Page 1

CUSTOMER

SUPPORT

INFORMATION

Order toll-free in the U.S. 24 hours, 7 A.M. Monday to midnight Friday: 877-877-BBOX

FREE technical support, 24 hours a day, 7 days a week: Call 724-746-5500 or fax 724-746-0746

Mail order: Black Box Corporation, 1000 Park Drive, Lawrence, PA 15055-1018

Web site: www.blackbox.com • E-mail: info@blackbox.com

MARCH 1998

ME375A-R2

ME375AE-R2

ME376A-R2

ME376AE-R2

Async/Sync 2-Wire Short Haul Modem

ASYNC/SYNC 2-WIRE SHORT HAUL MODEM

DIG

ANA

PWR

RTS

TD

RD

DCD

LOS

ERR

TEST

REM

PATT

RESET

Page 2

3

FCC/IC RFI STATEMENTS, SAFETY WARNING

FEDERAL COMMUNICATIONS COMMISSION

AND

CANADIAN DEPARTMENT OF COMMUNICATIONS

RADIO FREQUENCY INTERFERENCE STATEMENTS

This equipment generates, uses, and can radiate radio frequency energy and if not

installed and used properly, that is, in strict accordance with the manufacturer’s

instructions, may cause interference to radio communication. It has been tested

and found to comply with the limits for a Class A computing device in accordance

with the specifications in Subpart J of Part 15 of FCC rules, which are designed to

provide reasonable protection against such interference when the equipment is

operated in a commercial environment. Operation of this equipment in a

residential area is likely to cause interference, in which case the user at his own

expense will be required to take whatever measures may be necessary to correct the

interference.

Changes or modifications not expressly approved by the party responsible for

compliance could void the user’s authority to operate the equipment.

This digital apparatus does not exceed the Class A limits for radio noise emission from digital

apparatus set out in the Radio Interference Regulation of the Canadian Department of

Communications.

Le présent appareil numérique n’émet pas de bruits radioélectriques dépassant les limites

applicables aux appareils numériques de classe A prescrites dans le Règlement sur le brouillage

radioélectrique publié par le ministère des Communications du Canada.

SAFETY WARNING

Always observe standard safety precautions during installation, operation, and

maintenance of this product. If you attempt to remove the power-supply fuse, be

sure to disconect the power cord from the power source first, in order to avoid the

possibility of electric shock.

Page 3

4

ASYNC/SYNC 2-WIRE SHORT-HAUL MODEMS

NORMAS OFICIALES MEXICANAS (NOM)

ELECTRICAL SAFETY STATEMENT

INSTRUCCIONES DE SEGURIDAD

1. Todas las instrucciones de seguridad y operación deberán ser leídas antes de

que el aparato eléctrico sea operado.

2. Las instrucciones de seguridad y operación deberán ser guardadas para

referencia futura.

3. Todas las advertencias en el aparato eléctrico y en sus instrucciones de

operación deben ser respetadas.

4. Todas las instrucciones de operación y uso deben ser seguidas.

5. El aparato eléctrico no deberá ser usado cerca del agua—por ejemplo, cerca

de la tina de baño, lavabo, sótano mojado o cerca de una alberca, etc..

6. El aparato eléctrico debe ser usado únicamente con carritos o pedestales que

sean recomendados por el fabricante.

7. El parato eléctrico debe ser montado a la pared o al techo sólo como sea

recomendado por el fabricante.

8. Servicio—El usuario no debe intentar dar servicio al equipo eléctrico más allá

a lo descrito en las instrucciones de operación. Todo otro servicio deberá ser

referido a personal de servicio calificado.

9. El aparato eléctrico debe ser situado de tal manera que su posición no

interfiera su uso. La colocación del aparato eléctrico sobre una cama, sofá,

alfombra o superficie similar puede bloquea la ventilación, no se debe colocar

en libreros o gabinetes que impidan el flujo de aire por los orificios de

ventilación.

Page 4

5

NOM STATEMENT

10. El equipo eléctrico deber ser situado fuera del alcance de fuentes de calor

como radiadores, registros de calor, estufas u otros aparatos (incluyendo

amplificadores) que producen calor.

11. El aparato eléctrico deberá ser connectado a una fuente de poder sólo del

tipo descrito en el instructivo de operación, o como se indique en el aparato.

12. Precaución debe ser tomada de tal manera que la tierra fisica y la polarización

del equipo no sea eliminada.

13. Los cables de la fuente de poder deben ser guiados de tal manera que no

sean pisados ni pellizcados por objetos colocados sobre o contra ellos,

poniendo particular atención a los contactos y receptáculos donde salen del

aparato.

14. El equipo eléctrico debe ser limpiado únicamente de acuerdo a las

recomendaciones del fabricante.

15. En caso de existir, una antena externa deberá ser localizada lejos de las lineas

de energia.

16. El cable de corriente deberá ser desconectado del cuando el equipo no sea

usado por un largo periodo de tiempo.

17. Cuidado debe ser tomado de tal manera que objectos liquidos no sean

derramados sobre la cubierta u orificios de ventilación.

18. Servicio por personal calificado deberá ser provisto cuando:

A: El cable de poder o el contacto ha sido dañado; u

B: Objectos han caído o líquido ha sido derramado dentro del aparato; o

C: El aparato ha sido expuesto a la lluvia; o

D: El aparato parece no operar normalmente o muestra un cambio en su

desempeño; o

E: El aparato ha sido tirado o su cubierta ha sido dañada.

