Page 1

LMC5207A-R2 LMC5228A LMC5205A LMC5234A LMC5227A

LMC5208A-R2 LMC5203A LMC5206A LMC5235A

LMC5227A-R2 LMC5204A LMC5233A LMC5236A

High-Density Media Converter System II

Choose from a wide variety of chassis and modules to

build a powerful media-converter solution.

Customer Order toll-free in the U.S.: Call 877-877-BBOX (outside U.S. call 724-746-5500)

Support FREE technical support 24 hours a day, 7 days a week: Call 724-746-5500 or fax

Information 724-746-0746

PA 15055-1018

z Mailing address: Black Box Corporation, 1000 Park Drive, Lawrence,

z Web site: www.blackbox.com z E-mail: info@blackbox.com

Page 2

FCC and Industry Canada RF Interference Statements

Class A

This equipment generates, uses, and can radiate radio-frequency energy, and if not installed and used

properly, that is, in strict accordance with the manufacturer’s instructions, may cause interference to

radio communication. It has been tested and found to comply with the limits for a Class A computing

device in accordance with the specifications in Subpart B of Part 15 of FCC rules, which are designed to

provide reasonable protection against such interference when the equipment is operated in a

commercial environment. Operation of this equipment in a residential area is likely to cause

interference, in which case the user at his own expense will be required to take whatever measures may

be necessary to correct the interference.

Changes or modifications not expressly approved by the party responsible for compliance could void the

user’s authority to operate the equipment.

This digital apparatus does not exceed the Class A limits for radio noise emission from digital apparatus

set out in the Radio Interference Regulation of Industry Canada.

Le présent appareil numérique n’émet pas de bruits radioélectriques dépassant les limites applicables

aux appareils numériques de la classe A prescrites dans le Règlement sur le brouillage radioélectrique

publié par le Industrie Canada.

Class B

Class B Digital Device. This equipment has been tested and found to comply with the limits for a Class

B computing device pursuant to Part 15 of the FCC Rules. These limits are designed to provide

reasonable protection against harmful interference in a residential installation. However, there is no

guarantee that interference will not occur in a particular installation. This equipment generates, uses,

and can radiate radio frequency energy, and, if not installed and used in accordance with the

instructions, may cause harmful interference to radio communications. If this equipment does cause

harmful interference to radio or telephone reception, which can be determined by turning the

equipment off and on, the user is encouraged to try to correct the interference by one of the following

measures:

• Reorient or relocate the receiving antenna.

• Increase the separation between the equipment and receiver.

• Connect the equipment into an outlet on a circuit different from that to which the receiver is

connected.

• Consult an experienced radio/TV technician for help.

CAUTION

Changes or modifications not expressly approved by the party responsible for compliance could void the

user’s authority to operate the equipment.

To meet FCC requirements, shielded cables and power cords are required to connect this device to a

personal computer or other Class B certified device.

ii

Page 3

This digital apparatus does not exceed the Class B limits for radio noise emission from digital apparatus

set out in the Radio Interference Regulation of Industry Canada.

Product Description Version FCC

20-Slot Rackmount Chassis

6-Slot Rackmount/Desktop Chassis

3-Slot Desktop Chassis

Dual AC

Dual DC

ACDC

AC

Dual AC

DC

Dual DC

AC

2AC

DC

2DC

ACDC

Class A

9

9

FCC

Class B

9

9

9

9

9

9

9

9

9

9

Normas Oficiales Mexicanas (NOM) Electrical Safety Statement

Instrucciones de Seguridad

Todas las instrucciones de seguridad y operación deberán ser leídas antes de que el aparato

1.

eléctrico sea operado.

Las instrucciones de seguridad y operación deberán ser guardadas para referencia futura.

2.

Todas las advertencias en el aparato eléctrico y en sus instrucciones de operación deben ser

3.

respetadas.

4.

Todas las instrucciones de operación y uso deben ser seguidas.

El aparato eléctrico no deberá ser usado cerca del agua—por ejemplo, cerca de la tina de baño,

5.

lavabo, sótano mojado o cerca de una alberca, etc.

6.

El aparato eléctrico debe ser usado únicamente con carritos o pedestales que sean recomendados

por el fabricante.

El aparato eléctrico debe ser montado a la pared o al techo sólo como sea recomendado por el

7.

fabricante.

Servicio—El usuario no debe intentar dar servicio al equipo eléctrico más allá a lo descrito en las

8.

instrucciones de operación. Todo otro servicio deberá ser referido a personal de servicio

calificado.

El aparato eléctrico debe ser situado de tal manera que su posición no interfiera su uso. La

9.

colocación del aparato eléctrico sobre una cama, sofá, alfombra o superficie similar puede

bloquear la ventilación. No se debe colocar en libreros o gabinetes que impidan el flujo de aire

por los orificios de ventilación.

El equipo eléctrico deber ser situado fuera del alcance de fuentes de calor como radiadores,

10.

registros de calor, estufas u otros aparatos (incluyendo amplificadores) que producen calor.

iii

Page 4

11. El aparato eléctrico deberá ser conectado a una fuente de poder sólo del tipo descrito en el

instructivo de operación, o como se indique en el aparato.

Precaución debe ser tomada de tal manera que la tierra física y la polarización del equipo no sea

12.

eliminada.

13.

Los cables de la fuente de poder deben ser guiados de tal manera que no sean pisados ni

pellizcados por objetos colocados sobre o contra ellos, poniendo particular atención a los

contactos y receptáculos donde salen del aparato.

El equipo eléctrico debe ser limpiado únicamente de acuerdo a las recomendaciones del

14.

fabricante.

