swappable DCE-DTE interface modules. Available

interfaces include V.24/RS-232 (part number ME481C-232), V.35 (part number

ME481C-35), RS-422/530 (part number ME481C-422), X.21 (part number

ME481C-X21), WAN Bridge (part number ME530A), and G.703 (part number

ME481C-G703). Fiber connections are made using an ST interface.

The Campus Drivers also incorporate V.54 compliant local and remote

loopback test modes that are activated by a convenient front panel switch. LED

status indicators monitor interface data and control signals as well as test mode

status. Available with a universal AC power supply, the Campus Drivers

conveniently fit in a wide range of applications and power supply environments.

If any questions or problems arise during installation or use of the Modular

Fiber Campus Drivers, please call Black Box Technical Support at 724-746-5500.

2.2 Features

• ME621A: Synchronous data rates: 4.8 to 128 kbps; Asynchronous data rates:

0 to 19.2 kbps

• ME620A: Synchronous data rates: 2.4 to 256 kbps; Asynchronous data rates:

0 to 38.4 kbps

• Full-duplex operation over a single multi-mode fiberoptic cable

• Point-to-point distances up to 3 miles (4.8 km)

• Internal, external or receive recovered clocking options

• Field-replaceable DTE-DCE interface modules: V.24/RS-232, V.35,

RS-422/530, X.21 and G.703 (modules ordered separately)

Page 9

8

MODULAR FIBER CAMPUS DRIVER, MFCD PLUS

• V.54-compliant local and remote digital loopback tests

• 8 front-panel LED status indicators

• Available with ST fiber connectors

• Made in the U.S.A.

Page 10

9

MODULAR FIBER CAMPUS DRIVER, MFCD PLUS

3. Configuration

Both Models ME621A and ME620A use a mini DIP-switch package that allows

configuration to a wide range of applications. These switches are located on the

bottom side of the PC board (see Figure 3-1). Because all eight switches are

externally accessible, you don’t have to open the case to configure the unit.

Figure 3-1. Underside of the Campus Driver, showing the location of the

DIP switches.

Configuration Switch “S1”

The switches shown in Figure 3-2 and on DIP switch S1 are used to set the async or

sync data rates, LAL and DL diagnostic functions, and the clock-mode setting. The

default settings for DIP switch S1 are shown in Table 3-1. Following the table are

detailed descriptions for each switch.

Figure 3-2. Close-up of configuration switches.

Page 11

10

MODULAR FIBER CAMPUS DRIVER, MFCD PLUS

Table 3-1. S1 Summary Table.

Position Function Factory Default

S1-1* Data Rate Off

S1-2* Data Rate Off

S1-3* Data Rate Off

S1-4* Data Rate On

S1-5 Clock Source On

S1-6 Clock Source On

S1-7 DTE Control of DL Off Disabled

S1-8 DTE Control of LAL Off Disabled

*NOTE

Both models ME621A and ME620A use Switches S1-S4 to set the async

or sync data rate. Refer to the sections below to set the ME621A or

ME620A rates.

S

WITCH

S1-1

THROUGH

S1-4 (M

ODEL

ME621A:): A

SYNC/SYNCDATARATE

On ME621A, Switches S1-1, S1-2, S1-3 and S1-4 set two parameters: synchronous or

asynchronous data rate and the maximum transmission distance between two

Model ME621As.

Data Max. Distance

S1-1 S1-2 S1-3 S1-4 Rate (kbps) in miles (km)

On Off Off On 0-19.2 3.0 (4.8) Async Setting

Off On On Off 4.8 3.0 (4.8)

Off On On On 9.6 3.0 (4.8)

On Off On Off 14.4 1.5 (2.4)

On Off On On 19.2 3.0 (4.8)

Off Off On Off 28.8 1.5 (2.4)

Off Off Off Off 32.0 3.0 (4.8)

Off On Off Off 56.0 1.5 (2.4)

Off Off Off On 64.0 3.0 (4.8)

On On On On 128.0 3.0 (4.8)

}

64 kbps

}

Internal

}

Sync

Setting

Page 12

11

MODULAR FIBER CAMPUS DRIVER, MFCD PLUS

S

WITCH

S1-1

THROUGH

S1-4 (M

ODEL

ME620A): A

SYNC/SYNCDATARATE

On Model ME620A, Switches S1-1, S1-2, S1-3 and S1-4 set two parameters:

synchronous or asynchronous data rate and the maximum transmission distance

between two Model ME620As.