Page 5

6

ASYNC/SYNC 2-WIRE SHORT-HAUL MODEMS

Contents

Chapter Page

1. Specifications ............................................................................................. 7

2. Introduction ............................................................................................. 10

3. Installation ................................................................................................ 11

3.1 Placement .......................................................................................... 11

3.2 Setting the Internal Controls ........................................................... 11

3.3 Connecting the Data Cables ............................................................. 16

3.4 Connecting to AC Power .................................................................. 17

4. Operation ................................................................................................. 19

4.1 The Front-Panel Controls and Indicators ....................................... 19

4.2 Power-Up, Normal Operation, and Power-Down ........................... 22

4.3 Reconfiguration ................................................................................ 23

5. Troubleshooting ...................................................................................... 24

5.1 Diagnostic Testing ............................................................................ 24

5.2 Calling Black Box .............................................................................. 28

5.3 Shipping and Packaging ................................................................... 28

Appendix: Pinouts .......................................................................................... 29

Legal Information ........................................................................................... 33

Page 6

7

CHAPTER 1: Specifications

1. Specifications

Compliance — FCC Part 15 Subpart J Class A, DOC Class/MDC classe A

Standard — T1: ANSI T1.601.1988

Interfaces — ME375 models: 2-wire telco, EIA RS-232;

ME376 models: 2-wire telco, ITU-TSS (CCITT) V.35

Protocols — DTE side: Synchronous or asynchronous;

Line side: 2B1Q encoding

Clock Source — Internal, external (from DTE), or received (from other

unit), user-selectable

Data Format — 7 or 8 data bits; 1 or 2 stop bits; even, odd, or no parity

(user-selectable)

Operation — Line side: Full duplex with echo cancellation

Data Rate — 128, 115.2, 64, 57.6, 48, 38.4, 19.2, 9.6, 4.8, 2.4, 1.2, and

0.6 Kbps

Transmission

Level — Up to 14 dBm

Maximum

Distance — DTE side:

ME375 models: 50 ft. (15.2 m);

ME376 models: 25 ft. (7.6 m);

Line side: 3.4 mi. (5.5 km) over 26-AWG wire,

independent of data rate

Page 7

8

ASYNC/SYNC 2-WIRE SHORT-HAUL MODEMS

User Controls — (5) Front-mounted:

(4) Pushbuttons: DIG (local digital loopback), ANA

(local analog loopback), REM (remote digital

loopback), and PATT (test pattern);

(1) Recessed RESET switch;

(6) Internal:

(1) 7-position DIP switch for protocol, data format,

and signaling options;

(1) Rotary switch for data rate;

(4) Jumpers for clock source, loopback testing, and

ground connection

Diagnostics — V.54-compliant loopback tests:

Local analog loopback (switch- or signal-triggerable);

Local digital loopback (switch-triggerable);

Remote digital loopback (switch- or signal-triggerable)

Indicators — (8) Front-mounted LEDs: PWR (power), RTS, TD, RD,

DCD, LOS (loss of signal), ERR (error), and TEST

Connectors — ME375 models: (1) RJ-45 female, (1) 3-clip terminal

block, and (1) DB25 female;

ME376 models: (1) RJ-45 female, (1) 3-clip terminal

block, and (1) 34-pin M-block female

Leads/Signals

Supported — See the Appendix

Power — From internal power supply through included or

alternate 5-ft. (1.5-m) power cord:

ME375A-R2, ME376A-R2:

Input: 103.5 to 131.5 VAC, 47 to 63 Hz;

ME375AE-R2, ME376AE-R2:

Input: 207 to 253 VAC, 47 to 63 Hz;

Consumption: 5 VA

Page 8

9

CHAPTER 1: Specifications

Fuse — ME375A-R2, ME376A-R2: 0.1-A slow-blow;

ME375AE-R2, ME376AE-R2: 0.2-A slow-blow

Other Power

Protection — AC/DC overvoltage-protection circuits connected

through transformers to transmit and receive leads on

the line side, plus special gas diodes

MTBF — 75,500 hours

Maximum

Altitude — 8000 ft. (2438.4 m)

Temperature

Tolerance — 32 to 122˚ F (0 to 50˚ C)

Humidity

Tolerance — Up to 90% noncondensing

Enclosure — High-impact plastic

Size — 1.8"H x 7.6"W x 9.6"D (4.6 x 19.3 x 24.3 cm), but the

unit’s pushbuttons protrude up to 0.1" (25 mm) from

the front panel and the connectors protrude up to 0.8"

(1.9 cm) from the rear panel

Weight — Net: 3.1 lb. (1.4 kg);

Shipping: 6 lb. (2.7 kg)

Page 9

10

ASYNC/SYNC 2-WIRE SHORT-HAUL MODEMS

2. Introduction

The Async/Sync 2-Wire Short Haul Modem (A/S2W SHM) operates synchronously

or asynchronously at high speeds (600 bps to 128 Kbps) and in full duplex over

one pair of dedicated telephone lines. It has a range of 3.4 miles (5.5 km) over

26-AWG wire.

The A/S2W SHM operates in full duplex over 2 wires by using the adaptive

“echo-canceling” technique. Because it also uses 2B1Q line coding, it can achieve

the range mentioned above no matter what the data rate is.

The A/S2W SHM incorporates interface circuits for the terminal/computer, an

adaptive echo-canceler, an automatic adaptive equalizer, a modulator, and a

demodulator. It is coupled to the telephone line through an isolation transformer,

which protects against AC or DC overvoltages. The protection circuitry would

enable the unit to operate even if DC were accidentally connected to the line.

The A/S2W SHM has diagnostic capabilities: It can perform local analog

loopback and local and remote digital loopback. The operator at either end of the

line may test both modems and the line in the remote digital loopback mode.

Loopback can be controlled with either the unit’s front-panel pushbuttons or

signals passed through the DTE (PC, data-terminal) interface.