En caso de existir, una antena externa deberá ser localizada lejos de las líneas de energía.

15.

El cable de corriente deberá ser desconectado cuando el equipo no sea usado por un largo

16.

período de tiempo.

17.

Cuidado debe ser tomado de tal manera que objecos líquidos no sean derramados sobre la

cubierta u orificios de ventilación.

Servicio por personal calificado deberá ser provisto cuando:

18.

a.

El cable de poder o el contacto ha sido dañado; u

b.

Objectos han caído o líquido ha sido derramado dentro del aparato; o

El aparato ha sido expuesto a la lluvia; o

c.

El aparato parece no operar normalmente o muestra un cambio en su desempeño; o

d.

e.

El aparato ha sido tirado o su cubierta ha sido dañada.

iv

Page 5

Table of Contents

FCC and Industry Canada RF Interference Statements ................................. ii

Normas Oficiales Mexicanas (NOM) Electrical Safety Statement ..................iii

Part Numbers ............................................................................................. 1

20-Slot Rackmount Chassis

Back Up, Spares, Sold Separately

6-Slot Rackmount/Desktop Chassis

Back Up, Spares, Sold Separately

3-Slot Desktop Chassis

Back Up, Spares, Sold Separately

About the 20-Slot Rackmount Chassis ......................................................... 3

20-Slot Rackmount Chassis Features

Alarm Reset, Last Gasp and Temperature Gauge

Reset Alarm Button

Last Gasp Alarm

Temperature Gauge

SNMP Write Lock

SNMP Management Module LEDs

Installing the 20-Slot Rackmount Chassis

Wiring Instruction Guidelines for DC Module in 2DC and ACDC

DC Power Supply Module Wiring Instructions

Installing SNMP Management and Application Modules

Replacing Power Supply Modules

User-Replaceable Power Supply Modules

Dual AC, Part Number LMC5207A-R2

Dual DC, Part Number LMC5208A-R2

ACDC, Part Number LMC5228A.................................................................... 10

20-Slot Rackmount Chassis Specifications ................................................. 10

......................................................................................... 4

............................................................................................. 4

............................................................................................ 4

............................................................................... 1

................................................................. 1

.................................................................. 1

................................................................. 1

...................................................................................... 2

................................................................. 2

................................................................ 3

....................................... 3

...................................................................................... 4

................................................................ 4

........................................................ 5

.............. 6

.............................................. 6

................................ 7

..................................................................... 8

.................................................... 8

......................................................... 8

......................................................... 9

About the 6-Slot Rackmount/Desktop Chassis ........................................... 11

6-Slot Rackmount/Desktop Chassis Features

Alarm Reset, Last Gasp, and Temperature Gauge

Alarm Reset Button

Last Gasp Alarm

Temperature Gauge

SNMP Write Lock

SNMP Management Module LEDs

Installing the 6-Slot Rackmount/Desktop Chassis

DC Power Wiring, Replacing Power Supply and Fans ................................. 14

....................................................................................... 11

........................................................................................... 11

.................................................................................... 12

.......................................................................................... 12

.............................................................. 12

................................................. 11

........................................ 11

......................................... 13

v

Page 6

DC Power Supply Wiring Instructions.............................................................. 14

User-Replaceable Power Supplies

Fans

............................................................................................................... 14

Installing Management and Application Modules

Installing Applications Modules

6-Slot Rackmount/Desktop Chassis Specifications...................................... 16

About the 3-Slot Desktop Chassis ............................................................. 17

............................................................... 14

......................................... 15

................................................................... 15

3-Slot Desktop Chassis Features

Alarm Reset, Last Gasp, and Temperature Gauge

Alarm Reset Button

Last Gasp Alarm

Temperature Gauge

Installing the 3-Slot Desktop Chassis

DC Power Wiring, Replacing Power Supply and Fans ................................. 19

DC Power Supply Wiring Instructions

Power Supply Modules

Fans

............................................................................................................... 20

Installing Management and Application Modules

Installing Applications Modules

SNMP Write Lock

SNMP Management Module LEDs

3-Slot Desktop Chassis Specifications

Hardware Feature Matrix .......................................................................... 22

Black Box Customer Service ...................................................................... 23

........................................................................................... 17

............................................................................................... 17

.................................................................................... 18

................................................................................. 19

.......................................................................................... 21

..................................................................... 17

........................................ 17

............................................................. 18

......................................................... 19

......................................... 20

................................................................... 20

.................................................................. 21

............................................................ 22

Fiber Optic Cleaning Guidelines ............................................................... 24

Electrostatic Discharge Precautions............................................................ 24

Certifications ............................................................................................ 25

vi

Page 7

Part Numbers

20-Slot Rackmount Chassis

Part Number Description

LMC5200A

LMC5207A-R2

LMC5208A-R2

LMC5227A-R2

LMC5228A

SNMP Management Module

20-Slot, w/Dual AC Power

20-Slot, w/Dual DC Power

20-Slot, W/Fixed Single AC Power

20-Slot, w/ACDC Power

Back Up, Spares, Sold Separately

Part Number Description

LMC5210A

LMC5210A-R2

LMC5212A

LMM090

Power Supply Module for LMC5207A-R2

Power Supply Module for LMC5207A-R2

Power Supply Module for LMC5208A-R2

Serial Cable for SNMP, DB9 Male to DB9 Female

6-Slot Rackmount/Desktop Chassis

Part Number Description

LMC5200A

LMC5203A

LMC5204A

LMC5205A

LMC5206A

SNMP Management Module

6-Slot, w/AC Power

6-Slot, w/Dual AC Power

6-Slot, w/Dual DC Power

6-Slot, w/ DC Power

Back Up, Spares, Sold Separately

Part Number Description

LMC5213A

LMC5214A

DC Power Supply

AC Power Supply

1

Page 8

3-Slot Desktop Chassis

Part Number Power Supply 2

LMC5233A

LMC5234A

LMC5235A

LMC5236A

LMC5237A

Back Up, Spares, Sold Separately

Part Number Description

LMC5200A

LMC5238A

3-Slot, w/AC Power

3-Slot, w/Dual AC Power

3-Slot, w/DC Power

3-Slot, w/Dual DC Power

3-Slot, w/ ACDC Power

SNMP Management Module includes Black Box and iView²

19 inch Rackmount shelf and screws

2

Page 9

About the 20-Slot Rackmount Chassis

pply

The 20-Slot Rackmount Chassis series is a modular chassis platform designed for use with