Data Max Distance

S1-1 S1-2 S1-3 S1-4 Rate (kbps) in miles (km)

On Off Off On 0-19.2 3.0 (4.8) Async Settings

On Off Off Off 0-38.4 1.5 (2.4)

On On On Off 2.4 1.5 (2.4)

Off On On On 9.6 3.0 (4.8)

On Off On Off 14.4 1.5 (2.4)

On Off On On 19.2 3.0 (4.8)

Off Off On Off 28.8 1.5 (2.4)

Off Off On On 38.4 3.0 (4.8)

On On Off On 48.0 3.0 (4.8)

Off On Off Off 56.0 1.5 (2.4)

Off Off Off On 64.0 3.0 (4.8)

Off On On Off 72.0 1.5 (2.4)

Off Off Off Off 128.0 1.5 (4.8)

On On Off Off 144.0 1.5 (2.4)

Off On Off On 192.0 1.5 (2.4)

On On On On 256.0 1.5 (2.4)

S

WITCHES

S1-5

AND

S1-6: C

LOCKSOURCE

Switches S1-5 and S1-6 are set in combination to determine the transmit clock

source for both models.

S1-5 S1-6 Setting Description

On Off Internal Transmit clock generated internally

On On Internal Transmit clock generated internally

Off On External Transmit clock derived from terminal

interface

Off Off Received Recover Transmit clock derived from the

received line signal

}

Sync

Setting

Page 13

12

MODULAR FIBER CAMPUS DRIVER, MFCD PLUS

NOTE

Because communication between two Model ME620As is always

synchronous, you must set these switches whether your application is

async or sync. For X.21 or async applications, configure one unit for

internal clock mode and the other for receive recover clock mode.

S

WITCH

S1-7: DTE C

ONTROL OF

DL

The setting for Switch S1-7 determines whether DTE control of remote digital

loopback test is enabled or disabled. If DTE control is disabled, the DL test can

only be initiated by the front-panel switch. If DTE control is not available, set

switch S1-7 to the Off position.

S1-7 Setting Description

On Enabled Respond to DL requests from DTE

Off Disabled Ignore DL requests from the DTE

S

WITCH

S1-8: DTE C

ONTROL OF

LAL

The setting for switch S1-8 determines whether DTE control of local analog

loopback test is enabled or disabled. If DTE control is disabled, the LAL test can

only be initiated by the front-panel switch. If DTE control is not available, set

switch S1-8 to the Off position.

S1-7 Setting Description

On Enabled Respond to LAL requests from DTE

Off Disabled Ignore LAL requests from the DTE

Page 14

13

MODULAR FIBER CAMPUS DRIVER, MFCD PLUS

4. Installation

Once the ME621A or ME620A is properly configured, it is ready to connect to the

fiber interface, to the serial port, and to the power source. This section tells you

how to make these connections.

4.1 Connection to the Fiber Interface

The ME621A supports communication at distances to 3 miles (4.8 km) and data

rates to 128 kbps (sync) or 19.2 kbps (async). The ME620A also supports distances

up to 3 miles (4.8 km), but at rates up to 256 kbps (sync) or 38.4 kbps (async).

Figure 4-1 shows the position of the interface connectors on the ME621A or

ME620A back panel.

Figure 4-1. Rear panel of Campus Driver, showing interface and power

connectors.

These short range modems are designed to work in pairs. You will need one at

each end of single 50- or 62.5-micron multi-mode fiber cable. The fiber cable

connects to each ME621A or ME620A using an ST connector. Figure 4-2 below

shows a close-up of the ST connector.

Figure 4-2. Close-up of the ST connector.