Page 10

11

CHAPTER 3: Installation

3. Installation

This chapter tells you how to configure and install the Async/Sync 2-Wire Short

Haul Modem. After you finish doing this, refer to Chapter 4 for operating

information.

3.1 Placement

The Async/Sync 2-Wire Short Haul Modem is designed to be placed on a tabletop,

shelf, or bench, and is delivered completely assembled. (No provisions are made

for bolting the A/S2W SHM to any surface.)

The A/S2W SHM should be installed within 1.5 m (5 ft) of a grounded AC

outlet and must be situated within 25 ft. (7.6 m—ME376 models) or 50 ft. (15 m—

ME375 models) of the associated data terminal.

Allow at least 36" (90 cm) of clearance in front of the unit so you can access it

during operation and maintenance. Make sure that there is at least 4" (10 cm) of

clearance behind the unit for signal lines and interface cables.

3.2 Setting the Internal Controls

Before you install any cabling and definitely before you plug in the unit, you

should set the Async/Sync 2-Wire Short Haul Modem’s internal controls to suit

your application. (If you don’t feel comfortable about doing this yourself, get an

experienced technician to do it or to help you.) To access the internal controls,

first make sure the A/S2W SHM is disconnected from AC power, then unscrew the

two screws on the unit’s rear panel and slide the bottom half of the unit out from

beneath its cover.

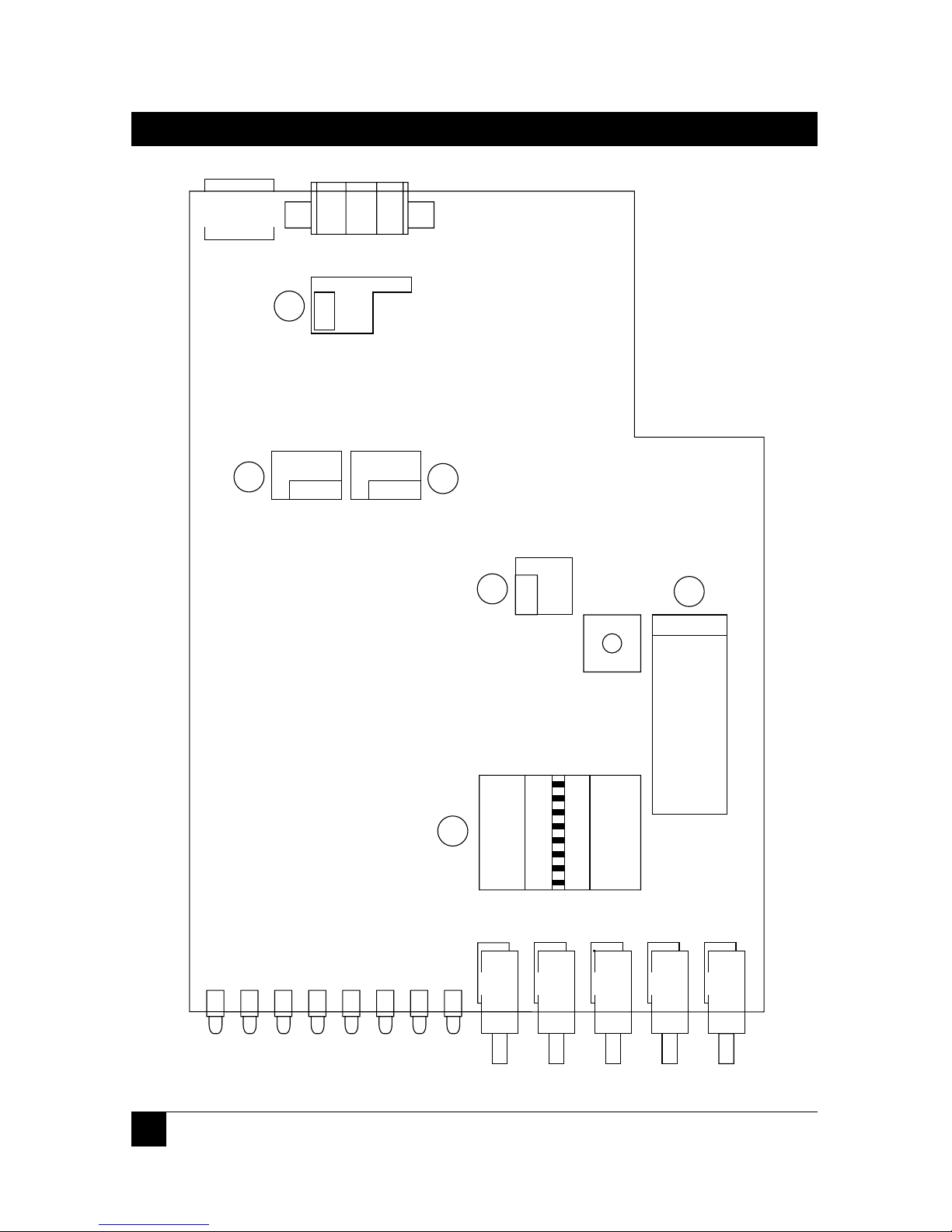

Refer to Figure 3-1 on the next page and Table 3-1 on the succeeding pages for

the locations of the controls and their possible settings respectively.

Page 11

12

ASYNC/SYNC 2-WIRE SHORT-HAUL MODEMS

DSR

DCD

1STB

EVEN

P.EN

8BIT

ASY

DTR

CNT

2STB

ODD

DIS

7BIT

SYNC

9MS

CLOCK

LBT

INT

EXT

SW

7

0 0.6K

1 1.2K

2 2.4K

3 4.8K

4 9.6K

5 19.2K

6 38.4K

7 48K

8 56K

9 64K

A 128K

POS BAUD

D

IS

EN

R

LB

DIS

EN

LLB

CHASS-GND

CON

DIS

1

2

3

4

5

6

ON

Figure 3-1. The A/S2W SHM’s internal controls and indicators.