Black Box Simple Network Management Protocol (SNMP) manageable series of modules. The

20-Slot Rackmount Chassis is a 3U high, Rackmountable chassis that features 20 slots for

installing application series modules plus an additional slot for installing an SNMP

Management Module. Some 20-Slot Rackmount Chassis models are capable of redundant

power supply modules. Power supply modules are user-replaceable and hot-swappable.

20-Slot Rackmount Chassis Features

The 20-Slot Rackmount Chassis offers models available in dual AC, dual DC and ACDC

versions. It offers features such as end-user replaceable power supply modules, temperature

monitoring, Last Gasp and an Alarm Reset Button.

Alarm Reset, Last Gasp and Temperature Gauge

The 20-Slot Rackmount Chassis series supports power supply modules, so that worn parts can

be replaced without having to send an entire unit in for repair.

User-Replaceable

Power Su

Modules

3

Page 10

Reset Alarm Button

When one power supply module malfunctions, an audible alarm sounds indicating the loss of

the power module. The alarm can be silenced by pressing the Alarm Reset Button, located

next to the power connector on the power supply module. If this occurs, remove and replace

the power supply module immediately. (LEDs on the Management Module and the power

supply module itself also indicate power supply module failures.)

Last Gasp Alarm

The 20-Slot Rackmount Chassis includes the Last Gasp trap feature, “Remote Chassis Down”,

which sends a Trap when the following occurs:

• Both power supply modules malfunction

• Both power supply modules are powered down

• When the AC line fails

Temperature Gauge

The 20-Slot Rackmount Chassis includes a temperature monitoring gauge with a heat sensor

on the backplane of the chassis. Users define a threshold for chassis temperature via SNMP.

If the chassis’ temperature rises above the specified level, the SNMP agent sends a trap

(configured in iView²) to the administrator. There is also an LED indicator on the SNMP

Management Module for chassis temperature.

SNMP Write Lock

There is an SNMP Write Lock switch located below slot #3 on the front of the 20-Slot

Rackmount Chassis. The SNMP Write Lock switch prevents a new management board from

re-configuring the application module settings (e.g., the status of

features such as LinkLoss, FiberAlert, Force mode, etc.) made via

SNMP on any previous Management Modules.

NOTE

Leave this switch in the

position should only be used when changing the SNMP management board.

NORMAL

position during day-to-day operation; the

LOCKED

The SNMP Management Module can be removed and replaced as necessary. Refer to the

SNMP Management Module manual for complete instructions about configuration and

operation. If an SNMP Management Module is installed, refer to the LED panel below for

indicators of Link, Temperature, Power supply modules and other functions.

SNMP Management Module LEDs

The SNMP Management Module features several LEDs. The LED functions are:

4

Page 11

LNK/ACT

FDX/COL

Glows green when a link is established on port.

Blinks green when data activity occurs.

Glows yellow when port is in Full-Duplex mode.

Blinks yellow when port is operating in HalfDuplex mode and collisions occur.

TEMP

PS

FAN A / FAN B

Glows yellow when temperature of unit surpasses a

user-defined level.

Glows yellow when one module malfunctions.

Glows yellow when a fan malfunctions.

Installing the 20-Slot Rackmount Chassis

Install the chassis first before installing any modules into a 20-Slot Rackmount Chassis. When

installing the chassis, be sure to observe the following precautions to prevent electrical or

mechanical damage:

Protect the chassis from exposure to sunlight and electrical or magnetic fields.

1.

2.

Ensure that the equipment rack remains stable, even with the addition of the chassis and

its associated cabling.

To install 20-Slot Rackmount chassis:

Have four #10 screws and four clip nuts available (hardware may vary depending on

1.

rack type). The rest of the hardware is supplied with the unit.

Locate a suitable location in the rack for installation and secure the clip-nuts onto the

2.

mounting rails. Use screws to attach the chassis to the rack.

Plug the chassis into a reliable, filtered power source.

3.

Elevated Operating Ambient - If installed in a closed or multi-unit rack assembly, the

4.

operating ambient temperature of the rack environment may be greater than room

ambient. Therefore, consideration should be given to installing the equipment in an

environment compatible with the maximum ambient temperature (Tma) specified by the

Black Box.

Reduced Air Flow - Installation of the equipment in a rack should be such that the

5.

amount of air flow required for safe operation of the equipment is not compromised.

Mechanical Loading - Mounting of the equipment in the rack should be such that a

6.

hazardous condition is not achieved due to uneven mechanical loading.

5

Page 12

7. Circuit Overloading - Consideration should be given to the connection of the equipment

to the supply circuit and the effect that overloading of the circuits might have on over

current protection and supply wiring.

Reliable Grounding - Reliable grounding of Rackmounted equipment should be

8.

maintained. Particular attention should be given to supply connections other than direct

connections to the branch circuit (e.g., use of power strips).