Page 15

14

MODULAR FIBER CAMPUS DRIVER, MFCD PLUS

4.2 Connection to the Serial Port

The serial port interface on the Campus Driver uses interchangeable modules.

Each module has a 50-pin card-edge connector on one side and a serial port on

the other. Figure 4-3 below shows how a Module plugs into the back of the Campus

Driver.

Figure 4-3. Installing a plug-in serial interface module.

4.2.1 C

HANGINGMODULES

When you purchase a particular version of the ME621A or ME620A, it should be

shipped to you without any modules installed. The modules mentioned on page 7

are ordered separately. If you need to install one of these Modules, follow these

steps:

Removing an Existing Module

1. Turn the power switch off. Leave the power cord plugged into a grounded

outlet to keep the unit grounded.

2. Loosen the two thumbscrews on the module by turning them

counterclockwise.

3. Grasp the two thumbscrews and gently pull the module from the unit. Apply

equal force to the thumbscrews to keep the module straight during the

removal process.

Installing the New Module

1. Make sure the power switch is off. Leave the power cord plugged into a

grounded outlet to keep the unit grounded.

Page 16

15

MODULAR FIBER CAMPUS DRIVER, MFCD PLUS

2. Hold the module with the faceplate toward you and align the module with

the guide slots in the rear panel of the Campus Driver.

3. While keeping the module’s faceplate parallel with the Campus Driver rear

panel, slide the module straight in, so that the card-edge contacts line up with

the socket inside the chassis.

NOTE

The card-edge connector should meet the socket when the Module is

almost all the way into the chassis. If you encounter a lot of resistance,

remove the module and repeat steps 2 & 3.

4. With the card-edge contacts aligned with the socket, firmly seat the module by

using your thumbs to apply pressure directly to the right and left edges of the

module faceplate. Applying moderate and even pressure should be sufficient

to seat the module. You should hear it “click” into place.

5. To secure the module in place, push the thumbscrews into the chassis and

turn the screws clockwise to tighten.

4.2.2 C

ONNECTION TO A

“DTE” D

EVICE

The serial port on most interface modules (all except the X.21 module) is hardwired as DCE. Therefore these modules “want” to plug into a DTE such as a

terminal, PC, or host. When making the connection to your DTE device, use a

straight-through cable of the shortest possible length—we recommend 6 feet

(1.8 m) or less. When purchasing or constructing an interface cable, please refer

to the pin diagrams in the Appendix as a guide.

4.2.3 C

ONNECTION TO A

“DCE” D

EVICE

The serial port on most interface modules is hard-wired as a DCE (all except the

X.21 module). Therefore you must use a null-modem cable when connecting to a

modem, multiplexor, or other DCE device. This cable should be of the shortest

possible length—we recommend 6 feet (1.8 m) or less. When purchasing or

constructing a null-modem cable, use the pin diagrams in the Appendix as a guide.

NOTE

Pin-out requirements for null-modem applications vary widely between

manufacturers. If you have any questions about a specific application,

contact Black Box Technical Support at 724-746-5500.

Page 17

16

MODULAR FIBER CAMPUS DRIVER, MFCD PLUS

4.2.4 R

E

-

CONFIGURING THE

X.21 M

ODULE

The serial port on the X.21 Module is wired by default as a DCE, but may be

switched to a DTE. This is done by reversing the orientation of the DCE/DTE

strap.

To reverse DCE/DTE orientation, remove the module according to the

instructions in Section 4.2.1. The DCE/DTE strap is located on the bottom side of

the module’s PC board. The arrows on the top of the strap indicate the

configuration of the X.21 port (for example, if the DCE arrows are pointing

toward the DB15 connector, the X.21 port is wired as a DCE). Reverse the

DCE/DTE orientation by pulling the strap out of its socket, rotating it 180°, then

plugging the strap back into the socket. You will see that the DCE/DTE arrows

now point in the opposite directions, showing the new configuration of the X.21

port. Reinstall the module according to the instructions in Section 4.2.1.