Page 12

13

CHAPTER 3: Installation

Table 3-1. Possible Settings of Internal Controls

Callout Description Position/Label Possible FactoryNo. in Settings Default

Fig. 3-1 Setting

1 DIP Switch Position 1 Async or sync Sync

ON = ASYNC operation

OFF = SYNC

Position 2 8 or 7 data bits 8 bits

ON = 8BIT

OFF = 7BIT

Position 3 Parity enabled Disabled

ON = PRTY or disabled

OFF = DIS

Position 4 Even or odd Even

ON = EVEN parity

OFF = ODD

Position 5 1 or 2 stop bits 1 bit

ON = 1STB

OFF = 2STB

Position 6* DCD independent DCD ind.

ON = DCD or controlled by

OFF = CNT RTS

Position 7† DSR always ON or DSR ON

ON = DSR follows DTR

OFF = DTR

*If DIP Switch Position 6 is set to:

• DCD: The DCD signal is ON as long as the local unit is in proper

synchronization with the remote unit. The DCD signal is OFF when

digital loopback is active or when there is no synchronization (for

example, while the unit is receiving the remote loopback command).

• CNT: The local unit’s DCD signal follows the remote unit’s RTS signal.

†If DIP Switch Position 7 is set to:

• DSR: The DSR signal is ON as long as the local unit is receiving AC

power; it does not indicate the existence of a communication channel

or the status of the remote site.

• DTR: The local unit’s DSR signal follows the remote unit’s DTR signal.

Page 13

14

ASYNC/SYNC 2-WIRE SHORT-HAUL MODEMS

Table 3-1. Possible Settings of Internal Controls (cont’d.)

Callout Description Position/Label Possible FactoryNo. in Settings Default

Fig. 3-1 Setting

2 Data-Rate Position 0 0.6K 0.6 Kbps

Dial* Position 1 1.2K 1.2 Kbps

Position 2 2.4K 2.4 Kbps

Position 3 4.8K 4.8 Kbps

Position 4 9.6K 9.6 Kbps

Position 5 19.2K 19.2 Kbps

Position 6 38.4K 38.4 Kbps

Position 7 48K 48 Kbps

(Position 8 56K)† (56 Kbps)

Position 9 64K 64 Kbps

64 Kbps (P9)

Position A 128K 128Kbps

(Position B 144K)† (144 Kbps)

Position C 57.6K** 57.6 Kbps

Position C 115.2K** 115.2 Kbps

*Setting this dial has no effect or purpose if the unit is set to use the

external clock.

†These data-rate settings are not supported by the standard A/S2W SHM.

If you need to transfer data at one of these speeds, call Black Box

Technical Support for a special quote on a unit that will.

**These settings (popular speeds for direct computer-to-computer

communication) do not work properly unless the A/S2W SHM

communicates with the DTE asynchronously (DIP Switch Position 1 set to

ON).

Page 14

15

CHAPTER 3: Installation

Table 3-1. Possible Settings of Internal Controls (cont’d.)

Callout Description Function/Label Possible FactoryNo. in Settings Default

Fig. 3-1 Setting

3 Clock-Source For master units, select INT INT

(CLOCK) either internal timing (INT) EXT

Jumper or external timing (EXT). LBT

For slave units, always select

loopback (received) timing

(LBT).

4 Local Enable/disable control of DIS DIS

Loopback local analog loopback EN

(LLB) testing with signals from

Jumper* the DTE

5 Remote Enable/disable control of DIS DIS

Loopback remote digital loopback EN

(RLB) testing with signals from

Jumper* the DTE

6 Chassis- Tie Signal Ground to Chassis CON CON

Ground (Protective, Frame) Ground DIS

(CHASS_ or isolate the two grounds

GND) from each other

Jumper

*Only connect the RLB and LLB jumpers (that is, set them to EN [enabled])

if you want to be able to turn local analog or remote digital loopbacks on

and off from the DTE using the proper RS-232 or V.35 signals. The settings

of these jumpers have no effect on the ANA and REM pushbutton switches

on the unit’s front panel; you will be able to control loopback testing with

those buttons whether these jumpers are connected or not. (There is no

way to control local digital loopback through the local DTE interface; you

must use the DIG button to do that.)

Page 15

16

ASYNC/SYNC 2-WIRE SHORT-HAUL MODEMS

3.3 Connecting the Data Cables

To connect your data cables to the Async/Sync 2-Wire Short Haul Modem, take

these steps, referring to Figure 3-2 below:

1. Connect the twisted-pair transmission line to the two clips marked LINE (or

Pins 4 and 5 of the RJ-45 connector) and (optionally) the cable shield to the

clip marked GND (or Pin 2 of the RJ-45 connector). If you are using the

connecting the line to the clips, refer to Wire-Insertion Details on the next

page. We highly recommend that for your transmission line you use twistedpair cable capable of supporting high data rates, especially Category 3 or

better, in order to prevent crosstalk. Our product code for a type of cable that

fits the bill, bulk unterminated Category 5 UTP, is EYN717A (specify the

length you want).

2. Run the DTE-side cable from the DTE to the A/S2W SHM. If your A/S2W

SHM is an ME375 model, this cable should be straight-through-pinned and 50

or fewer feet (15.2 or fewer meters) long; it should also have a DB25 female

connector on the DTE end and a DB25 male connector on the A/S2W SHM

end. (Our product code for this type of cable is ECM25C; specify the length

you want and “male-female” genders).