9.

All AC and DC versions are intended for use in a Restricted Access Location (RAL

).

Wiring Instruction Guidelines for DC Module in 2DC and ACDC

1. Connection of a suitable grounding conductor to the grounding terminal at each

power supply module (a minimum 14AWG copper conductor should be

suitable based on a 15A circuit breaker requirement).

2. Connection of suitable supply wiring to the plus and minus terminals at each

power supply module (a minimum 14AWG copper conductors is considered

suitable based on the 11A input maximum). The input terminal block at the

power supply module is suitable for 22-14 AWG copper wire.

3. A suitable listed circuit breaker shall be provided in the building installation as

the unit's disconnect device. The branch circuit rating (i.e. minimum 15A listed

circuit breaker, etc.).

DC Power Supply Module Wiring Instructions

The following diagram shows the wiring configuration for a -48 VDC power supply module for

the 20-Slot Rackmount Chassis 2DC and ACDC.

NOTE

The chassis is protected against incorrect wiring configurations. When wired incorrectly, the

chassis will not function, but no damage will occur.

6

Page 13

Installing SNMP Management and Application Modules

To install a module:

Remove the blank bracket (if present) covering the slot where the module will be

1.

installed. Black Box recommends installing blank brackets in unused module slots.

Slide the module into the chassis using the card guides.

2.

Secure the module to the chassis by tightening the captive screw. (Refer to the

3.

documentation shipped with the module for configuration information.)

When installing modules observe ESD precautions, refer to the Electrostatic Discharge

4.

Precautions section.

In order to manage a 20-Slot Rackmount Chassis, the SNMP Management Module needs to

be installed in the appropriate slot of the chassis.

Install the 20-Slot Rackmount Chassis SNMP Management Module into the first slot

of the chassis.

NOTE

This slot is ONLY for the Management Module; do not install Application Modules such as

media conversion and mode conversion modules in this slot.

7

Page 14

Replacing Power Supply Modules

User-Replaceable Power Supply Modules

While power supply modules are redundant, failed power supply modules should promptly

be replaced to maintain network integrity and prevent data loss.

To replace a power supply module:

Disconnect the power source from the power supply module.

1.

Remove the screws of the retainer plate (on some AC modules).

2.

3.

Move the Power Supply Release switch toward the right or unscrew captive release

screw.

Before grasping the power supply module by the silver handle, press the release screw

4.

and then slide out of the chassis (Power supply modules are hot-swappable).

5.

Install new power supply module. If module is equipped with an ON/OFF switch install

the module with the switch in the OFF position.