4.3 Power Connection

The Fiber Campus Driver comes with a universal-interface AC power supply, which

operates in environments ranging from 85 to 256 VAC, with no re-configuration

necessary.

C

ONNECTING TO AN

AC P

OWERSOURCE

The universal AC power supply is equipped with a male IEC-320 power

connection. A domestic (US) power supply cord is supplied with the unit at no

extra charge. To connect the universal power supply, follow these steps:

1. Attach the power cord (supplied) to the shrouded male IEC-320 connector

on the rear of the Campus Driver.

2. Plug the power cord into a nearby AC power outlet.

3. Turn the rear power switch ON.

Page 18

17

MODULAR FIBER CAMPUS DRIVER, MFCD PLUS

5. Operation

Once the Campus Driver is properly configured and installed, it should operate

transparently. This section describes power-up, reading the LED status monitors,

and using the built-in loopback tests.

5.1 Power-Up

To apply power to the Campus Driver, first be sure that you have read Section 4.3,

and that the unit is connected to the appropriate power source. Then power up

the unit using the rear power switch.

5.2 LED Status Monitors

The Campus Drivers feature eight front-panel LEDs that monitor power, the DTE

signals, network connection, and test modes. Figure 5-1 shows the front-panel

location of each LED. Following Figure 5-1 is a description of each LED’s function.

Figure 5-1. ME620A front panel.

TD & RD: Glows red to indicate an idle condition of Binary “1” data on the

respective terminal interface signals. Green indicates Binary “0” data.

RTS: Glows green to indicate that the Request to Send signal from the DTE is

active.

CD: Glows red if no carrier signal is being received from the remote modem.

Green indicates that the remote modem’s carrier is being received.

DTR: Glows green to indicate that the Data Terminal Ready signal from the

terminal is active.

Page 19

18

MODULAR FIBER CAMPUS DRIVER, MFCD PLUS

ER: Glows red to indicate the likelihood of a Bit Error in the received signal.

During the 511 or 511/E test, ER will flash to indicate that the Test Pattern

Detector has detected a bit error.

TM: Glows red to indicate that the ME620A or ME621A has been placed in Test

Mode. The unit can be placed in test mode by the local or remote user.

NS: Glows red to indicate that the local Campus Driver has not yet connected with

the remote Campus Driver.

5.3 Diagnostics

The Campus Drivers are equipped with V.54 diagnostics that may be used to to

evaluate the condition of the local and remote units, as well as the twisted-pair link

between them: local loopback (LAL) and remote digital loopback (DL).

5.3.1 L

OCALANALOGLOOPBACK

The Local Analog Loopback (LAL) test checks the operation of the local Campus

Driver and is performed separately on each unit. Any data sent to the local Campus

Driver in this test mode will be echoed back (returned) to the user device. (See

Figure 5-2, below). For example, characters typed on the keyboard of a terminal

will appear on the terminal screen.

Figure 5-2. Local analog loopback.

To perform a Local Analog Loopback test, follow these steps.

1. Activate LAL either by moving the front panel toggle switch DOWN to

“Local,” or by raising the appropriate signal on the DTE interface. Once

Local Analog Loopback is activated, the Campus Driver transmit output is

connected to its own receiver. The test LED should glow.

Page 20

19

MODULAR FIBER CAMPUS DRIVER, MFCD PLUS

NOTE

Although the local Campus Driver cannot communicate with the remote

Campus Driver in this mode, the synchronized connection between the

two modems remains intact.

2. Verify that the data terminal equipment is operating properly and can be

used for a test. If a fault is indicated, call a technician or replace the unit.

3. Perform a BER (bit error rate) test on each unit using a separate BER tester.

If the BER test equipment indicates no faults but the data terminal indicates a

fault, follow the manufacturer’s checkout procedures for the data terminal.

Also, check the interface cable between the terminal and the Campus Driver.

5.3.2 R

EMOTEDIGITALLOOPBACK

The Remote Digital Loopback test checks the performance of both the local and

remote Campus Driver, and the communication link between them. Any

characters sent to the remote unit in this test mode will be returned back to the

originating device (see Figure 5-2).