If your A/S2W SHM is an ME376 model, this cable should be straightthrough-pinned and 25 or fewer feet (7.6 or fewer meters) long; it should also

have a 34-pin M-block male connector on the A/S2W SHM end. (Our

product code for this type of cable is EYN450; specify the length and genders

you want.)

Fig. 3-2. The A/S2W SHM’s rear panel.

DTE

LINE

GND

24 5

100-115 VAC/

0.2A T 250

230V/ O.1A T 250V

Page 16

17

CHAPTER 3: Installation

3.4 Connecting to AC Power

AC power is supplied to the A/S2W SHM through an included or alternate 1.5-m

(5 ft) cord terminated with a grounded plug. Make sure that, before you plug the

cord into the unit and an outlet, that proper grounding rules are observed:

• If you are using an alternate cord, it must have a ground wire that runs from

the unit’s ground (earth) terminal (the topmost of the three prongs on the

unit’s IEC 320 male power inlet) to the ground terminal on the outlet.

• Do not use an extension cord with the unit unless it also has a ground wire

that runs between ground terminals at either end.

Once you are sure of proper grounding, run the power cord from the A/S2W

SHM’s IEC320 male power inlet to a working outlet. As soon as the cord is plugged

in at both ends, the unit will begin operating, because it has no power switch. (To

turn the unit on and off, you must plug it in and unplug it.) The PWR LED should

light; see Section 4.2.

Wire Insertion Details

1) Insert screwdriver into square hole.

2) Raise inserted screwdriver,

putting pressure on the

ramp within the square hole.

The wire clamp within the

round hole will open.

3) Insert the stripped end of the wire

and remove the screwdriver.

LINE

GND

24 5

Page 17

18

ASYNC/SYNC 2-WIRE SHORT-HAUL MODEMS

While the A/S2W SHM is ON, operating personnel are not exposed to more

than 30 volts on any card or on any accessible area of the DC power supply.

Nevertheless, never open the unit or try to maintain or reconfigure it while it is

plugged in.

The AC cord is fused at the rear panel of the unit. If this fuse blows, make sure

you replace it only with a fuse rated for the required current and of the specified

type (0.2-A slow-blow for ME375A-R2 and ME376A-R2, 0.1-A slow-blow for

ME375AE-R2 and ME376AE-R2). An extra fuse should have been included with

the unit. Until you replace a blown, damaged, or missing fuse, unplug the unit and

make sure that no one attempts to use it. Avoid using repaired fuses, and never

“get by” without the fuse by short-circuiting the fuse holders!

Page 18

19

CHAPTER 4: Operation

4. Operation

This chapter lists the Async/Sync 2-Wire Short Haul Modem’s external controls

and indicators, describes their functions, and describes operating procedures.

Complete and confirm the installation procedures described in Chapter 3 before

you attempt to operate the A/S2W SHM. If you have difficulty, refer to Chapter 5.

4.1 The Front-Panel Controls and Indicators

FIgure 4-1 below shows the front panel of the Async/Sync 2-Wire Short Haul

Modem, including all of the controls and LED indicators mounted on it. These

controls and indicators are described in Tables 4-1 and 4-2 on the next two pages.

Fig. 4-1. The A/S2W SHM’s front panel.

Page 19

20

ASYNC/SYNC 2-WIRE SHORT-HAUL MODEMS

Table 4-1. Front-Panel Controls and Their Functions

Control Function

DIG Press this Local Digital Loopback button to cause the local A/S2W

SHM to loop received data and clock signals from the line back

out of its own transmitter. This is equivalent to activating remote

digital loopback (see below) on the remote unit. Press this button

again to terminate local digital loopback.

ANA* Press this Local Analog Loopback button to cause the local

A/S2W SHM to loop its transmitter output back into its own

receiver. Press this button again to terminate local analog

loopback. While the A/S2W SHM’s LLB jumper is set to EN

(enabled—see the third part of Table 3-1 on page 15), you can

also control this type of loopback by raising and lowering the LL

signal from the DTE on the appropriate pin for your interface.

REM* Press this Remote Digital Loopback button to cause the remote

A/S2W SHM to loop received data and clock signals back out of

its own transmitter. (Data Set Ready goes low when this

happens.) Press this button again to terminate remote digital

loopback. While the A/S2W SHM’s RLB jumper is set to EN

(enabled—see the third part of Table 3-1 on page 15), you can

also control this type of loopback by raising and lowering the RL

signal from the DTE on the appropriate pin for your interface.

PATT Press this Pattern button to cause the local A/S2W SHM to send

the remote unit a continuous Bit Error Rate test pattern. Press this

button again to stop sending the test pattern.

RESET Carefully press a long thin object such as a tack or the end of a

paper clip into this recessed switch to reset the A/S2W SHM. Do

this to clear abnormal conditions (the indication of an error

condition, for example) instead of unplugging the unit and plugging

it back in.

*The ANA and REM buttons are not affected by the settings of the RLB and

LLB jumpers (see the third part of Table 3-1 on page 15). Even if those

jumpers are set to DIS (disabled), you can still control loopback testing with

these buttons.

Page 20

21

CHAPTER 4: Operation

Table 4-2. Front-Panel Indicators and Their Functions

Indicator ITU-TSS Function

(CCITT)

Circuit

PWR Green LED is steadily lit while power is present.

RTS 105 Yellow LED is steadily lit while the Request to Send

(RTS) signal from the DTE is high.

TD 103 Yellow LED is steadily lit while the local A/S2W

SHM transmits steady SPACE. It flickers while the

local unit transmits data.

RD 104 Yellow LED is steadily lit while the local A/S2W

SHM receives steady SPACE. It flickers while the

local unit receives data.