Dual AC, Part Number LMC5207A-R2

8

Page 15

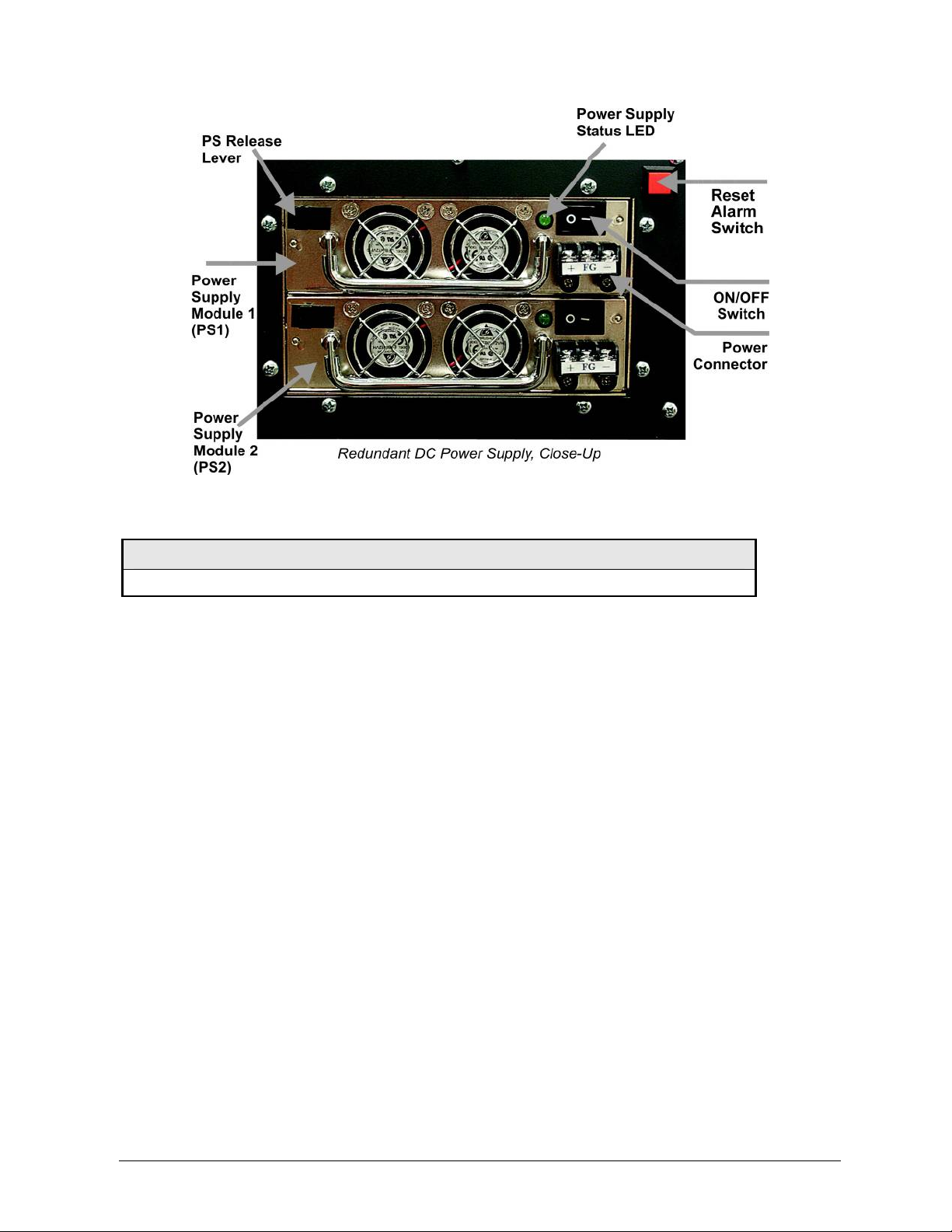

Dual DC, Part Number LMC5208A-R2

NOTE

Do not mix AC and DC power supply modules.

9

Page 16

ACDC, Part Number LMC5228A

PS

PS

Release

Release

Screw

Screw

Power

Supply

Module

1 (PS1)

Power

Supply

Module

2 (PS2)

Redundant ACDC Power Supply, Close-Up

PS1

Status

LED

Reset

Alarm

Switch

DC Power

Connector

PS2 Status

LED

AC P ower

Connector

NOTE

For LMC5228A 20-Slot Rackmount Chassis, all models in that model number series can

support Dual AC, Dual DC or ACDC. The power supply modules for that model number

series are interchangeable.

20-Slot Rackmount

Chassis Specifications

Input Specifications

Dual AC 100 to 240V AC, 50/60Hz, 3.5/1.5A

Dual DC -48V DC, 5A

ACDC 100 to 240V AC, 50/60HZ, 2A

-48V DC, 4.4A

Operating Temperature: 0° C to 50° C (32° F to 122° F)

Storage Temperature

Dual AC & ACDC -20° C to 80° C (-4° F to 176° F)

Dual DC -20° C to 60° C (-4° F to 140° F)

Humidity: 20 to 90% (non-condensing at 40° C)

Shipping Weight: 25 lbs (11.3 kg)

Dimensions: 5.2" x 19.0" x 13.8" (13.21cm x 48.26cm x 35.05cm)

10

Page 17

About the 6-Slot Rackmount/Desktop Chassis

The

6-Slot Rackmount/Desktop Chassis, is a modular chassis platform designed for use with

Black Box Simple Network Management Protocol (SNMP) manageable series of modules.

The

6-Slot Rackmount/Desktop Chassis is 1U high, Rackmountable, and supports optional

redundant power supply modules, as well as an SNMP Management Module.

6-Slot Rackmount/Desktop Chassis Features

The 6-Slot Rackmount/Desktop Chassis offers a line of models including single AC, single DC,

dual AC and Dual DC. It offers features such as redundant power supply modules,

temperature monitoring, Last Gasp and an Alarm Reset Button.

Alarm Reset, Last Gasp, and Temperature Gauge

The 6-Slot Rackmount/Desktop Chassis supports modular power supply modules, so that

worn parts can be replaced without having to send an entire unit in for repair. Keeping fans

functional ensures that the modules will operate within their temperature specifications.

Alarm Reset Button

When one power supply module malfunctions, an audible alarm sounds indicating the loss of

the power supply module. The alarm can be silenced by pressing the Alarm Reset Button,

located next to the power connector on the power supply module. If this occurs, remove and

replace the power supply module immediately. (LEDs on the Management Module and the

power supply itself also indicate power supply failures.) After stopping the alarm, remove the

power supply and replace the power supply module.

Last Gasp Alarm

The 6-Slot Rackmount/Desktop Chassis includes the Last Gasp trap feature, “Remote Chassis

Down”, which sends a Trap when the following occurs:

11

Page 18

• Both power supply modules malfunction

• Both power supply modules are powered down

• When the AC line fails

Temperature Gauge

The 6-Slot Rackmount/Desktop Chassis includes a temperature monitoring gauge with a heat

sensor on the backplane of the chassis. Users define a threshold for chassis temperature via

SNMP. If the chassis’ temperature rises above the specified level, the SNMP agent sends a

trap (configured in iView²) to the administrator. There is also an LED indicator on the SNMP

Management Module for chassis temperature.

SNMP Write Lock

There is an SNMP Write Lock switch located above the SNMP module slot on the front of the

6-Slot Rackmount/Desktop Chassis. The SNMP Write Lock switch prevents a new

management board from re-configuring the

application module settings (e.g., the status of features

such as LinkLoss, FiberAlert, Force mode, etc.) made

via SNMP on any previous Management Modules.

NOTE

Leave this switch in the

position should only be used when changing the SNMP management board.

NORMAL

position during day-to-day operation; the

LOCKED

The SNMP Management Module can be removed and replaced as necessary. Refer to the

SNMP Management Module manual for complete instructions about configuration and

operation. If an SNMP Management Module is installed, refer to the LED panel below for

indicators of Link, Temperature, Power Supply modules and other functions.

SNMP Management Module LEDs

The SNMP Management Module features several LEDs. The LED functions are:

12

Page 19

LNK/ACT

FDX/COL

Glows green when a link is established on port.

Blinks green when data activity occurs.

Glows yellow when port is in Full-Duplex mode.

Blinks yellow when port is operating in HalfDuplex mode and collisions occur.

TEMP

PS

FAN A / FAN B

Glows yellow when temperature of unit

surpasses a user-defined level.

Glows yellow when one power supply module

malfunctions.

Glows yellow when a fan malfunctions.