Figure 5-2. Remote digital loop.

To perform an DL test, follow these steps:

1. Activate DL. This may be done in one of two ways: First, by moving the front

panel toggle switch DOWN to “Remote.” Or, second, by raising the DL signal

on the terminal interface (for pin numbers, see the Appendix).

2. Perform a BER (bit error rate) test on the system, using BER testers on both

ends.

Page 21

20

MODULAR FIBER CAMPUS DRIVER, MFCD PLUS

3. If the BER test equipment indicates a fault and the Local Analog Loopback

test was successful for both Campus Drivers, you may have a problem with the

line between the units. You should inspect the line for proper connections.

Page 22

21

MODULAR FIBER CAMPUS DRIVER, MFCD PLUS

Appendix: Interface Pin

Assignments

V.35 Interface Pin Description, M/34 Female Connector

Pin # Signal

B SGND (Signal Ground)

C RTS (Request to Send)

D CTS (Clear to Send)

E DSR (Data Set Ready)

F CD (Carrier Detect)

H DTR (Data Transfer Ready)

L LLB (Local Line Loop)

M TM (Test Mode)

N DL (Remote Digital Loop)

P TD (Transmit Data)

R RD (Receive Data)

S TD/ (Transmit Data-B)

T RD/ (Receive Data-B)

U XTC (External Transmit Clock)

V RC (Receive Timing)

W XTC/ (External Transmit Clock)

X RC/ (Receive Timing)

Y TC (Test Control-A)

AA TC/ (Test Control-B)

Page 23

22

MODULAR FIBER CAMPUS DRIVER, MFCD PLUS

RS-232, RS-530 Interface Pin Description (DB25 Female Connector)

Pin # Signal

1 FG (Frame Ground)

2 TD (Transmit Data)

3 RD (Receive Data)

4 RTS (Request to Send)

5 CTS (Clear to Send)

6 DSR (Data Set Ready)

7 SGND (Signal Ground)

8 CD (Carrier Detect)

9 RC/ (Receive Timing-B)

10 CD/ (Carrier Detect-B)

11 XTC/ (External Transmit Clock)

12 TC/ (Test Control-B)

13 CTS/ (Clear to Send)

14 TD/ (Transmit Data-B)

15 TC (Test Control-A)

16 RD (Receive Data)

17 RC (Receive Timing)

18 LLB (Local Line Loop)

19 RTS/ (Request to Send)

20 DTR (Data Transfer Rate)

21 DL (Remote Digital Loop)

22 DSR/ (Data Set Ready)

23 DTR/ (Data Transfer Rate)

24 XTC (External Transmit Clock)

25 TM (Test Mode)

Page 24

23

MODULAR FIBER CAMPUS DRIVER, MFCD PLUS

X.21 Interface Pin Description (DB15 Female Connector)

Pin # Signal

1 Frame Ground

2 T (Transmit Data-A)

3 C (Control-A)

4 R (Receive Data-A)

5 I (Indication-A)

6 S (Signal Element Timing-A)

7 BT (Byte Timing-A)

8 SGND (Signal Ground)

9 T/ (Transmit Data-B)

10 C/ (Control-B)

11 R/ (Receive Data-B)

12 I/ (Indication-B)

13 S/ (Signal Element Timing-B)

14 BT/ (Byte Timing-B)

Page 25

24

MODULAR FIBER CAMPUS DRIVER, MFCD PLUS

G.703 Interface Pin Assignment (RJ-45 8-Pin Modular)

Pin # Signal

1 RD+ (Receive Data Tip)

2 RD- (Receive Data Ring)

3 Not Used

4 TD- (Transmit Data Ring)

5 TD+ (Transmit Data Tip)

6 Not Used

7 Not Used

8 Not Used

Page 26

1000 Park Drive • Lawrence, PA 15055-1018 • 724-746-5500 • Fax 724-746-0746

© Copyright 1998. Black Box Corporation. All rights reserved.

Loading...

Loading...