DCD 109 Yellow LED is steadily lit while:

a) The local and remote A/S2W SHMs are in sync,

and the local unit’s DCD switch is set to “DCD”;

b) The local and remote A/S2W SHMs are in sync,

the local unit’s DCD switch is set to “CNT”, and the

remote unit has RTS high.

LOS Red LED is steadily lit when synchronization

between the local and remote A/S2W SHMs is lost.

ERR Red LED is steadily lit when the local A/S2W SHM’s

PATT button is in the ON position (depressed) and

the unit detects an error in the BERT pattern.

TEST Yellow LED is steadily lit while the local A/S2W

SHM’s internal BERT is active (the PATT button is

depressed) or the unit is in any of the three

loopback modes.

Page 21

22

ASYNC/SYNC 2-WIRE SHORT-HAUL MODEMS

4.2 Power-Up, Normal Operation, and Power-Down

Making sure that you follow the guidelines in Section 3.4, power up the

Async/Sync 2-Wire Short Haul Modem by plugging its AC power cord to an

working AC outlet. (The unit has no power switch. To power it down, unplug it.)

The PWR LED should light, indicating that the unit is on.

If the local and remote A/S2W SHM units are both operating and transmitting

data, the units’ front-panel indicators should look like this:

PWR Steadily lit

TD Steadily lit or flickering depending on the data being transmitted.

RD Steadily lit or flickering depending on the data being received.

RTS Steadily lit or dark depending on the status of the RTS signal from the

local DTE.

DCD If the local unit’s DCD jumper is set to DCD, steadily lit; if the local unit’s

DCD jumper is set to CNT, steadily lit or dark depending on the status

of the RTS signal from the remote unit.

LOS Flashing until the units synchronize with each other, then dark.

ERR Flashing until the units synchronize with each other, then dark.

TEST Flashing until the units synchronize with each other, then dark.

If the LEDs don’t look like this, make sure that:

• One A/S2W SHM’s CLOCK jumper is set to internal (INT) or external (EXT)

clock, and the other unit’s CLOCK jumper is set to loopback (LBT) clock.

• Both units’ four front-panel pushbuttons are in the OFF position (not

depressed).

Once a A/S2W SHM begins operating normally, it will continue to do so

indefinitely without needing to be attended, except when occasional monitoring of

LED indicators is required. If you have difficulty, perform the diagnostic tests

described in Section 5.1. If you still can’t solve the problem, call Black Box as

described in Section 5.2.

Page 22

23

CHAPTER 4: Operation

4.3 Reconfiguration

If it becomes necessary to reconfigure your A/S2W SHMs for a different type of

operation, you will have to reposition the units’ internal controls. (If you don’t feel

comfortable about doing this yourself, get an experienced technician to do it or to

help you.) Take these steps:

1. Unplug the local unit and temporarily detach the data cables from it.

3. Open the unit’s cover.

4. Referring to Figure 3-1 on page 12 and Table 3-1 on pages 13 through 15, set

the unit’s internal controls to suit the new application.

5. Close the cover.

6. Perform Steps 1 through 5 at the remote site.

7. Reattach the data cables to both units and plug both units back in.

The A/S2W SHMs should begin operating with their new parameters. If there are

problems, make sure that both units are set correctly. If they are, perform the

diagnostic tests described in Section 5.1. If you still can’t solve the problem, call

Black Box as described in Section 5.2.

Page 23

24

ASYNC/SYNC 2-WIRE SHORT-HAUL MODEMS

5. Troubleshooting

5.1 Diagnostic Testing

If you have problems with data communication on your Async/Sync 2-Wire Short

Haul Modem system, or if you just want to verify proper system operation, the

A/S2W SHM has diagnostic capabilities that can help you. You can use the A/S2W

SHM’s front-panel pushbuttons to control different kinds of tests with which you

can quickly check the A/S2W SHM, the attached cables (including the

transmission line), and the local DTE. By performing these tests, you can quickly

find out which components of your A/S2W SHM system are operating properly

and which aren’t.

Before you begin testing, make sure that both of the A/S2W SHMs and both

DTEs are powered up and configured normally. When you have verified this,

perform the tests described in Sections 5.1.1, 5.1.2, and 5.1.3, in that order.

5.1.1 L

OCALANALOGLOOPBACK

Use this test to check the performance of the local modem, the local DTE, and the

cables between them. Perform this test separately at both the local and remote sites

(refer to Figure 5-1 on the next page). Take these steps:

1. Push the local A/S2W SHM’s ANA (Local Analog Loopback) button or (if the

unit’s LLB jumper is set to EN) raise the LL signal from the DTE to the unit.

The unit should light its TEST LED as it internally connects its transmitter

output to its own receiver circuits.

2. Verify that the DTE is operating properly and can be used for a test. If the

DTE is malfunctioning, replace it or have it repaired.

3. Observe what happens to test data that you send and get back: Set the DTE to

half duplex and get an “echo” through the system and/or use special Bit

Error Rate Test (BERT) equipment.

Page 24

25

CHAPTER 5: Troubleshooting

Fig. 5-1. Local analog loopback.

4. If you use a BERT unit and it indicates an error, make sure the cables

connecting it to the A/S2W SHM are securely connected. If they are, try

swapping in known-good cables. If the error goes away, the problem was

probably in the old cables. Otherwise, the A/S2W SHM is probably faulty; call

Black Box for technical support.

If you use a BERT unit and it indicates all clear, but you get errors when

you perform the DTE test, the DTE is probably the source of the problem.

Make sure that it is physically intact and that it is configured correctly. Refer

to your DTE’s manual if necessary, and if you can’t solve the problem, call

your DTE’s supplier.