Installing the 6-Slot Rackmount/Desktop Chassis

Install the chassis first before installing any modules into a 6-Slot Rackmount/Desktop Chassis.

When installing the chassis, be sure to observe the following precautions to prevent electrical

or mechanical damage:

Protect the chassis from exposure to sunlight and electrical or magnetic fields.

1.

2.

Ensure that the equipment rack remains stable, even with the addition of the chassis and

its associated cabling.

To install a 6-Slot Rackmount/Desktop Chassis:

1. Have four #10 screws and four clip nuts available (hardware may vary depending on

rack type). The rest of the hardware is supplied with the unit.

2.

Locate a suitable location in the rack for installation and secure the clip-nuts onto the

mounting rails. Use screws to attach the chassis to the rack.

Plug the chassis into a reliable, filtered power source.

3.

4. Elevated Operating Ambient - If installed in a closed or multi-unit rack assembly,

the operating ambient temperature of the rack environment may be greater

than room ambient. Therefore, consideration should be given to installing the

equipment in an environment compatible with the maximum ambient

temperature (Tma) specified by the manufacturer.

5. Reduced Air Flow - Installation of the equipment in a rack should be such that

the amount of air flow required for safe operation of the equipment is not

compromised.

6. Mechanical Loading - Mounting of the equipment in the rack should be such

that a hazardous condition is not achieved due to uneven mechanical loading.

7. Circuit Overloading - Consideration should be given to the connection of the

equipment to the supply circuit and the effect that overloading of the circuits

might have on over current protection and supply wiring.

13

Page 20

8. Reliable Grounding - Reliable grounding of Rackmounted equipment should be

maintained. Particular attention should be given to supply connections other

than direct connections to the branch circuit (e.g., use of power strips).

9. All AC and DC versions are intended for use in a Restricted Access Location (RAL).

DC Power Wiring, Replacing Power Supply and Fans

DC Power Supply Wiring Instruction

s

The following diagram shows the wiring configurations for -48 VDC power supply for the 6Slot Rackmount or Desktop.

User-Replaceable Power Supplies

The 6-Slot Rackmount/Desktop Chassis ships from Black Box with one or two power supply

installed depending on the model. Chassis ordered with one power supply come with a filler

tray installed in the second slot.

To install a second power supply:

Remove the filler tray.

1.

2.

Slide the power supply module into the chassis and click into place.

Attach power cord.

3.

To remove a power supply module:

1.

Disconnect the power source from the power supply.

Move the Power Supply Release switch toward the right and hold while grasping the

2.

power supply module by the silver handle.

3.

Slide out of the chassis. (Power supply modules are hot-swappable.)

4.

Install new power supply module

.

Fans

Users can define a threshold for fan operation via SNMP (when installed in a managed

environment). If a fan’s speed falls below the specified level, SNMP sends a trap (configured

14

Page 21

in iView²) to the administrator. There are also two LED indicators on the SNMP Management

Module for fan failure.

The red Alarm Reset Button also functions as a Fan Test button. To verify fan functionality,

hold the button down for several seconds, the fans should engage. The fans will turn off

when the button is released.

SNMP Management Modules include two twisted pair ports, one for management and one

reserved for future use. The Management Module also features a DB-9 serial port, and

supports SNMP V1/V2c.

Installing Management and Application Modules

Installing Applications Modules

To install a module:

Remove the blank bracket (if present) covering the slot where the module will be

1.

installed. Black Box recommends installing blank brackets in unused module slots.

2.

Slide the module into the chassis using the card guides.

Secure the module to the chassis by tightening the captive screw. (Refer to the

3.

documentation shipped with the module for configuration information.)

4.

When installing modules observe ESD precautions, refer to the Electrostatic Discharge

Precautions section.

In order to manage a 6-Slot Rackmount/Desktop Chassis, the SNMP Management Module

needs to be installed in the appropriate slot of the chassis.

• Install the 6-Slot Rackmount/Desktop Chassis into the first slot on the far left of the

chassis.

NOTE

This slot is ONLY for the Management Module; do not install Application Modules such as

media conversion and mode conversion modules into this slot.

15

Page 22

6-Slot Rackmount/Desktop Chassis Specifications

Input Specifications

Dual AC Input 90/264VAC 47-63Hz

1.8A @ 100V

0.8A @ 240V

Dual DC Input 35-75VDC, 3.3A

Operating Temperature

AC -25° C to 50° C (-130° F - 122° F)

DC -40° C to 100° C (-40° F - 212° F)

Storage Temperature

AC -40° C to 85° C (-40° F - 185° F)

DC -55° C to 125° C (-67° F - 257° F)

Humidity: 5 - 95% (non-condensing); 0-10,000 ft. altitude

Shipping Weight: 13 lbs (5.90 kg)

Dimensions: 1.75” x 17.35” x 10.65” (4.45cm x 44.07cm x 27.05cm)

16

Page 23

About the 3-Slot Desktop Chassis

The 3-Slot Desktop Chassis series

Simple Network Management Protocol (SNMP) manageable series of modules. The

Desktop Chassis

is a 1U high, a Rackmountable, capable of offering redundant power supply

is a modular chassis platform designed for use with Black Box

3-Slot

modules, and supports a SNMP Management Module.

3-Slot Desktop Chassis Features

The 3-Slot Desktop Chassis series offers a line of models including single AC, single DC, dual

AC, dual DC and ACDC version. All contain internal fixed power supply modules that are not

end-user replaceable. It offers features such as redundant power supply modules,

temperature monitoring, Last Gasp and an Alarm Reset Button.

Alarm Reset, Last Gasp, and Temperature Gauge

The 3-Slot Desktop Chassis ships with one or two AC or DC power supply modules,

depending on the model. Fans are included in all models.

Alarm Reset Button

When one power supply module malfunctions, an audible alarm sounds indicating the loss of

the power supply. The alarm can be silenced by pressing the Alarm Reset Button, located

next to the power connector on the power supply module. If this occurs the unit needs to be

returned to Black Box for repair.

Last Gasp Alarm

The 3-Slot Desktop Chassis includes the Last Gasp trap feature, “Remote Chassis Down”, which

sends a Trap when the following occurs:

• Both power supply modules malfunction

Both power supply modules are powered down

•

• When the AC line fails

17

Page 24

Temperature Gauge

The 3-Slot Desktop Chassis includes a temperature monitoring gauge with a heat sensor on

the backplane of the chassis. Users define a threshold for chassis temperature via SNMP. If

the chassis’ temperature rises above the specified level, the SNMP agent sends a trap

(configured in iView²) to the administrator. There is also an LED indicator on the SNMP

Management Module for chassis temperature.

Installing the 3-Slot Desktop Chassis

Install the chassis first before installing any modules into a 3-Slot Desktop Chassis.

When installing the chassis, be sure to observe the following precautions to prevent electrical

or mechanical damage:

Stay within the chassis’ power rating to prevent overload of supply circuits or damage to

1.

any overcurrent protection and supply wiring.

2.

Maintain reliable ground, especially when connecting to a power strip instead of directly

to a branch circuit.

3.

Protect the chassis from exposure to sunlight and electrical or magnetic fields.

4.

Ensure that the equipment rack remains stable, even with the addition of the chassis and

its associated cabling.

Use the 3-Slot Desktop Chassis. as a table-top chassis, mount in a Rackmount shelf or mount

it to a wall surface.

Install the 3-Slot Desktop Chassis by placing it on a flat surface.

1.

Make sure to leave adequate space on the sides of the unit to accommodate cooling.

2.

If mounting on a Rackmount shelf, align holes of the chassis to the shelf and secure with

3.

screws.

The Rackmount shelf is sold separately. To purchase the Rackmount shelf (part number

(LMC5238); visit the Black Box Product Accessories page:

http://www.blackbox.com/Store/Results.aspx/search-LMC5238%5e%5e%5e/p-0

Rackmounting requires a Rackmount shelf for mounting up to two units side by side.

Attach the cables between the chassis and the device that will be interconnected, and

4.

then plug the unit into a reliable, filtered power source.

If mounting the chassis on a wall, place two #10 panhead screws (not supplied) on the

5.

wall according to the distance of the holes on the chassis, and then hang the unit on the

screws.

All versions are intended for use in a Restricted Access Location (RAL).

6.

18

Page 25

7. A readily accessible disconnect device shall be incorporated in the building installation

wiring.

A suitable listed circuit breaker shall be provided in the building installation as the unit’s

8.

disconnect device. The branch circuit rating (i.e. minimum 15A listed circuit breaker,

etc.).

DC Power Wiring, Replacing Power Supply and Fans

DC Power Supply Wiring Instructions

The following image shows the wiring configuration for a 48 VDC power supply in a negative

ground system application. For positive ground system applications remove the chassis

ground shorting jumper and connect it between the positive terminal and the chassis ground

terminal. Alternatively, the chassis grounding jumper can be eliminated and the chassis

ground connected at the power source. The ground terminal and the negative terminal are

not connected inside the iMediaChassis/3.

DC Power Supply

Negative ground system configuration (default position)

NOTE

Incorrect wiring will result in chassis malfunction.

The 3-Slot Desktop Chassis is compliant with Isolated Grounding Plane practices. The

POSITIVE and NEGATIVE terminals are isolated from chassis ground and must have a ground

reference at the power-sourcing equipment.

Power Supply Modules

Power supply in all models of the 3-Slot Desktop Chassis are fixed, and not end-user

replaceable.

19

Page 26

Fans

The

3-Slot Desktop Chassis

chassis reaches 40° C, the two fans activate to cool the chassis. The fans’ operation can be tested

by holding the Alarm Reset Button down for 4 to 5 seconds. The fans will activate and then they

will turn off when the button is released. If the fans do not activate, contact Black Box. Fans are

not end-user replaceable.

The red Alarm Reset Button also functions as a Fan Test button. To verify fan functionality, hold

the button down for several seconds, the fans should engage. The fans will turn off when the

button is released.

includes temperature-triggered fans. When the temperature of the

Installing Management and Application Modules

SNMP Management Modules include two twisted pair ports, one for management and one

reserved for future use. The Management Module also features a DB-9 serial port, and

supports SNMP V1/V2c.

Installing Applications Modules

To install a module:

Remove the blank bracket (if present) covering the slot where the module will be

1.

installed. Black Box recommends installing blank brackets in unused module slots.

2.

Slide the module into the chassis using the card guides.

Secure the module to the chassis by tightening the captive screw. (Refer to the

3.

documentation shipped with the module for configuration information.)

In order to manage a Desktop Chassis, the SNMP Management Module needs to be installed

in the appropriate slot of the chassis.

• Install the 3-Slot Desktop Chassis slot SNMP Management Module into the bottom

left slot.

NOTE

This slot is ONLY for the Management Module; do not install Application Modules such as

media conversion and mode conversion modules in this slot.

20

Page 27

SNMP Write Lock

The SNMP Write Lock switch is located on the back of the 3-Slot Desktop Chassis. The

SNMP Write Lock switch prevents a new management board from re-configuring the

application module settings (e.g., the status of features

such as LinkLoss, FiberAlert, Force mode, etc.) made via SNMP

on any previous Management Modules.