If you don’t have a BERT unit, and the DTE test indicates an error, make

sure the cables connecting the DTE to the A/S2W SHM are securely

connected. If they are, try swapping in known-good cables. If the error goes

away, the problem was probably in the old cables. Otherwise, the DTE is

probably the source of the problem. Make sure that it is physically intact and

that it is configured correctly. Refer to your DTE’s manual if necessary, and if

you can’t solve the problem, call your DTE’s supplier.

5. After completing the test (or when the fault has been corrected), return the

ANA button to the OFF position by pushing it again or, if you’re controlling

the test electronically, lower the LL signal from the DTE to the unit.

6. Repeat Steps 1 through 5 at the remote site.

Proceed with the Remote Digital Loopback test.

DATA

TERMINAL

CLK

DATA

DATA

CLK

XMTR

RCVR

LINE

Page 25

26

ASYNC/SYNC 2-WIRE SHORT-HAUL MODEMS

5.1.2 R

EMOTEDIGITALLOOPBACK

Use this test to determine how the line-side circuits of the local and remote A/S2W

SHMs and the 2-wire line between them are performing:

1. Push the local unit’s REM (Remote Digital Loopback) pushbutton or (if the

unit’s RLB jumper is set to EN) raise the RL signal from the DTE to the unit.

The TEST LED should light on both units as the local unit sends a remoteloopback command to the remote unit and the remote unit internally

connects its receiver input to its transmitter output (see Figure 5-2 below).

2. Perform a DTE test and/or BERT as described in Step 3 of the Local Analog

Loopback procedure. You can also press the local unit’s PATT button to have

it send a test pattern through the loop. (Press the PATT button again to stop

the test pattern.)

3. If Step 2 indicates a fault, but Local Analog Loopback testing was successful

for both A/S2W SHMs, either the line connection between the units is faulty,

or the 2-wire line circuits inside one or both of the units are not operating

properly. If possible, try a different line. If this is impossible, or if the problem

does not go away when you use a different line, call Black Box for technical

support.

4. After completing the test (or when the fault has been corrected), return the

REM button to the OFF position by pushing it again or, if you’re controlling

the test electronically, lower the RL signal from the DTE to the unit.

Proceed with the Local Digital Loopback test.

Fig. 5-2. Remote digital loopback.

LOCAL

DATA

TERMINAL

REMOTE

DATA

TERMINAL

RLB active

DATA

CLK

XMTR

XMTR

RCVR

RCVR

CLK

DATA

Page 26

27

CHAPTER 5: Troubleshooting

5.1.3 L

OCALDIGITALLOOPBACK

This test is essentially the same as the Remote Digital Loopback test, but

performed “in reverse,” so to speak. It allows you to make doubly sure of the line

and the A/S2W SHMs’ line-side circuitry by setting up a loop in the opposite

direction. Take these steps:

1. Push the local unit’s DIG (Local Digital Loopback) pushbutton. (There is no

way to initiate this test electronically.) The TEST LED should light on both

units as the local unit sends a local-loopback notification to the remote unit

and then internally connects its receiver input to its transmitter output (see

Figure 5-3 below).

2. The operator at the remote site can test the units and the lines and take

remedial action as described in Steps 2 and 3 of the Remote Digital Loopback

procedure.

3. When the operator at the remote site notifies you that he or she has finished,

return the DIG button to the OFF position by pushing it again.

If you have been unable to solve the problem, call Black Box for technical support

as described in the next section.

Fig. 5-3. Local digital loopback.

REMOTE

DATA

TERMINAL

LOCAL

DATA

TERMINAL

DIG active

DATA

CLK

XMTR

XMTR

RCVR

RCVR

CLK

DATA

Page 27

28

ASYNC/SYNC 2-WIRE SHORT-HAUL MODEMS

5.2 Calling Black Box

If you determine that your Async/Sync 2-Wire Short Haul Modem is

malfunctioning, do not attempt to alter or repair it. It contains no user-serviceable

parts. Contact Black Box Technical Support at 724-746-5500; the problem might be

solvable over the phone.

Before you do, make a record of the history of the problem. We will be able to

provide more efficient and accurate assistance if you have a complete description,

including:

• The nature and duration of the problem.

• When the problem occurs.

• The components involved in the problem.

• Any particular application that, when used, appears to create the problem or

make it worse.

• The results of any testing you’ve already done.

5.3 Shipping and Packaging

If you need to transport or ship your Async/Sync 2-Wire Short Haul Modem:

• Package it carefully. We recommend that you use the original container.

• Before you ship a unit for repair or return, contact Black Box to get a Return

Materials Authorization (RMA) number, and make sure you include

everything you received with the unit when you ship it.

Page 28

ITU-TSS EIA Signal Name/ ITU-TSS Signal Name/ Description

(CCITT) RS-232 Abbreviation for V.35 Abbreviation for

V.24 Pin EIA RS-232 Pin(s) ITU-TSS V.35

Circuit (ME375) (ME375) (ME376) (ME376)

101 1 Protective Ground A Frame Ground (FGND) Chassis ground. May be

(PGND) connected to or isolated

from Signal Ground by

setting the GROUND

jumper.

102 7 Signal Ground (SGND) B Signal Ground (SGND) Signal ground. May be

connected to or isolated

from Protective/Frame

Ground by setting the

GROUND jumper.

103 2 Transmit Data (TD) P Send Data A (SD A) Serial digital data received

S Send Data B (SD B) from the DTE. In

synchronous applications,

the data transitions must

occur on the rising edge of

the transmit clock.

104 3 Receive Data (RD) R Receive Data A (RD A) Serial digital data sent to

T Receive Data B (RD B) the DTE. In synchronous

applications, the data

transitions occur on the

rising edge of the clock.

105 4 Request to Send (RTS) C Request to Send (RTS) The DTE raises this signal

to the A/S2W SHM when it

wants to transmit data.

106 5 Clear to Send (CTS) D Clear to Send (CTS) The A/S2W SHM raises

this signal to the DTE

when it is ready to receive.

29

APPENDIX: Pinouts

Appendix: Pinouts

The table below and on the following pages describes the leads and signals

supported by the two models of the Async/Sync 2-Wire Short Haul Modem.

Page 29

30

ASYNC/SYNC 2-WIRE SHORT-HAUL MODEMS

ITU-TSS EIA Signal Name/ ITU-TSS Signal Name/ Description

(CCITT) RS-232 Abbreviation for V.35 Abbreviation for

V.24 Pin EIA RS-232 Pin(s) ITU-TSS V.35

Circuit (ME375) (ME375) (ME376) (ME376)

107 6 Data Set Ready (DSR) E Data Set Ready (DSR) If DIP Switch Position 7 is

set to DSR, the A/S2W

SHM holds this signal high

unless it is in digital

loopback or receives a

remote-loopback signal

from the remote unit.

If DIP Switch Position 7

is set to DTR, the A/S2W

SHM lets this signal follow

(reflect) the remote unit’s

DTR.

108.2 20 Data Terminal Ready H Data Terminal Ready The DTE raises this signal

(DTR) (DTR) when it is ready to transmit

or receive. If the remote

unit’s DIP Switch Position

7 is set to DTR, the remote

unit’s DSR will follow

(reflect) this signal.

109 8 Received Line Signal F Received Line Signal More commonly known as

Detector (RLSD) Detector (RLSD) Data Carrier Detect (DCD).

The A/S2W SHM holds

this signal high unless

RTS goes low or carrier is

lost.

113 24 Transmitter Signal U Serial Clock Transmit More commonly known as

Element Timing [DTE] Exetrnal A (SCTE A) External Clock (EXC). The

(TSETT) W Serial Clock Transmit DTE sends this data-rate

External B (SCTE B) clock signal to the A/S2W

SHM, which in turn passes

it to the remote unit. The

A/S2W SHM derives its

sync clock from this signal

only if its CLOCK jumper is

set to EXT. Positive clock

transitions correspond to

positive data transitions.

Page 30

31

APPENDIX: Pinouts

ITU-TSS EIA Signal Name/ ITU-TSS Signal Name/ Description

(CCITT) RS-232 Abbreviation for V.35 Abbreviation for

V.24 Pin EIA RS-232 Pin(s) ITU-TSS V.35

Circuit (ME375) (ME375) (ME376) (ME376)

114 15 Transmitter Signal Y Serial Clock Transmit A More commonly known as

Element Timing [DCE] (SCT A) Transmit Clock (TXC). The

(TSETC) AA Serial Clock Transmit B A/S2W SHM sends this

(SCT B) data-rate clock signal to

the DTE and the remote

unit. The A/S2W SHM

derives its sync clock from

this signal only if its

CLOCK jumper is set to

INT. Positive clock

transitions correspond to

positive data transitions.

115 17 Receiver Signal V Serial Clock Receive A More commonly known as

Element Timing [DCE] (SCR A) Receive Clock (RXC). The

(RSETC) X Serial Clock Receive B remote A/S2W SHM sends

(SCR B) this data-rate clock signal

to the lccal unit, which in

turn passes it to the DTE.

The A/S2W SHM derives

its sync clock from this

signal only if its CLOCK

jumper is set to LBT.

Positive clock transitions

correspond to positive

data transitions.

140 21 Remote Loopback (RL) HH Remote Loopback (RL) The DTE raises this signal

to the A/S2W SHM to

cause it to begin and

maintain remote digital

loopback (V.54 Loop 2).

The A/S2W SHM ignores

this signal unless its RLB

jumper is set to EN.

141 18 Local Loopback (LL) JJ Local Loopback (LL) The DTE raises this signal

to the A/S2W SHM to

cause it to begin and

maintain local analog

loopback (V.54 Loop 3).

The A/S2W SHM ignores

this signal unless its LLB

jumper is set to EN.

Page 31

32

ASYNC/SYNC 2-WIRE SHORT-HAUL MODEMS

ITU-TSS EIA Signal Name/ ITU-TSS Signal Name/ Description

(CCITT) RS-232 Abbreviation for V.35 Abbreviation for

V.24 Pin EIA RS-232 Pin(s) ITU-TSS V.35

Circuit (ME375) (ME375) (ME376) (ME376)

142 25 Test Mode (TM) KK Test Mode (TM) The A/S2W SHM raises

this signal during any test

and any time its internal

BERT is activated (the

PATT button is

depressed).

Page 32

33

LEGAL INFORMATION

DISCLAIMERS

No representation for fitness of this product for any purpose other than those

specifically mentioned in this manual is made either by the manufacturer or its

agents.

The manufacturer shall not be liable for any direct, indirect, special, incidental,

or consequential damages, whether based on contract, tort, or any legal theory.

RESERVED RIGHTS

This document contains materials protected by copyright, including information

belonging to the manufacturer. All rights are reserved. No part of this manual may

be reproduced or transmitted in any form, by any means or for any purpose,

without express written consent.

The manufacturer and its agents reserve the right to revise this publication or

make changes without obligation to notify any person of such revisions or changes.

Page 33

NOTES

Page 34

1000 Park Drive • Lawrence, PA 15055-1018 • 724-746-5500 • Fax 724-746-0746

©Copyright 1998. Black Box Corporation. All rights reserved.

Loading...

Loading...