NOTE

Leave this switch in the

position should only be used when changing the SNMP management board.

NORMAL

position during day-to-day operation; the

LOCKED

The SNMP Management Module can be removed and replaced as necessary. Refer to the

SNMP Management Module manual for complete instructions about how to configure and

operate. If an SNMP Management Module is installed, refer to the LED panel below for

indicators of Link, Temperature, Power Supply modules and other functions.

SNMP Management Module LEDs

The SNMP Management Module features several LEDs. The LED functions are:

LNK/ACT

FDX/COL

Glows green when a link is established on port.

Blinks green when data activity occurs.

Glows yellow when port is in Full-Duplex mode.

Blinks yellow when port is operating in Half-

TEMP

Duplex mode and collisions occur.

Glows yellow when temperature of unit

surpasses a user-defined level.

PS

FAN A / FAN B

Glows yellow when one power supply module

malfunctions.

Glows yellow when a fan malfunctions.

21

Page 28

3-Slot Desktop Chassis Specifications

Input Specifications

AC 100 to 240V AC, 50/60Hz, 0.75A

DC 35V DC to 75V DC Max, 1.6A

Operating Temperature

AC 0° C to 50° C (32° F to 122° F)

DC -40° C to 50° C (-67° F to 122° F)

Storage Temperature

AC -40° C to 85° C (-40° F to 185° F)

DC -55° C to 125° C (-40° F to 212° F)

Humidity: 5 to 95% (non-condensing); 0 to 10,000 ft. altitude

Shipping Weight: 5 lbs (2.3 kg)

Dimensions: H=1.73” W=7.45” D=8.74” (4.4 x 19x 22 cm)

Hardware Feature Matrix

Power Supply 3-Slot Desktop Chassis

Versions

Type Fixed

End user replaceable No

LEDs Yes

Redundant upgrade on single slot chassis No

*Trap can be set for exceeding a temperature value

AC, 2AC, DC, 2DC*, ACDC

22

Page 29

Black Box Customer Service

Order toll-free in the U.S.:

Free technical support

, 24 hours a day, 7 days a week.

Call:

Mail order:

Black Box Corporation

1000 Park Drive, Lawrence, PA 15055-1018

Web site:

E-mail:

www.blackbox.com

info@blackbox.com

Call 877-877-BBOX

(outside U.S. call 724-746-5500)

724-746-5500 or

WARNING

Disconnect all power supplies before servicing.

Fax:

724-746-0746

23

Page 30

Fiber Optic Cleaning Guidelines

Fiber Optic transmitters and receivers are extremely susceptible to contamination by particles

of dirt or dust, which can obstruct the optic path and cause performance degradation. Good

system performance requires clean optics and connector ferrules.

1.

Use fiber patch cords (or connectors, if you terminate your own fiber) only from a

reputable supplier; low-quality components can cause many hard-to-diagnose problems

in an installation.

Dust caps are installed at Black Box to ensure factory-clean optical devices. These

2.

protective caps should not be removed until the moment of connecting the fiber cable to

the device. Should it be necessary to disconnect the fiber device, reinstall the protective

dust caps.

3.

Store spare caps in a dust-free environment such as a sealed plastic bag or box so that

when reinstalled they do not introduce any contamination to the optics.

If it is suspected that the optics have been contaminated, alternate between blasting with

4.

clean, dry, compressed air and flushing with methanol to remove particles of dirt.

Electrostatic Discharge Precautions

Electrostatic discharge (ESD) can cause damage to any product, add-in modules or stand

alone units, containing electronic components. Always observe the following precautions

when installing or handling these kinds of products

Do not remove unit from its protective packaging until ready to install.

1.

Wear an ESD wrist grounding strap before handling any module or component. If the

2.

wrist strap is not available, maintain grounded contact with the system unit throughout

any procedure requiring ESD protection.

Hold the units by the edges; do not touch the electronic components or gold connectors.

3.

After removal, always place the boards on a grounded, static-free surface, ESD pad or in

4.

a proper ESD bag. Do not slide the modules or stand alone units over any surface.

WARNING!

Integrated circuits and fiber optic components are

extremely susceptible to electrostatic discharge damage. Do not

handle these components directly unless you are a qualified service

technician and use tools and techniques that conform to accepted

industry practices.

24

Page 31

Certifications

UL/CUL: Listed to Safety of Information Technology Equipment, including Electrical Business

Equipment.

Class 1 Laser product, Luokan 1 Laserlaite,

Laser Klasse 1, Appareil A’Laser de Classe 1

European Directive 2002/96/EC (WEEE) requires that any equipment that bears this symbol on

product or packaging must not be disposed of with unsorted municipal waste. This symbol

indicates that the equipment should be disposed of separately from regular household waste.

It is the consumer’s responsibility to dispose of this and all equipment so marked through

designated collection facilities appointed by government or local authorities. Following these

steps through proper disposal and recycling will help prevent potential negative consequences

to the environment and human health. For more detailed information about proper disposal,

please contact local authorities, waste disposal services, or the point of purchase for this

equipment.

25

Page 32

Black Box Tech Support: FREE! Live. 24/7.

Tech support the

way it should be

.

Great tech support is just 20 seconds away at

724-746-5500 or www.blackbox.com

About Black Box

Black Box Network Services is your source for more than 118,000 networking and

infrastructure products. You'll find everything from cabinets and racks and power and surge

protection products to media converters and Ethernet switches all supported by free, live 24/7

Tech support available in 20 seconds or less.

© Copyright 2010. Black Box Corporation. All rights reserved. 50-80054BB-00 A2

724-746-5500 www.blackbox.com

Loading...

Loading...